Page 1

ISP1122

Universal Serial Bus stand-alone hub

Rev. 02 — 4 October 1999 Product specification

1. General description

The ISP1122 is a stand-alone Universal Serial Bus (USB) hub devicewhichcomplies

with

USB Specification Rev. 1.1

repeater,hubcontroller, USB data transceivers and a 3.3 V voltage regulator.Ithasa

configurable number of downstream ports, ranging from 2 to 5.

The ISP1122 can be bus-powered, self-powered or hybrid-powered. When it is

hybrid-poweredthehubfunctions are poweredby the upstream power supply (V

but the downstream ports are powered by an external 5 Volt supply. The low power

consumption in ‘suspend’ mode allows easy design of equipment that is compliant

with the ACPI™, OnNow™ and USB power management requirements.

. It integrates a Serial Interface Engine (SIE), hub

BUS

),

2. Features

The ISP1122 has built-in overcurrent sense inputs, supporting individual and global

overcurrent protection for downstream ports. All ports (including the hub) have

GoodLink™ indicator outputs for easy visual monitoring of USB traffic. The ISP1122

has a serial I2C-bus interface for external EEPROM access and a reduced frequency

(6 MHz) crystal oscillator. These features allow significant cost savings in system

design and easy implementation of advanced USB functionality into PC peripherals.

c

c

■ High performance USB hub device with integrated hub repeater, hub controller,

Serial Interface Engine (SIE), data transceivers and 3.3 V voltage regulator

■ Complies with

USB power management requirements

■ Configurable from 2 to 5 downstream ports with automatic speed detection

■ Internal power-on reset and low voltage reset circuit

■ Supports bus-powered, hybrid-powered and self-powered application

■ Individual or ganged power switching for downstream ports

■ Individual or global port overcurrent protection with built-in sense circuits

■ 6 MHz crystal oscillator with on-chip PLL for low EMI

■ Visual USB traffic monitoring (GoodLink™) for hub and downstream ports

■ I2C-bus interface to read vendor ID, product ID and configuration bits from

external EEPROM

■ Operation over the extended USB bus voltage range (4.0 to 5.5 V)

■ Operating temperature range −40 to +85 °C

■ 8 kV in-circuit ESD protection for lower cost of external components

Universal Serial Bus Specification Rev. 1.1

and ACPI, OnNow and

Page 2

Philips Semiconductors

d

ISP1122

USB stand-alone hub

■ Full-scan design with high test coverage

■ Available in 32-pin SDIP, SO and LQFP packages.

3. Ordering information

Table 1: Ordering information

Type number Package

Name Description Version

ISP1122D SO32 plastic small outline package; 32 leads; body width 7.5 mm SOT287-1

ISP1122NB SDIP32 plastic shrink dual in-line package; 32 leads (400 mil) SOT232-1

ISP1122BD

[1]

[1] For the availability of the LQFP32 package please contact your local Philips Semiconductors sales office.

LQFP32 plastic low profile quad flat package; 32 leads; body 7 x 7 x 1.4 mm SOT358-1

