Page 1

HA13565F

Three-Phase Brushless DC Motor Driver IC

ADE-207-226A (Z)

2nd. Edition

April 1997

Description

HA13565F is a 3-phase brushless DC motor driver IC with digital speed control. It is developed for direct

drive of the spindle motor of 5V floppy disk drives. It has the following functions and features.

Functions

• 3 sensor 1.0A/phase, 3-phase drive circuit

• Digital speed control circuit

• Sensorless index circuit

• Current limiter circuit

• Over-temperature shutdown circuit (OTSD)

• Circuit for switching between 300 and 360rpm speeds

Features

• Low saturation voltage 0.5V Typ (at 0.7A)

• Soft switching drive circuit

• Small surface mount package

Page 2

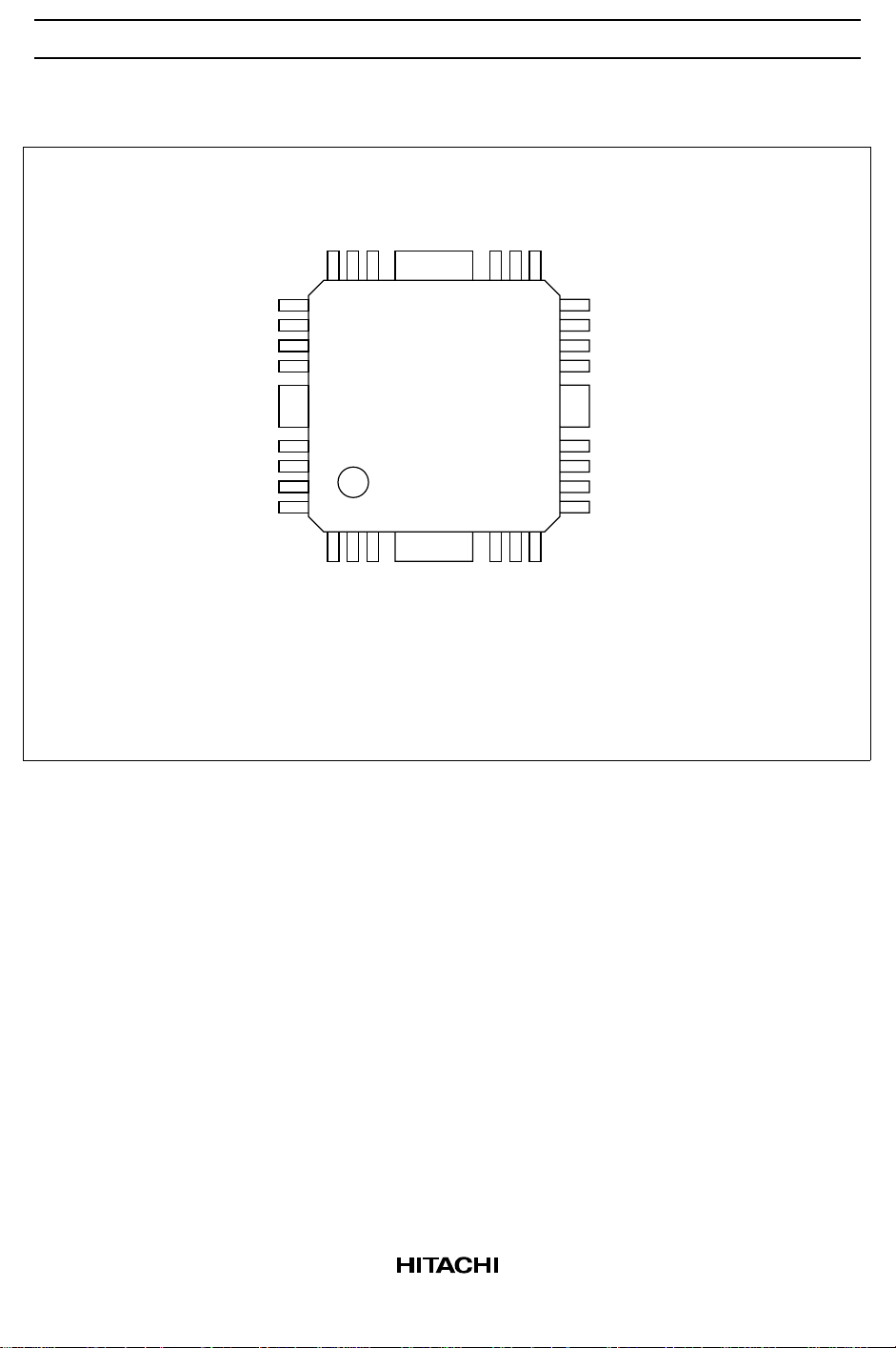

HA13565F

Pin Arrangement

CC

U(–)input

U(+)input

V

Hall bias

Bias(–)pin

Bias(+)pin

V(+)input

V(–)input

W(+)input

W(–)input

AGC

NC

NC

FG(+)input

18

19

20

21

22

23

24

TAB

25

26

27

28

123

FG(–)input

RPM control pin

TAB

TAB

Index PC

(Top view)

16 15

17

TAB

456

Index TC

Index output

14

13

12

11

10

9

8

7

CEB

Bias output

U phase output

V phase output

Current detection

W phase output

Phase compensation

Charge pump output

CLK input

2

Page 3

HA13565F

Pin Function

Pin No. Pin Name Function

1 FG (–) input FG amp. (–) input terminal

2 RPM control pin Control terminal for motor rotation speed

“H” → 360 rpm, “L” → 300 rpm

3 Index PC Connection for the time constant circuit that adjusts the index circuit Vth

level.

4 Index TC Burst setting time constant circuit for index circuit

5 Index output Index signal output terminal (Open collector)

6 CEB Chip enable terminal “H”: disable, “L”: enable

7 CLK input Reference clock input terminal

8 Charge pump output Connection for the time constant circuit that integrates the speed error

signal.

9 Phase compensation Connection for the phase compensation capacitor that stabilizes the

operation of the control system.

10 W phase output W phase output

11 Current detection Output current detection and terminal which is connected with resistor

for current limiter.

