Page 1

■ ■

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

1 OKI SEMICONDUCTOR

INTRODUCTION

With the continuing demand for smaller and more efficient systems, designers are seeking new ways to reduce power

and increase integration. This paper describes how good use of OKI Semiconductor’s monolithic display drivers can

reduce power consumption and component count in systems that incorporate liquid crystal displays (LCDs). Information in this paper is applicable both to small LCD panels (with a dozen or less segmented digits) and to large LCD

panels (such as used for laptop screens).

LCD elements are capacitive in nature and dissipate virtually no power, whether selected or deselected. When an

LCD element is selected, a voltage is applied across the liquid crystal that varies the element’s reflectivity. Removing

the voltage deselects the LCD element and returns the liquid crystal to its original state.

In general, an alternating-current (AC) source is required to illuminate the individual elements in an LCD panel. A

direct-current (DC) source is not suitable for driving an LCD panel because of electrolytic reactions in the LCD’s

liquid. Placing a potential difference across the liquid in an LCD panel causes ion migration, which gradually erodes

the anode terminal and causes destructive deposition on the cathode terminal. The electrolytic reaction could be

diminished by plating the electrodes with a non-reactive conductive element, such as gold, for example; however,

the high cost of gold and similar non-reactive elements makes this solution impractical for all but the most esoteric

applications.

A far simpler way to eliminate electrolytic corrosion is to use an AC source to drive the LCD panel, eliminating unidirectional ion migration and the associated problems. AC configurations for driving LCDs fall in two main categories, which are:

• Static driver configurations

• Multiplexed driver configurations

The next two sections describe these two configurations. The third section in this application note addresses powerrelated issues. This application note concludes with some complete circuit examples.

USING STATIC DRIVERS

In configurations using static drivers, a separate driver signal (SEG) provides an AC source for each element, and all

elements use a single shared common (COM) terminal.

LCD elements are often segments of an alphanumeric digit. In larger configurations, LCD elements are individual

dots that emulate the appearance of a CRT monitor. Static driver configurations are simple to use and are generally

suitable for LCDs with less than 80 segments.

OKI Semiconductor supplies a range of single-chip solutions for static LCD driver configurations, some of which

also include built-in RC oscillation circuits, in small-outline IC (SOIC) and plastic quad flat pack (PQFP) packages.

