Page 1

MP3410

1.3A, 550kHz Synchronous

Rectified Step-up Converter

The Future of Analog IC Technology

DESCRIPTION

The MP3410 is a highly efficient, synchronous,

fixed frequency, current-mode step-up converter

with output to input disconnect, inrush current

limiting and internal soft-start. It includes an error

amplifier, ramp generator, comparator, N-Channel

switch and P-Channel synchronous rectified

switch (which greatly improves efficiency). The

output disconnect feature allows the output to be

completely isolated from the input in shutdown

mode.

The 550kHz switching frequency allows for

smaller external components producing a

compact solution for a wide range of load currents.

The internal compensation and soft-start

minimizes the external component count and

limits the inrush current during startup. The

MP3410 has integrated power MOSFET which

can support up to 6V output and typical 1.3A

switch current.

The MP3410 is offered in a thin SOT23-5

package.

FEATURES

• Over 90% Efficiency

• Output to Input Disconnect at Shutdown Mode

• Internal Synchronous Rectifier

• Inrush Current Limiting and Internal Soft-Start

• Internal Compensation

• 1.3A Typical Switch Current Limit

• 550kHz Fixed Switching Frequency

• Zero Current Shutdown Mode

• Thermal Shutdown

• 5-Pin TSOT-23 Package

APPLICATIONS

• MP3 Players

• Handheld Computers and PDAs

• Digital Still and Video Cameras

• External Modems

• Small LCD Displays

For MPS green status, please visit MPS website under Quality Assurance.

“MPS” and “The Future of Analog IC Technology” are Registered Trademarks of

Monolithic Power Systems, Inc.