12 V phase output V phase output

13 U phase output U phase output

14 Bias output Smoothing circuit for the pumped output circuit

15 Bias (+) pin Output circuit used for bias pumping

16 Bias (–) pin Input circuit used for bias pumping

17 Hall bias Hall element bias input

18 V

19 U phase (+) input U phase (+) input terminal

20 U phase (–) input U phase (–) input terminal

21 V phase (+) input V phase (+) input terminal

22 V phase (–) input V phase (–) input terminal

23 W phase (+) input W phase (+) input terminal

24 W phase (–) input W phase (–) input terminal

25 AGC Smoothing circuit for hall amplifier output amplitude control

26 NC No connection

27 NC No connection

28 FG (–) input Index amp (+) input terminal

CC

Power supply

3

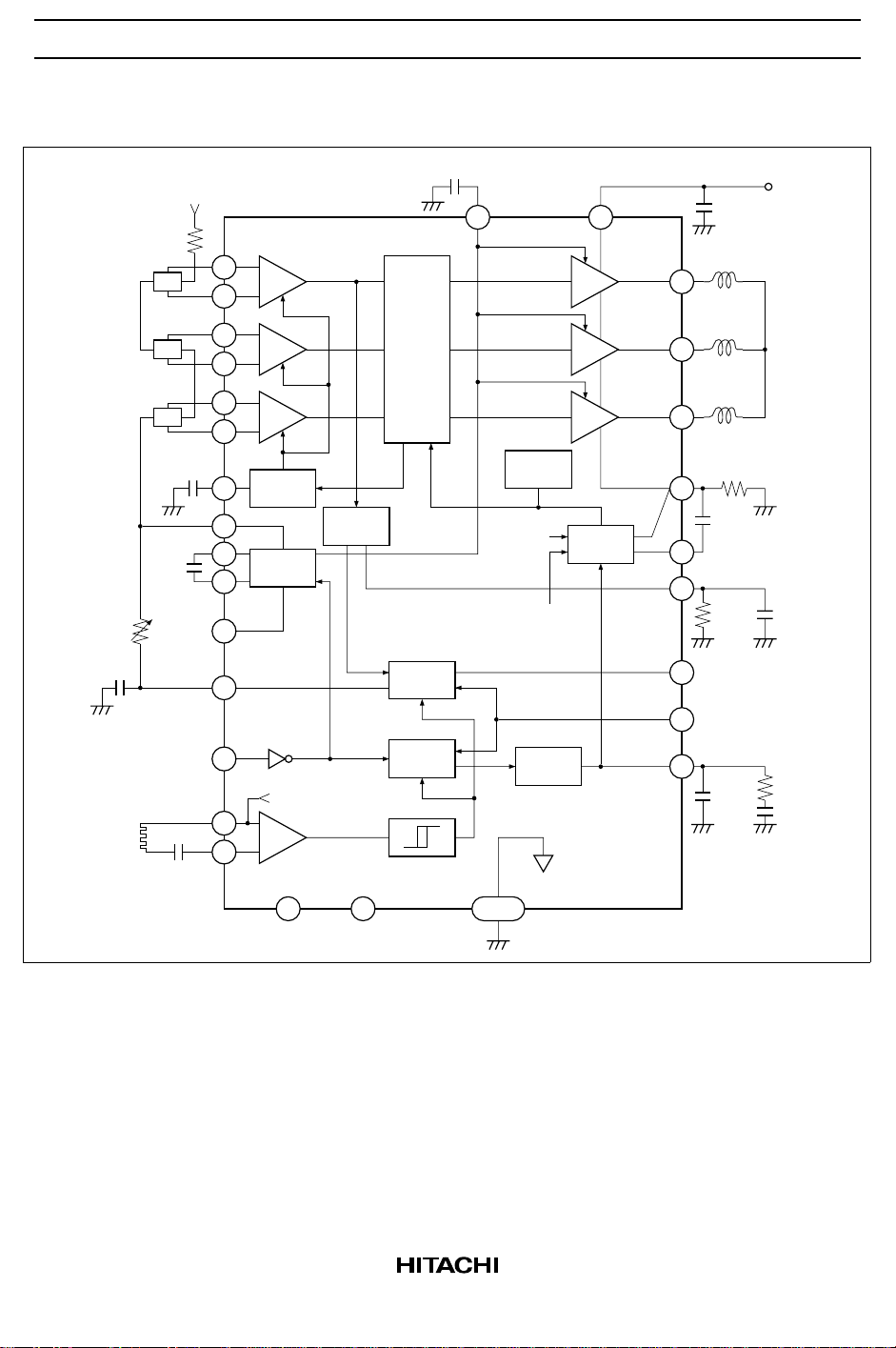

Page 4

HA13565F

Block Diagram

Rt2

Ct2

FG

60ppr

R101

Hu

Hv

Hw

C104

C103

V

CC

C102

CLK

1MHz

19

20

21

22

23

24

25

17

16

15

28

C105

1814

+

u

–

+

v

–

+

w

–

AGC

Index

detection

Bias

6CEB

4

7

1.6V

+

–

1

FG amp.

