Page 1

®

ISO175

Precision, Isolated

INSTRUMENT ATION AMPLIFIER

ISO175

FEATURES

● RATED

1500Vrms Continuous

2500Vrms for One Minute

100% TESTED FOR PARTIAL DISCHARGE

● HIGH IMR: 115dB at 50Hz

● LOW NONLINEARITY:

±0.01%

● LOW INPUT BIAS CURRENT: 10nA max

● LOW INPUT OFFSET VOLTAGE: 101mV max

● INPUTS PROTECTED TO

● BIPOLAR OPERATION: V

±40V

= ±10V

O

● SYNCHRONIZATION CAPABILITY

● 24-PIN PLASTIC DIP: 0.3" Wide

APPLICATIONS

● INDUSTRIAL PROCESS CONTROL

Transducer Isolator, Thermocouple

Isolator, RTD Isolator, Pressure Bridge

Isolator, Flow Meter Isolator

● POWER MONITORING

● MEDICAL INSTRUMENTATION

● ANALYTICAL MEASUREMENTS

● BIOMEDICAL MEASUREMENTS

● DATA ACQUISITION

● TEST EQUIPMENT

● POWER MONITORING

● GROUND LOOP ELIMINATION

V

1

IN–

R

22

G

2

R

G

24

V

IN+

