Page 1

DATA SH EET

Product specification

Supersedes data of 1999 Mar 19

File under Integrated Circuits, IC19

1999 May 27

INTEGRATED CIRCUITS

OQ2541HP; OQ2541U

SDH/SONET data and clock

recovery unit STM1/4/16

OC3/12/48 GE

Page 2

1999 May 27 2

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

FEATURES

• Data and clock recovery up to 2.5 Gbits/s

• Multirate configurable (155, 622, 1250 or 2500 Mbits/s)

• Differential data input with 2.5 mV (p-p) typical

sensitivity

• Differential Current-Mode Logic (CML) data and clock

outputs with 50 Ω driving capability

• Adjustable CML output level

• Loop mode for system testing

• Bit error rate related loss of signal detection

• Few external components needed

• Single supply voltage

• Power dissipation 350 mW (typical value)

• LQFP48 plastic package.

APPLICATIONS

• Data and clock recovery in STM1/OC3, STM4/OC12

and STM16/OC48 transmission systems

• Data and clock recovery in Gigabit Ethernet (GE)

transmission systems.

DESCRIPTION

The OQ2541 is a data and clock recovery IC intended for

use in Synchronous Digital Hierarchy (SDH) and

Synchronous Optical Network (SONET) systems.

The circuit recovers data and extracts the clock signal

from an incoming bitstream up to 2.5 Gbits/s. It can be

configured for use in STM1/OC3, STM4/OC12,

STM16/OC48 and Gigabit Ethernet systems.

ORDERING INFORMATION

TYPE

NUMBER

PACKAGE

NAME DESCRIPTION VERSION

OQ2541HP LQFP48 plastic low profile quad flat package; 48 leads; body 7 × 7 × 1.4 mm SOT313-2

OQ2541U − bare die; 2360 × 2360 × 380 µm −

Page 3

1999 May 27 3

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

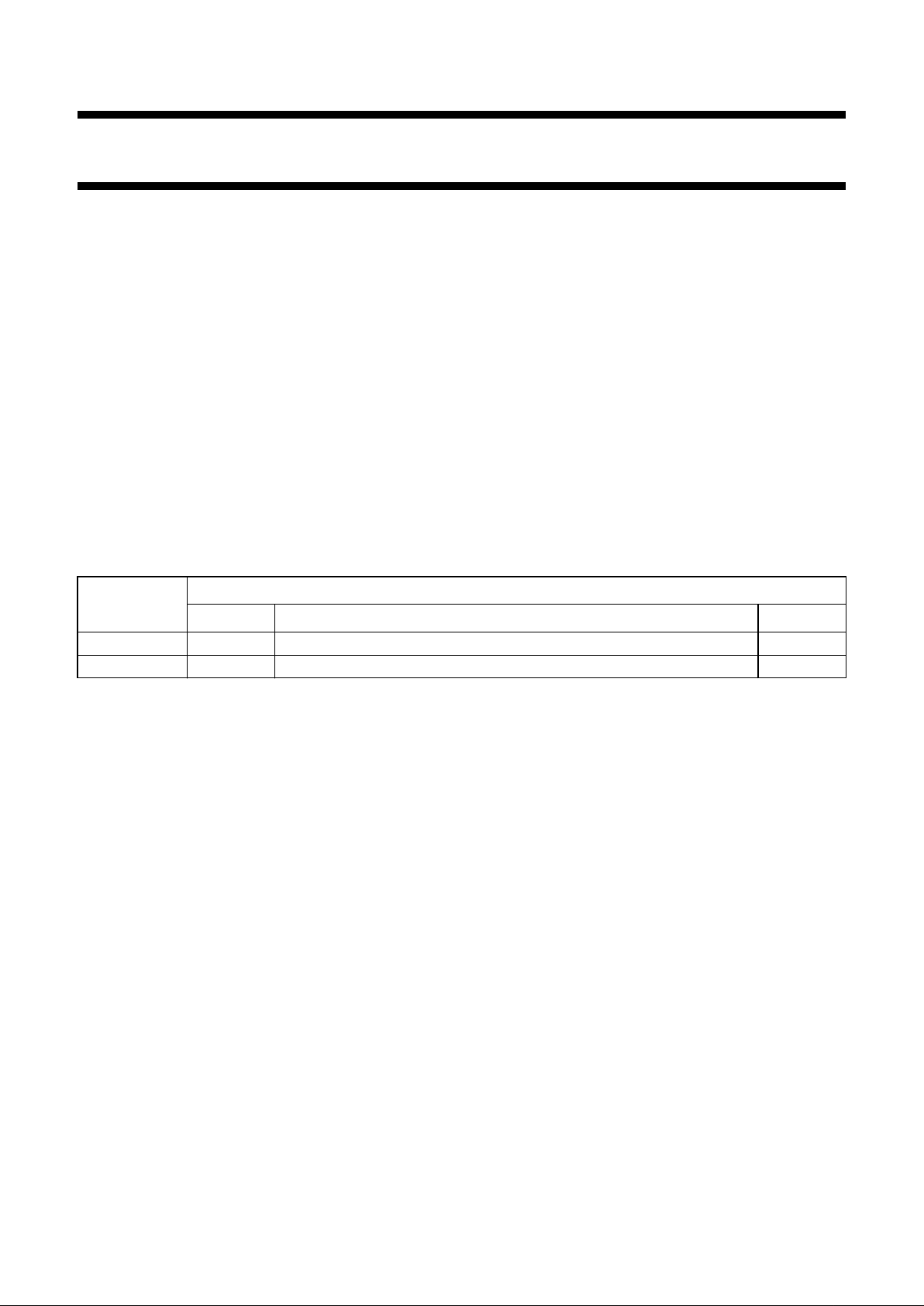

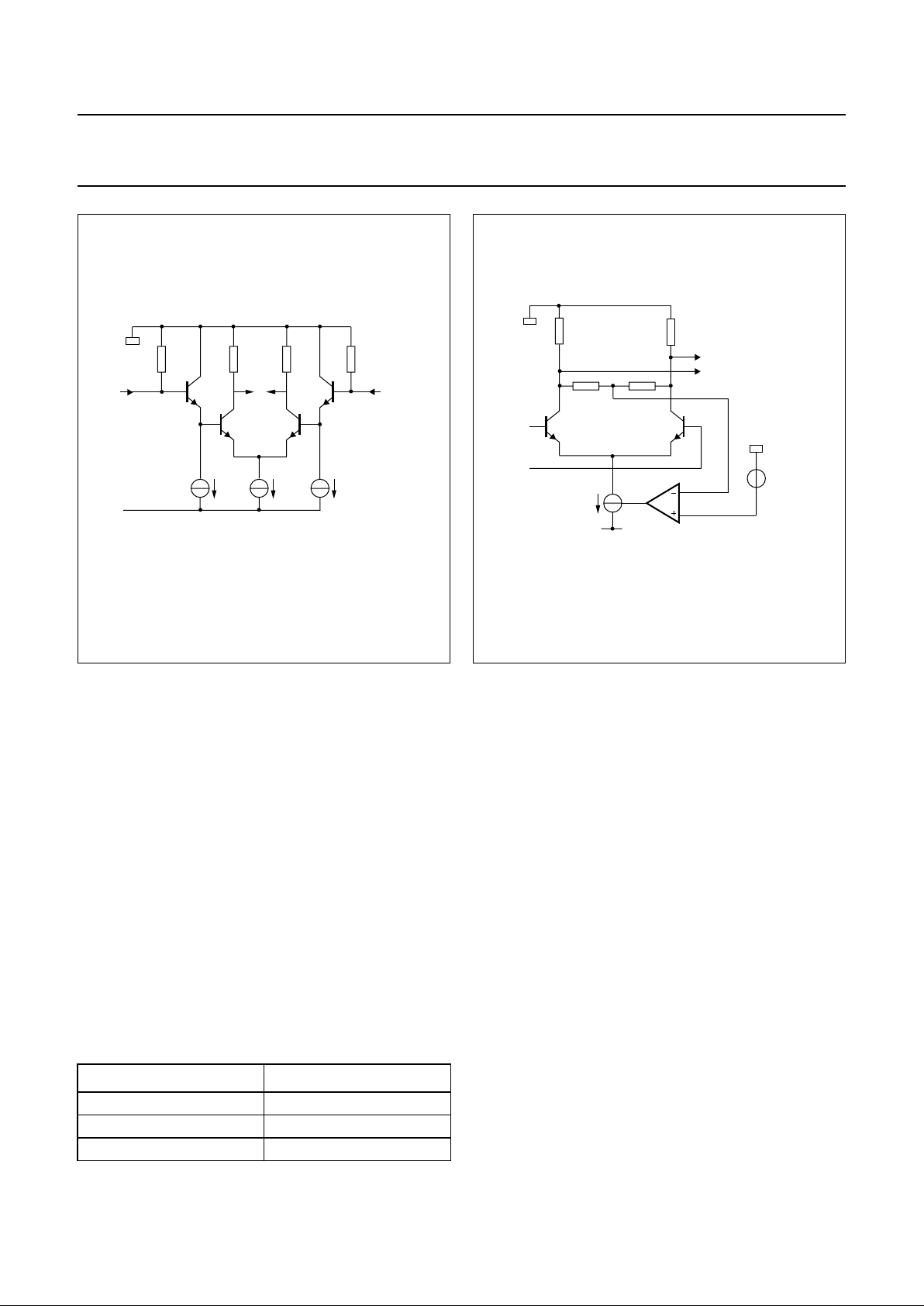

BLOCK DIAGRAM

Fig.1 Block diagram.

handbook, full pagewidth

MBH972

FREQUENCY

WINDOW

DETECTOR

(1000 ppm)

+

ALEXANDER

PHASE

DETECTOR

FREQUENCY

DIVIDER 1

1/2/4/16

FREQUENCY

DIVIDER 2

64/128

DATA

AND

CLOCK

OUTPUT

VCRO

2.5 GHz

proportional

path

integrating

path

POWER

CONTROL

1

2, 5, 8, 10, 11, 14, 17,

20, 23, 26, 29, 32, 35,

38, 41, 44, 47

13, 18, 19,

36, 40

9

33

28

30

1516

21

22

enable

48

42

45

46

7

37

39

12 24 25

OQ2541

DIN

34

DINQ

DOUT622

DOUT155

27

DOUT1250

V

EE1

31

V

EE2

DOUT

DOUTQ

COUT

COUTQ

DLOOP

DLOOPQ

CLOOP

CLOOPQ

43

LOS

PC

AREF

GND

3

4

6

DREF19LOCK

CAPUPQ

CAPDOQDREF39

CREF

CREFQ

i.c.

