Page 1

Measuring sensor with multiple switch points

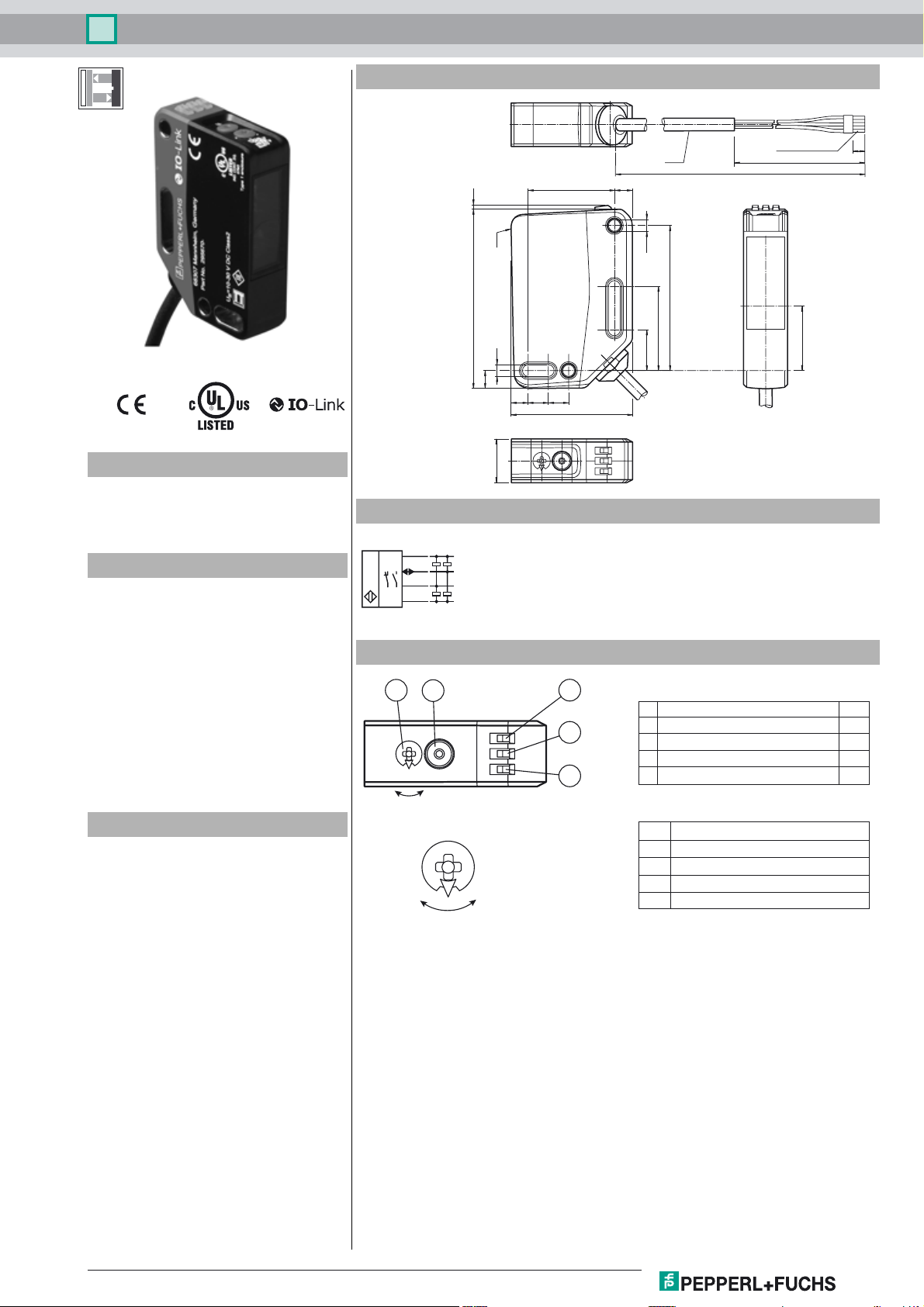

Dimensions

1.461.7

OQT400-R201-2EP-IO

Cable/clamping

ø 4.3

629.9

sleeve

L

L1

4

Model Number

OQT400-R201-2EP-IO

Triangulation sensor (SbR)

with fixed cable

Features

• Medium design with versatile

mounting options

• Multi Pixel Technology (MPT) flexibility and adaptability

• Reduction of device variety - several

switch points within one sensor

• Reliable detection of all surfaces,

independent of color and structure

• Low sensitivity to target color

• IO-link interface for service and

process data

Ref.

