Page 1

TM

MP2106

The Future of Analog IC Technology

DESCRIPTION

The MP2106 is a 1.5A, 800KHz synchronous

buck converter designed for low voltage

applications requiring high efficiency. It is

capable of providing output voltages as low as

0.9V, and integrates top and bottom switches to

minimize power loss and component count. The

800KHz switching frequency reduces the size

of filtering components, further reducing the

solution size.

The MP2106 includes cycle-by-cycle current

limiting and under voltage lockout. The internal

power switches, combined with the tiny 10-pin

MSOP and QFN packages, provide a solution

requiring a minimum of surface area.

EVALUATION BOARD REFERENCE

Board Number Dimensions

EV2106DQ/DK-00A 2.5”X x 2.0”Y x 0.5”Z

TM

1.5A, 15V, 800KHz

Synchronous Buck Converter

FEATURES

• 1.5A Output Current

• Synchronous Rectification

• Internal 210m and 255m Power Switches

• Input Range of 2.6V to 15V

• >90% Efficiency

• Zero Current Shutdown Mode

• Under Voltage Lockout Protection

• Soft-Start Operation

• Thermal Shutdown

• Internal Current Limit (Source & Sink)

• Tiny 10-Pin MSOP or QFN Package

APPLICATIONS

• DC/DC Regulation from Wall Adapters

• Portable Entertainment Systems

• Set Top Boxes

• Digital Video Cameras, DECT

• Networking Equipment

• Wireless Modems

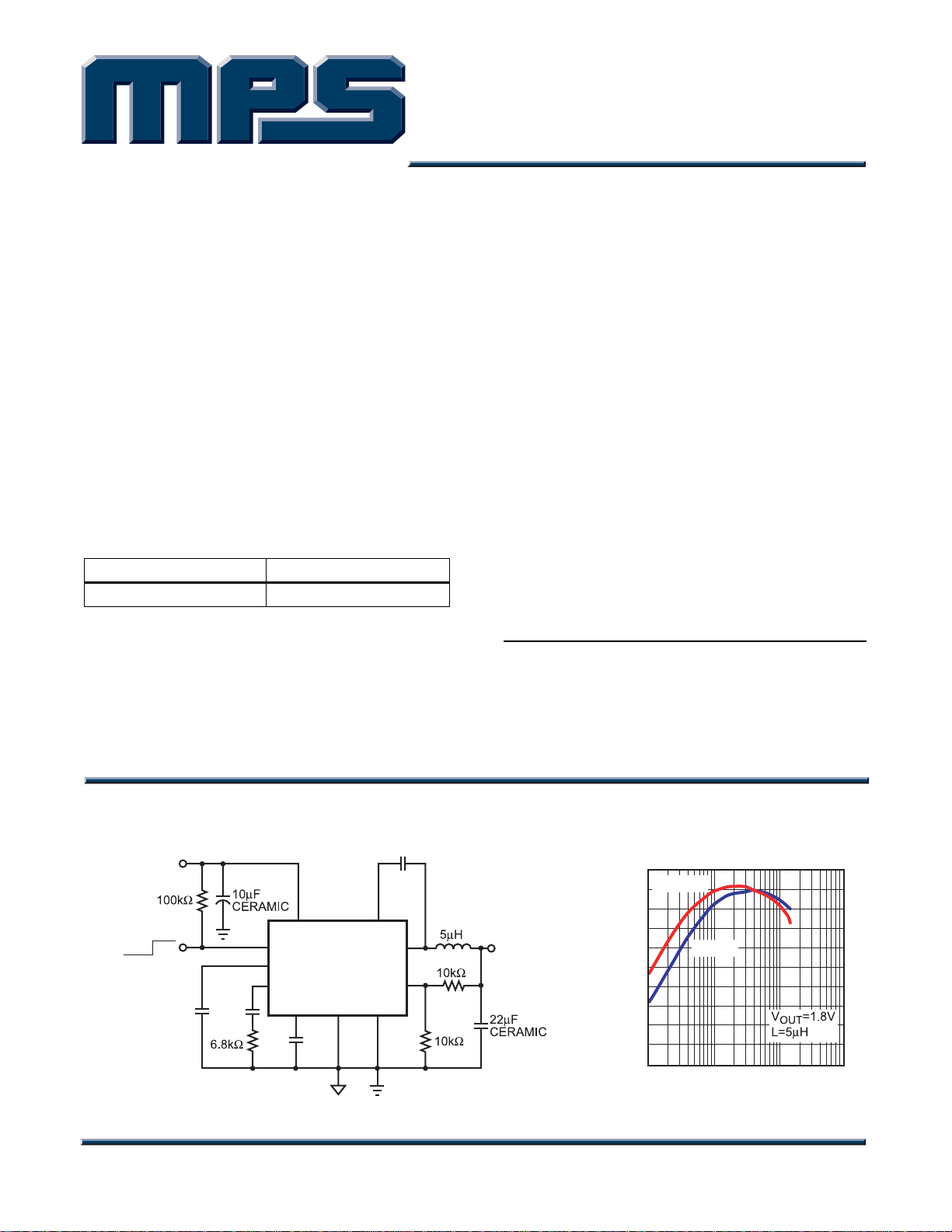

TYPICAL APPLICATION

INPUT

2.6V to 15V

R4

OFF ON

C5 C3

10nF

C1

3.3nF

R3

VIN BST

5

RUN

1

SS

COMP

MP2106

C6

10nF

3

“MPS” and “The Future of Analog IC Technology” are Trademarks of Monolithic

Power Systems, Inc.

Efficiency vs.

C7

10nF

67

LX

FB

PGNDSGNDVREF

9104

L1

8

2

R2

R1

OUTPUT

1.8V / 1.5A

C2

MP2106_TAC_S01

Load Current

100

VIN=3.3V

90

80

70

60

50

40

30

EFFICIENCY (%)

20

10

0

0.01 0.1 1 10

VIN=5V

LOAD CURRENT (A)

