Page 1

Programmable Three Phase Power / Energy Metering

IC for Stepper Motor / Impulse Counter Applications

SA2005P

FEATURES

+ Direct drive for electro-mechanical counters or stepper

motors

+ Calibration and setup stored on external EEPROM - no

trim-pots required

+ Flexible programmable features providing ease of

implementation for meter manufacturers

+ Per phase energy direction and voltage fail indication

+ Precision oscillator on chip

DESCRIPTION

The SAMES SA2005P provides a single chip active energy

metering solution for three phase mechanical counter-based

meter designs.

Th SA2005P does not require any external trim-pots or resistor

ladders for meter calibration. Calibration and meter

configuration information is stored on a small external

EEPROM.

Meter setup stored on the EEPROM includes various metering

direction modes (total sum, absolute sum, positive or negative

energy) phase calibration data, rated metering conditions,

LED pulse rate, counter pulse width, counter resolution and

creep current.

samessames

+ Meets the IEC 521/1036 Specification requirements for

Class 1 AC Watt hour meters

+ Operates over a wide temperature range

+ Easily adaptable to different signal levels

+ Adaptable to different types of sensors

+ Precision voltage reference on-chip

+ Protected against ESD

A programmable rate pulse output is available for meter

calibration purposes. Per phase voltage fail and voltage

sequence faults as well as energy direction indication are

available as LED outputs. Programmable dividers enable

various mechanical counter or stepper motor counter

resolutions.

A precision oscillator, that replaces an external crystal, is

integrated on chip. A voltage reference is integrated on chip.

The SA2005P integrated circuit is available in 24-pin dual in

line plastic (DIP-24) and small outline (SOIC-24) package

options.

IIN1

IIP1

IVN1

IIN2

IIP2

IVN2

IIN3

IIP3

IVN3

GND

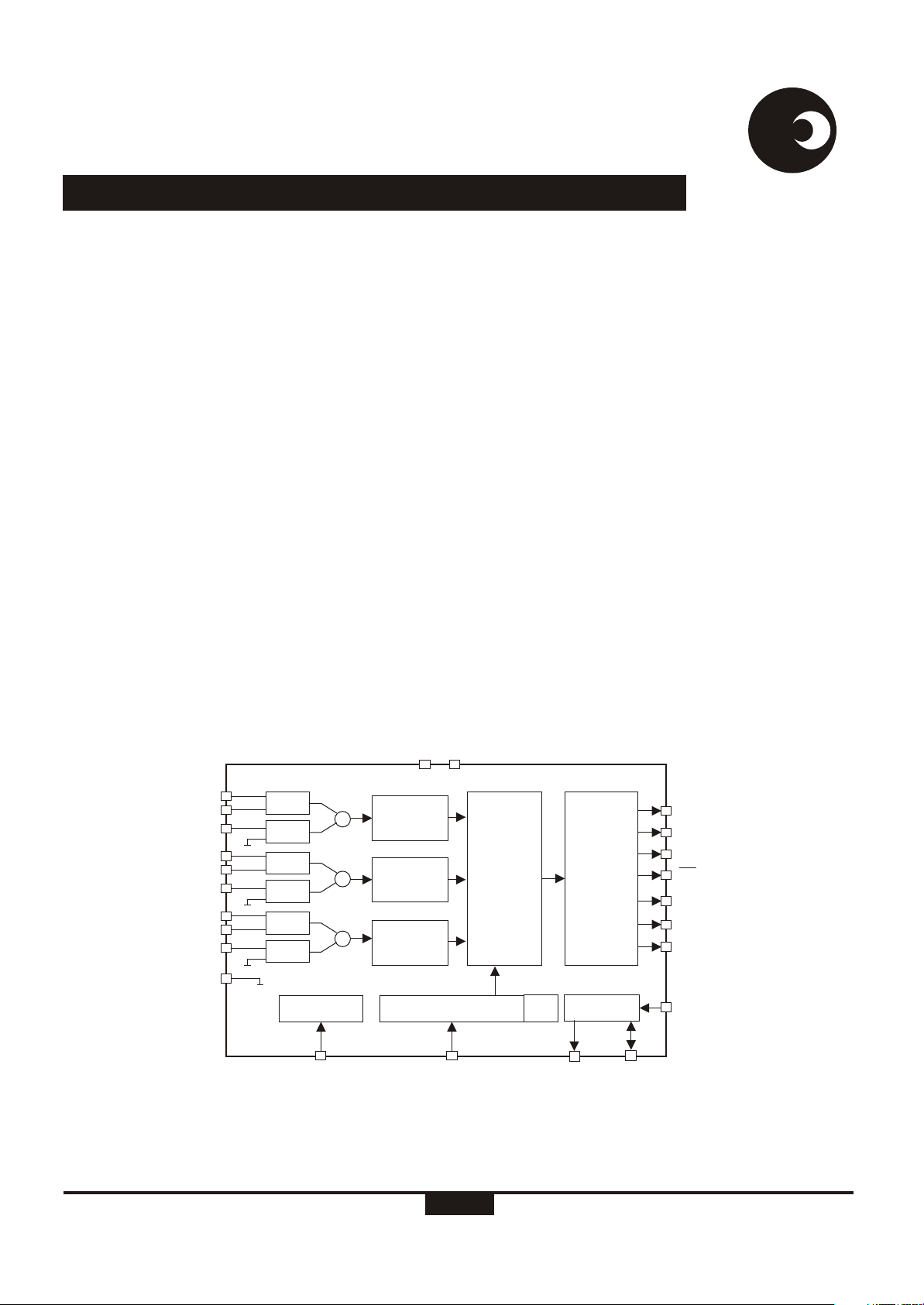

dr-01605

I1

V1

I2

V2

I3

V3

REF

VREF

X

X

X

VDD VSS

CHANNEL

BALANCE

PROG.

CHANNEL

ADDER

BALANCE

CHANNEL

BALANCE

TIMING & CONTROL

Figure 1: Block diagram

PROGRAM-

MABLE

ADDER

TEST

OSC

POWER

TO

PULSE

RATE

INTERFACE

SCL

LED

MON

MOP

PH / DIR

PH1

PH2

PH3

RLOAD

SDA

SPEC-0086 (REV. 2)

