Page 1

Genesys Logic, Inc.

GL600USB

Genesys Logic, Inc.

GL600USB-A

GL600USB-B

USB MOUSE MICROCONTROLLER

SPECIFICATION 1.3

Jun 19, 2000

10F, No.11, Ln.3, Tsao Ti Wei, Shenkeng, Taipei, Taiwan

Tel: 886-2-2664-6655 Fax: 886-2-2664-5757

http://www.genesyslogic.com

Page 2

GL600USB/GL600USB-A/GL600USB-B

TABLE OF CONTENTS

TABLE OF CONTENTS.............................................................................................................................................1

TABLE OF CONTENTS.............................................................................................................................................2

TABLE OF FIGURES .................................................................................................................................................3

1 FEATURES ............................................................................................................................................................4

2 FUNCTIONAL OVERVIEW ...........................................................................................................................5

3 PIN DEFINITIO NS AND DESCRIPTIONS ................................................................................................6

3.1 GL600USB ......................................................................................................................................................6

3.2 GL600USB-A ..................................................................................................................................................8

3.3 GL600USB-B ..................................................................................................................................................9

4 FUNCTIONAL DESCRIPTION....................................................................................................................10

4.1 MEMORY ORGANIZATION......................................................................................................................10

4.1.1 Program Memory Organization ...................................................................................................10

4.1.2 Data Memory Organization ........................................................................................................... 10

4.2 USB FUNCTION REGISTERS..................................................................................................................11

4.3 MCU FUNCTION REGISTERS ................................................................................................................14

4.4 FULL-RANGE DETECTION AND ANALOG -TO-DIGITAL CONVERTER.....................................18

4.5 GENERAL PURPOSE I/O PORTS ...........................................................................................................19

4.6 TIMER INTERRUPT ...................................................................................................................................19

4.7 USB ENGINE................................................................................................................................................19

4.7.1 Voltage Regulator .............................................................................................................................19

4.7.2 USB Transceiver................................................................................................................................20

4.7.3 Serial Interface Engine (SIE).........................................................................................................22

4.8 INSTRUCTION SET SUMMARY..............................................................................................................22

4.8.1 Operand Field Descriptions ...........................................................................................................22

4.8.2 Instruction Set....................................................................................................................................22

5 ABSOLUTE MAXIMUM RATINGS ...........................................................................................................31

6 ELECTRICAL CHARACTERISTICS........................................................................................................31

7 PACKAGE DIAGRAMS ..................................................................................................................................33

7.1 16-pin P-DIP..............................................................................................Error! Bookmark not defined.

7.2 18-pin P-DIP..............................................................................................Error! Bookmark not defined.

2 06/19/2000

Revision 1. 3

Page 3

GL600USB/GL600USB-A/GL600USB-B

7.3 20-pin P-DIP..............................................................................................Error! Bookmark not defined.

7.4 16-pin SOP.................................................................................................Error! Bookmark not defined.

7.5 18-pin SOP....................................................................................................................................................37

7.6 20-pin SOP....................................................................................................................................................38

TABLE OF FIGURES

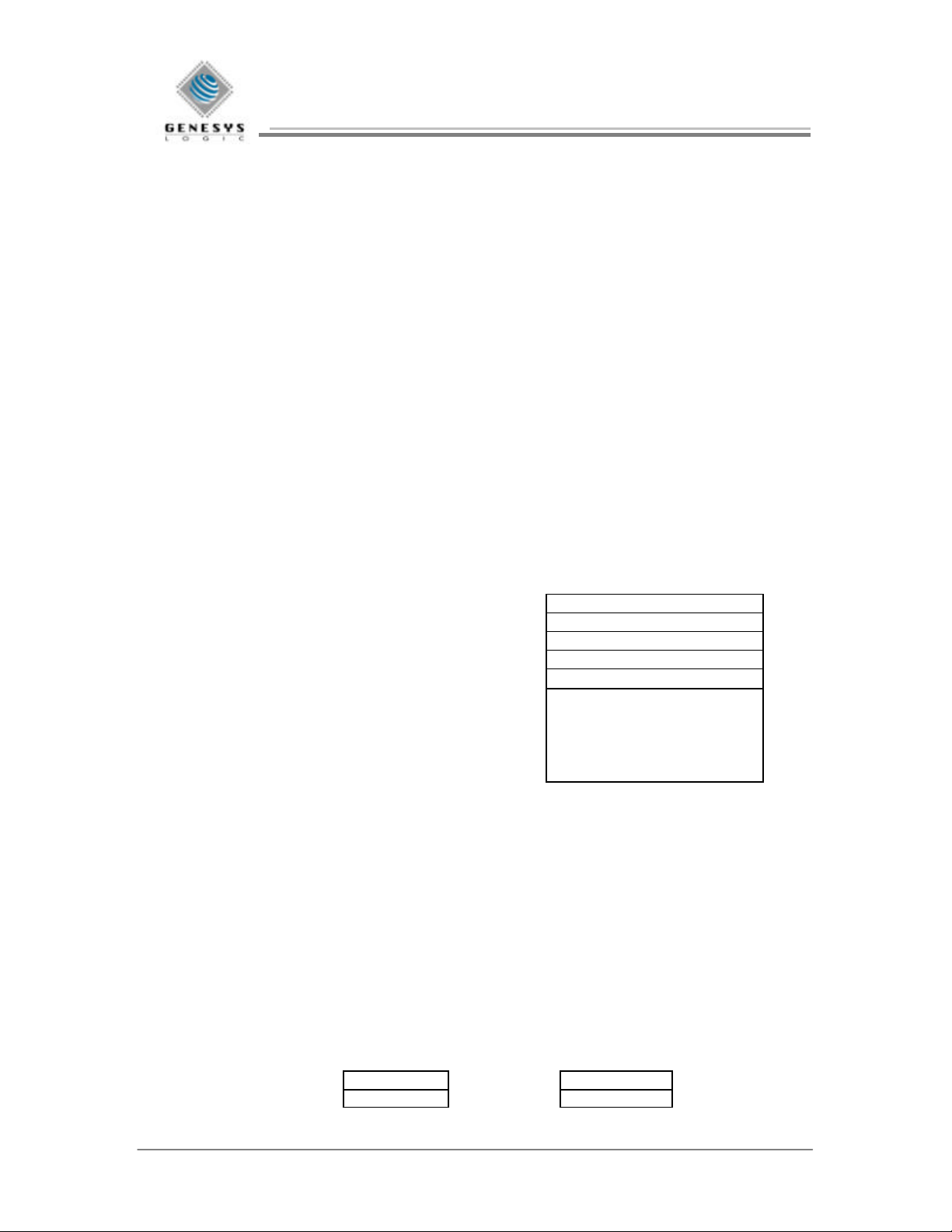

Figure 2-1 Block Diagram of GL600USB .......................................................................... 5

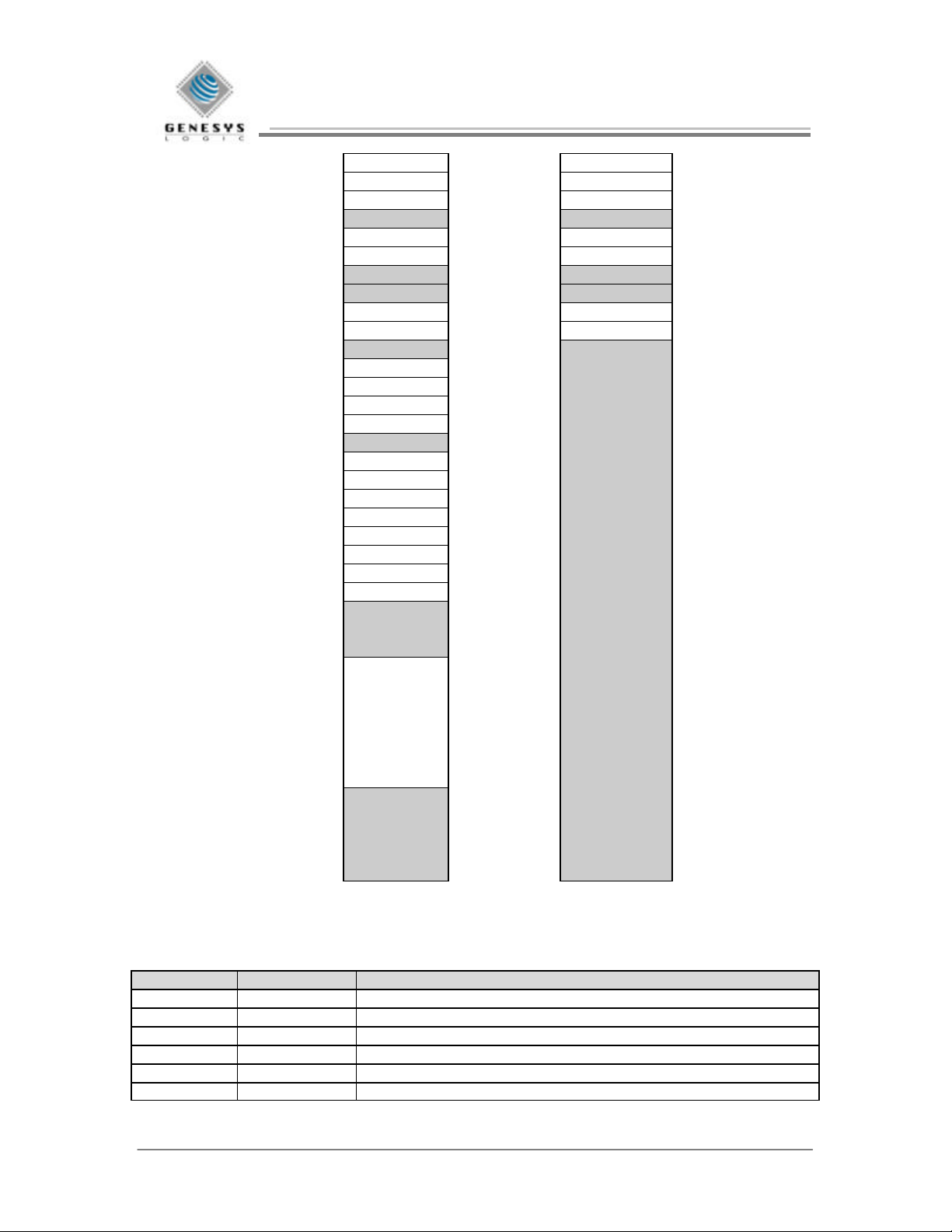

Figure 3-1 20-pin DIP (GL600USB) .................................................................................. 7

Figure 3-2 18-pin DIP (GL600USB-A).............................................................................. 8

Figure 3-3 16-pin DIP (GL600USB-B) .............................................................................. 9

