Page 1

www.fairchildsemi.com

User Guide for

AN-8026: FAN9611 / FAN9612 400W

1-Layer Evaluation Board (FEB-301)

Featured Fairchild Product:

FAN9611 / FAN9612

Direct questions or comments

about this Evaluation Board to:

“Worldwide Direct Support”

Fairchild Semiconductor.com

© 2009 Fairchild Semiconductor Corporation AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 2

www.fairchildsemi.com

Table of Contents

1.Overview of the Evaluation Board ............................................................................................. 3

2.General Specification .................................................................................................................. 3

3.Test Procedures ........................................................................................................................... 4

4.Schematic .................................................................................................................................... 6

5.Specification Approval ............................................................................................................... 7

6.Boost Inductor Specification ...................................................................................................... 9

6.1. Electrical Specification ............................................................................................... 10

7.Bill of Materials ........................................................................................................................ 12

8.Test Results ............................................................................................................................... 16

8.1. Startup ......................................................................................................................... 16

8.2. Normal Operation ....................................................................................................... 17

8.3. Line and Load Transient ............................................................................................. 18

8.4. Brown in/out Protection ............................................................................................. 19

8.5. Phase Management ..................................................................................................... 20

8.6. Efficiency.................................................................................................................... 21

8.7. Harmonic Distortion and Power Factor ...................................................................... 22

9.References ................................................................................................................................. 24

© 2009 Fairchild Semiconductor Corporation 2 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 3

www.fairchildsemi.com

The following user guide supports the FAN9611 / FAN9612 400W evaluation board for

interleaved boundary-conduction mode power factor corrected supply. The user guide

should be used in conjunction with the FAN9611/FAN9611 / FAN9612 datasheet as well

as the Fairchild application note AN-6086 — Design Considerations for Interleaved

Boundary-Conduction Mode PFC Using FAN9611 / FAN9612. The user guide and the

evaluation board can also be used to evaluate FAN9611 controller which has the lower

turn-on threshold. Please visit Fairchild’s website at www.fairchildsemi.com

information.

1. Overview of the Evaluation Board

The FAN9611 / FAN9612 interleaved dual Boundary-Conduction-Mode (BCM) PowerFactor-Correction (PFC) controller operates two parallel-connected boost power trains

180º out of phase. Interleaving extends the maximum practical power level of the control

technique from about 300W to greater than 800W. Unlike the continuous conduction

mode (CCM) technique often used at higher power levels, BCM offers inherent zerocurrent switching of the boost diodes (no reverse-recovery losses), which permits the use

of less expensive diodes without sacrificing efficiency. Furthermore, the input and output

filters can be smaller due to ripple current cancellation between the power trains and

effectively doubling the switching frequency.

The advanced line feedforward with peak detection circuit minimizes the output voltage

variation during line transients. To guarantee stable operation with less switching loss at

light load, the maximum switching frequency is clamped at 600kHz. Synchronization is

maintained under all operating conditions.

for

Built-in protection functions include output over-voltage, over-current, open-feedback,

under-voltage lockout, brownout, and redundant latching over-voltage. The FAN9611 /

FAN9612 is available in a lead-free 16-lead SOIC package.

Fairchild offers and evaluation board to aide in design and test of applications using the

FAN9611 / FAN9612. The FAN9611 / FAN9612 evaluation board is a single-layer board

designed for 400W (400V/1A) rated power. Thanks to the phase management, the

efficiency is maintained above 95% at low-line and high-line, even down to 10% of the

rated output power. The efficiencies for full-load condition are 96.3% and 98.0% at line

voltages of 115V

and 230VAC, respectively.

AC

2. General Specification

Specification Min. Max. Units

Input

VIN AC Voltage 90 264 VAC

VIN AC Frequency 47 63 Hz

VDD Supply 13 16 VDC

Output

Output Voltage 400 V

Output Current 1 A

Total Output Power

Maximum Load Output Power 400 W

© 2009 Fairchild Semiconductor Corporation 3 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 4

www.fairchildsemi.com

3. Test Procedures

Before testing the board; DC voltage supply for VDD, AC voltage supply for line input,

and DC electric load for output should be connected to the board properly.

1. Supply V

specification for V

2. When V

the inrush current limit relay is turned on by 5V reference (pin #3), the relay turns on

when FAN9611 / FAN9612 comes out of UVLO by supplying V

3. Connect the AC voltage (90~264V

FAN9611 / FAN9612 has brownout protection and line OVP, any input voltages out

of operation range trigger protections.

4. Change load current (0~1A) and check the operation. The board is designed to go

into phase shedding for output power below around 55W. It goes back to twochannel interleaving operation for output power above around 110W.

Table 1. Test Equipment

Test Model

Test Date

Test Temperature

Test Equipment

Test Items

for the control chip first. It should be higher than 13V (refer to the

DD

turn-on threshold voltage).

DD

is supplied, a "click" sound from the relay is heard. This is normal. Since

DD

FEB301-001

Sept.7, 2009

Ambient

AC Source: Chroma 61603 AC POWER SOURCE

Electronic Load: Chroma 63108

Power Meter: WT210

Oscilloscope: Lecroy wavesurfer 24Xs

DC Source: ABM 9306D

Startup

Normal Operation

Normal Operation

Line and Load Transient

Brown in/out Protection

Phase Management

Efficiency

Harmonic Distortion and Power Factor

higher than 13V.