1/16

07-02-01

Page 2

SA2005P

samessames

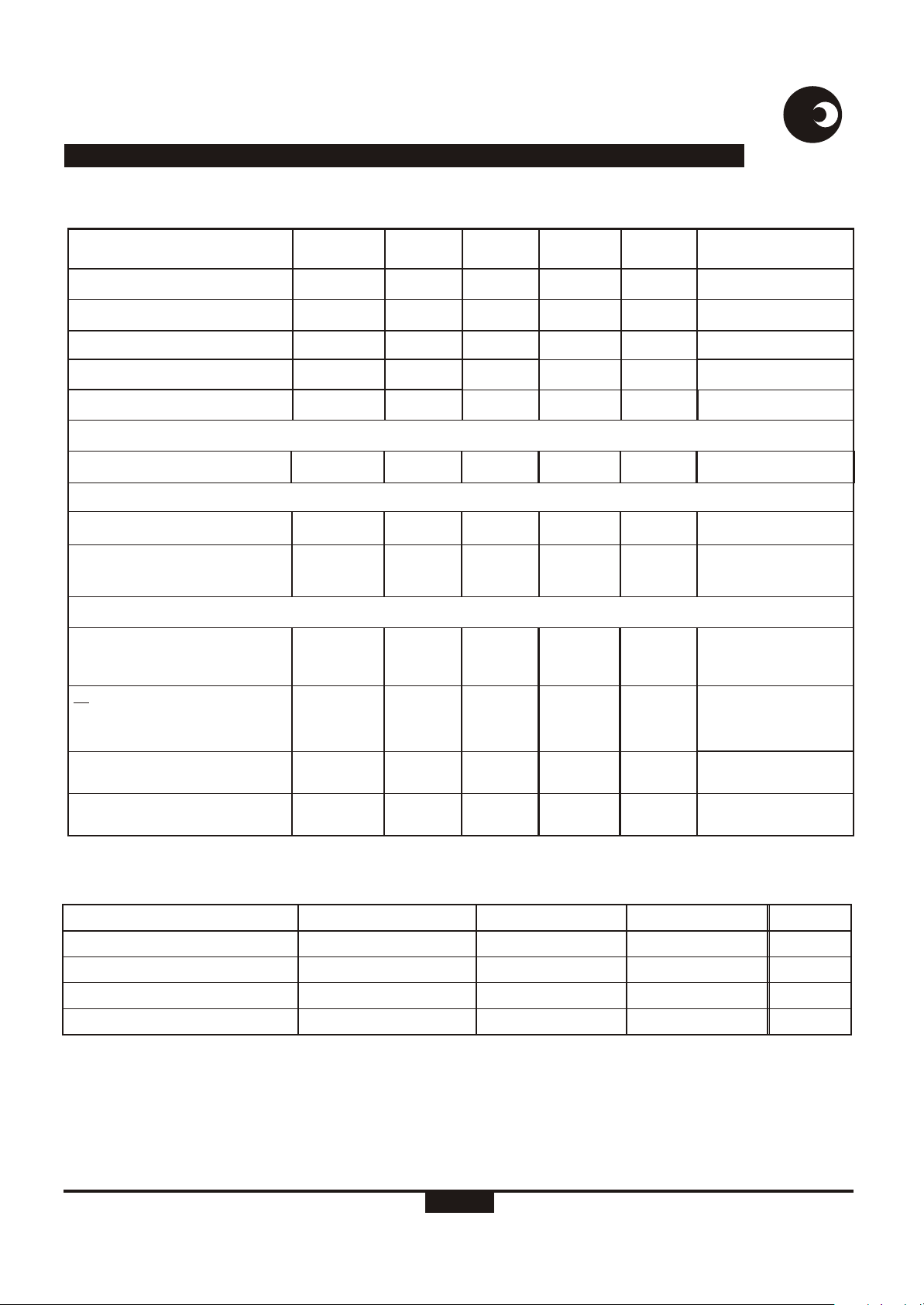

ELECTRICAL CHARACTERISTICS

(V = 2.5V, V = -2.5V, over the temperature range -10°C to +70°C , unless otherwise specified.)

DD SS

Parameter

Operating temp. Range

Supply Voltage: Positive

Supply Voltage: Negative

Supply Current: Positive

Supply Current: Negative

Symbol

T

O

V

DD

V

SS

I

DD

I

SS

Min

-25

2.25

-2.75 -2.25

#

Typ

Max

+85

2.75

15

15

16

16

Current Sensor Inputs (Differential)

Input Current Range

I

II

-25

+25

Voltage Sensor Input (Asymmetrical)

Input Current Range

Pin VREF

Ref. Current

Ref. Voltage

I

IV

-I

R

V

R

-25

45

1.1

50

+25

55

1.3

Digital I/O

Pins RLOAD, TEST, SDA

Input High Voltage

Input Low Voltage

V

IH

V

IL

V-1

DD

V+1

SS

Pins MOP, MON, LED, SCL,

PH/DIR, PH1, PH2, PH3

Output High Voltage

Output Low Voltage

V

OH

V

OL

V-1

DD

V+1

SS

Pin SDA

Pull up current

-I

IL

24

54 µA

Unit

°C

V

V

mA

mA

µA

µA

µA

V

V

V

V

V

Condition

Peak value

Peak value

With R = 24kW

connected to V

Reference to V

I = -2mA

OH

I = 5mA

OL

V = V

ISS

SS

SS

Pins TEST, RLOAD

Pull down current

I

IH

48 110 µA

V = V

IDD

#Extended Operating Temperature Range available on request.

ABSOLUTE MAXIMUM RATINGS*

Parameter Symbol Min Max Unit

Supply Voltage V -V -0.3 6.0 V

Current on any pin I -150 +150 mA

Storage Temperature T -40 +125 °C

Operating Temperature T -40 +85 °C

*Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress

rating only. Functional operation of the device at these or any other condition above those indicated in the operational sections of

this specification, is not implied. Exposure to Absolute Maximum Ratings for extended periods may affect device reliability.

