Page 1

INTEGRATED CIRCUITS

NE56604-42

System reset with built-in watchdog timer

Product data

Supersedes data of 2001 Jun 19

File under Integrated Circuits, Standard Analog

2001 Aug 22

Page 2

Philips Semiconductors Product data

TYPE NUMBER

NE56604-42System reset with built-in watchdog timer

GENERAL DESCRIPTION

The NE56604-42 is designed to generate a reset signal at a

threshold voltage of 4.2 V for a variety of microprocessor and logic

systems. Accurate reset signals are generated during momentary

power interruptions, or whenever power supply voltages sag to

intolerable levels. The NE56604-42 has a built-in Watchdog Timer to

monitor the microprocessor and ensure it is operating properly. Any

abnormal system operations due to microprocessor malfunctions

are terminated by a system reset generated by the watchdog. The

NE56604-42 has a watchdog monitoring time of 100 ms (typical).

The NE56604-42 is offered in the SO8 surface mount package.

FEATURES

•Both positive and negative logic reset output signals are available

•Accurate threshold detection

•Internal power-on reset delay

•Internal watchdog timer programmable with external resistor

•Watchdog monitoring time of 100 ms (typical)

•Reset assertion with V

•Few external components required.

down to 0.8 VDC (typical)

CC

APPLICA TIONS

•Microcomputer systems

•Logic systems.

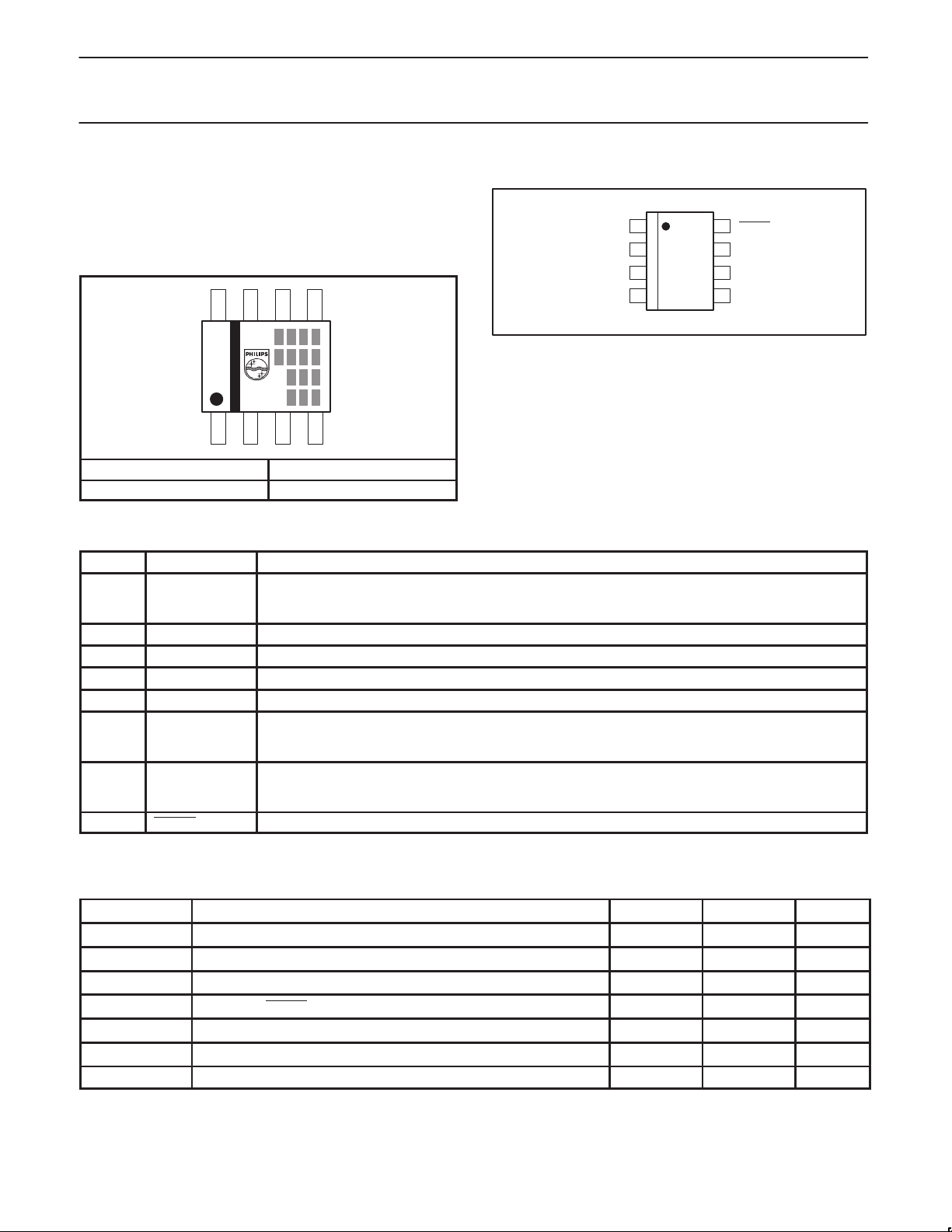

SIMPLIFIED SYSTEM DIAGRAM

V

CC

5

V

C

R

S

7

R

R

CT

R

6

CT

NE56604-42

RESET

GENERATOR

V

REF

4

GND

PROGRAMMABLE

WATCHDOG TIMER

1

C

T

Figure 1. Simplified system diagram.

8

2

3

RESET

RESET

CLK

LOGIC

SYSTEM

RESET

RESET

CLK

GND

SL01281

ORDERING INFORMATION

PACKAGE

NAME DESCRIPTION

TEMPERATURE

RANGE

NE56604-42D SO8 plastic small outline package; 8 leads; body width 3.9 mm –20 to +70 °C

2001 Aug 22 853–2250 26949

2

Page 3

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

Part number marking

PIN CONFIGURATION

The package is marked with a four letter code in the first line to the

right of the logo. The first three letters designate the product. The

fourth letter, represented by ‘x’, is a date tracking code. The

remaining two or three lines of characters are internal manufacturing

codes.

5

6

7

8

2

1

3

4

Part number Marking

NE56604-42 A A D x

PIN DESCRIPTION

PIN SYMBOL DESCRIPTION

1 C

T

2 RESET Reset HIGH output pin.

3 CLK Clock input pin from logic system for watchdog timer.

4 GND Circuit ground.

5 V

6 R

7 V

CC

CT

S

8 RESET Reset LOW output pin.

t

, t

WDM

t

WDM

Diagram) for definition of t

, tPR adjustment pin.

WDR

, t

, tPR times are dependent on the value of external CT capacitor used. See Figure 20 (Timing

WDR

WDM

, t

WDR

, tPR times.