Soft

switch

matrix

Time

constant

Discrim-

inator

OTSD

Vref1

0.175V

0.63V

Charge

pump

U

V

W

Current

control

Vref2

C101

13

12

10

11

C106

9

3

5 INDEX output

RPM select

2

H : 360rpm

L : 300rpm

8

C1

Rnf

V

Ct1Rt1

R2

C2

CC

27

NC

26 TAB

NC

4

Page 5

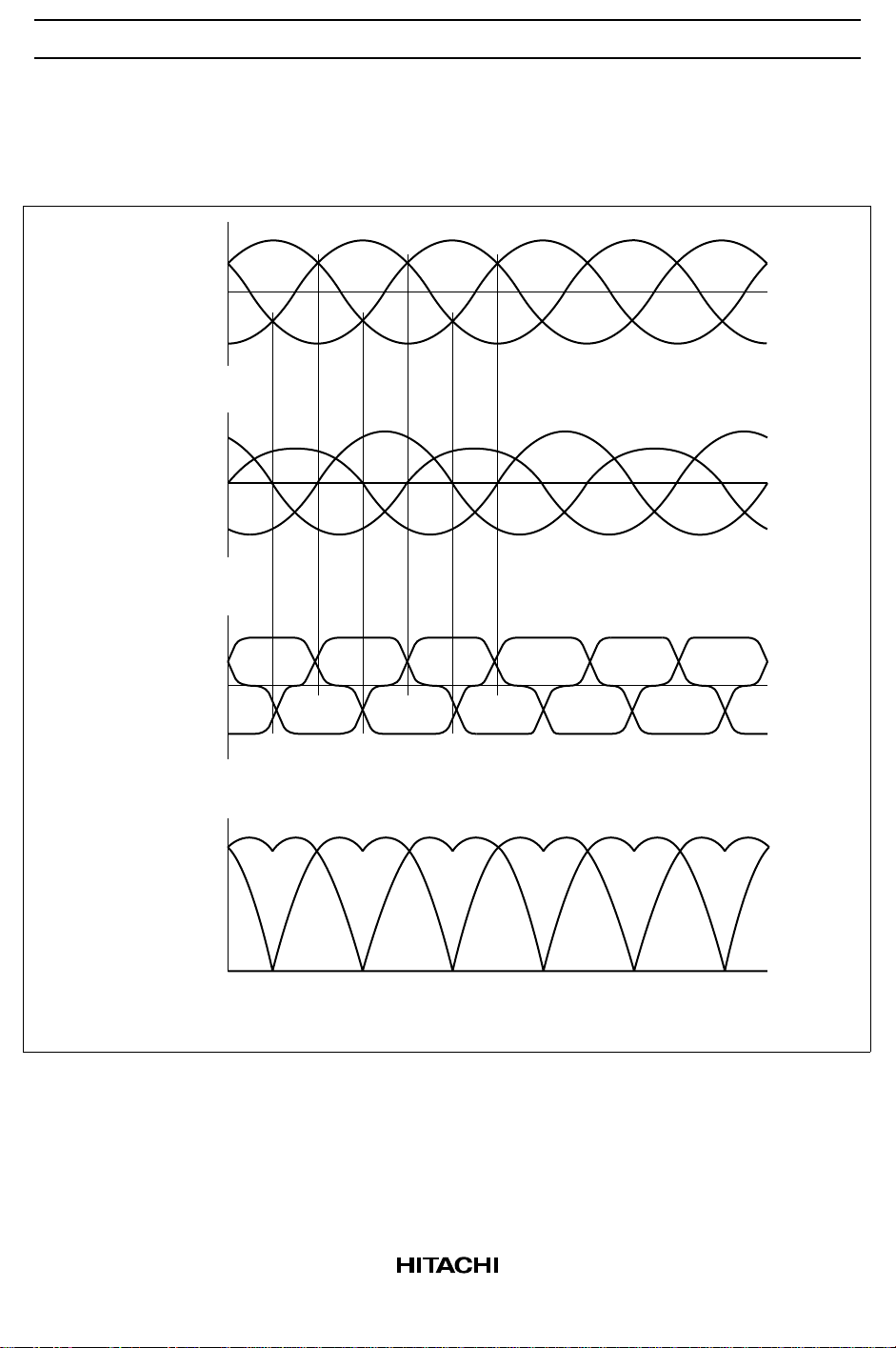

Timing Chart

Hall Amp. Input vs. Output Voltage and Current

HA13565F

B-EMF

Hall amp.

input

Output

current

U

+

0

–

U

+

0

–

UVW

+

0

–

VW

VW

UVW

Output

voltage

0

Note: 1. The input waveforms to the hall amp. should be sine waves with a third harmonic content

of less than 20%.