ENL

130 pF130 pF

∫ dt

17

5

Page 4

1999 May 27 4

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

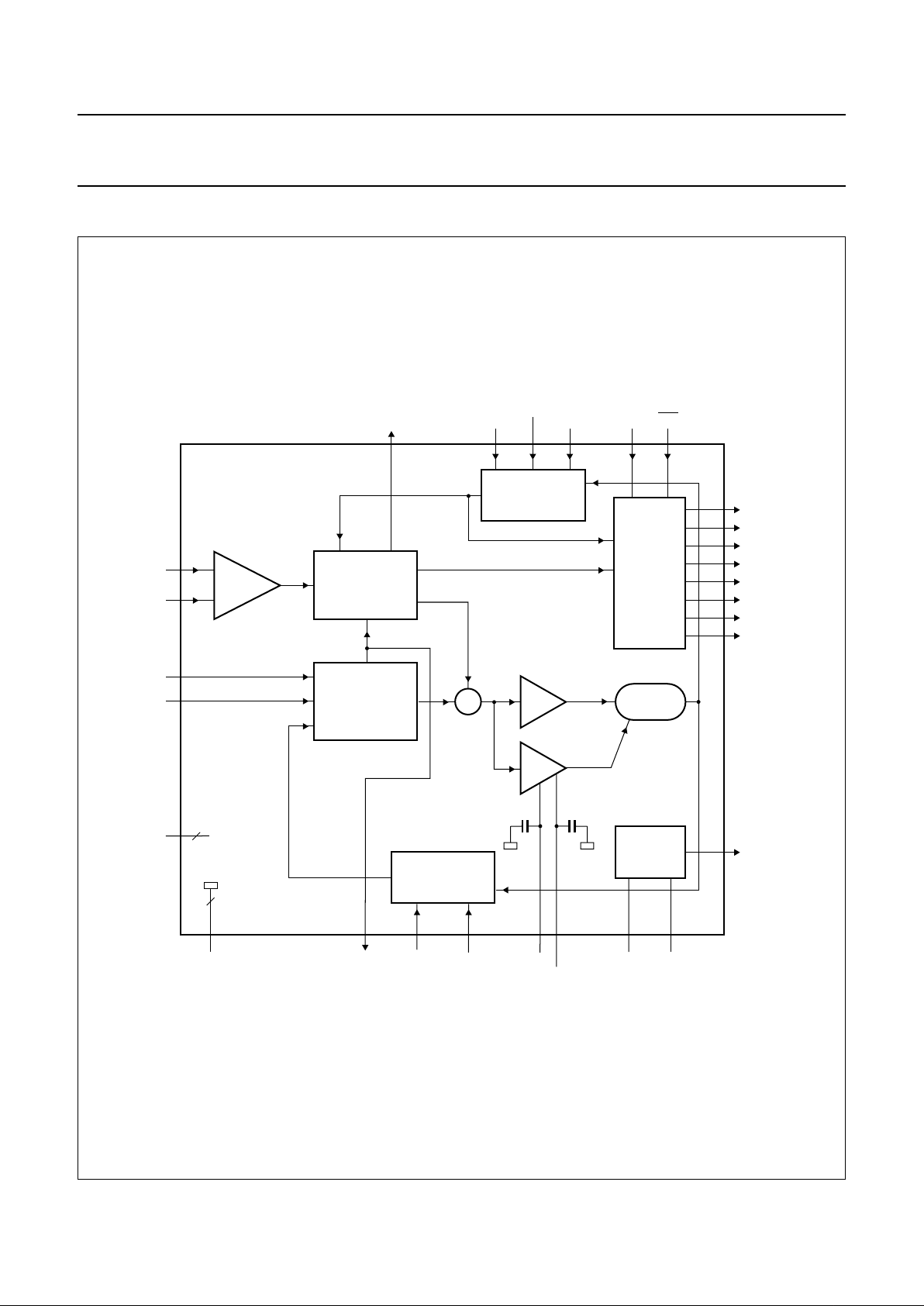

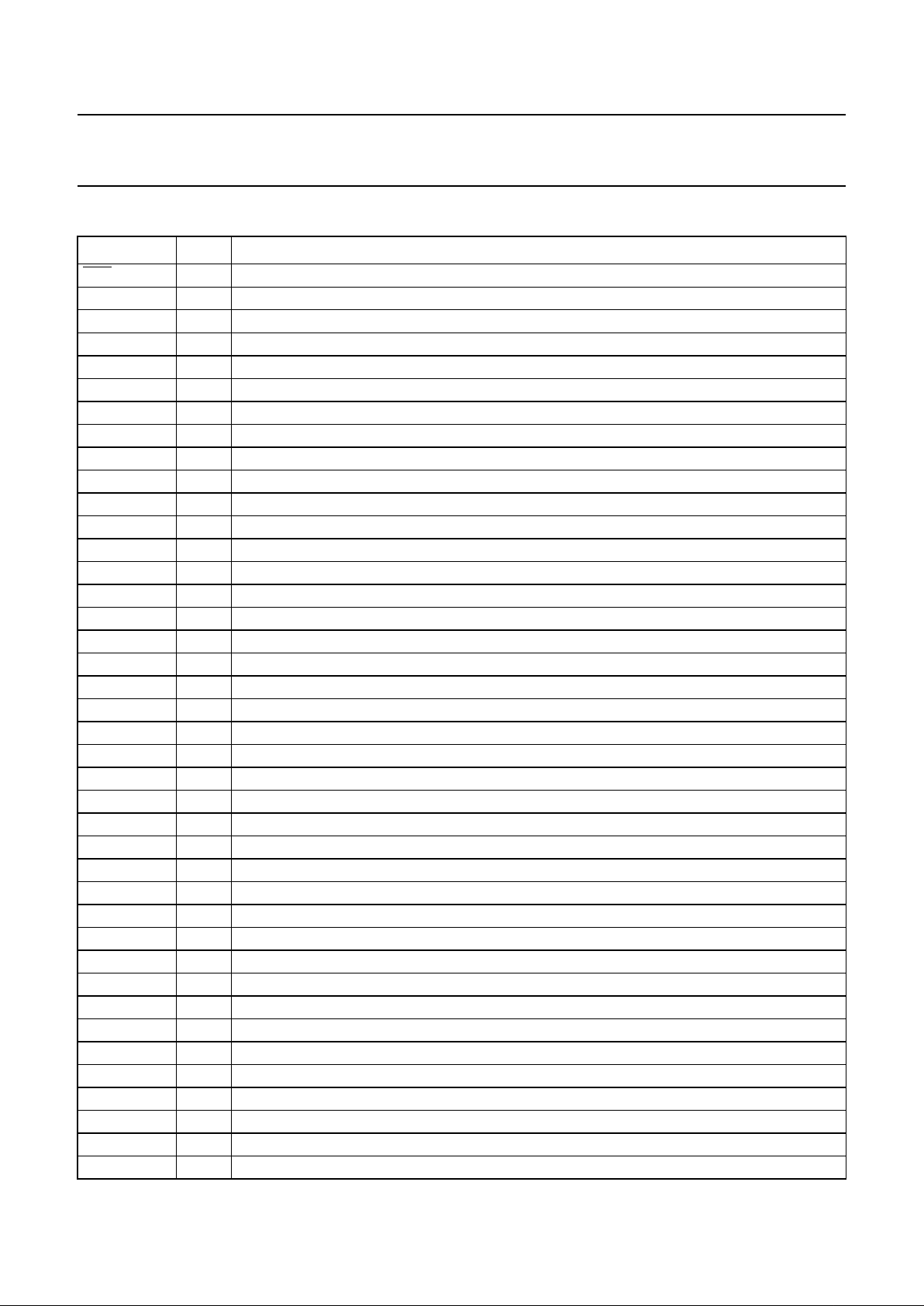

PINNING

SYMBOL PIN DESCRIPTION

ENL 1 loop mode enable input (active LOW)

GND 2 ground; note 1

CLOOP 3 clock output in loop mode (differential)

CLOOPQ 4 inverted clock output in loop mode (differential)

GND 5 ground; note 1

DLOOP 6 data output in loop mode (differential)

DLOOPQ 7 inverted data output in loop mode (differential)

GND 8 ground; note 1

DREF19 9 reference frequency select input 1 (see Table 2)

GND 10 ground; note 1

GND 11 ground; note 1

LOCK 12 phase lock detection output

i.c. 13 internally connected; note 2

GND 14 ground; note 1

CAPUPQ 15 external loop filter capacitor connection

CAPDOQ 16 external loop filter capacitor return connection

GND 17 ground; note 1

i.c. 18 internally connected; note 2

i.c. 19 internally connected; note 2

GND 20 ground; note 1

CREF 21 reference clock input (differential)

CREFQ 22 inverting reference clock input (differential)

GND 23 ground; note 1

DREF39 24 reference frequency select input 2 (see Table 2)

V

EE1

25 negative supply voltage (−3.3 V); note 3

GND 26 ground; note 1

DOUT1250 27 STM mode select input 1 (see Table 3)

DOUT622 28 STM mode select input 2 (see Table 3)

GND 29 ground; note 1

DOUT155 30 STM mode select input 3 (see Table 3)

V

EE2

31 negative supply voltage (−3.3 V); note 3

GND 32 ground; note 1

DIN 33 data input (differential)

DINQ 34 inverting data input (differential)

GND 35 ground; note 1

i.c. 36 internally connected; note 2

PC 37 control output for negative power supply

GND 38 ground; note 1

LOS 39 loss of signal detection output

i.c. 40 internally connected; note 2

Page 5

1999 May 27 5

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Notes

1. ALL GND pins or pads must be bonded; do not leave one single GND pin or pad unconnected.

2. ALL pins or pads denoted ‘i.c.’ should not be connected. Connections to these pins or pads degrade device

performance.

