Page 1

FSL156MRIN

Green-Mode Fairchild Power Switch (FPS™)

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

June 2012

Features

Advanced Soft Burst Mode for Low Standby Power

and Low Audible Noise

Random Frequency Fluctuation (RFF) for Low EMI

Pulse-by-Pulse Current Limit

Overload Protection (OLP), Over-Voltage

Protection (OVP), Abnormal Over-Current

Protection (AOCP), Internal Thermal Shutdown

(TSD) with Hysteresis, Output-Short Protection

(OSP), and Under-Voltage Lockout (UVLO) with

Hysteresis , Line Over Voltage Protection (LOVP)

Low Operating Current (0.4mA) in Burst Mode

Internal Startup Circuit

Internal High-Voltage SenseFET: 650V

Built-in Soft-Start: 15ms

Auto-Restart Mode

Applications

Power Supply for Home Appliances, LCD Monitors,

STBs, and DVD Players

Description

The FSL156MRIN is an integrated Pulse Width

Modulation (PWM) controller and SenseFET specifically

designed for offline Switched Mode Power Supplies

(SMPS) with minimal external components. The PWM

controller includes an integrated fixed-frequency

oscillator, Line-Over Voltage Protection (LOVP), UnderVoltage Lockout (UVLO), Leading-Edge Blanking (LEB),

optimized gate driver, internal soft-start, temperaturecompensated precise current sources for loop

compensation, and self-protection circuitry. Compared

with a discrete MOSFET and PWM controller solution,

the FSL156MRIN reduces total cost, component count,

size, and weight; while simultaneously increasing

efficiency, productivity, and system reliability. This

device provides a basic platform suited for cost-effective

design of a flyback converter.

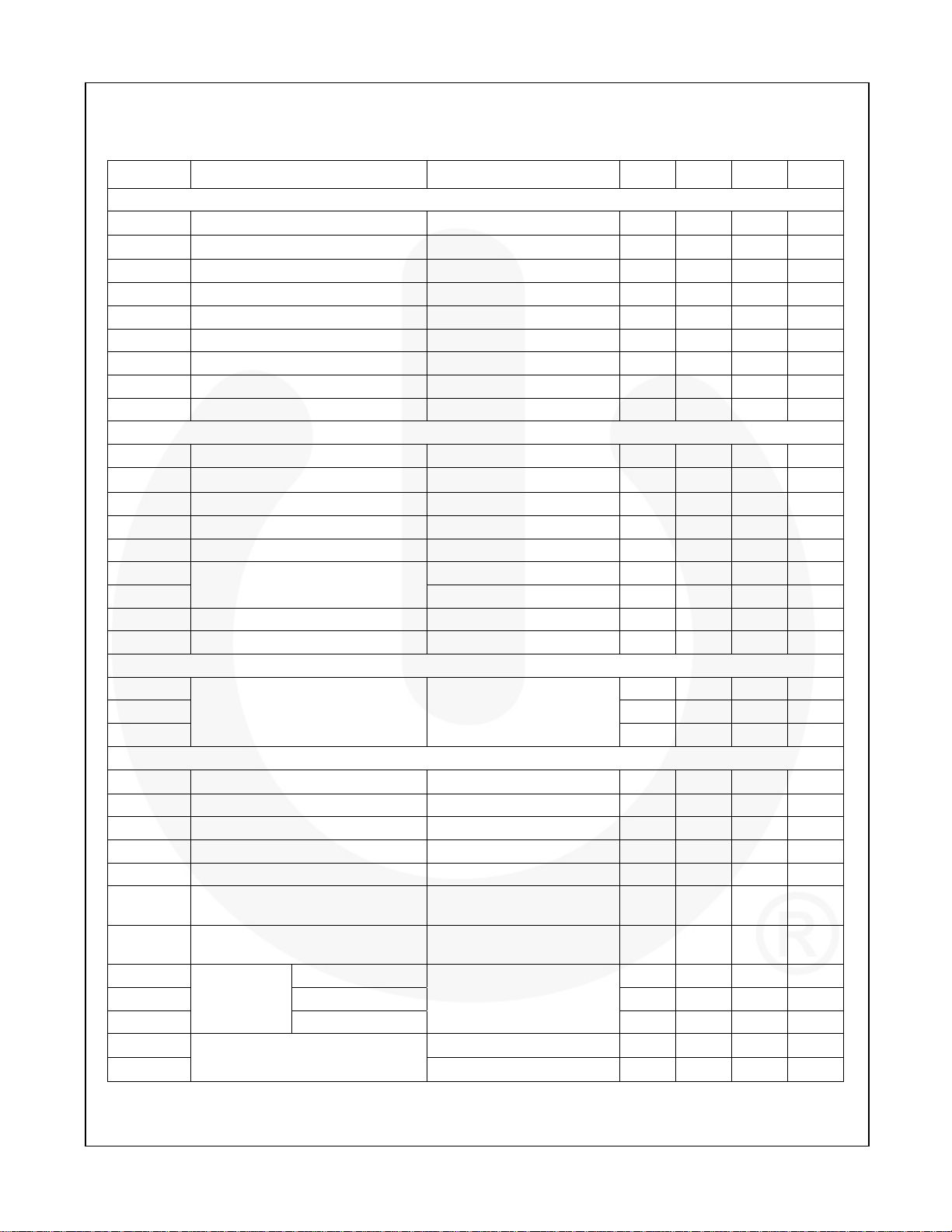

Ordering Information

Output Power Table

Operating

Part Number

Package

(1)

