Page 1

Ordering number :ENN6209B

12800RM (OT) No. 6209-1/9

Functions

• Three-phase current linear drive with switching between

full-wave and half-wave operations

• Torque ripple correction circuit

• Current limiter circuit

• Upper and lower sides output stage saturation prevention

circuits

• Short brake circuit

• FG amplifier

• Thermal shutdown circuit

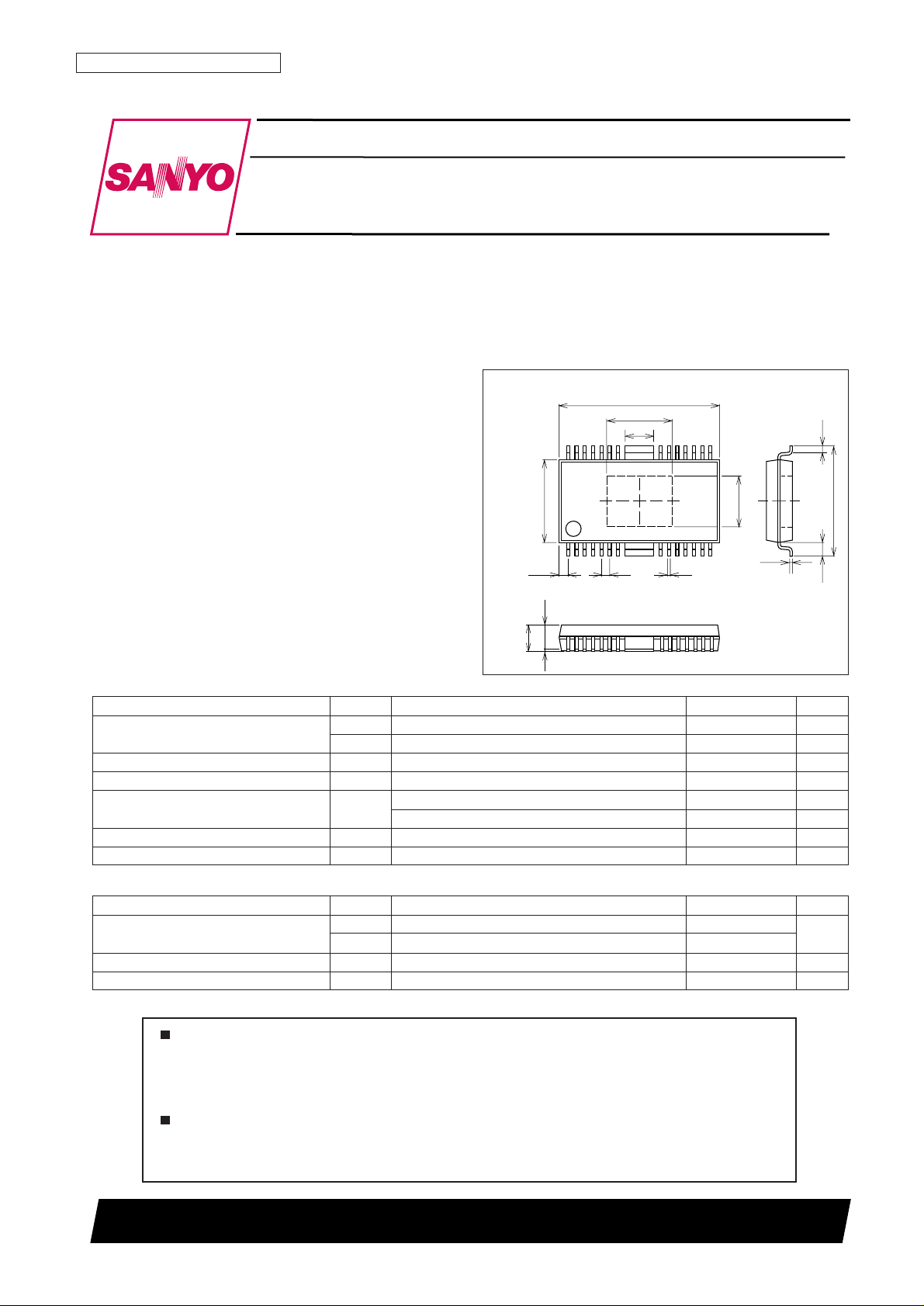

Package Dimensions

unit: mm

3233-HSOP28H

6.2

28 15

114

0.8

15.3

2.7

0.3

4.9

1.3

10.5

0.65

0.25

0.85

7.9

2.25

2.5max

0.1

SANYO: HSOP28H

[LB11985H]