Power supply pin for circuit.

Watchdog timer control and program pin.

Serves to ENABLE the watchdog function when connected to pull-up resistor (RCT) to VCC, and DISABLE

the watchdog when connected to ground. Used in conjunction with C

Detection threshold adjustment pin.

The detection threshold can be increased by connecting this pin to VCC with a pull-up resistor. The detection

threshold can be decreased by connecting this pin to ground with a pull-down resistor.

TOP VIEW

8

7

6

5

SL01280

RESET

CLK

GND

1

C

T

2

SO8

3

4

Figure 2. Pin configuration.

pin to program t

T

RESET

V

S

R

CT

V

CC

WDM

time.

MAXIMUM RATINGS

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

V

VS

V

CLK

V

OH

T

oper

T

stg

P Power dissipation – 250 mW

2001 Aug 22

Power supply voltage –0.3 10 V

VS pin voltage –0.3 10 V

CLK pin voltage –0.3 10 V

RESET and RESET pin voltage –0.3 10 V

Operating temperature –20 70 °C

Storage temperature –40 125 °C

3

Page 4

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

DC ELECTRICAL CHARACTERISTICS

Characteristics measured with VCC = 5.0 V, and T

See Figure 26 (Test circuit 1) for test configuration used for DC parameters.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I

CC

V

SL

V

SH

∆VS/∆T

V

hys

V

TH

I

IH

I

IL

V

OH1

V

OH2

V

OL1

V

OL2

V

OL3

V

OL4

I

OL1

I

OL2

I

CT1

I

CT2

V

CCL1

V

CCL2

Supply current during watchdog timer

operation

Reset detection threshold

Temperature coefficient of reset threshold –20 °C ≤ T

amb

Threshold hysteresis V

CLK input threshold 0.8 1.2 2.0 V

CLK input current, HIGH-level V

CLK input current, LOW-level V

Output voltage, HIGH-level

Output voltage, LOW-level

Output sink current

CT charge current (Note 1)

Supply voltage to assert reset operation

NOTE:

1. I

source current is determined by the value of the RCT pull-up resistor to VCC.

CT

= 25 °C, unless otherwise specified.

amb

VS = open; VCC = falling 4.05 4.20 4.35 V

VS = open; VCC = rising 4.15 4.30 4.45 V

amb

= VSH (rising VCC) – V

hys

(falling VCC)

= 5.0 V – 0 1.0 µA

CLK

= 0 V –20 –10 –3.0 µA

CLK

I

= –5.0 µA; VS = open 4.5 4.8 – V

RESET

I

current = –5.0 mA; VS = 0 V 4.5 4.8 – V

RESET

I

= 3.0 mA; VS = 0 V – 0.2 0.4 V

RESET

I

= 10 mA; VS = 0 V – 0.3 0.5 V

RESET

I

= 0.5 mA; VS = open – 0.2 0.4 V

RESET

I

= 1.0 mA; VS = open – 0.3 0.5 V

RESET

V

= 1.0 V; VS = 0 V 10 16 – mA

RESET

V

= 1.0 V; VS = open 1.0 2.0 – mA

RESET

VCT = 1.0 V; RCT = open during

watchdog operation

VCT = 1.0 V;

during power-on reset operation

V

= 0.4 V; I

RESET

V

RESET

1 MΩ resistor (pin 2 to GND)

RESET

= VCC – 0.1 V;

– 0.7 1.0 mA

≤ 70 °C – ±0.01 – %/°C

SL

50 100 150 mV

–0.8 –1.2 –2.4 µA

–0.8 –1.2 –2.4 µA

= 0.2 mA – 0.8 1.0 V

– 0.8 1.0 V

2001 Aug 22

4

Page 5

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

AC ELECTRICAL CHARACTERISTICS

Characteristics measured with VCC = 5.0 V, and T

See Figure 27 (Test circuit 2) for test configuration used for AC parameters.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

t

P1

t

CLKW

t

CLK

t

WDM

t

WDR

t

PR

t

PD1

t

PD2

t

R1

t

R2

t

F1

t

F2

Minimum power supply pulse width for

detection

Clock input pulse width 3.0 – – µs

Clock input cycle 20 – – µs

Watchdog monitoring time (Notes 1, 6) CT = 0.1 µF; RCT = open 50 100 150 ms

Watchdog reset time (Notes 2, 6) CT = 0.1 µF 1.0 2.0 3.0 ms

Power-on reset delay time (Notes 3, 6) VCC = rising from 0 V; CT = 0.1 µF 50 100 150 ms

Reset propagation delay time (Note 4)

Reset rise time (Note 5)

Reset fall time (Note 5)

NOTES:

1. ‘Watchdog monitoring time’ is the duration from the last pulse (negative-going edge) of the timer clear clock pulse until reset output pulse

occurs (see Figure 20). A reset signal is output if a clock pulse is not input during this time. Watchdog monitoring time can be modified by

changing the value of the R

2. ‘Watchdog reset time’ is the reset pulse width (see Figure 20).

pull-up resistor. Monitoring time adjustments are shown in Figure 25.

CT

3. ‘Power-on reset delay time’ is the duration measured from the time V

release is experienced (RESET

output HIGH; RESET output LOW).

4. ‘Reset response time’ is the duration from when the supply voltage sags below the lower detection threshold (V

output LOW, RESET output HIGH).

5. Reset rise and fall times are measured at 10% and 90% output levels.

6. Watchdog monitoring time (t

varying the C

to 10 µF.

capacitance. The times can be approximated by applying the following formula. The recommended range for CT is 0.001 µF

T

), watchdog reset time (t

WDM

Formula 1. Calculation for approximate t

(ms) ≈ 1000 × CT (µF)

t

PR

t

(ms) ≈ 1000 × CT (µF)

WDM

t

(ms) ≈ 20 × CT (µF)

WDR

Example: When CT = 0.1 µF and RCT = open:

t

≈ 100 ms

PR

t

≈ 100 ms

WDM

t

≈ 2.0 ms

WDR

= 25 °C, unless otherwise specified.

amb

4.0 V ≤ negative-going VCC pulse ≤ 5.0 V 8.0 – – µs

RESET: RL1 = 2.2 kΩ; CL1 = 100 pF – 2.0 10 µs

RESET: RL2 = 10 kΩ; CL2 = 20 pF – 3.0 10 µs

RESET: RL1 = 2.2 kΩ; CL1 = 100 pF – 1.0 1.5 µs

RESET: RL2 = 10 kΩ; CL2 = 20 pF – 1.0 1.5 µs

RESET: RL1 = 2.2 kΩ; CL1 = 100 pF – 0.1 0.5 µs

RESET: RL2 = 10 kΩ; CL2 = 20 pF – 0.5 1.0 µs

CC

), and power-on reset delay time (tPR) during power-on can be modified by

WDR

, t

PR

WDM

, and t

WDR

values:

exceeds the upper detection threshold (VSH) and power-on reset

) and reset occurs (RESET

SL

2001 Aug 22

5

Page 6

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

TYPICAL PERFORMANCE CURVES

1.4

T

= 35 °C

amb

1.2

1.0

0.8

0.6

0.4

POWER SUPPLY CURRENT (mA)

CC

0.2

I

0

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

WITHOUT

CLOCK SIGNALS

TO WATCHDOG

WITH

CLOCK SIGNALS

TO WATCHDOG

VCC, POWER SUPPLY VOLTAGE (V)

Figure 3. Power supply current vs. voltage.