http://www.sames.co.za

DD SS

PIN

STG

O

2/16

Page 3

SA2005P

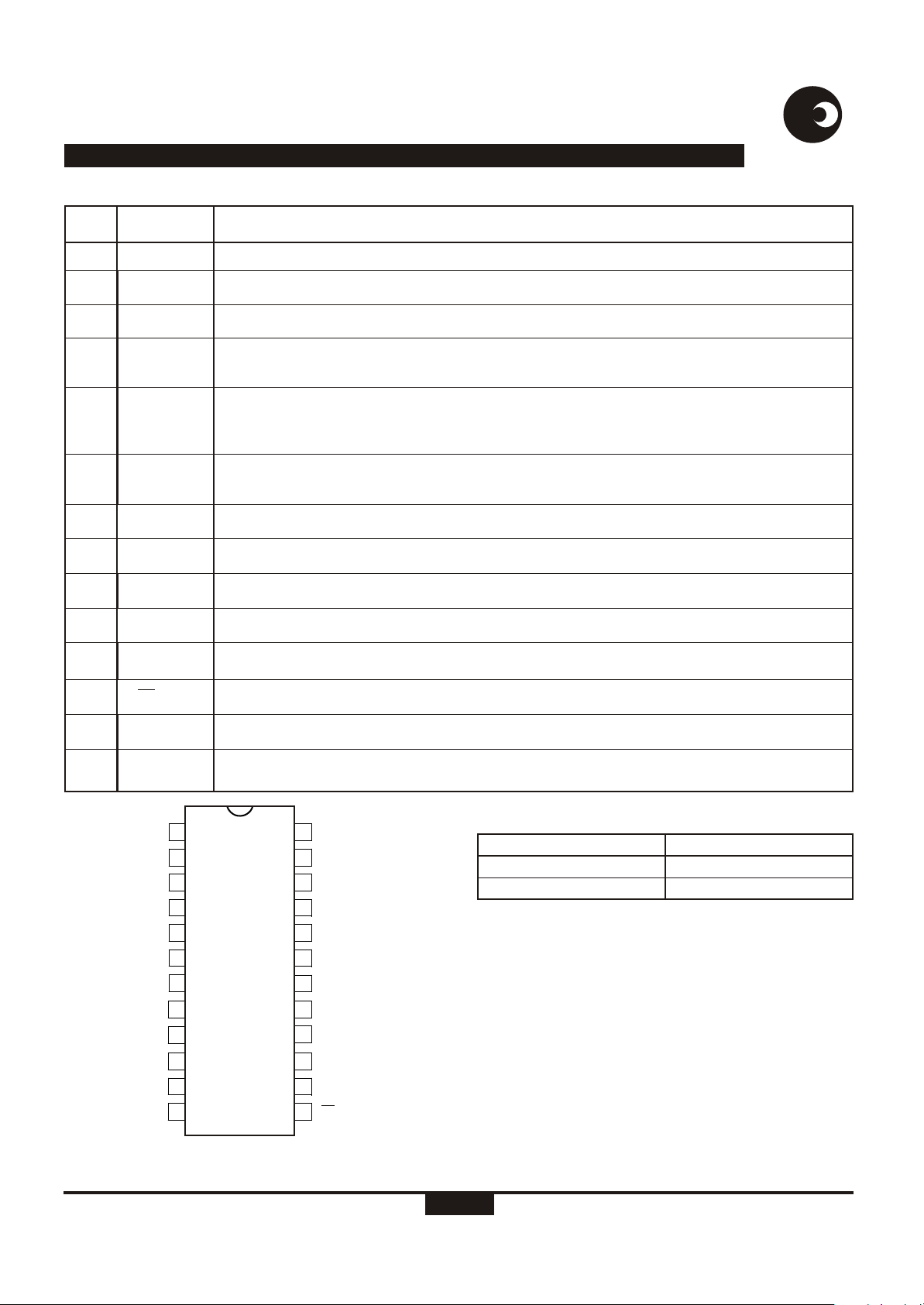

PIN DESCRIPTION

Designation Description

PIN

samessames

20

6

18

21, 24,

3

23, 22,

2, 1,

5, 4

19

8

9

17

10

11, 12

13

GND

V

DD

V

SS

IVN1, IVN2,

IVN3

IIN1, IIP1,

IIN2, IIP2,

IIN3, IIP3

VREF

SCL

SDA

TEST

LED

MON, MOP

PH / DIR

Analog Ground. The voltage to this pin should be mid-way between V and V .

DD SS

Positive supply voltage. Typically +5V if a current transformer is used for current sensing.

Negative supply voltage. Typically 0V if a current transformer is used for current sensing.

Voltage sense inputs. The current into the A/D converter should be set at 14µA at nominal mains

RMS

voltage. The voltage sense input saturates at an input current of ±25µA peak.

Inputs for current sensors. The termination resistor voltage from each current transformer is

converted to a current of 16µA at rated conditions. The current sense input saturates at an input

RMS

current of ±25µA peak.

This pin provides the connection for the reference current setting resistor. A 24kW resistor

connected to V sets the optimum operating condition.

SS

Serial clock output. This output is used to strobe data from the external EEPROM.

Serial data. Send and receive data from an external EEPROM.

Test input. For normal operation connect this pin to V .

SS

Calibration LED output. Refer to section Led Output (LED) for the pulse rate output options.

Motor pulse outputs. These outputs can be used to drive an impulse counter or stepper motor directly.

Multiplexed phase or direction driver output.

7

14, 15,

16

RLOAD

PH1, PH2,

PH3

1IIP2 IVN2

IIN2 IIN1

2

3

IVN3 IIP1

IIP3

4

IIN3

5

VDD

6 19

RLOAD

SCL

SDA

LED

MON

MOP

7

8

9

10

11

12

Triggers a data reload from the external EEPROM.

Multiplexed LED drivers for direction and mains fail indication.

24

23

22

IVN1

21

GND

20

VREF

VSS

18

TEST

17

PH3

16

PH2

15

PH1

14

PH / DIR

13

dr-01602

Figure 2: Pin connections: Package: DIP-24, SOIC-24

ORDERING INFORMATION

Part Number

SA2005PPA

SA2005PSA

Package

DIP-24

SOIC-24

http://www.sames.co.za

3/16

Page 4

SA2005P

FUNCTIONAL DESCRIPTION

The SAMES SA2005P is a CMOS mixed signal analog/digital

integrated circuit that performs three phase power/energy

calculations across a power range of 1000:1 to an overall

accuracy of better than Class 1.

The integrated circuit includes all the required functions for 3phase power and energy measurement such as oversampling

A/D converters for the voltage and current sense inputs, power

calculation and energy integration. Internal offsets are

eliminated through the use of cancellation procedures.

samessames

operation of the meter. Every data byte stored in the EEPROM

is protected with a checksum byte to ensure data integrity.

ELECTROSTATIC DISCHARGE (ESD) PROTECTION

The SA2005P integrated circuit's inputs/outputs are protected

against ESD.

POWER CONSUMPTION

The overall power consumption rating of the SA2005P

integrated circuit is less than 80mW with a 5V supply.

The integrated circuit includes all the required functions for a

three phase mechanical counter-based meter design. A

precision oscillator, that replaces an external crystal, is

integrated on chip providing a temperature stable time base for

the digital circuitry. A temperature stable voltage reference

integrated on chip generates the reference current used by the

analog circuitry.

Voltage and currents are sampled simultaneously by means of

a sigma delta modulator type ADC and power is calculated for

each individual phase. A programmable channel balance on

each channel is used for individual channel calibration.

The scaled power is fed to a programmable adder that allows

the representation of the measured energy to be either total

sum or absolute sum.

The summed power is integrated and divided down to

represent integrated energy. Pulses on the LED output and on

the mechanical counter outputs represent measured amounts

of energy. The programmable dividers provide flexible counter

and calibration LED resolutions.

Outputs for phase voltage fail and voltage sequence faults and

energy direction are available.

The SA2005P does not require any external trim-pots or

resistor ladders as meter calibration and configuration data is

stored on a small external EEPROM. The SA2005P configures

itself from the EEPROM during power up. These features

enables meter manufacturers flexible meter designs from a

single integrated circuit.

AUTOMATIC DEVICE CONFIGURATION (BOOT UP)

During power up, registers containing configuration and

calibration information is updated from an external EEPROM.