5

Page 6

HA13565F

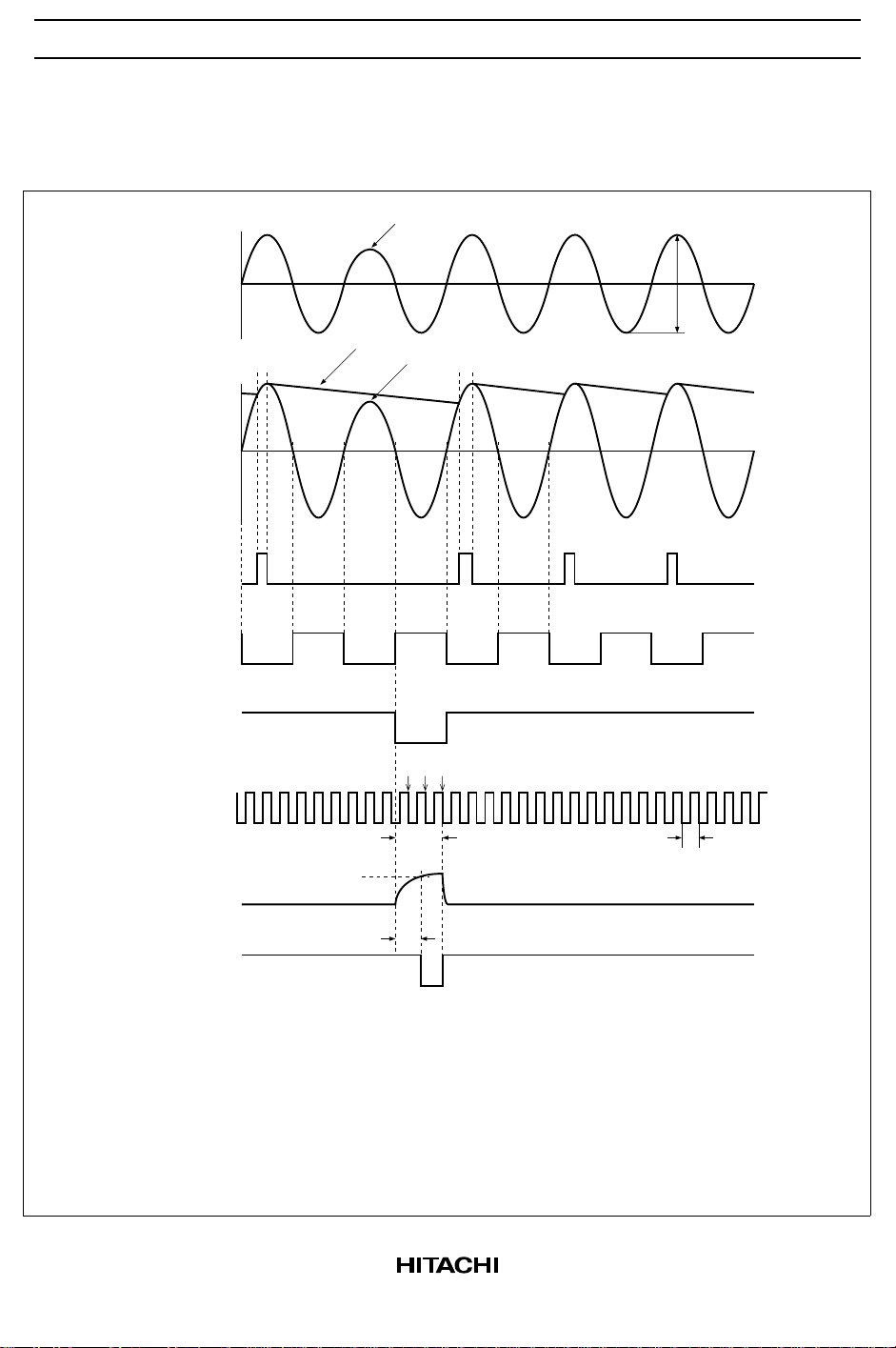

Input Detection Timing

RPM Control Pin = L

U phase hall

amp. input

Pin 19–Pin 20

Index detection

input

Index detection

output-1 *

Index detection

output-2 *

Index detection

output-3 *

2

2

2

Magnetization reduced

by 30% *

1

65 to 200mVpp

+

0

–

Pin 3

Hall amp. output *

2

+

0

–

0

0

0

FG amp.

2

output *

Index TC

Pin 4

0

6.67 to 10ms

(@300rpm) *

3

3.33ms

(@300rpm)

Vth2L

0

Burst adjustment

Index output

Pin 5

Note: 1.

To generate the index output, one pole of the main magnetization must be reduced so that

0

a difference of at least 30% is assured at the Hall amp. input.

These waveforms are shown to indicate the principles of operation, and are not actual

2.

measured waveforms.

Burst adjustment is started by the fall of the index detector output 3, and then, it ends by

3.

the third of fall of FG amp. output.

Incorrect pulses may be output immediately after (i.e., within about 200ms of) start-up.

4.

If the reduction in the magnetization is inadequate, the index signal may not be generated.

5.

Also note that excessive modulation of the Hall amp. input can cause incorrect pulses to be

generated.