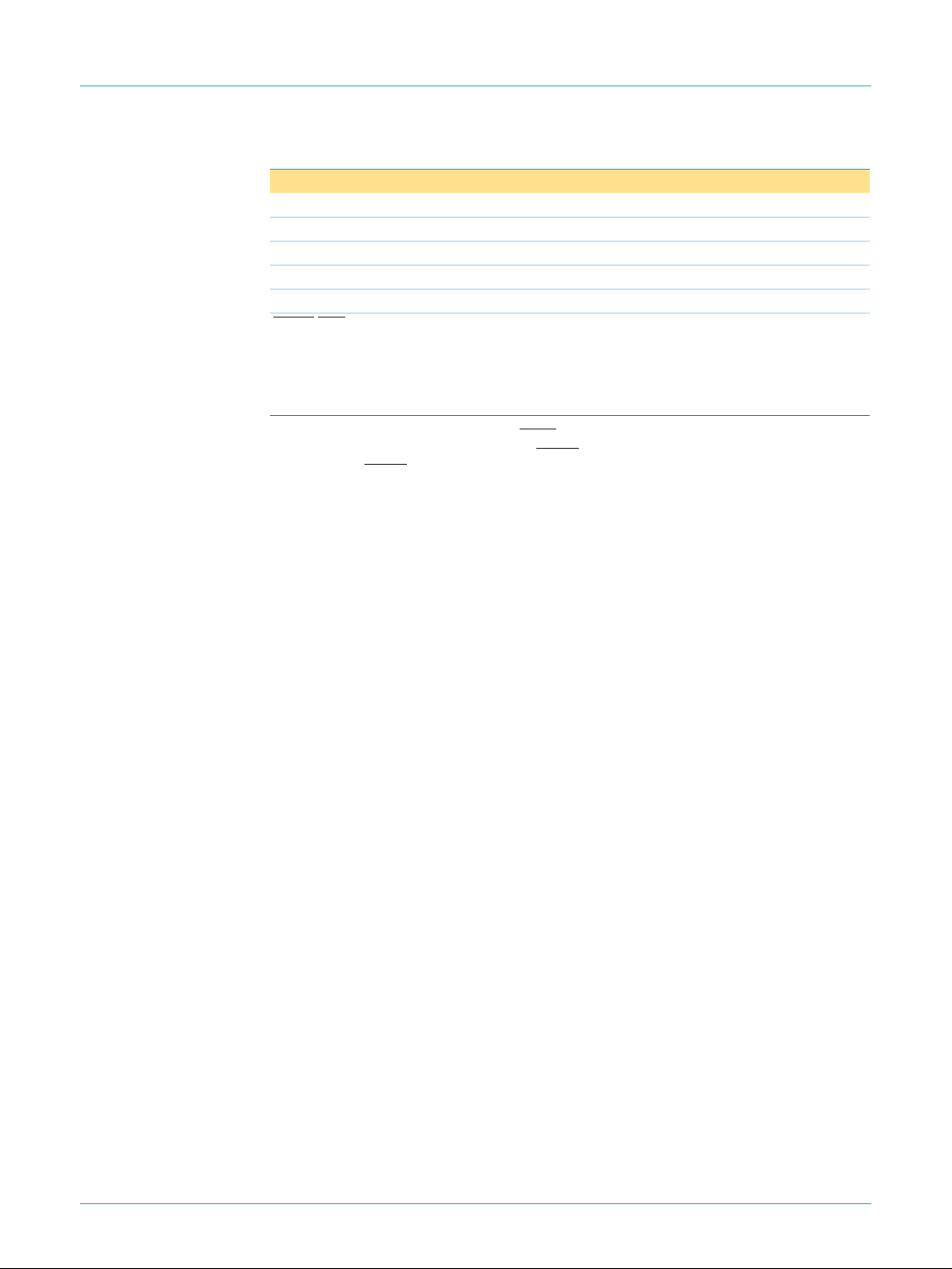

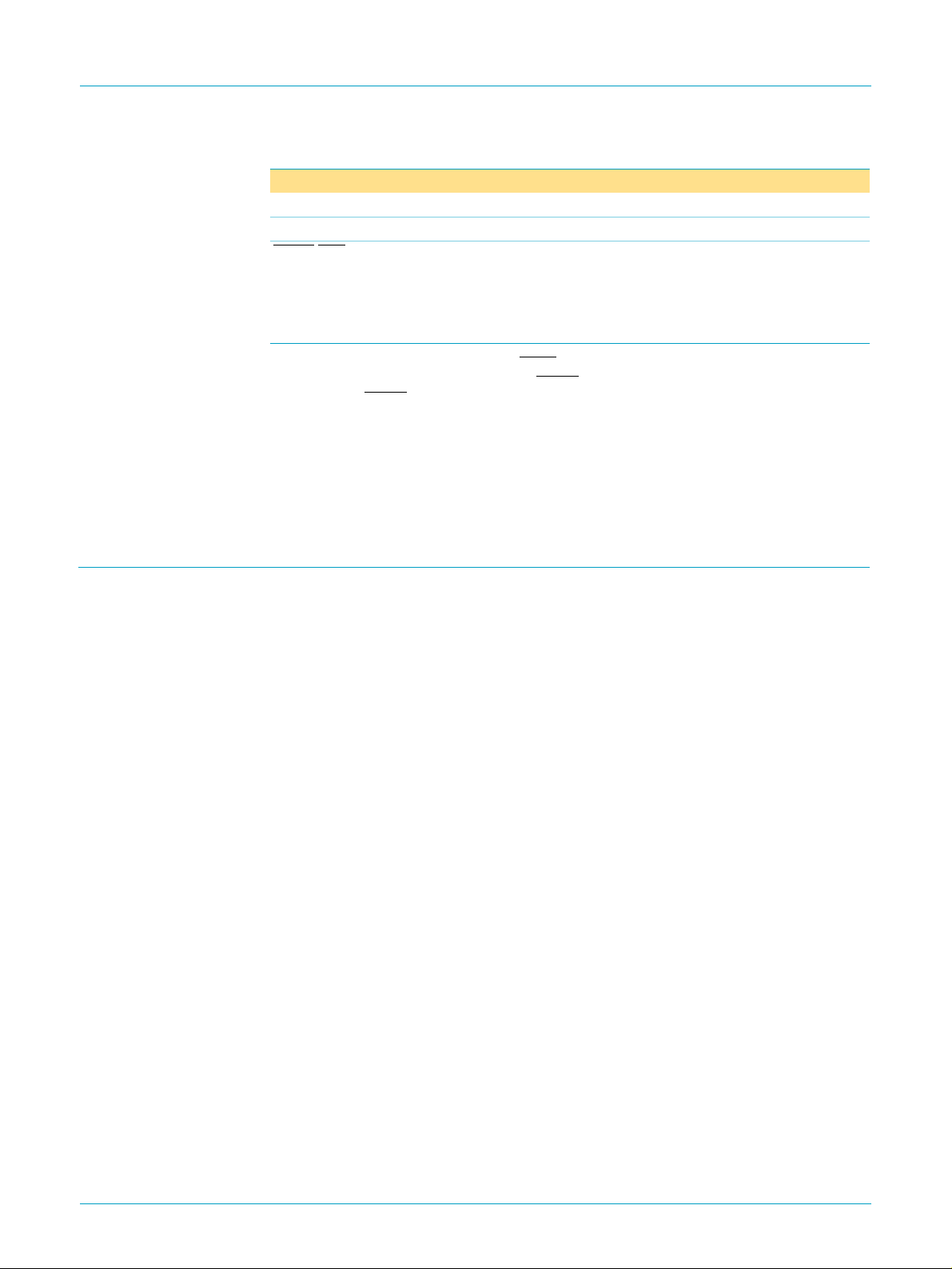

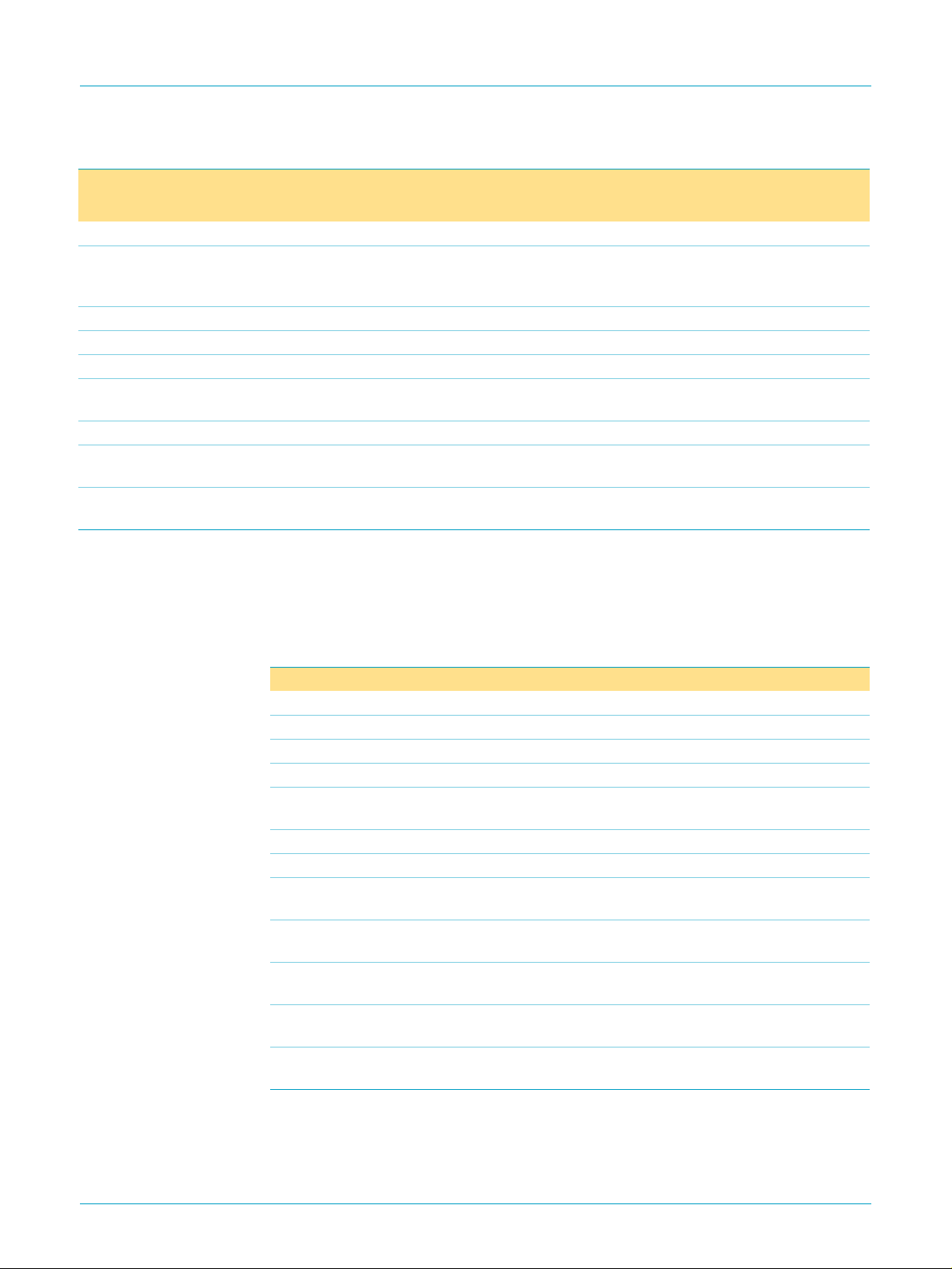

4. Block diagram

th

upstream

detection

downstream

port

D+ D−

ANALOG

Tx/Rx

full

speed

GoodLink/

POWER SWITCH/

OC DETECT

LED/

power switch

port 3

ANALOG

Tx/Rx

POWER SWITCH/

OC DETECT

D+ D− overcurrent

detection

downstream

port 1

ISP1122

GoodLink/

power switch

LED/

ANALOG

Tx/Rx

POWER SWITCH/

OC DETECT

D+ D− overcurrent

detection

downstream

port 2

REGULATOR

GoodLink/

power switch

V

CC

SUPPLY

LED/

5 V

3.3 V

V

reg(3.3)

HUB

REPEATER

ANALOG

Tx/Rx

D+ D− overcurrent

This is a conceptual block diagram and does not include each individual signal.

Fig 1. Block diagram of the ISP1122.

LED

HUB

GoodLink

ANALOG

Tx/Rx

D+ D− overcurrent

6 MHz

PLL

BIT CLOCK

RECOVERY

PHILIPS

SIE

GoodLink/

POWER SWITCH/

OC DETECT

detection

power switch

downstream

port 4

LED/

PACKET

GENERATOR

HUB

CONTROLLER

ANALOG

Tx/Rx

D+ D− overcurrent

detection

downstream

I2C-BUS

INTERFACE

INDV

OPTION

END OF

FRAME

TIMERS

GoodLink/

POWER SWITCH/

OC DETECT

LED/

power switch

port 5

SDA

SCL

GENERAL

PORT

CONTROLLER

self/bus

powered

MGR774

9397 750 06389

© Philips Electronics N.V. 1999. All rights reserved.

Product specification Rev. 02 — 4 October 1999 2 of 48

Page 3

Philips Semiconductors

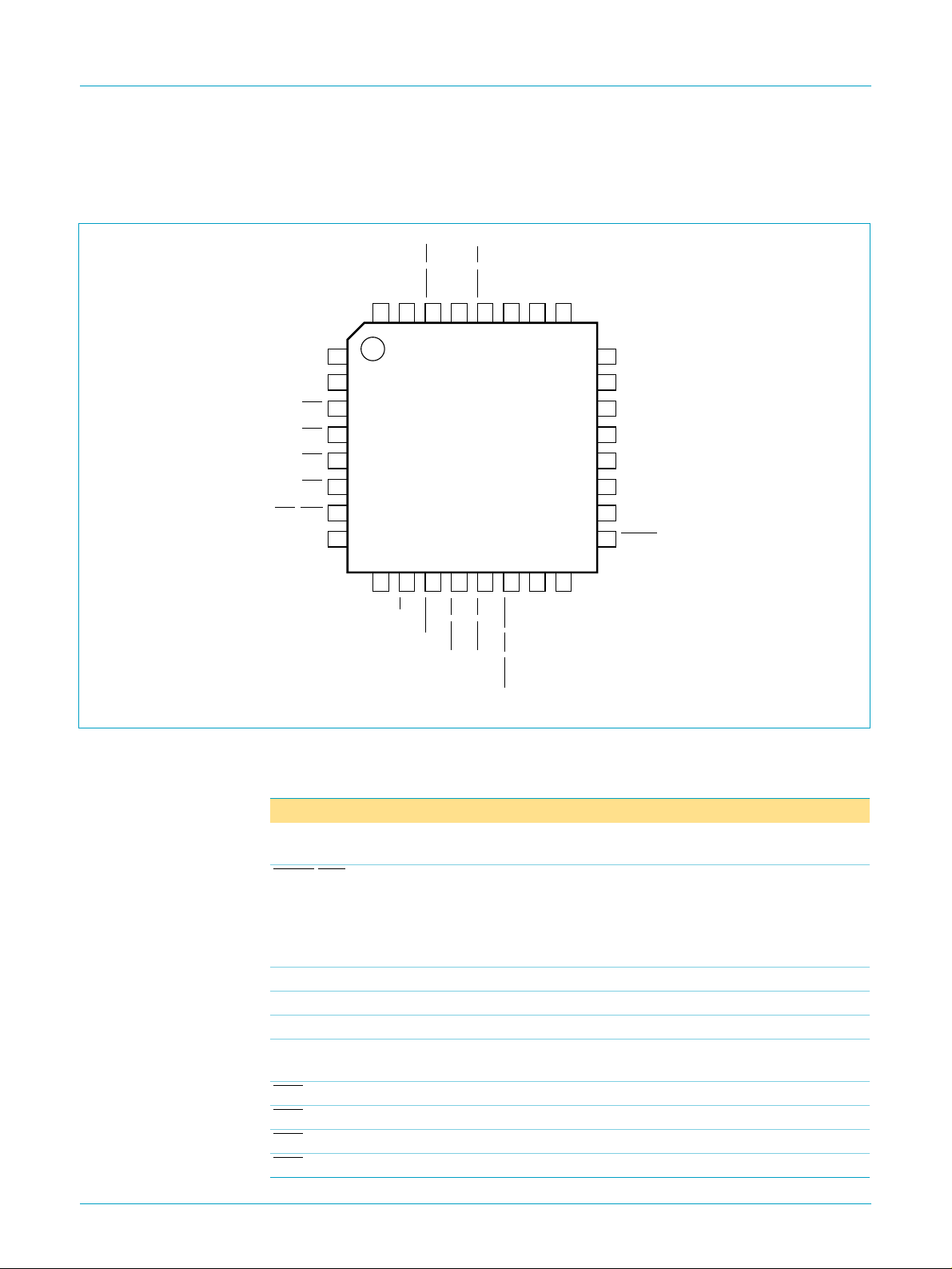

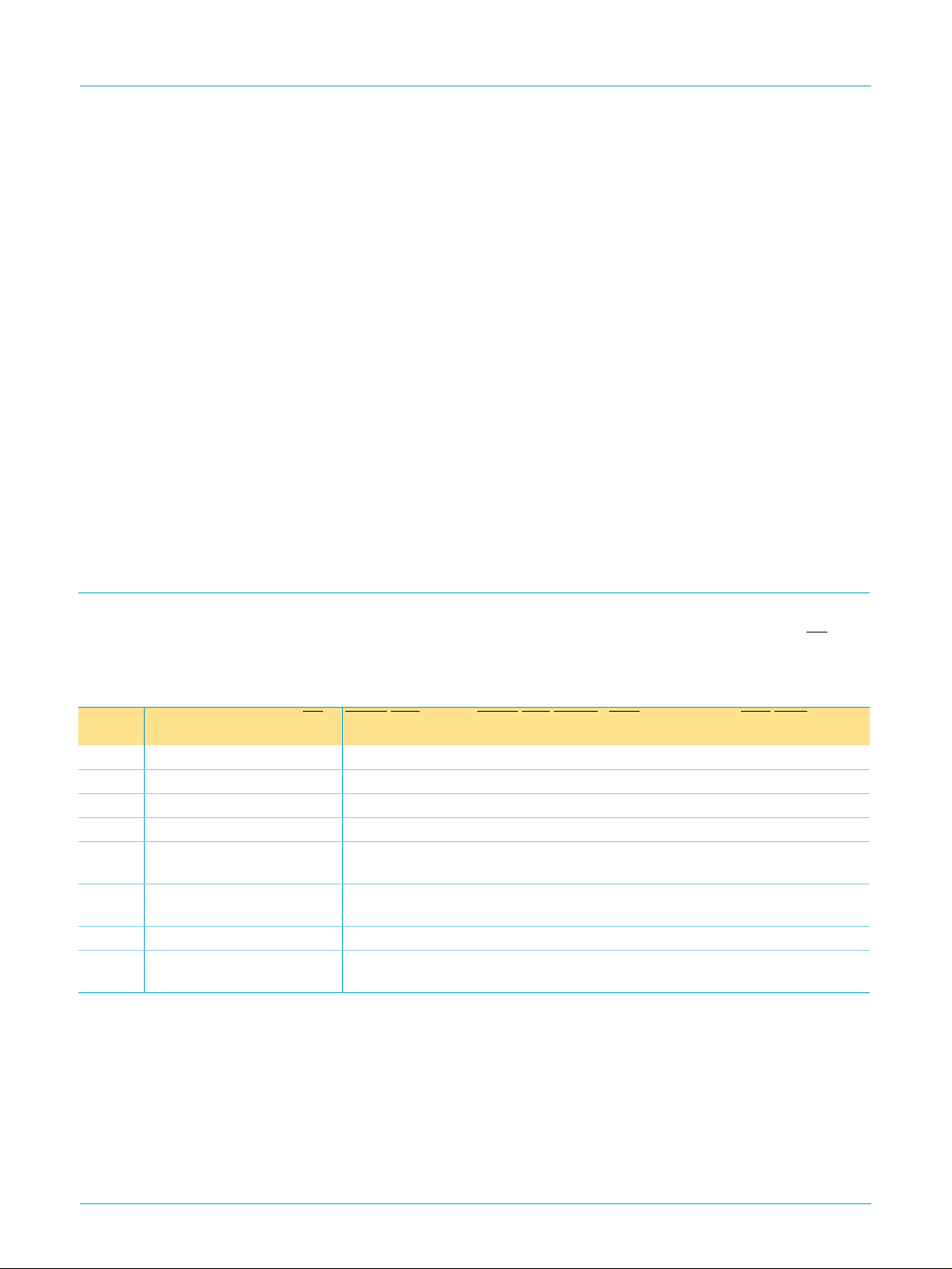

5. Pinning information

5.1 ISP1122D (SO32) and ISP1122NB (SDIP32)

5.1.1 Pinning

ISP1122

USB stand-alone hub

handbook, halfpage

PSW2/GL2

OC5/GOC

V

reg(3.3)

SP/BP

HUBGL

GND

DM3

DP3

V

CC

OC1

OC2

OC3

OC4

DM4

DP4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ISP1122D

MGR772

32

PSW1/GL1

DP2

31

DM2

30

DP0

29

DM0

28

DP1

27

DM1

26

DP5

25

DM5

24

INDV/SDA

23

OPTION/SCL

22

21

RESET

XTAL2

20

XTAL1

19

18

PSW5/GL5/GPSW

17

PSW4/GL4PSW3/GL3

handbook, halfpage

PSW2/GL2

OC5/GOC

V

reg(3.3)

SP/BP

HUBGL

GND

DM3

DP3

V

CC

OC1

OC2

OC3

OC4

DM4

DP4

1

2

3

4

5

6

7

8

ISP1122NB

9

10

11

12

13

14

15

16

MGR773

Fig 2. Pin configuration SO32. Fig 3. Pin configuration SDIP32.