4.2

6.2

5.8 7 7

15

Electrical connection

BN

L+

BK

C/Q

WH

Q2

BU

L-

Indicators/operating means

1

2

41.7

ø 4.2

50

29

14

3

1 Mode rotary switch

4

5

2 Teach-in button

3 Switching output display Q2

4 Switching output display Q1

5 Operating indicator

22.1

YE

YE

GN

Product information

The optical sensors in the series are the first

devices to offer an end-to-end solution in a

medium-sized standard design—from the

thru-beam sensor through to the measuring

distance sensor. As a result of this design,

the sensors are able to perform practically all

standard automation tasks.

The entire series enables sensors to

communicate via IO-Link.

The DuraBeam laser sensors are durable and

can be used in the same way as a standard

sensor.

Multi Pixel Technology (MPT) ensures that

the standard sensors are flexible and

can be adapted to the application

environment.

Release date: 2018-07-27 10:13 Date of issue: 2019-10-31 295670-100169_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

Q2

0

B

A

B

Q1

A

Q1B Switching output 1/switch point B

Q1A Switching output 1/switch point A

Q2A Switching output 2/switch point A

Q2B Switching output 2/switch point B

0 Keylock

1

Page 2

Measuring sensor with multiple switch points

OQT400-R201-2EP-IO

Technical data

General specifications

Detection range 40 ... 400 mm

Detection range min. 40 ... 100 mm

Detection range max. 40 ... 400 mm

Adjustment range 100 ... 400 mm

Reference target standard white, 100 mm x 100 mm

Light source LED

Light type modulated visible red light

LED risk group labelling exempt group

Black/White difference (6 %/90 %) < 5 %

Diameter of the light spot approx. 15 mm at a distance of 400 mm

Angle of divergence approx. 2.5 °

Ambient light limit EN 60947-5-2 : 70000 Lux

Functional safety related parameters

MTTFd 600 a

Mission Time (TM) 20 a

Diagnostic Coverage (DC) 0 %

Indicators/operating means

Operation indicator LED green:

Function indicator LED yellow:

Control elements Teach-In key

Control elements 5-step rotary switch for operating modes selection

Electrical specifications

Operating voltage UB10 ... 30 V DC

Ripple max. 10 %

No-load supply current I

Protection class III

Interface

Interface type IO-Link ( via C/Q = BK )

Device profile Identification and diagnosis

Transfer rate COM 2 (38.4 kBaud)

IO-Link Revision 1.1

Min. cycle time 2.3 ms

Process data witdh Process data input 2 Bit

SIO mode support yes

Device ID 0x111811 (1120273)

Compatible master port type A

Output

Switching type The default setting is:

Signal output 2 push-pull (4 in 1)outputs, short-circuit protected, reverse

Switching voltage max. 30 V DC

Switching current max. 100 mA , resistive load

Usage category DC-12 and DC-13

Voltage drop Ud≤ 1.5 V DC

Switching frequency f 217 Hz

Response time 2.3 ms

Conformity

Communication interface IEC 61131-9

Product standard EN 60947-5-2

Ambient conditions

Ambient temperature -40 ... 60 °C (-40 ... 140 °F) , fixed cable

Storage temperature -40 ... 70 °C (-40 ... 158 °F)

Mechanical specifications

Housing width 15 mm

Housing height 61.7 mm

Housing depth 41.7 mm

Degree of protection IP67 / IP69 / IP69K

Connection 2 m fixed cable

Material

Housing PC (Polycarbonate)

Optical face PMMA

Mass approx. 83 g

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

2

constantly on - power on

flashing (4Hz) - short circuit

flashing with short break (1 Hz) - IO-Link mode

constantly on - switch output active

constantly off - switch output inactive

< 25 mA at 24 V supply voltage

0

Smart Sensor type 0

Process data output 2 Bit

C/Q - BK: NPN normally open, PNP normally closed, IO-Link

Q2 - WH: NPN normally open, PNP normally closed

polarity protected, overvoltage protected

-20 ... 60 °C (-4 ... 140 °F) , movable cable not appropriate for

conveyor chains

Accessories

IO-Link-Master02-USB

IO-Link master, supply via USB port or

separate power supply, LED indicators,

M12 plug for sensor connection

OMH-RL31-02

Mounting bracket narrow

OMH-RL31-03

Mounting bracket narrow

OMH-RL31-04

Mounting aid for round steel ø 12 mm or

sheet 1.5 mm ... 3 mm

OMH-RL31-07

Mounting bracket including adjustment

OMH-R20x-Quick-Mount

Quick mounting accessory

Other suitable accessories can be found at

Release date: 2018-07-27 10:13 Date of issue: 2019-10-31 295670-100169_eng.xml

Page 3

Measuring sensor with multiple switch points

Cable length 2 m

Approvals and certificates

UL approval E87056 , cULus Listed , class 2 power supply , type rating 1

CCC approval CCC approval / marking not required for products rated ≤36 V

Curves/Diagrams

Characteristic response curve

Offset Y [mm]