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Monolithic Digital IC

LB11985H

VCR Capstan Motor Brushless Motor Driver

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage

V

CC

max 6V

V

S

max 15.5 V

Maximum output current I

O

max 1.5 A

Maximum output voltage V

O

max 30 V

Allowable power dissipation Pdmax

Independent IC 0.8 W

76.1

× 114.3 × 1.6 mm3: With glass epoxy 2.0 W

Operating temperature Topr –20 to +75 °C

Storage temperature Tstg –55 to +150 °C

Specifications

Absolute Maximum Ratings at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

Supply voltage

V

S

8 to 15

V

V

CC

4.5 to 5.5

Hall input amplitude V

HALL

Between Hall inputs ±20 to ±100 mV 0-P

GSENSE input range V

GSENSE

With respect to the control system ground –0.20 to +0.20 V

Allowable Operating Ranges at Ta = 25°C

Note : Forward/reverse switching is not possible in half-wave operation mode.

Page 2

No. 6209-2/9

LB11985H

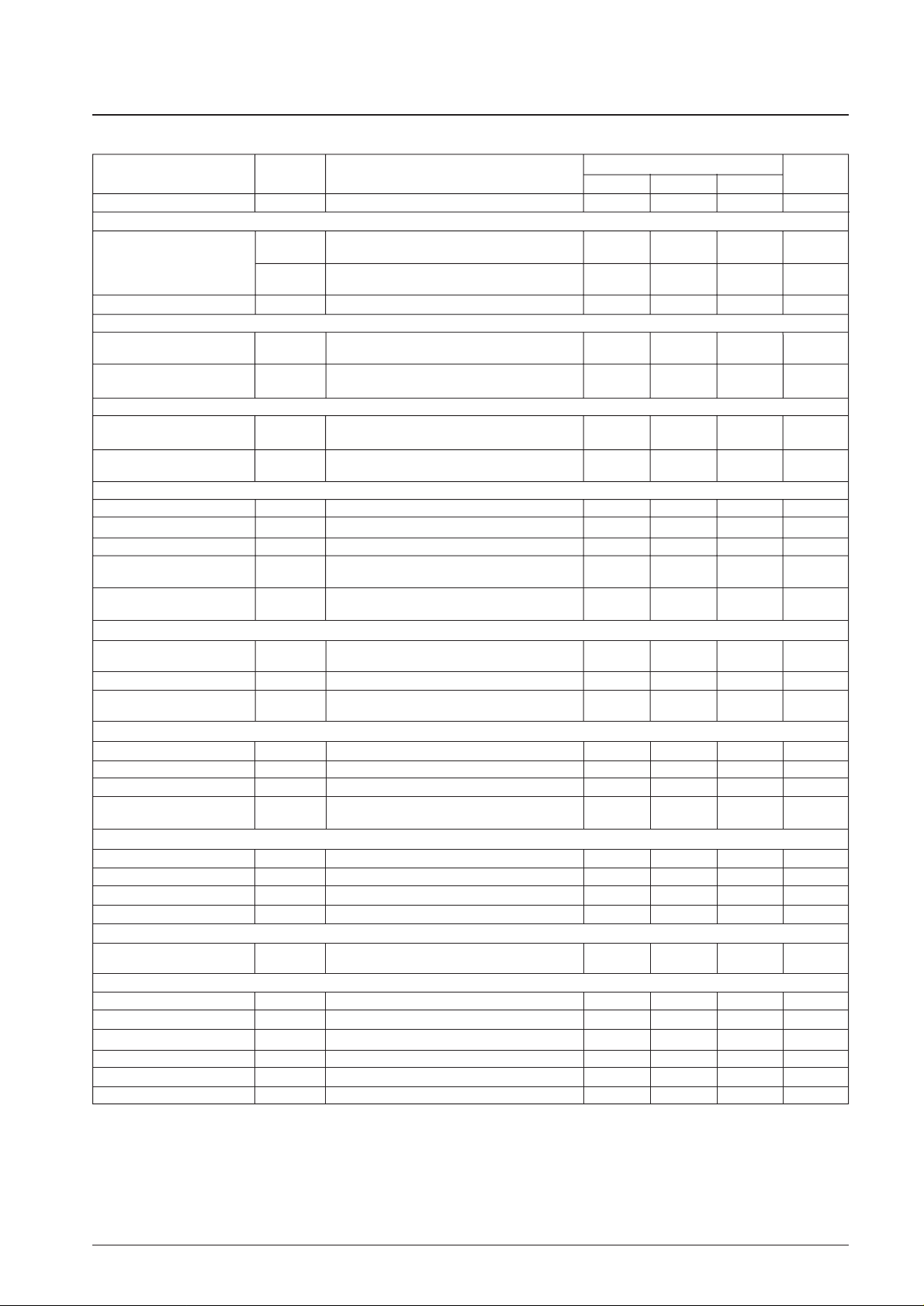

Electrical Characteristics at Ta = 25°C, VCC= 5 V, VS= 15 V

Parameter Symbol Conditions

Ratings

Unit

min typ max

V

CC

current drain I

CC

RL = ∞, VCTL = 0 V (quiescent mode) 10 15 mA

[Output]

Output saturation voltage

V

Osat

1

I

O

= 500 mA, Rf = 0.5 Ω, Sink + Source

2.2 2.7 V

VCTL = VLIM = 5 V (with saturation prevention)

V

Osat

2

I

O

= 1.0 A, Rf = 0.5 Ω, Sink + Source

2.8 3.7 V

VCTL = VLIM = 5 V (with saturation prevention)

Output leakage current I

Oleak

1.0 mA

[FR]

FR pin input

V

FR

14V

Threshold voltage

FR pin input

Ib (FR) VFR = 5 V 100 150 µA

Input bias current

[BR]

BR pin input

V

BRTH

14V

Threshold voltage

BR pin input

Ib (BR) VBR = 5 V 100 150 µA

Input bias current

[Control]

CTLREF pin voltage V

CREF

2.0 2.15 2.3 V

CTLREF pin input range V

CREF

IN 1 4 V

CTL pin input bias current Ib (CTL) VCTL = 5 V, with CTLREF open 5 µA

CTL pin control start voltage V