MP2106_TAC_EC02

MP2106 Rev. 1.6 www.MonolithicPower.com 1

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 2

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

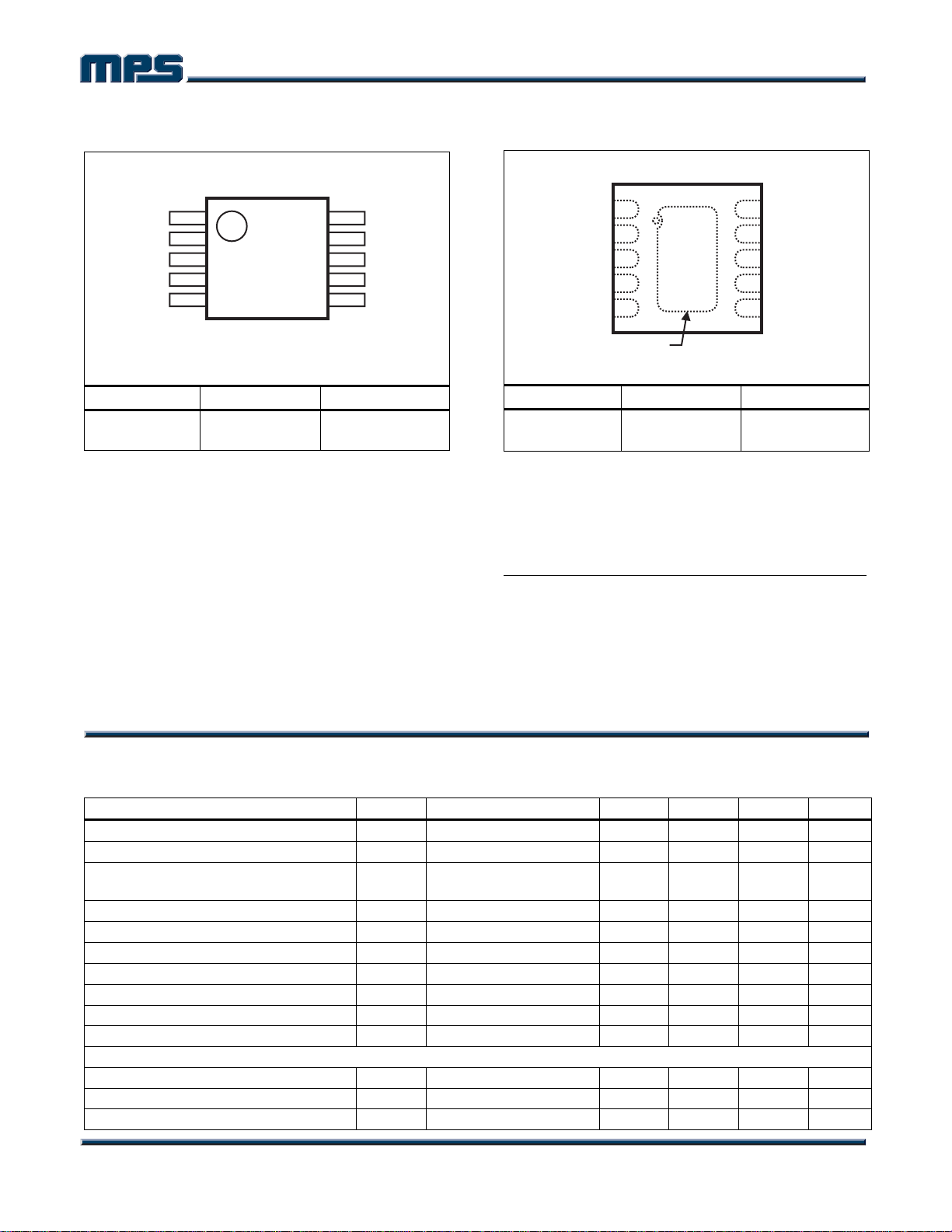

PACKAGE REFERENCE

TOP VIEW

SGND

1

SS

2

FB

COMP

VREF

RUN

3

4

5

Part Number* Package Temperature

MP2106DK MSOP10

For Tape & Reel, add suffix –Z (eg. MP2106DK–Z)

*

For Lead Free, add suffix –LF (eg. MP2106DK–LF–Z)

ABSOLUTE MAXIMUM RATINGS

Input Supply Voltage VIN.............................. 16V

LX Voltage V

BST to LX Voltage .........................

Voltage on All Other Pins...............

Storage Temperature...............

Recommended Operating Conditions

Input Supply Voltage VIN..................2.6V to 15V

Output Voltage V

Operating Temperature..............

..................... –0.3V to VIN + 0.3V

LX

........................0.9V to 5.5V

OUT

10

PGND

9

LX

8

VIN

7

BST

6

MP2106_PD01-MSOP10

–40°C to +85°C

(1)

–0.3V to +6V

–0.3V to +6V

–55°C to +150°C

(2)

–40°C to +85°C

TOP VIEW

SS

1

FB

2

COMP

VREF

3

4

RUN

5

EXPOSED PAD

ON BACKSIDE

Part Number** Package Temperature

MP2106DQ

For Tape & Reel, add suffix –Z (eg. MP2106DQ–Z)

**

For Lead Free, add suffix –LF (eg. MP2106DQ–LF–Z)

Thermal Resistance

QFN10

(3mm x 3mm)

(3)

MSOP10 ................................150 ..... 65... °C/W

QFN10 ....................................50 ...... 12... °C/W

Notes:

1) Exceeding these ratings may damage the device.

2) The device is not guaranteed to function outside of its

operating conditions.

3) Measured on approximately 1” square of 1 oz copper.