3. ALL VEE pins or pads must be bonded; do not leave one single VEE pin or pad unconnected.

GND 41 ground; note 1

DOUT 42 data output in normal mode (differential)

DOUTQ 43 inverted data output in normal mode (differential)

GND 44 ground; note 1

COUT 45 clock output in normal mode (differential)

COUTQ 46 inverted clock output in normal mode (differential)

GND 47 ground; note 1

AREF 48 reference voltage input for controlling voltage swing on data and clock outputs

SYMBOL PIN DESCRIPTION

Fig.2 Pin configuration.

handbook, full pagewidth

1

2

3

4

5

6

7

8

9

10

11

36

35

34

33

32

31

30

29

28

27

26

13

14

15

16

17

18

19

20

21

22

23

48

47

46

45

44

43

42

41

40

39

38

12

24 37

25

OQ2541HP

MBH971

i.c.

GND

DINQ

DIN

V

EE2

DOUT155

GND

DOUT622

DOUT1250

GND

V

EE1

GND

GND

COUTQ

COUT

GND

DOUTQ

DOUT

i.c.

LOS

GND

PC

AREF

GND

ENL

GND

CLOOP

CLOOPQ

GND

DLOOP

GND

DREF19

GND

LOCK

DLOOPQ

GND

GND

CAPUPQ

CAPDOQ

GND

i.c.

i.c.

GND

CREFQ

GND

DREF39

i.c.

CREF

Page 6

1999 May 27 6

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

FUNCTIONAL DESCRIPTION

The OQ2541 recovers data and clock signals from an

incoming high speed bitstream. The input signal on

pins DIN and DINQ is buffered and amplified by the input

circuitry (see Fig.1). The signal is then fed to the Alexander

phase detector where the phase of the incoming data

signal is compared with that of the internal clock. If the

signals are out of phase, the phase detector generates

correction pulses (up or down) that shift the phase of the

Voltage Controlled Ring Oscillator (VCRO) output in

discrete amounts (∆ϕ) until the clock and data signals are

in phase. The technique used is based on principles first

proposed by J.D.H. Alexander, hence the name of the

phase detector.

Data sampling

The eye pattern of the incoming data is sampled at three

instants A, T and B (see Fig.3). When clock and data

signals are synchronized (locked):

• A is the centre of the data bit

• T is in the vicinity of the next transition

• B is in the centre of the bit following the transition.

If the same level is recorded at both A and B, a transition

has not occurred and no action is taken regardless of the

level T. However, if levels A and B are different a transition

has occurred and the phase detector uses level T to

determine whether the clock was too early or too late with

respect to the data transition.

If levels A and T are the same, but different from level B,

the clock was too early and needs to be slowed down a

little. The Alexander phase detector then generates a

down pulse which stretches a single output pulse from the

ring oscillator by approximately 0.25% which is 1 ps of the

400 ps bit period in the STM16/OC48 mode. This forces

the VCRO to run at a slightly lower frequency for one bit

period. The phase of the clock signal is thus shifted

fractionally with respect to the data signal.

Fig.3 Data sampling.

handbook, halfpage

MGK143

DATADATA

CLOCK

ATB

If, on the other hand, levels B and T are the same but

different from level A, the clock was too late and needs to

be speeded up for synchronization. The phase detector

generates an up pulse forcing the VCRO to run at a slightly

higher frequency (+0.25%) for one bit period. The phase of

the clock signal is shifted with respect to the data signal (as

above, but in the opposite direction). Only the proportional

path is active while these phase adjustments are being

made. Because the instantaneous frequency of the VCRO

can be changed only in one of two discrete steps

(±0.25%), this type of loop is also known as a Bang/Bang

Phase-Locked Loop (PLL).

If not only the phase but also the frequency of the VCRO

is incorrect, a long train of up or down pulses will be

generated. This pulse train is integrated to generate a

control voltage that is used to shift the centre frequency of

the VCRO. Once the correct frequency has been

established, only the phase will need to be adjusted for

synchronization. The proportional path adjusts the phase

of the clock signal, whereas the integrating path adjusts

the centre frequency.

Frequency window detector

The frequency window detector checks the VCRO

frequency which must be within a 1000 ppm (parts per

million) window around the required frequency.

It compares the output of frequency divider 2 with the

reference frequency on pins CREF and CREFQ

(19.44 or 38.88 MHz; see Table 2). If the VCRO frequency

is found to be outside this window, the frequency window

detector disables the Alexander phase detector and forces

the VCRO output to a frequency within the window.

The phase detector then starts acquiring lock again.

Because of the loose coupling of 1000 ppm, the reference

frequency does not need to be highly accurate or stable.

Any crystal based oscillator that generates a reasonably

accurate frequency (e.g. 100 ppm) will do.

Since sampling point A is always in the centre of the eye

pattern when the data and clock signals are in phase

(locked), the values recorded at this point are taken as the

retrieved data. The data and clock signals are available at

the CML output buffers, which are capable of driving a

50 Ω load.

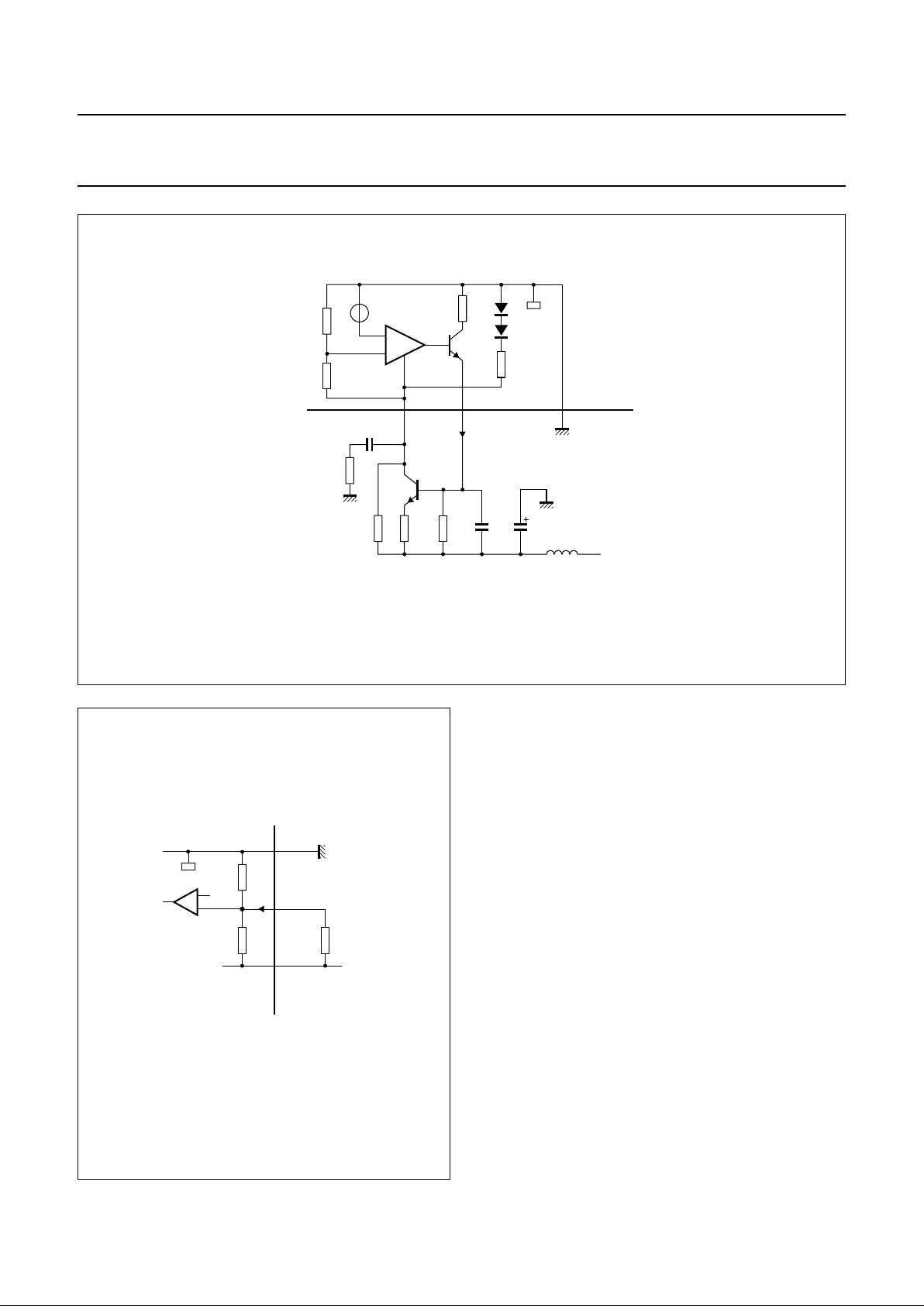

RF data and clock input circuit

The schematic of the input circuit is shown in Fig.4.