The device itself never writes tot he EEPROM so any write

protect features offered by manufacturer of EEPROM’s may

be used to protect the configuration and calibration constant of

the meter. The device reloads its configuration every 1193

seconds from the external EEPROM in order to ensure correct

INPUT SIGNALS

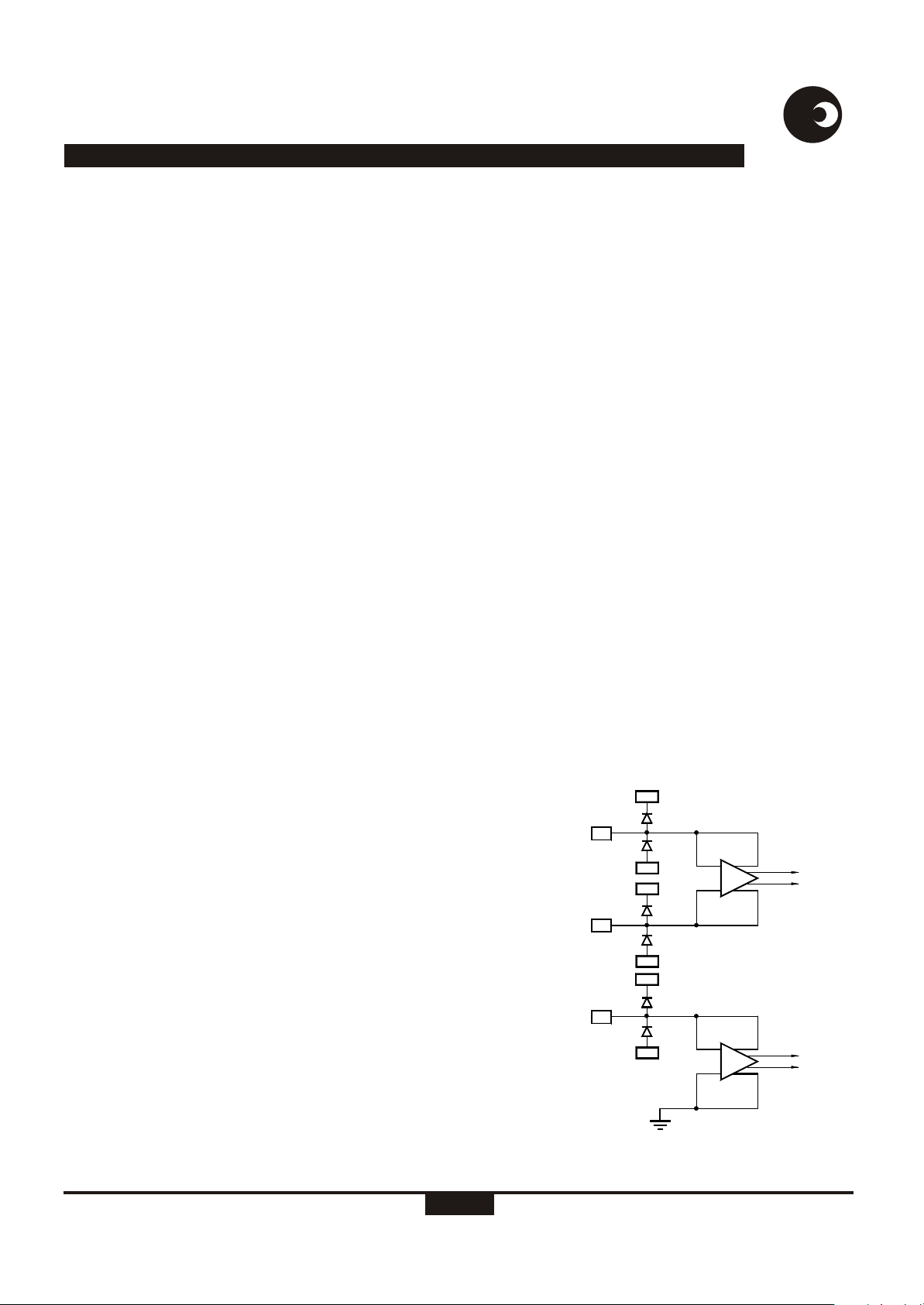

ANALOG INPUT CONFIGURATION

The current and voltage sensor inputs are illustrated in figure 3.

These inputs are protected against electrostatic discharge

through clamping diodes, in conjunction with the amplifiers

input configuration. The feedback loops from the outputs of the

amplifiers A and A generate virtual shorts on the signal inputs.

Exact duplications of the input currents are generated for the

analog processing circuitry. The current and voltage sense

inputs are identical. Both inputs are differential current driven

up to ±25µA peak. One of the voltage sense amplifiers input

terminals is internally connected to GND. This configuration is

possible because the voltage sense input is much less

sensitive to externally induced parasitic signals compared to

the current sense inputs.

Current Sense Inputs (IIN1, IIP1, IIN2, IIP2, IIN3, IIP3)

The current sense inputs connects to a termination resistor

connected across the terminals of a current transformer. At

I V

V

DD

IIP

V

CURRENT

SENSOR

INPUTS

IIN

IVP

VOLTAGE

SENSOR

INPUT

DR-01288

SS

V

DD

V

SS

V

DD

V

SS

GND

A

I

A

V

Figure 3: Analog input internal configuration

http://www.sames.co.za

4/16

Page 5

SA2005P

samessames

rated current the resistor values should be selected for input

currents of 16µA . Referring to figure 8, the resistors R1 and

RMS

R2 on current channel 1, resistors R3 and R4 on current

channel 2 and resistors R5 and R6 on current channel 3, define

the current level into the current sense inputs of the SA2005P.

The current sense inputs saturates at an input current of

±25µA peak. Resistors R29, R30 and R31 are used as current

transformer termination resistors. The voltage drop across the

termination resistors should be at least 20mV at rated

conditions. Values for the current sense inputs are calculated

as follows:

R1 = R2 = ( IL / 16µARMS ) x R29 / 2

R3 = R4 = ( IL / 16µARMS ) x R30 / 2

R5 = R6 = ( IL / 16µARMS ) x R31 / 2

Where:

I = Line current/CT-ratio

L

In case a current transformer is used for current sensing the

value of the termination resistors should be less than the

resistance of the CT's secondary winding.

Voltage Sense Inputs (IVN1, IVN2, IVN3)

The mains voltage are measured by means of a resistor divider

and the divided voltage are converted to a current. The current

into the voltage sense inputs (virtual ground) should be set to

14µARMS at rated voltage conditions. The individual mains

voltages are divided down to 14V per phase. The resistors

RMS

R12, R13 and R14 (figure 8) set the current for the voltage

sense inputs. The voltage sense inputs saturate at an input

current of ±25uA peak.

Voltage Reference Connection (VREF)

A bias resistor of 24k provides an optimum bias conditions on

chip. Calibration of the SA2005P is done by means of divider

ratios stored on an external EEPROM. This is described in the

Device Configuration section.

Serial Data (SDA)

The SDA pin connects directly to the SDA pin of an external

EEPROM. The pin is used to transfer data between the

EEPROM and the SA2005P. An external pull-up resistor in not

needed.

Serial Clock (SCL)

The SCL pin connects directly to the SCL of an external

EEPROM. The SCL output is used to strobe data at a rate of

50kHz out of the EEPROM. An external pull up resistor is not

needed. The SCL output uses a soft driver and may be

overdriven by the calibration equipment.

Reload (RLOAD)

A falling edge on the RLOAD pin will trigger a register update

from the external EEPROM. This feature may be used during

calibration to load updated register data in the SA2005P. For

normal operation of the SA2005P the RLOAD pin may be left

floating.