32

PSW1/GL1

DP2

31

DM2

30

DP0

29

DM0

28

DP1

27

DM1

26

DP5

25

DM5

24

INDV/SDA

23

OPTION/SCL

22

21

RESET

XTAL2

20

XTAL1

19

18

PSW5/GL5/GPSW

17

PSW4/GL4PSW3/GL3

5.1.2 Pin description

Table 2: Pin description for SO32 and SDIP32

reg(3.3)

CC

[1]

[2]

Pin Type Description

1 - regulated supply voltage (3.3 V ± 10%) from internal

regulator; used to connect pull-up resistor on DP0 line

[3]

2Omodes 4 to 6: power switch control output for downstream

port 2 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 2 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

[4]

[4]

6 - supply voltage;connectto USB supply V

hybrid-powered) or to local supply V

DD

© Philips Electronics N.V. 1999. All rights reserved.

(bus-poweredor

BUS

(self-powered)

[5]

)

Symbol

V

PSW2/GL2

GND 3 - ground supply

DM3 4 AI/O downstream port 3 D− connection (analog)

DP3 5 AI/O downstream port 3 D+ connection (analog)

V

OC1 7 AI/I overcurrent sense input for downstream port 1 (analog

9397 750 06389

Product specification Rev. 02 — 4 October 1999 3 of 48

Page 4

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 2: Pin description for SO32 and SDIP32

Symbol

[1]

Pin Type Description

OC2 8 AI/I overcurrent sense input for downstream port 2 (analog

OC3 9 AI/I overcurrent sense input for downstream port 3 (analog

OC4 10 AI/I overcurrent sense input for downstream port 4 (analog

OC5/GOC

[3]

11 AI/I modes 5, 7: overcurrent sense input for downstream port 5

(analog

[5]

)

modes 0, 1, 3: global overcurrent sense input (analog

DM4 12 AI/O downstream port 4 D− connection (analog)

DP4 13 AI/O downstream port 4 D+ connection (analog)

…continued

[5]

[5]

[5]

[5]

[4]

[4]

SP/BP 14 I selects power mode:

self-powered: connect to V

(local power supply); also use

DD

this mode for hybrid-powered operation

bus-powered:connect to GND;disable downstream port 5 to

meet supply current requirements

[4]

HUBGL 15 O hub GoodLink LED indicator output (open-drain, 6 mA);

to connect an LED use a 330 Ω series resistor; if unused

via a 10 kΩ resistor

CC

PSW3/GL3

connect to V

[3]

16 O modes 4 to 6: power switch control output for downstream

port 3 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 3 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

PSW4/GL4

[3]

17 O modes 4 to 6: power switch control output for downstream

port 4 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 4 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

PSW5/GL5/

[3]

GPSW

18 O mode 5: power switch control output for downstream port 5

(open-drain, 6 mA)

modes 3, 7: GoodLink LED indicator output for downstream

port 5 (open-drain, 6 mA); to connect an LED use a 330 Ω

series resistor

modes 0 to 2: gang mode power switch control output

(open-drain, 6 mA)

XTAL1 19 I crystal oscillator input (6 MHz)

XTAL2 20 O crystal oscillator output (6 MHz)

RESET

[2]

21 I reset input (Schmitt trigger); a LOW level produces an

asynchronous reset; connect to V

for power-on reset

CC

(internal POR circuit)

2

OPTION/SCL 22 I/O mode selection input; also functions as I

C-bus clock output

(open-drain, 6 mA)

INDV/SDA 23 I/O selects individual (HIGH) or global (LOW) power switching

and overcurrent detection; also functions as bidirectional

2

C-bus data line (open-drain, 6 mA)

I

DM5 24 AI/O downstream port 5 D− connection (analog)

DP5 25 AI/O downstream port 5 D+ connection (analog)

DM1 26 AI/O downstream port 1 D− connection (analog)

[4]

[4]

[6]

)

)

)

)

9397 750 06389

Product specification Rev. 02 — 4 October 1999 4 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 5

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 2: Pin description for SO32 and SDIP32

Symbol

[1]

Pin Type Description

DP1 27 AI/O downstream port 1 D+ connection (analog)

…continued

[6]

DM0 28 AI/O upstream port D− connection (analog)

DP0 29 AI/O upstream port D+ connection (analog)

DM2 30 AI/O downstream port 2 D− connection (analog)

DP2 31 AI/O downstream port 2 D+ connection (analog)

PSW1/GL1

[3]

32 O modes 4 to 6: power switch control output for downstream

[6]

[6]

port 1 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 1 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

[1] Symbol names with an overscore (e.g. NAME) indicate active LOW signals.

[2] The voltage at pin V

connecting RESET to V

[3] See Table 4 “Mode selection”.

[4] To disable a downstream port connect both D+ and D− to VCCvia a 1 MΩ resistor; unused ports must

be disabled in reverse order starting from port 5.

[5] Analog detection circuit can be switched off using an external EEPROM, see Table 23; in this case,

the pin functions as a logic input (TTL level).

[6] Downstream ports 1 and 2 cannot be disabled.

is gated by the RESET pin. This allows fully self-powered operation by

reg(3.3)

(+5 V USB supply). If V

BUS

is lost upstream port D+ will not be driven.

BUS

9397 750 06389

Product specification Rev. 02 — 4 October 1999 5 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 6

Philips Semiconductors

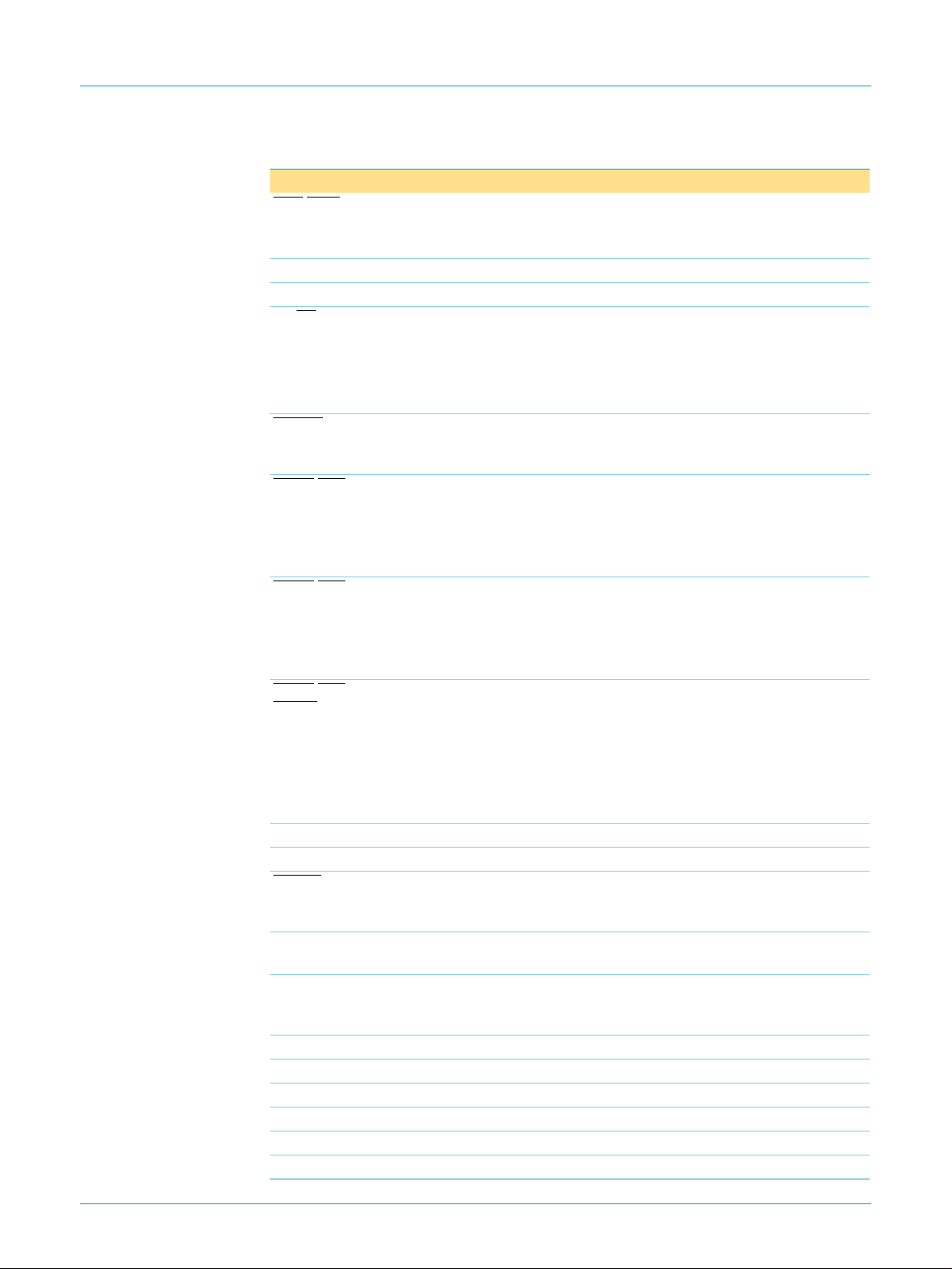

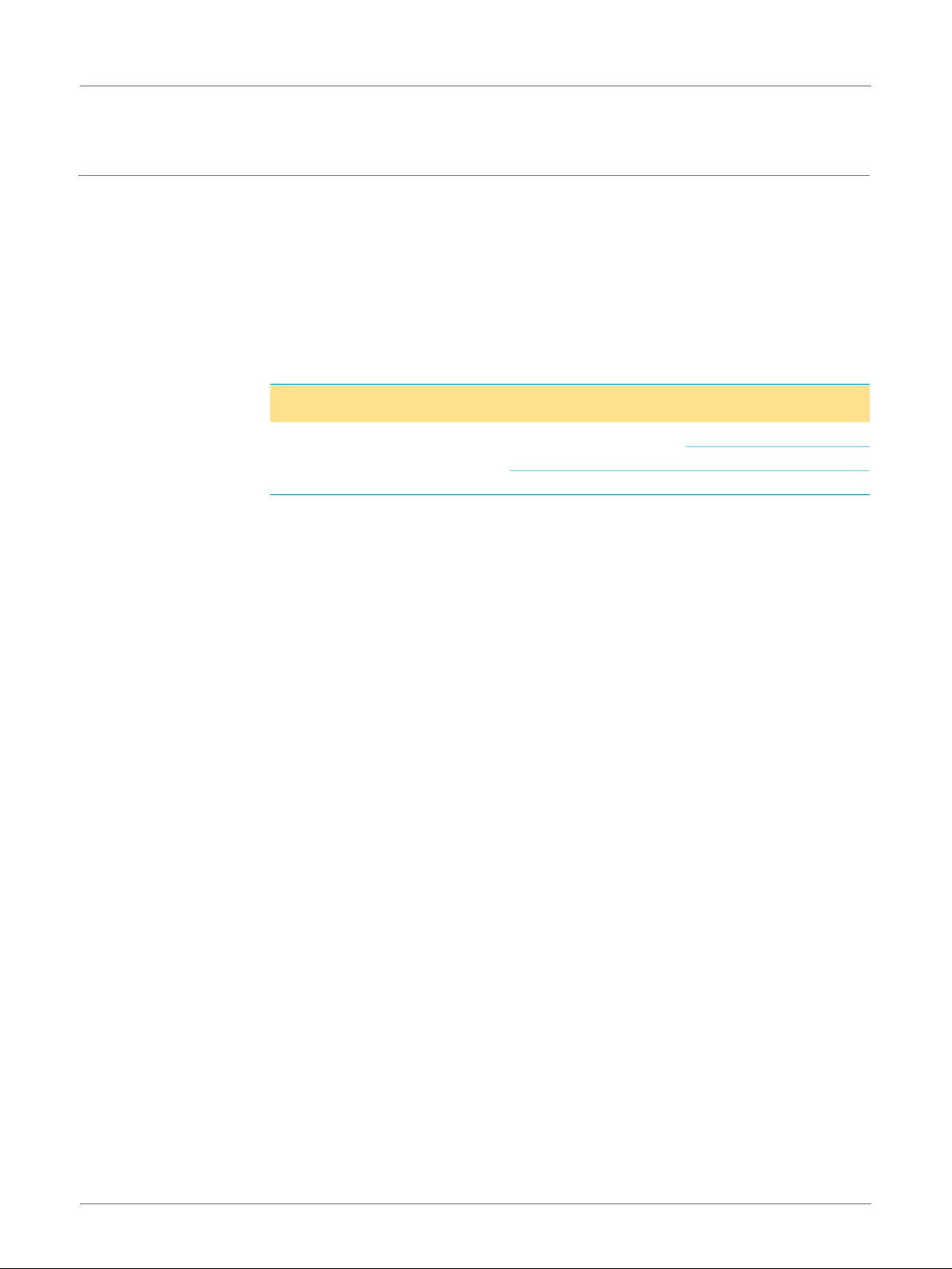

5.2 ISP1122BD (LQFP32)

5.2.1 Pinning

handbook, full pagewidth

ISP1122

USB stand-alone hub

DP3

V

OC1

OC2

OC3

OC4

OC5/GOC

DM4

Fig 4. Pin configuration LQFP32.