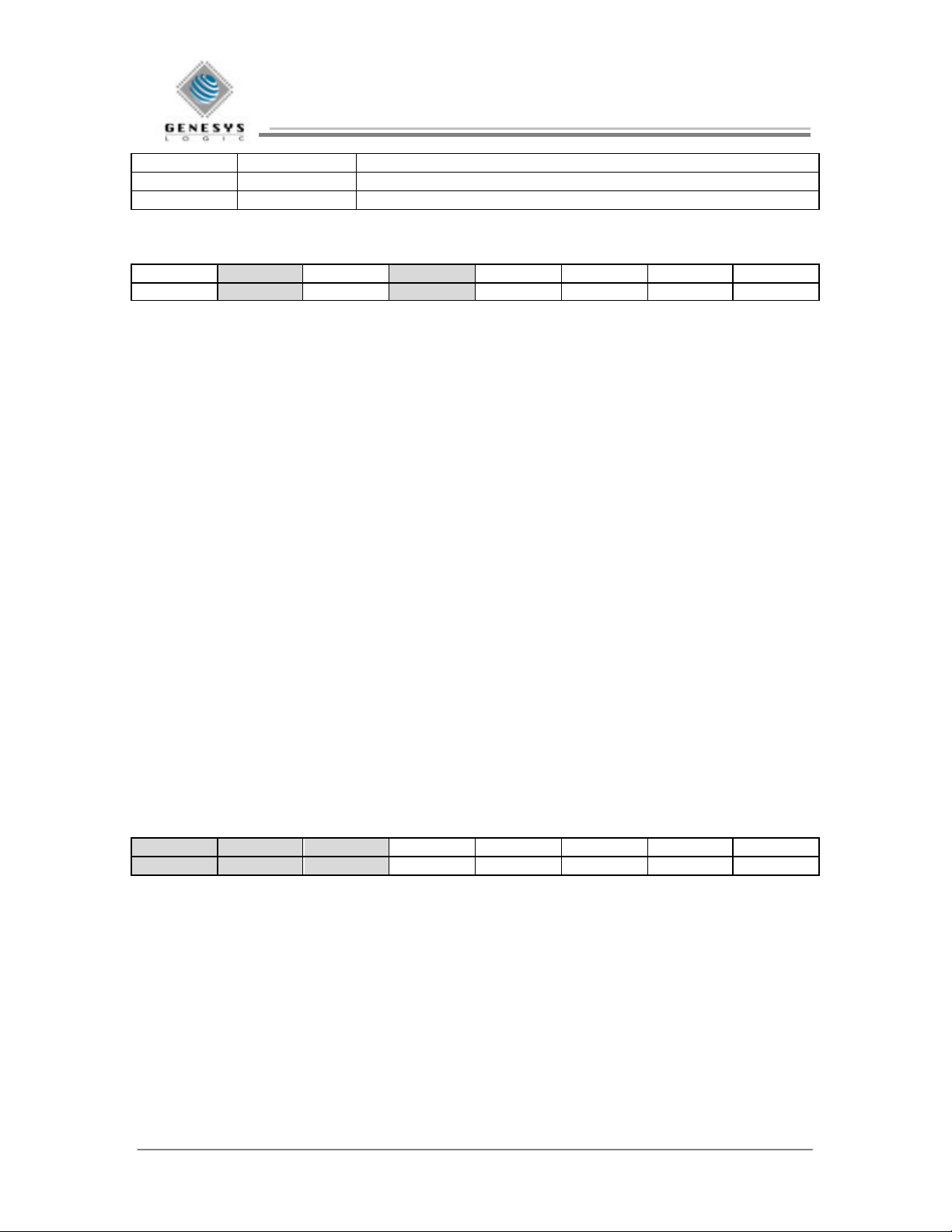

Figure 4-1 Program Memory Space .................................................................................. 10

Figure 4-2 Data Memory Space........................................................................................ 11

Figure 4-3 Differential Input Sensitivity over Entire Common Mode Range .................. 20

Figure 4-4 Receiver Jitter Tolerance ................................................................................. 21

Figure 4-5 Data Signal Rise and Fall Time ...................................................................... 22

Figure 7-1 Package outline dimension for 16-pin P-DIP.....Error! Bookmark not defined.

Figure 7-2 Package outline dimension for 18-pin P-DIP.....Error! Bookmark not defined.

Figure 7-3 Package outline dimension for 20-pin P-DIP.....Error! Bookmark not defined.

Figure 7-4 Package outline dimension for 16-pin SOP .................................................... 36

Figure 7-5 Package outline dimension for 18-pin SOP .................................................... 37

Figure 7-6 Package outline dimension for 20-pin SOP .................................................... 38

3 06/19/2000

Revision 1. 3

Page 4

GL600USB/GL600USB-A/GL600USB-B

1 FEATURES

• Low-cost solution for low-speed USB mouse

• 8-bit micro-controller

− Operation Speed: DC to 6MHz clock input

− Performance: 3 MIPS @ 6MHz

− Single cycle instruction execution

− RISC-like architecture

− USB optimized instruction set

• USB Specification Compliance

− Conforms to USB 1.5Mbps Specification, Version 1.1

− Conforms to USB HID Class Specification, Version 1.1

− Supports 1 device address and 2 endpoints (include endpoint 0)

• I/O ports

− Up to 13(GL600USB)/11(GL600USB-A)/9(GL600USB-B) general purpose I/O pins (OTP type is

less a GPIO pin than mask type)

− Internal RC clock to wakeup periodically (about 500ms) when suspend

− Up to 8(GL600USB)/6(GL600USB-A)/4(GL600USB-B) special purpose I/O pins optimized for

photo-sensor (Internal build in 4 bits ADC)

− Up to 2 I/O pins with large current drive capability to drive LED (Sink current up to 16 mA)

• Internal memory

− 64 bytes of RAM (special purpose register is not included)

− 1.75K x 14 of program ROM

• Integrated USB transceiver

• Patented full-range detection for photo-sensor

− Removes the expensive process of matching LED and photo-sensor

• On-chip 3.3v output

− No external regulator required

• Improved output drivers with slew -rate control to reduce EMI

• 6 MHz external clock

• Internal power -on reset(POR)

• Internal power -fail detector

• Supports suspend/normal mode power management

− Suspend current lower than 400µA for whole mouse system (mask type)

• 8-bits free-running timer

• Available in cost saving 20-pin(GL600USB) PDIP, 18-pin(GL600USB-A) PDIP and 16-

pin(GL600USB-B) PDIP

4 06/19/2000

Revision 1. 3

Page 5

GL600USB/GL600USB-A/GL600USB-B

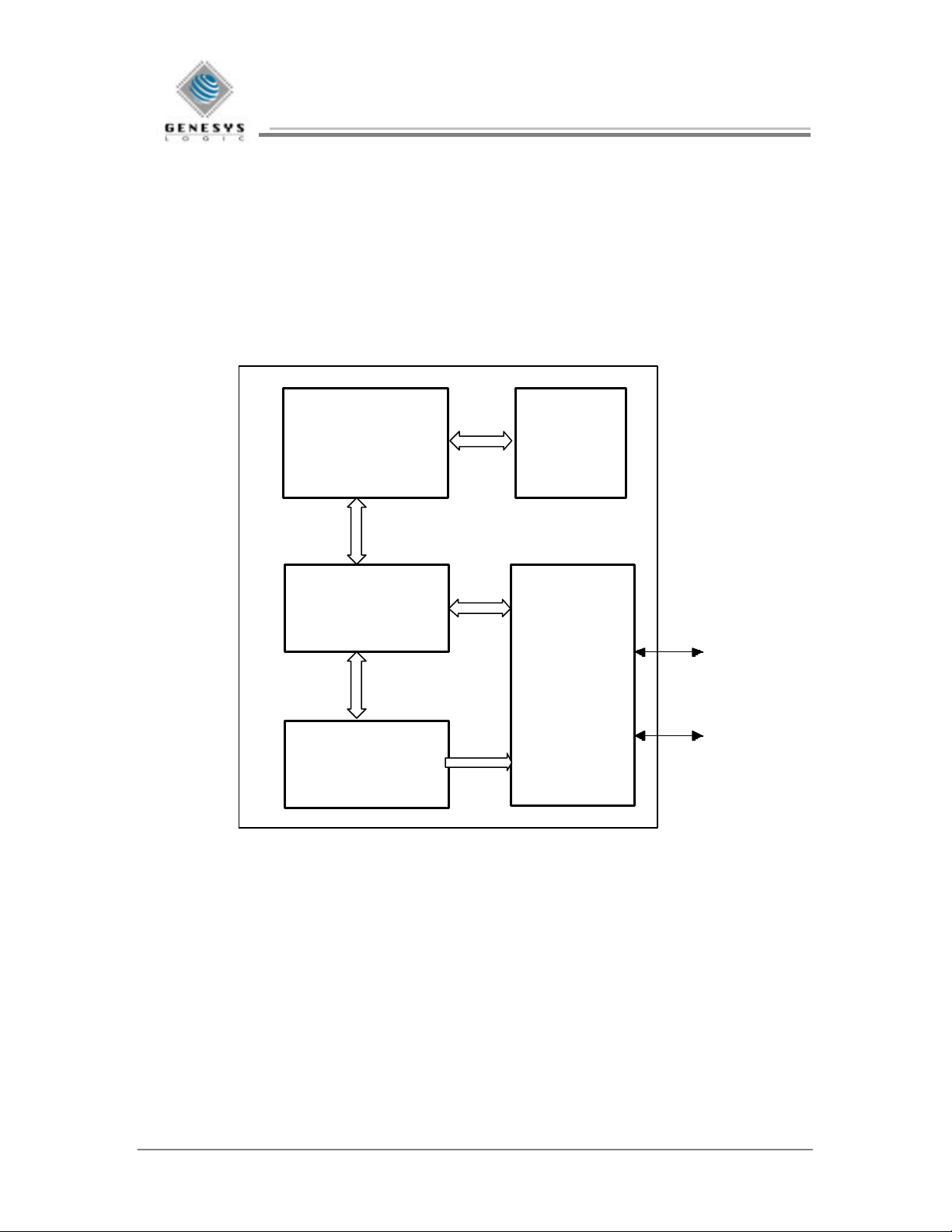

2 FUNCTIONAL OVERVIEW

The GL600USB is a 8-bits RISC-like high performance microcontroller with a built-in 1.5Mbps SIE and

transceiver. The microcontroller features 33 instructions optimized for USB applications. There are 64

bytes on-chip RAM and 1.75K x 14 program ROM incorporated into the microcontroller. The GL600USB

accepts a 6MHz ceramic resonator or a crystal as its clock source. The microcontroller features 12 general

purpose I/Os (GPIOs). 8 GPIO pins build in 4 bits ADC for photo-sensor input to remove the expensive

process of matching LED and photo-sensor. Additionally, 2 GPIO pins are strong enough to drive LEDs.

All GPIO ports feature low EMI emissions as a result of improved output drivers with slew -rate control.