DD

) to start the FAN9611 / FAN9612. Since

AC

© 2009 Fairchild Semiconductor Corporation 4 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 5

www.fairchildsemi.com

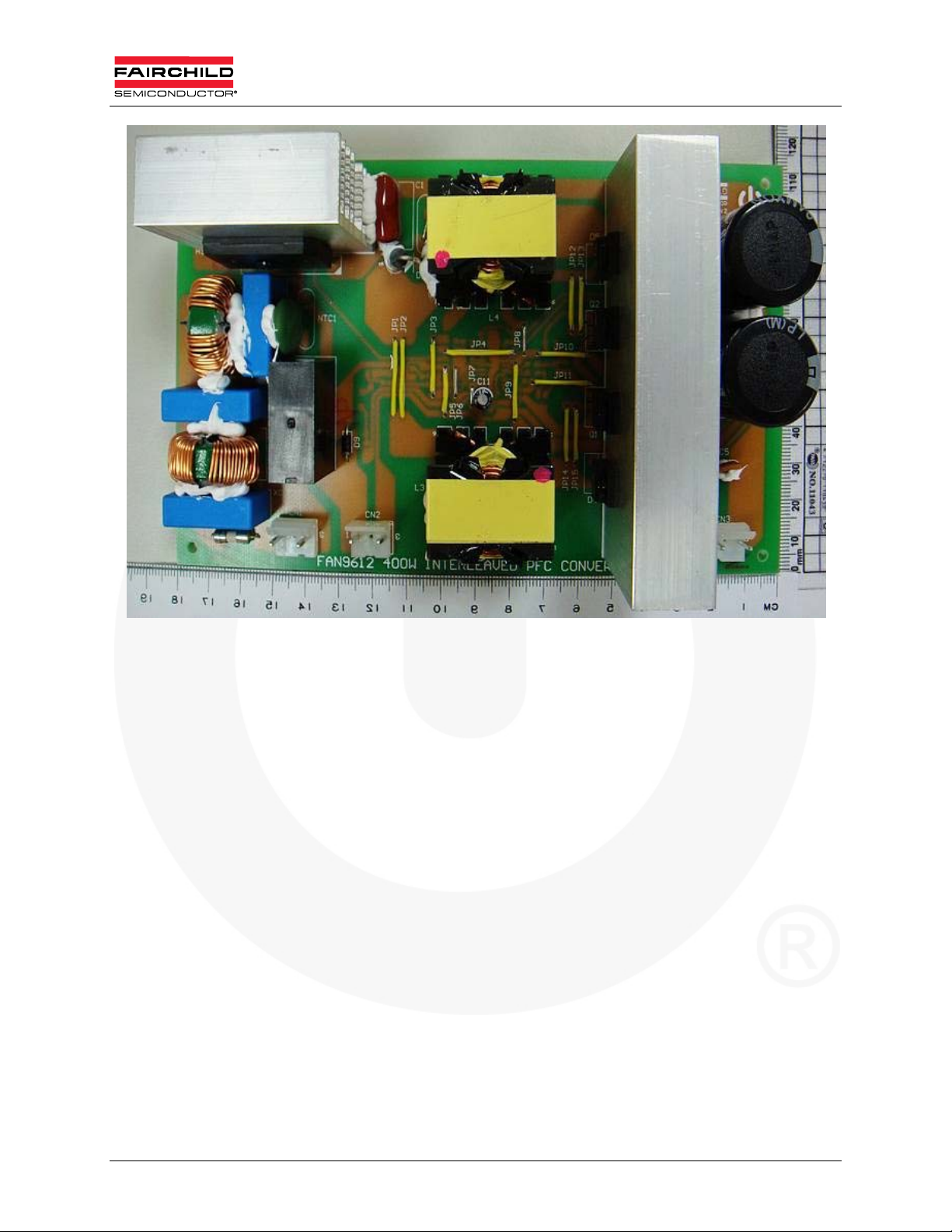

Figure 1. Photograph of Tested Board

© 2009 Fairchild Semiconductor Corporation 5 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 6