8

6

4

2

0

-2

-4

-6

-8

0 50 100 150 200 250 300 350 400

X

white 90 %

Y

grey 18 %

black 6 %

Distance X [mm]

OQT400-R201-2EP-IO

Detection ranges

Object colour

black

grey

white

0 40 80 120 160 200 240 280 320 360 400

X

Distance X [mm]

Settings

Teach-In (TI)

Use the rotary switch for switching signal Q1 or Q2 to select the relevant switching threshold A and/or B to teach in.

• The yellow LEDs indicate the current state of the selected output.

To teach in a switching threshold, press and hold the "TI" button for approximately 1 s, until the yellow and green LEDs flash in phase. Teach-in

starts when the "TI" button is released.

• Teach-in successful: the yellow and green LEDs flash alternately at 2.5 Hz.

• Teach-in unsuccessful: the yellow and green LEDs quickly flash alternately at 8 Hz.

After an unsuccessful Teach-in, the sensor continues to operate with the previous valid setting after the relevant visual fault signal is issued.

Set switching mode: you can define different switching modes by teaching in the relevant distance data for switching thresholds A and B.

1. Single point mode:

A leer

Release date: 2018-07-27 10:13 Date of issue: 2019-10-31 295670-100169_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

B leer

B

A

3

Page 4

Measuring sensor with multiple switch points

2. Window mode:

OQT400-R201-2EP-IO

A > B

BA

Teach in switching thresholds: you can teach in or overwrite a taught-in switching threshold at any time. To do this, press the "TI" button again.

Reset a value: you can reset a taught-in value. To do this, press the "TI" button for > 4 s, until the yellow and green LEDs go out. The reset

process itself starts when the "TI" button is released.

• Reset successful: the yellow and green LEDs flash alternately at 2.5 Hz.

B > A

AB

Resetting to Factory Settings

To revert back to factory settings, press the "TI" button for > 10 s with the rotary switch set to position "O," until the yellow and green LEDs go out

at the same time. The reset process itself starts when the "TI" button is released.

• Reset to factory settings successful: the yellow and green LEDs light up at the same time. The sensor then continues to operate with factory

settings.

OQT

• Factory setting for switching signal Q1:

Switching signal high active, BGS mode (background suppression)

• Factory setting for switching signal Q2:

Switching signal high active, BGS mode (background suppression)

Configuration via IO-Link interface

Configuring different operating modes via the IO-Link interface

The devices are equipped with an IO-Link interface as standard for diagnostics and parameterization tasks to ensure optimum

adjustment of the sensors to the relevant application. Four different operating modes can be set, among other features:

Background suppression operating mode (one switch point):

• Detection of objects irrespective of type and color in a defined detection range. Objects in the background are suppressed.

active detection range

Background

suppression

Background evaluation operating mode (one switch point):

• Detection of objects irrespective of type and color against a defined background. Reliable detection of objects at close range (detection range

>= 0 mm). The background serves as reference.

active detection range

Background evaluation

Single point mode operating mode (one switch point):

• Detection of objects irrespective of type and color in a defined detection range. Objects in the background are suppressed.

• The switch point corresponds exactly to the set point.

active detection range

Background

suppression

Window mode operating mode (two switch points):

• Detection of objects irrespective of type and color in a defined detection range. Reliable detection when object leaves the detection range.

• Window mode with two switch points.

active detection range

Background suppressionForeground suppression

Center window mode operating mode (one switch point):

• Detection of objects irrespective of type and color in a defined detection range. Sets a defined window around a given object. Objects outside

this window are not detected.

• Window mode with one switch point.

active detection range

Background suppressionForeground suppression

Two point mode operating mode (hysteresis operating mode):

• Detection of objects irrespective of type and color between a defined switch-on and switch-off point.

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

4

Release date: 2018-07-27 10:13 Date of issue: 2019-10-31 295670-100169_eng.xml

Page 5

Measuring sensor with multiple switch points

active detection range

Hysteresis

Output

Inactive operating mode:

• Evaluation of switching signals is deactivated.

The associated IODD device description file can be found in the download area at

OQT400-R201-2EP-IO

Output

Release date: 2018-07-27 10:13 Date of issue: 2019-10-31 295670-100169_eng.xml

Refer to "General Notes Relating to Pepperl+Fuchs Product Information".

Pepperl+Fuchs Group

5

Loading...

Loading...