6.0

RESET PULL-UP R = 2.2 kΩ

5.0

4.0

3.0

2.0

, RESET OUTPUT VOLTAGE (V)

RST

1.0

V

0

0 1.0 2.0 3.0 4.0 5.0 6.0

T

= –25 °C

amb

T

= 25 °C

amb

T

= 75 °C

amb

VCC POWER SUPPLY VOLTAGE (V)

V

SL

V

OL

Figure 5. RESET output voltage vs. supply voltage.

6.0

RESET PULL-UP R = 10 kΩ

SL01303

5.0

4.0

3.0

2.0

, RESET OUTPUT VOLTAGE (V)

1.0

RST

V

0

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

VCC, POWER SUPPLY VOLTAGE (V)

T

= –25 °C, 25 °C, 75 °C

amb

V

SL

V

SH

V

OL

SL01304

Figure 4. RESET output voltage vs. supply voltage.

4.5

VCC = RISING (VSH)

VCC = FALLING (VSL)

4.4

V

4.3

V

SH

4.2

, DETECTION THRESHOLD (V)

SH

4.1

, V

SL

V

4.0

–40 –20 0 20 40 60 80 100

T

, AMBIENT TEMPERATURE (°C)

amb

SL01302

SH

V

SL

SL01301

Figure 6. Detection threshold vs. temperature.

600

500

400

300

200

100

, RESET OUTPUT SATURATION (mV)

OL

V

0

0 –0.6 –0.8 –1.0 –1.2 –1.4 –1.6 –1.8

Figure 7. RESET saturation vs. sink current.

2001 Aug 22

VCC = 5.0 V

RESET PULL-UP R = 10 kΩ

T

amb

–0.2 –0.4

IOL, RESET OUTPUT SINK CURRENT (mA)

= 25 °C

T

amb

= 75 °C

T

amb

= –25 °C

SL01300

600

500

400

300

200

100

, RESET OUTPUT SATURATION (mV)

OL

V

0

0 –6 –8 –10 –12 –14 –16 –18

VCC = 5.0 V

RESET

PULL-UP R = 2.2 kΩ

T

= 75 °C

amb

–2 –4

IOL, RESET OUTPUT SINK CURRENT (mA)

T

amb

T

= –25 °C

amb

= 25 °C

SL01299

Figure 8. RESET saturation vs. sink current.

6

Page 7

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

5.2

5.0

4.8

4.6

4.4

, RESET HIGH LEVEL OUTPUT (V)

4.2

OM

V

4.0

0 –2 –4 –6 –8 –10 –12 –14 –16 –18

IOM, RESET HIGH OUTPUT LEAKAGE CURRENT (µA)

VCC = 5.0 V

T

amb

Figure 9. RESET HIGH-level voltage vs. current.

140

VCC = 5.0 V

CT = 0.1 µF

= Open

R

CT

120

100

= 25 °C

SL01298

5.0

4.8

VCC = 5.0 V

4.6

T

= 25 °C

amb

4.4

4.2

4.0

, RESET HIGH LEVEL OUTPUT (V)

OM

3.8

V

3.6

0 –2.0 –4.0 –6.0 –8.0 –10 –16–14–12

IOM, RESET HIGH OUTPUT LEAKAGE CURRENT (µA)

Figure 10. RESET HIGH-level voltage vs. current.

140

VCC = 5.0 V

CT = 0.1 µF

= Open

R

CT

120

100

SL01297

80

, POWER-ON RESET HOLD (ms)

PR

t

60

–40 –20

T

, AMBIENT TEMPERATURE (5C)

amb

Figure 11. Power–on reset hold time vs. temperature.

3.0

VCC = 5.0 V

CT = 0.1 µF

2.5

2.0

1.5

, WATCHDOG RESET (ms)

WDR

t

1.0

040

, AMBIENT TEMPERATURE (°C)

T

amb

Figure 13. Watchdog reset time vs. temperature.

100806040200

SL01296

SL01294

80

, WATCHDOG MONIT ORING (ms)

WDM

t

60

–40 –20

T

, AMBIENT TEMPERATURE (5C)

amb

100806040200

SL01295

Figure 12. Watchdog monitoring time vs. temperature.

100

RCT = 5 MΩ

VCC = 5.0V

CT = 0.1 µF

10

RCT = 100 kΩ

, WATCHDOG MONIT ORING (ms)

WDM

t

100806020–20–40

1

0 40 100806020–20–40

T

, AMBIENT TEMPERATURE (°C)

amb

SL01308

Figure 14. Watchdog monitoring time vs. temperature.

2001 Aug 22

7

Page 8

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

4

10

VCC = 5.0 V

T

= 25 °C

amb

3

10

2

10

10

, POWER-ON RESET HOLD (ms)

PR

t

1.0

–3

10

–2

10

–1

10

CT, CAPACITANCE (µF)

Figure 15. Power-on reset hold time vs. CT.

4

10

VCC = 5.0 V

T

= 25 °C

amb

3

10

2

10

10

, WATCHDOG MONIT ORING (ms)

WDM

t

1.0

–3

10

–2

10

–1

10

CT, CAPACITANCE (µF)

Figure 17. Watchdog reset time vs. CT.

1.0 10

SL01290

1.0 10

SL01307

2

10

VCC = 5.0 V

T

= 25 °C

amb

10

1.0

–1

10

, WATCHDOG RESET (ms)

WDR

t

–2

10

–3

10

–2

10

–1

10

CT, CAPACITANCE (µF)

Figure 16. Watchdog reset time vs. CT.

5

10

VCC = 5.0 V

T

= 25 °C

amb

4

10

3

10

2

10

10

1.0

, WATCHDOG MONIT ORING (ms)

–1

10

WDM

t

–2

10

–3

10

–2

10

C

–1

10

, CAPACITANCE (µF)

T

Figure 18. Watchdog monitoring time vs. CT.