Test Inputs (TEST)

The TEST input is the manufacturers test pin and must be

connected to VSS in a metering application.

OUTPUT SIGNALS

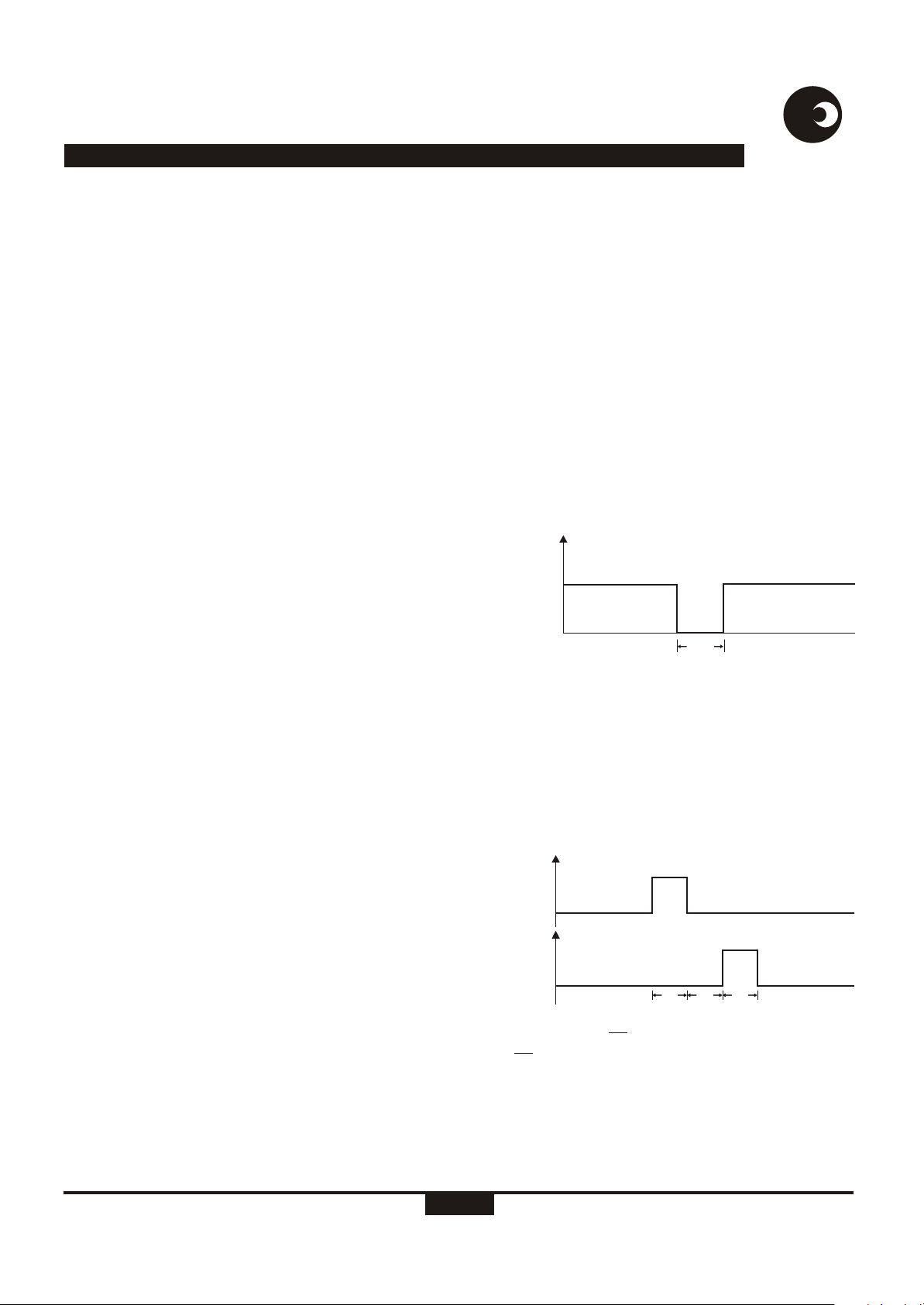

LED Output (LED)

Four options for the LED output pulse rate are available, 6400,

3200, 1600 pulses per kWh, and a pulse rate of 1252 pulses

per second at rated conditions. At 1252 pulses per second t LED

is 71µs, for the other options tLED is 10ms. The LED output is

active low as shown in figure 4.

VDD

LED

VSS

DR-01332

Figure 4: LED pulse output

Motor Output (MOP, MON)

The motor pulse width is programmable for 71ms, 142ms and

284ms. The MON pulse will follow the MOP pulse within the

selected pulse width time. This prevents the motor armature

being in the wrong position after a power failure. Both MOP

and MON outputs are active high. A MOP pulse followed by a

MON pulse represents one energy pulse. The motor drive

waveforms are shown in figure 5.

VDD

MOP

VSS

VDD

MON

VSS

DR-01559

Figure 5: Motor drive on MON and MOP pins of device

Multiplex Output (PH/ DIR)

The PH/DIR output enables either direction or voltage

information on the phase LED driver outputs (PH1, PH2 and

PH3). This multiplex output switches between logic 1 and 0 at

a frequency of approximately 280Hz. A logic 1 enables energy

direction information on the LED driver outputs and a logic 0

enables voltage information.

t

LED

t

m

t

t

m

m

http://www.sames.co.za

5/16

Page 6

SA2005P

samessames

The PH/Dir output is used in conjunction with the LED driver

outputs to display information about each individual phase, see

figure 6.

Phase LED Drivers (PH1, PH2, PH3)

The LED driver outputs present either direction information or

voltage information. The three LED driver outputs are used in

conjunction with the PH/DIR output to display information

about each individual phase (refer to figure 6) as follows:

PH/DIR = 1 (Direction indication)

When PH/DIR is high (logic 1) energy direction information for

each individual phase is available on PH1, PH2 and PH3. A

logic 0 indicates reverse energy flow and a logic 1 indicates

positive energy flow. Reverse energy flow is defined as the

condition where the voltage sense input and the current sense

inputs are out of phase (greater than 90 degrees). Positive

energy flow is defined as the condition where the voltage

sense and current sense inputs are in phase.

PH/DIR = 0 (Voltage fail / phase sequence error)

When PH/DIR is low (logic 0) voltage information is available

on PH1, PH2 and PH3. A logic 0 on any of these pins indicates

a voltage failure, the SA2005P does not detect a zero crossing

on the applicable voltage sense input. Referring to figure 6 the

voltage fail LED will be on when the voltage phase is present

and off when the voltage phase is missing.

In the case of a phase sequence error all three LED driver

outputs PH1, PH2 and PH3 will pulse with a repetition rate of

approximately 1Hz.