SGND

10

PGND

9

LX

8

VIN

7

BST

6

MP2106_PD02-QFN10

–40°C to +85°C

θ

JA

θJC

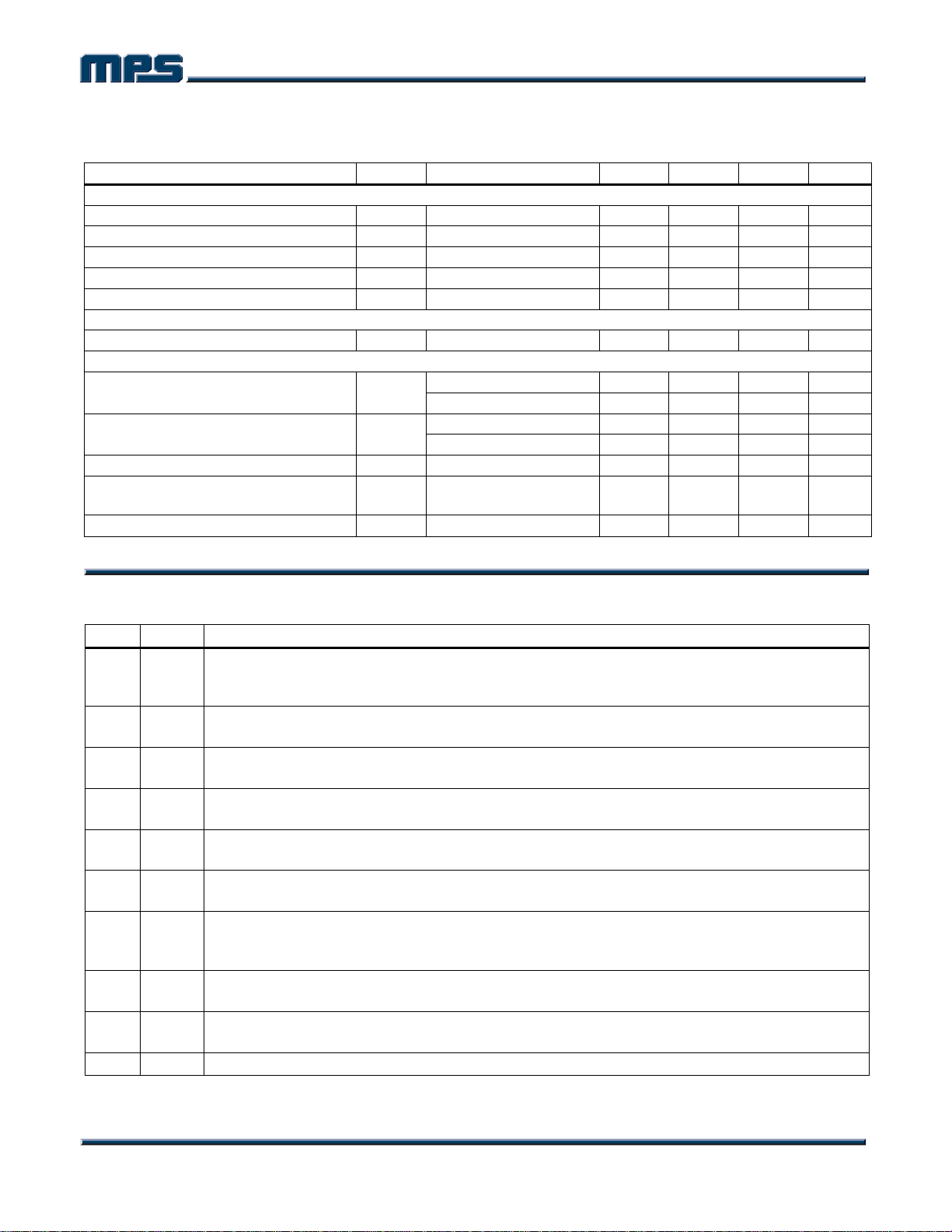

ELECTRICAL CHARACTERISTICS

VIN = 5.0V, TA = +25°C, unless otherwise noted.

Parameter Symbol Condition Min Typ Max Units

Input Voltage Range VIN 2.6 15 V

Input Under Voltage Lockout 2.2 V

Input Under Voltage Lockout

Hysteresis

Shutdown Supply Current V

Operating Supply Current V

VREF Voltage V

RUN Input Low Voltage VIL 0.4 V

RUN Input High Voltage VHL 1.5 V

RUN Hysteresis 100 mV

RUN Input Bias Current 1 µA

Oscillator

Switching Frequency fSW 700 800 900 KHz

Maximum Duty Cycle D

Minimum On Time tON 200 ns

MP2106 Rev. 1.6 www.MonolithicPower.com 2

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

100 mV

0.3V 0.5 1.0 µA

RUN

> 2V, VFB = 1.1V 1.2 1.8 mA

RUN

VIN = 2.6V to 15V 2.4 V

REF

VFB = 0.7V 85 %

MAX

Page 3

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

ELECTRICAL CHARACTERISTICS (continued)

VIN = 5.0V, TA = +25°C, unless otherwise noted.