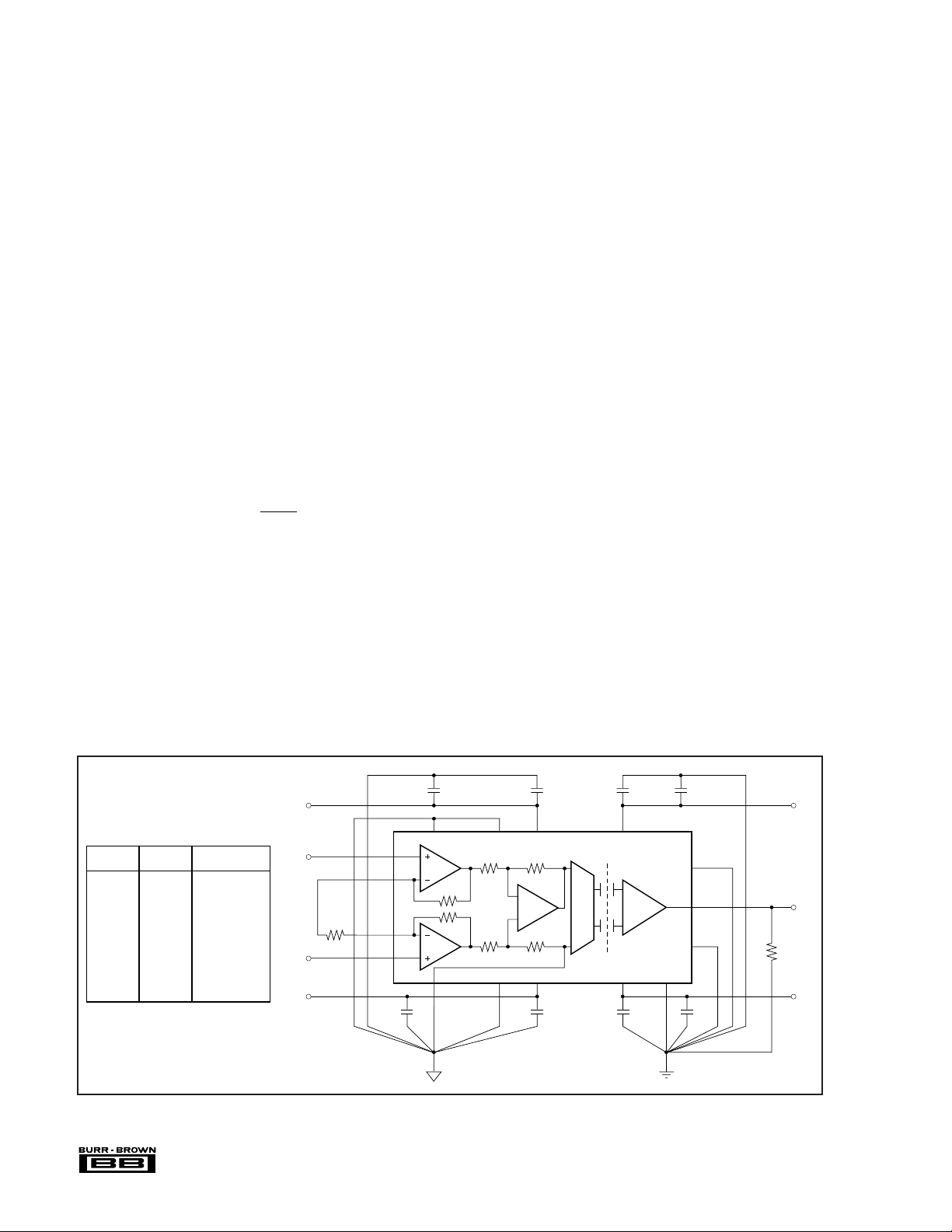

DESCRIPTION

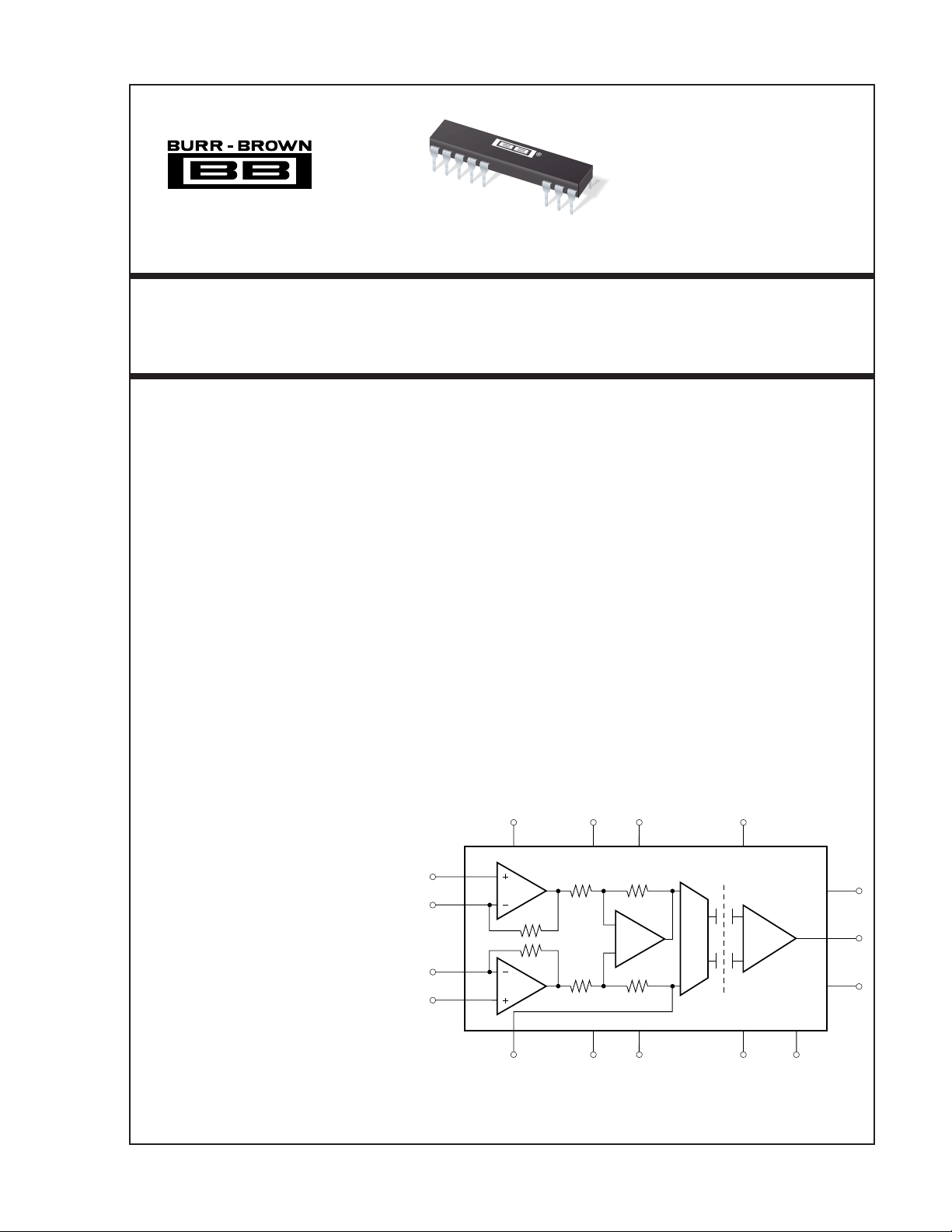

ISO175 is a precision isolated instrumentation amplifier incorporating a novel duty cycle modulationdemodulation technique and excellent accuracy. A

single external resistor sets the gain. Internal input

protection can withstand up to ±40V without damage.

The signal is transmitted digitally across a differential

capacitive barrier. With digital modulation the barrier

characteristics do not affect signal integrity. This results in excellent reliability and good high frequency

transient immunity across the barrier. Both the amplifier and barrier capacitors are housed in a plastic DIP.

ISO175 is easy to use. A power supply range of ±4.5V

to ±18V makes this amplifier ideal for a wide range of

applications.

