Page 1

IMAGE SENSORS

FXA 1012

Frame Transf er CCD Image Sensor

Objective specification 2000 January 7

File under Image Sensors

Philips

Semiconductors

Page 2

Philips Semiconductors Objective specification

g

Frame Transfer CCD Image Sensor FXA 1012

• 2M active pixels (1616H x 1296V)

• 2/3-inch type optical format

• Still and monitor modes

• RGB Bayer pattern colour filter s

• Progressive scan

• Excellent anti-blooming (V ertical Overflow

Drain)

• High dynamic range (>70dB)

• High sensitivity

• Low dark current and low fixed pattern noise

• Low read-out noise

• V ariable electr onic shuttering

• Data rate up to 25 MHz, 5 frames/s

• Small outline LCC package

• Low cost

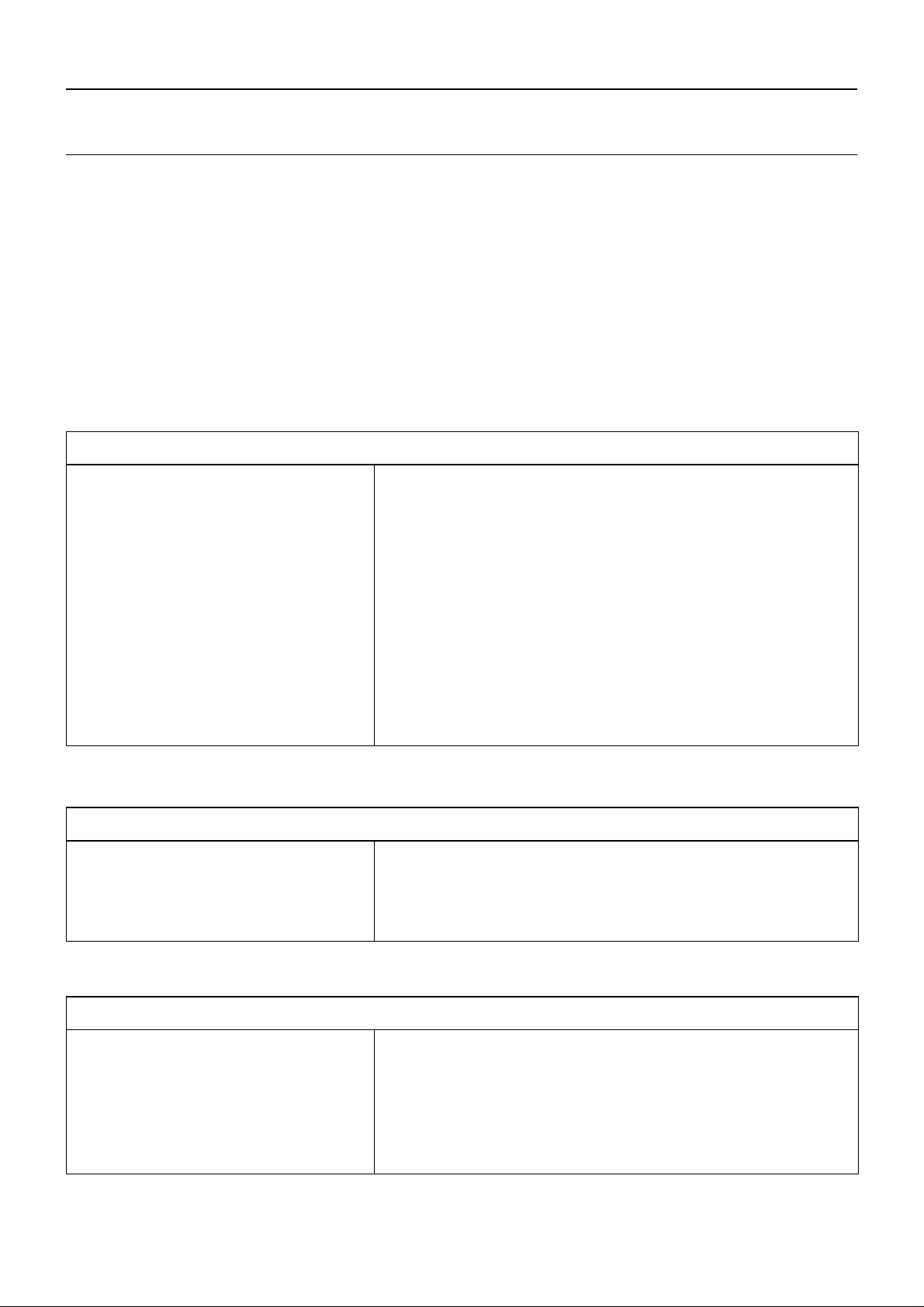

Device structure

Optical size: 8.16 mm (H) x 6.53 mm (V)

Chip size: 9.49 mm (H) x 9.32 mm (V)

Pixel size: 5.1 µm x 5.1 µm

Active pixels: 1616 (H) x 1296 (V)

Total no. of pixels: 1688 (H) x 1324 (V)

Optical black pixels: Left: 2 Right: 70

Optical black lines: Top: 12 Bottom: 12

Total no. of storage lines: 298

Dummy register cells: 8

Description

The FXA 1012 is a colour frame-transfer CCD image sensor designed

for consumer digital photography applications. The combination of

high speed and a high linear dynamic range of over 10 true bits

makes this device the perf ect solution for use in compact high quality

imaging applications. Two modes of operation provide both a

monitoring image for LCD screens, and a full resolution, zero-smear

still image with excellent colour rendition. The device structure is

shown in figure 1.