CTL

(ST)

Rf = 0.5 Ω, VLIM = 5 V, Io ≥ 40 mA

2.0 2.2 2.4 V

With the Hall input logic states fixed (U, V, W = high, high, low)

CTL pin control Gm Gm (CTL)

Rf = 0.5 Ω, ∆Io = 200 mA

1.8 2.25 2.7 V

With the Hall input logic states fixed (U, V, W = high, high, low)

[Current Limiter]

LIM current limit offset voltage V

off

(LIM)

Rf = 0.5 Ω, VCTL = 5 V, Io ≥ 40 mA

80 200 320 mV

With the Hall input logic states fixed (U, V, W = high, high, low)

LIM pin input bias current Ib (LIM) VCTL = 5 V,VREF: OPEN, VLIM = 0 V –2 –1 µA

LIM pin current limit level Gm (LIM)

Rf = 0.5 Ω, VCTL = 5 V

0.37 0.47 0.57 mA

With the Hall input logic states fixed (U, V, W = high, high, low)

[Hall Amplifier]

Input offset voltage V

off

(HALL) –6 +6 mV

Input bias current I

b

(HALL) 1.0 3.0 µA

Common-mode input voltage V

cm

(HALL) 1.3 3.3 V

Torque ripple correction ratio TRC

At the bottom and peak that occur in the Rf

14.5 %

waveform at 200 mA (Rf = 0.5 Ω)

[FG Amplifier]

FG amplifier input offset voltage

V

off

(FG) –8 +8 mV

FG amplifier input bias current I

b

(FG) –100 nA

FG amplifier output saturation voltage

V

Osat

(FG) For the sink side, at the internal pull-up resistor 0.4 0.55 V

FG amplifier common-mode input voltage

V

CM

(FG) 1.0 4.0 V

[Saturation]

Saturation prevention circuit V

Osat

(DET) Io = 10 mA, Rf = 0.5 Ω, VCTL = VLIM = 5 V

0.13 0.25 0.42 V

lower side set voltage

The voltages between the OUT-Rf pairs at full wave.

[Schmitt Amplifier]

Duty DUTY 60 mVp-p, 1 kHz input *

1

49 50 51 %

Upper side output saturation voltage

V

satu

(SH) 4.8 V

Lower side output saturation voltage

V

satd

(SH) 0.2 V

Hysteresis Vhys Design target values *

2

45 mV

TSD operating temperature T-TSD Design target values *

2

180 °C

TSD hysteresis ∆T-TSD Design target values *

2

15 °C

Note *1 : The ratings are just the measured value with no margin afforded.