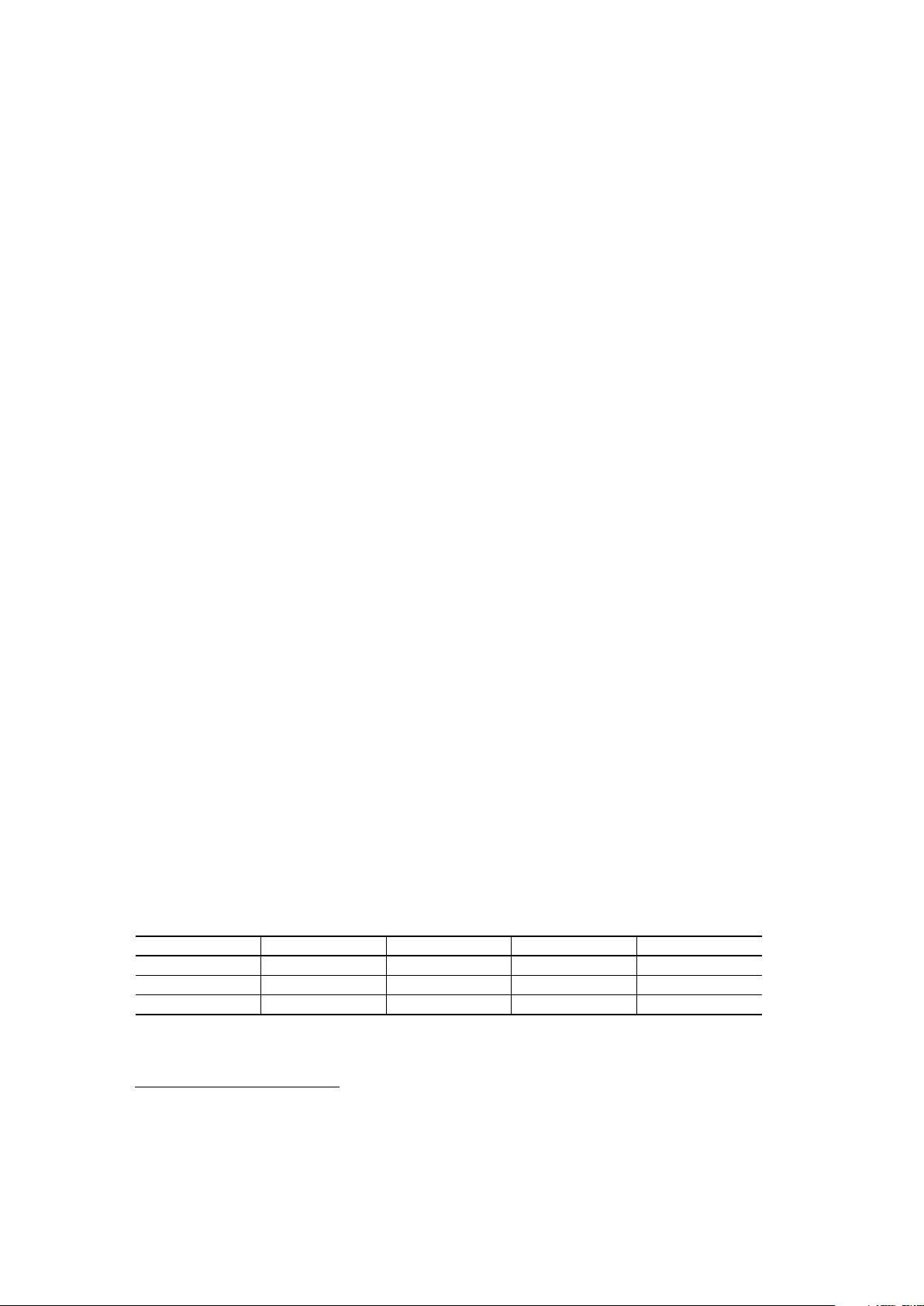

The table below lists the main characteristics of single-chip static LCD drivers from OKI Semiconductor.

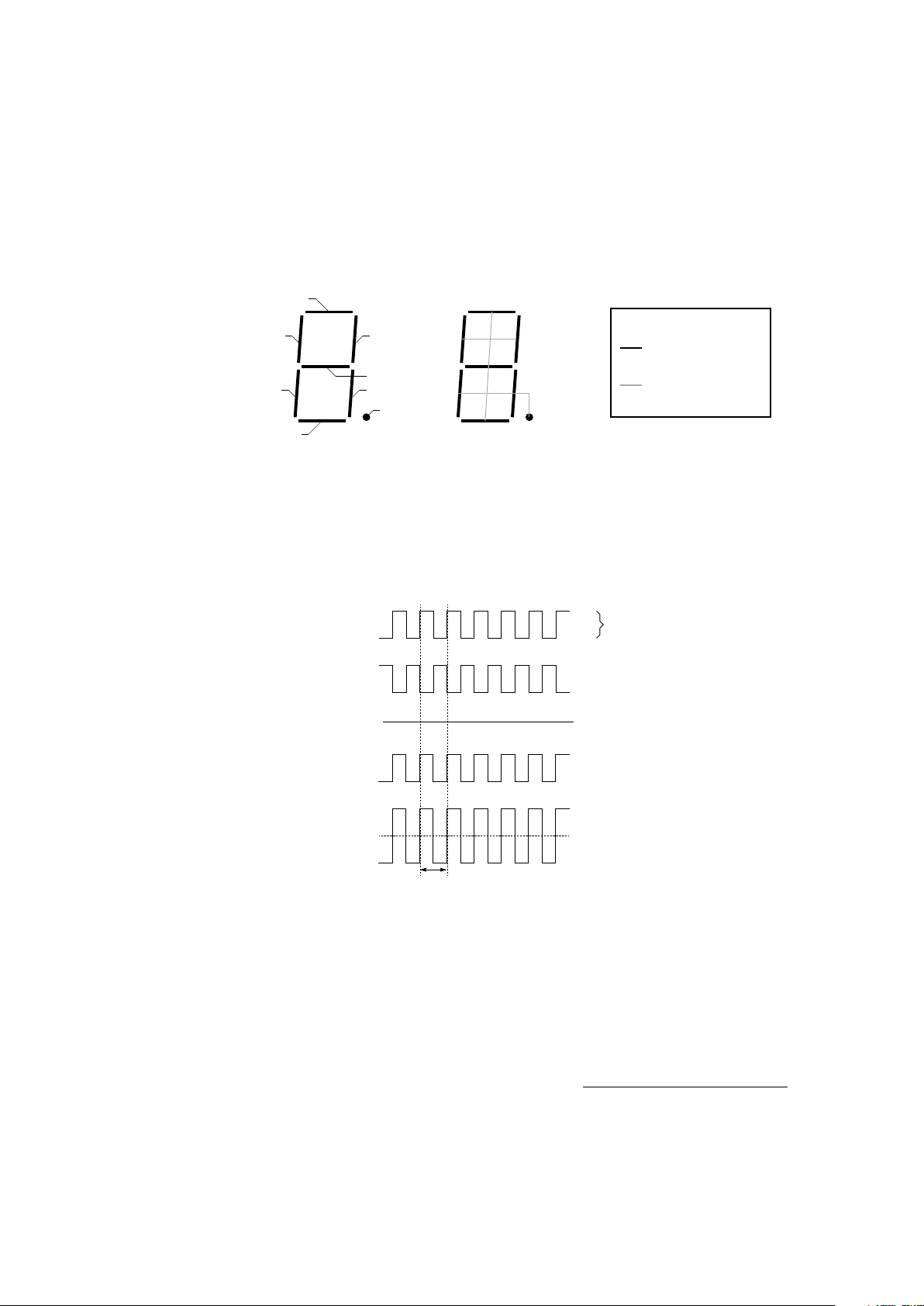

Figure 1 below shows static driver connections to a single-digit, seven-segment alphanumeric display. Separate driv-

ers, SEG1 - SEG8, power each segment. All segments share a common ground connection, COM.