www.fairchildsemi.com

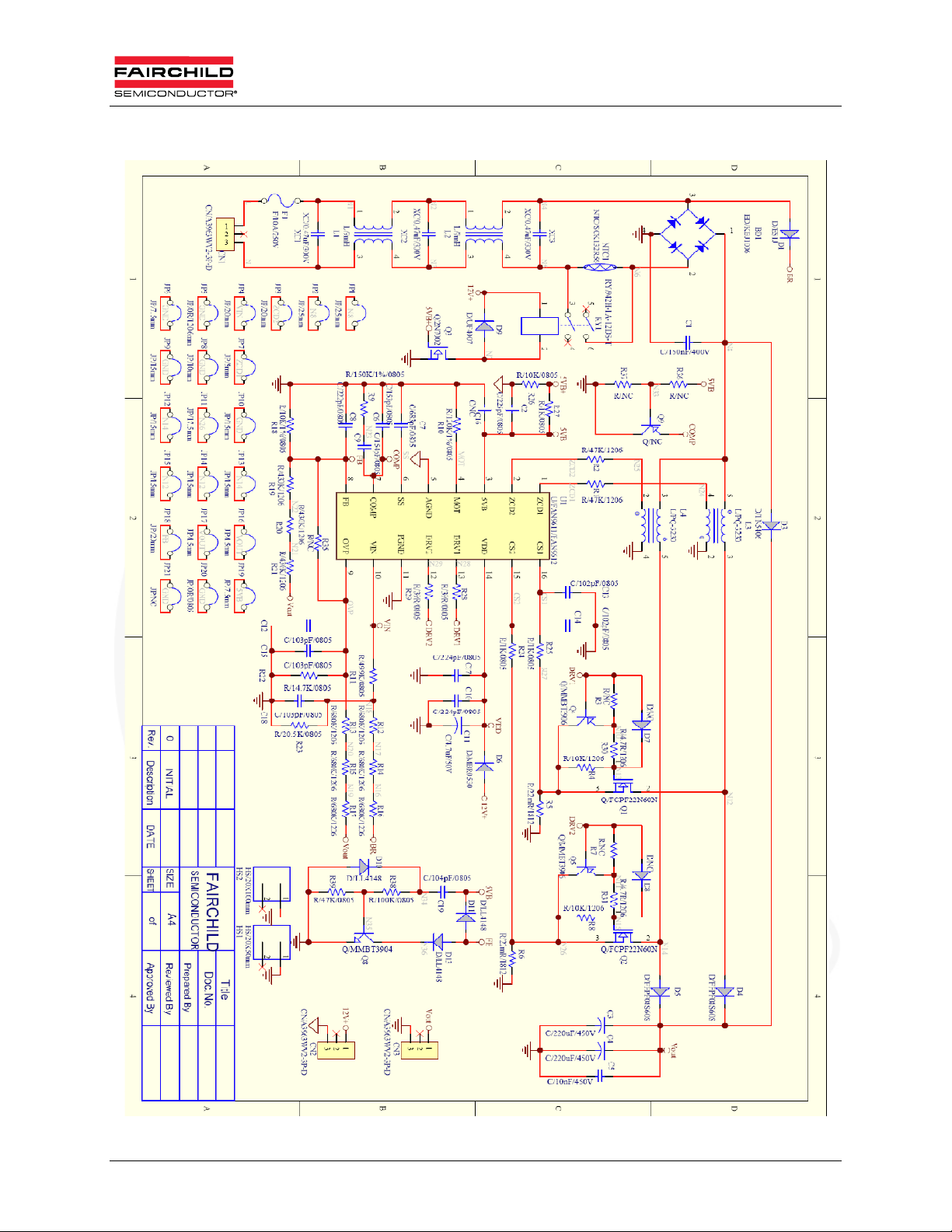

4. Schematic

Figure 2. FAN9611 / FAN9612 400W Evaluation Board Schematic

© 2009 Fairchild Semiconductor Corporation 6 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 7