Channel 1

Channel 2

Channel 3

PH (Sink)

DIR (Drive)

VFAIL 1

DIR 1

VFAIL 2

DIR 2

VFAIL 3

DIR 3

dr-01603

PH/DIR

R9

PH1

R10

PH2

R11

PH3

D1

DIR1

D2

VFAIL1

Figure 6: Multiplexing of the LED Drivers

D3

DIR2D4VFAIL2

D5

DIR3

D6

VFAIL3

http://www.sames.co.za

6/16

Page 7

SA2005P

ANTI-TAMPER CONDITIONS

The SA2005P cater for the following meter tamper conditions and are indicated as follows:

samessames

Method Result

Phase

Voltages

Phase Failure,

no voltage

Phase

Sequence

Error

Input / Output

Terminals

Interchanged

Missing

Neutral

Connection

Return

through Earth

Load

Imbalance

Calibration

One LED is provided for each phase to indicate abnormal

operating conditions.

In case of a phase failure, the corresponding LED is

switched off.

In case of phase sequence error, all LEDs are flashing with a repetition rate of approximately 1 Hz. A connection of a line voltage

to the neutral terminal would be indicated in the same way.

One LED is provided for each current sensor to indicate reverse

energy flow. If detected, the corresponding LED is switched on.

The SA2005P can be configured to accumulate the absolute

energy consumption for each phase measured, irrespective of

the direction of the energy flow.

The architecture of the meter should provide for a good "phantom

neutral" in cases where the neutral is disconnected from the

meter.

The SA2005P will therefore record the energy consumption

accurately under this condition.

The calibration data is stored in an EEPROM. There are no

trim-pots required in this design.

Description

During normal conditions, the LEDs

are continuously switched on.

The SA2005P will record the energy

consumption accurately under this condition

The SA2005P will record the energy

consumption accurately under this condition

The SA2005P will record the energy

consumption accurately under this condition

In this case, the meter would register the

energy consumption correct.

A indication for this condition could be

realized external to the IC.

The SA2005P will record the energy

consumption accurately under this condition

The meter can not be re-adjusted, only

reprogrammed.

http://www.sames.co.za

7/16

Page 8

SA2005P

samessames

DEVICE CONFIGURATION

SIGNAL FLOW DESCRIPTION

The following is an overview of the SA2005P’s registers. For a

detailed description of each parameter please refer to

parameter description section. Figure 7 shows the various

registers in the SA2005P’s power to pulse rate block. The

inputs to this block are three single bit pulse density modulated

signals, each having a pulse rate of 641454 pulses per second

at rated conditions. The parameters Cb1, Cb2, Cb3, Sum, Ct,

Kr, CresH, CresL, Cled and Pw contain values that are read

from the external EEPROM during power up.

The Pre-Divider registers are used for calibration and to

balance the gain of each channel. The Programmable Adder is

used to select between the total sum or absolute sum of the

measured energy. The Creep current threshold detector

selects the creep current which is relative to the meters rated

current. The Rated Condition register is used to program the

rated condition of the meter and feeds the registers LED-

constant and Counter Resolution with the applicable pulse

rate. These two registers are programmed to select the LED

output rate and the counter resolution (pulses per kWh)

respectively. The Counter Pulse Width register is used to

program the pulse width for the mechanical counter driver

output MOP and MON.

EEPROM Memory Allocation

The following table shows the EEPROM memory allocation as

well as the corresponding name. The uneven byte always

Power from converters

S - D Power from converters

641454 pulses/s

Pre-Divider

÷Cb1

Creep current threshold detector

Rated Condition

÷Kr

Counter

Resolution

CresH, CresL

Counter Pulse

width

Pw

MOP MON

Ct

S - D Power from converters

641454 pulses/s

Pre-Divider

÷Cb2

Programmable Adder SUM

Normally 1253p/s

Normally 6400p/kWh

S - D

641454 pulses/s

Pre-Divider

÷Cb3

LED-Constant

Cled

LED

Figure 7: Signal flow block diagram

contains a XORed byte of the previous even byte. This is the

checksum byte used by the SA2005P to ensure data integrity.

Description

Channel Balance 3

Channel Balance 1

Channel Balance 2

Summing mode

Creep current threshold

Rated Condition

Led Pulse-rate

Counter Resolution (LSB)

Counter Resolution (MSB)

Counter Pulse-Width

2

E Address

10

11

12

13

14

15

16

16

17

20

21

22

23

24

25

26

26

27

Contents

Cb3

XOR of ADDR 10

Cb1

XOR of ADDR 12

Cb2

XOR of ADDR 14

SUM

Ct

XOR of ADDR 16

Kr

XOR of ADDR 20

Cled

XOR of ADDR 22

CresL

XOR of ADDR 24

ClresH

Pw

XOR of ADDR 26

---v vvvv

xxxx xxxx

---v vvvv

xxxx xxxx

---v vvvv

xxxx xxxx

---- --vv

v--- ----

xxxx xxxx

vvvv vvvv

xxxx xxxx

---- --vv

xxxx xxxx

vvvv vvvv

xxxx xxxx

---v vvvv

vv-- ----

xxxx xxxx

KEY: (- = DON’T CARE); (V = VALUE/PARAMETER); (0,1 = LOGICAL VALUE); (X = BIT-XOR)

Bit [7:0]

Name

D10

D12

D13

D16

D16

D20

D22

D24

D26

D26

http://www.sames.co.za

8/16

Page 9

SA2005P

samessames

PARAMETER DESCRIPTION

Refer to the EEPROM memory allocation map as well as the

Signal flow diagram figure 7, for a description of the registers

used in this section.

Rated Condition (Kr)

Kr is used to program the rated condition of the meter. Rated

conditions from less than 10A to several 100A are possible.

The rated conditions divider as well as the pre-divider is used

to compensate for individual phase calibration. The three

phases are calibrated to the phase with the lowest gain.

Kr is calculated as follows:

Krx=642 000/Rated volt/Rated current/6400x3600x1000/512

The SA2005P’s internal counters count from 0 so 1 must be

subtracted from Kr:

Kr = round(Krx)-1

Where:

Krx is the real value

Kr is the integer value

Kr is made up of 1 byte (D20)

LED Pulse-Rate (Cled)

Two bits of byte D22 allow for the selection of 4 different LEDPulse-rates. The LED pulse-width is 10ms. In fast pulse mode,

the pulse-width is set to 71µs.

D22[1]

0

1

1

0

Counter Resolution (Cres)

A 13 bit divider divide the pulse rate from the rated conditions

divider down to the desired counter resolution.

Cres is made up of bits 0 of 4 of byte D26 and byte D27.

D26[4:0] D27[7:0]

Counter Pulse-Width (Pw)

The pulse width for the mechanical counter driver output is

selectable to accommodate various step-motor and impulsecounter requirements.

D22[0]

1

0

1

0

Calibration LED - Output

6400 p/kWh

3200 p/kWh

1600 p/kWh

1252 pulses/second @ rated for

fast calibration

Counter Resolution

Pre-divider (Cb1, Cb2, Cb3)

The channel balance (Cb) value is used to balance the three

phases. The rated conditions divider ratio must be calculated.

Error measurements per phase are done with channel balance

values set to zero. The measured error values are used to

correct the error measurements of the three phases. The

rounding error in the rated conditions divider is also

compensated for in the channel balance calculations. One

count on the channel balance value represent 100%/256.

Gain = ((Krx-Kr+1) / Krx) x 100

Gain calculates the rounding error made by the rated

conditions divider.