6

Page 7

HA13565F

External Parts

Part No. Recommended Value Purpose Notes

R2 — Integration constant 1

R101 — Hall bias

Rnf 0.33Ω Spindle current detection and current limitation 2

Rt1 1MΩ Index circuit Vth adjustment

Rt2 — Index burst adjustment 5

C1, C2 — Integration constants 1

C101 ≥0.1µF Power supply bypass 3

C102 0.047µF AGC filter 4

C103 0.47µF FG amp. AC coupling

C104 ≥0.1µF Bias pumping

C105 ≥0.1µF Smoothing for bias pumping 6

C106 0.1µF Control amp. phase compensation

Ct1 0.1µF Index circuit Vth adjustment

Ct2 — Index burst adjustment 5

Notes: 1. Use the following formulas as a design target when determining the integration constants for

actual systems.

2π f

ω

O

R2 = (Ω)

C1 = (F)

FG

≤ (rad/S)

20

1

J ωO NO Rnf

9.55

Gctl Icp

K

T

1

101ω

R2

O

C2 = 10 C1 (F)

where,

w

: Time constant of servo loop

O

f

: FG frequency (Hz)

FG

N

: Motor speed (rpm)

O

J : Motor moment of inertia (kg · cm · s)

K

: Motor torque constant (kg · cm / A)

T

Rnf : Current detection resistance (Ω)

Gctl : Control gain (see Electrical Characteristics)

Icp : Charge pump output current (see Electrical Characteristics)

2. The current limiter operates according to the following formula.

I

OMAX

Vref1

=

Rnf

(A)

where, Vref1 is the current limiter reference voltage (see Electrical Characteristics)

7

Page 8

HA13565F

3. Place as close to the IC as possible.

4. Determine C102 according to the following formulas.

C102 ≥ (µF)

C103 ≥ (µF)

where,

P = Number of motor poles

5. The burst time t1 is defined as follows. (see Electrical Characteristics)

t1

H

t1

L

where, Rt2 is resistance inter pin 4 and pin 17.

6. If the circuit is affected by noise, a large capacitance value should be set.

200

N

· P

O

100

f

FG

= –Ct2 × Rt2 × ln (1 – Vth2H / Vhb)

= –Ct2 × Rt2 × ln (1 – Vth2L / Vhb)

8

Page 9

HA13565F

Absolute Maximum Ratings (Ta = 25°C)

Item Symbol Value Unit Notes

Power supply voltage V

CC

Peak output current Iop 1.0 A

Normal output current Io 0.7 A

Input voltage Vi 0 to VCC + 0.3 V 2

Power dissipation P

T

Junction temperature Tj +150 °C1

Storage temperature range Tstg –55 to +125 °C

Notes: 1. The operating range is as follows.

V

= 4.25 to 6.5 V

CC

Tjop = 0 to +125°C

2. Applied to the logic input pin.

3. Permissible value when Tpin = 113°C and thermal resistance is as follows:

θj-pin ≤ 25°C/W

θj-a1 ≤ 55°C/W (when mounted on a metal substrate)

θj-a2 ≤ 80°C/W (when mounted on a glass epoxy substrate)

7.0 V 1

1.5 W 3

9

Page 10

HA13565F

CC

Electrical Characteristics (VCC = 5V, Ta = 25°C)

Item Symbol Min Typ Max Unit

Quiscent current I

Logic

input

Input

current

I

I

CCO

CC

CEB

— — 0.45 mA CEB=H,

— 9 13 mA CEB=L,

——±80 µAV

(Pin 6)

Input

I

RPM

——±100 µAV

current

(Pin 2)

Input

I

CLK

——±320 µA Vclk=0 to 5V 7

current

(Pin 7)

Input low

V

IL

— — 0.8 V 2, 6, 7

voltage

Input high

V

IH

2.0 — — V

voltage

Index

output

Output

low

V

OL

— — 0.4 V Io=2mA 5

voltage

Leakage

I

OH

——±10 µA V=7.0V

current

Hall

amp.

Input

resistance

Commonmode

Rhi — 10 — kΩ 19 to 24

Vh 2.0 — V

–

V

0.5

input

voltage

Differential

vh 65 — 200 mVpp

input

voltage

Index

Vth1 80 — 90 %

detection

threshold

Output

amp.