*2 : Items shown to be design target values in the conditions column are not measured.

Page 3

No. 6209-3/9

LB11985H

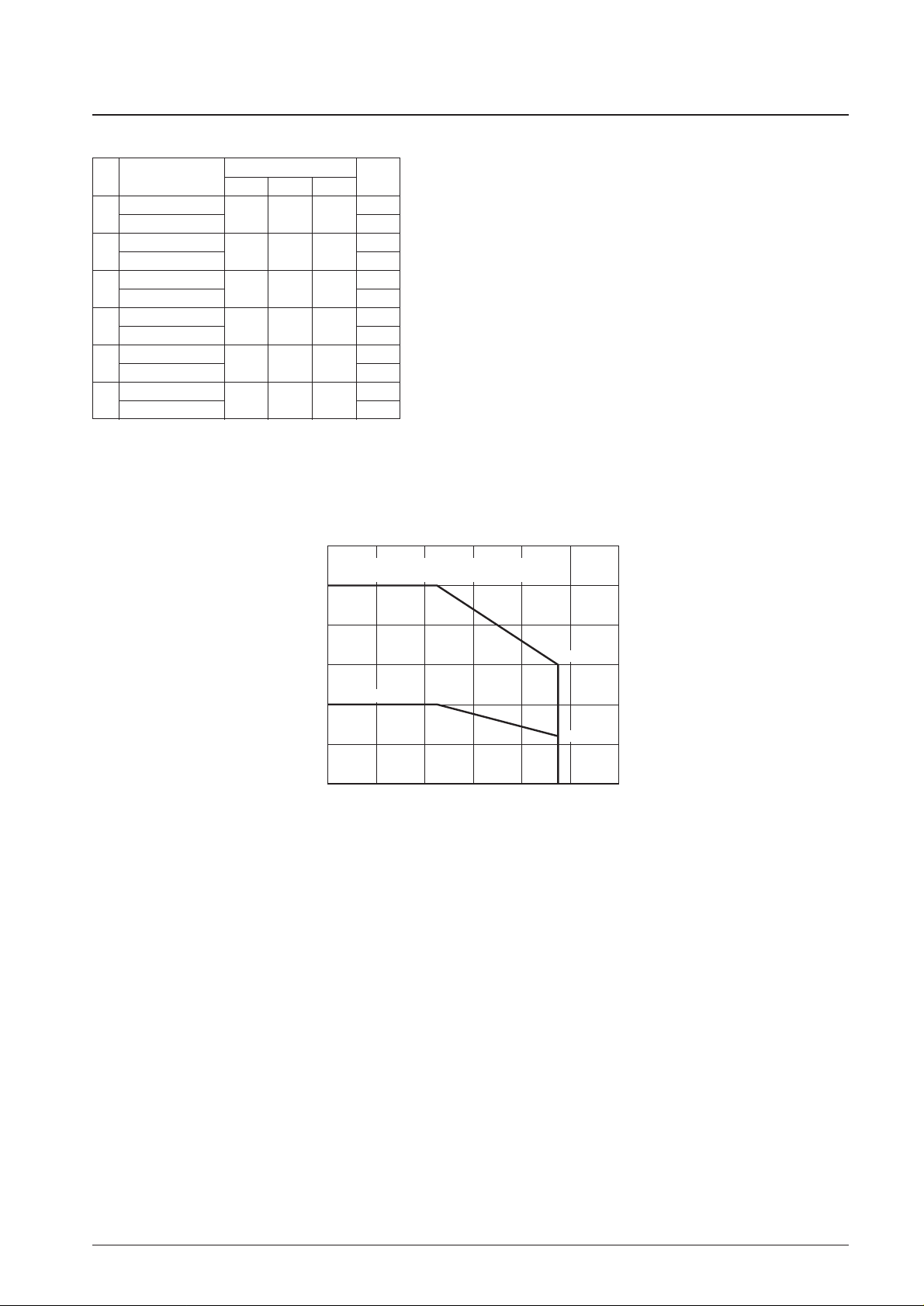

Truth Table and Control Functions

Source → Sink

Hall input

FR

UVW

1

V → W

HHL

H

W → VL

2

U → W

HLL

H

W → UL

3

U → V

HLH

H

V → UL

4

W → V

LLH

H

V → WL

5

W → U

LHH

H

U → WL

6

V → U

LHL

H

U → VL

Note: 1. In the FR column, “H” indicates a voltage of 2.75 V or higher, and “L”

indicates a voltage of 2.25 V or lower. (When V

CC

is 5 V.)