5214 15

Shield 1 Ext Osc +V

S1

+V

S2

Shield 2

V

OUT

Com2

14

11

10

Com1

23 20 3 13 12

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111 • Twx: 910-952-1111

Internet: http://www.burr-brown.com/ • FAXLine: (800) 548-6133 (US/Canada Only) • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

©

1996 Burr-Brown Corporation PDS-1293A Printed in U.S.A. May, 1996

GND1 –V

S1

–V

GND2

S2

Page 2

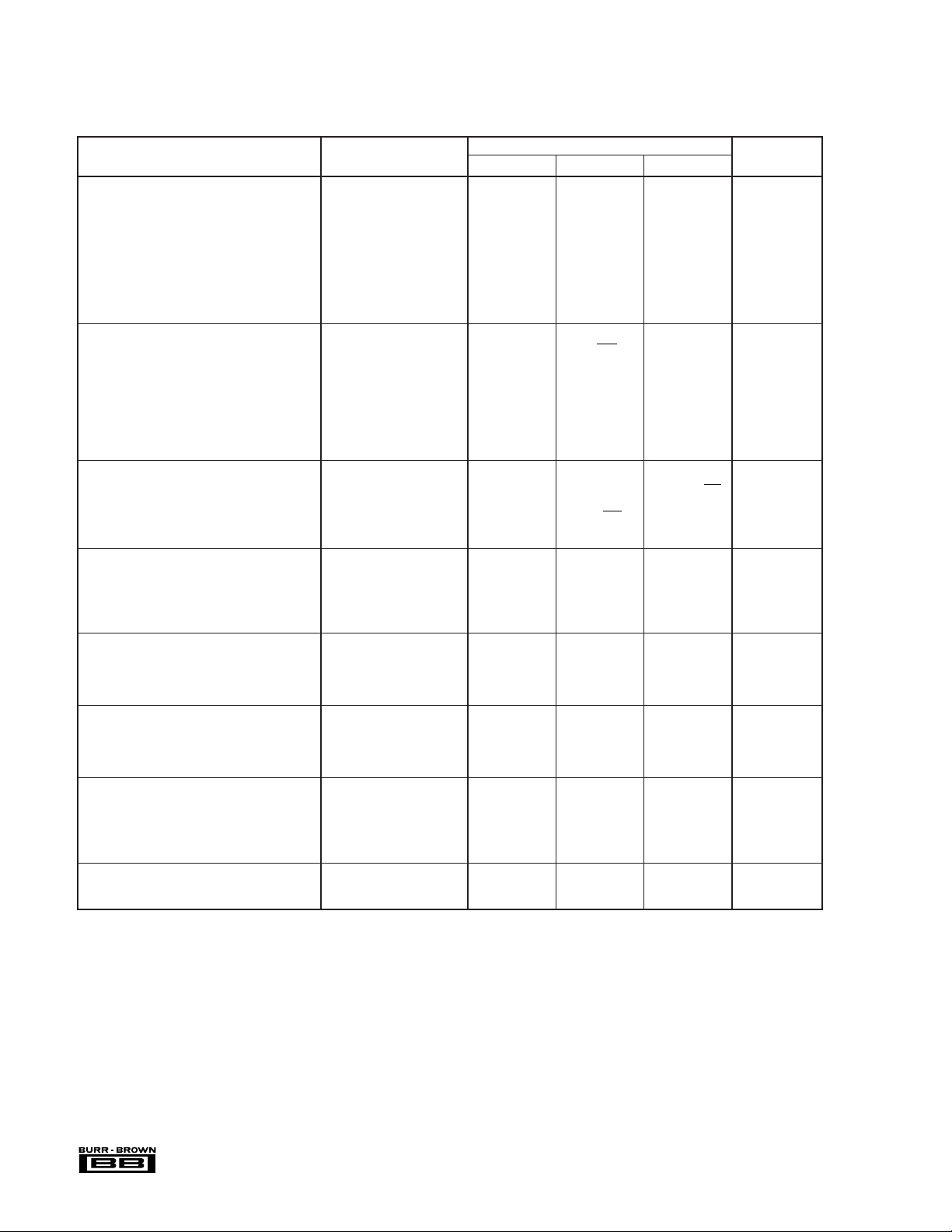

SPECIFICATIONS

At TA = +25°C, VS1 = VS2 = ±15V, and RL = 2kΩ unless otherwise noted.

ISO175P

PARAMETER CONDITIONS MIN TYP MAX UNITS

ISOLATION

Voltage Rated Continuous:

AC T

DC T

100% Test (AC, 50Hz) 1s; Partial Discharge ≤ 5pC 2500 Vrms

Isolation-Mode Rejection

AC 50Hz 1500Vrms 115 dB

DC 160 dB

Barrier Impedance 10

Leakage Current VISO = 240Vrms, 50Hz 0.8 1 µArms

GAIN

Gain Error G = 1 ±0.35 %

Gain vs Temperature G = 1 ±11 ppm/°C

Nonlinearity G = 1 ±0.102 %

INPUT OFFSET VOLTAGE

Initial Offset G = 1, 100 mV

vs Temperature µV/°C

vs Supply G = 1 ±2 mV/V

INPUT

Voltage Range ±10 V

Bias Current ±10 nA

vs Temperature ±40 pA/°C

Offset Current ±10 nA

vs Temperature ±40 pA/°C

OUTPUT

Voltage Range ±10 V

Current Drive ±5mA

Capacitive Load Drive 0.1 µF

Ripple Voltage 10 mVp-p

FREQUENCY RESPONSE

Small Signal Bandwidth G = 1 60 kHz

Slew Rate V

POWER SUPPLIES

Rated Voltage 15 V

Voltage Range ±4.5 ±18 V

Quiescent Current

V

V

TEMPERATURE RANGE

Operating –40 85 °C

Storage –40 125 °C

NOTE: (1) All devices receive a 1s test. Failure criterion is ≥ 5 pulses of ≥ 5pc.