www.fairchildsemi.com

5. Specification Approval

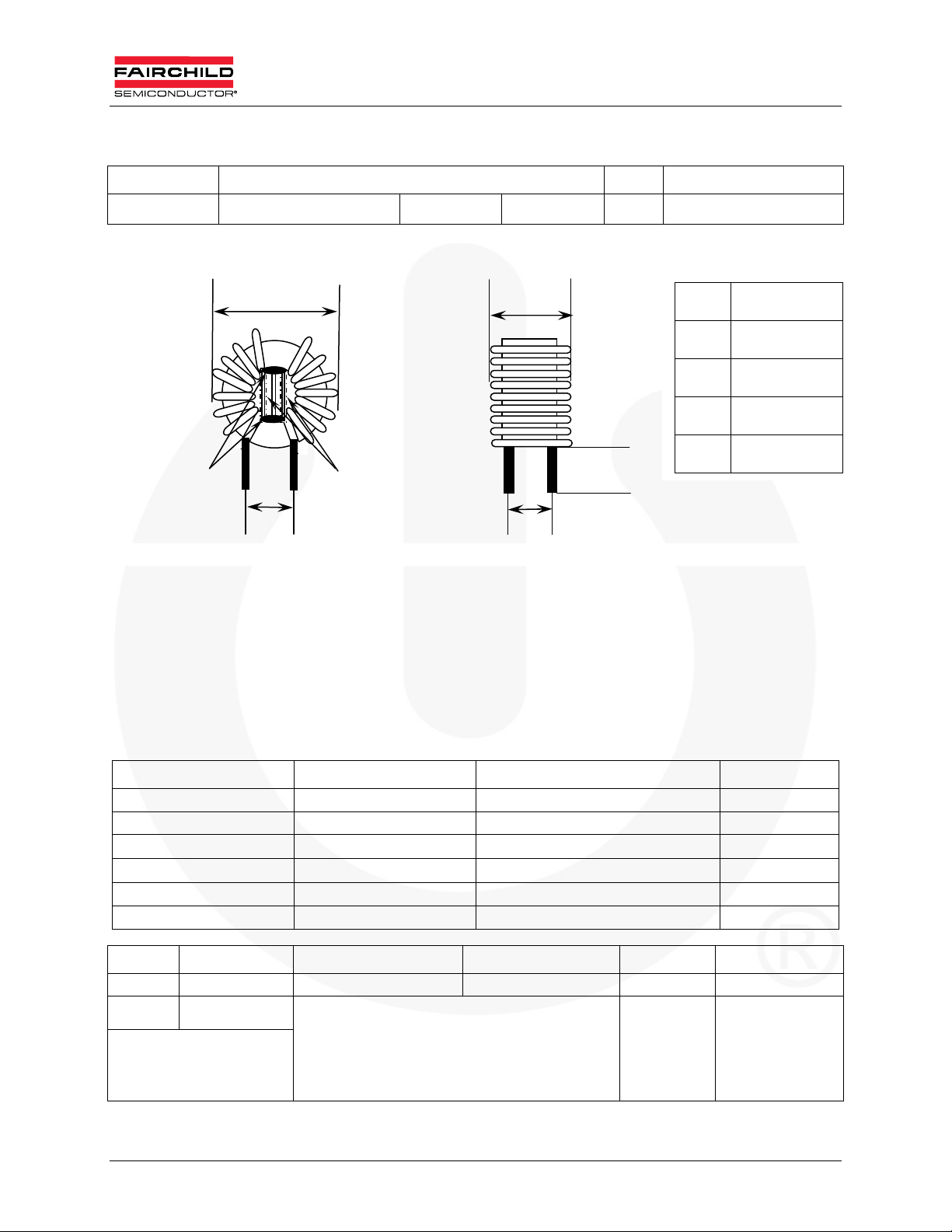

Customer Fairchild Semiconductor P/N: TRN-0197

Date 08/04/2006 Version A Page 1/1

Dimension Unit: mm

A B

Black Glue E

tube

C D

Middle partition board thickness of 2mm

(Safety Regulation)

A 30 max

B 5 max

C 11 ref

D 13 ref

E

151

Electrical Specification: 1kHz 1V

Inductance:L1=L2:9.0mH minimum

DC Resistance: L1=L2:0.05 maximum

Turn and Wire: L1=L2:0.9 x 30.5TSx2

Materials List:

Component Material Manufacturer UL File #

1. CORE T22x14x08 TOMITA

2. WIRE THFN-216 Ta Ya Electric Wire Co., Ltd. E197768

UEWN/U

UEWE

UWY Jang Shing Wire Co., Ltd. E174837

3. Solder 96.5% Sn,3% Ag,0.5% Cu, Xin Yuan Co., Ltd.

Unit m/m Drawn Check Title

TEL (02)29450588 Ci wun Chen Guo long Huang IDENT#. TRN-0197

FAX (02)29447647

No.26-1, Lane 128, Sec. 2,

Singnan Rd., Jhonghe City,

Taipei County 235, Taiwan

(R.O.C.)

SEN HUEI INDUSTRIAL CO.,LTD. D W G# I0060

PACIFIC Wire Cable Co., Ltd.

Tai-l Electric Wire Cable Co., Ltd.

E201757

E85640

© 2009 Fairchild Semiconductor Corporation 7 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 8