LCD Drivers for Static Configurations

Part Number Segments On-Chip Oscillator Drive Voltage (V

LCD

) Package

MSM5219B 48

√

4.0 - 7.0 60-lead PQFP

MSM5221 56 X 3.0 - 7.0 80-lead PQFP

MSM5265 80

√

3.0 - 6.0 100-lead PQFP

Page 2

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

2OKI SEMICONDUCTOR

Figure 2 below shows the AC waveforms for driving the illustrated display. When an element is deselected, the com-

bined COM and SEG signals negate each other, as shown for the (COM – SEG1) signal illustrated below. When an

element is selected, the combined COM and SEG signals constructively reinforce each other, as shown for the (COM

– SEG2) signal below.

In static drive configurations, the AC frequency used to drive each segment is identical. This AC frequency is called

the frame frequency . In static drive configurations, a single element is selected or deselected in any one individual

frame, as shown in Figure 2 above.

Static driver configurations generally use a frame frequency in the 20-200 Hz range. Lower frame frequencies can

cause visible flicker. Higher frame frequencies do not provide sufficient time for charging the capacitive LCD elements.

SEG7

SEG6

SEG1

SEG2

SEG3

SEG5

SEG4

SEG8

Figure 1. Segment Connections for Static-Drive Configurations

COM

Segment connections over

the liquid crystal.

KEY:

Common base connections

under the liquid crystal.

Figure 2. Functional Waveforms for Static Drive Configurations

COM

SEG1

SEG2

COM – SEG2

V

DD

V

L

V

DD

V

L

V

DD

V

L

V

LCD

-V

LCD

0V

COM – SEG1

(Selected)

(Deselected)

0V

V

LCD

1 Frame

(Deselected)

(Selected)

Page 3

■ ■

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

3 OKI SEMICONDUCTOR

USING MULTIPLEXED DRIVERS

For configurations requiring more than about 80 drivers, it is more efficient to multiplex the COM and SEG signals

than to use a static driver configuration. In multiplexed configurations, each SEG driver signal powers more than one

segment, and the circuit uses more than one COM signal. The SEG and COM signals actually form a grid, with each

segment driven by a unique SEG/COM node. The multiplexed drive method reduces the number of driver circuits

and the number of connections between the circuit and the display cell. This reduces cost when driving many display

elements.