12 dark lines

8 black lines

Image

Section

1616 active pixels

12 dark + 4 dummy lines

Storage Section

298 lines x 1688 cells

1688 cells

Output re

ister

GBGB

RGRG

GBGB

1296

active

lines

GBGB

RGRG

70

Output

amplifier

8

GBGB

RGRG

GBGB

2

GBGB

RGRG

Figure 1 - Device structure

2000 January 2

Page 3

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

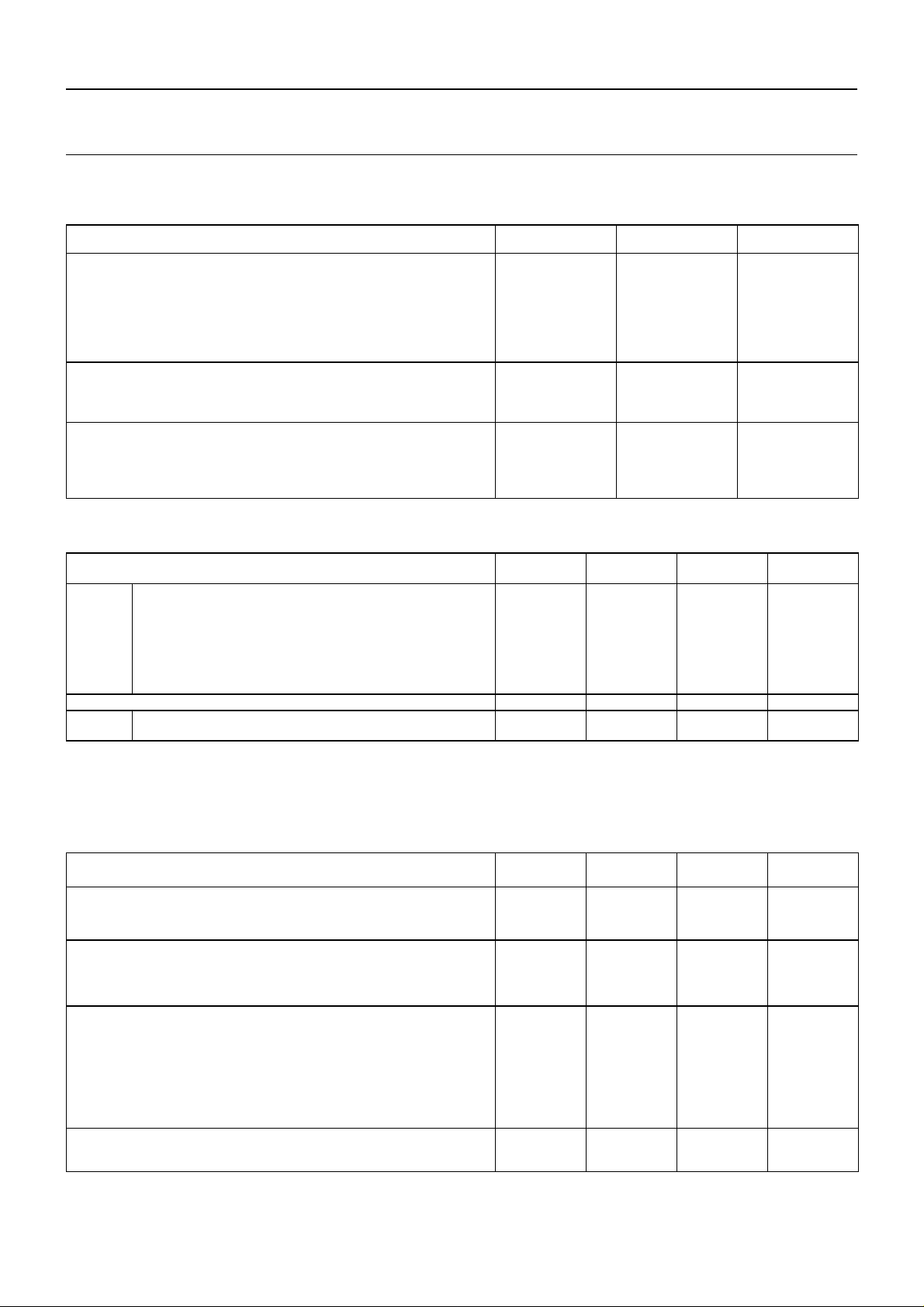

Architecture of the FXA 1012

The FXA 1012 consists of an open image section and a storage

section with an optical light shield. An output register and amplifier

are located below the storage section for read-out.