Junction

Temperature

FSL156MRIN

Notes:

1. Lead-free package per JEDEC J-STD-020B.

2. The junction temperature can limit the maximum output power.

3. Typical continuous power in a non-ventilated enclosed adapter measured at 50C ambient temperature.

4. Maximum practical continuous power in an open-frame design at 50C ambient temperature.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0

8-DIP

-40°C ~ +125°C

Current

Limit

(Typ.)

1.6A

R

DS(ON)

(Max.)

2.2

230VAC ±15% 85-265V

Open

Adapter

(3)

Frame

26W 40W 20W 30W

(4)

Adapter

(2)

(3)

Frame

AC

Open

(4)

Page 2

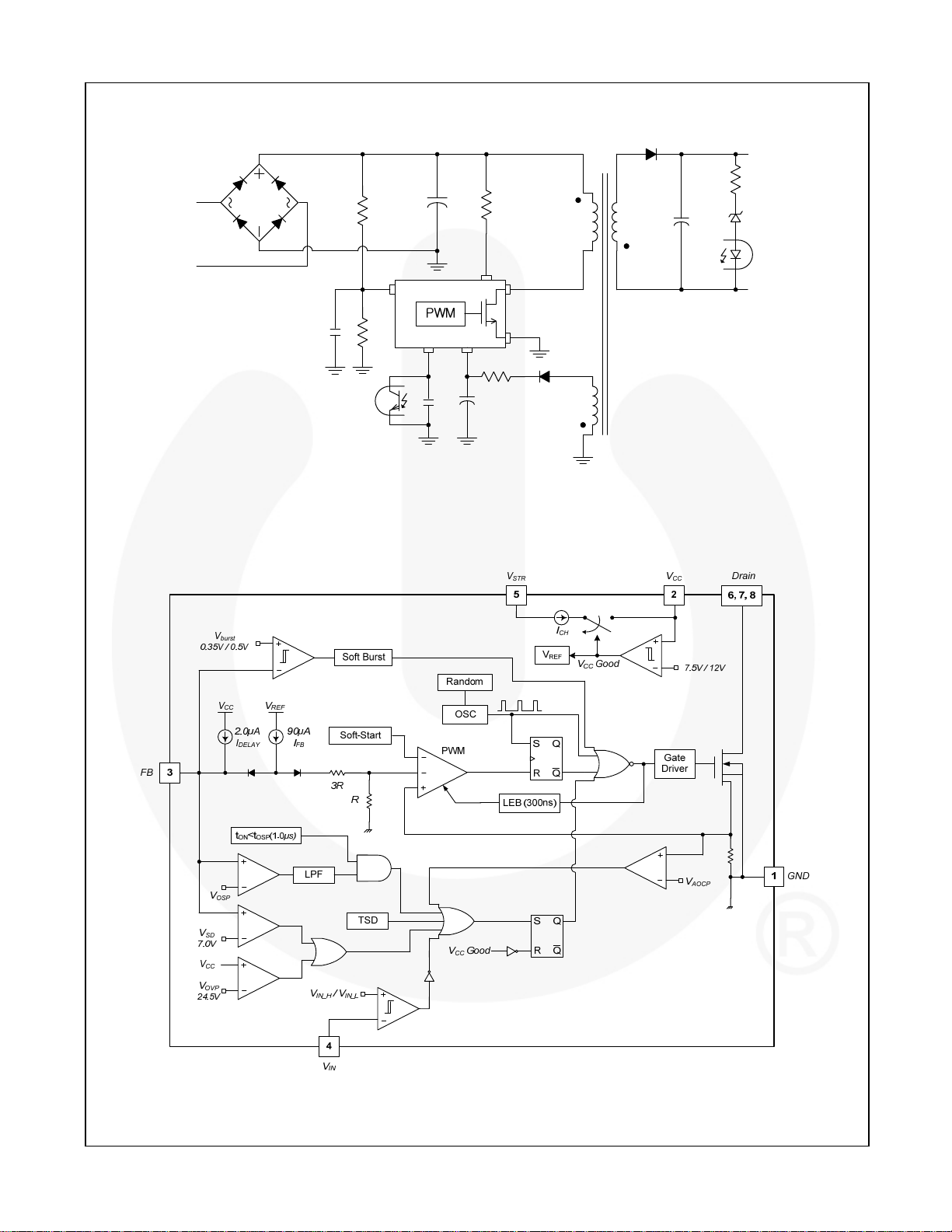

Application Circuit

AC

IN

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

V

O

V

V

IN

STR

Drain

GND

Internal Block Diagram

FB

V

CC

Figure 1. Typical Application Circuit

Figure 2. Internal Block Diagram