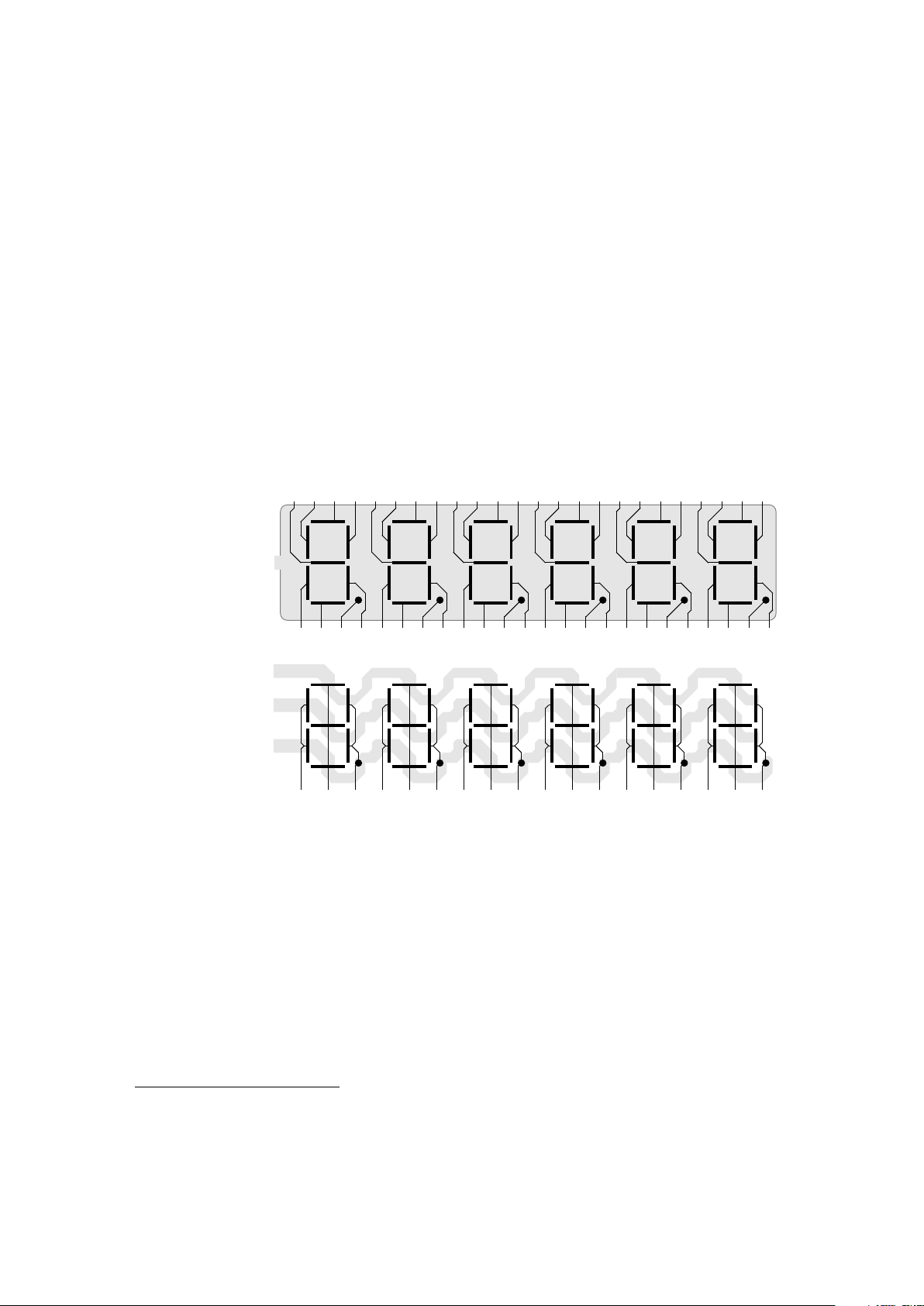

Figure 1 below illustrates this reduction in driver count by comparing static and multiplexed drive configurations for

a six-digit display. The static driver configuration requires 49 connections to the LCD, whereas the multiplexed configuration requires only 21 connections. Increasing the degree of multiplexing can further reduce the number of connections; however, increased multiplexing also reduces the circuit’s tolerance to voltage variation.

A range of multiplexed configurations are possible, distinguished by:-

• Bias , indicating the number of voltage levels used to power the LCD display.

• Duty Cycle , indicating the number of segments driven by each individual output driver.

• Frame Frequency Type, indicating whether the COM signal alternates over one frame (Type A) or two frames

(Type B).

For example, in a 1/2 bias, 1/2 duty-cycle configuration, each individual output driver uses two voltage levels to drive

two segments. Similarly, in a 1/3 bias, 1/3 duty-cycle configuration, each driver uses three voltage levels to drive

three segments ( Figure 1 above is a 1/3 bias, 1/3 duty cycle configuration).