The optical centres of all pixels in the image section form a square

grid. The image area has RGB Bay er colour filter pattern. The charge

is generated and integrated in the image section. This section is

controlled by four image cloc k phases (A1 to A4). After the integration

time the image charge is shifted one line at a time to the storage

section.

The storage section is controlled by four storage clock phases (B1

to B4). In the still mode the image inf ormation is transported straight

IMAGE SECTION

Image diagonal (active video only)

Aspect ratio

Active image width x height

Pixel width x height

Image clock pins

Capacity of each clock phase

Number of active lines

Number of black reference lines

Number of dummy lines

Total number of lines

Number of active pixels per line

Number of black reference pixels per line

Total number of pixels per line

10.4 mm

5:4

8.24 x 6.61 mm

5.1 x 5.1 µm

A1, A2, A3, A4

5.4 nF per pin

1296

24 (12+12)

4

1324

1616

72 (2+70)

1688

through the storage section to the horizontal output register. In the

monitoring mode subsampling of the image is performed at the

image-to-storage transition and the subsampled image is stored in

the storage section. The stored image is shifted one line at a time

into the horizontal output register.

In the next active line time the pixels are transpor ted towards the

output amplifier. Four clock phases (C1 to C4) control the pixel

transport in the output register. In the output amplifier the charge

packets are dumped one by one on a floating diffusion area. The

voltage of this area is sensed and buffered by a three-stage FET

source-follower. Figure 2 shows the detailed internal structure.

2

2

STORAGE SECTION

Cell width x height

Storage clock pins

Capacity of each clock phase

Number of cells per line x number of lines

5.1 x 5.1 µm

B1, B2, B3, B4

1.5 nF per pin

1688 x 298

2

OUTPUT REGISTER

Number of dummy cells

Total number of register cells

Output register clock pins

Capacity of each clock phase

Reset Gate (RG) capacity

Output stage

8

1696

C1, C2, C3, C4

60 pF per pin

15 pF

3-stage source follower (open source)

2000 January 3

Page 4

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Operational modes

The FXA 1012 is designed for high-resolution digital photography

with real time monitoring at reduced resolution. T w o diff erent modes

of operation make this possible.

In the still picture mode the high-resolution image is read-out directly .

A mechanical shutter ensures a 100% smear-free image with a

resolution of 1600 (H) x 1280 (V).

A1

A2

A3

A4

12 lines

1296 active

images

lines

16 lines

OG: output gate

RG: reset gate

One Pixel

A1

A2

A3

A4

A1

A2

A3

A4

A1

A2

A3

A4

A1

A2

A3

A4

A1

A2

A3

A4

B1

B2

B3

B4

RD: reset drain

B1

B2

B3

OUT

RG

RD

OG

8 dummy pixels

B4

C4C2 C1C3C4C2 C1C3 C4C2 C1C3C4C2 C1 C4C2 C1C3 C4C2 C1C3 C4C2 C1C3 C4C2 C1C3 C4C2 C1C3 C4C2 C1C3

column

1

2 black timing

columns

298 storage

lines

column

2+1

1616 image pixels

In the monitoring mode, images with reduced vertical resolution are

produced that are suitable for LCD displa ys. These images can hav e

for example, 120, 240 or 256 lines at up to 40 images per second.

A1

A2

A3

A4

A1

A2

A3

A4

A1

A2

A3

A4

IMAGE

FT CCD

STORAGE

column

2+1616

70 black timing columns

A1

A2

A3

A4

A1

A2

A3

A4

A1

A2

A3

A4

B1

B2

B3

B4

B1

B2

B3

B4

column

2+1616+70

A1, A2, A3, A4: clocks of image section

B1, B2, B3, B4: clocks of storage section

C1, C2, C3, C4: clocks of horizontal register

Figure 2 - Detailed internal structure

2000 January 4

Page 5

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Specifications

Absolute Maximum Ratings Min. Max. Unit

GENERAL:

storage temperature

ambient temperature during operation

voltage between any two gates

DC current through any clock phase (absolute value)

OUT current (no short circuit protections)

VOLTAGES IN RELAT ION TO VPS:

VNS, RD

all other pins

VOLTAGES IN RELAT ION TO VNS:

RD

VPS

all other pins

-40

-20

-20

-0.2

0

-0.5

-10

-10

-30

-30

+80

+60

+20

+2.0

4

+30

+25

+0.5

+0.5

+0.5

°C

°C

V

µA

mA

V

V

V

V

V

Max. current

[mA]

2

2

2

3

5.5

1

-

-

VNS

VPS

SFD

SFS

OG

RD

1

N substrate

P substrate

Source Follower Drain

Source Follower Source

Output Gate

Reset Drain

DC Conditions Min. [V] Typical [V] Max. [V]

20

6

19

0

3.5

19

24

7

20

0

4

20

28

9

21

0

4.5

21

Min. Typical Max. Pin

Number of adjustments 0 0 1 VNS

1

To set the VNS voltage for optimal Anti-Blooming (vertical overflow drain), it should be adjustable between minimum and maximum values.