Parameter Symbol Condition Min Typ Max Units

Error Amplifier

Voltage Gain A

Transconductance GEA 300 µA/V

COMP Maximum Output Current ±30 µA

FB Regulation Voltage VFB 875 895 915 mV

FB Input Bias Current IFB VFB = 0.895V –100 nA

Soft-Start

Soft-Start Current ISS 2 µA

Output Switch On-Resistance

Switch On Resistance

Synchronous Rectifier On Resistance

Switch Current Limit (Source) 2.5 A

Synchronous Rectifier Current Limit

(Sink)

Thermal Shutdown 160

VEA

400 V/V

VIN = 5V 255 m

V

= 3V 315 m

IN

VIN = 5V 210 m

V

= 3V 255 m

IN

350 mA

°C

PIN FUNCTIONS

Pin # Name Description

Soft-Start Input. Place a capacitor from SS to SGND to set the soft-start period. The MP2106

1 SS

2 FB

3 COMP

4 VREF

5 RUN

6 BST

7 VIN

8 LX

9 PGND

10 SGND Signal Ground.

sources 2µA from SS to the soft-start capacitor at startup. As the SS voltage rises, the

feedback threshold voltage increases to limit inrush current during startup.

Feedback Input. FB is the inverting input of the internal error amplifier. Connect a resistive

voltage divider from the output voltage to FB to set the output voltage value.

Compensation Node. COMP is the output of the error amplifier. Connect a series RC network

to compensate the regulation control loop.

Internal 2.4V Regulator Bypass. Connect a 10nF capacitor between VREF and SGND to

bypass the internal regulator. Do not apply any load to VREF.

On/Off Control Input. Drive RUN high to turn on the MP2106; low to turn it off. For automatic

startup, connect RUN to VIN via a pullup resistor.

Power Switch Boost. BST powers the gate of the high-side N-Channel power MOSFET switch.

Connect a 10nF or greater capacitor between BST and LX.

Internal Power Input. VIN supplies the power to the MP2106 through the internal LDO

regulator. Bypass VIN to PGND with a 10µF or greater capacitor. Connect VIN to the input

source voltage.

Output Switching Node. LX is the source of the high-side N-Channel switch and the drain of the

low-side N-Channel switch. Connect the output LC filter between LX and the output.

Power Ground. PGND is the source of the N-Channel MOSFET synchronous rectifier. Connect

PGND to SGND as close to the MP2106 as possible.

MP2106 Rev. 1.6 www.MonolithicPower.com 3

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 4

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

TYPICAL PERFORMANCE CHARACTERISTICS

Circuit of Figure 2, VIN = 5V, V

otherwise noted.

= 1.8V, L1 = 5µH, C1 = 10µF, C2 = 22µF, TA = +25°C, unless

OUT

V

SW

5V/div.

V

AC Coupled

10mV/div.

V

AC Coupled

200mV/div.

1A/div.

Steady State Operation

1.5A Load

O

IN

I

L

Startup from Shutdown

1.5A Resistive Load

V

EN

2V/div.

V

OUT

1V/div.

MP2106-TPC01

V

SW

5V/div.

V

AC Coupled

10mV/div.

V

AC Coupled

20mV/div.

1A/div.

Steady State Operation

No Load

O

IN

I

L

Load Transient

V

OUT

AC Coupled

200mV/div.

I

L

1A/div.

I

LOAD

1A/div.

MP2106-TPC02

Startup from Shutdown

No Load

V

EN

2V/div.

V

OUT

1V/div.

MP2106-TPC03

I

L

1A/div.

V

SW

5V/div.

1ms/div.

Short Circuit Protection

V

OUT

1V/div.

I

L

1A/div.

MP2106-TPC04

MP2106-TPC06

I

L

1A/div.

V

SW

5V/div.

1ms/div.

Short Circuit Recovery

V

OUT

1V/div.

I

L

1A/div.