(1)

MIN

MIN

to T

to T

MAX

MAX

1500 Vrms

2121 VDC

14

|| 6 Ω || pF

50k

1+

R

G

V/V

G = 10 ±0.07 %

G = 100 ±0.95 %

G = 10 ±0.04 %

G = 100 ±0.104 %

101

± 1+

520

G

± 0.125 +

G

G = 10 60 kHz

G = 100 50 kHz

= ±10V, G = 10 0.9 V/µs

O

S1

S2

±7.4 mA

±7.5 mA

®

ISO175

2

Page 3

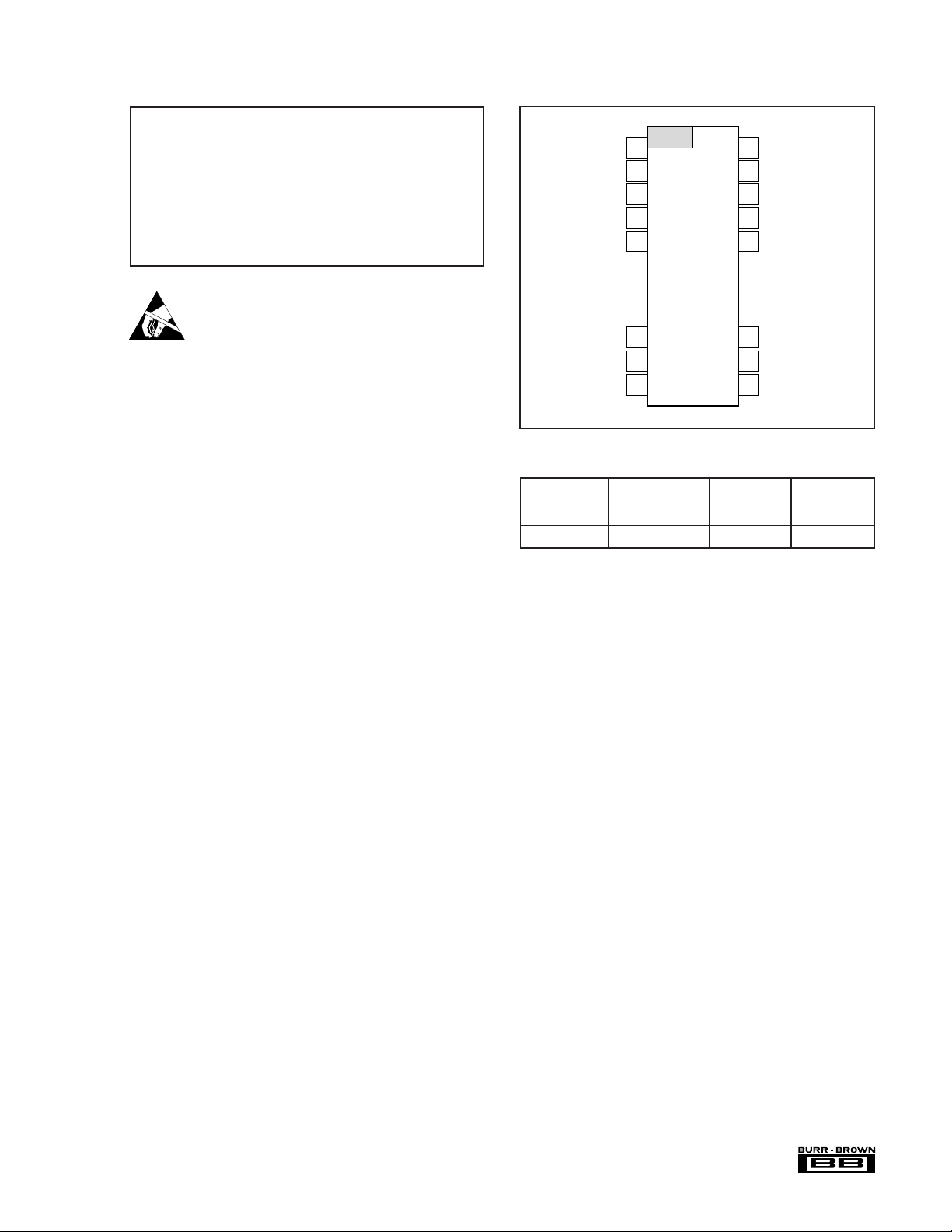

V

S1–

V

S1+

Shield 1

Com 2

V

OUT

GND 2

R

G

EXT OSC

GND 1

V

S2+

Shield 2

V

S2–

R

G

Com 1

V

IN–

1

2

3

4

5

10

11

12

24

23

22

21

20

15

14

13

V

IN+

ABSOLUTE MAXIMUM RATINGS

Supply Voltage................................................................................... ±18V

Analog Input Voltage Range .............................................................. ±40V

External Oscillator Input..................................................................... ±25V

Com 1 to GND1 ................................................................................... ±1V

Com 2 to GND2 ................................................................................... ±1V

Continuous Isolation Voltage: ....................................................1500Vrms

IMV, dv/dt...................................................................................... 20kV/µs

Junction Temperature ...................................................................... 150°C

Storage Temperature...................................................... –40°C to +125°C

Lead Temperature (soldering, 10s)................................................ +300°C

Output Short Duration .......................................... Continuous to Common

ELECTROSTATIC

DISCHARGE SENSITIVITY

Any integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet

published specifications.