2. For the Hall inputs, the input high state is defined to be the state where

the (+) input is higher than the corresponding (–) input by at least 0.02 V,

and the input low state is defined to be the state where the (+) input is

lower than the corresponding (–) input by at least 0.02 V.

Allowable Power Dissipation

0.4

0

0.8

1.2

1.6

2.0

2.4

–20 0 20 40 60 80 100

Pd max — Ta

0.48

1.20

Allowable power dissipation, Pd [W]

Ambient temperature, Ta [°C]

Independent IC

Mounted on the specified printed circuit board

(76.1 × 114.3 × 1.6 mm3glass epoxy board)

Page 4

No. 6209-4/9

LB11985H

Pin Assignment

1 2 3 4 5

6

7 8 9 10

11

12 13 14

28 27 26 25 24 23 22 21 20 19 18 17 16 15

VS1

VS2

GSENSE

RF(SENSE)

RF(POWER)

U

OUTVOUT

FRAME GND

W

OUT

MCOM

W

IN

+

W

IN

–

V

IN

+

V

IN

–

U

IN

+

VCCADJ

FR

CTL

LIM

CTLREF

FC

FRAME GND

FGS

SL

BR

FG

OUTFGIN

–

FG

IN

+

U

IN

–

Top view

LB11985H

HSOP-28H

Sample Application Circuit

1 2 3 4 5 6 7 8 9 10 11 12 13 14

28 27 26 25 24 23 22 21 20 19 18 17 16 15

VS1

VS2

GSENSE

RF(SENSE)

RF(POWER)

U

OUT

V

OUT

V

CC

V

CC

ADJ

FR

CTL

LIM

CTLREF

FC

W

OUT

MCOM

W

IN

+

W

IN

–

V

IN

+

V

IN

–

U

IN

+

FGS

SL

FRAME

GND

FRAME

GND

BR

FG

OUT

FG

IN

–

FG

IN

+

U

IN

–

LB11985H

A12221

HSOP-28H

MR

Page 5

No. 6209-5/9

LB11985H

FC

FGIN+

U

OUT

VOUT

WOUT

Bandgap 1.2V

UIN+

U

IN–

V

IN+VIN–

W

IN–

W

IN+

FR

CTLREF

CTL

BR

V

CC

RF(SENSE)

VS1

FG

IN–

FG

OUT FGS

5 kΩ

5 kΩ

150 kΩ

RF(PWR)

LIM

MCOM

SL

VS2

GND

ADJ

GSENSE

Block Diagram

Forward/

reverse switching

FG amplifier

Hall input synthesis block (linear matrix)

Reference

voltage

Differential

distribution and

torque ripple

correction block

Logarithmic conversion and

differential distribution

Control

amplifier

Synthesized output logarithmic

compression block

Feedback amplifier

Short braking

Upper side saturation

prevention control

Drive distribution circuit

and lower side saturation

prevention control

Full-wave/half-wave

switching

Schmitt amplifier

TSD

Page 6

No. 6209-6/9

LB11985H

Pin Functions

Pin No. Symbol Pin Voltage Description Equivalent circuit

Ground for circuits other than the output transistors.

The lowest potential of the output transistors will be

the that of the RF pin.

Output block power supply1 VS1 8 V to 15 V

6

7

8

2

1

5

20 Ω

50 kΩ

20 Ω

50 kΩ

10 kΩ10 kΩ

A13015

9

VS1

A13016

Coil output

6

U

OUT

Motor midpoint connection.

Half-wave drive is implemented by connecting the

motor midpoint to this pin.

9 MCOM

Continued on next page.

A diode is internally connected between VS1 and

this pin to prevent reverse current flow in half-wave

operating mode.

2 VS2

Ground sensing.

The influence of the common ground impedance on

Rf can be excluded by connecting this pin to the

ground near the Rf resistor in the motor ground lines

that include RF. (This pin must not be left open.)

3 GSENSE

Output current detection.