USB Registers

&

FIFO Control

Micro-

controller

Endpoint 0

8 Bytes FIFO

D+

USB

Interface

D-

Endpoint 1

8 Bytes FIFO

Figure 2-1 Block Diagram of GL600USB

5 06/19/2000

Revision 1. 3

Page 6

GL600USB/GL600USB-A/GL600USB-B

3 PIN DEFINITIONS AND DESCRIPTIONS

3.1 GL600USB

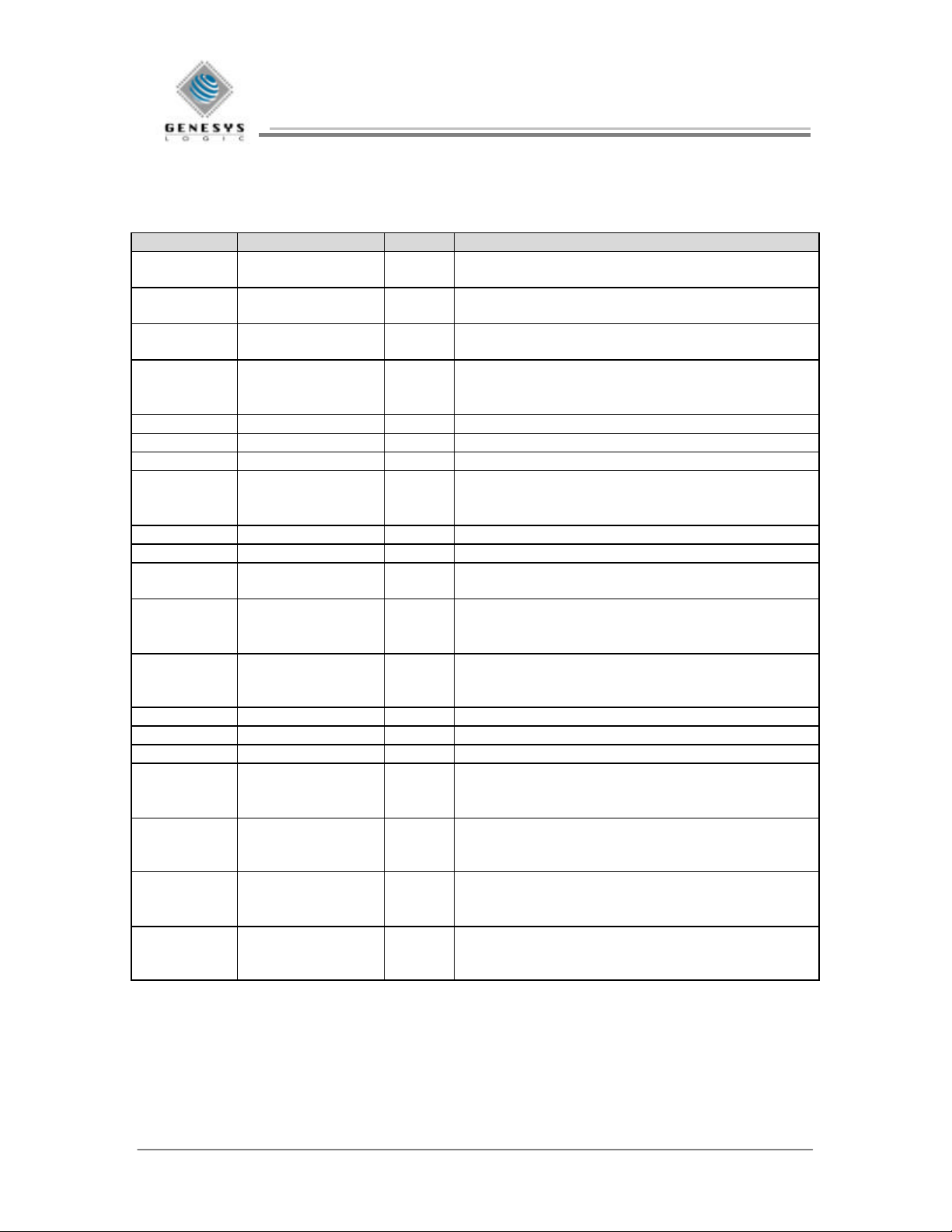

Pin No. Name I/O Description

1 P1.2/LB

2 P1.3/MB I/O Port 1 bit 3/mouse middle button

3 P1.4/RB I/O Port 1 bit 4/mouse right button

4 P2.7/W2 I/O Port 2 bit 7/photo-sensor input for horizontal scroll 2

5 VCC - Voltage supply

6 XTAL2 O Ceramic resonator or crystal out

7 XTAL1 I Ceramic resonator or crystal in

8 P2.4/Z1 I/O Port 2 bit 4/photo-sensor input for vertical scroll 1

9 D+ I/O USB data+

10 D- I/O USB data11 V3.3 O 3.3V output, a 0.1uF to 1uF capacitor should be added

12 P2.5/Z2 I/O Port 2 bit 5/photo-sensor input for vertical scroll 2

13 P2.6/W1 I/O Port 2 bit 6/photo-sensor input for horizontal scroll 1

14 P1.0 I/O Port 1 bit 0 with LED drive capability

15 P1.1 I/O Port 1 bit 1 with LED drive capability

16 GND - Ground

17 P2.3/Y1 I/O Port 2 bit 3/photo-sensor input for Y axis 1

18 P2.2/Y2 I/O Port 2 bit 2/photo-sensor input for Y axis 2

19 P2.1/X1 I/O Port 2 bit 1/photo-sensor input for X axis 1

20 P2.0/X2 I/O Port 2 bit 0/photo-sensor input for X axis 2

Note 1: Name or description after “/” means default function specified by Genesys Logic firmware

[1]

I/O Port 1 bit 2/mouse left button

Internal pull up 10K

Internal pull up 10K

Internal pull up 10K

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

on external circuit for this pin

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pul l down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Table 3-1 GL600USB Pin Definitions and Descriptions

6 06/19/2000

Revision 1. 3

Page 7

GL600USB/GL600USB-A/GL600USB-B

P1.2

P1.3

P1.4

P2.7

V

CC

XTAL2

XTAL1

P2.4

D+

D-

1 20

2 19

3 18

4 17

5 16

6 15

7 14

8 13

9 12

10 11

P2.0

P2.1

P2.2

P2.3

GND

P1.1

P1.0

P2.6

P2.5

V3.3

Figure 3-1 20-pin DIP & SOP (GL600USB)

7 06/19/2000

Revision 1. 3

Page 8

GL600USB/GL600USB-A/GL600USB-B

V3.3

9 10

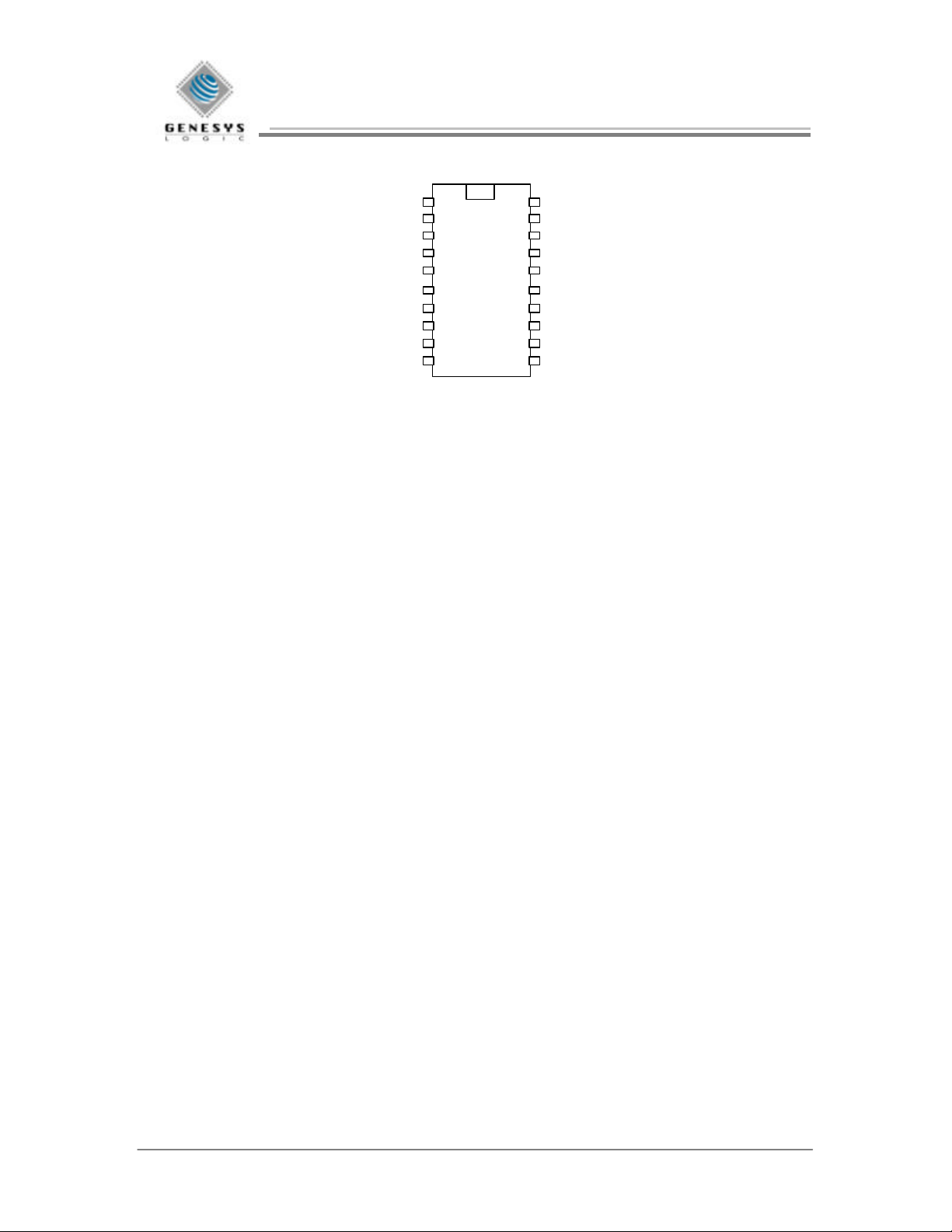

3.2 GL600USB-A

Pin No. Name I/O Description

1 P1.2/LB

2 P1.3/MB I/O Port 1 bit 3/mouse middle button

3 P1.4/RB I/O Port 1 bit 4/mouse right button

4 VCC - Voltage supply

5 XTAL2 O Ceramic resonator or crystal out

6 XTAL1 I Ceramic resonator or crystal in

7 P2.4/Z1 I/O Port 2 bit 4/photo-sensor input for vertical scroll 1

8 D+ I/O USB data+

9 D- I/O USB data10 V3.3 O 3.3V output, a 0.1uF to 1uF capacitor should be added

11 P2.5/Z2 I/O Port 2 bit 5/photo-sensor input for vertical scroll 2

12 P1.0 I/O Port 1 bit 0 with LED drive capability

13 P1.1 I/O Port 1 bit 1 with LED drive capability

14 GND - Ground

15 P2.3/Y1 I/O Port 2 bit 3/photo-sensor input for Y axis 1

16 P2.2/Y2 I/O Port 2 bit 2/photo-sensor input for Y axis 2

17 P2.1/X1 I/O Port 2 bit 1/photo-sensor input for X axis 1

18 P2.0/X2 I/O Port 2 bit 0/photo-sensor input for X axis 2

[1]

I/O Port 1 bit 2/mouse left button

Table 3-2 GL600U SB-A Pin Definitions and Descriptions

8 06/19/2000

Internal pull up 10K

Internal pull up 10K

Internal pull up 10K

Optional internal pull down from 4K ~ 32K or

no pull down resistor

on external circuit for this pin

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

P1.2

P1.3

P1.4

V

CC

XTAL2

XTAL1

P2.4

D+

D-

Figure 3-2 18-pin DIP & SOP (GL600USB-A)