PIN CONFIGURATION

PACKAGE/ORDERING INFORMATION

PACKAGE

DRAWING

PRODUCT PACKAGE NUMBER

ISO175P 24-Pin Plastic DIP 243-2 60kHz

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix C of Burr-Brown IC Data Book.

(1)

BANDWIDTH

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user's own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

3

ISO175

®

Page 4

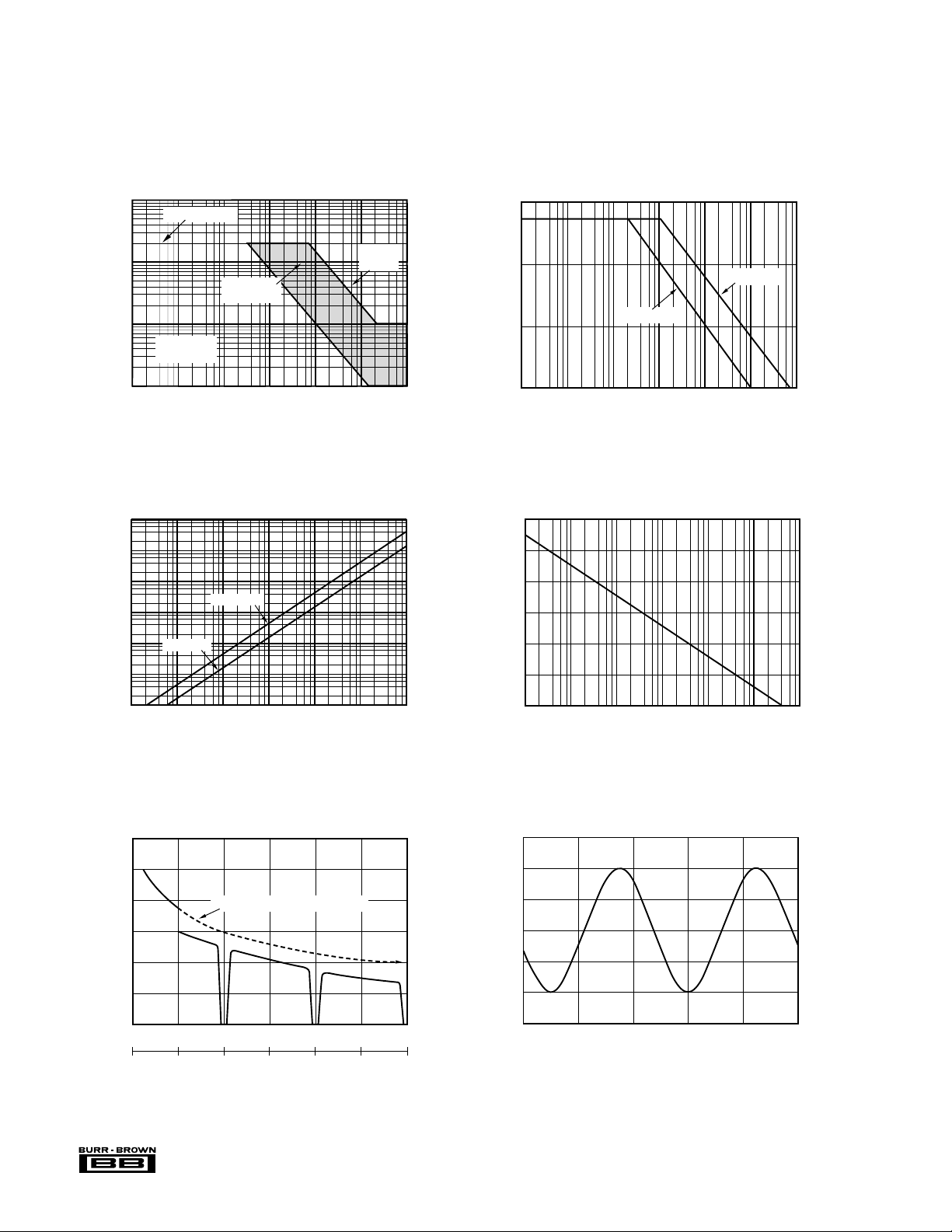

TYPICAL PERFORMANCE CURVES

At TA = +25°C, VS1 = VS2 = ±15V, and RL = 2kΩ, unless otherwise noted.