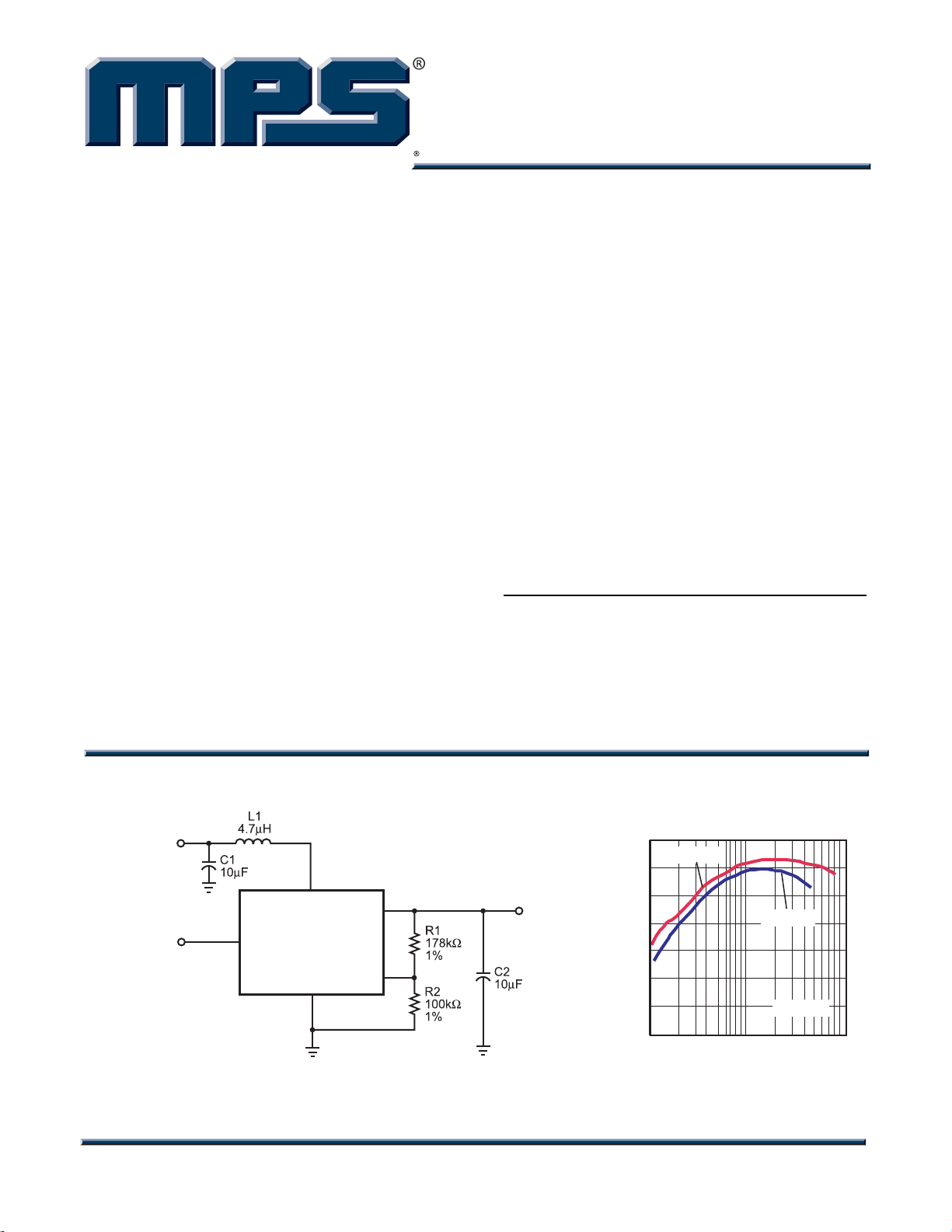

TYPICAL APPLICATION

V

IN

1.8V - 3.2V

4

SW

EN

5

EN

MP3410

GND

2

OUT

FB

Efficiency vs

Load Current

100

3

1

V

OUT

3.3V

400mA

EFFICIENCY (%)

VIN=3.6V

90

80

70

60

50

40

30

10 100 1000

LOAD CURRENT (mA)

VIN=2.4V

V

OUT

=5V

MP3410 Rev. 1.12 www.MonolithicPower.com 1

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 2

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

ORDERING INFORMATION

Part Number* Package Top Marking Free Air Temperature (TA)

MP3410DJ

TSOT23-5

P3

-40°C to +85°C

* For Tape & Reel, add suffix –Z (e.g. MP3410DJ–Z)

For RoHS compliant packaging, add suffix –LF (e.g. MP3410DJ–LF–Z)