www.fairchildsemi.com

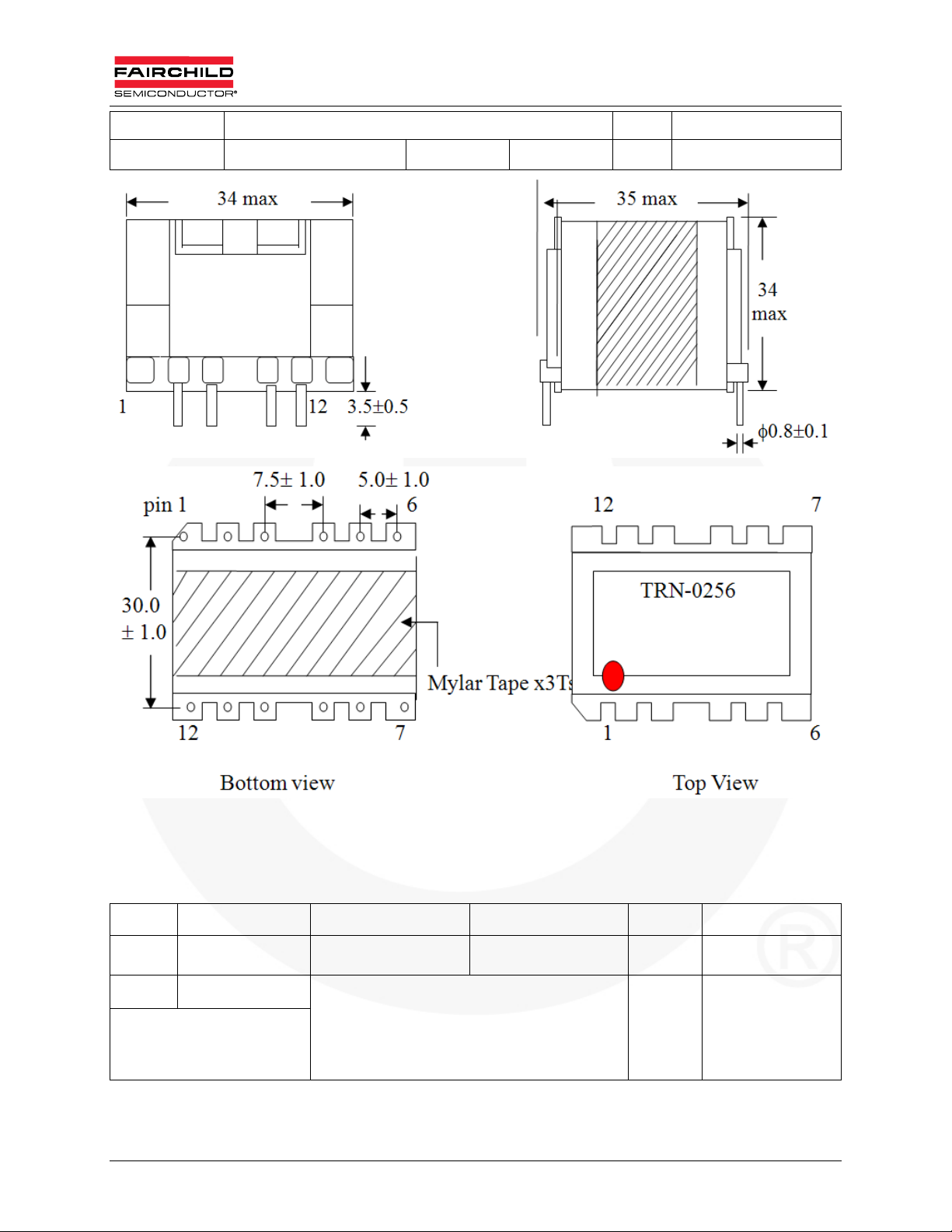

Customer Fairchild Semiconductor P/N: TRN-0256

Date 09/02/2009 Version A Page 1/4

Notes:

1. Pin 1,6,7,8,10,11,12 removed.

2. Add insulation tape *3 turns to fix core and bobbin.

3. The red symbol indicates first pin.

Unit m/m Drawn Check Title

TEL (02)2 945-0588 Ci wun Chen Guo long Huang IDENT# TRN-0256

FAX (02)2944-7647

No.26-1, Lane 128, Sec. 2,

Singnan Rd., Jhonghe City,

Taipei County 235, Taiwan

(R.O.C.)

© 2009 Fairchild Semiconductor Corporation 8 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

SEN HUEI INDUSTRIAL CO.,LTD. D W G# I3205

Page 9

www.fairchildsemi.com

Customer Fairchild Semiconductor P/N: TRN-0256

Date 09/02/2009 Version A Page 3/4

6. Boost Inductor Specification

Figure 3. Boost Inductor in the FAN9611 / FAN9612 Evaluation Board

Note:

1. Pins 2, 4, 5 add tube.

Unit m/m Drawn Check Title

TEL (02)2945-0588 Ci wun Chen Guo long Huang IDENT# TRN-0256

FAX (02)2944-7647

No.26-1, Lane 128, Sec. 2,

Singnan Rd., Jhonghe City,

Taipei County 235, Taiwan

(R.O.C.)

SEN HUEI INDUSTRIAL CO.,LTD. D W G# I3205

© 2009 Fairchild Semiconductor Corporation 9 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 10

www.fairchildsemi.com

6.1. Electrical Specification

Inductance Test: at 1kHz, 1V

P(5-3): 200µH 5%

DC Resistance test at TA = 25°C

P(5-3): 62.44m maximum

P(2-4): 196.7m maximum

Hi-Pot Test:

AC 1000V / 60Hz / 0.5mA hi-pot for one minute between pri to sec

AC 500V / 60Hz/ 0.5mA hi-pot for one minute between pri to core

Insulation Test:

The insulation resistance is between pri to sec and windings to core measured by DC

500V

Must be over 100M

Terminal Strength:

Kg on terminals for 30 seconds, test the breakdown

UNIT m/m DRAWN CHECK TITLE

TEL (02)2945-0588 Ci wun Chen Guo long Huang IDENT# TRN-0256

FAX (02)2944-7647

No.26-1, Lane 128, Sec. 2,

Singnan Rd., Jhonghe City,

Taipei County 235, Taiwan

(R.O.C.)

SEN HUEI INDUSTRIAL CO.,LTD. D W G# I3205

© 2009 Fairchild Semiconductor Corporation 10 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 11

www.fairchildsemi.com

Customer Fairchild Semiconductor P/N: TRN-0256

Date 09/02/2009 Version A Page 3/4

Materials List:

Component Material Manufacturer File#

1.Bobbin

2.Core MB4 Ferrite Core PQ3230

3.Wire

4.Varnish

5.Tape

0.025tmm

6.Tube

7.Terminals

Phenolic

94v-0,T373J,150°C

UEWE

130°C

UEW-2

130°C

UEW-B

130°C

BC-346A

180°C

468-2FC

130°C

Polyester 3M

#1350 130°C

#31CT 130°C Nitto Denko Corp.

Teflon tube

TFS

600V,200°C

Tin coated-

Copper wire

PQ3230

Chang Chun Plastics Co., Ltd.

Tai-I Electric Wire & Cable Co., Ltd.

Jung Shing Wire Co., Ltd. E174837

Chuen Yih wire co., Ltd.

John C Dolph Co., Ltd.

Ripley Resin Engineering Co., Inc.

Minnesota mining &MFG Co., Ltd.

Great Holding Industrial Co., Ltd.