1.0 10

SL01291

RCT = OPEN

R

= 2.2 MΩ

CT

= 1.0 MΩ

R

CT

R

= 470 kΩ

CT

= 200 kΩ

R

CT

1.0 10

SL01309

2001 Aug 22

8

Page 9

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

TECHNICAL DESCRIPTION

General discussion

The NE56604-42 combines a watchdog timer and an undervoltage

reset function in a single SO8 surface mount package. This provides

a space-saving solution for maintaining proper operation of typical

5.0 volt microprocessor-based logic systems. Either function, or

both, can force the microprocessor into a reset.

While the watchdog monitors the microprocessor operation, the

undervoltage reset monitors the supply voltage to the

microprocessor. If the microprocessor clock signal ceases or

becomes erratic, the NE56604-42 outputs a reset signal to the

microprocessor. If the microprocessor supply voltage sags to

4.2 volts or less, the NE56604-42 outputs a reset signal for the

duration of the supply voltage deficiency. The undervoltage reset

signal allows the microprocessor to shut down in an orderly manner

to avoid system corruption. In addition to a single reset output, the

NE56604-42 has complementary RESET

system use. The undervoltage detection threshold incorporates

hysteresis to prevent generating erratic resets.

V

CC

5

and RESET outputs for

R

CT

6

R

CT

The watchdog timer requires a pulse input. Normally this signal

comes from the system microprocessor’s clock. For operation, an

external resistor (R

external capacitor (C

capacitor is used for C

) must be connected from Pin 6 to VCC and an

CT

) from Pin 1 to ground. Normally a 0.1 µF

T

. The external RCT resistor and CT capacitor

T

establish the required minimum frequency of watchdog input signal

for the device to not output a reset signal. The RCT resistor

establishes, in part, the rate of charge of the C

absence of a watchdog input pulse, the C

capacitor. In the

T

capacitor charges to the

T

0.2 volt threshold of the internal comparator, causing a reset signal

to be output. If microprocessor clock signals are received within the

required interval, no watchdog reset signal will be output. The

watchdog function can be disabled by grounding Pin 6 without

affecting the undervoltage detection function.

Although the temperature coefficient of detection threshold is

specified over a temperature of –20 °C to +70 °C, the device will

support operation in excess of this temperature range. See the

supporting curves for performance over the full temperature range of

–40 °C to +85 °C. Some degradation in performance will be

experienced at the temperature extremes and the system designer

should take this into account.

0.1 V

R

R

54 kΩ

7

C

26 kΩ

3

58 kΩ

R

PULSE

GENERATOR

Q

1.2 µA

S

Q

R

R

R

0.2 V

1C

T

S

R

Q

S

R

4

GND

R

47 kΩ

12 µA

2

RESET

R

8

RESET

SL01310

R

Figure 19. Functional diagram.

2001 Aug 22

9

Page 10

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

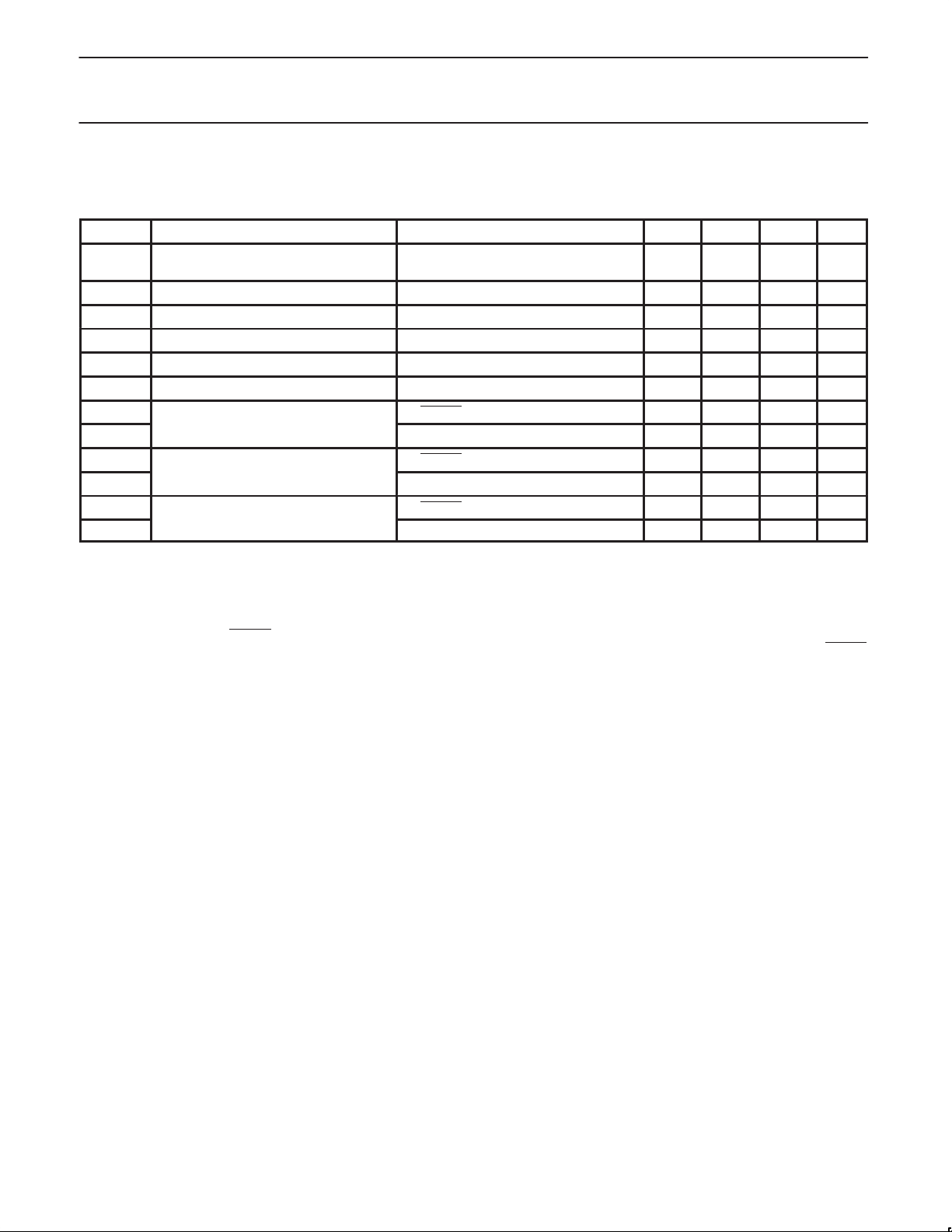

Timing diagram

The timing diagram shown in Figure 20 depicts the operation of the

device. Letters indicate events on the TIME axis.