RF data and clock output circuit

The schematic of the output circuit is shown in Fig.5.

Page 7

1999 May 27 7

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.4 RF data and clock input circuit.

MGL669

VEE

DINQ,

CREFQ

DIN,

CREF

50 Ω50 Ω

Fig.5 RF data and clock output circuit.

handbook, halfpage

MGL670

V

AREF

V

EE

DOUTQ, COUTQ

100 Ω100 Ω

DOUT, COUT

Power supply and power control loop

The OQ2541 contains an on-board voltage regulator.

An external power transistor is needed to deliver the

supply to this circuit. The required external circuit is

straightforward, and can be built using a few components.

A suitable circuit with a power supply of−4.5 V is illustrated

in Fig.6.

A different configuration could be used, as long as the

power supply rejection ratio is greater than 60 dB for all

frequencies. The inductor is a RF choke with an

impedance greater than 50 Ω at frequencies higher than

2 MHz. Any transistor with a β > 100 and enough current

sink capability can be used.

The OQ2541 can also be used with a power supply of

−5.0 or −5.2 V. The only adaptation to be made to the

power control circuit is to change the emitter resistor R1

(see Table 1).

Table 1 Value of resistor R1.

POWER SUPPLY RESISTOR R1

−4.5 V 2.0 Ω

−5.0 V 6.8 Ω

−5.2 V 8.2 Ω

Output amplitude reference

The voltage swing at the CML compatible output stages

(pins DOUT, DOUTQ, COUT, COUTQ, DLOOP,

DLOOPQ, CLOOP and CLOOPQ) can be controlled by

adjusting the voltage on pin AREF (see Fig.7). An internal

voltage divider of 500 Ω and 16 kΩ connected between

ground and VEE initially fixes this level.

In most applications the outputs will be DC-coupled to a

load of 50 Ω. The output level regulation circuit will

maintain a 200 mV (p-p) single-ended swing across this

load. The voltage on pin AREF is half the single-ended

peak-to-peak value of the output signal (−100 mV).

No adjustments are necessary with DC-coupling.

If the outputs are AC-coupled, the voltage on pin AREF is

half the single-ended peak-to-peak value of the output

signal multiplied by a factor

where R

L

is the external load and Ro is the output

impedance of the OQ2541 (100 Ω).

R

LRo

+

R

L

--------------------

Page 8

1999 May 27 8

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.6 Schematic diagram of OQ2541 power control loop.

(1) L1 = RF choke type Murata BLM21 or equivalent.

handbook, full pagewidth

2 Ω

R1

2 Ω

1 kΩ

1

kΩ

1 µF

L1

(1)

−4.5 V

β > 100

100 nF

3.3

nF

MGL732

BAND GAP

REFERENCE

V

EE

PC

GND

off chip

on chip

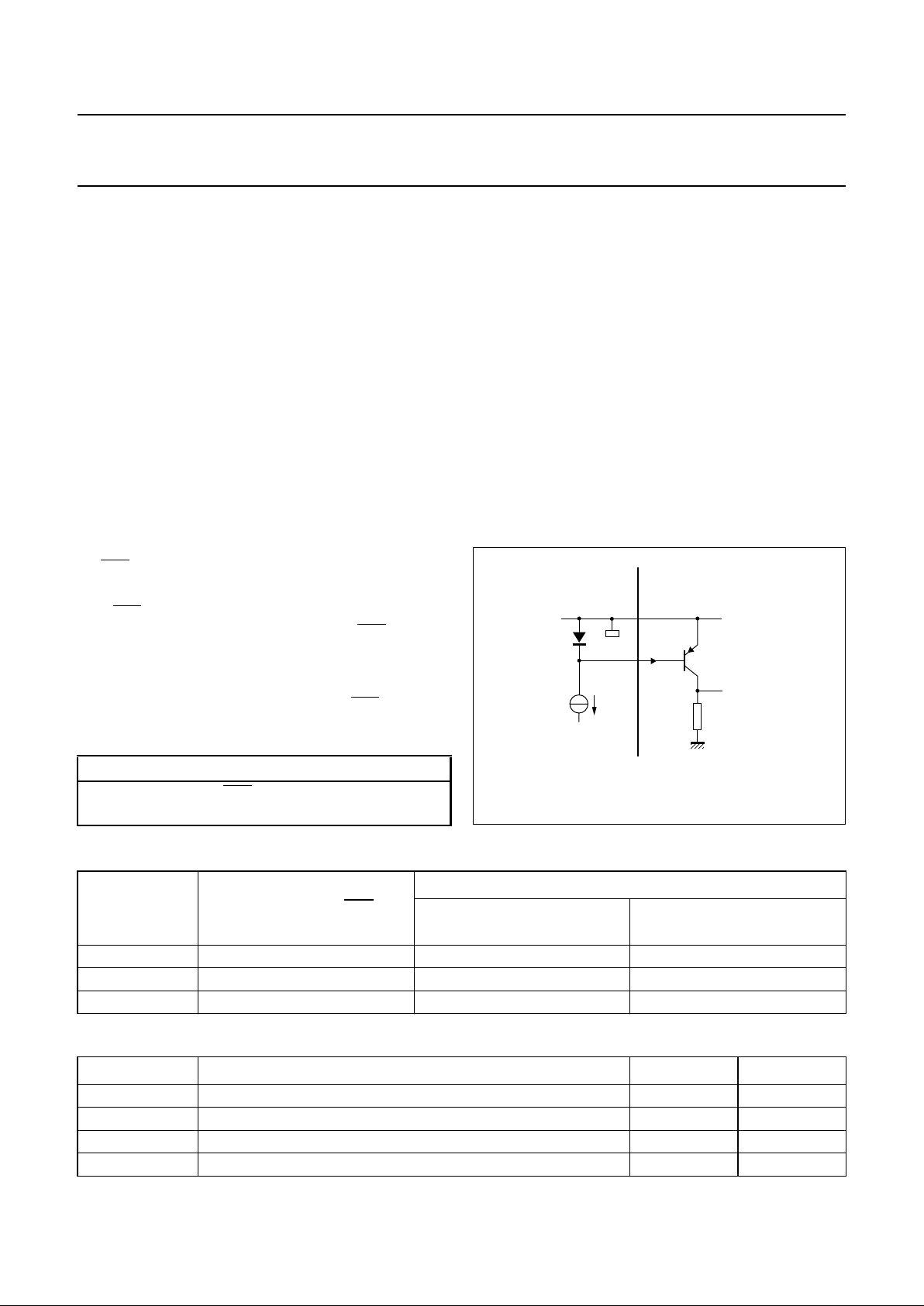

Fig.7 Functionality of pin AREF.

handbook, halfpage

MGL667

500 Ω

16 kΩ R

AREF

V

EE

AREF

off chipon chip

V

AREF

GND

If the outputs are AC-coupled, the formulae for calculating

the required voltage on pin AREF and the value of the

resistor connected between pins AREF and VEE as

follows:

(1)

and:

(2)

where R1 = 500 Ω, R2 = 16 kΩ and V

EE

= −3.3 V.

To maintain a single-ended swing of 200 mV (p-p) across

a 50 Ω AC-coupled load, the voltage on pin AREF must be

This can be achieved by connecting a 7.3 kΩ resistor

between pins AREF and V

EE

.

V

AREF

RLRo+

R

L

--------------------

0.5V

swing

×–=

R

AREF

R1

V

EE

V

AREF

---------------- -

1–

×

1

R1

R2

------- -

V

EE

V

AREF

---------------- -

1–

×

–

----------------------------------------------------------------

=

100 mV–

50 + 100()Ω

50 Ω

-----------------------------------

× 300 mV–=

Page 9

1999 May 27 9

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

External capacitor for loop filter

The loop filter is an integrator with a built-in capacitance of

2 × 130 pF. An external capacitance of 200 nF must be

connected between pins CAPUPQ and CAPDOQ to

ensure loop stability while the frequency window detector

is active.

Loop mode enable

The loop mode is provided for system testing (see Fig.8).

The loop mode is enabled by applying a voltage lower than

0.8 V (TTL LOW-level) to pin

ENL. This selects the loop

mode: the outputs on pins DLOOP, DLOOPQ, CLOOP

and CLOOPQ are switched on.

If a voltage higher than 2.0 V (TTL HIGH-level) is applied

to pin ENL, then pins DOUT, DOUTQ, COUT and COUTQ

are switched on while pins DLOOP, DLOOPQ, CLOOP

and CLOOPQ are disabled to minimize power

consumption.

If pin ENL is connected to VEE(−3.3 V), all outputs are

enabled.

Lock detection

Pin LOCK should be interpreted as an indication for the

presence of the reference clock on pin CREF and for

properly functioning of the acquisition aid (frequency

window detector).

Fig.8 Input circuit of pin ENL.

handbook, halfpage

MGL668

DECODER

LOGIC

ENL

GND

V

EE

36 kΩ

off chip on chip

Pin LOCK is an open-collector TTL output and should be

pulled up with a 10 kΩ resistor to a positive supply voltage.