1 18

2 17

3 16

4 15

5 14

6 13

7 12

8 11

P2.0

P2.1

P2.2

P2.3

GND

P1.1

P1.0

P2.5

Revision 1. 3

Page 9

GL600USB/GL600USB-A/GL600USB-B

8 9

D-

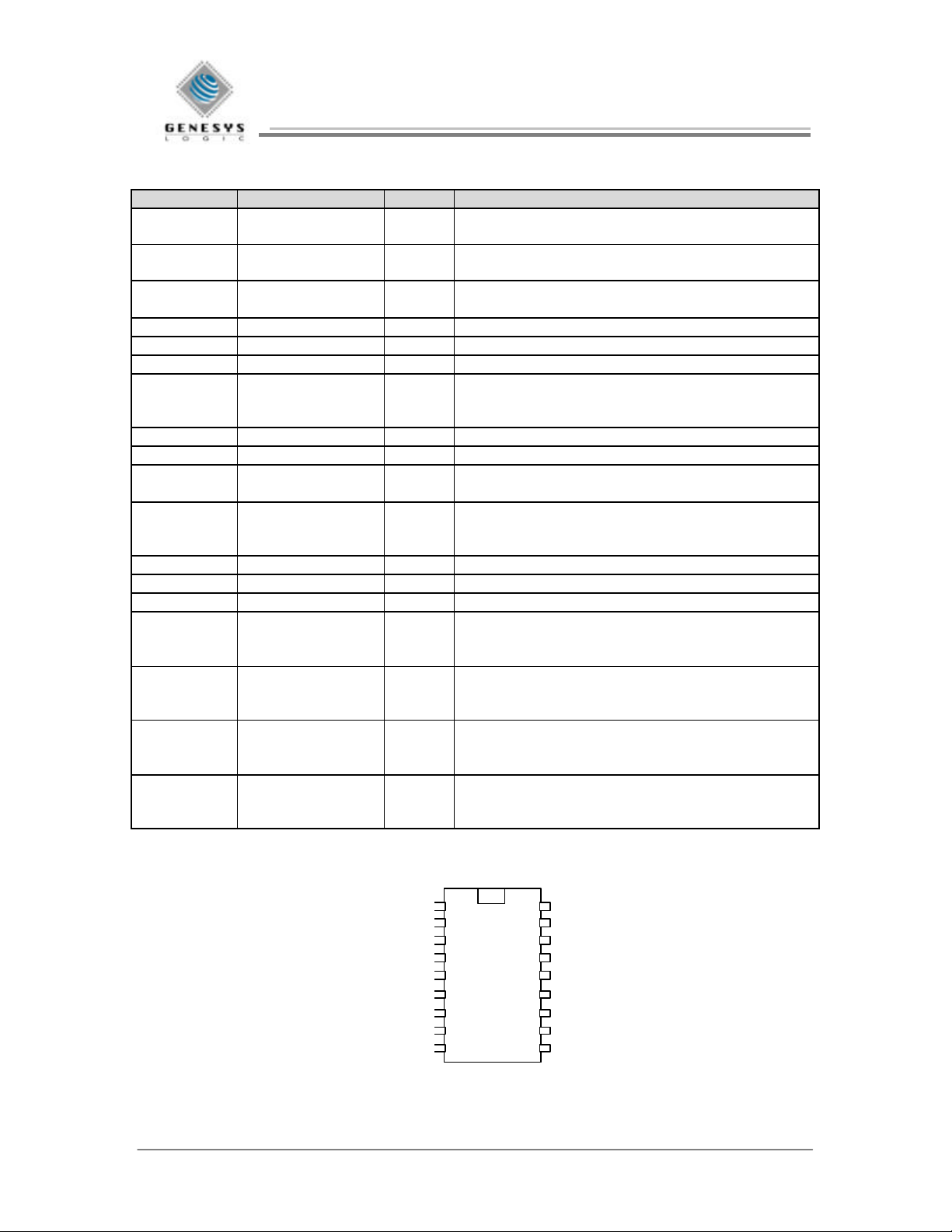

3.3 GL600USB-B

Pin No. Name I/O Description

1 P1.2/LB

2 P1.3/MB I/O Port 1 bit 3/mouse middle button

3 P1.4/RB I/O Port 1 bit 4/mouse right button

4 VCC - Voltage supply

5 XTAL2 O Ceramic resonator or crystal out

6 XTAL1 I Ceramic resonator or crystal in

7 D+ I/O USB data+

8 D- I/O USB data-

9 V3.3 O 3.3V output, a 0.1uF to 1uF capacitor should be added

10 P1.0 I/O Port 1 bit 0 with LED drive capability

11 P1.1 I/O Port 1 bit 1 with LED drive capability

12 GND - Ground

13 P2.3/Y1 I/O Port 2 bit 1/photo-sensor input for X axis 1

14 P2.2/Y2 I/O Port 2 bit 1/photo-sensor input for X axis 2

15 P2.1/X1 I/O Port 2 bit 2/photo-sensor input for Y axis 1

16 P2.0/X2 I/O Port 2 bit 3/photo-sensor input for Y axis 1

Table 3-3 GL600USB-B Pin Definitions and Descriptions

[1]

I/O Port 1 bit 2/mouse left button

Internal pull up 10K

Internal pull up 10K

Internal pull up 10K

on external circuit for this pin

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

Optional internal pull down from 4K ~ 32K or

no pull down resistor

P1.2

P1.3

P1.4

V

CC

XTAL2

XTAL1

D+

Figure 3-3 16-pin DIP & SOP (GL600USB-B)

1 16

2 15

3 14

4 13

5 12

6 11

7 10

P2.0

P2.1

P2.2

P2.3

GND

P1.1

P1.0

V3.3

9 06/19/2000

Revision 1. 3

Page 10

GL600USB/GL600USB-A/GL600USB-B

4 FUNCTIONAL DESCRIPTION

The Genesys Logic GL600USB microcontroller is optimized for USB 2D/3D/4D mouse. This USB

microcontroller conforms to the low -speed (1.5Mbps) requirements of the USB Specification version 1.1.

The microcontroller is a self-contained unit with an USB SIE, an USB transceiver, an 8-bits RISC-like

microcontroller, a timer, data and program memories. It supports one USB device address and two

endpoints (include endpoint 0).

4.1 MEMORY ORGANIZATION

The memory in the microcontroller is organized into user program memory in program ROM and data

memory in SRAM space.

4.1.1 Program Memory Organization

The 11-bit Program Counter (PC) is capable of addressing 2K x 14 of program space. However , the

program space of the GL600USB is 1.75K x 14. The program memory space is divided into two functional

groups: Interrupt Vectors and program code. After a reset, the Program Counter points to location zero of

the program space. After a timer interrupt, the Program Counter points the location 0x0004 of the program

space.

After Reset

0x0000 Reset Vector

After Timer Interrupt

0x0005

0x06FF

Figure 4-1 Program Memory Space

4.1.2 Data Memory Organization

The data memory is partitioned into two banks which contain the General Purpose Registers, MCU

Function Registers and USB Function Registers. Bit RP0 is the bank select bit.

RP0 (STATUS<5>) = 1 → Bank 1

RP0 (STATUS<5>) = 0 → Bank 0

The lower locations of each Bank are reserved for MCU Function Registers and USB Function Registers.

Above the MCU Function Registers and USB Function Registers are General Purpose Registers

implemented as SRAM. Both Bank 0 and Bank 1 contain MCU Function Registers. USB Function

Registers are located in Bank 0. Some “high use” MCU Function Registers from Bank 0 are mirrored in

Bank 1 for code reduction and quicker access.

Data Memory

Address

00h INDR 80h INDR

01h TIMER 81h PSCON

Data Memory

Address

→

0x0004 Timer Interrupt Vector

→

1.75K x 14 ROM

Address

10 06/19/2000

Revision 1. 3

Page 11

GL600USB/GL600USB-A/GL600USB-B

02h PCL 82h PCL

03h STATUS 83h STATUS

04h INDAR 84h INDAR

05h 85h

06h PORT1 86h PORT1CON

07h PORT2 87h PORT2CON

08h 88h

09h 89h

0Ah PCHBUF 8Ah PCHBUF

0Bh INTEN 8Bh INTEN

0Ch 8Ch

0Dh PHVAL 8Dh

0Eh PHSEL 8Eh

0Fh DMODE 8Fh

10h DEVCTL 10h

11h 11h

12h EVTFLG 12h

13h DEVADR 13h

14h FFCNT0 14h

15h FFCNT1 15h

16h FFCTL 16h

17h FFDAT0 17h

18h FFDAT1 18h

19h EP0RXST 19h

1Ah

1Fh

20h

5Fh

60h

7Fh

Bank 0 Bank 1

4.2 USB FUNCTION REGISTERS

Address Name Function

10h DEVCTL Device control register

12h EVTFLG Event flag register

13h DEVADR USB device address register

14h FFCNT0 Byte count buffer for endpoint 0

15h FFCNT1 Byte count buffer for endpoint 1

16h FFCTL FIFO control register

General

Purpose

Registers

(64 bytes)

FFh

Figure 4-2 Data Memory Space

11 06/19/2000

Revision 1. 3

Page 12

GL600USB/GL600USB-A/GL600USB-B

17h FFDAT0 Endpoint 0 FIFO port

18h FFDAT1 Endpoint 1 FIFO port

19h EP0RXST Endpoint 0 receiving status register

Table 4-1 USB Function Register Summary

DEVCTL (Address 10h, Device control register)

[1]

R/W

R/W R/W R/W R/W R/W

TXSE0 EP0STL EP1STL WAKE WKDIS PWRDN

TXSE0: Set and clear transmitting SE0 bit

1: Set transmitting SE0

0: Clear transmitting SE0

EP0STL: Endpoint 0 stall bit. This bit will be cleared automatically by hardware when SETUP packet is

received

1: Endpoint 0 will respond with a STALL to a valid transaction except SETUP

0: Endpoint 0 will not respond with a STALL to a valid transaction

EP1STL: Endpoint 1 stall bit

1: Endpoint 1 will respond with a STALL to a valid IN transaction

0: Endpoint 1 will not respond with a STALL to a valid IN transaction

WAKE: Wake-up bit

1: Set this bit to wake up host controller by placing USB bus into K state

0: Clear this bit to force USB bus leave K state

WKDIS: Wake-up disable bit. The WAKE bit has no effect if WKDIS bit is set to 1.

1: Disable remote wake-up capability

0: Enable remote wake-up capability

PWRDN: Power -down mode bit. Writing 1 to this bit will enter power-down mode

If USB suspend is detected, firmware can set this bit to enter power -down mode. In power-down

mode, crystal/resonator will stop. The PWRDN bit will be cleared automatically by hardware and

crystal/resonator will restart when the internal RC timer ti meout (about 500ms). Firmware should

check buttons and photo position encoders of the mouse. If mouse status is not changed, Firmware

should set the PWRDN bit to enter power down mode again. Power consumption in suspend mode

depends on how much time the firmware checking mouse status changed. Hardware will also clear

PWRDN bit automatically when USB D+ or D- is toggled.

0: Normal mode, not power -down

Value on POR: “1 - 0 - 0 0 0 0”

[2]

Note 1: “R/W” means readable and writable bit. All reserved fields should not be changed by firmware.

Note 2: “-“ means unimplemented read as 0

EVTFLG (Address 12h, Event flag register)

R/W1C

[1]

R/W1C R/W1C R/W1C R/W1C

RESUME SUSPD EP1TX EP0TX EP0RX

RESUME: Global resume bit

1: Global resume (USB D+/D - toggle) was detected

0: Global resume was not detected

SUSPD: Global suspend bit

1: Global suspend (USB idle more than 3ms) was detected

0: Global suspend was not detected

EP1TX: Endpoint 1 transmitting status bit

1: Data has been sent from endpoint 1

0: Data has not been sent from endpoint 1

EP0TX: Endpoint 0 transmitting status bit

1: Data has been sent from endpoint 0

0: Data has not been sent from endpoint 0

EP0RX: Endpoint 0 receiving status bit

12 06/19/2000

Revision 1. 3

Page 13

GL600USB/GL600USB-A/GL600USB-B

1: Data has been received by endpoint 0

0: Data has not been received by endpoint 0

Value on POR: “- - - 0 0 0 0 0”

Note 1: “R/W1C” means read-only and write “1” to clear bit

DEVADR (Address 13h, USB device address register)

R/W R/W R/W R/W R/W R/W R/W

DADR6 DADR5 DADR4 DADR3 DADR2 DADR1 DADR0

Write this register to set the USB device address

Value on POR: “- 0 0 0 0 0 0 0”

FFCNT0 (Address 14h, Byte count buffer for endpoint 0)

[1]

R/O

R/O R/O R/O R/W R/W R/W R/W

RXCNT3 RXCNT2 RXCNT1 RXCNT0 TXCNT3 TXCNT2 TXCNT1 TXCNT0

RXCNT[3:0]: Number of bytes received by endpoint 0 OUT transaction

TXCNT[3:0]: Number of bytes to be sent by endpoint 0 IN transaction

Value on POR: “x x x x x x x x”

Note 1: “R/O” means read-only bit. Writing this bit is no effect.