ISOLATION MODE VOLTAGE

vs FREQUENCY

Max DC Rating

2k

1k

100

Peak Isolation Voltage

Typical

Performance

Degraded

Performance

Max AC

Rating

60

54

40

PSRR (dB)

20

PSRR vs FREQUENCY

–VS1, –V

S2

+VS1, +V

S2

10

100

1k 100k 10M

100mA

10mA

1mA

100µA

10µA

Leakage Current (rms)

1µA

240 Vrms

0.1µA

1

SIGNAL RESPONSE vs CARRIER FREQUENCY

10k 1M 100M

Frequency (Hz)

ISOLATION LEAKAGE CURRENT

vs FREQUENCY

1500 Vrms

100 10k 1M10 1k 100k

Frequency (Hz)

0

160

140

120

100

IMR (dB)

80

60

40

15

1

100 10k 1M

10 1k 100k

Frequency (Hz)

IMR vs FREQUENCY

1

100 10k 1M10 1k 100k

Frequency (Hz)

SINE RESPONSE ISO175

(f = 2kHz, Gain = 10)

0

(dB)

IN

–20

/V

OUT

V

–40

0

(Hz)

f

IN

f

(Hz)

0000f

OUT

®

–20dB/dec (for comparison only)

f

C

/2 fC/2 fC/2

c

2f

C

ISO175

10

5

0

–5

Output Voltage (V)

–10

–15

3f

C

0

400 1000200 600 800

Time (µs)

4

Page 5

GAIN vs FREQUENCY

80

60

40

20

0

–20

Gain (dB)

Frequency (Hz)

1k 10k 100k

G = 100

G = 10

G = 1

G = 1000

0

Time (µs)

10

5

0

–5

–10

–15

Output Voltage (V)

15

10

5

0

–5

–10

Input Voltage (V)

200 500100 300 400

STEP RESPONSE

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, VS1 = VS2 = ±15V, and RL = 2kΩ, unless otherwise noted.

SINE RESPONSE

15

10

5

0

–5

Output Voltage (V)

–10

–15

0

(f = 20kHz, Gain = 10)

400 1000200 600 800

Time (µs)

10

5

0

–5

–10

Output Voltage (V)

–15

0

INPUT COMMON-MODE RANGE

15

G ≥ 10

10

G = 1 G = 1

5

0

V

V

–5

Common-Mode Voltage (V)

–10

–15

–15 –10 0 5 15–5

All

Gains

STEP RESPONSE

40 10020 60 80

Time (µs)

vs OUTPUT VOLTAGE

–

D/2

+

–

D/2

+

V

CM

Output Voltage (V)

G ≥ 10

V

O

All

Gains

10

15

10

5

0

–5

Input Voltage (V)

–10

5

INPUT BIAS AND OFFSET CURRENT

vs TEMPERATURE

5

4

3

2

1

I

OS

±I

b

0

–1

–2

–3

Input Bias and Offset Current (nA)

–4

–5

–75 –50 –25 0 25 50 75 100 125

Temperature (°C)

ISO175

®

Page 6

BASIC OPERATION

ISO175 instrumentation input isolation amplifier comprises

of a precision instrumentation amplifier followed by an

isolation amplifier. The input and output isolation sections

are galvanically isolated and EMI shielded by matched

capacitors.

Signal and Power Connections

Figure 1 shows power and signal connections. Each power

supply pin should be bypassed with a 1µF tantalum capacitor located as close to the amplifier as possible. All ground

connections should be run independently to a common point

if possible. Signal Common on both input and output sections provide a high-impedance point for sensing signal

ground in noisy applications. Com 1 and Com 2 must have

a path to ground for bias current return and should be

maintained within ±1V of GND1 and GND2, respectively.

SETTING THE GAIN

Gain of the ISO175 is set by connecting a single external

resistor R

, connected between pins 2 and 22.

G

G = 1 +

50 kΩ

R

G

(1)

Commonly used gains and resistor values are shown in

Figure 1.

The 50kΩ term in equation (1) comes from the sum of the

two internal feedback resistors. These on-chip metal film

resistors are laser trimmed to accurate absolute values. The

accuracy and temperature coefficient of this resistor are

included in the gain accuracy and drift specifications of the

ISO175.

The stability and temperature drift of the external gain

setting resistor R

, also affects gain. RG’s contribution to

G

gain accuracy and drift can be directly inferred from the

gain equation (1). Low resistor values required for high

gain can make wiring resistance important. Sockets add to

the wiring resistance which will contribute additional gain

error (possibly an unstable gain error) in gains of approximately 100 or greater.

INPUT COMMON-MODE RANGE

The linear voltage range of the input circuitry of the ISO175

is from approximately 2.5V below the positive supply voltage to 2.5V above the negative supply. As a differential

input voltage causes the output voltage to increase, however,

the linear input range will be limited by the output voltage

swing of the internal amplifiers. Thus, the linear commonmode input range is related to the output voltage of the

complete input amplifier.

This behavior also depends on the supply voltage—see

performance curves “Input Common-Mode Range vs Output Voltage.”

Input-overload can produce an output voltage that appears

normal. For example, if an input overload condition drives

both input amplifiers to their positive output swing limit, the

difference voltage measured by the output amplifier will be

near zero. The output of the ISO175 will be near 0V even

though both inputs are overloaded.