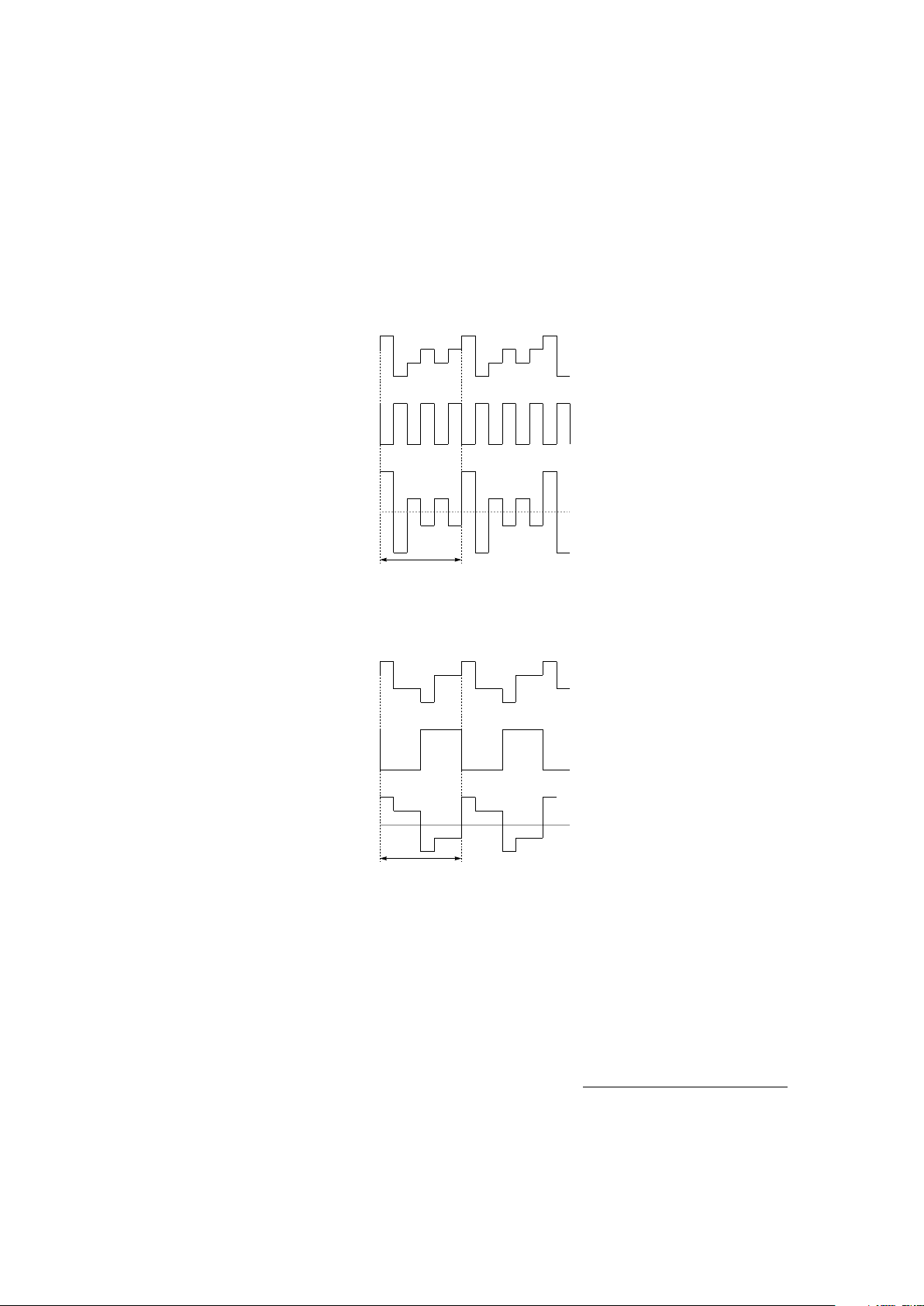

Frame frequency determines the degree of flickering and vividness. For a high degree of multiplexing, the type-B

configuration can make the display more vivid, but can also introduce flickering at lower clock frequencies. Figure 4

1

A

ComA

ComB

ComC

Common

Static

Multiplex

1/3 bias,

1/3 duty cycle

2

A

3

A

4A5

A

7A6

A

8

A

1B2

B

3

B

4B5

B

7B6

B

8

B

1C2

C

3

C

4C5

C

7C6

C

8

C

1D2

D

3

D

4D5

D

7D6

D

8

D

1E2

E

3

E

4E5

E

7E6

E

8

E

1F2

F

3

F

4F5

F

7F6

F

8

F

S

3

S1S

2

S

6

S4S

5

S

9

S7S

8

S10S11S12S13S14S15S16S17S

18

Figure 3. Static versus Multiplexed Configurations

Page 4

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

4OKI SEMICONDUCTOR

and Figure 5 below illustrate the difference between type-A and type-B configurations for the LCD driver network

shown in Figure 1 above.

Type B configurations are more common, as the maximum required frequency is lower. Figure 6 through Figure 10

illustrate various multiplexed configuration, all of which use a Type B configuration to reduce frame frequency.

Figure 6 on the next page illustrates how a 1/2 bias, 1/2 duty cycle, Type B configuration can drive 62 outputs. This

particular example is suitable for systems using the MSM6660. Full V

LCD

voltage is applied across the selected seg-

ment for display and less than full V

LCD

voltage is applied across the deselected segment.

COM

SEG

COM – SEG

1 Frame

Figure 4. A-Type Waveforms for a 1/3 Duty Cycle, 1/3 Bias Configuration

SEG

COM – SEG

1 Frame

Figure 5. B-Type Waveforms for a 1/3 Duty Cycle, 1/3 Bias Configuration

COM

Page 5

■ ■

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

5 OKI SEMICONDUCTOR

Figure 7 below shows the waveforms for the 1/2 bias, 1/2 duty cycle configuration shown in Figure 6 above.

Figure 8 illustrates a 1/3 bias, 1/3 duty cycle, Type B LCD network, suitable for connection to OKI’s MSM6606.

SEG1

SEG2

SEG3 SEG4

COMA

COMB

Figure 6. A 1/2 Bias, 1/2 Duty Cycle, Type B Configuration

COM1 V

LC1, 2

V

DD

V

LC3

COM2 V

LC1, 2

V

DD

V

LC3

SEGn V

LC1, 2

V

DD

V

LC3

On Off On Off On Off On Off On Off On Off On

Figure 7. Waveforms for 1/2 Bias, 1/2 Duty Cycle, Type B Configuration

Note:When 1/2 duty is selected and 1/2 bias is used, perform the following:

When the code is -01, short VLC1 and VLC2 to supply the bias voltage.

When the code is -02 or -03, externally short VLC1 and VLC2.

COM2 - SEGn

V

LCD

-V

LCD

0

Page 6

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

6OKI SEMICONDUCTOR

Figure 9 below depicts waveforms for the 1/3 bias, 1/3 duty cycle, Type B network in Figure 8 above.