A: At start-up ‘A’, the V

the RESET

voltage initially rises, but then abruptly returns to a LOW

state. This is due to V

activates the internal bias circuitry, asserting RESET

B: Just before ‘B’, the C

by, and coincident to, V

and RESET voltages begin to rise. Also

CC

reaching the level (RESET 0.8 V) that

CC

.

voltage starts to ramp up. This is caused

T

reaching the threshold level of VSH. At

CC

this level the device is in full operation. The RESET output continues

to rise as V

C: At ‘C’, V

rises above VSH. This is normal.

CC

is above the undervoltage detect threshold, and C

CC

T

has ramped up to its upper detect level. At this point, the device

removes the hold on the resets. RESET

goes HIGH while RESET

goes LOW. Also, an internal ramp discharge transistor activates,

discharging C

.

T

In a microprocessor-based system these events remove the reset

from the microprocessor, allowing it to function normally. The system

must send clock signals to the Watchdog Timer often enough to

prevent C

signals from being generated. Each clock signal discharges C

from ramping up to the CT threshold, to prevent reset

T

.

T

C–D: Midway between ‘C’ and ‘D’, the CLK signals cease allowing

the C

voltage to ramp up to its RESET threshold at ‘D’. At this time,

T

reset signals are generated (RESET

HIGH). The device attempts to come out of reset as the C

goes LOW; RESET goes

voltage

T

is discharged and finally does come out of reset when CLK signals

are re-established after two attempts of C

.

T

E–F: Immediately before ‘E’, falling V

to sag. CLK signals are still being received, C

operating range, and reset signals are not output. V

sag until the V

undervoltage threshold is reached. At that time,

SL

reset signals are generated (RESET

causes the RESET signal

CC

is within normal

T

continues to

CC

goes LOW; RESET goes

HIGH).

At ‘E’, V

However, C

starts to rise, and the RESET voltage rises with VCC.

CC

voltage does not start to ramp up until ‘F’, when V

T

CC

reaches the VSH upper threshold.

G: The reset outputs are released at ‘G’ when C

reaches the

T

upper threshold level again. After ‘G’, normal CLK signals are

received, but at a lower frequency than those following event ‘C’.

The frequency is above the minimum frequency required to keep the

device from outputting reset signals.

G–H: At ‘H’, V

no reset signals are output. At event ‘H’, the V

causing RESET

J: At event ‘J’, V

is normal, CLK signals are being received, and

CC

starts falling,

CC

to also fall.

sags to the point where the VSL undervoltage

CC

threshold point is reached, and at that level reset signals are output

(RESET

to a LOW state, and RESET to a HIGH state). As the V

CC

voltage falls lower, the RESET voltage falls lower.

K: At event ‘K’, the V

normal internal circuit bias is no longer able to maintain a RESET

voltage has deteriorated to a level where

CC

,

and as a result may exhibit a slight rise to something less than 0.8 V .

As V

decays even further, RESET also decreases to zero.

CC

V

V

V

CLK

C

Tthresh

RESET

0.8 V

RESET

SH

SL

CC

t

CLK

C

T

t

PR

AB C D EF G HJK

t

WDM

TIME

t

WDR

Figure 20. Timing diagram.

SL01283

2001 Aug 22

10

Page 11

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

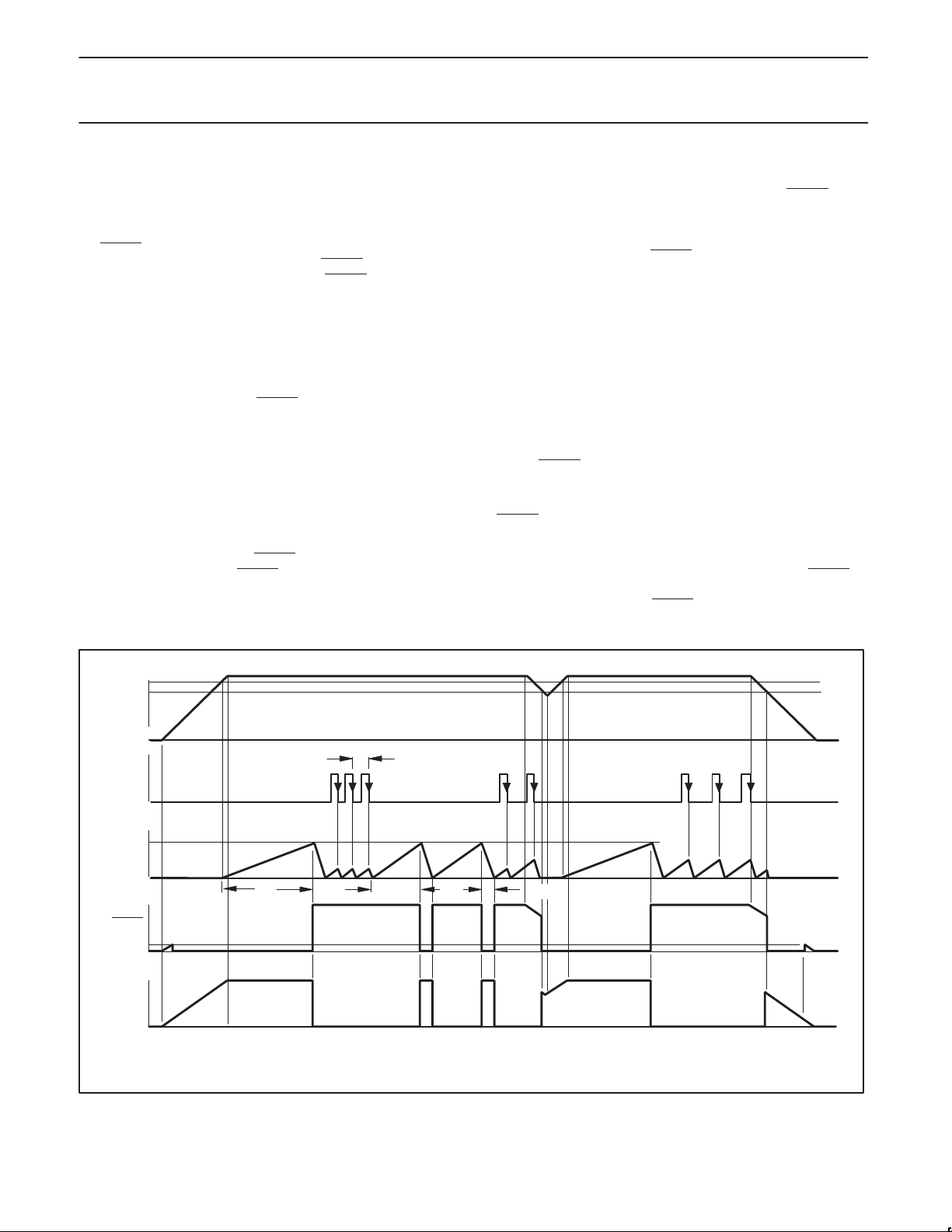

Application information

The watchdog timer’s external component values are critical to its

performance.