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 2

Page 3

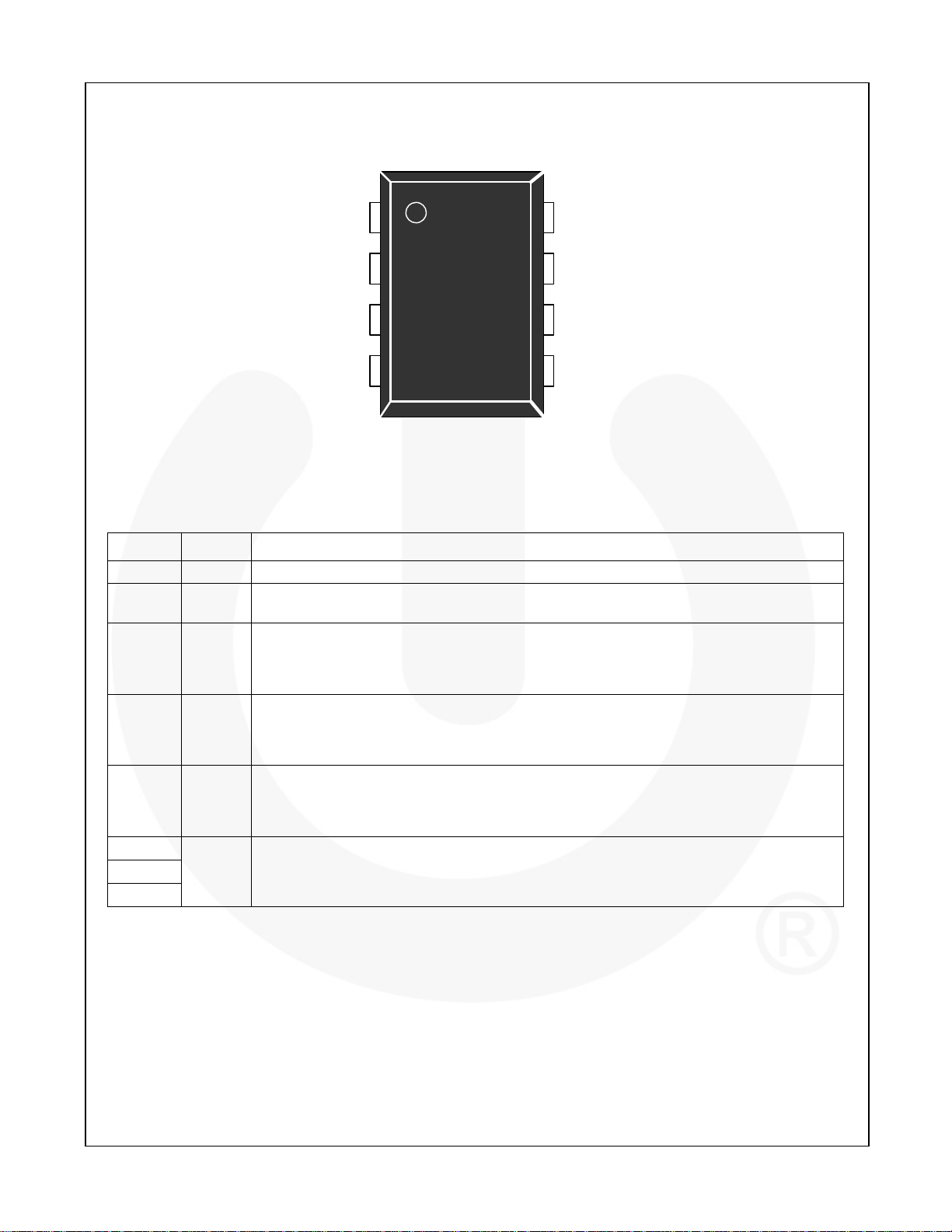

Pin Configuration

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

1. GND

2. V

CC

FSL156MRIN

3. FB

4. V

IN

Figure 3. Pin Assignments (Top View)

Pin Definitions

Pin # Name Description

1 GND

2 V

3 FB

4 V

5 V

6

7

Drain

8

Ground. This pin is the control ground and the SenseFET source.

Power Supply. This pin is the positive supply input, which provides the internal operating

CC

current for both startup and steady-state operation.

Feedback. This pin is internally connected to the inverting input of the PWM comparator.

The collector of an opto-coupler is typically tied to this pin. For stable operation, a capacitor

should be placed between this pin and GND. If the voltage of this pin reaches 7V, the

overload protection triggers, which shuts down the FPS.