INPUT PROTECTION

The input of the ISO175 is individually protected for voltages up to ±40V referenced to GND1. For example, a

condition of –40V on one input and +40V on the other input

will not cause damage. Internal circuitry on each input

provides low series impedance under normal signal conditions. To provide equivalent protection, series input resistors

would contribute excessive noise. If the input is overloaded,

DESIRED

GAIN

1

2

8

10

20

50

100

200

500

1000

2000

6000

10000

NOTE: (1) No Connection.

R

(Ω)

NC

50.00k

12.50k

5.556k

2.632k

1.02k

505.1

251.2

100.2

50.05

25.01

10.00

5.001

G

(1)

NEAREST 1% R

(Ω)

(1)

NC

49.9k

12.4k

5.62k

2.61k

1.02k

511

249

100

49.9

24.9

10

4.99

FIGURE 1. Basic Connections.

®

ISO175

+V

S1

V

G

IN–

R

G

V

IN+

–V

S1

1

22

2

24

0.1µF

0.1µF 1µF

521

Shield 1 Ext Osc +V

Com 1

23 20 3 13 12

GND 1

+

415

S1

–V

S1

1µF

+

1µF 0.1µF

+

+V

S2

–V

GND 2

S2

1µF

+

Shield 2

V

Com2

+V

S2

14

11

OUT

10

0.1µF

V

OUT

R

LOAD

–V

S2

6

Page 7

the protection circuitry limits the input current to a safe

value of approximately 1.5 to 5mA. The inputs are protected

even if the power supplies are disconnected or turned off.

SYNCHRONIZED OPERATION

ISO175 can be synchronized to an external signal source.

This capability is useful in eliminating troublesome beat

frequencies in multichannel systems and in rejecting AC

signals and their harmonics. To use this feature, an external

signal must be applied to the Ext Osc pin. ISO175 can be

synchronized over the 400kHz to 700kHz range.

The ideal external clock signal for the ISO175 is a ±4V sine

wave or ±4V, 50% duty-cycle triangle wave. The Ext Osc

pin of the ISO175 can be driven directly with a ±3V to ±5V

sine or 25% to 75% duty-cycle triangle wave and the ISO

amp’s internal modulator/demodulator circuitry will synchronize to the signal.

ISO175 can also be synchronized to a 400kHz to 700kHz

Square-Wave External Clock since an internal clamp and

filter provide signal conditioning. A square-wave signal of

25% to 75% duty cycle, and ±3V to ±20V level can be used

to directly drive the ISO175.

With the addition of the signal conditioning circuit shown in

Figure 2, any 10% to 90% duty-cycle square-wave signal

can be used to drive the ISO175 Ext Osc pin. With the values

shown, the circuit can be driven by a 4Vp-p TTL signal. For

a higher or lower voltage input, increase or decrease the 1kΩ

resistor, R

(8Vp-p) R

, proportionally, e.g. for a ±4V square-wave

X

should be increased to 2kΩ. The value of C

X

used in the Figure 2 circuit depends on the frequency of the

external clock signal. C

1µF

Sq Wave In

should be 30pF for ISO175.

X

10kΩ

C

R

1kΩ

X

X

OPA602

Triangle Out

ISO175

Ext Osc

generates an output signal component that varies in both

amplitude and frequency, as shown by the lower curve. The

lower horizontal scale shows the periodic variation in the

frequency of the output component. Note that at the carrier

frequency and its harmonics, both the frequency and amplitude of the response go to zero. These characteristics can be

exploited in certain applications.

It should be noted that for the ISO175, the carrier frequency

is nominally 500kHz and the –3dB point of the amplifier is

60kHz. Spurious signals at the output are not significant

under these circumstances unless the input signal contains

significant components above 250kHz.

When periodic noise from external sources such as system

clocks and DC/DC converters are a problem, ISO175 can

be used to reject this noise. The amplifier can be synchronized to an external frequency source, f

EXT

amplifier response curve at one of the frequency and

amplitude nulls indicated in the “Signal Response vs Carrier Frequency” performance curve. Figure 3 shows circuitry with opto-isolation suitable for driving the Ext Osc

input from TTL levels.

+15V+5V

200Ω

X

TTL

f

IN

3

6N136

2.5kΩ

C

82

2.5kΩ

6

10kΩ

5

= 10 X C1, with a minimum 10nF

C

2

2

C

1

140E-6

C1 = – 350pF

()

FIGURE 3. Synchronization with Isolated Drive Circuit for

Ext Osc Pin.

, placing the

Ext Osc on

ISO175

(Pin 21)

f

IN

FIGURE 2. Square-Wave to Triangle Wave Signal Condi-

tioner for Driving ISO175 Ext Osc Pin.

CARRIER FREQUENCY CONSIDERATIONS

ISO175 amplifier transmit the signal across the ISO-barrier

by a duty-cycle modulation technique. This system works

like any linear amplifier for input signals having frequencies

below one half the carrier frequency, f

cies above f

/2, the behavior becomes more complex. The

C

. For signal frequen-

C

“Signal Response vs Carrier Frequency” performance curve

describes this behavior graphically. The upper curve illustrates the response for input signals varying from DC to

fC/2. At input frequencies at or above fC/2, the device

ISOLATION MODE VOLTAGE

Isolation Mode Voltage (IMV) is the voltage appearing

between isolated grounds GND1 and GND2. The IMV can

induce errors at the output as indicated by the plots of IMV

versus Frequency. It should be noted that if the IMV frequency exceeds f

/2, the output will display spurious out-

C

puts in a manner similar to that described above, and the

amplifier response will be identical to that shown in the

“Signal Response vs Carrier Frequency” performance curve.