The detection threshold voltage can be adjusted by externally

influencing the internal divider reference voltage. Figures 21 and 23

show a method to lower and raise the threshold voltage. Figures 22

and 24 show the influence of the pull-down and pull-up resistors on

the threshold voltage. The use of a capacitor (1000 pF or larger)

from Pin 7 to ground is recommended to filter out noise from being

imposed on the threshold voltages.

V

CC

1

2

3

C

T

4

8

7

6

NE56604-42

5

1000 pF

R

1

LOGIC SYSTEM

RESET

CLK

RESET

GND

The Reset Detection Threshold can be decreased by connecting an

external resistor R

Figure 22 to determine the approximate value of R

from Pin 7 to VCC, as shown in Figure 21. See

1

to use.

1

The Reset Detection Threshold can be increased by connecting an

external resistor R

See Figure 24 to determine the approximate value of R

5.0

4.0

3.5

Vs, RESET DETECTION THRESHOLD (V)

3.0

0 100 200 300 400 500 600 700

from Pin 7 to ground, as shown in Figure 23.

2

VCC = 5.0 V

T

= 25 °C

amb

V

SH

V

SL

R1, EXTERNAL PIN 7 TO VCC RESISTOR (kΩ)

to use.

2

Figure 21. Circuit to lower detection threshold.

V

CC

1

2

3

C

T

4

8

7

6

NE56604-42

5

1000 pF

Figure 23. Circuit to raise detection threshold.

LOGIC SYSTEM

R

2

SL01327

RESET

CLK

RESET

SL01328

GND

Figure 22. Reset detection threshold vs. external R1.

5.1

5.0

4.9

4.8

4.7

4.6

4.5

4.4

Vs, RESET DETECTION THRESHOLD (V)

4.3

0 100 200 300 400 500 600 700

, EXTERNAL PIN 7 TO GROUND RESISTOR (kΩ)

R

2

V

V

SL

VCC = 5.0 V

T

amb

SH

Figure 24. Reset detection threshold vs. external R2.

SL01326

= 25 °C

SL01325

2001 Aug 22

11

Page 12

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

The values of R

(t

), the watchdog reset time (t

WDM

time (t

). See Formula 1 in the AC Electrical Characteristics and

PR

and CT affect the watchdog monitoring time

CT

), and power-on reset delay

WDR

the Timing diagram shown in Figure 20 for parameter definitions.

Also see Figures 11 through 18 for typical time relationship

performance.

The effect of R

temperature for C

on the watchdog timer monitoring time at room

CT

= 0.1 mF is shown in Figure 25.

T

100

CT = 0.1 µF

T

= 25 °C

amb

80

60

40

20

, WATCHDOG MONIT OR TIME (ms)

WDM

t

0

10k 100k 1M 10M 100M

, WATCHDOG TIMER CURRENT RESISTOR (Ω)

R

CT

SL01329

Figure 25. Watchdog monitoring vs. pull-up resistor RCT.