SEG1

SEG2 SEG3

COM1

COM3

Figure 8. 1/3 Duty Cycle, 1/3 Bias, Type B Configuration

COM2

COM1

V

DD

V

LC1

V

LC2

V

LC3

On Off On Off On Off On Off On Off On Off On

COM2

V

DD

V

LC1

V

LC2

V

LC3

COM3

V

DD

V

LC1

V

LC2

V

LC3

SEGn

V

DD

V

LC1

V

LC2

V

LC3

COM2 - SEGn

V

3

V

2

V

1

V

SS

-V

1

-V

2

-V

3

V

LCD

V

LCD

Figure 9. 1/3 Duty Cycle, 1/3 Bias, Type B Waveforms

Page 7

■ ■–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

7 OKI SEMICONDUCTOR

Figure 10, below, illustrates a 1/5 bias, 1/16 duty cycle, Type B configuration, together with COM and SEG waveforms. This example uses the dot-matrix configuration for display.

V

DD

V

a

V

b

V

c

V

d

V

e

COM 0

1

V

LCD

V

DD

V

a

V

b

V

c

V

d

V

e

COM 0

2

1 2 3 4 16 1

V

DD

V

a

V

b

V

c

V

d

V

e

SEG 0

1

V

DD

V

a

V

b

V

c

V

d

V

e

SEG 0

2

V

LCD

4

/5 V

LCD

3

/5 V

LCD

2

/5 V

LCD

1

/5 V

LCD

0

-1/5 V

LCD

-2/5 V

LCD

-3/5 V

LCD

-4/5 V

LCD

-V

LCD

V

LCD

4

/5 V

LCD

3

/5 V

LCD

2

/5 V

LCD

1

/5 V

LCD

0

-1/5 V

LCD

-2/5 V

LCD

-3/5 V

LCD

-4/5 V

LCD

-V

LCD

1 Frame

COM 01 - SEG 0

1

(Select Waveform)

COM 02 - SEG 0

2

(Non-Select Waveform)

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

10

0

11

0

12

0

13

0

14

0

15

0

16

010203040

5

Va = VDD - 1/5 V

LCD

Vb = VDD - 2/5 V

LCD

Vc = VDD - 3/5 V

LCD

Vd = VDD - 4/5 V

LCD

Ve = VDD - 5/5 V

LCD

Figure 10. A 1/5 bias, 1/16 duty cycle, Type B Configuration and Waveforms

Page 8

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

8OKI SEMICONDUCTOR

Larger configurations are simply extensions of the above principles. OKI Semiconductor supplies a range of singlechip and multi-chip solutions for multiplexed LCD driver configurations supporting any required number of dots or

segments. The table below lists single-chip LCD drivers, indicating major differences for each part.

For larger dot configurations, such as found in laptop displays for example, common and segment drivers are located

on separate chips.

The table below shows critical features for ICs that provide common drivers only. Note the use of thin quad flat packs

(TQFPs) and Tape Automated Bonding (TAB) for devices with higher lead counts.

The next table, opposite, shows the same critical features for ICs that provide segment drivers only.

[1] On-chip bias resistors.

Single-Chip LCD Drivers for Multiplexed Configurations

Part Number Dots Duty Cycle Ratio

On-Chip

Oscillator

Drive Voltage

(V

LCD

) Package

MSM6544 42 1/2 √ 3.0 - 6.0 56-lead PQFP

MSM6606 40 1/2 X 4.5 - 5.5 64-lead PQFP

MSM6660-01 62 1/2 X 4.0 - 6.0 80-lead PQFP

MSM6660-02 62 1/3 X

[1]

4.0 - 6.0 80-lead PQFP

MSM6660-03 62 1/3 X

[1]

4.0 - 6.0 80-lead PQFP

MSM5265 80 1/2 √ 3.0 - 6.0 100-lead PQFP

MSM5260 80 1/32 - 1/64 X 8.0 - 18.0 100-lead PQFP

MSC5301B-01 16 COM

64 SEG

1/16 X 4.0 - 16.0 100-lead PQFP

MSC5301B-02 8 COM

64 SEG

1/8 X 4.0 - 16.0 100-lead PQFP

Common Drivers for Multiplexed Configurations

Part Number Drivers Duty Cycle Ratio Max. Dots

Drive Voltage

(V

LCD

) Package

MSM5238 32 1/32 - 1/64 2,048 3.0 - 16.0 44-lead PQFP

MSM5298A 68 1/64 - 1/256 17,408 8.0 - 28.0 80-lead TQFP

MSM6368 80 1/256 - 1/480 38,400 25.0 - 40.0 100-lead TQFP

Segment Drivers for Multiplexed Configurations

Part Number Drivers

Duty Cycle

Ratio Max. Dots Inputs

Drive Voltage

(V

LCD

) Package

MSM5259 40 1/8 - 1/16 640 1 3.0 - 6.0 56-lead PQFP

MSM5839B 40 1/32 - 1/128 5,120 1 8.0 - 18.0 56-lead PQFP

MSM5839C 40 1/3 - 1/64 2,560 1 4.0 - 11.0 56-lead PQFP

MSM5299A 80 1/64 - 1/256 20,480 4 8.0 - 28.0 100-lead PQFP

Page 9

■ ■–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

9 OKI SEMICONDUCTOR

POWER SUPPLY

The table below shows the relationship between the required number of driving biases and the display duty ratios.