Line Over-Voltage Input. This pin is the input pin of line voltage. The voltage, which is

divided by resistors, is the input of this pin. If this pin voltage is higher than V

IN

LOVP triggers, which shuts down the FPS. Do not leave this pin floating. If LOVP is not used,

this pin should be directly connected to the GND.

Startup. This pin is connected directly, or through a resistor, to the high-voltage DC link.

At startup, the internal high-voltage current source supplies internal bias and charges the

STR

external capacitor connected to the V

source (I

SenseFET Drain. High-voltage power SenseFET drain connection.

) is disabled.

CH

pin. Once VCC reaches 12V, the internal current

CC

8. Drain

7. Drain

6. Drain

5. V

STR

voltage, the

INH

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 3

Page 4

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

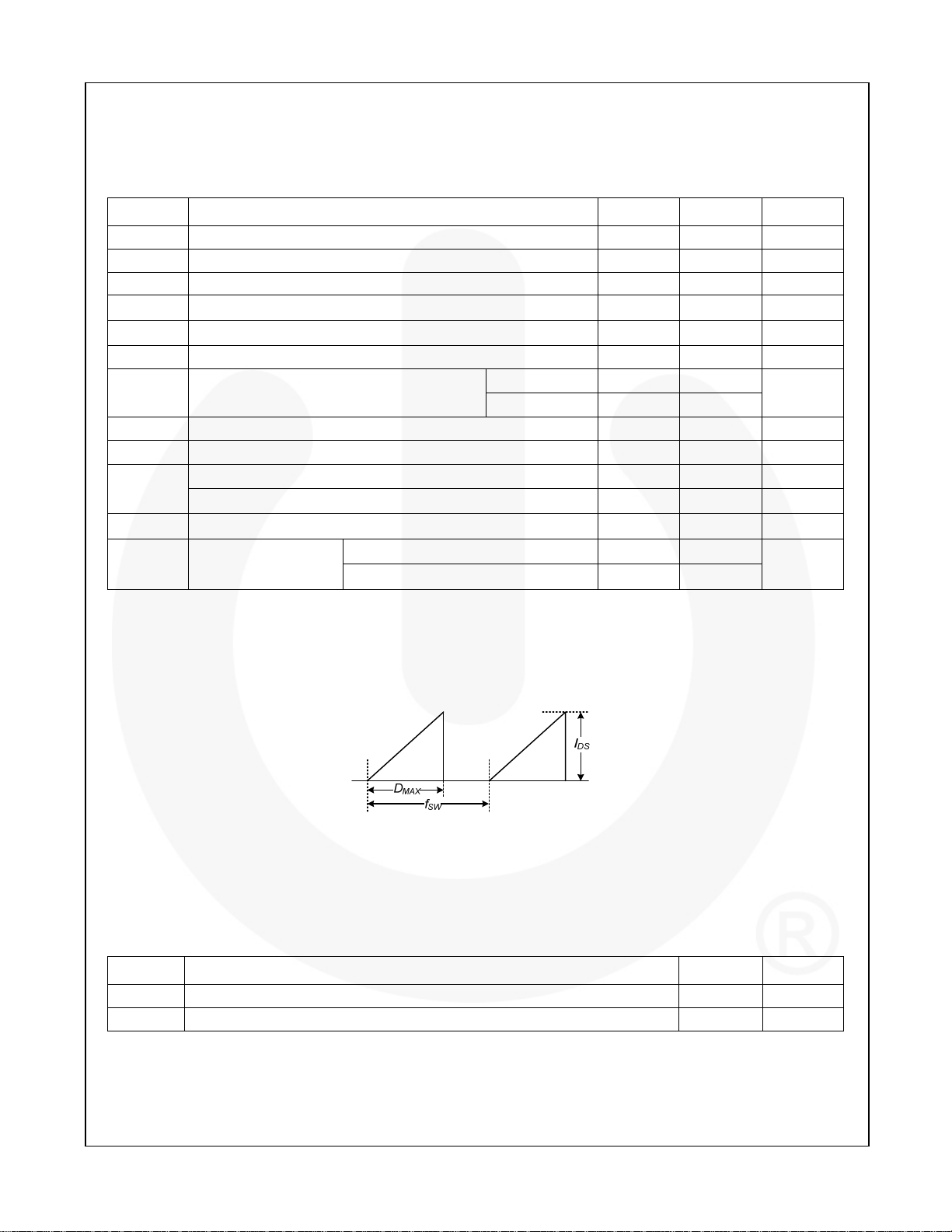

Absolute Maximum Ratings

Stresses exceeding the absolute maximum ratings may damage the device. The device may not function or be

operable above the recommended operating conditions and stressing the parts to these levels is not recommended.

In addition, extended exposure to stresses above the recommended operating conditions may affect device reliability.