If the VCO frequency is within a 1000 ppm window around

the desired frequency, pin LOCK will remain at a

HIGH-level. If no reference clock is present, or the VCO is

outside the 1000 ppm window, pin LOCK will be at a

LOW-level. The logic level on pin LOCK does not indicate

locking of the PLL to the incoming data; this is indicated by

the signal on pin LOS.

Loss of signal detection

The Loss Of Signal (LOS) function is closely related to the

functionality of the Alexander phase detector; see Fig.3 for

the meaning of A, B and T in this section.

In the functional description it is described that the phase

detector does not take any action if the value at sample

points A and B are the same, because there has not been

any transition. However, if levels A and B are the same but

different from level T, this still means there has not been

any transition, but level T has got the wrong level

somehow. This is probably due to noise or bad signal

integrity, which will lead to a bit error. Hence the

occurrence of this particular situation is an indication for bit

errors. If too many of these bit errors occur per time and

the PLL is gradually losing lock, the LOS alarm is asserted.

The LOS alarm assert level is around a Bit Error Rate

(BER) for BER = 5 ⋅ 10

−2

and the de-assert level is around

BER = 1 ⋅ 10−3.

The LOS function will only work properly if the input signal

is larger than the input offset of the OQ2541; otherwise,

the signal will be masked by the input offset and

interpreted as consecutive bits of the same sign, thus

obstructing a proper LOS detection. In practice an optical

front-end device with a noise level (RMS value) larger than

the specified offset of the OQ2541 will ensure a proper

LOS indication.

The LOS detection is BER related, but neither dependent

on the data stream content, nor protocol. Therefore, an

SDH/SONET data stream is no prerequisite for a proper

LOS function. Since the LOS function of the OQ2541 is

derived from digital signals, it is a good supplement to an

analog, amplitude based, LOS indication.

Pin LOS is an open-collector TTL compatible output.

A pull-up resistor should be connected to a positive supply

voltage.

Pin LOS will be at a HIGH-level (TTL) if the data signal is

absent on pins DIN and DINQ or if BER > 5 ⋅ 10−2;

otherwise pin LOS will be at a LOW-level if BER < 1 ⋅ 10−3.

Page 10

1999 May 27 10

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Reference frequency select

A reference clock signal of 19.44 or 38.88 MHz must be

connected to pins CREF and CREFQ. It should be noted

that the reference frequency should be either

39.0625 MHz or 19.53125 MHz in a Gigabit Ethernet

system. Pins DREF19 and DREF39 are used to select the

appropriate output frequency at frequency divider 2

(see Table 2).

To minimize the adverse influence of reference clock

crosstalk, a differential signal with an amplitude from

75 to 150 mV (p-p) is advised.

Since the reference clock is only used as an acquisition aid

for the PLL of the frequency window detector, the quality

of the reference clock (i.e. phase noise) is not important.

There is no phase noise specification imposed on the

reference clock generator and even frequency stability

may be in the order of 100 ppm. In general, most

inexpensive crystal based oscillators are suitable.

When the OQ2541 is used in an application with a fixed

reference clock frequency, it is best to connect the planes

of pins DREF19 and DREF39 with a short trace or a via to

the plane of pin GND or pin V

EE

. If a selectable reference

clock frequency is required in the application, the pins can

be controlled through low ohmic switching FETs,

e.g. BSH103 or equivalent (low R

DSon

).

Table 2 Reference frequency selection

STM mode selection

The VCRO has a very large tuning range. However, the

performance of the OQ2541 is optimized for SDH/SONET

bit rates.

FREQUENC

Y (MHz)

DIVISION

FACTOR

LEVEL ON PIN

DREF19 DREF39

38.88 64 ground V

EE

19.44 128 V

EE

V

EE

Due to the nature of the PLL, the very wide tuning range is

a necessity for proper lock behaviour over the guaranteed

temperature range, aging and batch to batch spread.

Though it might seem that the OQ2541 is capable of

recovering other bit rates than SDH/SONET and Gigabit

Ethernet rates (STM1/OC3, STM4/OC12, STM16/OC48

and 1250 Mbits/s), the behaviour can not be guaranteed.

The required SDH/SONET bit rate is selected by

connecting pins DOUT155, DOUT622 and DOUT1250

to ground or to the supply voltage VEE (see Table 3):

• For STM16/OC48 (2488.32 Mbits/s) operation:

all three pins must be connected to ground

• For Gigabit Ethernet (1250 Mbits/s) operation:

pin DOUT1250 must be connected to V

EE

• For STM4/OC12 (622.08 Mbits/s) operation:

pins DOUT1250 and DOUT622 must be connected to

VEE (the dividers are daisy chained)

• For STM1/OC3 (155,52 Mbits/s) operation:

all three pins must be connected to VEE.

The connections to VEE and ground carry a current of a few

milliamperes and should have low resistance and

inductance, so short printed-circuit board tracks are

recommended. In some cases a decoupling capacitor near

the selection pins can be necessary to provide a clean

return path for RF signals.

When the OQ2541 is used in an application with a fixed

data rate, it is best to connect the planes of

pins DOUT155, DOUT622 and DOUT1250 with a short

trace or a via to the plane of pin GND or pin VEE. If a

selectable reference clock frequency is required in the

application, the pins can be controlled through low-ohmic

switching FETs, e.g. BSH103 or equivalent (low R

DSon

).

Table 3 STM mode select

MODE

BIT RATE

(Mbits/s)

DIVISION

FACTOR

LEVEL ON PIN

DOUT155 DOUT622 DOUT1250

STM1/OC3 155.52 16 V

EE

V

EE

V

EE

STM4/OC12 622.08 4 ground V

EE

V

EE

Gigabit Ethernet 1250.00 2 ground ground V

EE

STM16/OC48 2488.32 1 ground ground ground

Page 11

1999 May 27 11

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Application with positive supply voltage

Due to the versatile design of the OQ2541 the device can

also operate in a positive supply voltage application,

although some pins have a different mode of operation.

This section deals with these differences and supports the

user with achieving a successful application of the

OQ2541 in a +5 V environment.

A

PPLICATION DIAGRAM

A sample application diagram can be found in Fig.29.

It should be noted that all pins GND are now connected to

VCC and all pins VEE are connected to the regulated

voltage from the power controller.

O

UTPUT SELECTION

In a positive supply voltage application, the loop mode is

the default RF output. Due to the decoding logic on

pin ENL, it is only possible to select the loop mode outputs

or enable all the outputs.

If pin ENL is connected to VCC (+5 V), only the loop mode

outputs are active (see Table 4). When pin ENL is

connected to VEE (the voltage is approximately 3.3 V

below VCC) all outputs become active. In the positive

supply voltage application the normal mode outputs can

not be selected, unless the voltage on pin ENL is 2 V

above the positive supply voltage (VCC).

CAUTION

Do not to connect pin ENL to ground, because this will

destroy the IC.

LOSS OF SIGNAL AND LOCK DETECTION

In the negative supply application, pins LOS and LOCK

are open-collector outputs that require pull-up resistors to

a positive supply voltage.

In the positive supply application, the pull-up voltage would

need to be higher then the positive supply voltage and the

signals on pins LOS and LOCK would not be TTL

compatible any more. However, the internal circuit on

pins LOS and LOCK can be used in a current mirror

configuration (see Fig.9). This requires only an external

PNP transistor (e.g. BC857 or equivalent) to mirror the

current. A 10 kΩ pull-down resistor from the collector of the

external transistor to ground yields a TTL compatible

signal again, albeit inverted. Table 5 shows the meaning of

the LOS and LOCK flag, when used in the positive supply

application.

Fig.9 Signal out for LOS and LOCK indication in a

positive supply voltage application.

handbook, halfpage

MGL671

GND

BC857

+5 V

signal out

LOS,

LOCK

10 kΩ

off chipon chip

Table 4 Output selection in a positive supply voltage application

Table 5 LOS and LOCK indication in a positive supply voltage application

MODE LEVEL ON PIN ENL

OUTPUT

DLOOP, DLOOPQ,

CLOOP AND CLOOPQ

DOUT, DOUTQ,

COUT AND COUTQ

Loop V

CC

(+5 V) active −

Loop and normal V

EE

(VCC− 3.3 V) active active

Normal V

CC

+2V − active

SIGNAL DESCRIPTION LEVEL TTL

LOS active loss of signal: BER > 5 ⋅ 10

−2

0 V (ground) LOW

LOS inactive no loss of signal: BER < 1 ⋅ 10

−3

+5 V (VCC) HIGH

LOCK active reference clock present and VCRO inside 1000 ppm window 0 V (ground) LOW

LOCK inactive no reference clock present or VCRO outside 1000 ppm window +5 V (V

CC

) HIGH

Page 12

1999 May 27 12

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

DIVIDER SETTINGS

The reference frequency dividers and the STM mode

selectors still operate the same in a positive supply voltage

application. The only difference is that pins formerly

connected to ground should now be connected to V

CC

(+5 V). Pins connected to VEE should still be connected to

VEE because connecting these pins to ground (0 V) will

damage the IC.

RF

INPUT AND OUTPUTS

All RF inputs, outputs and internal signals of the OQ2541

are referenced to pins GND. In the positive supply voltage

application, this means that all RF signals are referenced

to VCC. Therefore a clean VCC rail is of ultimate importance

for proper RF performance. The best performance is

obtained when the transmission line reference plane is

also decoupled to VCC. Careful design of VCC and good

decoupling schemes should be taken into account. While

designing the printed-circuit board, bear in mind that the

VCC has become what was formerly ground.

While laying out the application, the return path is the most

important issue to be considered. It is always advised to

examine carefully the current carrying loops in the design.