Either passive or active bias generation circuitry can provide the required voltage levels, as described in the next two

subsections.

Passive Bias Generation

A resistor ladder is the most common way to generate the required bias voltage levels. Figure 11 below shows a typ-

ical resistor ladder. V

REF

may be tied to VSS, or, for displays with larger voltage bias ranges, V

REF

may be tied to a

negative power source.

MSM5299A-01 80 1/64 - 1/256 20,480 4 8.0 - 28.0 100-lead TQFP

MSM5299C 80 1/64 - 1/256 20,480 4 8.0 - 28.0 100-lead PQFP

MSM6669 80 1/100 - 1/256 20,480 4 14.0 - 28.0 0.25mm TAB

Relationship between Duty Cycle and Driving Bias

Duty Ratio Drive Bias Voltage Levels

Static – 2

1/2 1/2 3

1/3 1/3 4

1/4 1/3 4

1/7 1/4 5

1/8 1/4 5

1/11 1/4 5

1/12 1/4 5

1/14 1/5 6

1/16 1/5 6

1/24 1/5 6

1/32 1/5 6

1/64 1/5 6

Segment Drivers for Multiplexed Configurations (Continued)

Part Number Drivers

Duty Cycle

Ratio Max. Dots Inputs

Drive Voltage

(V

LCD

) Package

Page 10

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

10OKI SEMICONDUCTOR

The required operating margin and power consumption determines the appropriate resistor values. Because the LCD

load is capacitive, the current during element charging and discharging distorts the waveform. Generally, the value

of resistor R is 1 kΩ to 10 kΩ. Lower resistor values reduce distortion but increase power dissipation. Larger LCD

panels exhibit greater capacitance, and so resistor values may be decreased proportionally as the display size

increases.

No capacitor is required, but a 1-µF capacitor can be used if necessary. Connecting a capacitor in parallel to the resis-

tors can reduce waveform distortion during the charge and discharge periods, but only to a limited degree. Larger

capacitor values generate a voltage level shift and reduce the operating margin. Figure 12 below illustrates how to

connect capacitors in a passive bias network.

In large arrays, the LCD source and common signals form a matrix configuration that complicate the path of the

charge/discharge current through the load. Moreover, current varies according to the demand for the power consumption of the equipment in which the LCD is incorporated. As a result, it is not possible to generate precise equations

for calculating resistor and capacitor values.

Active Bias Generation

In larger displays, such as graphic displays, the liquid crystal is larger and the duty cycle ratio is smaller. Stability of

the liquid crystal’s drive level is therefore more important for a large display than for a small display.

Because graphic displays are large and contain many picture elements, the LCD driver’s impedance produces distortion in the drive waveforms and degrades display quality. For this reason, the impedance of the LCD driver bias

sources should be reduced with operational amplifiers. Figure 13 below shows examples of op amp configurations

to provide this reduced impedance.

R

LCD

R

LCD

V

DD

VLC1 VLC2 VLC3

For 1/2 bias (when 1/2 duty is selected)

R

LCD

R

LCD

V

DD

VLC1 VLC2 VLC3

For 1/3 bias (when 1/3 duty is selected)

R

LCD

Figure 11. Network for Simple Passive Bias Generation

V

REF

V

REF

R

LCD

R

LCD

VDDVLC1 VLC2 VLC3

For 1/2 bias (when 1/2 duty is selected)

R

LCD

R

LCD

V

DD

VLC1 VLC2 VLC3

For 1/3 bias (when 1/3 duty is selected)

R

LCD

Figure 12. Network for Passive Bias Generation with Capacitor Filters

C C C C C C

V

REF

V

REF

Page 11

■ ■–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

11 OKI SEMICONDUCTOR

No load current flows through the dividing resistors because of the high input impedance of the operational amplifiers. A resistor value for R of 10 kΩ is suitable for the above circuit.

APPLICATION CIRCUITS

This application note concludes with two illustrative application circuits. The first, shown in Figure 14 below, uses

two MSM6660 LCD drivers to provide three bias signals and 124 segment drivers for a 1/3 bias, 1/3 duty cycle, Type

B LCD panel containing 372 dots.

In the example on the previous page, a microcontroller may be necessary to provide an appropriate interface to the

overall system. Figure 15 below depicts a more complex example that may not require an additional microcontroller.