FFCNT1 (Address 15h, Byte count buffer for endpoint 1)

R/W R/W R/W R/W

TXCNT3 TXCNT2 TXCNT1 TXCNT0

TXCNT[3:0]: Number of bytes to be sent by endpoint 1 IN transaction

Value on POR: “- - - - x x x x”

FFCTL (Address 16h, FIFO control register)

W/O

[1]

R/W R/W R/W W/O R/W R/W

FFRST1 TXSEQ1 TXOE1 RXDIS0 FFRST0 TXSEQ0 TXOE0

FFRST1: Reset endpoint 1 FIFO read/write pointer

Write “1” to this bit will reset endpoint 1 FIFO read/write pointer. Data in endpoint 1 FIFO remain

unchanged. Before data are written into endpoint 1 FIFO, FFRST1 should be written first.

TXSE Q1: Endpoint 1 transmitting data sequence bit

1: Transmitting data use DATA1 as PID

0: Transmitting data use DATA0 as PID

TXOE1: Endpoint 1 FIFO data ready bit

1: Endpoint 1 FIFO data are ready to be transmitted. Data will be transmitted when a valid IN

token is received. This bit is automatically cleared by hardware after the transaction complete

(ACK is received).

0: Endpoint 1 FIFO data are not ready to be transmitted. Endpoint 1 will respond with a NAK to a

valid IN transaction.

RXDIS0: Endpoint 0 receiving not available bit

1: Endpoint 0 FIFO is not available. The received data cannot be pushed into FIFO. The USB

controller will respond with a NAK to a valid OUT transaction. This bit is set by hardware when

endpoint 0 data is received (both SETUP and OUT transaction) and should be cleared by firmware

after data is read from FIFO.

0: Endpoint 0 FIFO is available for data receiving

FFRST0: Reset endpoint 0 FIFO read/write pointer

Write “1” to this bit will reset endpoint 0 FIFO read/write pointer. Data in endpoint 0 FIFO remain

unchanged. Before data are written into endpoint 0 FIFO, FFRST0 should be written first.

TXSEQ0: Endpoint 0 transmitting data sequence bit

1: Transmitting data use DATA1 as PID

0: Transmitting data use DATA0 as PID

TXOE0: Endpoint 0 FIFO data ready bit

13 06/19/2000

Revision 1. 3

Page 14

GL600USB/GL600USB-A/GL600USB-B

1: Endpoint 0 FIFO data are ready to be transmitted. Data will be transmitted when a valid IN

token is received. This bit is automatically cleared by hardware after the transaction complete

(ACK is received).

0: Endpoint 0 FIFO data are not ready to be transmitted and respond with a NAK to a valid IN

transaction.

Value on POR: “- 0 0 0 0 0 0 0”

Note 1: “W/O” means write-only bit. 0 will be returned when reading this bit

FFDAT0 (Address 17h, Endpoint 0 FIFO port)

R/W R/W R/W R/W R/W R/W R/W R/W

FFDAT7 FFDAT6 FFDAT5 FFDAT4 FFDAT3 FFDAT2 FFDAT1 FFDAT0

Endpoint 0 FIFO data port

Endpoint 0 FIFO is a 8 bytes FIFO. Firmware can read/write this port 8 times to get/put the FIFO

data.

Value on POR: “x x x x x x x x”

FFDAT1 (Address 18h, Endpoint 1 FIFO port)

R/W R/W R/W R/W R/W R/W R/W R/W

FFDAT7 FFDAT6 FFDAT5 FFDAT4 FFDAT3 FFDAT2 FFDAT1 FFDAT0

Endpoint 1 FIFO data port

Endpoint 1 FIFO is 8 bytes FIFO. Firmware can read this port 8 times to get the FIFO data.

Value on POR: “x x x x x x x x”

EP0RXST (Address 19h, Endpoint 0 receiving status register)

R/O R/O R/O R/O

RXST3 RXST2 RXST1 RXST0

RXST[3:0]: If EP0RX is set, then there’s a complete transaction. RXST[3:0] indicate the packet received.

Bit Value Packet received

1001 SETUP token with DATA0 packet

0101 OUT token with DATA0 packet

0110 OUT token with DATA1 packet

Value on POR: “- - - - x x x x”

4.3 MCU FUNCTION REGISTERS

Address Name Function

00h INDR Addressing this location will use the content of INDAR to addr ess data

memory (not a physical address)

01h TIMER Timer register

02h PCL Program Counter’s low byte

03h STATUS Status register

04h INDAR Indirect address register

06h PORT1 Port 1 data register

07h PORT2 Port 2 data register

0Ah PCHBUF Write buffer of Program Counter’s bit 10-8

0Bh INTEN Interrupt enable register

0Dh PHVAL Photo-sensor value register

0Eh PHSEL Photo-sensor input select register

0Fh DMODE Photo-sensor input mode register

80h INDR Addressing this location will use the content of INDAR to address data

memory (not a physical address)

81h PSCON Prescaler control register

14 06/19/2000

Revision 1. 3

Page 15

GL600USB/GL600USB-A/GL600USB-B

82h PCL Program Counter’s low byte

83h STATUS Status register

84h INDAR Indirect address register

86h PORT1CON Port 1 direction control register

87h PORT2CON Port 2 direction control register

8Ah PCHBUF Write buffer of Program Counter’s bit 10-8

8Bh INTEN Interrupt enable register

Table 4-2 MCU Function Register Summary

INDR (Address 00h/80h)

INDR is not a physical register. Addressing INDR register will cause indirect addressing. Any instruction

using the INDF register actually accesses the register pointed by the INDAR register. The indirect

addressing method only can be used for general purpose registers.

TIMER (Address 01h, Timer register)

R/W R/W R/W R/W R/W R/W R/W R/W

TIMER7 TIMER6 TIMER5 TIMER4 TIMER3 TIMER2 TIMER1 TIMER0

The timer starts to count up after power on reset. The TMROF bit at INTEN register will be set when the

TIMER register overflows from FFh to 00h. If both TMROEN and GIE bits at INTEN register are set, an

interrupt will be generated when TIMER register overflows.

Value on POR: “0 0 0 0 0 0 0 0”

PCL (Address 02h/82h, Program Counter’s low byte)

R/W R/W R/W R/W R/W R/W R/W R/W

PCL7 PCL6 PCL5 PCL4 PCL3 PCL2 PCL1 PCL0

The Program Counter (PC) is 11-bits wide. The low byte comes from the PCL register, which is a readable

and writable register. The high byte is not directly readable or writable and comes from PCHBUF. The

GL600USB has a 4 level deep x 11-bits wide hardware stake. The st ake space is not part of either program

or data space and the stack pointer is not readable or writable. The PC is pushed onto the stack when a

CALL instruction is executed or an interrupt causes a branch. The stack is poped in the event of a RETIA,

RETI or a RET instruction execution. PCHBUF is not affected by a push or pop operation.

When write to PCL command executed, all 3 bits of PCHBUF will be loaded to PC because PCL is only a

8 bits register.

Value on POR: “0 0 0 0 0 0 0 0”

Status (Address 03h, Status register)

R/W R/W R/W R/W

BS ZO HC CA

BS: Bank Select. Because only 7 bits (bit 0~bit 6) operand implied by instruction for register address, this

bit is used as address bit 7 when register access.

1: Bank 1 (80h-FFh)

0: Bank 0 (00h-7Fh)

ZO: Zero bit

1: The result of an arithmetic or logic operation is zero

0: The result of an arithmetic or logic operation is not zero

HC: Half Carry/Borrow bit

1: Carry or not borrow from the 4th low order bit

0: Borrow or not carry from the 4th low order bit

CA: Carry/Borrow bit

1: Carry or not borrow from the most significant bit

0: Borrow or not carry from the most significant bit

15 06/19/2000

Revision 1. 3

Page 16

GL600USB/GL600USB-A/GL600USB-B

Value on POR: “- - 0 - - 0 0 0”

INDAR: (Address 04h/84h, Indirect address register)

R/W R/W R/W R/W R/W R/W R/W R/W

INDAR7 INDAR6 INDAR5 INDAR4 INDAR3 INDAR2 INDAR1 INDAR0

Any instruction using the INDF register actually accesses the register pointed by the INDAR register.

Value on POR: “x x x x x x x x”

[1]

Note 1: “x” means unknown

PORT1 (Address 06h, Port 1 data regist er)

R/W R/W R/W R/W R/W

PORT1.4 PORT1.3 PORT1.2 PORT1.1 PORT1.0

PORT1 is a 5-bits latch for Port 1.0~Port 1.4. Reading the PORT1 register gets the status of the pins.

Writing to it will write to the port latch. All write operations are read-modify-write operations.

PORT1CON is used to enable/disable every bits of the port latch.

Value on POR: “- - - x x x x x”

PORT2 (Address 07h, Port 2 data register)

R/W R/W R/W R/W R/W R/W R/W R/W

PORT2.7 PORT2.6 PORT2.5 PORT2.4 PORT2.3 PORT2.2 PORT2.1 PORT2.0

PORT2 is an 8-bits latch for Port 2.0~Port 2.7. Reading the PORT2 register reads the status of the pins.

Writing to it will write to the port latch. All write operations are read-modify-write operations.

PORT2CON is used to enable/disable every bits of the port latch.

Value on POR: “x x x x x x x x”

PCHBUF (Address 0Ah/8Ah, Write buffer of Program Counter’s bit 10-8)

R/W R/W R/W

PCHBUF2 PCHBUF1 PCHBUF0

Write buffer for upper 3-bits of Program Counter. The upper byte of Program Counter is not di rectly

accessible. PCHBUF is a holding register for the PC[10:8] that are transferred to the upper byte of the

Program Counter when branch occur. Please see PCL register to get more detail information.

Value on POR: “- - - - - 0 0 0”

INTEN (Address 0Bh/8Bh, Interrupt enable register)

R/W R/W R/W

GIE TMROEN TMROF

GIE: Global interrupt enable bit

1: Enable all interrupts

0: Disable all interrupts

TMROEN: Timer overflow interrupt enable bit

1: Enable timer interrupt

0: Disable timer interrupt

TMROF: Timer overflow interrupt flag bit. This bit should be cleared to ‘0’ by firmware after it is set by

hardware.

1: Timer register has overflowed

0: Timer register did not overflow

Value on POR: “0 - 0 - - 0 - -“

PHVAL (Address 0Dh, Photo-sensor val ue register)

R/O R/O R/O R/O

PHVAL3 PHVAL2 PHVAL1 PHVAL0

PHVAL[3:0]: the 8 channel, 4 bits analog-to-digital converter data. The ADC input is select by PHSEL

register from Port 2.0~Port 2.7

16 06/19/2000

Revision 1. 3

Page 17

GL600USB/GL600USB-A/GL600USB-B

Bit Value Analog value

0000 0 V - 5/16 V

0001 5/16 V - 5/8 V

0010 5/8 V - 15/16 V

0011 15/16 V - 5/4 V

0100 5/4 V - 25/16 V

0101 25/16 V - 15/8 V

0110 15/8 V - 35/16 V

0111 35/16 V - 5/2 V

1000 5/2 V - 45/16 V

1001 45/16 V - 25/8 V

1010 25/8 V - 55/16 V

1011 55/16 V - 15/4 V

1100 15/4 V - 65/16 V

1101 65/16 V - 75/16 V

1110 75/16 V - 5V

1111 5V

Value on POR: “- - - - x x x x”

PHSEL (Address 0Eh, Photo-sensor analog input select register)

R/W R/W R/W

PHSEL2 PHSEL1 PHSEL0

PHSEL[2:0]: The selection register for 8 channel 4 bits, ADC.