Leakage

current

I

CER

–0.1 — 5 mA Vo=7.0V 10, 12, 13

–0.1 — 0.1 mA Vo=0V

Saturation

Vsat1 — 1.15 1.65 V Io=0.7A 1

voltage

Vsat2 — 0.6 0.85 V Io=0.35A

Test

conditions

V

=6.5V

CC

V

=6.5V

CC

=0 to 5V 6

CEB

=0 to 5V 2

RPM

Applicable

Pins Note

18

10

Page 11

Electrical Characteristics (VCC = 5V, Ta = 25°C) (cont)

HA13565F

Item Symbol Min Typ Max Unit

FG amp. Input

voltage

range

Noise

margin

Speed

discriminator

and

charge

pump

Current

control

Index

circuit

Number of

counts

Operating

frequency

Leakage

current

Output

current

Threshold

voltage

Voltage

gain

Current

limitter

voltage

Index TC

input

threshold

voltage

Index TC

Input

current

vfg 2 — 20 mVpp 1, 28

nd — — 0.5 mVpp Differential

nc — — 0.5 Vpp Common

N — 1666.5 — — RPM control

— 1388.5 — — RPM control

f

CLK

Ioff — — ±50 nA V8=0.8V 8

Icp+ — 10 — µA Speed

Icp– — –10 — µA Acceleration

Vref2 — 0.63 — V (Control start

Gctl — –10 — dB 11

Vref1 157 175 193 mV (Rnf=0.33Ω)

Vth2L — 0.65 ×

Vth2H — 0.58 ×

Itc — — ±2 µA

0.9 1.0 1.1 MHz 7

— V RPM control

Vhb

— V RPM control

Vhb

Test

conditions

noise

noise

pin=L

pin=H

reduction full

scale

full scale

voltage)

pin=L

pin=H

Applicable

Pins Note

82

43

11

Page 12

HA13565F

Electrical Characteristics (VCC = 5V, Ta = 25°C) (cont)

Item Symbol Min Typ Max Unit

Hall bias Output

voltage

Leakage

current

OTSD Operating

temperature

Hysteresis Thys — 25 — °C

Notes: 1. Total of sink and source.

2. Refer to the figure 1. Gctl = ∆Vrnf / ∆vcp.

vhb 1.9 2.2 2.5 V Ih=10mA,

Ihoff — — ±10 µA CEB=H,

Tsd 125 150 — °C4

Vrnf

Vref1

∆Vrnf

10mV

0

∆Vcp

Vref2 Vcp

Figure 1

Test

conditions

CEB=L

Vh=7.0V,

V

=7.0V

CC

Applicable

Pins Note

17

3. Refer to the timing chart.

4. At the delivery, this characteristics is not tested.

12

Page 13

Characteristics Data

(mA)

CC

Quiescent Current I

HA13565F

Quiescent Current vs. Power Supply Voltage

20

16

12

TBD

8

4

0

2845673

Power Supply Voltage VCC (V)

Disenable Quiescent Current vs. Power Supply Voltage

1.0

0.8

(mA)

CCO

0.6

0.4

0.2

Disenable Quiescent Current I

0

2845673

Power Supply Voltage VCC (V)

TBD

13

Page 14

HA13565F

Output Saturation Voltage vs. Output Current

2.0

1.6

1.2

TBD

0.8

0.4

Output Saturation Voltage VsatH & VsatL (V)

0

0 1.00.2 0.4 0.6 0.8

Output Current IO (A)

Current Limiter Voltage vs. Rnf

200

190

180

TBD

170

Current Limiter Voltage Vrnf (V)

160

150

0.2 1.20.4 0.6 0.8 1.0

Rnf (Ω)

14

Page 15

Hall Bias Voltage vs. Hall Bias Current

2.5

2.0

1.5

TBD

1.0

Hall Bias Voltage Vhb (V)

0.5

0

0204 8 12 16

Hall Bias Current Ih (mA)

HA13565F

Current limiter Voltage vs. Junction Temperature

200

190

180

TBD

170

Current limiter Voltage Vrnf (V)

160

150

0 12525 50 75 100

Junction Temperature Tj (°C)

15

Page 16

HA13565F

Package Dimensions

9.0 ± 0.2

0.32 ± 0.08

0.30 ± 0.06

9.0 ± 0.2

7.0

20 15

0.65

21

28

1

0.575 0.575

14

7

6

M

0.13

1.40

1.7 Max

0.17 ± 0.05

0.15 ± 0.04

Unit: mm

1.0

0 – 8°

2.25 ± 0.1

0.10

+ 0.09

– 0.05

0.13

0.95 ± 0.10

0.50 ± 0.10

Hitachi Code

JEDEC Code

EIAJ Code

Weight

FP-28TB

—

—

0.19 g

16

Page 17

Cautions

1. Hitachi neither warrants nor grants licenses of any rights of Hitachi’s or any third party’s patent,

copyright, trademark, or other intellectual property rights for information contained in this document.