Cb1 = (CHB1 - CBMIN + Gain) x 256 / 100

Cb2 = (CHB2 - CBMIN + Gain) x 256 / 100

Cb3 = (CHB3 - CBMIN + Gain) x 256 / 100

CHB1, CHB2, CHB3 is the measured channel balance %error

that will be corrected

CBMIN is the lowest channel balance %error measured

between the three phases.

Pw is made up of bits 7 and 6 of byte D26.

D26[7]

1

0

0

Creep current threshold (Ct)

The creep current is expressed relative to the rated current of

the meter. The SA2005P will not meter currents below the

creep current. The creep current is implemented to prevent

the meter from accumulating energy when no load is

connected.

Cs is made up of bit 7 of byte D16

D16[7]

0

1

D26[6]

-

1

0

Creep threshold

0.02% of rated current

0.01% of rated current

Counter Pulse-Width

284 ms

142 ms

71 ms

http://www.sames.co.za

9/16

Page 10

SA2005P

Programmable adder mode (SUM)

The SA2005P can be programmed to sum the energy

measurement as follows:

Total sum

This represents the total sum of the energy measured on all

three phases flowing through the current sensors. Negative

energy flow is taken into consideration.

Energy = Energy phase 1 + Energy Phase 2 + Energy

Phase 3

Absolute sum

This represents the sum of the energy measured on all three

phases, regardless of the direction of energy flow through

the current sensors.

Power = abs (Energy phase 1) + abs (Energy phase 2) +

abs (Energy phase 3)

During calibration the device may be programmed to use only

a specific phase for energy measurement. This can be used for

channel balancing.

D16[2]

Example of calculating rated conditions and channel

balance values

Meter rating = 80A / 230V (The SA2005P only uses integer

values)

D16[1]

0

0

0

0

1

1

1

1

D16[0]

0

0

1

1

0

0

1

1

Counter Resolution

Total sum all three phases

0

Only phase 1 measurement

1

Only phase 2 measurement

0

Only phase 3 measurement

1

Absolute sum of all three phases

0

Only phase 1 measurement

1

Only phase 2 measurement

0

Only phase 3 measurement

1

samessames

Calculate the Channel balance values:

During the rated conditions calculation the rated condition

register was rounded and any rounding errors is now taken

into account:

Gain = ((Krx - Kr+1 ) / Krx) x 100

Gain = ((38.3327 - 38) / 38.337) x 100

Gain = 0.8679

The real channel balance errors still need to be measured so

CHB1,CHB2, CHB3 and CBMIN are set to 0 for all phases.

Calculate the Pre-divider values:

Cb1 = (CHB1 - CBMIN + Gain ) x 256 / 100

Cb1 = (0% - 0% + Gain ) x 256 / 100

Cb1 = Gain x 256 / 100

Cb1 = 0.8679 x 256 / 100

Cb1 =2.2218

Convert to integer

Cb1 = 2

At this stage all three channels will be set with the same

values, Cb1= Cb2= Cb3. Store the calculated values in the

EEPROM. Ensure that the SA2005P reload’s its registers from

the EEPROM by means of the reload pin (RLOAD) or power

down the meter and power up again.

The meter is now set up with the correct register values but not

yet calibrated.

The following example shows how to calibrate the meter

Use the rated conditions divider value and the channel

balance values calculated above and program the EEPROM.

Set the programmable adder for a single phase to be

measured. Measure the %error for each individual phase

without changing any of the calibration constants.

%Error=(Measured Energy-Real Energy)/Real Energyx100

Calculate the rated conditions:

Krx=642 000/Rated volt/Rated current/6400x3600x1000/512

Krx = 642 000/230/80/6400x3600x1000/512

Krx = 38.3327

Krx = 38 (round Krx) - convert to integer

Kr = 38 - 1 = 37

The value 37 is stored in the rated register (Kr).

http://www.sames.co.za

The %Error will be worked back into the calculations above.

For the example we will assume a 1.5%, 5.2%, and 3.2% for

the three individual phases. The rated conditions value is

recalculated relative to the phase with the lowest error. Phase

1 has the lowest error so 1.5% = MinError;

10/16

Page 11

SA2005P

Recalculate the rated conditions

Krx = 642 000 / Rated volt / Rated current / 6400 x 3600 x

1000 / 512 x (1 + %MinError / 100 )

Krx = 642 000 / 230 / 80 / 6400 x 3600 x 1000 / 512 x 1.015

Krx = 38.9077

Kr = 38 - 1 = 37

The 37 are stored in the rated register.

The channel balance values are adjusted to make provision for

the rounding error.

Gain = ((Krx - Kr +1 ) / Krx ) x 100

Gain = (( 38.9077 - 38 ) / 38.9077 ) x 100

Gain = 2.33

The channel balance pre-devider value must be recalculated.

(BMIN will be the lowest %error value, in this case 1.5%,

CHB1, CHB2 and CHB3 are the individual phase %errors

measured.

samessames

Cb1 = (CHB1 - CBMIN + Gain ) x 256 / 100

Cb1 = (1.5 - 1.5 + 2.33 ) x 256 / 100 = 5.97 =5

Cb2 = (CHB2 - CBMIN + Gain ) x 256 / 100

Cb2 = ( 5.2 - 1.5 + 2.33 ) x 256 / 100 = 15.43 = 15

Cb3 = (CHB3 - CBMIN + Gain ) x 256 / 100

Cb3 = (3.2 - 1.5 + 2.33 ) x 256 / 100 = 10.316 = 10

Store the calculated values in the EEPROM and the meter is

calibrated.

http://www.sames.co.za

11/16

Page 12

SA2005P

TYPICAL APPLICATION

CALCULATION OF EXTERNAL RESISTOR VALUES

In figure 8, all the components required for a three-phase

power/energy metering section, is shown. The application

uses current transformers for current sensing. The 4-wire

meter section is capable of measuring 3x230V/80A with

precision better than Class 1

The most important external components for the SA2005P

integrated circuit are the current sense resistors, the voltage

sense resistors as well as the bias setting resistor.

samessames

Voltage Divider

The three voltage divider for voltage measurement are

identical so resistor values for one phase will be calculated.

The voltage divider is calculated for a voltage drop of 14V.

Equations for the voltage divider in figure 5 are:

RA = R16 + R19 + R22

RB = R8 || R13

Combining the two equations gives:

Bias Resistor

R7 defines all on-chip and reference currents. With R7=24kW,

optimum conditions are set.

CT Termination Resistor

The voltage drop across the CT termination resistor at rated

current should be at least 20mV. The CT's used have low

phase shift and a ratio of 1:2500.The CT is terminated with a

2.7W resistor giving a voltage drop across the termination

resistor 864mV at rated conditions (Imax for the meter).

Current Sense Resistors

The resistors R1 and R2 define the current level into the

current sense inputs of phase one of the device. The resistor

values are selected for an input current of 16µA on the current

inputs at rated conditions.