Care should be taken that for all frequencies (both of

interest and not of interest) low ohmic and low inductance

return paths are available. These return paths should

preferably have an enclosed area as small as possible,

both horizontally and vertically (by means of through-holes

or vias). The position of a decoupling capacitor is very

important. A decoupling capacitor on an unfavourable

position could do more damage than completely omitting

the capacitor, while on the right location it can mean the

difference between mediocre results and the ultimate

achievement.

Page 13

1999 May 27 13

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

HANDLING INSTRUCTIONS

Precautions should be taken to avoid damage through electrostatic discharge. This is particularly important during

assembly and handling of the bare die. Additional safety can be obtained by bonding the V

EE

and GND pads first, the

remaining pads may then be bonded to their external connections in any order.

THERMAL CHARACTERISTICS

Note

1. Thermal resistance from junction to ambient is determined with the IC soldered on a standard single sided

57 × 57 × 1.6 mm FR4 epoxy PCB with 35 µm thick copper traces. The measurements are performed in still air.

SYMBOL PARAMETER MIN. MAX. UNIT

V

EE

negative supply voltage −6 +0.5 V

V

n

DC voltage on pins

CLOOP, CLOOPQ, DLOOP, DLOOPQ, CREF, CREFQ, DIN, DINQ,

DOUT, DOUTQ, COUT and COUTQ

−1 +0.5 V

ENL, LOCK and LOS, VEE− 0.5 +5.5 V

DREF19, DREF39, DOUT1250, DOUT622, DOUT155, PC and AREF V

EE

− 0.5 +0.5 V

CAPUPQ and CAPDOQ V

EE

+ 0.5 −0.5 V

I

n

input current on pins

ENL − 1mA

CREF, CREFQ, DIN and DINQ −20 +10 mA

P

tot

total power dissipation − 700 mW

T

amb

ambient temperature −40 +85 °C

T

j

junction temperature −40 +110 °C

T

stg

storage temperature −65 +150 °C

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-s)

thermal resistance from junction to solder point 46 K/W

R

th(j-a)

thermal resistance from junction to ambient in free air; note 1 67 K/W

Page 14

1999 May 27 14

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

CHARACTERISTICS

V

EE

= −3.3 V; T

amb

= −40 to +85 °C; typical values measured at T

amb

=25°C; all voltages are measured with respect

to GND.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

EE

negative supply voltage see Fig.12; note 1 −3.50 −3.30 −3.10 V

I

EE

negative supply current open outputs; see Fig.13 − 105 155 mA

P

tot

total power dissipation − 350 550 mW

Data and clock inputs: pins DIN, DINQ, CREF and CREFQ

V

i(p-p)

input voltage

(peak-to-peak value)

50 Ω measurement system;

see Fig.10; notes 2 and 3

7 200 450 mV

V

i(sens)(p-p)

input sensitivity

(peak-to-peak value)

50 Ω measurement system;

notes 2 and 4

− 2.5 7 mV

V

IO

DC input offset voltage 50 Ω measurement system −3 0 +3 mV

V

I

input voltage 50 Ω measurement system −600 −200 +250 mV

Z

i

input impedance single-ended; see Fig.4; note 5 − 50 −Ω

Data and clock outputs: pins DOUT, DOUTQ, DLOOP, DLOOPQ, COUT, COUTQ, CLOOP and CLOOPQ

V

o(p-p)

output voltage swing

(peak-to-peak value)

50 Ω measurement system;

single-ended; see Fig.10

default adjustment; note 6 170 200 210 mV

special adjustment; note 7 50 − 400 mV

V

O

output voltage −600 − 0mV

Z

o

output impedance single-ended − 100 −Ω

t

r(C)

clock output rise time differential; 20% to 80% − 54 − ps

t

f(C)

clock output fall time differential; 20% to 80% − 54 − ps

t

r(D)

data output rise time differential; 20% to 80% − 116 − ps

t

f(D)

data output fall time differential; 20% to 80% − 116 − ps

t

d(D-C)

data-to-clock delay see Fig.11; note 8 250 280 310 ps

Output amplitude adjustment: pin AREF

V

AREF

output amplitude reference

voltage

floating pin −110 −100 −90 mV

Power control output: pin PC

g

m

transconductance −84 −60 −42 mA/V

I

O

output current 1 − 3.5 mA

Loop mode enable input: pin

ENL

V

IL

LOW-level input voltage −−0.8 V

V

IH

HIGH-level input voltage 2.0 −−V

Phase lock indicator: pin LOCK

V

OL

LOW-level output voltage note 9 −0.6 −−V

V

OH

HIGH-level output voltage note 9 −−3.3 V

Page 15

1999 May 27 15

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Loss of signal indicator: pin LOS

V

OL

LOW-level output voltage note 9 −0.6 −−V

V

OH

HIGH-level output voltage note 9 −−3.3 V

t

as

assert time note 10 − 0.1 −µs

t

das

de-assert time note 10 − 10 −µs

BER

as

assert bit error rate note 10 − 5 ⋅ 10−2− BER

BER

das

de-assert bit error rate note 10 − 1 ⋅ 10−3− BER

PLL characteristics

t

acq

acquisition time CREF = 19.44 MHz − 100 200 µs

CREF = 38.88 MHz − 50 200 µs

J

tol(p-p)

jitter tolerance

(peak-to-peak value)

STM1/OC3 mode; note 11

f = 6.5 kHz 1.5 >10 − UI

f = 65 kHz 0.15 1.3 − UI

f = 1 MHz 0.15 0.8 − UI

STM4/OC12 mode; note 11

f = 25 kHz 1.5 >10 − UI

f = 100 kHz 0.7 3 − UI

f = 250 kHz 0.15 1.3 − UI

f = 1 MHz 0.15 0.50 − UI

f = 5 MHz 0.15 0.35 − UI

STM16/OC48 mode; note 11

f = 100 kHz 1.5 >10 − UI

f = 1 MHz 0.15 1.1 − UI

f = 10 MHz 0.15 0.23 − UI

J

gen(p-p)

jitter generation

(peak-to-peak value)

STM1/OC3 mode; note 12

f = 500 Hz to 1.3 MHz − 0.039 0.50 UI

f = 12 kHz to 1.3 MHz − 0.032 0.10 UI

f = 65 kHz to 1.3 MHz − 0.032 0.10 UI

STM4/OC12 mode; note 12

f = 1 kHz to 5 MHz − 0.050 0.50 UI

f = 12 kHz to 5 MHz − 0.040 0.10 UI

f = 250 kHz to 5 MHz − 0.052 0.10 UI

STM16/OC48 mode; note 12

f = 5 kHz to 20 MHz − 0.079 0.50 UI

f = 12 kHz to 20 MHz − 0.063 0.10 UI

f=1to20MHz − 0.053 0.10 UI

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 16

1999 May 27 16

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Notes

1. Typical power supply voltage for the voltage regulator is −4.5 V (see Fig.6).

2. It is assumed that both CML inputs carry a complementary signal with the specified peak-to-peak value (true

differential excitation).

3. The specified input voltage range is the guaranteed and tested range for proper operation; BER < 1 ⋅ 10

−10

.

4. An input sensitivity of 7 mV (p-p) for BER < 1 ⋅ 10

−10

is guaranteed. The typical input sensitivity for BER < 1 ⋅ 10

−10

is 2.5 mV (p-p).

5. CML inputs are terminated internally using on-chip resistors of 50 Ω connected to ground.

6. Output voltage range with default reference voltage on pin AREF (floating).

7. Output voltage range with adjustment of voltage on pin AREF (see Section “Output amplitude reference”).

8. Measured with 1010 data pattern, single-ended output signals and rising edges of the signals on

pins COUT to DOUT or pins CLOOP to DLOOP. It should be noted that small deviations of the specified value are

possible if measured differentially.

9. External pull-up resistor of 10 kΩ connected to supply voltage of +3.3 V.

10. LOS assert or de-assert timing and BER level are for indication only. The values are neither production tested nor

guaranteed.

11. Measured in accordance with ITU specification G.958. Measured on demoboard OM5801 for STM16/OC48 and

demoboard OM5802 for STM1/OC3 and STM4/OC12. See for more information

“Application note AN96051

” and

“Application note AN97065”

.

12. Measured in accordance with ITU specification G.813 and 1 dB above the system input sensitivity power level.

Measured on demoboard OM5801 for STM16/OC48 and on demoboard OM5802 for STM1/OC3 and STM4/OC12.

13. TDR is bit rate independent.

J

gen(rms)

jitter generation (RMS value) STM1/OC3 mode; note 12

f = 500 Hz to 1.3 MHz − 0.0060 − UI

f = 12 kHz to 1.3 MHz − 0.0046 − UI

f = 65 kHz to 1.3 MHz − 0.0041 − UI

STM4/OC12 mode; note 12

f = 1 kHz to 5 MHz − 0.0093 − UI

f = 12 kHz to 5 MHz − 0.0079 − UI

f = 250 kHz to 5 MHz − 0.0081 − UI

STM16/OC48 mode; note 12

f = 5 kHz to 20 MHz − 0.0143 − UI

f = 12 kHz to 20 MHz − 0.0139 − UI

f=1to20MHz − 0.0079 − UI

TDR transitionless data run note 13 − 2000 − bits

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Page 17

1999 May 27 17

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.10 Logic level symbol definitions for CML.

handbook, full pagewidth

MGK144

V

IO

V

I(max)

V

IQH

V

IH

V

IQL

V

IL

V

I(min)

V

i(p-p)

GND

CML INPUT

V

OO

V

O(max)

V

OQH

V

OH

V

OQL

V

OL

V

O(min)

V

o(p-p)

GND

CML OUTPUT

Fig.11 Data-to-clock delay for CML outputs: COUT to DOUT or CLOOP to DLOOP.

handbook, full pagewidth

MGL672

GND

t

d(D-C)

−200 mV

GND

COUT or

CLOOP

DOUT or

DLOOP

−200 mV

Page 18

1999 May 27 18

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

TYPICAL PERFORMANCE CHARACTERISTICS

Fig.12 Supply voltage as a function of the

temperature.