MP2106-TPC05

MP2106-TPC07

MP2106 Rev. 1.6 www.MonolithicPower.com 4

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 5

TM

OPERATION

OFF ON

RUN

5

ENABLE

CKT & LDO

REGULATOR

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

V

IN

2.6V to 15V

C1

GATE

DRIVE

REGULATOR

Vdr

CURRENT

SENSE

AMPLIFIER

V

IN

7

+

--

C6

C5

V

REF

SS

4

OSCILLATOR

1

V

BP

2.4V

800KHz

V

BP

PWM

COMPARATOR

RAMP

CURRENT

LIMIT

THRESHOLD

+

-CONTROL

LOGIC

CURRENT

LIMIT

COMPARATOR

UVLO &

THERMAL

SHUTDOWN

Vdr

ERROR

AMPLIFIER

BST

Vdr

6

LX

8

C7

L1

V

OUT

C2

+

-R2

+

-PGND

9

--

GM

--

+

V

0.895V

FB

2

FB

R1

310

SGND

COMP

R3

C4

C3

MP2106_BD01

Figure 1—Functional Block Diagram

MP2106 Rev. 1.6 www.MonolithicPower.com 5

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 6

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

The MP2106 measures the output voltage

through an external resistive voltage divider and

compares that voltage to the internal 0.9V

reference in order to generate the error voltage

at COMP. The current-mode regulator uses the

voltage at COMP and compares it to the

inductor current to regulate the output voltage.

The use of current-mode regulation improves

transient response and improves control loop

stability.

At the beginning of each cycle, the high-side

N-Channel MOSFET is turned on, forcing the

inductor current to rise. The current at the drain

of the high-side MOSFET is internally

measured and converted to a voltage by the

current sense amplifier.

That voltage is compared to the error voltage at

COMP. When the inductor current rises

sufficiently, the PWM comparator turns off the

high-side switch and turns on the low-side

switch, forcing the inductor current to decrease.

The average inductor current is controlled by

the voltage at COMP, which in turn is controlled

by the output voltage. Thus the output voltage

controls the inductor current to satisfy the load.

Since the high-side N-Channel MOSFET

requires voltages above V

to drive its gate, a

IN

bootstrap capacitor from LX to BST is required

to drive the high-side MOSFET gate. When LX

is driven low (through the low-side MOSFET),

the BST capacitor is internally charged. The

voltage at BST is applied to the high-side

MOSFET gate to turn it on, and maintains that

voltage until the high-side MOSFET is turned

off and the low-side MOSFET is turned on, and

the cycle repeats. Connect a 10nF or greater

capacitor from BST to SW to drive the high-side

MOSFET gate.

APPLICATION INFORMATION

INPUT

2.6V to 15V

5

RUN

1

SS

3

C5

10nF

C4

OPEN

Figure 2—Typical Application Circuit

Internal Low-Dropout Regulator

The internal power to the MP2106 is supplied

from the input voltage (VIN) through an internal

2.4V low-dropout linear regulator, whose output

is VREF. Bypass VREF to SGND with a 10nF

or greater capacitor for proper operation. The

internal regulator can not supply more current

than is required to operate the MP2106.

Therefore, do not apply any external load to

VREF.

C3

3.3nF

C6

10nF

C7

10nF

67

VIN BST

MP2106

PGNDSGNDVREF

8

LX

2

FBCOMP

9104

OUTPUT

1.8V / 1.5A

MP2106_TAC_F02

Soft-Start

The MP2106 includes a soft-start timer that

slowly ramps the output voltage at startup to

prevent excessive current at the input.

When power is applied to the MP2106, and

RUN is asserted, a 2µA internal current source

charges the external capacitor at SS. As the

capacitor charges, the voltage at SS rises. The

MP2106 internally limits the feedback threshold

voltage at FB to that of the voltage at SS. This

forces the output voltage to rise at the same

rate as the voltage at SS, forcing the output

MP2106 Rev. 1.6 www.MonolithicPower.com 6

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 7

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

voltage to ramp linearly from 0V to the desired

regulation voltage during soft-start.

The soft-start period is determined by the

equation:

5C45.0t

SS

Where C5

(in nF) is the soft-start capacitor from

SS to GND, and t

SS

×=

(in ms) is the soft-start

period. Determine the capacitor required for a

given soft-start period by the equation:

t22.25C ×=

SS

Use values between 10nF and 22nF for C5 to

set the soft-start period (between 4ms and

10ms).