According to equation described in the Current Sense inputs

section:

R1 = R2 = ( I / 16µA ) x R / 2

= 80A /2500 / 16µA x 2.7W / 2

= 2.7kW

I = Line current / CT Ratio

L

LSH

(RA + RB ) / 230V = RB / 14V

Resistor values R11 = R12 = R13= 24kW and R8 =1MW is

chosen.

Substituting the values result in:

RB = 23.4375kW

RA = RB x (230V / 14V - 1)

RA = 361.607kW.

Resistor values of R16, R19 and R22 is chosen to be 130k,

130k and 100k.

The three voltage channels are identical so R14= R15= R16 ,

R17 = R18 = R19 and R20 = R21= R22.

The three current channels are identical so R1 = R2 = R3 = R4

= R5 = R6.

http://www.sames.co.za

12/16

Page 13

http://www.sames.co.za

Neutral

V3 In

GND

R18

R21

SA2005P

R24

R16

13/16

V2 In

V1In

CT1

Figure 8: Typical application circuit

CT2

CT3

V3 Out

V2 Out

V1 Out

VSS

1

2

3

4

U2

24C01A

A0

A1

A2

VSS

VCC

TEST

SCL

SDA

R19

R20

GND

GND

GND

8

7

6

5

R29

R30

R31

VDD

VSS

R22

R23

R1

R2

R3

R4

R5

R6

R7

23

22

19

18

17

2

1

5

4

8

9

R25

R26

U1

IIN1

IIP1

IIN2

IIP2

IIN3

IIP3

VREF

VSS

TEST

SCL

SDA

dr-01604

GND

IVN1

IVN2

IVN3

PH/DIR

PH1

PH2

PH3

MOP

MON

LED

VDD

RLOAD

R15

RELOAD

SDA

SCL

R17

D1

DIR1

R8

C5

C4

C3

D2

VFAIL1

VDD

CNT1

.1123456

Counter

D3

DIR2

D4

VFAIL2

GND

R27

R28

D5

DIR3

D6

VFAIL3

VDD

C2

C1

C6

VSS

samessames

20

GND

R12

21

R13

24

R14

3

13

R9

14

R10

15

R11

16

12

11

10

6

7

D7

Page 14

SA2005P

samessames

Parts List for Application Circuit: Figure 7

Symbol

U1

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

C1

C2

C3

C4

C5

C6

D1

D2

D3

D4

D5

D6

U2

CNT1

CT1

CT2

CT3

Note 1: Resistor (R1 to R6) values are dependent on the selection of the termination resistors (R29 to R31) and CT combination

Note 2: Capacitor values may be selected to compensate for phase errors caused by the current transformers.

Note 3: Capacitor C6 to be positioned as close as possible to supply pins V and V of U1 as possible.

Description

SA2005P

Resistor, 2.7k, 1/4W, 1%, metal

Resistor, 2.7k, 1/4W, 1%, metal

Resistor, 2.7k, 1/4W, 1%, metal

Resistor, 2.7k, 1/4W, 1%, metal

Resistor, 2.7k, 1/4W, 1%, metal

Resistor, 2.7k, 1/4W, 1%, metal

Resistor, 24k, 1/4W, 1%, metal

Resistor, 1k, 1/4W, 5%, carbon

Resistor, 1k, 1/4W, 5%, carbon

Resistor, 1k, 1/4W, 5%, carbon

Resistor, 1k, 1/4W, 5%, carbon

Resistor, 1M, 1/4W, 1%, metal

Resistor, 1M, 1/4W, 1%, metal

Resistor, 1M, 1/4W, 1%, metal

Resistor, 24k, 1/4W, 1%, metal

Resistor, 24k, 1/4W, 1%, metal

Resistor, 24k, 1/4W, 1%, metal

Resistor, 130k, 1/4W, 1%, metal

Resistor, 130k, 1/4W, 1%, metal

Resistor, 130k, 1/4W, 1%, metal

Resistor, 130k, 1/4W, 1%, metal

Resistor, 130k, 1/4W, 1%, metal

Resistor, 130k, 1/4W, 1%, metal

Resistor, 100k, 1/4W, 1%, metal

Resistor, 100k, 1/4W, 1%, metal

Resistor, 100k, 1/4W, 1%, metal

Resistor, 1k, 1/4W, 1%, metal

Resistor, 1k, 1/4W, 1%, metal

Resistor, 2.7 , 1/4W, 1%, metal

Resistor, 2.7 , 1/4W, 1%, metal

Resistor, 2.7 , 1/4W, 1%, metal

Capacitor, 220nF

Capacitor, 220nF

Capacitor, 1.5µF, 16V, electrolytic

Capacitor, 1.5µF, 16V, electrolytic

Capacitor, 1.5µF, 16V, electrolytic

Capacitor, 820nF

3mm Light emitting diode

3mm Light emitting diode

3mm Light emitting diode

3mm Light emitting diode

3mm Light emitting diode

3mm Light emitting diode

24C01A, 1kbit EEPROM

Mechanical stepper motor counter

Current Transformer, TZ76

Current Transformer, TZ76

Current Transformer, TZ76

W

W

W

Detail

DIP-24 / SOIC-24

Note 1

Note 1

Note 1

Note 1

Note 1

Note 1

Note 1

Note 1

Note 1

Note 2

Note 2

Note 2

Note 3

Direction indicator

V1 Fail indicator

Direction indicator

V2 Fail indicator

Direction indicator

V3 Fail indicator

2500:1

2500:1

2500:1

DD SS

http://www.sames.co.za

14/16

Page 15

PM9607AP

SA2005P

samessames

samessames

http://www.sames.co.za

15/16

Page 16

PM9607AP

SA2005P

samessames

samessames

DISCLAIMER:

The information contained in this document is confidential and proprietary to South African Micro-Electronic Systems (Pty) Ltd

("SAMES") and may not be copied or disclosed to a third party, in whole or in part, without the express written consent of SAMES.

The information contained herein is current as of the date of publication; however, delivery of this document shall not under any

circumstances create any implication that the information contained herein is correct as of any time subsequent to such date.

SAMES does not undertake to inform any recipient of this document of any changes in the information contained herein, and

SAMES expressly reserves the right to make changes in such information, without notification, even if such changes would render

information contained herein inaccurate or incomplete. SAMES makes no representation or warranty that any circuit designed by

reference to the information contained herein, will function without errors and as intended by the designer.

Any sales or technical questions may be posted to our e-mail address below:

For the latest updates on datasheets, please visit our web site:

SOUTH AFRICAN MICRO-ELECTRONIC SYSTEMS

DIVISION OF LABAT TECHNOLOGIES (PTY) LTD

P O BOX 15888

33 ELAND STREET

LYNN EAST 0039

REPUBLIC OF SOUTH AFRICA

energy@sames.co.za

http://www.sames.co.za.

Tel : (012) 333-6021

Tel: Int +27 12 333-6021

Fax: (012) 333-8071

Fax: Int +27 12 333-8071

33 ELAND STREET

KOEDOESPOORT INDUSTRIAL AREA

PRETORIA

REPUBLIC OF SOUTH AFRICA

http://www.sames.co.za

16/16

Loading...

Loading...