It should be noted that the voltage on pins VEE is regulated by the

power controller.

handbook, halfpage

−40

−3.30

−3.35

−3.40

−3.45

0 40 12080

V

EE

(V)

T (°C)

MGL650

Fig.13 Supply current as a function of the

temperature.

handbook, halfpage

−40 0 40 120

160

120

40

0

80

80

T (°C)

I

EE

(mA)

MGL649

Fig.14 Clock output rise time as a function of the

temperature.

Measured on single-ended output.

handbook, halfpage

−40 0 40 120

80

60

76

80

T (°C)

t

r(C)

(ps)

72

68

64

MGL653

Fig.15 Clock output fall time as a function of the

temperature.

Measured on single-ended output.

handbook, halfpage

−40 0 40 120

70

50

66

80

T (°C)

t

f(C)

(ps)

62

58

54

MGL652

Page 19

1999 May 27 19

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.16 Data output rise time as a function of the

temperature.

Measured on single-ended output.

handbook, halfpage

−40

170

160

150

140

0 40 12080

t

r(D)

(ps)

T (°C)

MGL655

Fig.17 Data output fall time as a function of the

temperature.

Measured on single-ended output.

handbook, halfpage

−40 0 40 120

110

100

80

70

90

80

T (°C)

t

f(D)

(ps)

MGL654

Fig.18 Data-to-clock delay time as a function of the

temperature.

See Fig.11 for the definition of td.

handbook, halfpage

−40 0 40 120

300

200

280

80

T (°C)

t

d(D-C)

(ps)

260

240

220

MGL651

Page 20

1999 May 27 20

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.19 Bit error rate as a function of the input signal

in STM1/OC3 mode (155.52 Mbits/s).

A complementary input signal of the indicated

value is applied to pins DIN and DINQ.

handbook, halfpage

10

−11

10

−10

10

−9

10

−8

10

−7

10

−6

10

−5

10

−4

10

−3

10

−2

10

−1

1

1.50.5 10

BER

V

i(p-p)

(mV)

MGL658

Fig.20 Bit error rate as a function of the input signal

in STM4/OC12 mode (622.08 Mbits/s).

A complementary input signal of the indicated

value is applied to pins DIN and DINQ.

handbook, halfpage

10

−11

10

−10

10

−9

10

−8

10

−7

10

−6

10

−5

10

−4

10

−3

10

−2

10

−1

1

1.50.5 10

BER

V

i(p-p)

(mV)

MGL657

Page 21

1999 May 27 21

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.21 Bit error rate as a function of the input signal

in STM16/OC48 mode (2488.32 Mbits/s).

A complementary input signal of the indicated value

is applied to pins DIN and DINQ.

handbook, halfpage

10

−11

10

−10

10

−9

10

−8

10

−7

10

−6

10

−5

10

−4

10

−3

10

−2

10

−1

1

1.50.5 10

BER

V

i(p-p)

(mV)

MGL656

Page 22

1999 May 27 22

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.22 Jitter tolerance as a function of the jitter frequency in the STM1/OC3 mode (155.52 Mbits/s).

(1) Device performance measured on OM5802 demoboard.

(2) ITU specification template.

handbook, full pagewidth

MGL659

10

3

10

2

10

1

10

−1

1

(1)

10

J

tol(p-p)

(UI)

f (kHz)

10

2

10

3

10

4

(2)

Fig.23 Jitter tolerance as a function of the jitter frequency in the STM4/OC12 mode (622.08 Mbits/s).

(1) Device performance measured on OM5802 demoboard.

(2) ITU specification template.

handbook, full pagewidth

MGL660

10

3

10

2

10

1

10

−1

1

(1)

(2)

10 10

2

10

3

10

4

J

tol(p-p)

(UI)

f (kHz)

Page 23

1999 May 27 23

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.24 Jitter tolerance as a function of the jitter frequency in the STM16/OC48 mode (2488.32 Mbits/s).

(1) Device performance measured on OM5801 demoboard.

(2) ITU specification template.

handbook, full pagewidth

MGL661

10

3

10

2

10

1

10

−1

11010

2103

10

4

(1)

(2)

J

tol(p-p)

(UI)

f (kHz)

Page 24

1999 May 27 24

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.25 Data and clock output waveforms in the STM4/OC12 mode (622.08 Mbits/s).

Measured single-ended.

handbook, full pagewidth

MGS228

200 mV/div

Fig.26 Data and clock output waveforms in the STM16/OC48 mode (2488.32 Mbits/s).

Measured single-ended.

handbook, full pagewidth

MGS229

200 mV/div

Page 25

1999 May 27 25

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

APPLICATION INFORMATION

Fig.27 Application diagram showing the OQ2541 configured for the STM16/OC48 mode (2488.32 Mbits/s).

(1) All pins GND must be connected directly to the PCB ground plane (pins 2, 5, 8, 10, 11, 14, 17, 20, 23, 26, 29, 32, 35, 38, 41, 44 and 47).

(2) L1 = RF choke type Murata BLM21.

handbook, full pagewidth

2 Ω

2 Ω

1

kΩ

1

kΩ

1 µF

L1

(2)

−4.5 V

+3.3 V

β > 100

100

nF

3.3

nF

MBH973

V

EE2

PC

GND

(1)

1

3

4

6

7

45

46

42

43

9

27

28

30

17

15

16

21

22

48

3731

V

EE1

25

24

OQ2541

normal

output

loop

output

output

select

DOUT1250

COUTQ

COUT

DOUTQ

DOUT

12

LOCK

AREF

CLOOP

CLOOPQ

DLOOP

DREF19

39 MHz

system clock

DLOOPQ

CAPUPQ

CAPDOQ

CREFQ

DREF39

CREF

ENL

DOUT155

DOUT622

10 kΩ

+3.3 V

39

LOS

10 kΩ

100 nF 100 nF

34

33

DINQ

DIN

PRE-

AMP

13, 18, 19,

36, 40

i.c.

5

Page 26

1999 May 27 26

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.28 Application diagram showing the OQ2541 configured for the STM4/OC12 mode (622.08 Mbits/s).

(1) All pins GND must be connected directly to the PCB ground plane (pins 2,5, 8, 10, 11, 14, 17, 20, 23, 26, 29, 32, 35, 38, 41, 44 and 47).

(2) L1 = RF choke type Murata BLM21.

handbook, full pagewidth

2 Ω

2 Ω

1

kΩ

1

kΩ

1 µF

L1

(2)

−4.5 V

+3.3 V

β > 100

100

nF

3.3

nF

MGL662

V

EE2

V

EE1

PC

GND

(1)

1

3

4

6

7

45

46

42

43

9

34

33

27

28

30

17

15

16

21

22

48

373125

24

OQ2541

normal

output

loop

output

output

select

DINQ

DIN

PREAMP

DOUT1250

COUTQ

COUT

DOUTQ

DOUT

12

LOCK

AREF

CLOOP

CLOOPQ

DLOOP

DREF19

39 MHz

system clock

DLOOPQ

CAPUPQ

CAPDOQ

CREFQ

DREF39

CREF

ENL

DOUT155

DOUT622

10 kΩ

+3.3 V

39

LOS

10 kΩ

100 nF 100 nF

13, 18, 19,

36, 40

i.c.

5

Page 27

1999 May 27 27

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Fig.29 Application diagram showing the OQ2541 configured for the STM16/OC48 mode (2488.32 Mbits/s) with

a positive supply voltage application.

(1) (1) All pins GND must be connected directly to VCC on the PCB plane of +5 V (pins 2, 5, 8, 10, 11, 14, 17, 20, 23, 26, 29, 32, 35, 38, 41, 44 and 47).

(2) L1 = RF choke type Murata BLM21.

(3) The loop mode outputs are used as main outputs:

pin ENL = HIGH-level selects loop mode outputs

pin ENL = LOW-level selects loop mode and normal mode outputs simultaneously.

handbook, full pagewidth

2 Ω

2 Ω

1

kΩ

1

kΩ

1 µF

L1

(2)

β > 100

100

nF

3.3

nF

MGL663

V

EE2

V

EE1

PC

GND

(1)

1

3

4

6

7

45

46

42

43

9

34

33

27

28

30

17

15

16

21

22

48

373125

24

OQ2541

normal

output

unused

output

loop

output

output

select

DINQ

DIN

PRE-

AMP

DOUT1250

COUTQ

COUT

DOUTQ

DOUT

12

LOCK

LOCK

AREF

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

CLOOP

CLOOPQ

DLOOP

DREF19

39 MHz

system clock

DLOOPQ

CAPUPQ

CAPDOQ

CREFQ

DREF39

CREF

ENL

DOUT155

DOUT622

39

LOS

LOS

10 kΩ

100 nF 100 nF

=

main

output

(3)

=

V

CC

10 kΩ

13, 18, 19,

36, 40

i.c.

5

Page 28

1999 May 27 28

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

BONDING PADS

Fig.30 Bonding pad locations of OQ2541U.

handbook, full pagewidth

1

2

3

4

5

6

7

8

9

10

11

12

ENL

GND

CLOOP

CLOOPQ

GND

DLOOP

DLOOPQ

GND

DREF19

GND

GND

LOCK

36

35

34

33

32

31

30

29

28

27

26

25

i.c.