Hitachi bears no responsibility for problems that may arise with third party’s rights, including

intellectual property rights, in connection with use of the information contained in this document.

2. Products and product specifications may be subject to change without notice. Confirm that you have

received the latest product standards or specifications before final design, purchase or use.

3. Hitachi makes every attempt to ensure that its products are of high quality and reliability. However,

contact Hitachi’s sales office before using the product in an application that demands especially high

quality and reliability or where its failure or malfunction may directly threaten human life or cause risk

of bodily injury, such as aerospace, aeronautics, nuclear power, combustion control, transportation,

traffic, safety equipment or medical equipment for life support.

4. Design your application so that the product is used within the ranges guaranteed by Hitachi particularly

for maximum rating, operating supply voltage range, heat radiation characteristics, installation

conditions and other characteristics. Hitachi bears no responsibility for failure or damage when used

beyond the guaranteed ranges. Even within the guaranteed ranges, consider normally foreseeable

failure rates or failure modes in semiconductor devices and employ systemic measures such as failsafes, so that the equipment incorporating Hitachi product does not cause bodily injury, fire or other

consequential damage due to operation of the Hitachi product.

5. This product is not designed to be radiation resistant.

6. No one is permitted to reproduce or duplicate, in any form, the whole or part of this document without

written approval from Hitachi.

7. Contact Hitachi’s sales office for any questions regarding this document or Hitachi semiconductor

products.

Hitachi, Ltd.

Semiconductor & Integrated Circuits.

Nippon Bldg., 2-6-2, Ohte-machi, Chiyoda-ku, Tokyo 100-0004, Japan

Tel: Tokyo (03) 3270-2111 Fax: (03) 3270-5109

URL NorthAmerica : http:semiconductor.hitachi.com/

For further information write to:

Hitachi Semiconductor

(America) Inc.

179 East Tasman Drive,

San Jose,CA 95134

Tel: <1> (408) 433-1990

Fax: <1>(408) 433-0223

Europe : http://www.hitachi-eu.com/hel/ecg

Asia (Singapore) : http://www.has.hitachi.com.sg/grp3/sicd/index.htm

Asia (Taiwan) : http://www.hitachi.com.tw/E/Product/SICD_Frame.htm

Asia (HongKong) : http://www.hitachi.com.hk/eng/bo/grp3/index.htm

Japan : http://www.hitachi.co.jp/Sicd/indx.htm

Hitachi Europe GmbH

Electronic components Group

Dornacher Stra§e 3

D-85622 Feldkirchen, Munich

Germany

Tel: <49> (89) 9 9180-0

Fax: <49> (89) 9 29 30 00

Hitachi Europe Ltd.

Electronic Components Group.

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire SL6 8YA, United Kingdom

Tel: <44> (1628) 585000

Fax: <44> (1628) 778322

Hitachi Asia Pte. Ltd.

16 Collyer Quay #20-00

Hitachi Tower

Singapore 049318

Tel: 535-2100

Fax: 535-1533

Hitachi Asia Ltd.

Taipei Branch Office

3F, Hung Kuo Building. No.167,

Tun-Hwa North Road, Taipei (105)

Tel: <886> (2) 2718-3666

Fax: <886> (2) 2718-8180

Copyright ' Hitachi, Ltd., 1999. All rights reserved. Printed in Japan.

Hitachi Asia (Hong Kong) Ltd.

Group III (Electronic Components)

7/F., North Tower, World Finance Centre,

Harbour City, Canton Road, Tsim Sha Tsui,

Kowloon, Hong Kong

Tel: <852> (2) 735 9218

Fax: <852> (2) 730 0281

Telex: 40815 HITEC HX

Loading...

Loading...