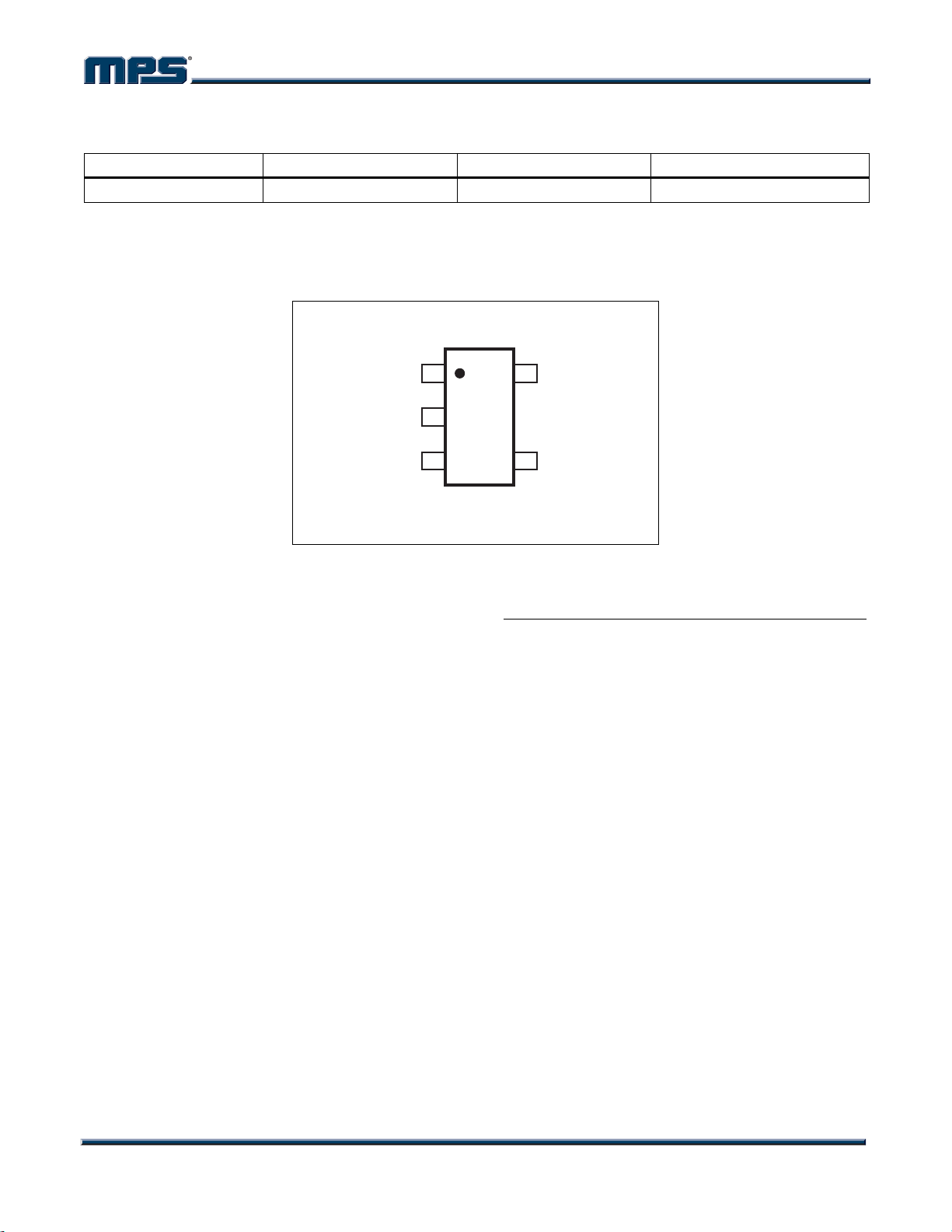

PACKAGE REFERENCE

TOP VIEW

FB

GND

OUT

1

2

3

TSOT23-5

54EN

SW

ABSOLUTE MAXIMUM RATINGS

(1)

All Pins.........................................-0.3V to +6.5V

Continuous Power Dissipation (T

= +25°C)

A

(2)

........................................................... 0.47W

Storage Temperature............... -65°C to +150°C

Recommended Operating Conditions

(3)

Supply Voltage VIN.............................1.8V to 6V

Output Voltage V

Maximum Junction Temp. (T

...........................2.5V to 6V

OUT

) .............. +125°C

J

Thermal Resistance

(4)

θ

JA

θJC

TSOT23-5.............................. 220.... 110.. °C/W

Notes:

1) Exceeding these ratings may damage the device.

2) The maximum allowable power dissipation is a function of the

maximum junction temperature T

ambient thermal resistance

. The maximum allowable continuous power dissipation at

T

A

any ambient temperature is calculated by P

)/JA. Exceeding the maximum allowable power dissipation

T

A

will cause excessive die temperature, and the regulator will go

into thermal shutdown. Internal thermal shutdown circuitry

protects the device from permanent damage.

3) The device is not guaranteed to function outside of its

operating conditions.

4) Measured on JESD51-7 4-layer board.