CC

DM3

GND

32

31

1

2

3

4

5

6

7

8

9

10

DP4

SP/BP

reg(3.3)

PSW2/GL2

V

PSW1/GL1

30

29

28

ISP1122BD

11

12

13

HUBGL

PSW3/GL3

PSW4/GL4

DP2

DM2

DP0

27

26

25

14

15

16

MBL018

XTAL1

XTAL2

PSW5/GL5/GPSW

DM0

24

DP1

23

DM1

22

DP5

21

DM5

20

INDV/SDA

19

OPTION/SCL

18

RESET

17

5.2.2 Pin description

Table 3: Pin description for LQFP32

reg(3.3)

CC

[1]

[2]

Pin Type Description

29 - regulated supply voltage (3.3 V ± 10%) from internal

regulator; used to connect pull-up resistor on DP0 line

[3]

30 O modes 4 to 6: power switch control output for downstream

port 2 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 2 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

[4]

[4]

2 - supply voltage; connect to USB supply V

hybrid-powered) or to local supply V

DD

© Philips Electronics N.V. 1999. All rights reserved.

(bus-poweredor

BUS

(self-powered)

[5]

)

[5]

)

[5]

)

[5]

)

Symbol

V

PSW2/GL2

GND 31 - ground supply

DM3 32 AI/O downstream port 3 D− connection (analog)

DP3 1 AI/O downstream port 3 D+ connection (analog)

V

OC1 3 AI/I overcurrent sense input for downstream port 1 (analog

OC2 4 AI/I overcurrent sense input for downstream port 2 (analog

OC3 5 AI/I overcurrent sense input for downstream port 3 (analog

OC4 6 AI/I overcurrent sense input for downstream port 4 (analog

9397 750 06389

Product specification Rev. 02 — 4 October 1999 6 of 48

Page 7

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 3: Pin description for LQFP32

Symbol

OC5/GOC

[1]

Pin Type Description

[3]

7 AI/I modes 5, 7: overcurrent sense input for downstream port 5

(analog

modes 0, 1, 3: global overcurrent sense input (analog

DM4 8 AI/O downstream port 4 D− connection (analog)

DP4 9 AI/O downstream port 4 D+ connection (analog)

…continued

[5]

)

[5]

[4]

[4]

SP/BP 10 I selects power mode:

self-powered: connect to V

(local power supply); also use

DD

this mode for hybrid-powered operation

bus-powered:connect to GND;disable downstream port 5 to

meet supply current requirements

[4]

HUBGL 11 O hub GoodLink LED indicator output (open-drain, 6 mA);

to connect an LED use a 330 Ω series resistor; if unused

via a 10 kΩ resistor

CC

PSW3/GL3

connect to V

[3]

12 O modes 4 to 6: power switch control output for downstream

port 3 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 3 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

PSW4/GL4

[3]

13 O modes 4 to 6: power switch control output for downstream

port 4 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 4 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

PSW5/GL5/

[3]

GPSW

14 O mode 5: power switch control output for downstream port 5

(open-drain, 6 mA)

modes 3, 7: GoodLink LED indicator output for downstream

port 5 (open-drain, 6 mA); to connect an LED use a 330 Ω

series resistor

modes 0 to 2: gang mode power switch control output

(open-drain, 6 mA)

XTAL1 15 I crystal oscillator input (6 MHz)

XTAL2 16 O crystal oscillator output (6 MHz)

RESET

[2]

17 I reset input (Schmitt trigger); a LOW level produces an

asynchronous reset; connect to V

for power-on reset

CC

(internal POR circuit)

2

OPTION/SCL 18 I/O mode selection input; also functions as I

C-bus clock output

(open-drain, 6 mA)

INDV/SDA 19 I/O selects individual (HIGH) or global (LOW) power switching

and overcurrent detection; also functions as bidirectional

2

C-bus data line (open-drain, 6 mA)

I

DM5 20 AI/O downstream port 5 D− connection (analog)

DP5 21 AI/O downstream port 5 D+ connection (analog)

DM1 22 AI/O downstream port 1 D− connection (analog)

DP1 23 AI/O downstream port 1 D+ connection (analog)

[4]

[4]

[6]

[6]

DM0 24 AI/O upstream port D− connection (analog)

DP0 25 AI/O upstream port D+ connection (analog)

)

9397 750 06389

Product specification Rev. 02 — 4 October 1999 7 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 8

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 3: Pin description for LQFP32

Symbol

DM2 26 AI/O downstream port 2 D− connection (analog)

DP2 27 AI/O downstream port 2 D+ connection (analog)

PSW1/GL1

[1] Symbol names with an overscore (e.g. NAME) indicate active LOW signals.

[2] The voltage at pin V

[3] See Table 4 “Mode selection”.

[4] To disable a downstream port connect both D+ and D− to VCCvia a 1 MΩ resistor; unused ports must

[5] Analog detection circuit can be switched off using an external EEPROM, see Table 23; in this case,

[6] Downstream ports 1 and 2 cannot be disabled.

[1]

connecting RESET to V

be disabled in reverse order starting from port 5.

the pin functions as a logic input (TTL level).

6. Functional description

The ISP1122 is a stand-alone USB hub with up to 5 downstream ports. The number

of ports can be configured between 2 and 5. The downstream ports can be used to

connect low-speed or full-speed USB peripherals. All standard USB requests from

the host are handled by the hardware without the need for firmware intervention. The

block diagram is shown in Figure 1.

…continued

Pin Type Description

[6]

[6]

[3]

28 O modes 4 to 6: power switch control output for downstream

port 1 (open-drain, 6 mA)

modes 0 to 3, 7: GoodLink LED indicator output for

downstream port 1 (open-drain, 6 mA); to connect an LED

use a 330 Ω series resistor

is gated by the RESET pin. This allows fully self-powered operation by

reg(3.3)

(+5 V USB supply). If V

BUS

is lost upstream port D+ will not be driven.

BUS

The ISP1122 requires only a single supply voltage. An internal 3.3 V regulator

provides the supply voltage for the analog USB data transceivers.

The ISP1122 supports both bus-powered and self-powered hub operation. When

using bus-powered operation a downstream port cannot supply more than 100 mA to

a peripheral. In case of self-powered operation an external supply is used to power

the downstream ports, allowing a current consumption of max. 500 mA per port.

A basic I2C-bus interface is provided for reading vendor ID, product ID and

configuration bits from an external EEPROM upon a reset.

6.1 Analog transceivers

The integrated transceiver interfaces directly to the USB cables through external

termination resistors. They are capable of transmitting and receiving serial data at

both ‘full-speed’ (12 Mbit/s) and ‘low-speed’ (1.5 Mbit/s) data rates. The slew rates

are adjusted according to the speed of the device connected and lie within the range

mentioned in the

USB Specification Rev. 1.1

.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 8 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 9

Philips Semiconductors

6.2 Philips Serial Interface Engine (SIE)

The Philips SIE implements the full USB protocol layer. It is completely hardwired for

speed and needs no firmware intervention. The functions of this block include:

synchronization pattern recognition, parallel/serial conversion, bit (de-)stuffing, CRC

checking/generation, Packet IDentifier (PID) verification/generation, address

recognition, handshake evaluation/generation.

6.3 Hub repeater

The hub repeater is responsible for managing connectivity on a ‘per packet’ basis. It

implements ‘packet signalling’ and ‘resume’ connectivity. Low-speed devices can be

connected to downstream ports. If a low-speed device is detected the repeater will

not propagate upstream packets to the corresponding port, unless they are preceded

by a PREAMBLE PID.

6.4 End-of-frame timers

This block contains the specified EOF1 and EOF2 timers which are used to detect

‘loss-of-activity’ and ‘babble’ error conditions in the hub repeater. The timers also

maintain the low-speed keep-alive strobe which is sent at the beginning of a frame.

ISP1122

USB stand-alone hub

6.5 General and individual port controller

The general and individual port controllers together provide status and control of

individual downstream ports. Any port status change will be reported to the host via

the hub status change (interrupt) endpoint.

6.6 GoodLink

Indication of a good USB connection is provided through GoodLink technology. An

LED can be directly connected via an external 330 Ω resistor.

During enumeration the LED blinks on momentarily. After successful configuration of

the ISP1122, the LED is permanently on. The LED blinks off for 100 ms upon each

successful packet transfer (with ACK). The hub GoodLink indicator blinks when the

hub receives a packet addressed to it. Downstream GoodLink indicators blink upon

an acknowledgment from the associated port. In ‘suspend’ mode the LED is off.

This featureprovides a user-friendly indication of the status of the hub,the connected

downstream devices and the USB traffic. It is a useful diagnostics tool to isolate faulty

USB equipment and helps to reduce field support and hotline costs.

6.7 Bit clock recovery

The bit clock recovery circuit recovers the clock from the incoming USB data stream

using a 4× oversampling principle. It is able to track jitter and frequency drift as

specified by the

USB Specification Rev. 1.1

.

6.8 Voltage regulator

A 5 to 3.3 V DC-DC regulator is integrated on-chip to supply the analog transceiver

and internal logic. This can also be used to supply the terminal 1.5 kΩ pull-up resistor

on the D+ line of the upstream connection.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 9 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 10

Philips Semiconductors

6.9 PLL clock multiplier

A 6 to 48 MHz clock multiplier Phase-Locked Loop (PLL) is integrated on-chip. This

allows for the use of low-cost 6 MHz crystals. The low crystal frequency also

minimizes Electro-Magnetic Interference (EMI). The PLL requires no external

components.

6.10 Overcurrent detection

An overcurrent detection circuit for downstream ports has been integrated on-chip. It

is self-reporting, resets automatically, has a low trip time and requires no external

components. Both individual and global overcurrent detection are supported.

6.11 I2C-bus interface

A basic serial I2C-bus interface (single master, 100 kHz) is provided to read VID, PID

and configuration bits from an external I2C-bus EEPROM (e.g. Philips PCF8582 or

equivalent). At reset the ISP1122 reads 6 bytes of data from the external memory.

The I2C-bus interface timing complies with the standard mode of operation as

described in

The I2C-bus and how to use it

ISP1122

USB stand-alone hub

, order number 9398 393 40011.