Bit Value Source pin of the ADC

000 PORT2.0

001 PORT2.1

010 PORT2.2

011 PORT2.3

100 PORT2.4

101 PORT2.5

110 PORT2.6

111 PORT2.7

Value on POR: “- - - - - x x x”

DMODE (Address 0Fh, Photo-sensor input mode register)

R/W R/W R/W R/W R/W R/W R/W R/W

DMODE7 DMODE6 DMODE5 DMODE4 DMODE3 DMODE2 DMODE1 DMODE0

DMODE[7:0]: Individual enabler for Port 2.7~Port 2.0 input buffer.

1: Indicate the corresponding pin on Port 2 can be used in input mode. This pin can be selected

with PHSEL and firmware can get its state from PHVAL also.

0: Indicate the corresponding pin on Port 2 cannot be used in input mode. But even firmware

cannot read this pin directly from Port 2 directly, this pin can be selected with PHSEL and

firmware can get its state from PHVAL also.

Val ue on POR: “0 0 0 0 0 0 0 0”

PSCON (Address 81h, Prescaler control register)

R/W R/W R/W R/W

PSDIS PS2 PS1 PS0

PSDIS: Prescaler disable bit

1: Set prescaler disable

0: Set prescaler enable

PS[2:0]: Prescaler rate select bits. These bits are used to control timer speed. The following table means

that how many instruction cycles the TIMER register should be added by 1 when PSDIS = 0.

17 06/19/2000

Revision 1. 3

Page 18

GL600USB/GL600USB-A/GL600USB-B

Bit Value Timer Rate

(PSDIS = 0)

000 1:2

001 1:4

010 1:8

011 1:16

100 1:32

101 1:64

110 1:128

111 1:256

Value on POR: “- - - - 1 1 1 1”

PORT1CON (Address 86h, Port 1 direction control register)

R/W R/W R/W R/W R/W

P1CON4 P1CON3 P1CON2 P1CON1 P1CON0

There is a data direction control bit to match every pin of Port 1. The direction control bits can configure

these pins as output or input. Setting a PORT1CON register bit put the corresponding output driver in a hiimpedance mode. Clearing a bit in the PORT1CON register puts the contents of the output latch on the

selected pin.

Value on POR: “- - - 1 1 1 1 1”

PORT2CON (Address 87h, Port 2 direction control register)

R/W R/W R/W R/W R/W R/W R/W R/W

P2CON7 P2CON6 P2CON5 P2CON4 P2CON3 P2CON2 P2CON1 P2CON0

There is a data direction control bit to match every pin of Port 2. The direction control bits can configure

these pins as output or input. Setting a PORT2CON register bit put the corresponding output driver in a hiimpedance mode. Clearing a bit in the PORT2CON register puts the contents of the output latch on the

selected pin.

Value on POR: “1 1 1 1 1 1 1 1”

4.4 FULL-RANGE DETECTION AND ANALOG -TO-DIGITAL CONVERTER

The GL600USB provides the unique “Full-Range Detection” ability. Over 95% of PC mouse market adopts

photo-sensor system to detect the mechanical movement of the roller inside the mouse. Because the

sensors may have varied characteristic on their output DC voltage level and output moving range, the

mouse manufacturers can’t avoid the expensive process of matching LED and photo-sensor. By providing

those photo-input pins with full-range detecti on function, the mouse makers can ignore the range difference

between those sensors, so the manufacturing procedure is simple and a huge cost is saved on the

manufacturing line.

By detecting the output signal came from the sensors, Genesys Logic’s patented algorithm could learn the

tiny difference of every signal and automatically adjust the threshold for the sensors without any side effect.

This new outstanding design can help the manufacturers decrease their inconvenience on mass -production

line and cut their human and mechanical cost tremendously.

There’s a 4-bit Analog-to-Digital Converter (ADC) module in the GL600USB. The input signal of ADC

can be connected to Port 2.0 ~ Port 2.7. When these I/O pins is used for analog input, the corresponding

bits in DMODE register should be set to 0 to disable input buffer of Port 2. This can save power consumed

by the pad of Port 2. The PHSEL register is used to select which input connected to the ADC and the

PHVAL register is used to store the digital value converted by the ADC. The Genesys Logic’s proprietary

18 06/19/2000

Revision 1. 3

Page 19

GL600USB/GL600USB-A/GL600USB-B

algorithm can detect any analog waveform from photo-sensor with amplitude larger than 1V. The ADC is a

high-speed converter. It takes less than 500ns to complete the conversion. Because GL600USB is running

at 3 MIPS for USB low speed application, only two dummy instructions should be added between write

PHSEL to read PHVAL.

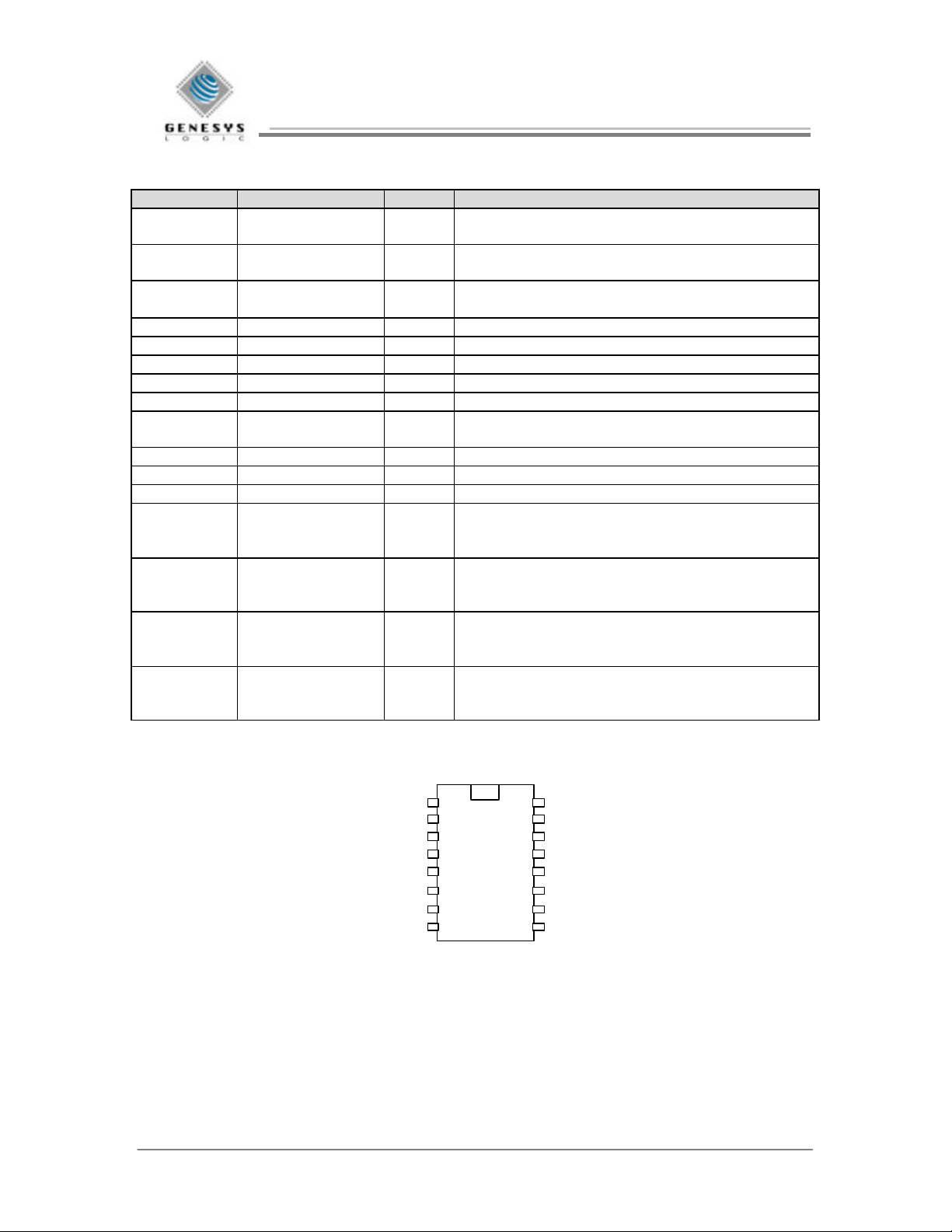

4.5 GENERAL PURPOSE I/O PORTS

Interface with peripherals is conducted via up to 13 GPIO signals. These 13 signals are divided into two

ports: Port 1 and Port 2. Port 1 contains five lines (PORT1.0-PORT1.4) and Port 2 contains eight lines

(PORT2.0-PORT2.7). The Port 1 data register is located at data memory address 06h while the Port 2 data

register is located at data memory address 07h.

Port 2 is a low current port with analog input capability suitable for connecting photo-sensor. Port 1 is a

high current port capable of LED drive. Each GPIO line may include an internal pull-up or pull-down

resistor. Port 2’s internal pull-down resistor value can be programmed by option-code. Each output drive

has slew -rate control to reduce EMI. Please see the following table for details.

Driving capability Pull-up resistor Pull-down resistor

PORT1.0 20 mA

PORT1.1 20 mA

PORT1.2 4 mA

PORT1.3 4 mA

PORT1.4 4 mA

PORT2.0 4 mA

PORT2.1 4 mA

PORT2.2 4 mA

PORT2.3 4 mA

PORT2.4 4 mA

PORT2.5 4 mA

PORT2.6 4 mA

PORT2.7 4 mA

Note 1: The pull-down resistor can be configured as 4KΩ, 8KΩ, 16KΩ or 32KΩ by option-code.

Table 4-3 General Purpose I/O Port Summary

10KΩ

10KΩ

10KΩ

4KΩ/8KΩ/16KΩ/32KΩ

4KΩ/8KΩ/16KΩ/32KΩ

4KΩ/8KΩ/16KΩ/32KΩ

4KΩ/8KΩ/16KΩ/32KΩ

4KΩ/8KΩ/16KΩ/32KΩ

4KΩ/8KΩ/16KΩ/32KΩ

4KΩ/8KΩ/16KΩ/32KΩ

4KΩ/8KΩ/16KΩ/32KΩ

[1]

4.6 TIMER INTERRUPT

The Timer Interrupt is generated when the TIMER register over flows from FFh to 00h. This overflow sets

bit TMROF (INTEN<2>). The interrupt can be masked by clearing bit TMROEN (INTEN<5>). Bit

TMROF must be cleared in software by the Timer module interrupt service routine otherwise the Timer

Interrupt will not be generated again. If prescaler is disabled, the timer register will increase every

instruction cycle. If prescaler is enabled, its increment cycle depends on PS0~PS2 bits in PSCON register.

4.7 USB ENGINE

The USB module contains three functional blocks: a 3.3-volt regulator, a low -speed USB transceiver, and

the Serial Interface Engine (SIE). The following details the function of the regulator, transceiver, and SIE.

4.7.1 Voltage Regulator

The USB data lines are required by the USB specification to have a maximum output voltage between 2.8V

and 3.6V. Because the GL600USB is a low speed USB device, the D- lines also are required to have an

19 06/19/2000

Revision 1. 3

Page 20

GL600USB/GL600USB-A/GL600USB-B

external 1.5-kΩ pull-up resistor connected between a data line and a voltage source between 3.0 V and 3.6

V. Since the power provided by the USB cable is specified to be between 4.4V and 5.0V, an on-chip

regulator is used to drop the voltage to the appropriate level for sourcing the USB transceiver and external

pull-up resistor. An output pin driven by the regulator is provided to source the 1.5-kΩ external resistor.