(MAX), the junction-to-

J

, and the ambient temperature

JA

(MAX)=(TJ(MAX)-

D

MP3410 Rev. 1.12 www.MonolithicPower.com 2

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 3

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

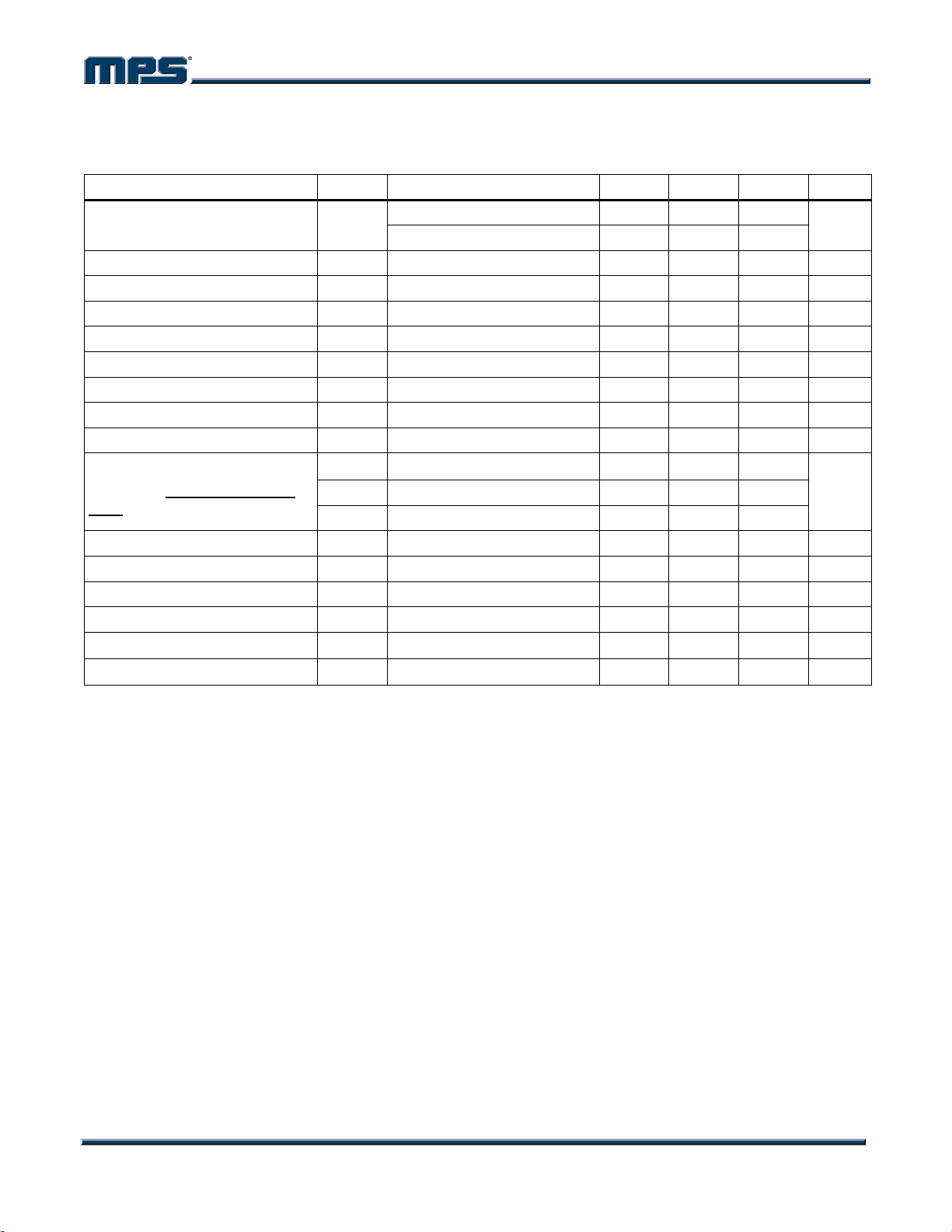

ELECTRICAL CHARACTERISTICS

VEN = V

Parameter Symbol Condition Min Typ Max Units

Startup Supply Voltage VST

Output Voltage Range V

Supply Current (Shutdown) VEN = V

Supply Current VFB = 1.3V 360 A

Feedback Voltage VFB 1.15 1.19 1.23 V

Feedback Input Current VFB = 1.19V 50 nA

Switching Frequency fSW 410 550 690 KHz

Maximum Duty Cycle D

EN Input Low Voltage 0.4 V

EN Input High Voltage

(see Chart EN high voltage vs

Input for details)