∞

2001 Aug 22

12

Page 13

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

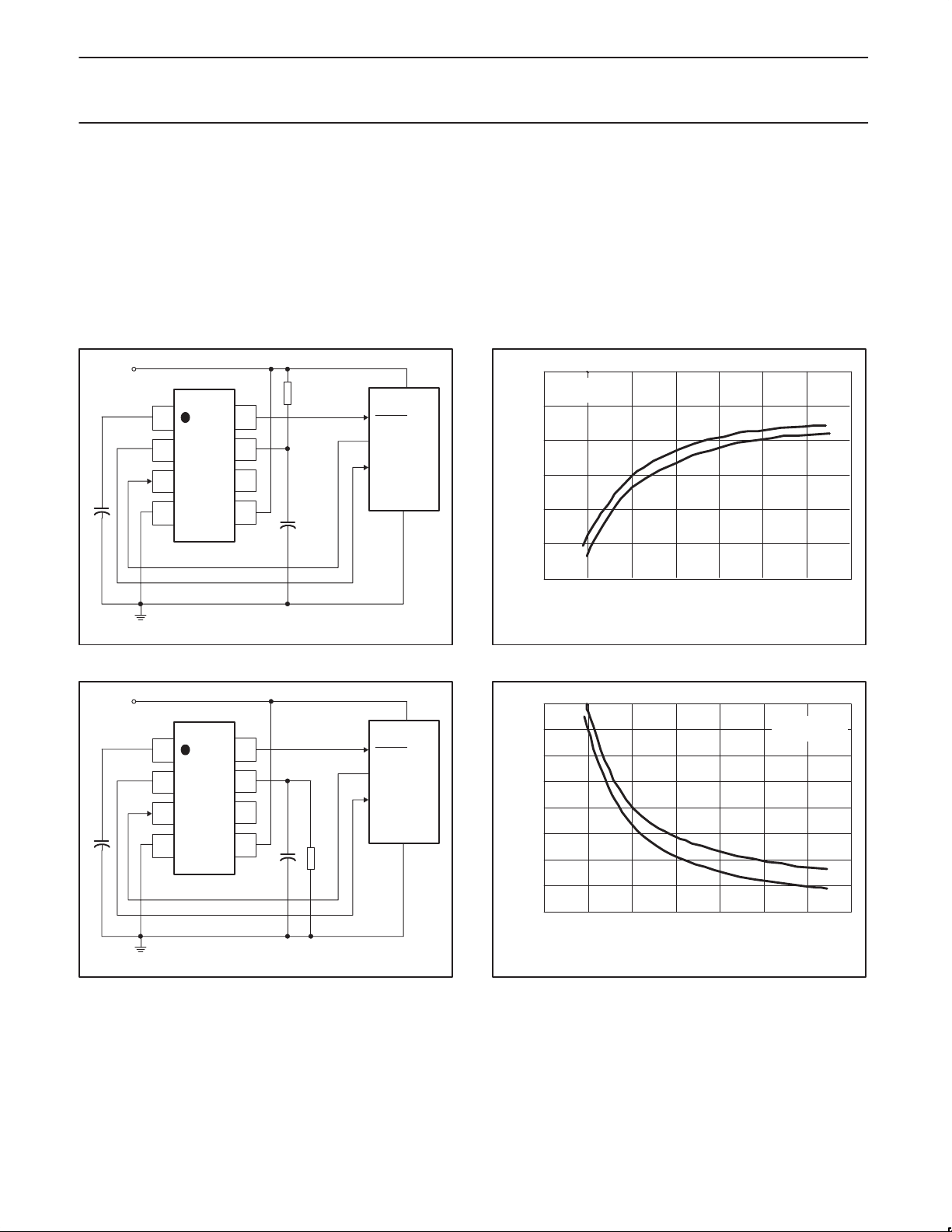

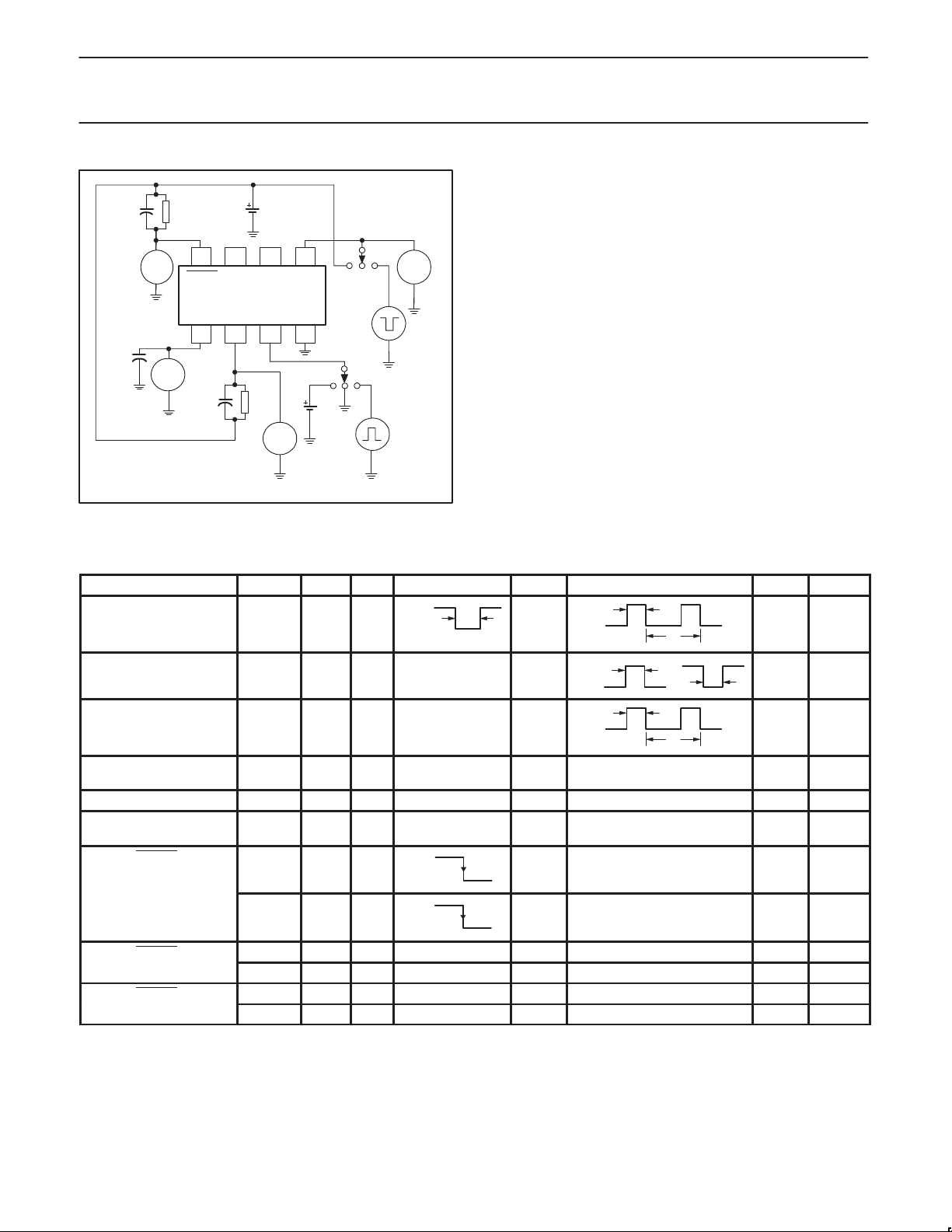

Parametric testing

DC and AC Characteristics can be tested using the circuits shown in

Figures 26 and 27. Associated switch and power supply settings are

shown in Table 1 and Table 2, respectively.

CLK

V

S

5

S

V

S

CLK

6

A

I

CC

V

CC

SL01284

7

0.1 µF

CC

42

V

O2

2

ABC

S

1

V

O0

CRT

S

2

V

CRT

V

O1

1

V

1.0 MΩ

CT

A

R

S

I

RESET

1000 pF

I

O1

8

VSRCTV

RESET

3

CTRESET CLK GND

A A A

I

CT

S

4

ABC

I

RESET

6 5

7

31

I

I

O2

CRT

CRT

Figure 26. Test Circuit 1 (DC parameters).

Table 1. DC characteristics Test Circuit 1 switch and power supply settings

Parameter Symbol S1S2S3S4S5S6S

Power supply current I

Reset threshold (LOW) (Note 1) V

Reset threshold (HIGH) (Note 2) V

Clock input threshold (Note 3) V

Clock input current (HIGH) I

Clock input current (LOW) I

Reset output voltage (HIGH)

Reset output voltage (LOW)

Reset output sink current

(Note 4)

CT charge current 1 I

CT charge current 2 I

Minimum power supply for

(Note 5)

RESET

Minimum power supply for

RESET (Note 6)

NOTES:

1. Decrease V

2. Increase V

3. Increase the Clock voltage (V

4. Measured with V

5. Increase V

will initially track the V

6. Increase V

from 5.0 V to 4.0 V and note the VCC value when VO1 (observed on CRT1) transitions to an abrupt LOW state.

CC

from 4.0 V to 5.0 V and note the VCC value when VO1 (observed on CRT1) transitions to an abrupt HIGH state.

CC

= 1.0 V.

O0

from 0 V to 2.0 V and note the VCC value when VO1 (observed on CRT1) transitions to an abrupt LOW state. The VO1 value

CC

from 0 V to 2.0 V and note the VCC value when VO2 (observed on CRT2) starts to track the VCC voltage.

CC

voltage increa se until the in ternal circuit bias beco mes active, at which time the VO1 value will return to a LOW state.