DINQ

GND

DIN

GND

V

EE2

DOUT155

GND

DOUT622

DOUT1250

GND

V

EE1

242322212019181716151413

i.c.

GND

CAPUPQ

CAPDOQ

GND

i.c.

i.c.

GND

CREF

CREFQ

GND

DREF39

COUTQ

COUT

GND

AREF

GND

DOUTQ

DOUT

GND

i.c.

LOS

GND

PC

373839404142434445464748

OQ2541U

x

y

0

0

MGL664

2.360 mm

2.360

mm

Page 29

1999 May 27 29

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Table 6 Bonding pad locations.

SYMBOL PAD

COORDINATES

(1)

xy

ENL 1 −1017.5 +852.5

GND 2 −1017.5 +697.5

CLOOP 3 −1017.5 +542.5

CLOOPQ 4 −1017.5 +387.5

GND 5 −1017.5 +232.5

DLOOP 6 −1017.5 +77.5

DLOOPQ 7 −1017.5 −77.5

GND 8 −1017.5 −232.5

DREF19 9 −1017.5 −387.5

GND 10 −1017.5 −542.5

GND 11 −1017.5 −697.5

LOCK 12 −1017.5 −852.5

i.c. 13 −852.5 −1017.5

GND 14 −697.5 −1017.5

CAPUPQ 15 −542.5 −1017.5

CAPDOQ 16 −387.5 −1017.5

GND 17 −232.5 −1017.5

i.c. 18 −77.5 −1017.5

i.c. 19 +77.5 −1017.5

GND 20 +232.5 −1017.5

CREF 21 +387.5 −1017.5

CREFQ 22 +542.5 −1017.5

GND 23 +697.5 −1017.5

DREF39 24 +852.5 −1017.5

V

EE1

25 +1017.5 −852.5

GND 26 +1017.5 −697.5

DOUT1250 27 +1017.5 −542.5

DOUT622 28 +1017.5 −387.5

GND 29 +1017.5 −232.5

DOUT155 30 +1017.5 −77.5

V

EE2

31 +1017.5 +77.5

GND 32 +1017.5 +232.5

DIN 33 +1017.5 +387.5

DINQ 34 +1017.5 +542.5

GND 35 +1017.5 +697.5

i.c. 36 +1017.5 +852.5

PC 37 +852.5 +1017.5

GND 38 +697.5 +1017.5

Note

1. All x and y coordinates represent the position of the

centre of the pad inµm with respect to the centre of the

die (see Fig.30).

LOS 39 +542.5 +1017.5

i.c. 40 +387.5 +1017.5

GND 41 +232.5 +1017.5

DOUT 42 +77.5 +1017.5

DOUTQ 43 −77.5 +1017.5

GND 44 −232.5 +1017.5

COUT 45 −387.5 +1017.5

COUTQ 46 −542.5 +1017.5

GND 47 −697.5 +1017.5

AREF 48 −852.5 +1017.5

SYMBOL PAD

COORDINATES

(1)

xy

Page 30

1999 May 27 30

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Table 7 Physical characteristics of bare die

Thermal considerations

To improve heat transfer away from the product, a large area fill is recommended as a die pad. The die should be

mounted on this with a heat conductive glue. Bonding ALL supply and ground pads is essential for the electrical

performance, but also improves heat transfer to the die pad or other copper area fills. The more copper is leading away

from the die, the better the heat transport. On its turn, this copper should be able to loose its heat to the environment

through radiation, natural convection (non forced airflow over the printed-circuit board) or forced cooling.

NAME DESCRIPTION

Glass passivation 0.8 µm silicon nitride on top of 0.9 µm PSG (PhosphoSilicate Glass)

Bonding pad dimension minimum dimension of exposed metallization is 90 × 90 µm (pad size = 100 × 100 µm)

Metallization 1.8 µm AlCu (1% Cu)

Thickness 380 µm nominal

Size 2.360 × 2.360 mm (5.5696 mm

2

)

Backing silicon; electrically connected to V

EE

potential through substrate contacts

Attache temperature <440 °C; recommended die attache is glue

Attache time <15 s

Page 31

1999 May 27 31

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

PACKAGE OUTLINE

UNIT

A

max.

A1A2A3b

p

cE

(1)

eH

E

LL

p

Zywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

1.60

0.20

0.05

1.45

1.35

0.25

0.27

0.17

0.18

0.12

7.1

6.9

0.5

9.15

8.85

0.95

0.55

7

0

o

o

0.12 0.10.21.0

DIMENSIONS (mm are the original dimensions)

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

0.75

0.45

SOT313-2

94-12-19

97-08-01

D

(1) (1)(1)

7.1

6.9

H

D

9.15

8.85

E

Z

0.95

0.55

D

b

p

e

E

B

12

D

H

b

p

E

H

v M

B

D

Z

D

A

Z

E

e

v M

A

1

48

37

36

25

24

13

θ

A

1

A

L

p

detail X

L

(A )

3

A

2

X

y

c

w M

w M

0 2.5 5 mm

scale

pin 1 index

LQFP48: plastic low profile quad flat package; 48 leads; body 7 x 7 x 1.4 mm

SOT313-2

Page 32

1999 May 27 32

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

SOLDERING

Introduction to soldering surface mount packages

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering is not always suitable

for surface mount ICs, or for printed-circuit boards with

high population densities. In these situations reflow

soldering is often used.

Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

infrared/convection heating in a conveyor type oven.

Throughput times (preheating, soldering and cooling) vary

between 100 and 200 seconds depending on heating

method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 230 °C.

Wave soldering

Conventional single wave soldering is not recommended

for surface mount devices (SMDs) or printed-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• For packages with leads on four sides, the footprint must

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

Page 33

1999 May 27 33

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

Suitability of surface mount IC packages for wave and reflow soldering methods

Notes

1. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

.

2. These packages are not suitable for wave soldering as a solder joint between the printed-circuit board and heatsink

(at bottom version) can not be achieved, and as solder may stick to the heatsink (on top version).

3. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

4. Wave soldering is only suitable for LQFP, TQFP and QFP packages with a pitch (e) equal to or larger than 0.8 mm;

it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

5. Wave soldering is only suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than 0.65 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

PACKAGE

SOLDERING METHOD

WAVE REFLOW

(1)

BGA, SQFP not suitable suitable

HLQFP, HSQFP, HSOP, HTSSOP, SMS not suitable

(2)

suitable

PLCC

(3)

, SO, SOJ suitable suitable

LQFP, QFP, TQFP not recommended

(3)(4)

suitable

SSOP, TSSOP, VSO not recommended

(5)

suitable

Page 34

1999 May 27 34

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

BARE DIE DISCLAIMER

All die are tested and are guaranteed to comply with all data sheet limits up to the point of wafer sawing for a period of

ninety (90) days from the date of Philips’ delivery. If there are data sheet limits not guaranteed, these will be separately

indicated in the data sheet. There is no post waffle pack testing performed on individual die. Although the most modern

processes are utilized for wafer sawing and die pick and place into waffle pack carriers, Philips Semiconductors has no

control of third party procedures in the handling, packing or assembly of the die. Accordingly, Philips Semiconductors

assumes no liability for device functionality or performance of the die or systems after handling, packing or assembly of

the die. It is the responsibility of the customer to test and qualify their application in which the die is used.

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Page 35

1999 May 27 35

Philips Semiconductors Product specification

SDH/SONET data and clock recovery unit

STM1/4/16 OC3/12/48 GE

OQ2541HP; OQ2541U

NOTES

Page 36

© Philips Electronics N.V. SCA

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

1999 65

Philips Semiconductors – a worldwide company

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Pakistan: see Singapore

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska 10, PL 04-123 WARSZAWA,

Tel. +48 22 612 2831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 319762,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 58088 Newville 2114,

Tel. +27 11 471 5401, Fax. +27 11 471 5398

South America: Al. Vicente Pinzon, 173, 6th floor,

04547-130 SÃO PAULO, SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 821 2382

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 93 301 6312, Fax. +34 93 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 5985 2000, Fax. +46 8 5985 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2741 Fax. +41 1 488 3263

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2886, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Yukari Dudullu, Org. San. Blg., 2.Cad. Nr. 28 81260 Umraniye,

ISTANBUL, Tel. +90 216 522 1500, Fax. +90 216 522 1813

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 181 730 5000, Fax. +44 181 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 62 5344, Fax.+381 11 63 5777

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p, P.O. Box 218,

5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +61 2 9805 4455, Fax. +61 2 9805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101 1248, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 20 0733, Fax. +375 172 20 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 68 9211, Fax. +359 2 68 9102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Sydhavnsgade 23, 1780 COPENHAGEN V,

Tel. +45 33 29 3333, Fax. +45 33 29 3905

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615 800, Fax. +358 9 6158 0920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 4099 6161, Fax. +33 1 4099 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 2353 60, Fax. +49 40 2353 6300

Hungary: see Austria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: PT Philips Development Corporation, Semiconductors Division,

Gedung Philips, Jl. Buncit Raya Kav.99-100, JAKARTA 12510,

Tel. +62 21 794 0040 ext. 2501, Fax. +62 21 794 0080

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IV Novembre 3,

20124 MILANO, Tel. +39 02 67 52 2531, Fax. +39 02 67 52 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku,

TOKYO 108-8507, Tel. +81 3 3740 5130, Fax. +81 3 3740 5057

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381, Fax +9-5 800 943 0087

Middle East: see Italy

Printed in The Netherlands 465012/150/03/pp36 Date of release: 1999 May 27 Document order number: 9397 750 05019

Loading...

Loading...