2

Currents INS and IPS are specified at overexposure of 100 x Qmax.

3

Measured with Rload = 3.3 kOhms.

AC Clock Level Conditions Min. Typical Max. Unit

IMAGE CLOCKS:

A-clock amplitude

A-clock low level

11 12

0

13 V

V

STORAGE CLOCKS:

B-clock amplitude

B-clock low level

11 12

0

13 V

V

HORIZONTAL AND RESET CLOCKS:

C-clock amplitude

C-clock low level C1, C3

C-clock low level C2, C4

Reset Gate (RG) amplitude

Reset Gate (RG) high level

4.5

2.5

4.5

21

5

0

3

5

22

5.5

3.5

5.25

23

VNS PULSE:

Charge Reset (CR) pulse on VNS 4.5 5 5.5 V

2000 January 5

V

V

V

V

V

Page 6

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

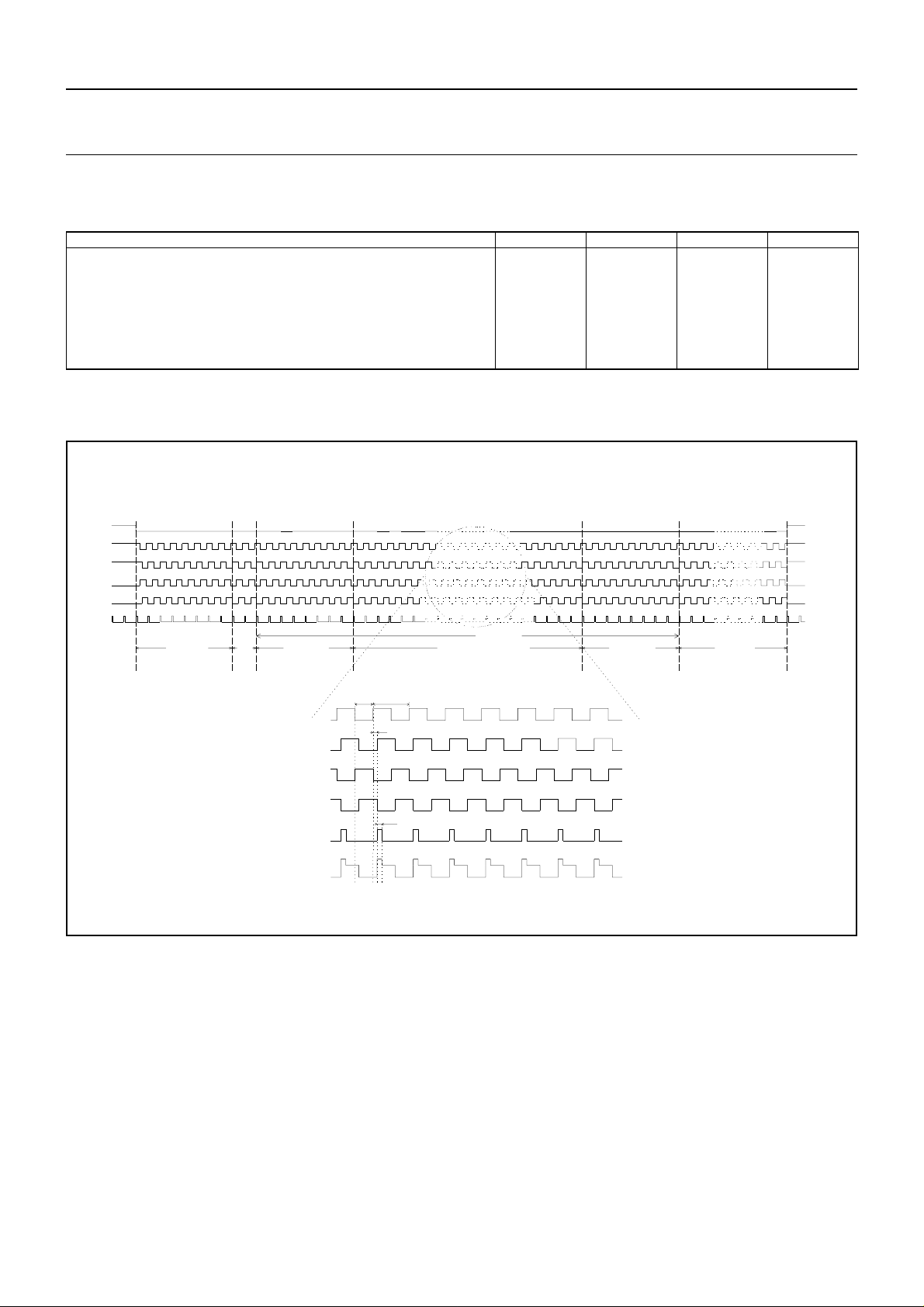

Timing diagrams (for default operation)