This occurs because IMV-induced errors behave like inputreferred error signals. To predict the total IMR, divide the

isolation voltage by the IMR shown in “IMR vs Frequency”

performance curve and compute the amplifier response to

this input-referred error signal from the data given in the

“Signal Response vs Carrier Frequency” performance curve.

7

ISO175

®

Page 8

Due to effects of very high-frequency signals, typical IMV

performance can be achieved only when dV/dT of the

isolation mode voltage falls below 1000V/µs. For convenience, this is plotted in the typical performance curve

for the ISO175 as a function of voltage and frequency for

sinusoidal voltages. When dV/dT exceeds 1000V/µs but

falls below 20kV/µs, performance may be degraded. At rates

of change above 20kV/µs, the amplifier may be damaged,

but the barrier retains its full integrity. Lowering the power

supply voltages below ±15V may decrease the dV/dT to

500V/µs for typical performance, but the maximum dV/dT

of 20kV/µs remains unchanged.

Leakage current is determined solely by the impedance of

the barrier capacitance and is plotted in the “Isolation Leakage Current vs Frequency” curve.

ISOLATION VOLTAGE RATINGS

Because a long-term test is impractical in a manufacturing

situation, the generally accepted practice is to perform a

production test at a higher voltage for some shorter time.

The relationship between actual test voltage and the continuous derated maximum specification is an important one.

Historically, Burr-Brown has chosen a deliberately conservative one: VTEST = (2 x ACrms continuous rating) +

1000V for 10 seconds, followed by a test at rated ACrms

voltage for one minute. This choice was appropriate for

conditions where system transients are not well defined.

Recent improvements in high-voltage stress testing have

produced a more meaningful test for determining maximum

permissible voltage ratings, and Burr-Brown has chosen to

apply this new technology in the manufacture and testing of

the ISO175.

PARTIAL DISCHARGE

When an insulation defect such as a void occurs within an

insulation system, the defect will display localized corona or

ionization during exposure to high-voltage stress. This ionization requires a higher applied voltage to start the

discharge and lower voltage to maintain it or extinguish it

once started. The higher start voltage is known as the

inception voltage, while the extinction voltage is that level

of voltage stress at which the discharge ceases. Just as the

total insulation system has an inception voltage, so do the

individual voids. A voltage will build up across a void until

its inception voltage is reached, at which point the void will

ionize, effectively shorting itself out. This action redistributes electrical charge within the dielectric and is known as

partial discharge. If, as is the case with AC, the applied

voltage gradient across the device continues to rise, another

partial discharge cycle begins. The importance of this

phenomenon is that, if the discharge does not occur, the

insulation system retains its integrity. If the discharge

begins, and is allowed to continue, the action of the ions and

electrons within the defect will eventually degrade any

organic insulation system in which they occur. The measurement of partial discharge is still useful in rating the devices

and providing quality control of the manufacturing process.

The inception voltage for these voids tends to be constant, so

that the measurement of total charge being redistributed

within the dielectric is a very good indicator of the size of the

voids and their likelihood of becoming an incipient failure.

The bulk inception voltage, on the other hand, varies with

the insulation system, and the number of ionization defects

and directly establishes the absolute maximum voltage (transient) that can be applied across the test device before

destructive partial discharge can begin. Measuring the bulk

extinction voltage provides a lower, more conservative voltage from which to derive a safe continuous rating. In

production, measuring at a level somewhat below the expected inception voltage and then derating by a factor

related to expectations about system transients is an accepted practice.

PARTIAL DISCHARGE TESTING

Not only does this test method provide far more qualitative

information about stress-withstand levels than did previous

stress tests, but it provides quantitative measurements from

which quality assurance and control measures can be based.

Tests similar to this test have been used by some manufacturers, such as those of high-voltage power distribution

equipment, for some time, but they employed a simple

measurement of RF noise to detect ionization. This method

was not quantitative with regard to energy of the discharge,

and was not sensitive enough for small components such as

isolation amplifiers. Now, however, manufacturers of HV

test equipment have developed means to quantify partial

discharge. VDE in Germany, an acknowledged leader in

high-voltage test standards, has developed a standard test

method to apply this powerful technique. Use of partial

discharge testing is an improved method for measuring the

integrity of an isolation barrier.

To accommodate poorly-defined transients, the part under

test is exposed to voltage that is 1.6 times the continuousrated voltage and must display less than or equal to 5pC

partial discharge level in a 100% production test.

APPLICATIONS

The ISO175 isolation amplifier is used in three categories of

applications:

• Accurate isolation of signals from high voltage ground

potentials,

• Accurate isolation of signals from severe ground noise and,

• Fault protection from high voltages in analog measurements.

®

ISO175

8

Loading...

Loading...