EN Pull Down Resistor 1 m

Low-Side On Resistance

Low-Side Current Limit I

High-Side On Resistance

Thermal Shutdown

Thermal Shutdown Hysteresis

Note:

5) Guaranteed by design, not tested.

= 3.3V, TA = +25°C, unless otherwise noted.

OUT

I

= 0mA 1.5 1.6 1.8

LOAD

R

= 50 1.65

LOAD

2.5 6.0 V

OUT

OUT

80 90 95 %

MAX

V

=1.8V

IN

VIN =3.3V 1.65

V

(5)

R

(5)

R

(5)

160

ONLS

1.3 A

LIM

ONHS

(5)

30

=5V 2.15

IN

V

V

= 3.3V 300 m

OUT

= 3.3V 530 700 m

OUT

V

=0V, VSW = 5V 0.15 0.5 A

1.05

V

°C

°C

MP3410 Rev. 1.12 www.MonolithicPower.com 3

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 4

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

TYPICAL PERFORMANCE CHARACTERISTICS

Circuit on front page, VIN = 2.4V, V

= 3.3V, TA = +25°C, unless otherwise noted.

OUT

MP3410 Rev. 1.12 www.MonolithicPower.com 4

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 5

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

Circuit on front page, V

= 2.4V, V

IN

= 3.3V, TA = +25°C, unless otherwise noted.

OUT

PIN FUNCTIONS

Pin # Name Description

1 FB

2 GND Ground.

3 OUT Supply Input for the MP3410. Connect to the output of the converter.

4 SW

5 EN

MP3410 Rev. 1.12 www.MonolithicPower.com 5

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Regulation Feedback Input. Connect to an external resistive voltage divider from the output to

FB to set the output voltage.

Output Switching Node. SW is the drain of the internal low-side N-Channel MOSFET and

high-side P-Channel MOSFET. Connect the inductor to SW to complete the step-up converter.

Regulator On/Off Control Input. A logic high input turns on the regulator. A logic low input (V

EN

< 0.4V) puts the MP3410 into low current shutdown mode. EN Input High Voltage will shift

upward for a higher V

. For a given VIN, as long as the voltage applied at EN pin is equal to or

IN

higher than correspondent EN-High-min value specified in the EC table , the part can turn on

normally.

Page 6

OPERATION

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

REFERENCE VOLTAGE

THERMAL SHUTDOWN

OSC

500KHz

RAMP

+

UVLO

BIAS CURRENT

PWM

COMPARATOR

CONTROL

LOGIC

Figure 1—Functional Block Diagram

The MP3410 uses a 550kHz fixed-frequency,

current-mode regulation architecture to regulate

the output voltage. The MP3410 measures the

output voltage through an external resistive

voltage divider and compares that to the

internal 1.2V reference to generate the error

voltage. The current-mode regulator compares

the error voltage to the inductor current to

regulate the output voltage. The use of

current-mode regulation improves transient

response and control loop stability.

When the MP3410 is disabled (EN = Low), both

power switches are off. The body of the

P-Channel MOSFET connects to SW and there

is no current path from SW to OUT. Therefore,

the output voltage discharges to ground. When

the MP3410 is enabled (EN = High), the body of

the P-Channel MOSFET connects to OUT and

forms a forward diode from SW to OUT. Thus

the output voltage rises up toward the input

voltage. When output voltage crosses 1.6V the

MP3410 starts the controller and regulates the

output voltage to the target value.