AC Characteristics Min. Typical Max. Unit

Horizontal frequency

Vertical frequency

Charge Reset (CR) time

Rise and fall times: image clocks (A)

register clocks (C)

reset gate (RG)

1

Typical value for monitor mode.

2

Duty cycle = 50%

3

Tp is pulse period of C clocks

C-clock pulses

FREQUENCY = 25 MHz

SSC

C1

C2

C3

C4

RG

blue (even) lines

red (odd) lines

8 dummy pixels

2

black 1600 active pixels within aspect ratio

pixels

10

2

10

3

3

COMPLETE LINE READOUT CYCLE

8 overscan pixels

RG G RGR

GBGB

RGR

C1

C2

G

GB

RG

20ns

G

R

6ns

G

B

BG BG

R

GRG

25MHz HORIZONTAL TRANSPORT PULSES

40ns

1616 active pixels

BGGBGBG G

....

..

.

..

..

.

.

.

G

1.56

12

20

5

5

GRG

8 overscan pixels

G

B

RGR

1

BGB

R

25

MHz

MHz

14

3

Tp/8

Tp/8

70 black pixels

BB

G

RG

µs

ns

ns

ns

C3

C4

RG

SENSOR SIGNAL

6.7ns

Figure 3 - Timing diagram for horizontal pulses

2000 January 6

Page 7

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

HORIZONTAL PULSES

C-clock frequency = 25MHz

Thorizontal = 1/25E6 * 2040 = 81.6us

1600 active pixels

phase count

SSC

CR_A1/A2

CR_NS

A1 / B1

A2 / B2

A3 / B3

A4 / B4

1696 sensor pixels

1960

1940

Line shift

Line shift

Line shift

Line shift

2020

2040/0

31 dummy

black

20

312 lineblanking

60

80

40

49

49

49

100

140

120

129

109

180

160

12 us

169

149

18989

240

220

200

8 overscan

1980

70 black

2000

Figure 4 - Pulse timing diagrams for vertical clocks during line blanking

2 black

8 dummy

8 overscan

phiC reg

300

320

280

260

34069360

349

349

36148

1600 active pixels

380

400

440

420

STILL PICTURE MODE - 1/30s Integration

Tvertical = (1/25E6 * 2040) * 2035 = 166.1 ms

298

storage lines

integration

line count

NS_pulse

A1 / A2

A3 / A4

B1 / B2

B3 / B4

2028

2029

2030

2031

2032

2033

2035/0

12345

2

678

9

292

293

291

1622 sensor lines

4

dummy

294

295

296

297

298

301

300

299

12 1281280

302

303

304

305

306

307

308

309

310

311

8

overscan

316

322

317

318

319

320

315

314

line shift

321

313

312

1324

image lines

active lines

327

325

324

323

328

326

Figure 5 - Still picture mode timing diagrams

1599

1600

1601

1602

1603

1604

1605

4

dummy

lines

1622

1623

1624

1626

1625

1626

1628

1628

CR

CR

integration

1627

1628

1629

1630

1631

1632

overscan black linesblack lines

1615

1612

1606

1609

1610

1611

1507

1608

1613

1614

1616

1617

1618

1619

1620

1621

2000 January 7

Page 8

Philips Semiconductors Objective specification

MONITOR MODE

1/60s int

FS

Frame Transfer CCD Image Sensor FXA 1012

-

Tvertical = (1/25E6 * 2040) * 315 = 25.7ms

314

315/0

2

1

1

2

2

2

2

3456789

frame shift line shift

line count

NS_pulse

A1 / A2

A3 / A4

B1 / B2

B3 / B4

and Subsampling pulses in monitor mode

4 phase - 4:4 Frame Shift with 2/10 subsampling

Transport frequency 1.56MHz

FS-counter

A1

A2

A3

A4

B1

B2

B3

B4

111213141516171819

10

4 dummy 12 black 1290 active image lines to 258 lines via subsampling

213

egration

4

4

dummy

dummyblack

14

18

567891011

4

20

12

black

24252627282930

232221

121314

31

323334

15

integration

298 sensor lines

264

subsampled

110

111

112

CR

113

CR

113

12

black

298

299

300

301

113

114

295

296

302

297

303

304

remaining storage lin

305

306

307

308

6

309

310

311

312

313

314

315/0

1

1

315

18

16

17

202122

19

2425262728

23

29

303132

3334353637

38

FS-counter

A1

A2

A3

A4

B1

B2

B3

B4

1293

1294

1295

1296

1297

1298

1299

1300

1301

1302

Remaining 6 active image lines

1313

1311

1303

1304

1305

1306

1307

1308

1309

1310

1312

1314

1315

1316

Figure 6 - Monitor mode timing diagrams

12 black Removing 6 storage gap lines

1325

1326

1317

1318

1319

1320

1321

1322

1323

1324

1327

1328

1329

1330

2000 January 8

Page 9

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Pixel timing

C1

C2

C3

C4

RG

Y : 5V/ Div. X : 10ns/ Div.