The absolute maximum ratings are stress ratings only.

Symbol Parameter Min. Max. Unit

V

V

STR

VDS Drain Pin Voltage 650 V

V

V

CC

V

Feedback Pin Voltage -0.3 10.0 V

FB

VIN VIN Pin Voltage -0.3 10.0 V

I

Drain Current Pulsed 4 A

DM

I

Continuous Switching Drain Current

DS

EAS Single-Pulsed Avalanche Energy

PD

T

J

T

Storage Temperature -55 +150

STG

ESD

Notes:

5. Repetitive peak switching current when the inductive load is assumed: limited by maximum duty (D

junction temperature (see Figure 4).

6. L=45mH, starting T

7. Infinite cooling condition (refer to the SEMI G30-88).

8. Although this parameter guarantees IC operation, it does not guarantee all electrical characteristics.

Pin Voltage 650 V

STR

Pin Voltage 26 V

CC

1.90

1.27

1.5 W

Total Power Dissipation (T

=25C)

C

T

=25C

(5)

C

TC=100C

(6)

190 mJ

(7)

Maximum Junction Temperature 150

Operating Junction Temperature

Electrostatic Discharge

Capability

=25C.

J

Human Body Model, JESD22-A114

Charged Device Model, JESD22-C101

(8)

-40 +125

4.5

2.0

MAX

A

C

C

C

kV

=0.73) and

Figure 4. Repetitive Peak Sw itching Current

Thermal Impedance

TA=25°C unless otherwise specified.

Symbol Parameter Value Unit

JA Junction-to-Ambient Thermal Impedance

JL Junction-to-Lead Thermal Impedance

Notes:

9. JEDEC recommended environment, JESD51-2, and test board, JESD51-10, with minimum land pattern.

10. Measured on drain pin #7, close to the plastic interface.

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 4

(9)

85 °C/W

(10)

11 °C/W

Page 5

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

Electrical Characteristics

TJ = 25C unless otherwise specified.

Symbol Parameter Conditions Min. Typ. Max. Unit

SenseFET Section

BV

Drain-Source Breakdown Voltage

DSS

I

Zero-Gate-Voltage Drain Current

DSS

R

Drain-Source On-State Resistance VGS=10V, ID=1A 1.8 2.2

DS(ON)

C

Input Capacitance

ISS

C

Output Capacitance

OSS

(11)

V

(11)

V

V

=0V, ID=250A

CC

V

=520V, TA=125C

DS

=25V, VGS=0V, f=1MHz 515 pF

DS

=25V, VGS=0V, f=1MHz 75 pF

DS

tr Rise Time VDS=325V, ID=4A, RG=25 26 ns

tf Fall Time VDS=325V, ID=4A, RG=25 25 ns

t

Turn-On Delay VDS=325V, ID=4A, RG=25 14 ns

d(on)

t

Turn-Off Delay VDS=325V, ID=4A, RG=25 32 ns

d(off)

Control Section

f

Switching Frequency

S

f

D

MAX

D

MIN

Switching Frequency Variation

S

Maximum Duty Ratio V

Minimum Duty Ratio V

IFB Feedback Source Current V

V

START

V

STOP

t

V

RECOMM

SS

UVLO Threshold Voltage

After Turn-on, V

Internal Soft-Start Time V

Recommended VCC Range 13 23 V

(11)

V

(11)

=14V, VFB=4V 61 67 73 kHz

CC

-25C < T

=14V, VFB=4V 61 67 73 %

CC

=14V, VFB=0V 0 %

CC

=0 65 90 115 µA

FB

V

=0V, V

FB

STR

J

CC

=40V, V

< 125C

Sweep 11 12 13 V

=0V 7.0 7.5 8.0 V

FB

Sweep 15 ms

CC

Burst Mode Section

V

BURH

V

BURL

Burst-Mode Voltage VCC=14V, VFB Sweep

0.30 0.35 0.40 V

Hys 150 mV

Protection Section

I

Peak Drain Current Limit

LIM

V

Shutdown Feedback Voltage V

SD

I

Shutdown Delay Current V

DELAY

t

Leading-Edge Blanking Time

LEB

V

Over-Voltage Protection VCC Sweep 23.0 24.5 26.0 V

OVP

V

INH

V

INHYS

t

OSP

V

OSP

t

OSP_FB

TSD

T

HYS

Line Over-Voltage Protection

Threshold Voltage

Line Over-Voltage Protection

Hysteresis

Output-Short

Threshold VFB 1.8 2.0 2.2 V

Protection

V

Thermal Shutdown Temperature

Hysteresis 60

Threshold Time

(11)

FB

Blanking Time 2.0 2.5 3.0 µs

(11,12)

di/dt=300mA/s

=14V, V

CC

=14V, VFB=4V 1.2 2.0 2.8 µA

CC

Sweep 6.45 7.00 7.55 V

FB

300 ns

VCC=14V, V

VCC=14V, V

Sweep 1.87 1.95 2.03 V

IN

Sweep 0.06 V

IN

OSP Triggered when

t

(Lasts Longer than t

Shutdown Temperature 125 135 145

(11)

ON<tOSP

& VFB>V

OSP

OSP_FB

650 V

250 µA

±5 ±10 %

0.45 0.50 0.55 V

1.45 1.60 1.75 A

0.7 1.0 1.3 µs

)

C

C

Continued on the following page…

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 5

Page 6

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

Electrical Characteristics (Continued)

TJ = 25C unless otherwise specified.