EN

OUT

SW

CURRENT

SENSE

AMPLIFIER

ERROR

AMPLIFIER

RS

GND

FB

1.2V

At the beginning of each cycle, the N-Channel

MOSFET switch is turned on, forcing the

inductor current to rise. The current at the

source of the switch is internally measured and

converted to a voltage by the current sense

amplifier. That voltage is compared to the error

voltage. When the inductor current rises

sufficiently, the PWM comparator turns off the

switch, forcing the inductor current to the output

capacitor through the internal P-Channel

MOSFET rectifier, which forces the inductor

current to decrease. The peak inductor current

is controlled by the error voltage, which in turn

is controlled by the output voltage. Thus the

output voltage controls the inductor current to

satisfy the load.

Soft-Start

The MP3410 includes a soft-start timer that

limits the voltage at the error amplifier output

during startup to prevent excessive current at

the input. This prevents premature termination

of the source voltage at startup due to inrush

current. This also limits the inductor current at

startup, forcing the input current to rise slowly to

the amount required to regulate the output

voltage during soft-start.

MP3410 Rev. 1.12 www.MonolithicPower.com 6

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 7

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

(

)

×

(

=

Δ

APPLICATION INFORMATION

COMPONENT SELECTION

Selecting the Inductor

Setting the Output Voltage

Set the output voltage by selecting the resistive

voltage divider ratio. The voltage divider drops

the output voltage to the 1.19V feedback

voltage. Use a 100k resistor for R2 of the

voltage divider. Determine the high-side resistor

R1 by the equation:

−

VV

FBOUT

⎞

⎟

⎟

2R

⎠

Where V

=

1R

is the output voltage, VFB is the

OUT

V

⎛

FB

⎜

⎜

⎝

1.19V feedback voltage and R2=100k.

Selecting the Input Capacitor

An input capacitor is required to supply the AC

ripple current to the inductor, while limiting noise

at the input source. Multi-layer ceramic

capacitors are the best choice as they have

extremely low ESR and are available in small

footprints. Use an input capacitor value of 4.7F

or greater. This capacitor must be placed

physically close to the device.

Selecting the Output Capacitor

A single 4.7µF to 10µF ceramic capacitor

usually provides sufficient output capacitance

for most applications. Larger values up to 22µF

may be used to obtain extremely low output

voltage ripple and improve transient response.

The impedance of the ceramic capacitor at the

switching frequency is dominated by the

capacitance, and so the output voltage ripple is

mostly independent of the ESR. The output

voltage ripple V

is calculated as:

RIPPLE

The inductor is required to force the output

voltage higher while being driven by the lower

input voltage. A good rule for determining the

inductance is to allow the peak-to-peak ripple

current to be approximately 30%-50% of the

maximum input current. Make sure that the

peak inductor current is below the minimum

current limit at the duty cycle used (to prevent

loss of regulation due to the current limit

variations).

Calculate the required inductance value L using

the equations:

) V- (VV

INOUTIN

IfV

Δ××

SWOUT

×

IV

LOADOUT

V

IN

)

I%50%30I −

)MAX(

η×

)MAX(IN

Where I

I

LOAD(MAX)

L

=

=

)MAX(IN

is the maximum load current, I

is the peak-to-peak inductor ripple current and

is efficiency. For the MP3410, typically, 4.7µH is

recommended for most applications. Choose an

inductor that does not saturate at the peak

switch current as calculated above with

additional margin to cover heavy load transients

and extreme startup conditions.

VVI

−

UT

××

IN

f2CV

SW

LOAD

is the load

Where V

V

RIPPLE

is the input voltage, I

IN

=

OLOAD

O

UT

current, C2 is the capacitance of the output

capacitor and f

is the 550kHz switching

SW

frequency.