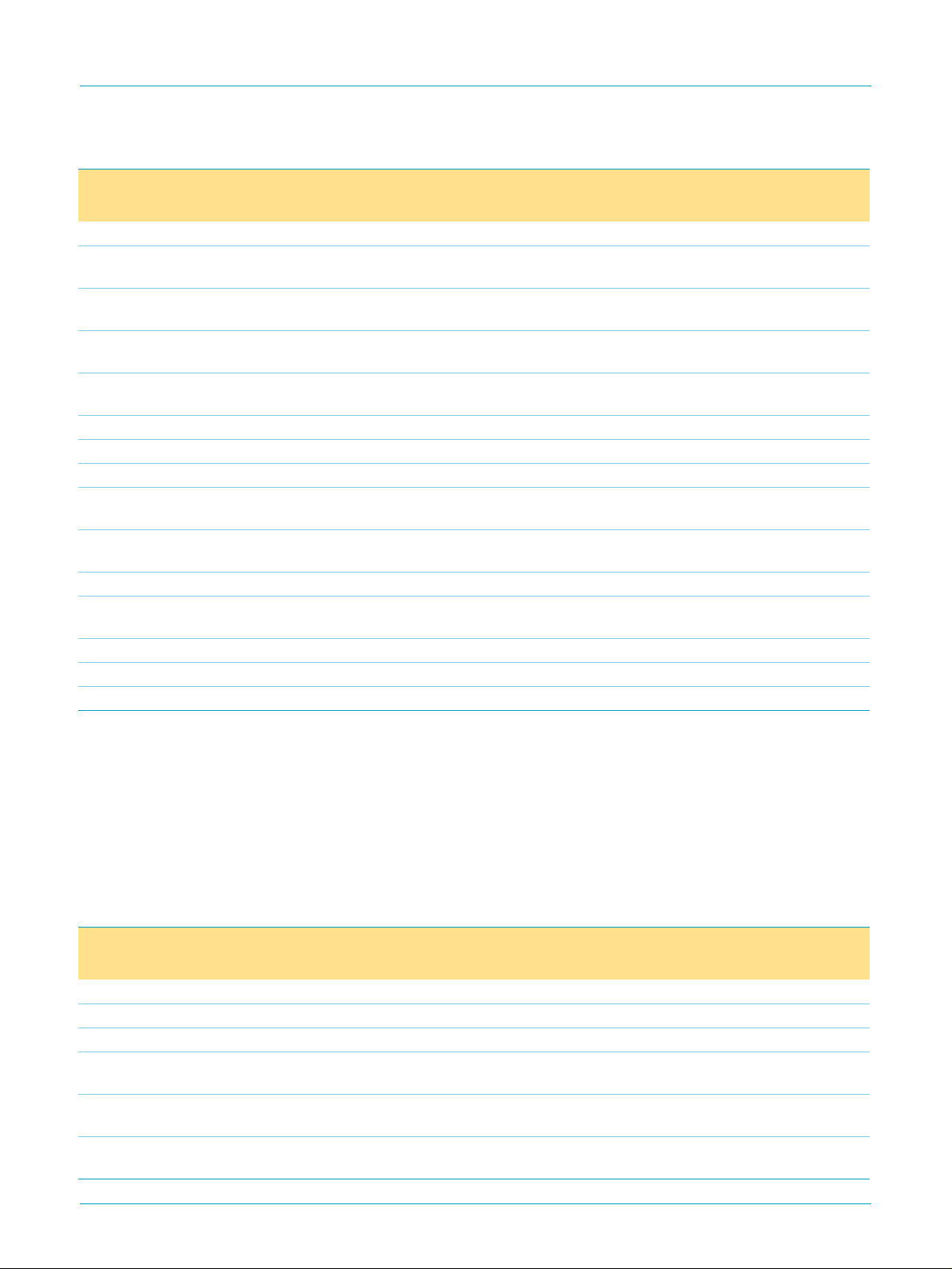

7. Modes of operation

The ISP1122 has several modes of operation, each corresponding with a differentpin

configuration. Modes are selected by means of pins INDV, OPTION and SP/BP, as

shown in Table 4.

Table 4: Mode selection

Mode INDV

0000GoodLink ganged power inactive global overcurrent

1001GoodLink ganged power inactive global overcurrent

2010GoodLink ganged power inactive

3011GoodLink

4100individual power inactive individual

5101individual power individual power individual

6110individual power inactive inactive

7111GoodLink

[1] Port power switching: logic 0 = ganged, logic 1 = individual.

[2] Power mode: logic0=bus-powered, logic 1 = self-powered (or hybrid-powered).

[3] No overcurrent detection.

[4] No power switching.

[1]

OPTION SP/BP

[2]

PSWn/GLn

(n = 1 to 4)

PSW5/GL5/GPSW OCn

[4]

[4]

GoodLink

GoodLink

[4]

[4]

(n = 1 to 4)

[3]

inactive global overcurrent

overcurrent

overcurrent

[3]

individual

overcurrent

OC5/GOC

inactive

inactive

individual

overcurrent

inactive

individual

overcurrent

[3]

[3]

9397 750 06389

Product specification Rev. 02 — 4 October 1999 10 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 11

Philips Semiconductors

8. Endpoint descriptions

Each USB device is logically composed of several independent endpoints. An

endpoint acts as a terminus of a communication flow between the host and the

device. At design time each endpoint is assigned a unique number (endpoint

identifier, see Table 5). The combination of the device address (given by the host

during enumeration), the endpoint number and the transfer direction allows each

endpoint to be uniquely referenced.

The ISP1122 has two endpoints, endpoint 0 (control) and endpoint 1 (interrupt).

Table 5: Hub endpoints

Function Ports Endpoint

Hub

[1] IN: input for the USB host; OUT: output from the USB host.

0: upstream

1 to 5: downstream

ISP1122

USB stand-alone hub

identifier

0 control

1 interrupt IN 1

Transfer

type

Direction

OUT 64

IN 64

[1]

Max. packet

size (bytes)

8.1 Hub endpoint 0 (control)

All USB devices and functions must implement a default control endpoint (ID = 0).

This endpoint is used by the host to configure the device and to perform generic USB

status and control access.

The ISP1122 hub supports the following USB descriptor information through its

control endpoint 0, which can handle transfers of 64 bytes maximum:

Device descriptor

•

Configuration descriptor

•

Interface descriptor

•

Endpoint descriptor

•

Hub descriptor

•

String descriptor.

•

8.2 Hub endpoint 1 (interrupt)

Endpoint 1 is used by the ISP1122 hub to provide status change information to the

host. This endpoint can be accessed only after the hub has been configured by the

host (by sending the Set Configuration command).

Endpoint 1 is an interrupt endpoint: the host polls it once every 255 ms by sending an

IN token. If the hub has detected no change in the port status it returns a NAK (Not

AcKnowledge) response to this request, otherwise it sends the Status Change byte

(see Table 6).

9397 750 06389

Product specification Rev. 02 — 4 October 1999 11 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 12

Philips Semiconductors

Table 6: Status Change byte: bit allocation

Bit Symbol Description

0 Hub SC a logic 1 indicates a status change on the hub’s upstream port

1 Port 1 SC a logic 1 indicates a status change on downstream port 1

2 Port 2 SC a logic 1 indicates a status change on downstream port 2

3 Port 3 SC a logic 1 indicates a status change on downstream port 3

4 Port 4 SC a logic 1 indicates a status change on downstream port 4

5 Port 5 SC a logic 1 indicates a status change on downstream port 5

6 reserved not used

7 reserved not used

9. Host requests

The ISP1122 handles all standard USB requests from the host via control endpoint 0.

The control endpoint can handle a maximum of 64 bytes per transfer.

Remark: Please note that the USB data transmission order is Least Significant Bit

(LSB) first. In the following tables multi-byte variables are displayed least significant

byte first.

ISP1122

USB stand-alone hub

9.1 Standard requests

Table 7 shows the supported standard USB requests. Some requests are explicitly

unsupported. All other requests will be responded with a STALL packet.

Table 7: Standard USB requests

Request name bmRequestType

Address

Set Address X000 0000 05 address

Configuration

Get Configuration 1000 0000 08 00, 00 00, 00 01, 00 configuration

Set Configuration (0) X000 0000 09 00, 00 00, 00 00, 00 none

Set Configuration (1) X000 0000 09 01, 00 00, 00 00, 00 none

Descriptor

Get Configuration

Descriptor

Get Device Descriptor 1000 0000 06 00, 01 00, 00 length

Get String Descriptor (0) 1000 0000 06 03, 00 00, 00 length

Get String Descriptor (1) 1000 0000 06 03, 01 00, 00 length

Get String Descriptor (2) 1000 0000 06 03, 02 00, 00 length

byte 0 [7:0]

(Bin)

1000 0000 06 00, 02 00, 00 length

bRequest

byte 1

(Hex)

wValue

byte 2, 3

(Hex)

wIndex

byte 4, 5

(Hex)

[1]

00, 00 00, 00 none

wLength

byte 6, 7

(Hex)

Data

value = 01H

[2]

[2]

[2]

[2]

[2]

configuration,

interface and

endpoint

descriptors

device

descriptor

language ID

string

manufacturer

string

product string

9397 750 06389

Product specification Rev. 02 — 4 October 1999 12 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 13

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 7: Standard USB requests

Request name bmRequestType

byte 0 [7:0]

(Bin)

…continued

bRequest

byte 1

(Hex)

wValue

byte 2, 3

(Hex)

wIndex

byte 4, 5

(Hex)

wLength

byte 6, 7

(Hex)

Data

Feature

Clear Device Feature

X000 0000 01 01, 00 00, 00 00, 00 none

(REMOTE_WAKEUP)

Clear Endpoint (1)

X000 0010 01 00, 00 81, 00 00, 00 none

Feature (HALT/STALL)

Set Device Feature

X000 0000 03 01, 00 00, 00 00, 00 none

(REMOTE_WAKEUP)

Set Endpoint (1)

X000 0010 03 00, 00 81, 00 00, 00 none

Feature (HALT/STALL)

Status

Get Device Status 1000 0000 00 00, 00 00, 00 02, 00 device status

Get Interface Status 1000 0001 00 00, 00 00, 00 02, 00 zero

Get Endpoint (0) Status 1000 0010 00 00, 00 00/80

[3]

, 00 02, 00 endpoint 0

status

Get Endpoint (1) Status 1000 0010 00 00, 00 81, 00 02, 00 endpoint 1

status

Unsupported

Set Descriptor 0000 0000 07 XX, XX XX, XX XX, XX descriptor;

STALL

Get Interface 1000 0001 0A 00, 00 XX, XX 01, 00 STALL

Set Interface X000 0001 0B XX, XX XX, XX 00, 00 STALL

Synch Frame 1000 0010 0C 00, 00 XX, XX 02, 00 STALL

[1] Device address: 0 to 127.

[2] Returned value in bytes.

[3] MSB specifies endpoint direction: 0 = OUT, 1 = IN. The ISP1122 accepts either value.

9.2 Hub specific requests

In Table 8 the supported hub specific requests are listed, as well as some

unsupported requests. Table 9 provides the feature selectors for setting or clearing

port features.

Table 8: Hub specific requests

Request name bmRequestType

byte 0 [7:0]

(Bin)

Descriptor

Get Hub Descriptor 1010 0000 06 00, 00/29

Feature

Clear Hub Feature

X010 0000 01 00, 00 00, 00 00, 00 none

(C_LOCAL_POWER)

Clear Port Feature

X010 0011 01 feature

(feature selectors)

Set Port Feature

X010 0011 03 feature

(feature selectors)

bRequest

byte 1

(Hex)

wValue

byte 2, 3

(Hex)

[1]

[3]

, 00 port

[3]

, 00 port

wIndex

byte 4, 5

(Hex)

wLength

byte 6, 7

(Hex)

00, 00 length

[4]

, 00 00, 00 none

[4]

, 00 00, 00 none

Data

[2]

, 00 hub descriptor

9397 750 06389

Product specification Rev. 02 — 4 October 1999 13 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 14

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 8: Hub specific requests

Request name bmRequestType

…continued

byte 0 [7:0]

(Bin)

bRequest

byte 1

(Hex)

wValue

byte 2, 3

(Hex)

wIndex

byte 4, 5

(Hex)

wLength

byte 6, 7

(Hex)

Data

Status

Get Hub Status 1010 0000 00 00, 00 00, 00 04, 00 hub status and

status change

field

[4]

Get Port Status 1010 0011 00 00, 00 port

, 00 04, 00 port status

Unsupported

[4]

Get Bus Status 1010 0011 02 00, 00 port

Clear Hub Feature

X010 0000 01 01, 00 00, 00 00, 00 STALL

, 00 01, 00 STALL

(C_OVER_CURRENT)

Set Hub Descriptor 0010 0000 07 XX, XX 00, 00 3E, 00 STALL

Set Hub Feature

X010 0000 03 00, 00 00, 00 00, 00 STALL

(C_LOCAL_POWER)

Set Hub Feature

X010 0000 03 01, 00 00, 00 00, 00 STALL

(C_OVER_CURRENT)

[1]

USB Specification Rev. 1.0

[2] Returned value in bytes.