Current feedback is applied to the control block by

inserting the resistor Rf between these pins and

ground. Also, both the lower side saturation

prevention circuit and the torque ripple correction

circuit operate according to the voltage on this pin. In

particular, since this voltage sets the oversaturation

prevention level, the lower side oversaturation

prevention operation can be degraded if the value of

this resistor is set too low.

Note that the POWER pin and the SENSE pin must

be connected together.

45RF(SENSE)

RF(POWER)

7

V

OUT

8

W

OUT

FRAME GND

Unit (resistance : Ω )

Page 7

No. 6209-7/9

LB11985H

Pin No. Symbol Pin Voltage Description Equivalent circuit

W phase Hall element input.

Logic “H” is defined as the state where

W

IN

+ > WIN–.

11

WIN–

1.3 V to 3.3 V

(V

CC

= 5 V)

17

150 kΩ

300 Ω 300 Ω

5 kΩ

6 µA

V

CC

16

A13018

19

20

45 kΩ

15 kΩ

15 kΩ

V

CC

A13020

FG amplifier linear output.

Short braking control input.

High: Short braking

Low: Normal motor drive

19 BR

Continued on next page.

FG amplifier + input.

This is the + input to the Schmitt amplifier.

There is no bias applied internally.

16

FG

IN

+

18

FG

OUT

Continued from preceding page.

10

WIN+

12

VIN+

13

V

IN

–

14

UIN+

15

UIN–

V phase Hall element input.

Logic “H” is defined as the state where

V

IN

+ > VIN–.

U phase Hall element input.

Logic “H” is defined as the state where

U

IN

+ > UIN–.

12

14

10

300 Ω

100 µA

13

15

11

V

CC

300 Ω

A13017

FG amplifier – input.

The input resistance is 5 kW and a 150 kW feedback

resistor is built in. (The gain is 30×.)

17

FG

IN

–

18

300 Ω

300 Ω

2 kΩ100 Ω

50 µA

V

CC

50 µA

A13019

0 V to V

CC

Full-wave/half-wave control input.

High: Half-wave drive

Low: Full-wave drive

20 SL

FG Schmitt amplifier output.

21 FGS

21

5 kΩ

20 kΩ

V

CC

A13021

Unit (resistance : Ω, current : A )

Page 8

No. 6209-8/9

LB11985H

Pin No. Symbol Pin Voltage Description Equivalent circuit

Frequency characteristics correction.

Oscillation in the current control system closed loop

can be prevented by inserting a capacitor between

this pin and ground.

23

300 Ω 300 Ω

18 kΩ

15 kΩ 20 kΩ

50 µA 50 µA

V

CC

25

A13023

26

45 kΩ

15 kΩ

15 kΩ

V

CC

A13025

Current limiter function control.

The voltage applied to this pin modifies the output

current linearly.

Forward/reverse control.

The voltage applied to this pin selects forward or

reverse operation.

26 FR

Speed control.

Control consists of a constant current drive scheme

implemented by applying current feedback from

RF.

25

CTL

24 LIM

Continued from preceding page.

22 FC

23

CTLREF

Control reference voltage.

Although this voltage is set to V

CC

× (15/35)

internally, it can be modified by applying a voltage

from a low-impedance circuit.

22

6 S

V

CC

A13022

60 kΩ

20 kΩ

24

1 kΩ

V

CC

A13024

0 V to V

CC

External torque ripple correction ratio adjustment.

To adjust the correction ratio, apply the stipulated

voltage to the ADJ pin from a low-impedance

external circuit.

If the applied voltage is increased, the correction

ratio rises, and if the applied voltage is lowered, the

correction ratio falls.

27

ADJ

Power supply for all circuits other than the IC

internal output block.

This voltage must be stabilized so that ripple and

noise do not enter the IC.

28

V

CC

27

6 kΩ 6 kΩ500 Ω

10 kΩ10 kΩ

10 kΩ10 kΩ

V

CC

A13026

1 V to 4 V

(V

CC

= 5 V)

0 V to V

CC

0 V to V

CC

4.5 V to 5.5 V

Unit (resistance : Ω, current : A )

Page 9

PS No.6209-9/9

LB11985H

This catalog provides information as of January, 2000. Specifications and information herein are subject

to change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products (including technical data, services) described or contained

herein are controlled under any of applicable local export control laws and regulations, such products must

not be exported without obtaining the export license from the authorities concerned in accordance with the

above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Loading...

Loading...