4.7.2 USB Transceiver

The USB transceiver provides the physical interface to the USB D+ and D- data lines. The transceiver is

composed of two parts: an output driver circuit and a receiver.

The USB transceiver uses a differential output driver to driver the USB data signal onto the USB cable. The

static output swing of the driver in its low state is below the V

of 0.3V with 1.5-kΩ load to 3.6V and in

OL

its high state is above the VOH of 2.8V with 15-kΩ load to ground. The output swings between the

differential high and low state are well balanced to minimize signal skew. Slew rate control on the driver is

used to minimize the radiated noise and cross talk. The driver’s outputs support 3-state operation to achieve

bi-directional half-duplex operation. The driver can tolerate a voltage on the signal pins of –0.5V to 3.8V

with respect to local ground reference without damage.

The rise and fall time of the signals on this cable are greater than 75ns to keep RFI (radio frequency

interference) emissions under FCC (Federal Communications Commission) class B limits and less than

300ns to limit timing delays, signaling skews, and distortions. The driver reaches the specified static signal

levels with smooth rise and fall times, and minimal reflections and ringing when driving the cable. This

driver is used only on segments between low -speed devices and the ports to which they are connected.

USB data transmission is done with differential signals. A differential input receiver is used to accept the

USB data signal. A differential 1 on the bus is represented by D+ being at least 200mV more positive than

D- as seen at the receiver, and a differential 0 is represented by D- being at least 200mV more positive than

D+ as seen at the receiver. The signal cross over point must be between 1.3V and 2.0V.

The receiver features an input sensitivity of 200mV when both differential data inputs are in the range of

0.8V and 2.5V with respect to the local ground reference. This is called the common mode input voltage

range. Proper data reception also is achieved when the differential data lines are outside the common mode

range. The receiver can tolerate static input voltage between –0.5V to 3.8V with respect to its local ground

reference without damage. In addition to the differential receiver, there is a single-ended receiver for each

of the two data lines.

1.0

0.8

0.6

0.4

0.2

Minimum Differential Sensitivity (volts)

0.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2

Figure 4-3 Differential Input Sensitivity over Entire Common Mode Range

20 06/19/2000

Common Mode Input Voltage (volts)

Revision 1. 3

Page 21

GL600USB/GL600USB-A/GL600USB-B

PERIOD

10%

90%

FtR

10%

90%

The data receivers for all types of devices must be able to properly decode the differential data in the

presence of jitter. The more of the bit time that any data edge can occupy and still be decoded, the more

reliable the data transfer will be. Data receivers are required to decode differential data transitions that

occur in a window plus and minus a nominal quarter bit time from the nominal (centered) data edge

position. Jitter will be caused by the delay mismatches and by mismatches in the source and destination

data rates (frequencies).

T

Differential

Data Lines

TJR TJR1 T JR2

Consecutive

Transitions

N * TPERIOD + TJR1

Paired

Transitions

N * TPERIOD + TJR2

Figure 4-4 Receiver Jitter Tolerance

The source of data can have some variation (jitter) in the timing of edges of the data transmitted. The time

between any set of data transitions is N*T

transitions and T

is defined as the actual period of the data rate. The data jitter is measured with the

Period

± jitter time, where N is the number of bits between the

Period

same capacitive load used for maximum rise and fall times and is measured at the crossover points of the

data lines.

For low -speed transmissions, the jitter time for any consecutive differential data transitions must be within

±25ns and within ±10ns for any set of paired differential data transitions. These jitter numbers include

timing variations due to differential buffer delay, rise/fall time mismatches, internal clock source jitter,

noise and other random effects.

The output rise time and fall time are measured between 10% and 90% of the signal. Edge transition time

for the rising and falling edges of low -speed signals is 75ns (minimum) into a capacitive load (CL) of 50pF

and 300ns (maximum) into a capacitive load of 350pF. The rising and falling edges should be transitioning

(monotonic) smoothly when driving the cable to avoid excessive EMI.

CL

Rise Time

Differential

Data Lines

Fall Time

CL

21 06/19/2000

t

Low Speed: 75ns at CL = 50pF, 300ns at C L = 350pFFull Speed: 4 to 20ns at CL = 50pF

Revision 1. 3

Page 22

GL600USB/GL600USB-A/GL600USB-B

Figure 4-5 Data Signal Rise and Fall Time

4.7.3 Serial Interface Engine (SIE)

The SIE manages data movement between the CPU and the transceiver. The SIE handles both transmit and

receive operations on the USB. It contains the logic used to manipulate the transceiver and the endpoint

registers.

The byte count buffer is loaded from TXCNT(TXCTL0<3~0>) during endpoint 0 transmit operations. This

same buffer is used for receive transactions to count the number of bytes received at endpoint 0 and, upon

the end of transaction, transfer the value to RXCNT(RXCTL0<3~0>).

When transmitting, the SIE handles parallel -to-serial conversion, CRC generation, NRZI encoding, and bit

stuffing. When receiving, the SIE handles sync detection, packet identification, end-of-packet detection, bit

(un)stuffing, NRZI decoding, CRC validation, and serial -to-parallel conversion. Errors detected by the SIE

include bad CRC, timeout while waiting for EOP, and bit stuffing violations.

All USB devices are required to have an endpoint 0 that is used to initialize and manipulate the device.

Endpoint 0 provides access to the device’s configuration information and allows generic USB status and

control accesses. Endpoint 0 can receive and transmit data. Both receive and transmit data share the same

8-byte Endpoint 0 FIFO, FFDAT0 . Received data may overwrite the data previously in the FIFO.

Endpoint 1 is of transmit only. This endpoint is used to transmit HID report data to host.

4.8 INSTRUCTION SET SUMMARY

4.8.1 Operand Field Descriptions

Field Description

r Register address

A Accumulator

i Immediate data

b Bit address within a 8-bit register

4.8.2 Instruction Set

Mnemonic,

Operands

Arithmetic Operations

ADDAR r, A Add r and A, r <- r + A 1 CA, HC, ZO

ADDAR A, r Add A and r, A <- A + r 1 CA, HC, ZO

ADDAI i Add A and i, A <- A + i 1 CA, HC, ZO

INCR r Increment r, r <- r +1 1 ZO

INCR A, r Increment r, A <- r + 1 1 ZO

INCRSZ r Increment r, r <- r +1, skip if (r = 0) 1 or 2

INCRSZ A, r Increment r, A <- r +1, skip if (A = 0) 1 or 2

SUBAR r, A Subtract A from r, r <- r - A 1 CA, HC, ZO

SUBAR A, r Subtract A from r, A <- r - A 1 CA, HC, ZO

SUBIA i Subtract A from i, A <- i - A 1 CA, HC, ZO

Description Cycles Flags

Affected

22 06/19/2000

Revision 1. 3

Page 23

GL600USB/GL600USB-A/GL600USB-B

DECR r Decrement r, r <- r -1 1 ZO

DECR A, r Decrement r, A <- r -1 1 ZO

DECRSZ r Decrement r, r <- r-1, skip if (r = 0) 1 or 2

DECRSZ A, r Decrement r, A <- r – 1, skip if (A = 0) 1 or 2

CLRR r Clear r, r <- 0 1 ZO

CLRA Clear A, A <- 0 1 ZO

NOP No operation 1

Logical Operations

ANDAR r, A And r and A, r <- r & A 1 ZO

ANDAR A, r And A and r, A <- A & r 1 ZO

ANDAI i And A and i, A <- A & i 1 ZO

CMPR r Complement r, r <- r ^ FF 1 ZO

CMPR A, r Complement r, A <- r ^ FF 1 ZO

ORAR r, A Inclusive OR r with A, r <- r | A 1 ZO

ORAR A, r Inclusive OR A with r, A <- A | r 1 ZO

ORIA i Inclusive OR i with A, A <- A | i 1 ZO

XORAR r, A Exclusive OR r with A, r <- r ^ A 1 ZO

XORAR A, r Exclusive OR A with r, A <- A ^ r 1 ZO

XORIA i Exclusive OR i with A, A <- A ^ i 1 ZO

Bit-wise Operations

BCR r, b Bit clear r, r.b <- 0 1

BSR r, b Bit set r, r.b <- 1 1

BTRSC r, b Bit test r, skip if (r.b = 0) 1 or 2

BTRSS r, b Bit test r, skip if (r.b =1) 1 or 2

Data Movement Operations

MOV r, A Move A into r, r <- A 1

MOV A, r Move r into A, A <- r 1 ZO

MOVIA i Move i into A, A <- i 1

Shift Operations

SWAPR r Swap high and low nibbles in r 1

SWAPR A, r Swap high and low nibbles in r,

result put into A

RLR r Rotate r left through C 1 CA

RLR A, r Rotate r left through C, (C, A) <- (r, C) 1 CA

RRR r Rotate r right through C 1 CA

RRR A, r Rotate r right through C, (A, C) <- (C, r) 1 CA

Control Transfer Operations

CALL i Call subroutine 2

JUMP i Jump to address 2

RETIA Return and load i to A 2

RETI Return from interrupt 2

RET Return from subroutine 2

1

23 06/19/2000

Revision 1. 3

Page 24

GL600USB/GL600USB-A/GL600USB-B

5 Firmware Programming Guide

5.1 USB Power On Reset and Bus Reset Initialization

USB reset detected

Wait host controller to

initialize the USB device

Power on reset

USB reset

(Address 0)

TXSE0 = 1No

Yes

Power on reset detected

Drive SE0 on USB

about 300 ms

Clear SE0 bit and

Wait for USB reset

24 06/19/2000

Revision 1. 3

Page 25

GL600USB/GL600USB-A/GL600USB-B

5.2 Suspend/Resume/Wakeup

Wait for resume or wakeup

SUSPD = 1

Write '1' to clear

SUSPD

Set PWRDN bit

to enter power down mode

No

wakeup event like

pressed or mouse

Set WAKE bit to drive

'K' state on USB

Delay about 1 ms

to clear WAKE bit

No

Check remote

mouse button

moved

Remote

wakeup event

occur ?

Yes

RESUME = 1

Yes

Write '1' to clear

RESUME

Suspend &

wakeup process

complete

25 06/19/2000

Revision 1. 3

Page 26

GL600USB/GL600USB-A/GL600USB-B

5.3 Receive Packet via Endpoint 0

EP0RX = 1

Packet received

complete

Write '1' to clear

EP0RX bit

Get received byte

count from

RXCNT of

FFCNT0 register

Read received data

continuous from

FFDAT0 (total RXCNT

bytes)

SETUP data

packet received

complete

Clear RXDIS0 bit to

enable endpoint 0

receiver

RXST = (1, 0, 0,

1)

NoYes

OUT data packet

received complete

26 06/19/2000

Revision 1. 3

Page 27

GL600USB/GL600USB-A/GL600USB-B

5.4 Transmit Packet via Endpoint 0

Start to transmit

function

Set FFRST0 to

reset FIFO

Push all

transmitting data

into FFDAT0

(maximum 8

bytes)

Set correct data toggle

sequence via

TXSEQ0

and

Set transmit data

length into TXCNT at

FFCNT0

Set TXOE0 bit

SIE will transmit

the packet while it

receives a IN

token

27 06/19/2000

Revision 1. 3

Page 28

GL600USB/GL600USB-A/GL600USB-B

5.5 Transmit Packet via Endpoint 1

Start to transmit

function

Set FFRST1 to

reset FIFO

Push all

transmitting data

into FFDAT1

(maximum 8

bytes)

Set correct data toggle

sequence via

TXSEQ1

Set transmit data

length into TXCNT in

SIE will transmit

the packet while it

and

FFCNT1

Set TXOE1 bit

receives a IN

token

28 06/19/2000

Revision 1. 3

Page 29

GL600USB/GL600USB-A/GL600USB-B

5.6 Timer Interrupt

Because CPU may enter timer interrupt routine at any time, the timer interrupt routine should

backup all special registers at its entry point and restore them before return.