R

LCD

R

LCD

V

DD

VLC1 VLC2 VLC3

For 1/2 bias (when 1/2 duty is selected)

R

LCD

R

LCD

V

DD

VLC1 VLC2 VLC3

For 1/3 bias (when 1/3 duty is selected)

R

LCD

Figure 13. Network for Active Bias Generation

V

REF

V

REF

R

LCD

SEL VLC1 VLC2 VLC3

R

0

C

0

OSC

SYNC

COMOUT

COM3

COM2

COM1

CE

DATA

CK

BL

BL

CK

DATA

CE1

CE2

SEL VLC1 VLC2 VLC3 OSC

SYNC

COMOUT

COM3

COM2

COM1

CE

DATA

CK

BL

R

LCD

R

LCD

SEG0 ~ SEG61 SEG0 ~ SEG61

LCD Panel

Figure 14. Application Circuit Example Using MSM6660 LCD Drivers

Page 12

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ■

12OKI SEMICONDUCTOR

Instead of using a separate LCD driver and microcontroller, this circuit integrates LCD driver and controller functions in the MSM6222GS LCD Controller, available from OKI Semiconductor.

LCD controllers can increase system integration and provide a more comprehensive feature set. For small and midsize displays, a single LCD controller may provide all the required COM and SEG signals. For larger configurations,

combinations of LCD controllers and drivers can provide exactly the required degree of functionality. In the above

example, the LCD controller provides all required COM signals and some of the SEG signals. Additional SEG drivers augment the LCD controller with the additional SEG drivers required.

OKI Semiconductor provides a family of advanced LCD controllers and drivers that augment the basic functionality

of standard LCD drivers and controllers with enhanced capabilities. Additional features found in OKI’s LCD controllers include key-scan logic, power saving modes, on-chip RAM, integrated oscillators, and optional on-chip bias

generation. The table on the following page lists some of the members of OKI’s advanced LCD controller/driver family.

The following table lists the main features of devices in OKI’s advanced LCD controller/driver family described in

this document.

DO

CP

L

DF

V

DD

GND

V

1

V

2

V

3

V

4

V

5

DI

1

CP

LOAD

DF

VDDVSSV2V3V

5

DO

40

DO

20

DI

21

01 ~ 0

40

DI

1

CP

LOAD

DF

VDDVSSV2V3V

5

DO

40

DO

20

DI

21

01 ~ 0

40

DI

1

CP

LOAD

DF

VDDVSSV2V3V

5

DO

40

DO

20

DI

21

01 ~ 0

40

SEG1 ~ 40COM1 ~ 16

MSM5259GS MSM5259GS MSM5259GS

LCD Panel

MSM6222GS

R

0V

C CRC C

R R R

C

+5V

Figure 15. Typical Application Circuit Using the MSM6222GS LCD Controller

Page 13

■ ■–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

13 OKI SEMICONDUCTOR

For more information, see the LCD Driver Controller Data Book and Advanced LCD Controller/Driver Products

from OKI Semiconductor, or contact your local OKI Semiconductor sales representative for additional assistance.

OKI’s Advanced LCD Controller/Driver Family

Part No. Controller Drivers Duty Cycle V

LCD

Interface

Pins /

Package Special Features

MSM5298A — 68 COM 1/64 - 1/256 8.0- 28.0 Serial shift

register I/O

80/ PQFP Bidirectional 68-bit shift register

Multi-chip configuration support

On-chip or external bias generation

MSM5299A — 80 SEG 1/64 - 1/256 8.0- 28.0 4-bit shift

register I/O

100/

PQFP

Bidirectional 4x20-bit shift register

80-bit latch

Multi-chip configuration support

On-chip or external bias generation

MSC5301B01

— 64 SEG

16 COM

1/16

(1/5 bias)

4.0 - 16.0 Serial

MCU

interface

100/

PQFP

1 kbit on-chip RAM

Multi-chip configuration support

Blanking support

On-chip RC oscillator

MSC5301B02

— 64 SEG

8 COM

1/8

(1/4 bias)

4.0 - 16.0 Serial

MCU

interface

100/

PQFP

1 kbit on-chip RAM

Multi-chip configuration support

Blanking support

On-chip RC oscillator

MSM6568A — 160 COM 1/200 - 1/480 14.0 - 28.0 2-bit shift

register I/O

Slim TAB Bidirectional 160-bit shift register

Multi-chip configuration support

On-chip or external bias generation

MSM6569 — 160 SEG 1/200 - 1/480 20.0 - 40.0 8-bit shift

register I/O

Slim TAB Unidirectional 160-bit shift register

160-bit latch

Power-saving mode

Multi-chip configuration support

On-chip or external bias generation

MSM6606 — 40 SEG

2 COM

1/2 5.5 Serial

MCU

interface

64/ PQFP Internal 5x6 key-scan circuit

(supporting up to 30 key switches)

Single LED driver output

Integrated bias voltage generation

On-chip RC oscillator

MSM666501

√ 80 SEG

17 COM

1/9 or 1/17 3.0 - 6.0 Serial

MCU

interface

128/

PQFP

256 5x7 characters in on-chip ROM

80 dot arbitrators

Character and arbitrator blink functions

On-chip RC oscillator

MSM6665B √ 80 SEG

17 COM

1/9 or 1/17 — Serial

MCU

interface

PBGA 256 5x7 characters in on-chip ROM

80 dot arbitrators

Character and arbitrator blink functions

Integrated bias voltage generation

Loading...

Loading...