Setting the Output Voltage (see Figure 2)

Set the output voltage by selecting the resistive

voltage divider ratio. The voltage divider drops

the output voltage to the 0.895V feedback

voltage. Use 10k for the low-side resistor of

the voltage divider. Determine the high-side

resistor by the equation:

V

⎛

OUT

⎜

2R

⎜

⎝

Where R2 is the high-side resistor, V

⎞

⎟

1R1

×

−=

⎟

V895.0

⎠

is the

OUT

output voltage and R1 is the low-side resistor.

Selecting the Input Capacitor

The input current to the step-down converter is

discontinuous, and so a capacitor is required to

supply the AC current to the step-down

converter while maintaining the DC input

voltage. A low ESR capacitor is required to

keep the noise at the IC to a minimum. Ceramic

capacitors are preferred, but tantalum or low

ESR electrolytic capacitors may also suffice.

The capacitor can be electrolytic, tantalum or

ceramic. Because it absorbs the input switching

current it must have an adequate ripple current

rating. Use a capacitor with RMS current rating

greater than 1/2 of the DC load current.

For stable operation, place the input capacitor

as close to the IC as possible. A smaller high

quality 0.1µF ceramic capacitor may be placed

closer to the IC with the larger capacitor placed

further away. If using this technique, it is

recommended that the larger capacitor be a

tantalum or electrolytic type. All ceramic

capacitors should be placed close to the

MP2106. For most applications, a 10µF ceramic

capacitor will work.

Selecting the Output Capacitor

The output capacitor (C2) is required to

maintain the DC output voltage. Low ESR

capacitors are preferred to keep the output

voltage ripple to a minimum. The characteristics

of the output capacitor also affect the stability of

the regulation control system. Ceramic,

tantalum, or low ESR electrolytic capacitors are

recommended.

The output voltage ripple is:

RIPPLE

OUT

×

=

⎛

V

OUT

V

⎞

⎜

⎟

⎟

IN

⎠

+×

R

ESR

⎜

⎝

is the input voltage,

IN

is the switching

SW

SW

⎛

⎜

−×

1

⎜

Lf

⎝

is the output voltage ripple, fSW is

RIPPLE

1

⎞

⎟

⎟

××

2Cf8

⎠

V

V

SW

Where V

the switching frequency, V

R

is the equivalent series resistance of the

ESR

output capacitors and f

frequency.

Choose an output capacitor to satisfy the output

ripple requirements of the design. A 22µF

ceramic capacitor is suitable for most

applications.

Selecting the Inductor

The inductor is required to supply constant

current to the output load while being driven by

the switched input voltage. A larger value

inductor results in less ripple current that will

result in lower output ripple voltage. However,

the larger value inductor is likely to have a

larger physical size and higher series

resistance. Choose an inductor that does not

saturate under the worst-case load conditions.

A good rule for determining the inductance is to

allow the peak-to-peak ripple current to be

approximately 30% to 40% of the maximum

load current. Make sure that the peak inductor

current (the load current plus half the peak-topeak inductor ripple current) is below 2.5A to

prevent loss of regulation due to the current

limit.

MP2106 Rev. 1.6 www.MonolithicPower.com 7

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 8

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

Calculate the required inductance value by the

equation:

()

VVV

−×

OUTINOUT

L

=

SWIN

IfV

∆××

Where I is the peak-to-peak inductor ripple

current. It is recommended to choose I to be

30%~40% of the maximum load current.

Compensation

The system stability is controlled through the

COMP pin. COMP is the output of the internal

transconductance error amplifier. A series

capacitor-resistor combination sets a pole-zero

combination to control the characteristics of the

control system.

The DC loop gain is:

A ×××

Where V

⎛

⎜

=

VDC

⎜

⎝

is the feedback voltage, A

FB

⎞

V

FB

⎟

⎟

V

OUT

⎠

RGA

LOADCSVEA

is the

VEA

transconductance error amplifier voltage gain,

G

is the current sense transconductance

CS

(roughly the output current divided by the

voltage at COMP) and R

is the load

LOAD

resistance:

V

OUT

I

OUT

Where I

R =

LOAD

is the output load current.