Figure 7 - Start horizontal readout

—> time

2000 January 9

Page 10

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Performance

The test conditions for the perfor mance characteristics in the still

mode of operation are as follows:

• All values are measured using typical operating conditions.

• Integration time = 1/30 sec (unless specified otherwise).

• Test temperature = 60°C (333K).

Performance Characteristics Min. Typical Max. Unit

• The light source is a 3200K lamp with a 1.7mm thick BG40 infrared

cut-off filter; F=16.

• Vertical Anti-Blooming condition

• Horizontal transport frequency = 25MHz.

Charge Transfer Efficiency 1 vertical

Charge Transfer Efficiency

1

horizontal

Image lag

Sensitivity, green S

Sensitivity, red SR

Sensitivity, blue SB

Sensitivity Ratio SG / S

Sensitivity Ratio SG / S

Sensitivity Ratio SR / S

Shading per colour plane

Differential colour shading

2

G

2

2

R

B

B

3

4

PRNU per colour plane

Green–green difference

Power consumption (Still mode)

5

40

Power consumption (Monitoring mode)

Full-well capacity saturation level (Q

Saturation signal

Dynamic range at 20°C : 20log(Q

Overexposure

1

Charge Transfer Efficiency values are expressed as the value per gate transfer.

2

The sensitivity when a light source directly illuminates the CCD.

3

Shading is defined as the one-σ value of the pixel output distribution expressed as a percentage of the mean value output (low-pass image).

4

Difference in shading between the four colour planes, with standard imaging condition, still mode.

5

Difference in average green signal between ‘green in red line’ and ‘green in blue line’, with standard imaging condition, still mode

6

Q

is determined from the lowpass filtered image.

max

7

Overexposure over entire area while maintaining good Ver tical Anti-Blooming (VAB). It is tested by measuring the dark line.

7

handling

6

)

max

/noise electrons)

max

35

720

0.999997

0.999997

295

240

175

1.25

1.7

1.4

2

0.8

50

45

1000

72

100

0

2.5

5

60

55

1500

%

mV/lux.s

mV/lux.s

mV/lux.s

%

%

%

%

mW

mW

3

x 10

mV

dB

x Q

level

max

2000 January 10

Page 11

Philips Semiconductors Objective specification

*

Frame Transfer CCD Image Sensor FXA 1012

RGB response

100

90

80

70

60

50

40

30

Response (A.U.)

20

10

0

400 450 500 550 600 650 700

*Arbitrary units

Output Buffer Min Typical Max Unit

Conversion factor at output node

Supply current

Bandwidth

RMS readout noise @ 5MHz bandwidth after CDS

Blue

Green

Waveleng ht (nm)

Figure 8 - RGB response

18 20

Red

4

95

12

25

15

µV/el.

mA

MHz

el.

Dark Condition at 60

Average no. of dark signal electrons per pixel aft er 1/30 sec integrat i o n

Dark signal shading

Dark current level @ 60° C

Fixed Pattern Noise

1

Typical operating conditions (Image capture mode; 60°C; 1/30s exp. time).

2

FPN is the one-σ value of the highpass image.

2

(FPN) @ 60° C

1

C

°°°°

Min. Typical Max. Unit

25

1

0.3

15

0.6

25

electrons

mV

nA/cm

electrons

2

2000 January 11

Page 12

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Application information

Current handling

One of the purposes of VPS is to drain the holes that are generated

during exposure of the sensor to light. Free electrons are either

transported to the VRD connection and, if excessive (from overexposure), free electrons are drained to VNS. No current should

flow into VPS. During overexposures a total current 0.5 to 1mA

through VPS ma y be expected. The PNP emitter f ollower in the circuit

diagram (figure 9) serves these current requirements.

VNS drains superfluous electrons as a result of overexposure. In

other words, it only sinks current. During overe xposures a total current

of 0.5 to 1mA through VNS may be expected. The NPN emitter

follower in the circuit diagram meets these current requirements.