[3] Feature selector value, seeTable 9.

[4] Downstream port identifier: 1 to N with N = number of enabled ports (2 to 5).

uses 00H,

USB Specification Rev. 1.1

specifies 29H.

Table 9: Port feature selectors

Feature selector name Value (Hex) Set feature Clear feature

PORT_CONNECTION 00 not used not used

PORT_ENABLE 01 not used disables a port

PORT_SUSPEND 02 suspends a port resumes a port

PORT_OVERCURRENT 03 not used not used

PORT_RESET 04 resets and enables a

not used

port

PORT_POWER 08 powers on a port powers off a port

PORT_LOW_SPEED 09 not used not used

C_PORT_CONNECTION 10 not used clears port connection

change bit

C_PORT_ENABLE 11 not used clears port enable

change bit

C_PORT_SUSPEND 12 not used clears port suspend

change bit

C_PORT_OVERCURRENT 13 not used clears port overcurrent

change bit

C_PORT_RESET 14 not used clears port reset

change bit

9397 750 06389

Product specification Rev. 02 — 4 October 1999 14 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 15

Philips Semiconductors

9.3 Descriptors

The ISP1122 hub controller supports the following standard USB descriptors:

•

•

•

•

•

•

Table 10: Device descriptor

Values in square brackets are optional.

Offset

(bytes)

0 bLength 1 12 descriptor length = 18 bytes

1 bDescriptorType 1 01 type = DEVICE

2 bcdUSB 2 10, 01

4 bDeviceClass 1 09 HUB_CLASSCODE

5 bDeviceSubClass 1 00 6 bDeviceProtocol 1 00 7 bMaxPacketSize0 1 40 packet size = 64 bytes

8 idVendor 2 CC, 04 Philips Semiconductors vendor ID

10 idProduct 2 22, 11 ISP1122 product ID; can be

12 bcdDevice 2 01, 01 device release 1.1; silicon revision

14 iManufacturer 1 00 no manufacturer string (default)

15 iProduct 1 00 no product string (default)

16 iSerialNumber 1 00 no serial number string

17 bNumConfigurations 1 01 one configuration

Device

Configuration

Interface

Endpoint

Hub

String.

Field name Size

(bytes)

ISP1122

USB stand-alone hub

Value

(Hex)

[01] manufacturer string enabled

[02] product string enabled

Comments

USB Specification Rev. 1.1

(04CC); can be customized using an

external EEPROM (see Table 23)

customized using an external

EEPROM (see Table 23)

increments this value

(using an external EEPROM)

(using an external EEPROM)

9397 750 06389

Product specification Rev. 02 — 4 October 1999 15 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 16

Philips Semiconductors

Table 11: Configuration descriptor

Values in square brackets are optional.

Offset

(bytes)

0 bLength 1 09 descriptor length=9bytes

1 bDescriptorType 1 02 type = CONFIGURATION

2 wTotalLength 2 19, 00 total length of configuration, interface

4 bNumInterfaces 1 01 one interface

5 bConfigurationValue 1 01 configuration value = 1

6 iConfiguration 1 00 no configuration string

7 bmAttributes 1 E0 self-powered with remote wake-up

8 MaxPower

[1] Selected by input SP/BP.

[2] Value in units of 2mA.

Field name Size

(bytes)

[2]

1 32 100 mA (default)

ISP1122

USB stand-alone hub

Value

(Hex)

A0 bus-powered with remote wake-up

[00] 0 mA (using an external EEPROM)

[FA] 500 mA (using an external EEPROM)

Comments

and endpoint descriptors (25 bytes)

[1]

[1]

Table 12: Interface descriptor

Offset

(bytes)

Field name Size

(bytes)

Value

(Hex)

Comments

0 bLength 1 09 descriptor length=9bytes

1 bDescriptorType 1 04 type = INTERFACE

2 bInterfaceNumber 1 00 3 bAlternateSetting 1 01 no alternate setting

4 bNumEndpoints 1 01 status change (interrupt) endpoint

5 bInterfaceClass 1 09 HUB_CLASSCODE

6 bInterfaceSubClass 1 00 7 bInterfaceProtocol 1 00 no class-specific protocol

8 bInterface 1 00 no interface string

Table 13: Endpoint descriptor

Offset

(bytes)

Field name Size

(bytes)

Value

(Hex)

Comments

0 bLength 1 07 descriptor length=7bytes

1 bDescriptorType 1 05 type = ENDPOINT

2 bEndpointAddress 1 81 endpoint 1, direction: IN

3 bmAttributes 1 03 interrupt endpoint

4 wMaxPacketSize 2 01, 00 packet size = 1 byte

6 bInterval 1 FF polling interval (255 ms)

9397 750 06389

Product specification Rev. 02 — 4 October 1999 16 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 17

Philips Semiconductors

Table 14: Hub descriptor

Values in square brackets are optional.

Offset

(bytes)

0 bDescLength 1 09 descriptor length=9bytes

1 bDescriptorType 1 29 type = HUB

2 bNbrPorts 1 05 to 02 number of enabled downstream ports;

3 wHubCharacteristics 2 09, 00 individual power switching

5 bPwrOn2PwrGood

6 bHubContrCurrent 1 64 maximum hub controller current

7 DeviceRemovable 1 00 all devices removable

8 PortPwrCtrlMask 1 FF must be all ones for compatibility with

Field name Size

(bytes)

[3]

1 32 100 ms (default; modes 0, 1, 2, 4, 5, 6)

ISP1122

USB stand-alone hub

Value

(Hex)

11, 00 individual power switching

00 0 ms (default; modes 3, 7)

[FA] 500 ms (using an external EEPROM;

Comments

selectable by DP/DM strapping

[1]

,

overcurrent protection active

(modes 0, 1, 3, 4, 5, 7)

[1]

, no

overcurrent protection (modes 2, 6)

modes 0, 1, 2, 4, 5, 6); see Table 23

(100 mA)

USB Specification Rev. 1.0

[2]

[1] ISP1122 always reports power management status on an individual basis, even for ganged/global

modes. This is compliant with

[2] Condition with no overcurrent detection is reported to the host.

[3] Value in units of 2ms.

USB Specification Rev. 1.1

.

Table 15: String descriptors

String descriptors are optional and therefore disabled by default; they can be enabled through

an external EEPROM.

Offset

(bytes)

Field name Size

(bytes)

Value

(Hex)

Comments

String descriptor (0): language ID string

0 bLength 1 04 descriptor length=4bytes

1 bDescriptorType 1 03 type = STRING

2 bString 2 09, 04 LANGID code zero

String descriptor (1): manufacturer string

0 bLength 1 2E descriptor length = 46 bytes

1 bDescriptorType 1 03 type = STRING

[1]

2 bString 44 UC

“Philips Semiconductors”

String descriptor (2): product string

0 bLength 1 10 descriptor length = 16 bytes

1 bDescriptorType 1 03 type = STRING

[1]

2 bString 14 UC

“ISP1122”

[1] Unicode encoded string.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 17 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 18

Philips Semiconductors

9.4 Hub responses

This section describes the hub responses to requests from the USB host.

9.4.1 Get device status

The hub returns 2 bytes, see Table 16.

Table 16: Get device status response

Bit # Function Value Description

0 self-powered 0 bus-powered

1 remote wake-up 0 no remote wake-up

2 to 15 reserved 0 -

9.4.2 Get configuration

The hub returns 1 byte, see Table 17.

Table 17: Get configuration response

Bit # Function Value Description

0 configuration value 0 device not configured

1 to 7 reserved 0 -

ISP1122

USB stand-alone hub

1 self-powered

1 remote wake-up enabled

1 device configured

9.4.3 Get interface status

The hub returns 2 bytes, see Table 18.

Table 18: Get interface status response

Bit # Function Value Description

0 to 15 reserved 0 -

9.4.4 Get hub status

The hub returns 4 bytes, see Table 19.

Table 19: Get hub status response

Bit # Function Value Description

0 local power source 0 local power supply good

1 overcurrent indicator 0 no overcurrent condition

2 to 15 reserved 0 16 local power status change 0 no change in local power status

17 overcurrent indicator change 0 no change in overcurrent condition

18 to 31 reserved 0 -

1 local power supply lost

1 hub overcurrent condition detected

1 local power status changed

1 overcurrent condition changed

9397 750 06389

Product specification Rev. 02 — 4 October 1999 18 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 19

Philips Semiconductors

9.4.5 Get port status

The hub returns 4 bytes. The first 2 bytes contain the port status bits (wPortStatus,

see Table 20). The last 2 bytes hold the port status change bits (wPortChange, see

Table 21).

Table 20: Get port status response (wPortStatus)

Bit # Function Value Description

0 current connect status 0 no device present

1 port enabled/disabled 0 port disabled

2 suspend 0 port not suspended

3 overcurrent indicator 0 no overcurrent condition

4 reset 0 reset not asserted

5 to 7 reserved 0 8 port power 0 port powered off

9 low-speed device attached 0 full-speed device attached

10 to 15 reserved 0 -

ISP1122

USB stand-alone hub

1 device present on this port

1 port enabled

1 port suspended

1 overcurrent condition detected

1 reset asserted

1 port power on

1 low-speed device attached

Table 21: Get port status response (wPortChange)

Bit # Function Value Description

0 connect status change 0 no change in current connect status

1 current connect status changed

1 port enabled/disabled

change

2 suspend change 0 no change in suspend status

3 overcurrent indicator change 0 no change in overcurrent status

4 reset change 0 no change in reset status

5 to 15 reserved 0 -

0 no port error

1 port disabled by a port error

1 resume complete

1 overcurrent indicator changed

1 reset complete

9397 750 06389

Product specification Rev. 02 — 4 October 1999 19 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 20

Philips Semiconductors

9.4.6 Get configuration descriptor

The hub returns 25 bytes containing the configuration descriptor (9 bytes, see

Table 11), the interface descriptor (9 bytes, see Table 12) and the endpoint descriptor

(7 bytes, see Table 13).

9.4.7 Get device descriptor

The hub returns 18 bytes containing the device descriptor, see Table 10.

9.4.8 Get hub descriptor

The hub returns 9 bytes containing the hub descriptor, see Table 14.

9.4.9 Get string descriptor (0)

The hub returns 4 bytes containing the language ID, see Table 15.

9.4.10 Get string descriptor (1)

The hub returns 46 bytes containing the manufacturer name, see Table 15.

9.4.11 Get string descriptor (2)

The hub returns 16 bytes containing the product name, see Table 15.

ISP1122

USB stand-alone hub

10. I2C-bus interface

A simple I2C-bus interface is provided in the ISP1122 to read customized vendor ID,

product ID and some other configuration bits from an external EEPROM. The

interface supports single master operation at a nominal bus speed of 93.75 kHz.

The I2C-bus interface is intended for bidirectional communication between ICs via two

serial bus wires, SDA (data) and SCL (clock). Both lines are driven by open-drain

circuits and must be connected to the positive supply voltage via pull-up resistors.

10.1 Protocol

The I2C-bus protocol defines the following conditions:

•

•

•

•

Each device on the I2C-bus has a unique slave address, which the master uses to

select a device for access.

The master starts a data transfer using a START condition and ends it by generating

a STOP condition. Transfers can only be initiated when the bus is free. The receiver

must acknowledge each byte by means of a LOW level on SDA during the ninth clock

pulse on SCL.

Bus free: both SDA and SCL are HIGH

START: a HIGH-to-LOW transition on SDA, while SCL is HIGH

STOP: a LOW-to-HIGH transition on SDA, while SCL is HIGH

Data valid: after a START condition, data on SDA are stable during the HIGH

period of SCL; data on SDA may only change while SCL is LOW.

For detailed information please consult

9398 393 40011.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 20 of 48

The I2C-bus and how to use it

© Philips Electronics N.V. 1999. All rights reserved.

., order number

Page 21

Philips Semiconductors

10.2 Hardware connections

Via the I2C-bus interface the ISP1122 can be connected to an external EEPROM

(PCF8582 or equivalent). The hardware connections are shown in Figure 5.

The SCL and SDA pins are multiplexed with pins OPTION and INDV respectively.