Symbol Parameter Conditions Min. Typ. Max. Unit

Total Device Section

I

OP

I

OPS

I

START

I

CH

V

STR

Notes:

11. These parameters are guaranteed; not 100% tested in production.

12. t

LEB

Operating Supply Current,

(Control Part in Burst Mode)

Operating Switching Current,

(Control Part and SenseFET Part)

Start Current

Startup Charging Current V

Minimum V

Supply Voltage VCC=VFB=0V, V

STR

includes gate turn-on time.

VCC=14V, VFB=0V 0.3 0.4 0.5 mA

VCC=14V, VFB=2V 1.1 1.5 1.9 mA

V

=11V (Before VCC

CC

Reaches V

=0V, V

CC=VFB

)

START

=40V 0.7 1.0 1.3 mA

STR

Sweep 26 V

STR

85 120 155 µA

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 6

Page 7

Typical Performance Characteristics

Characteristic graphs are normalized at TA=25°C.

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

Figure 5. Operating Supply Current (IOP) vs. TA Figure 6. Operating Switching Current (I

1.20

1.15

1.10

1.05

1.00

0.95

Norm alized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

OPS

) vs. T

A

Figure 7. Startup Charging Current (ICH) vs. TA Figure 8. Peak Drain Current Li mit (I

1.40

1.30

1.20

1.10

1.00

0.90

Norm alized

0.80

0.70

0.60

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110 'C 120'C 125'C

Temperature [ °C]

) vs. TA

LIM

Figure 9. Feedback Sou rce Current (IFB) vs. TA Figure 10. Shutdown Delay Current (I

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 7

DELAY

) vs. TA

Page 8

Typical Performance Characteristics

Characteristic graphs are normalized at TA=25°C.

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

Figure 11. UVLO Threshold Voltage (V

1.20

1.15

1.10

1.05

1.00

0.95

Norm alized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110 'C 120'C 125'C

Temperature [ °C]

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

) vs. TA Figure 12. UVLO Threshold Voltage (V

START

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

STOP

) vs. TA

Figure 13. Shutdown Feedback Voltage (VSD) vs. T

1.20

1.15

1.10

1.05

1.00

0.95

Norm alized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

Figure 15. Switching Frequency (f

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 8

) vs. TA Figure 16. Maximum Duty Ratio (D

S

Figure 14. Over-Voltage Protection (V

A

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐20'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

OVP

MAX

) vs. TA

) vs. TA

Page 9

Typical Performance Characteristics

Characteristic graphs are normalized at TA=25°C.

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐25'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C]

Figure 17. Line OVP (V

1.20

1.15

1.10

1.05

1.00

0.95

Normalized

0.90

0.85

0.80

‐40'C ‐25'C 0'C 25'C 50'C 75'C 90'C 110'C 120'C 125'C

Temperature [ °C ]

) vs. TA Figure 18. Hysteresis of LOVP (V

INH

INHYS

) vs. TA

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 9

Page 10

Functional Description

1. Startup: At startup, an internal high-voltage current

source supplies the internal bias and charges the

external capacitor (C

illustrated in Figure 19. When V

FSL156MRIN begins switching and the internal highvoltage current source is disabled. Normal switching

operation continues and the power is supplied from the

auxiliary transformer winding unless VCC goes below the

stop voltage of 7.5V.

Figure 19. Startup Block

2. Soft-Start: The internal soft-start circuit increases

PWM comparator inverting input voltage, together with

the SenseFET current, slowly after startup. The typical

soft-start time is 15ms. The pulse width to the power

switching device is progressively increased to establish

the correct working conditions for the transformers,

inductors, and capacitors. The voltage on the output

capacitors is progressively increased to smoothly

establish the required output voltage. This helps prevent

transformer saturation and reduces stress on the

secondary diode during startup.

) connected to the VCC pin, as

VCC

reaches 12V, the

CC

3. Feedback Control: This device employs Current-

Mode control, as shown in Figure 20. An opto-coupler

(such as the FOD817) and shunt regulator (such as the

KA431) are typically used to implement the feedback

network. Comparing the feedback voltage with the

voltage across the R

resistor makes it possible to

SENSE

control the switching duty cycle. When the reference pin

voltage of the shunt regulator exceeds the internal

reference voltage of 2.5V, the opto-coupler LED current

increases, pulling down the feedback voltage and

reducing drain current. This typically occurs when the

input voltage is increased or the output load is decreased.