The clamp circuit, consisting of the diode and electrolytic capacitor,

enables the addition of a Charge Reset (CR) pulse on top of an

otherwise stable VNS voltage. To protect the CCD, the current

resulting from this pulse should be limited. This can be accomplished

by designing a pulse generator with a rather high output impedance.

a current source or more simply with a resistance to GND. In order

to prevent the output (which typically has an output impedance of

about 400 Ohm) from bandwidth limitation as a result of capacitive

loading, load the output with an emitter follower built from a highfrequency transistor. Mount the base of this transistor as close as

possible to the sensor and keep the connection between the emitter

and the next stage short. The CCD output buffer can easily be

destroyed by ESD. By using this emitter follower, this danger is

suppressed; do NOT reintroduce this danger by measuring directly

on the output pin of the sensor with an oscilloscope probe. Instead,

measure on the output of the emitter follower. Slew rate limitation is

prevented by avoiding a too-small quiescent current in the emitter

follower; about 10mA should do the job. The collector of the emitter

follower should be decoupled properly to suppress the Miller effect

from the base-collector capacitance. A CCD output load resistor of

3.3 kΩ typically results in a bandwidth of 95MHz.

Decoupling of DC voltages

All DC voltages (not VNS, which has additional CR pulses as

described above) should be decoupled with a 100nF decoupling

capacitor. This capacitor must be mounted as close as possible to

the sensor pin. Further noise reduction (by bandwidth limiting) is

achieved by the resistors in the connections between the sensor

and its voltage supplies. The electrons building up the charge pac kets

that will reach the floating diffusion only add up to a small current,

which will flow through VRD. Therefore a large series resistor in the

VRD connection may be used.

Output

To limit the on-chip power dissipation, the output buffer is designed

with open source output. The output should theref ore be loaded with

B1

B2

VNS

A4

NC

B1

BAT74

BAT74

C4

3K3

B2

VPS

NC

OUT

SFD

100n

BAT74

SFS RD RG

R3

22K

100K

BC860C

47K

R9

100E

R7

R8

2K2

CCD OUT

VSFD

C1

Cstray

47E

R6

100n

R1

R2

BFR92

From V-Drivers From PPGFrom CCD Supply

A3

A4

A3

FXA 1012

C6

100n

Device protection

The output buffer or VNS of the FXA 1012 is likely to be damaged if

VPS rises above SFD or RD at any time. This danger is most realistic

during power-on or power-off of the camera.

Never exceed the maximum output current. This may damage the

device permanently. The maximum output current should be limited

to 6mA. Be especially aware that the output buffers of these image

sensors are very sensitive to ESD damage.

Because of the fact that our CCDs are built on an n-substrate, we

are dealing with some parasitic NPN transistors. To avoid activation

of these transistors during switch-on and switch-off of the camera,

we recommend the application diagram of figure 9.

3

2

1

4

A2

A2 A1

C4

A1

B3

B4

ES

NC

B3

4.7uF

B4

VNS

NC

OG

C3

C2

C1

C2

1K

R5

BAS28

C3

R4

47K

100n

C5

C7

100n

C8

100n

C9

100n

100n

100K

H DRIVER

R18

1

G

R

C

C

C

C

R11

100K

R14

22K

Figure 9 - Application diagram to protect the FXA 1012

2000 January 12

R15

100K

BAS28

BAS28

R16

6K8

R12

100K

R17

18K

BAS28

100nC11100nC10

R13

100K

74ACT04

Page 13

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Peripheral ICs

To allow compact and low-cost applications, use of the following

peripheral circuits for the FXA 1012 is suggested:

• Pulse Patter n Generator

The PPG (pulse pattern generator) delivers all the pulses, at logic

level, to drive the ver tical clocks of the CCD. For this sensor, the

PPG is included in the DSP SAA8122 or separately in the Timing

Generator SAA8103.

• Vertical Drivers + DC/DC Converter

The vertical drivers convert the 3.3V or 5V logic pulses from the

PPG to 12V analog pulses to drive the vertical clocks of the CCD.

The recommended driver is the Philips TDA9991.

• CDS - AGC - ADC

The combined CDS (correlated double sampling) - AGC (automatic

gain control) and ADC (10 bit analog-to-digital convertor) is the

easiest way to link the output of the CCD to a DSP (digital signal

processor). Philips Semiconductors # TDA8783

• DSP

A dedicated DSP has been developed that can handle the image

format and different modes of the FXA 1012. Philips

Semiconductors # SAA8122.

Special modes of operation

Monitor mode with 240 lines vertical resolution is achieved with 1:5

subsampling, yielding 1200/5 = 240 lines. When 1:4 subsamlping is

applied, an image with 288 lines vertical resolution is obtained.

Device Handling

An image sensor is a MOS device which can be destroy ed by electrostatic discharge (ESD). Therefore, the device should be handled

with care.

Always store the device with short-circuiting clamps or on conductive

foam. Alwa ys s witch off all electric signals when inserting or removing

the sensor into or from a camera (the ESD protection in a CCD

image sensor is less effective than the ESD protection of standard

CMOS circuits).