MP3410 Rev. 1.12 www.MonolithicPower.com 7

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 8

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

Selecting the Feed-Forward Capacitor

A feed-forward capacitor C3 in parallel with the

high-side resistor R1 can be added to improve

the output ripple at discontinuous conduction

mode and the load transient response (see

Figure 2). Up to 220pF for this capacitor is

recommended for 3.3V output applications.

Selecting the Schottky Diode

A Schottky diode D1 in parallel with the highside P-Channel MOSFET is necessary to clamp

the SW node to a safe level for outputs of 4V or

above. A 0.5A, 20V Schottky diode can be used

for this purpose. See Figure 3.

V

IN

1.8V - 3.2V

4

EN

SW

5

EN

MP3410

OUT

LAYOUT CONSIDERATIONS

High frequency switching regulators require

very careful layout for stable operation and low

noise. All components must be placed as close

to the IC as possible. All feedback components

must be kept close to the FB pin to prevent

noise injection on the FB pin trace. The ground

return of C1 and C2 should be tied close to the

GND pin. See the MP3410 demo board layout

for reference.

3

C3

Up to 220pF

OPTIONAL

V

OUT

3.3V

400mA

1

GND

FB

2

Figure 2—3.3V Typical Application Circuit with Feed-Forward Capacitor

4

SW

5

EN

MP3410

GND

2

OUT

FB

3

1

Figure 3—5V Typical Application Circuit with External Schottky Diode and Output Disconnect

Not Required

MP3410 Rev. 1.12 www.MonolithicPower.com 8

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 9

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

D1

V

IN

2.5V - 4.2V

P1

V

OUT

5V

400mA

EN

4

SW

5

EN

MP3410

GND

2

OUT

FB

3

1

Figure 4—5V Typical Application Circuit with External Schottky Diode and Output Disconnect

Required

V

2.5V-4.2V

EN

Vin

3V

EN

L1

C3

470pF

IN

4

SW

OUT

3

V

OUT

5V

5

EN

MP3410

GND

FB

1

400mA

2

Figure 5—5V Typical Application Circuit

10

C1

L1

4.7

4

SW

MP3410

5

EN

GND

2

OUT

FB

B130

3

R1

220 k

1

R2

100 k

Vout

3.8 V

750 m A

C2

10

Figure 6—3V-3.8V/750mA Application

MP3410 Rev. 1.12 www.MonolithicPower.com 9

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Page 10

MP3410 — 1.3A, 550kHz SYNCHRONOUS RECTIFIED STEP-UP CONVERTER

PACKAGE INFORMATION

2.80

3.00

45

TSOT23-5

1.20

TYP

0.60

TYP

0.95

BSC

0.84

0.90

0.30

0.50

1

TOP VIEW

0.95 BSC

1.50

1.70

3

1.00 MAX

0.00

0.10

2.60

3.00

RECOMMENDED LAND PATTERN

SEATING PLANE

SEE DETAIL "A"

FRONT VIEW SIDE VIEW

2.60

TYP

0.09

0.20

NOTE:

GAUGE PLANE

0.25 BSC

o

0o-8

DETAIL A

0.30

0.50

1) ALL DIMENSIONS ARE IN MILLIMETERS.

2) PACKAGE LENGTH DOES NOT INCLUDE MOLD FLASH,

PROTRUSION OR GATE BURR.

3) PACKAGE WIDTH DOES NOT INCLUDE INTERLEAD FLASH

OR PROTRUSION.

4) LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING)

SHALL BE 0.10 MILLIMETERS MAX.

5) DRAWING CONFORMS TO JEDEC MO-193, VARIATION AA.

6) DRAWING IS NOT TO SCALE.

NOTICE: The information in this document is subject to change without notice. Users should warrant and guarantee that third

party Intellectual Property rights are not infringed upon when integrating MPS products into any application. MPS will not

assume any legal responsibility for any said applications.

MP3410 Rev. 1.12 www.MonolithicPower.com 10

6/30/2011 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2011 MPS. All Rights Reserved.

Loading...

Loading...