Will Fore Special Wire Corp.

E59481(S)

E85640﹙S﹚

E154709﹙S﹚

E51047﹙M﹚

E81777﹙N﹚

E17385﹙N﹚

E34833﹙M﹚

E156256﹙S﹚

Unit m/m Drawn Check Title

TEL (02)2945-0588 Ci wun Chen Guo long Huan g IDENT# TRN-0256

FAX (02)2944-7647

No.26-1, Lane 128, Sec. 2,

Singnan Rd., Jhonghe City,

Taipei County 235, Taiwan

(R.O.C.)

SEN HUEI INDUSTRIAL CO.,LTD. D W G# I3205

© 2009 Fairchild Semiconductor Corporation 11 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 12

www.fairchildsemi.com

7. Bill of Materials

Component Qty. Part # Reference

JUMPER WIRE 0.8ψ(mm) 18 JP1~ JP4 JP6~JP19

Resistor 0805 0Ω+/-5% 1 JP20

Resistor 0805 39Ω+/-5% 2 R28 R29

Resistor 0805 1KΩ+/-5%

Resistor 0805 14K7Ω +/-1% 1 R22

Resistor 0805 10KΩ+/-1% 2 R18 R26

Resistor 0805 20K5Ω +/-1%

Resistor 0805 47KΩ+/-5% 1 R39

Resistor 0805 49K9Ω +/-1% 1 R11

Resistor 0805 100KΩ+/-5%

Resistor 0805 120KΩ+/-1% 1 R10

Resistor 0805 150KΩ+/-1% 1 R9

Resistor 1206 0Ω+/-5% 1 JP5

3 R24 R25 R27

1 R23

1 R38

Resistor 1206 4Ω7+/-5% 2 R30 R31

Resistor 1206 10KΩ+/-5% 2 R4 R8

Resistor 1206 47KΩ+/-5% 2 R1 R2

Resistor 1206 430KΩ+/-5% 3 R19 R20 R21

Resistor 1206 680KΩ+/-5% 6 R12~R17

NTC13ψ 2Ω SCK132 1 NTC1

Resistor 1812 0Ω022 +/-5% 2 R5 R6

0805 MLCC X7R +/-10% 102P 50V 2 C13 C14

0805 MLCC X7R +/-10% 103P 50V 3 C12 C15 C18

0805 MLCC X7R +/-10% 473P 50V 1 C19

0805 MLCC X7R +/-10% 104P 50V 1 C6

0805 MLCC X7R +/-10% 154P 25V 1 C9

0805 MLCC X7R +/-10% 222P 50V 1 C8

0805 MLCC X7R +/-10% 224P 50V 2 C10 C17

0805 MLCC X7R +/-10% 225P 25V 1 C2

0805 MLCC X7R +/-10% 683P 50V 1 C7

© 2009 Fairchild Semiconductor Corporation 12 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 13

www.fairchildsemi.com

Bill of Materials (Continued)

Component Qty. Part # Manufacturer Reference

Ceramic Capacitor 103P 500V +80/-20% 1 C5

Electrolytic Capacitor 47µ 50V 105°C 1 LHK JACKCON C11

Electrolytic Capacitor 220µF 450V 105°C 2 LKP JACKCON C3 C4

MPP Capacitor 0.15µF 400V ±5% 1 MPP154J2G15 ALL-RISE C1

X1 Capacitor 0.47µ 300V +/-10% 3

Common Mode Choke 2 TRN0197 SEN HUEI L1 L2

Custom Inductor PQ3230 L=200µH 2 TRN0256 SEN HUEI L3 L4

Rectifier 3A/600V DO-201AD 1 1N5406 Fairchild Semiconductor D3

Ultra Fast Recovery Rectifier 1A/600V 1 ES1J Fairchild Semiconductor D1

Ultra Fast Diode 1A/1000V DO-41 1 UF 4007 Fairchild Semiconductor D9

SMD Diode LL4148 4 D7 D8 D10 D13

Bridge 10A/600V 1 KBJ1006 CP BD1

SX1-S4741K300S1

SHINY XC1 XC2 XC3

SMD Schottky Rectifiers 0.5A/30V SOD-123 1 MBR0530 Fairchild Semiconductor D6

Rectifier 8A/600V TO-220F 2 FFPF08S60S Fairchild Semiconductor D4 D5

MOSFET N-CH 300mA/60V 1 2N7002 Fairchild Semiconductor Q3

SMD NPN Amplifier 1 MMBT3904 Fairchild Semiconductor Q8

SMD PNP Amplifier 2 MMBT3906 Fairchild Semiconductor Q4 Q5

MOS 18A/500V TO-220F 2 FDPF18N50 Fairchild Semiconductor Q1 Q2

FUSE CERAMIC 250V10A SLOW 1 37SG SLEEK F1

RELAY 942H-1A-12DS-T 1 BRIGHT TOWARD RY1

WAFER(8639HS) 3-1P 3.96mm180° 3 CN1 CN2 CN3

HS 50(L)*50(H)*20(W)mm 1 MCH0597 SHUN TEH HS1

HS 100(L)*50(H)*20(W)mm 1 MCH0598 SHUN TEH HS2

IC FAN9611 / FAN9612 SMD 1 SOIC-16 Fairchild Semiconductor U1

PCB FCS0390 REV 4 1 Fairchild Semiconductor

© 2009 Fairchild Semiconductor Corporation 13 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 14

www.fairchildsemi.com

Figure 4. PCB Layout Top Overlay

Figure 5. PCB Layout Bottom Layer

© 2009 Fairchild Semiconductor Corporation 14 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 15

www.fairchildsemi.com

Figure 6. PCB Layout Bottom Overlay

© 2009 Fairchild Semiconductor Corporation 15 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 16

www.fairchildsemi.com

/

/

/

/

8. Test Results

8.1. Startup

Test Condition: 115V

Figure 7. 115V

/ 60Hz, 230V

AC

AC

/ 50Hz, no load and full load.