ISP1122

USB stand-alone hub

dth

Fig 5. EEPROM connection diagram.

The slave address which ISP1122 uses to access the EEPROM is 1010000B. Page

mode addressing is not supported, so pins A0, A1 and A2 of the EEPROM must be

connected to GND (logic 0).

10.3 Data transfer

When the ISP1122 is reset, the I2C-bus interface tries to read 6 bytes of configuration

data from an external EEPROM. If no response is detected, the levels on inputs SDA

and SCL are interpreted as INDV and OPTION to select the operating mode (see

Table 4).

OPTION/SCL

INDV/SDA

ISP1122

USB HUB

DD

R

P

2

I

C-bus

V

DD

R

P

SCL

SDA

PCF8582

EEPROM

equivalent

A0

A1

A2

or

MGR780

V

The data in the EEPROM memory are organized as shown in Table 22.

Table 22: EEPROM organization

Address

(Hex)

00 CC idVendor

01 04 idVendor

02 22 idProduct

03 11 idProduct

04 - configuration bits C7 to C0; see Table 23

05 AA signature

[1] Vendor ID code in the Device descriptor, see Table 10.

[2] Product ID code in the Device descriptor, see Table 10.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 21 of 48

Default value

(Hex)

Contents

[1]

(lower byte)

[1]

(upper byte)

[2]

(lower byte)

[2]

(upper byte)

© Philips Electronics N.V. 1999. All rights reserved.

Page 22

Philips Semiconductors

Table 23: Configuration bits

Bit Function Value

C0 OPTION see Table 4 “Mode selection”

C1 INDV see Table 4 “Mode selection”

C2 reserved 0

C3 PwrOn2PwrGood

C4 string descriptor enable 0

C5 internal analog overcurrent

C7, C6 MaxPower

detection enable

[3]

ISP1122

USB stand-alone hub

(Bin)

[1]

[2]

[1]

0

1 500 ms (bPwrOn2PwrGood = FAH)

[1]

1 string descriptors enabled (strings:

0 internal analog overcurrent detection

[1]

1

[1]

00

01 500 mA (MaxPower= FAH)

1X 0 mA (MaxPower = 00H)

Description

must always be programmed to logic 0

100 ms (bPwrOn2PwrGood = 32H)

string descriptors disabled

“Philips Semiconductors”, “ISP1122”)

circuit disabled; overcurrent pins

function as digital inputs (TTL level)

internal analog overcurrent detection

circuit enabled

100 mA (MaxPower = 32H)

OCn

[1] Default value at reset if no external EEPROM is present.

[2] Modifies the Hub Descriptor field ‘bPwrOn2PwrGood’, see Table 14.

[3] Modifies the Hub Descriptor field ‘MaxPower’, see Table 14.

11. Hub power modes

USB hubs can either be self-powered or bus-powered.

Self-powered — Self-powered hubs have a 5 V local power supply on board which

provide power to the hub and the downstream ports. The

requires that these hubs limit the current to 500 mA per downstream port and report

overcurrent conditions to the host. The hub may optionally draw 100 mA from the

USB supply (V

Bus-powered — Bus-powered hubs obtain all power from the host or an upstream

self-powered hub. The maximum current is 100 mA per downstream port. Current

limiting and reporting of overcurrent conditions are both optional.

Power switching of downstream ports can be done individually or ganged, where all

ports are switchedsimultaneously with one power switch.The ISP1122 supports both

modes, which can be selected using input INDV (see Table 4).

11.1 Voltage drop requirements

USB Specification Rev. 1.1

) to power the interface functions (hybrid-powered).

BUS

11.1.1 Self-powered hubs

Self-powered hubs are required to provide a minimum of 4.75 V to its output port

connectors at all legal load conditions. To comply with Underwriters Laboratory Inc.

(UL) safety requirements, the power from any port must be limited to 25 W (5 A at

5 V). Overcurrent protection may be implemented on a global or individual basis.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 22 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 23

Philips Semiconductors

Assuming a 5 V ± 3% powersupply the worst case supply voltage is 4.85 V. This only

allows a voltage drop of 100 mV across the hub printed-circuit board (PCB) to each

downstream connector. This includes a voltage drop across:

•

•

•

•

PCB resistance and power supply connector resistance may cause a drop of 25 mV,

leaving only 75 mV as the voltage drop allowed across the power switch and

overcurrent sense device. The individual voltage drop components are shown in

Figure 6.

ISP1122

USB stand-alone hub

Power supply connector

Hub PCB (power and ground traces, ferrite beads)

Power switch (FET on-resistance)

Overcurrent sense device.

handbook, full pagewidth

5 V

POWER SUPPLY

± 3% regulated

(1) Includes PCB traces, ferrite beads, etc.

4.85 V(min)

+

−

voltage drop

ISP1122

power

switch

75 mV

low-ohmic

PMOS switch

voltage drop

25 mV

hub board

resistance

4.75 V(min)

(1)

V

BUS

D+

D−

GND

SHIELD

MGR781

downstream

port

connector

Fig 6. Typical voltage drop components in self-powered mode using individual overcurrent detection.

In case of global overcurrent detection an increased voltage drop is needed for the

overcurrent sense device (in this case a low-ohmic resistor). This can be realized by

using a special power supply of 5.1 V ± 3%, as shown in Figure 7.

handbook, full pagewidth

5.1 V KICK-UP

POWER SUPPLY

± 3% regulated

(1) Includes PCB traces, ferrite beads, etc.

4.95 V(min)

+

−

Fig 7. Typical voltage drop components in self-powered mode using global overcurrent detection.

voltage drop

100 mV

low-ohmic

sense resistor

for overcurrent

detection

voltage drop

ISP1122

power

switch

75 mV

PMOS switch

low-ohmic

voltage drop

25 mV

hub board

resistance

4.75 V(min)

(1)

V

BUS

D+

D−

GND

SHIELD

MGR782

downstream

connector

port

11.1.2 Bus-powered hubs

Bus-powered hubs are guaranteed to receive a supply voltage of 4.5 V at the

upstream port connector and must provide a minimum of 4.4 V to the downstream

port connectors. The voltage drop of 100 mV across bus-powered hubs includes:

Hub PCB (power and ground traces, ferrite beads)

•

Power switch (FET on-resistance)

•

Overcurrent sense device.

•

9397 750 06389

Product specification Rev. 02 — 4 October 1999 23 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 24

Philips Semiconductors

The PCB resistance may cause a drop of 25 mV, which leaves 75 mV for the power

switch and overcurrent sense device. The voltage drop components are shown in

Figure 8.

For bus-powered hubs overcurrent protection is optional. It may be implemented for

all downstream ports on a global or individual basis.

ISP1122

USB stand-alone hub

handbook, full pagewidth

V

BUS

upstream

port

connector

(1) Includes PCB traces, ferrite beads, etc.

D+

D−

GND

SHIELD

voltage drop

ISP1122

power

switch

75 mV

low-ohmic

PMOS switch

voltage drop

25 mV

hub board

resistance

4.40 V(min)4.50 V(min)

(1)

Fig 8. Typical voltage drop components in bus-powered mode (no overcurrent detection).

12. Overcurrent detection

The ISP1122 has an analog overcurrent detection circuit for monitoring downstream

port lines. This circuit automatically reports an overcurrent condition to the host and

turns off the power to the faulty port. The host must reset the condition flag.

Pins OC1 to OC5/GOC are used for individual port overcurrent detection. Pin

OC5/GOC can also be used for global overcurrent detection. This is controlled by

input INDV (see Table 4).

The overcurrentdetection circuit can be switched off using an external EEPROM (see

Table 23). In this case, the overcurrent pins OCn function as logic inputs (TTL level).

V

BUS

D+

D−

GND

SHIELD

MGR783

downstream

port

connector

12.1 Overcurrent circuit description

The integrated overcurrent detection circuit of ISP1122 senses the voltage drop

across the power switch or an extra low-ohmic sense resistor. When the port draws

too much current, the voltage drop across the power switch exceeds the trip voltage

threshold (∆V

switch control signal after a delay of 15 ms (t

). The overcurrent circuit detects this and switches off the power

trip

). This delay acts as a ‘debounce’

trip

period to minimize false tripping, especially during the inrush current produced by ‘hot

plugging’ of a USB device.

12.2 Power switch selection

From the voltage drop analysis given in Figure 6, Figure 7 and Figure 8, the power

switch has a voltage drop budget of 75 mV. For individual self-powered mode, the

current drawn per port can be up to 500 mA. Thus the power switch should have

maximum on-resistance of 150 mΩ.

If the voltage drop due to the hub board resistance can be minimized, the power

switch can have more voltage drop budget and therefore a higher on-resistance.

Power switches with a typical on-resistance of around 100 mΩ fit into this application.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 24 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 25

Philips Semiconductors

The ISP1122 overcurrent detection circuit has been designed with a nominal trip

voltage (∆V

a power switch with an on-resistance of 100 mΩ1.

12.3 Tuning the overcurrent trip voltage

The ISP1122 trip voltage can optionally be adjusted through external components to

set the desired trip current. This is done by inserting tuning resistors at pins SP/BP or

OCn (see Figure 9). Rtu tunes up the trip voltage ∆V

according to Equation 1.

ISP1122

USB stand-alone hub

) of 85 mV. This gives a typical trip current of approximately 850 mA for

trip

and Rtd tunes it down

trip

handbook, halfpage

V

CC

I

=5µA

ref(nom)

I

= 0.5 µA

OC(nom)

VCCSP/BP

I

ref

R

tu

ISP1122

∆V

with I

trip

ref(nom)

low-ohmic

PMOS switch

∆V

trip intrinsic()

=5µA and I

I

OC

R

td

OCn

MBL042

I

⋅ IOCRtd⋅–+=

refRtu

OC(nom)

= 0.5 µA.

handbook, halfpage

V

BUS

I

= 0.5 µA

OC(nom)

VCCSP/BP

a. Self-powered mode. b. Bus-powered mode.

Fig 9. Tuning the overcurrent trip voltage.

12.4 Reference circuits

ISP1122

low-ohmic

PMOS switch

R

OCn

MBL043

(1)

I

OC

td

Some typical examples of port power switching and overcurrent detection modes are

given in Figure 10 to Figure 13.

The RC circuit (10 kΩ and 0.1 µF) around the PMOS switch provides for soft turn-on.

The series resistor connecting the SP/BP pin to VCC tunes up the overcurrent trip

voltage slightly (see Figure 9). In the schematic diagram the resistor separates the

net names for pins VCC and SP/BP. This allows an automatic router to use a wide

trace for VCC and a narrow trace to connect pin SP/BP.

1. The following PMOS power switches have been tested to work well with the ISP1122: Philips PHP109, Vishay Siliconix Si2301DS,

Fairchild FDN338P.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 25 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 26

Philips Semiconductors

ISP1122

USB stand-alone hub

handbook, full pagewidth

+4.85 V(min)

100 Ω

to

1 kΩ

5 V

POWER SUPPLY

± 3%

V

CC

GND

INDV

SP/BP

OPTION

PSW1/GL1

PSW2/GL2

PSW3/GL3

PSW4/GL4

PSW5/GL5/GPSW

ISP1122

OC5/GOC

+4.85 V(min)

+

−

330 kΩ

(5×)

OC1

OC2

OC3

OC4

0.1 µF

10 kΩ

0.1 µF

10 kΩ

0.1 µF

10 kΩ

0.1 µF

10 kΩ

0.1 µF

10 kΩ

low-ohmic

PMOS switch

low-ohmic

PMOS switch

low-ohmic

PMOS switch

low-ohmic

PMOS switch

low-ohmic

PMOS switch

downstream

(min)

(min)

(min)

(min)

(min)

ports

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

MGR784

1

2

3

4

5

ferrite bead

1

2

3

4

5

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

Power switches 1 to 5 are low-ohmic PMOS devices as specified in Section 12.2.