CC

B OFF OFF B OFF ON ON 5.0 V 5.0 V 0 V – – I

CC

B OFF OFF B ON ON ON 5.0 to 4.0 V 3.0 V 3.0 V – – VO1, CRT

SL

B OFF OFF B ON ON ON 4.0 to 5.0 V 3.0 V 3.0 V – – VO1, CRT

SH

B OFF OFF B OFF ON ON 5.0 V 0 to 3.0 V 1.0 V – – I

TH

B OFF OFF B OFF ON ON 5.0 V 5.0 V 0 V – – I

TH

B OFF OFF B OFF ON ON 5.0 V 0 V 0 V – – I

TL

V

V

V

V

V

V

V

V

CLK

I

OL1

I

OL2

CT1

CT2

CCL1

CCL2

B OFF ON B ON ON ON 5.0 V 5.0 V 3.0 V –5.0 µA – V

OH1

B ON OFF C ON ON ON 5.0 V 5.0 V 3.0 V – –5.0 µA V

OH2

B ON ON B ON ON ON 5.0 V 5.0 V 3.0 V 3.0 mA – V

OL1

B ON ON B ON ON ON 5.0 V 5.0 V 3.0 V 10 mA – V

OL2

B OFF OFF C ON ON ON 5.0 V 5.0 V 3.0 V – 0.5 mA V

OL3

B OFF OFF C ON ON ON 5.0 V 5.0 V 3.0 V – 1 mA V

OL4

C ON OFF B ON ON ON 5.0 V 5.0 V 3.0 V – – I

A OFF OFF B ON ON ON 5.0 V 5.0 V 3.0 V – – I

B OFF OFF B OFF OFF ON 5.0 V – 1.0 V – – I

B OFF OFF B ON OFF ON 5.0 V – 1.0 V – – I

B OFF ON B ON ON ON 0 to 2.0 V 0 V 0 V – – VO1, V

B ON OFF A ON ON ON 0 to 2.0 V 0 V 0 V – – VO2, V

) from 0 V to 3.0 V and observe the value of V

V

7

CC

when I

CLK

V

CLK

transitions to an abrupt increase.

CLK

VCTI

RESETIRESET

Read

CC

1

1

CLK

CLK

CLK

O1

O2

O1

O1

O2

O2

O1

O2

CT

CT

CC

CC

2001 Aug 22

13

Page 14

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

R

100 pF

0.1 µF

CRT

CRT

1

2.2 kΩ

8 6 57

RESET

CTRESET CLK GND

CRT

CRT

2

20pF

V

CC

V

R

V

S

R

10 kΩ

CT

CRT

CRT

CC

42 31

V

3

AC

S

AC

B

CLK

S

1

CRT

B

2

V

CLKA

V

CCA

SL01285

CRT

4

Figure 27. Test Circuit 2 (AC parameters).

Table 2. Switch and power supply settings, AC parameters

Parameter Symbol S

VCC pulse width for

detection (Note 1)

Clock input pulse width

(Note 2)

Clock input cycle

(Note 3)

Watchdog monitoring

time

Watchdog reset time t

Power-on reset delay

time

RESET, RESET

propagation delay time

RESET, RESET rise time

RESET, RESET fall time

NOTES:

= 8.0 µs.

1. t

1

2. t

= 3.0 µs.

2

= 20 µs.

3. t

3

t

P1

t

CLKW

t

CLK

t

WDM

WDR

t

PR

t

PD1

t

PD2

t

R1

t

R2

t

F1

t

F2

B to A A – 5.0 V – 5.0 V 1, 2, 3

1

C C

S

2

5.0 V

4.0 V

V

CCA

t

1

A C – 5.0 V

A C – 5.0 V

A A – 5.0 V – 5.0 V 1, 2, 3

A A – 5.0 V – 5.0 V 1, 2, 3

C B

C B

5.0 V

4.0 V

5.0 V

4.0 V

A A – 5.0 V – 5.0 V 1

A A – 5.0 V – 5.0 V 3

A A – 5.0 V – 5.0 V 1

A A – 5.0 V – 5.0 V 3

V

CC

–

1.4 V

0 V

1.4 V

0 V

1.4 V

0 V

V

CLKA

t

2

t

3

t

2

t

2

t

2

t

3

V

CLK

– 1, 2, 3

– 1, 2, 3

– 1, 2, 3

– – 0 V 1, 2

– – 0 V 2, 3

CRT

2001 Aug 22

14

Page 15

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

PACKING METHOD

The NE56604-42 is packed in reels, as shown in Figure 28.

GUARD

BAND

BARCODE

LABEL

BOX

TAPE

REEL

ASSEMBLY

Figure 28. Tape and reel packing method

TAPE DETAIL

COVER TAPE

CARRIER TAPE

SL01305

2001 Aug 22

15

Page 16

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

SO8: plastic small outline package; 8 leads; body width 3.9 mm

1.73

0.068

pin 1 index

B

2

4.95

4.80

0.189

0.195

0.51

0.33

0.013

0.020

4.95

4.80

1.27

0.38

0.050

0.015

0.076

0.003

2001 Aug 22

SO8

16

Page 17

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

NOTES

2001 Aug 22

17

Page 18

Philips Semiconductors Product data

NE56604-42System reset with built-in watchdog timer

Data sheet status

Product

Data sheet status

Objective data

Preliminary data

Product data

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at URL

http://www.semiconductors.philips.com.

[1]

status

Development

Qualification

Production

[2]

Definitions

Short-form specification — The data in a short-form specification is extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 60134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or

at any other conditions above those given in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended

periods may affect device reliability.

Application information — Applications that are described herein for any of these products are for illustrative purposes only. Philips

Semiconductors make no representation or warranty that such applications will be suitable for the specified use without further testing or

modification.

Disclaimers

Life support — These products are not designed for use in life support appliances, devices or systems where malfunction of these products can

reasonably be expected to result in personal injury . Philips Semiconductors customers using or selling these products for use in such applications

do so at their own risk and agree to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

Contact information

For additional information please visit

http://www.semiconductors.philips.com . Fax: +31 40 27 24825

For sales offices addresses send e-mail to:

sales.addresses@www.semiconductors.philips.com.

Definitions

This data sheet contains data from the objective specification for product development.

Philips Semiconductors reserves the right to change the specification in any manner without notice.

This data sheet contains data from the preliminary specification. Supplementary data will be

published at a later date. Philips Semiconductors reserves the right to change the specification

without notice, in order to improve the design and supply the best possible product.

This data sheet contains data from the product specification. Philips Semiconductors reserves the

right to make changes at any time in order to improve the design, manufacturing and supply.

Changes will be communicated according to the Customer Product/Process Change Notification

(CPCN) procedure SNW-SQ-650A.

Koninklijke Philips Electronics N.V. 2001

All rights reserved. Printed in U.S.A.

Date of release: 10-01

Document order number: 9397 750 08732

2001 Aug 22

18

Loading...

Loading...