OUT

The system has 2 poles of importance, one is

due to the compensation capacitor (C3), and

the other is due to the load resistance and the

output capacitor (C2), where:

f

=

1P

P1 is the first pole, and G

EA

VEA

is the error amplifier

EA

3CA2

××π

G

transconductance (300µA/V) and

f

=

2P

1

LOAD

2CR2

××π

The system has one zero of importance, due to

the compensation capacitor (C3) and the

compensation resistor (R3). The zero is:

f

=

1Z

1

3C3R2

××π

If large value capacitors with relatively high

equivalent-series-resistance (ESR) are used,

the zero due to the capacitance and ESR of the

output capacitor can be compensated by a third

pole set by R3 and C4. The pole is:

f

=

3P

1

4C3R2

××π

The system crossover frequency (the frequency

where the loop gain drops to 1, or 0dB, is

important. Set the crossover frequency to below

one tenth of the switching frequency to insure

stable operation. Lower crossover frequencies

result in slower response and worse transient

load recovery. Higher crossover frequencies

degrade the phase and/or gain margins and

can result in instability.

Table 1—Compensation Values for Typical

Output Voltage/Capacitor Combinations

V

OUT

1.8V 22µF Ceramic 6.8k 3.3nF None

2.5V 22µF Ceramic 9.1k 2.2nF None

3.3V 22µF Ceramic 12k 1.8nF None

47µF Tantalum

1.8V

(300m)

47µF Tantalum

2.5V

(300m)

47µF Tantalum

3.3V

(300m)

C2 R3 C3 C4

13k 2nF 1nF

18k 1.2nF 750pF

24k 1nF 560pF

Choosing the Compensation Components

The values of the compensation components

given in Table 1 yield a stable control loop for

the given output voltage and capacitor. To

optimize the compensation components for

conditions not listed in Table 1, use the

following procedure.

MP2106 Rev. 1.6 www.MonolithicPower.com 8

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 9

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

Choose the compensation resistor to set the

desired crossover frequency. Determine the

value by the following equation:

fV2C2

×××π

COUT

VGG

FBCSEA

Where f

3R

=

is the desired crossover frequency

C

××

(preferably 33KHz).

Choose the compensation capacitor to set the

zero below one fourth of the crossover

frequency. Determine the value by the following

equation:

3C

>

2

××π

f3R

C

Determine if the second compensation

capacitor, C4 is required. It is required if the

ESR zero of the output capacitor happens at

less than half of the switching frequency. Or:

1fR2C

>×××π

SWESR

If this is the case, then add the second

compensation capacitor.

External Boost Diode

For input voltages less than or equal to 5V, it is

recommended that an external boost diode be

added. This will help improve the regulator

efficiency. The diode can be a low cost diode

such as an IN4148 or BAT54.

5V

BOOST

DIODE

10nF

MP2106_F03

MP2106

BST

LX

6

8

Figure 3—External Boost Diode

This diode is also recommended for high duty

V

cycle operation (when

output voltage (V

OUT

>65%) and high

V

IN

>12V) applications.

OUT

However, do not exceed the absolute maximum

voltage for these pins.

Determine the value by the equation:

R2C

×

(max)ESR

3R

Where R

ESR(MAX)

4C

=

is the maximum ESR of the

output capacitor.

MP2106 Rev. 1.6 www.MonolithicPower.com 9

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 10

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

PACKAGE INFORMATION

MSOP10

MP2106 Rev. 1.6 www.MonolithicPower.com 10

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 11

TM

MP2106 – 1.5A, 15V, 800KHz SYNCHRONOUS BUCK CONVERTER

QFN10 (3mm x 3mm)

NOTICE: The information in this document is subject to change without notice. Please contact MPS for current specifications.

Users should warrant and guarantee that third party Intellectual Property rights are not infringed upon when integrating MPS

products into any application. MPS will not assume any legal responsibility for any said applications.

MP2106 Rev. 1.6 www.MonolithicPower.com 11

2/22/2006 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2006 MPS. All Rights Reserved.

Page 12

Loading...

Loading...