AC

60Hz No Load Figure 8. 115V

60Hz Full Load

AC

Note:

2. Only 29V overshoot is observed (7.44% of nominal output voltage) for no-load startup and only 18V (4.62% of

normal output voltage) overshoot is observed for full-load startup.

Figure 9. 230V

50Hz No Load Figure 10.230V

AC

50Hz Full Load

AC

Note:

3. Only 17V overshoot is observed (4.36% of nominal output voltage) for no-load startup and only 18V (4.62% of

normal output voltage) overshoot is observed for full-load startup.

© 2009 Fairchild Semiconductor Corporation 16 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 17

www.fairchildsemi.com

/

/

/

/

8.2. Normal Operation

Test Condition: Inductor current of 115VAC / 60Hz, 230VAC / 50Hz full load.

Figure 11. 115V

60Hz Full Load Figure 12.115V

AC

60Hz Full Load

AC

Note:

4. Figure 11 and Figure 12 show the two inductor currents and the sum of two inductor currents at 115V

voltage and full-load conditions. The sum of the inductor currents has relativel y small ri pple due to the ripple

cancellation of interleaving operation.

Figure 13. 230V

50Hz Full Load Figure 14.230V

AC

50Hz Full Load

AC

AC

line

Note:

5. Figure 13 and Figure 14 show the two inductor currents and the sum of two inductor currents at 230V

AC

line

voltage and full-load conditions. The sum of the inductor currents has relativel y small ri pple due to the ripple

cancellation of interleaving operation.

© 2009 Fairchild Semiconductor Corporation 17 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 18

www.fairchildsemi.com

8.3. Line and Load Transient

Test Condition: 115VAC to 230VAC full load transient and 230VAC load transient.

Figure 15. 230VAC to 115VAC Line Transient Figure 16.115VACto 230VAC Line Transient

Note:

6. Figure 15 and Figure 16 show the line transient operation and minimal effect on the output voltage due to the line

feed forward function. When the line voltage changes from 230VAC to 115VAC, 14.5V (3.72% of nominal output

voltage) voltage undershoot is observed. When the line voltage changes from 115V

voltage undershoot is observed.

to 230VAC, almost no

AC

Figure 17. 230V

Note:

7. Figure 17 and Figure 18 show the load-transient operation. When the output load chang es from 100% to 0%,

23.6V (6.1% of nominal output voltage) voltage overshoot is observed. When the output load changes from 0%

to 100%, 23.9V (6.13% of nominal output voltage) voltage undershoot is observed.

100% to 0% Line Transient Figure 18.230VAC0% to 100% Line Transient

AC

© 2009 Fairchild Semiconductor Corporation 18 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 19

www.fairchildsemi.com

8.4. Brown in/out Protection

Test Condition: startup and shutdown when slowly increasing and decreasing the line voltage.

Figure 19. Brow nin Figure 20.Brownout

Note:

8. Figure 19 and Figure 20 show the startup and shutdown operation at slowl y increasing and decreasing line

voltage, respectively. The power supply starts when the line voltage reaches around 80VAC and shuts down

when line voltage drops below 70V

AC

.

© 2009 Fairchild Semiconductor Corporation 19 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 20

www.fairchildsemi.com

A

8.5. Phase Management

Test Condition: Change the output load to observe the phase shedding and addin g.

Figure 21. Phase-Shedding Figure 22.Zoom-In

Note:

9. Figure 21 and Figure 22 show the phase-shedding waveforms. The duty cycle of the channel 1 gate drive signal

is doubled when the other channel gate drive signal is disabled to minimize the line current glitch.

Figure 23. Phase-Adding Figure 24.Zoom-In

Note:

10. Figure 23 and Figure 24 show the phase-adding waveforms. The duty cycle of Channel 1 gate drive signal

becomes half just before the other channel gate drive signal is enabled to minimize the line current glitch.

Figure 25. Phase-Shedding and Line Current Figure 26.Phase-

Note:

11. Figure 25 and Figure 26 show the sum of two-inductor current and line current for phase shedding and adding,

respectively. As shown, the phase management causes no visible change in the line current waveforms.

© 2009 Fairchild Semiconductor Corporation 20 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

dding and Line Current

Page 21

www.fairchildsemi.com

/

/

8.6. Efficiency

Test Condition: 115V

FEB301‐001,FAN9612Efficiencyvs.Load

100%

95%

90%

Efficiency(%)

85%

/ 60Hz and 230V

AC

/ 50Hz efficiency.