Being a high quality optical device, it is important that the cover

glass remain undamaged. When handling the sensor , use fingercots.

T o remo ve the protectiv e tape from the cov er glass, use the f ollowing

procedure:

• do not scratch or tear off the protective tape before mounting.

• peel off the tape slowly.

• the use of an ionised air blow er is recommended when peeling off

the tape.

• once peeled off, do not reuse the tape.

To clean stains from the package surface, use a cotton stick soak ed

in ethanol. Wipe carefully in order not to scratch the glass surface.

Dry rubbing of the cover glass may cause electro-static discharges

which can destroy the device.

Soldering information

The CCD package temperature must not exceed 150°C. Soldering

iron temperature should be under 300°C when mounting a CCD on

a printed circuit board. Aim for a solder ing time of 3 seconds per

pad. Use a soldering iron that has an adjustab le temperature control

function (that is grounded) that holds the soldering iron tip at a

constant temperature.

2000 January 13

Page 14

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Pin configuration

Pin Number Symbol

1

2

3

4

5

6

7

8

9

10

11

12

4

a3

a4

NC

b1

b2

vps

NC

out

sfd

sfs

rd

rg

123 242322

Pin Number Symbol

13

14

15

16

17

18

19

20

21

22

23

24

21

21

c4

c1

c2

c3

og

NC

vns

b4

b3

NC

a1

a2

123242322

4

5

6

7

8

9

10 11 12 13 14 15

20

19

18

17

16

Figure 10 - Pin configuration

20

19

18

17

16

13 12 11 101415

5

6

7

8

9

2000 January 14

Page 15

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Pack age inf ormation

16. 3 +/ - 0. 2

14. 1 +/ - 0. 4

8. 605 +/ - 0. 2

0. 3 +/ - 0. 13

Optical center

8. 3 +/ - 0. 2 8. 3 +/ - 0. 2

6. 3 +/ - 0. 4 6. 4 +/ - 0. 4

R0.5

a

(R0.6)

1. 865 +/ - 0. 2

12. 7 +/ - 0. 1

2. 54

Glass

1. 2 +/ - 0. 15

Resin

V

H

1. 2

1. 685 +/ - 0. 168

2. 05 +/ - 0. 14

3. 55 +/ - 0. 2

1+/-0.1

B

a-a'

2. 9 +/ - 0. 4

1

(1.2)

2- 1

c

1. 2

a'

A

Sensor

0. 7 +/ - 0. 08

4-R0.3

R0.25

1. The bottom of the package [A] is the height reference.

2. The height from the bottom [A] to the effective image area is 1.685 +/-0.168mm.

The height from the top of the cover glass [B] to the effective image area is 1.865 +/-0.2mm.

3. The tilt of the effective image area relative to the height reference is less than 0.095mm.

4. The thickness of the Au plating is more than 1.0um.

The thickness of the Au plating is less than 3.0um.

5. The point [C] is the origin of H&V direction.

6. The center of effective image area relative to [C] is (V,H)=(8.605,0)+/-0.2mm.

7. The rotation angle of the effective image area relative to H and V is less than +/-1.5 degrees.

8. The rotation angle of the cover glass relative to H and V is less than +/-2degrees.

9. The thickness of the cover glass is 1.5 +/-0.05mm, and the refractive index 1.5.

10. The refractive index of the resin is 1.5.

11. The tolerances that are not shown are +/-0.13mm.

12. D=2.18 +/-0.44mm

D: Distance between left edge of imaging area and left edge of cover glass.

+/-0.44mm means 4sgm = 0.44mm.

13. No horizontal force is allowed to cover glass lid.

ALL LINEAR DIMENSIONS ARE IN MILLIMETERS

Figure 11 - Mechanical drawing of the FXA 1012 package

2000 January 15

Page 16

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

13. 5

6. 7

2

R

a

a'

Protection foil

Glass

Resin

12

14. 5

Sensor

0. 06

a-a'

Figure 12 - Protective foil on top of cover glass

2000 January 16

Page 17

Philips Semiconductors Objective specification

Frame Transfer CCD Image Sensor FXA 1012

Order codes

The sensor can be ordered using the following code:

FXA 1012 sensor

Description Order Code

FXA 1012 WC 9352 670 10117

You can contact the Image Sensors division of Philips

Semiconductors at the following address:

Philips Semiconductors

Image Sensors

Internal Postbox WAG-05

Prof. Holstlaan 4

5656 AA Eindhoven

The Netherlands

phone +31 - 40 - 27 44 400

fax +31 - 40 - 27 44 090

www.semiconductors.philips.com/imagers/

Philips reserves the right to change any information contained herein without notice. All information furnished by Philips is believed to be accurate. © Philips Electronics N.V. 2000

9352 670 10117

Philips

Semiconductors

Loading...

Loading...