3.1 Pulse-by-Pulse Current Limit: Because Current-

Mode control is employed, the peak current through

the SenseFET is limited by the inverting input of PWM

comparator (V

*), as shown in Figure 20. Assuming

FB

that the 90A current source flows only through the

internal resistor (3R + R =25k), the cathode voltage

of diode D2 is about 2.8V. Since D1 is blocked when

the feedback voltage (V

) exceeds 2.8V, the

FB

maximum voltage of the cathode of D2 is clamped at

this voltage. Therefore, the peak value of the current

through the SenseFET is limited.

3.2 Leading-Edge Blanking (LEB): At the instant the

internal SenseFET is turned on, a high-current spike

usually occurs through the SenseFET, caused by

primary-side capacitance and secondary-side rectifier

reverse recovery. Excessive voltage across the R

SENSE

resistor leads to incorrect feedback operation in

Current-Mode PWM control. To counter this effect, the

LEB circuit inhibits the PWM comparator for t

(300ns) after the SenseFET is turned on.

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

LEB

Figure 20. Pulse Width Modulation Circuit

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 10

Page 11

4. Protection Circuits: The FSL156MRIN has several

self-protective functions, such as Overload Protection

(OLP), Abnormal Over-Current Protection (AOCP),

Output-Short Protection (OSP), Over-Voltage Protection

(OVP), and Thermal Shutdown (TSD). All the

protections are implemented as auto-restart. Once the

fault condition is detected, switching is terminated and

the SenseFET remains off. This causes V

B

When V

B falls to the Under-Voltage Lockout (UVLO)

CC

to fall.

CC

stop voltage of 7.5V, the protection is reset and the

startup circuit charges the V

capacitor. When VCC

CC

reaches the start voltage of 12.0V, normal operation

resumes. If the fault condition is not removed, the

SenseFET remains off and V

drops to stop voltage

CC

again. In this manner, the auto-restart can alternately

enable and disable the switching of the power

SenseFET until the fault condition is eliminated.

Because these protection circuits are fully integrated

into the IC without external components, reliability is

improved without increasing cost.

Figure 21. Auto-Restart Protection Waveforms

4.1 Overload Protection (OLP): Overload is defined

as the load current exceeding its normal level due to

an unexpected abnormal event. In this situation, the

protection circuit should trigger to protect the SMPS.

However, even when the SMPS is in normal

operation, the overload protection circuit can be

triggered during the load transition. To avoid this

undesired operation, the overload protection circuit is

designed to trigger only after a specified time to

determine whether it is a transient situation or a true

overload situation. Because of the pulse-by-pulse

current-limit capability, the maximum peak current

through the SenseFET is limited and, therefore, the

maximum input power is restricted with a given input

voltage. If the output consumes more than this

maximum power, the output voltage (V

) decreases

OUT

below the set voltage. This reduces the current

through the opto-coupler LED, which also reduces the

opto-coupler transistor current, increasing the

feedback voltage (VFB). If VFB exceeds 2.5V, D1 is

blocked and the 2.0µA current source starts to charge

CFB slowly up. In this condition, VFB continues

increasing until it reaches 7.0V, when the switching

operation is terminated, as shown in Figure 22. The

delay for shutdown is the time required to charge C

from 2.5V to 7.0V with 2.0µA. A 25 ~ 50ms delay is

typical for most applications. This protection is

implemented as auto-restart.

Figure 22. Overload Protection

4.2 Abnormal Over-Current Protection (AOCP):

When the secondary rectifier diodes or the

transformer pins are shorted, a steep current with

extremely high di/dt can flow through the SenseFET

during the minimum turn-on time. Even though the

FSL156MRIN has overload protection, it is not

enough to protect the FSL156MRIN in that abnormal

case; due to the severe current stress imposed on the

SenseFET until OLP is triggered. The internal AOCP

circuit is shown in Figure 23. When the gate turn-on

signal is applied to the power SenseFET, the AOCP

block is enabled and monitors the current through the

sensing resistor. The voltage across the resistor is

compared with a preset AOCP level. If the sensingresistor voltage is greater than the AOCP level, the

set signal is applied to the S-R latch, resulting in the

shutdown of the SMPS.

Figure 23. Abnormal Over-Current Protection

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

FB

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 11

Page 12

4.3. Output-Short Protection (OSP): If the output is

shorted, steep current with extremely high di/dt can

flow through the SenseFET during the minimum turnon time. Such a steep current creates high-voltage

stress on the drain of the SenseFET when turned off.