Fig 10. Mode 5: self-powered hub; individual port power switching; individual overcurrent detection.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 26 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 27

Philips Semiconductors

ISP1122

USB stand-alone hub

book, full pagewidth

+4.95 V(min)

100 Ω

to

1 kΩ

5.1 V KICK-UP

POWER SUPPLY

± 3%

V

CC

GND

INDV

SP/BP

OPTION

PSW1/GL1

PSW2/GL2

PSW3/GL3

PSW4/GL4

PSW5/GL5/GPSW

ISP1122

OC5/GOC

+4.95 V(min)

+

−

OC1

OC2

OC3

OC4

330

kΩ

low-ohmic

sense resistor

for overcurrent

detection

low-ohmic

PMOS switch

0.1 µF

10 kΩ

ferrite bead

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

ferrite bead

+4.75 V

120

µF

(min)

(min)

(min)

(min)

(min)

downstream

ports

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

MGR785

1

2

3

4

5

Power switch is low-ohmic PMOS device as specified in Section 12.2.

Fig 11. Mode 1: self-powered hub; ganged port power switching; global overcurrent detection.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 27 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 28

Philips Semiconductors

ISP1122

USB stand-alone hub

handbook, full pagewidth

upstream

port

V

BUS

D+

D−

GND

SHIELD

V

CC

GND

PSW5/GL5/GPSW

INDV

SP/BP

OPTION

ISP1122

+4.50 V(min)

330 kΩ

PSW1/GL1

PSW2/GL2

PSW3/GL3

PSW4/GL4

OC1

OC2

OC3

OC4

OC5/GOC

(4×)

0.1 µF

10 kΩ

0.1 µF

10 kΩ

0.1 µF

10 kΩ

0.1 µF

10 kΩ

low-ohmic

PMOS switch

low-ohmic

PMOS switch

low-ohmic

PMOS switch

low-ohmic

PMOS switch

downstream

(min)

(min)

(min)

(min)

ports

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

MGR786

1

2

3

4

ferrite bead

1

2

3

4

+4.40 V

120

µF

ferrite bead

+4.40 V

120

µF

ferrite bead

+4.40 V

120

µF

ferrite bead

+4.40 V

120

µF

Power switches 1 to 4 are low-ohmic PMOS devices as specified in Section 12.2.

Fig 12. Mode 4: bus-powered hub; individual port power switching; individual overcurrent detection.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 28 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 29

Philips Semiconductors

ISP1122

USB stand-alone hub

handbook, full pagewidth

upstream

port

V

BUS

D+

D−

GND

SHIELD

V

CC

GND

PSW5/GL5/GPSW

INDV

SP/BP

OPTION

ISP1122

+4.50 V(min)

PSW1/GL1

PSW2/GL2

PSW3/GL3

PSW4/GL4

OC1

OC2

OC3

OC4

OC5/GOC

330

kΩ

0.1 µF

10 kΩ

low-ohmic

PMOS switch

ferrite bead

+4.40 V

120

µF

ferrite bead

+4.40 V

120

µF

ferrite bead

+4.40 V

120

µF

ferrite bead

+4.40 V

120

µF

(min)

(min)

(min)

(min)

downstream

ports

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

V

BUS

D+

D−

GND

SHIELD

MGR787

1

2

3

4

Power switch is low-ohmic PMOS device as specified in Section 12.2.

Fig 13. Mode 0: bus-powered hub; ganged port power switching; global overcurrent detection.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 29 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 30

Philips Semiconductors

ISP1122

USB stand-alone hub

13. Limiting values

Table 24: Absolute maximum ratings

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

CC

V

I

I

latchup

V

esd

T

stg

P

tot

[1] Equivalent to discharging a 100 pF capacitor via a 1.5 kΩ resistor.

[2] Values are given for device only; in-circuit V

[3] For open-drain pins V

Table 25: Recommended operating conditions

Symbol Parameter Conditions Min Max Unit

V

CC

V

I

V

I(AI/O)

V

O(od)

T

amb

supply voltage −0.5 +6.0 V

input voltage −0.5 VCC+ 0.5 V

latchup current VI< 0 or VI>V

electrostatic discharge voltage ILI<15µA

CC

- 200 mA

[1] [2]

- ±4000

[3]

V

storage temperature −60 +150 °C

total power dissipation - 95 mW

= ±8000 V.

esd(max)

= ±2000 V.

esd(max)

supply voltage 4.0 5.5 V

input voltage 0 5.5 V

input voltage on analog I/O pins

0 3.6 V

(D+/D−)

open-drain output pull-up voltage 0 5.5 V

operating ambient temperature −40 +85 °C

9397 750 06389

Product specification Rev. 02 — 4 October 1999 30 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 31

Philips Semiconductors

ISP1122

USB stand-alone hub

14. Static characteristics

Table 26: Static characteristics; supply pins

VCC= 4.0 to 5.5 V; V

Symbol Parameter Conditions Min Typ Max Unit

V

reg(3.3)

I

CC

) suspend supply current 1.5 kΩ pull-up on upstream

I

CC(susp

[1] In ‘suspend’ mode the minimum voltage is 2.7 V.

regulated supply voltage 3.0

operating supply current - 18 - mA

Table 27: Static characteristics: digital pins

VCC= 4.0 to 5.5 V; V

Symbol Parameter Conditions Min Typ Max Unit

Input levels

V

IL

V

IH

LOW-level input voltage - - 0.8 V

HIGH-level input voltage 2.0 - - V

Schmitt trigger inputs

V

th(LH)

positive-going threshold

voltage

V

th(HL)

negative-going threshold

voltage

V

hys

hysteresis voltage 0.4 - 0.7 V

Output levels

V

OL

LOW-level output voltage

(open drain outputs)

Leakage current

I

LI

input leakage current - - ±1 µA

Open-drain outputs

I

OZ

OFF-state output current - - ±1 µA

GND

GND

=0V; T

=0V; T

=−40 to+85°C; unless otherwise specified.

amb

port D+ (pin DP0)

no pull-up on upstream port

D+ (pin DP0)

=−40 to+85°C; unless otherwise specified.

amb

IOL= 6 mA - - 0.4 V

=20µA - - 0.1 V

I

OL

[1]

3.3 3.6 V

- - 270 µA

--80µA

1.4 - 1.9 V

0.9 - 1.5 V

Table 28: Static characteristics: overcurrent sense pins

VCC= 4.0 to 5.5 V; V

GND

=0V; T

=−40 to+85°C; unless otherwise specified.

amb

Symbol Parameter Conditions Min Typ Max Unit

∆V

trip

[1] Bus-powered mode.

[2] Self-powered or hybrid-powered mode.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 31 of 48

overcurrent detection

trip voltage on

OCn pins

∆V=V

∆V=V

CC

SP/BP

− V

OCn

− V

OCn

[1]

65 85 105 mV

[2]

© Philips Electronics N.V. 1999. All rights reserved.

Page 32

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 29: Static characteristics: analog I/O pins (D+, D−)

VCC= 4.0 to 5.5 V; V

GND

=0V; T

=−40 to+85°C; unless otherwise specified.

amb

[1]

Symbol Parameter Conditions Min Typ Max Unit

Input levels

V

DI

V

CM

differential input sensitivity |V

differential common mode

− V

I(D+)

| 0.2 - - V

I(D−)

includes VDI range 0.8 - 2.5 V

voltage

V

IL

V

IH

LOW-level input voltage - - 0.8 V

HIGH-level input voltage 2.0 - - V

Output levels

V

OL

V

OH

LOW-level output voltage RL= 1.5 kΩ to +3.6V - - 0.3 V

HIGH-level output voltage RL=15kΩ to GND 2.8 - 3.6 V

Leakage current

I

LZ

OFF-state leakage current - - ±10 µA

Capacitance

C

IN

transceiver capacitance pin to GND - - 20 pF

Resistance

[2]

Z

DRV

Z

INP

driver output impedance steady-state drive 28 - 44 Ω

input impedance 10 - - MΩ

Termination

V

TERM

[3]

termination voltage for

upstream port pull-up (R

PU

)

3.0

[4]

- 3.6 V

[1] D+ is the USB positive data pin (DPn); D− is the USB negative data pin (DMn).

[2] Includes external resistors of 20 Ω±1% on both D+ and D−.

[3] This voltage is available at pin V

[4] In ‘suspend’ mode the minimum voltage is 2.7 V.

reg(3.3)

.

15. Dynamic characteristics

Table 30: Dynamic characteristics

VCC= 4.0 to 5.5 V; V

Symbol Parameter Conditions Min Typ Max Unit

Reset

t

W(RESET)

pulse width on input RESET crystal oscillator running 10 - - µs

Crystal oscillator

f

XTAL

[1] Dependent on the crystal oscillator start-up time.

crystal frequency - 6 - MHz

GND

=0V; T

=−40 to+85°C; unless otherwise specified.

amb

crystal oscillator stopped - 2

[1]

-ms

9397 750 06389

Product specification Rev. 02 — 4 October 1999 32 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 33

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 31: Dynamic characteristics: overcurrent sense pins

VCC= 4.0 to 5.5 V; V

Symbol Parameter Conditions Min Typ Max Unit

t

trip

overcurrent trip response time

from

[1] Operating modes 0, 1, 4 and 5; see Table 4.

GND

=0V; T

=−40 to+85°C; unless otherwise specified.

amb

OCn LOW to PSWn HIGH

see Figure 14

[1]

--15ms

Table 32: Dynamic characteristics: analog I/O pins (D+, D−); full-speed mode

VCC= 4.0 to 5.5 V; V

GND

=0V;T

=−40 to+85°C; CL= 50 pF; RPU= 1.5 kΩon D+to V

amb

[1]

.; unless otherwise specified.

TERM

Symbol Parameter Conditions Min Typ Max Unit

Driver characteristics

t

FR

t

FF

rise time CL=50pF;

fall time CL=50pF;

FRFM differential rise/fall time

V

CRS

matching (t

output signal crossover voltage

FR/tFF

)

10 to 90% of |V

10 to 90% of |V

OH

OH

− VOL|

− VOL|

4 - 20 ns

4 - 20 ns

[2]

90 - 111.11 %

[2] [3]

1.3 - 2.0 V

Data source timing

t

DJ1

source differential jitter for

see Figure 15

[2] [3]

−3.5 - +3.5 ns

consecutive transitions

t

DJ2

source differential jitter for

see Figure 15

[2] [3]

−4- +4ns

paired transitions

t

FEOPT

t

FDEOP

source EOP width see Figure 16

sourcedifferentialdata-to-EOP

see Figure 16

[3]

160 - 175 ns

[3]

−2- +5ns

transition skew

Receiver timing

t

JR1

receiverdata jitter tolerance for

see Figure 17

[3]

−18.5 - +18.5 ns

consecutive transitions

t

JR2

receiverdata jitter tolerance for

see Figure 17

[3]

−9- +9ns

paired transitions

t

FEOPR

receiver SE0 width accepted as EOP;

[3]

82--ns

see Figure 16

t

FST

width of SE0 during differential

transition

rejected as EOP;

see Figure 18

[3]

--14ns

Hub timing (downstream ports configured as full-speed)

t

FHDD

t

FSOP

hub differential data delay

(without cable)

data bit width distortion after

see Figure 19;

=0pF

C

L

see Figure 19

[3]

--44ns

[3]

−5- +5ns

SOP

t

FEOPD

t

FHESK

hub EOP delay relative to t

HDD

see Figure 20

hub EOP output width skew see Figure 20

[3]

0 - 15 ns

[3]

−15 - +15 ns

[1] Test circuit: see Figure 22.

[2] Excluding the first transition from Idle state.

[3] Characterized only, not tested. Limits guaranteed by design.

9397 750 06389

Product specification Rev. 02 — 4 October 1999 33 of 48

© Philips Electronics N.V. 1999. All rights reserved.

Page 34

Philips Semiconductors

ISP1122

USB stand-alone hub

Table 33: Dynamic characteristics: analog I/O pins (D+, D−); low-speed mode

VCC= 4.0 to 5.5 V; V

GND

=0V;T

=−40 to+85°C; CL= 50 pF; RPU= 1.5 kΩon D−to V

amb

[1]

; unless otherwise specified.

TERM

Symbol Parameter Conditions Min Typ Max Unit

Driver characteristics

t

LR

t

LF

rise time CL= 200 to 600 pF;

fall time CL= 200 to 600 pF;

LRFM differential rise/fall time

V

CRS

matching (t

output signal crossover voltage

LR/tLF

)

10 to 90% of |V

10 to 90% of |V

OH

OH

− VOL|

− VOL|

75 - 300 ns

75 - 300 ns

[2]

80 - 125 %

[2] [3]

1.3 - 2.0 V