(Address 0x004)

TIMER_ENTRY: MOV A_TEMP, A

SWAPR A, STATUS

BCR STATUS, BS

MOV S_TEMP, A

MOV A, INDAR

MOV I_TEMP, A

;

; Execute interrupt service routine

;

MOV A, I_TEMP

MOV INDAR, A

SWAPR A, S_TEMP

MOV STATUS, A

SWAPR A_TEMP

SWAPR A, A_TEMP

BCR INTEN, TMROF

RETI

5.7 Conditional Branch

Example: Conditional branch can be according to value of Accumulator. Firmware can use this

method to return value for lookahead table. Because Accumulator is only 8 bits wide, the higher 3

bits of Program Counter should be load into PCHBUF before the conditional branch executed.

(Address 0x540)

LOOKAHEAD: MOVIA 0x05

MOV PCHBUF, A

MOVIA LOOKAHEAD_VAL

ADDAR PCL, A

RETIA 0 ; Acc = 0

RETIA 1 ; Acc = 1

RETIA 2 ; Acc = 2

. .

. .

. .

5.8 Change Register Bank

Usually keeps BS = 0. If firmware want to access register address 0x80 to 0x8F, set BS = 1. After

process register address 0x80 to 0x8F complete, clear BS = 0 to address 0x00 to 0x7F.

BSR STATUS, BS

MOV PORT1CON, A

BCR STATUS, BS

29 06/19/2000

Revision 1. 3

Page 30

GL600USB/GL600USB-A/GL600USB-B

5.9 Read Photo Sensor Input

Start to Read

Photo Sensor

Select 1 of 8 channels by

write 0~7 to PHSEL

register

Add two dummy

instructions to

delay 667 us

Get phtot sensor

voltage value from

PHVAL register

30 06/19/2000

Revision 1. 3

Page 31

GL600USB/GL600USB-A/GL600USB-B

6 ABSOLUTE MAXIMUM RATINGS

Maximum ratings are the extreme limits to which the micro-controller can be exposed without permanently

damaging it. The micro-controller contains circuitry to protect the inputs against damage from high static

voltages; however, do not apply voltages higher than those shown in the table. Keep VIN and V

the range GND ≤ (VIN or V

) ≤ VCC. Connect unused inputs to the appropriate voltage level, either GND

OUT

OUT

within

or VDD.

Symbol Characteristic Val ue Unit

T

Storage temperature -55 to +150

STG

TOP Operating temperature 0 to +70

°C

°C

VCC Supply voltage -0.5 to +7.0 V

VIN DC input voltage -0.5 to +V

+ 0.5 V

DD

I Maximum current per pin excluding VDD and VSS 25 mA

I

Maximum current out of GND 100 mA

MGND

I

Maximum current out of VCC 100 mA

MVCC

V

Static discharge voltage >4000 V

ESD

7 ELECTRICAL CHARACTERISTICS

F

= 6MHz; Operating Temperature = 0 to 85°C; V

OSC

Symbol Characteristic Min Max Units Conditions

General

ICC Operating supply current 20 mA

ISB Supply current – suspend

300

mode

USB Interface

VOH Static output high 2.8 3.6 V

VOL Static output low 0.3 V

VDI Differential input

0.2 V |(D+) – (D-)|

sensitivity

VCM Differential common mode

0.8 2.5 V Include VDI range

range

VSE Single ended receiver

0.8 2.0 V

threshold

ILO Hi-Z state data line leakage -10 +10 V 0V < VIN < 3.3V

V3.3 Regulator supply voltage 3.0 3.6 V IL = 4mA

GPIO Interface

RUP PORT2.2-4 pull-up

68 120

resistance

R

PORT1.0-7 pull-down

DOWN

4 32

resistance

V

Static output high for

OH1

2.4 V V

PORT1.2-4, PORT2.0-7

V

Static output low for

OL1

0.4 V V

PORT1.2-4, PORT2.0-7

V

Static output high for

OH2

2.4 V V

PORT1.0-1

V

Static output low for

OL2

0.4 V V

PORT1.0-1

= 4.4 to 5.5V

CC

µA

KΩ

KΩ

See note 1

RL of 15KΩ to GND

RL of 15KΩ to V3.3

Code option

= 5V; IOH = 4mA

CC

= 5V; IOL = 4mA

CC

= 5V; IOH = 20mA

CC

= 5V; IOL = 20mA

CC

31 06/19/2000

Revision 1. 3

Page 32

GL600USB/GL600USB-A/GL600USB-B

VIH Static input high 2.0 V V

VIL Static input low 0.9 V V

I

Sink current for PORT1.2-

SINK1

4 m A V

4, PORT2.0-7

I

Sink current for PORT1.0-1 20 mA V

SINK2

CC

CC

OUT

OUT

= 5V

= 5V

= 0.4V;

= 0.4V;

IIN Input leakage current -1 +1

µA

V

OUT

= 0V or VCC

USB Low -speed Source

fOP Internal operating

1.5 1.5 MHz

frequency

Transition time

tR Rise time 75 ns CL = 50pF

300 ns CL = 350pF

tF Fall time 75 ns CL = 50pF

300 ns CL = 350pF

t

Rise/Fall time matching 80 120 % tR / tF

RFM

V

Output signal crossover

CRS

1.3 2.0 V

voltage

t

Low speed data rate 1.4775

DRATE

Source differential driver

676.8

1.5225

666.0

Mbs

ns

1.5Mbs ± 1.5%

jitter

t

To next transition -25 25 ns

UDJ1

t

For paired transition -10 10 ns

UDJ2

Receiver data jitter

CL = 350pF measured at

crossover point

tolerance

t

To next transition -75 75 ns

DJR1

t

For paired transition -45 45 ns

DJR2

t

Source EOP width 1.25 1.50

EOPT

t

Differential to EOP

DEOP

-40 100 ns Measured at crossover point

µs

CL = 350pF measured at

crossover point

Measured at crossover point

transition skew

Receiver EOP width

t

Must reject as EOP 330 ns

EOPR1

t

Must accept 675 ns

EOPR2

Measured at crossover point

Notes:

1. ISB measured with USB in suspend mode; using external square wave clock source (F

OSC

=

6MHz); transceiver pull-up resistor of 1.5KΩ between V3.3 and D- and 1.5KΩ termination resistors on D+

and D- pins; no port pins sourcing current. The I

value is including power consumed by external resistors.

SB

32 06/19/2000

Revision 1. 3

Page 33

GL600USB/GL600USB-A/GL600USB-B

B1

E1

8 PACKAGE DIAGRAMS

8.1 16-pin P-DIP

15" (2X)

5" (2X)

Symbol

Min Nom Max Min Nom Max

A -- 130 -- -- 3.302 --

A1 59 60 61 1.499 1.524 1.549

B -- 18 -- -- 0.457 --

B1 -- 60 -- -- 1.524 --

C -- 10 -- -- 0.254 -D 740 750 760 18.796 19.050 19.304

E1 259 260 -- 6.579 6.604 --

F 290 300 310 7.366 7.620 7.874

L -- 130 -- -- 3.302 --

L1 -- 20 -- -- 0.508 --

e -- 100 -- -- 2.540 --

EB 345 355 365 8.763 9.017 9.271

θ 4ο 5.5ο 7ο 4ο 5.5ο 7ο

Figure 8-1 Package outline dimension for 16-pin P-DIP

D

e

Dimension in mil

F

A

A1

L1

L

B

15' (4X)

eB

Dimension in mm

C

33 06/19/2000

Revision 1. 3

Page 34

GL600USB/GL600USB-A/GL600USB-B

ο

ο

ο

ο

ο

ο

8.2 18-pin P-DIP

15"(2X

)

B

B1

e

D

F

E1

C

A

A1

L1

L

15"(4X)

£c

eB

Symbol

Dimension in mils Dimension in mils

Min Nom Max Min Nom Max

A -- 130 -- -- 3.302 --

A1 59 60 61 1.499 1.524 1.549

B -- 18 -- -- 0.457 --

B1 -- 60 -- -- 1.524 --

C -- 10 -- -- 0.254 --

D 890 900 910 22.606 22.860 23.114

E1 259 260 -- 6.579 6.604 --

F 290 300 310 7.366 7.620 7.874

L -- 130 -- -- 3.302 --

L1 -- 20 -- -- 0.508 --

1 e 1

-- 100 -- -- 2.540 --

eB 345 355 365 8.763 9.017 9.271

Figure 8-2 Package outline dimension for 18-pin P-DIP

4

5.5

7

4

5.5

7

34 06/19/2000

Revision 1. 3

Page 35

GL600USB/GL600USB-A/GL600USB-B

£c

8.3 20-pin P-DIP

E1

F

A

A1

e

B

eB

B1

D

Symbol

A -- 130 -- -- 3.302 --

A1 59 60 61 1.499 1.524 1.549

B -- 18 -- -- 0.457 --

B1 -- 60 -- -- 1.524 --

C -- 10 -- -- 0.254 -D 1015 1025 1035 25.781 26.035 26.289

E1 259 260 -- 6.579 6.604 --

F 290 300 310 7.366 7.620 7.874

e -- 100 -- -- 2.540 --

eB 345 355 365 8.763 9.017 9.271

θ 4ο 5.5ο 7ο 4ο 5.5ο 7ο

Min Nom Max Min Nom Max

Figure 8-3 Package outline dimension for 20-pin P-DIP

Dimension in mil

Dimension in mm

C

35 06/19/2000

Revision 1. 3

Page 36

GL600USB/GL600USB-A/GL600USB-B

A

A

e

8.4 16-pin SOP

C

B

e

E1

Symbol

Dimension in mils

Min Nom Max Min Nom Max

Dimension in mm

A --- 58 --- --- 1.473 --A1 6 --- --- 0.152 --- --A2 --- 24 --- --- 0.610 ---

B --- 16 --- --- 0.406 --C --- 8 --- --- 0.203 --D 388 390 392 9.855 9.906 9.957

E1 152 154 156 3.861 3.912 3.962

e --- 50 --- --- 1.270 ---

eB --- 238 --- --- 6.045 ---

L 25 --- --- 0.635 --- --θ 0° 3° 6° 0° 3° 6°

Figure 8-4 Package outline dimension for 16-pin SOP

A2

D

θ

L

36 06/19/2000

Revision 1. 3

Page 37

GL600USB/GL600USB-A/GL600USB-B

8.5 18-pin SOP

E

H

0.020 X 45

0.016typ

0.050typ

D

0.004 mox

SYMBOLS MIN MAX

A 0.093 0.104

A1 0.004 0.012

D 0.447 0.463

E 0.291 0.299

H 0.394 0.419

L 0.016 0.050

0 8

Figure 8-5 Package outline dimension for 18-pin SOP

A1

A

SEATING PLANE

L

37 06/19/2000

Revision 1. 3

Page 38

GL600USB/GL600USB-A/GL600USB-B

8.6 20-pin SOP

0.016typ

E

H

0.050typ

D

A

SEATING PLANE

0.004 max

A1

SYMBOLS MIN MAX

A 0.093 0.104

A1 0.004 0.012

D 0.496 0.508

E 0.291 0.299

H 0.394 0.419

L 0.016 0.050

0 8

Figure 8-6 Package outline dimension for 20-pin SOP

0.020 X 45

L

38 06/19/2000

Revision 1. 3

Loading...

Loading...