To protect the device from this abnormal condition,

OSP is included. It is comprised of detecting V

SenseFET turn-on time. When the V

is higher than

FB

FB

2.0V and the SenseFET turn-on time is lower than

1.0s, this condition is recognized as an abnormal

error and PWM switching shuts down until V

reaches V

again. An abnormal condition output

START

short is shown in Figure 24.

and

CC

4.6 Line Over-Voltage Protection (LOVP): If the line

input voltage is increased to an unwanted level, high

line input voltage creates high-voltage stress on the

entire system. To protect from this abnormal condition,

LOVP is included. It is comprised of detecting V

divided resistors. When V

is higher than 1.95V, this

IN

condition is recognized as an abnormal error and PWM

switching shuts down until VIN decreases to around

1.89V (60mV hysteresis).

using

IN

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

Figure 25. Line Over-Voltage Protection

Figure 24. Output-Short Protection

4.4 Over-Voltage Protection (OVP): If the

secondary-side feedback circuit malfunctions or a

solder defect causes an opening in the feedback path,

the current through the opto-coupler transistor

becomes almost zero. Then VFB climbs up in a similar

manner to the overload situation, forcing the preset

maximum current to be supplied to the SMPS until the

overload protection is triggered. Because more

energy than required is provided to the output, the

output voltage may exceed the rated voltage before

5. Soft Burst Mode: To minimize power dissipation in

Standby Mode, the FSL156MRIN enters Burst-Mode

operation. As the load decreases, the feedback voltage

decreases. As shown in Figure 22, the device

automatically enters Burst Mode when the feedback

voltage drops below V

(350mV). At this point,

BURL

switching stops and the output voltages start to drop at

a rate dependent on standby current load. This causes

the feedback voltage to rise. Once it passes V

BURH

(500mV), switching resumes. The feedback voltage then

falls and the process repeats. Burst Mode alternately

enables and disables SenseFET switching, reducing

switching loss in Standby Mode.

the overload protection is triggered, resulting in the

breakdown of the devices in the secondary side. To

prevent this situation, an OVP circuit is employed. In

general, the V

and the FSL156MRIN uses V

monitoring the output voltage. If V

is proportional to the output voltage

CC

instead of directly

CC

exceeds 24.5V,

CC

an OVP circuit is triggered, resulting in the termination

of the switching operation. To avoid undesired

activation of OVP during normal operation, V

should

CC

be designed to be below 24.5V.

4.5 Thermal Shutdown (TSD): The SenseFET and

the control IC on a die in one package makes it easier

for the control IC to detect the temperature of the

SenseFET. If the temperature exceeds ~135C, the

thermal shutdown is triggered and stops operation.

The FSL156MRIN operates in Auto-Restart Mode

until the temperature decreases to around 75C,

when normal operation resumes.

Figure 26. Burst-Mode Operation

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 12

Page 13

6. Random Frequency Fluctuation (RFF): Fluctuating

switching frequency of an SMPS can reduce EMI by

spreading the energy over a wide frequency range. The

amount of EMI reduction is directly related to the

switching frequency variation, which is limited internally.

The switching frequency is determined randomly by

external feedback voltage and an internal free-running

oscillator at every switching instant. RFF effectively

scatters EMI noise around typical switching frequency

(67kHz) and can reduce the cost of the input filter

included to meet the EMI requirements (e.g. EN55022).

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

Figure 27. Random Frequency Fluctuation

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 13

Page 14

Package Dimensions

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

9.83

9.00

6.67

6.096

8.255

7.61

3.60

3.00

3.683

3.20

0.356

0.20

5.08 MAX

0.33 MIN

(0.56)

2.54

0.56

0.355

1.65

1.27

7.62

NOTES: UNLESS OTHERWISE SPECIFIED

A) THIS PACKAGE CONFORMS TO

JEDEC MS-001 VARIATION BA

B) ALL DIMENSIONS ARE IN MILLIMETERS.

C) DIMENSIONS ARE EXCLUSIVE OF BURRS,

MOLD FLASH, AND TIE BAR EXTRUSIONS.

D) DIMENSIONS AND TOLERANC

ES PER

ASME Y14.5M-1994

E) DRAWING FILENAME AND REVSION: MKT-N08FREV2.

7.62

9.957

7.87

Figure 28. 8-Lead, MDIP, JEDEC MS-001, .300" Wide

Package drawings are provided as a service to customers considering Fairchild components. Drawings may change in any manner

without notice. Please note the revision and/or date on the drawing and contact a Fairchild Semiconductor representative to verify or

obtain the most recent revision. Package specifications do not expand the terms of Fairchild’s worldwide terms and conditions,

specifically the warranty therein, which covers Fairchild products.

Always visit Fairchild Semiconductor’s online packaging area for the most recent package drawings:

http://www.fairchildsemi.com/packaging/

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 14

.

Page 15

FSL156MRIN — Green-Mode Fairchild Power Switch (FPS™)

© 2012 Fairchild Semiconductor Corporation www.fairchildsemi.com

FSL156MRIN • Rev. 1.0.0 15

Loading...

Loading...