AC

(115VAC Input,390VDC Output,400W)

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

OutputPower(%)

Figure 27. 115V

60Hz Efficiency vs. Load

AC

FEB301‐001,FAN9612Efficiencyvs.Load

(230VAC Input,390VDC Output,400W)

100%

95%

90%

Efficiency(%)

85%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

OutputPower(%)

Figure 28. 230V

Note:

12. Figure 27 and Figure 28 show the measured efficiency of the evaluation board at input voltages of

115V

and 230V, respectively. Since phase shedding reduces the switching loss by effectively

AC

decreasing the switching frequency at light-load, a greater efficiency im provement is achieved at

high line where switching losses are greater. Relatively less improvement is obtained for low line

since the MOSFET is turned on with zero voltage and switching losses are negligible.

50Hz Efficiency vs. Load

AC

© 2009 Fairchild Semiconductor Corporation 21 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 22

www.fairchildsemi.com

/

/

8.7. Harmonic Distortion and Power Factor

Test Condition: Measure the harmonic and power factor at 115V

/ 60Hz and 230V

AC

/ 50Hz output full load.

AC

Figure 29. 115V

60Hz, Output Full Load

AC

Figure 30.230V

50Hz, Output Full Load

AC

Note:

13. To compare the measured harmonic current with EN61000 class D and C, respectively, at input voltage of 115V

and 230V

. Class D is applied to TV and PC power, while Class C is applied to lighting applications. As can be

AC

observed, both regulations are met with sufficient margin.

AC

© 2009 Fairchild Semiconductor Corporation 22 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 23

r

PF

www.fairchildsemi.com

1

0.98

0.96

0.94

0.92

115Vac/60Hz

0.9

0.88

230Vac/50Hz

0.86

0.84

0.82

0.8

Load(%)

Figure 31. Measured Power Facto

Table 2. Total Harmonic Distortion at Input Voltage of 115VAC and 230VAC

50% 75% 100%

115V

230V

/ 60Hz

AC

/ 50Hz

AC

12.88 9.91 7.99

13.06 11.47 9.33

© 2009 Fairchild Semiconductor Corporation 23 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Page 24

www.fairchildsemi.com

9. References

FAN9611 / FAN9612 — Interleaved Dual BCM PFC Controller

AN-6086 — Design Consideration for Interleaved Boundary Conduction Mode

(BCM) PFC Using FAN9611 / FAN9612

AN-8018 — FAN9611 / FAN9612 400W Interleaved Dual-BCM PFC Controller

Evaluation Board User Guide

WARNING AND DISCLAIMER

Replace components on the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Users’ Guide. Contact an

authorized Fairchild representative with any questions.

This board is intended to be used by certified professionals, in a lab environment, following proper safety procedures. Use at your own risk. The

Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this User’s Guide constitute a sales contract or create any kind

of warranty, whether express or implied, as to the applications or products involved. Fairchild warrantees that its products meet Fairchild’s published

specifications, but does not guarantee that its products work in any specific application. Fairchild reserves the right to make changes without notice to

any products described herein to improve reliability, function, or design. Either the applicable sales contract signed by Fairchild and Buyer or, if no

contract exists, Fairchild’s standard Terms and Conditions on the back of Fairchild invoices, govern the terms of sale of the products described herein.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO

IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR

USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR

THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems which, (a)

are intended for surgical implant into the body, or (b) support or

sustain life, or (c) whose failure to perform when properly used in

accordance with instructions for use provided in the labeling, can

be reasonably expected to result in significant injury to the user.

2. A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect

its safety or effectiveness.

NTI-COUNTERFEITING POLICY

Fairchild Semiconductor Corporation's Anti-Counterfeiting Policy. Fairchild's Anti-Counterfeiting Policy is also stated on our external website,

www.fairchildsemi.com, under Sales Support.

Counterfeiting of semiconductor parts is a growing problem in the industry. All manufacturers of semiconductor products are experiencing

counterfeiting of their parts. Customers who inadvertently purchase counterfeit parts experience many problems such as loss of brand reputation,

substandard performance, failed applications, and increased cost of production and manufacturing delays. Fairchild is taking strong measures to

protect ourselves and our customers from the proliferation of counterfeit parts. Fairchild strongly encourages customers to purchase Fairchild parts

either directly from Fairchild or from Authorized Fairchild Distributors who are listed by country on our web page cited above. Products customers buy

either from Fairchild directly or from Authorized Fairchild Distributors are genuine parts, have full traceability, meet Fairchild's quality standards for

handling and storage and provide access to Fairchild's full range of up-to-date technical and product information. Fairchild and our Authorized

Distributors will stand behind all warranties and will appropriately address any warranty issues that may arise. Fairchild will not provide any warranty

coverage or other assistance for parts bought from Unauthorized Sources. Fairchild is committed to combat this global problem and encourage our

customers to do their part in stopping this practice by buying direct or from authorized distributors.

EXPORT COMPLIANCE STATEMENT

These commodities, technology, or software were exported from the United States in accordance with the Export Administration Regulations for the

ultimate destination listed on the commercial invoice. Diversion contrary to U.S. law is prohibited.

U.S. origin products and products made with U.S. origin technology are subject to U.S Re-export laws. In the event of re-export, the user will be

© 2009 Fairchild Semiconductor Corporation 24 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

Loading...

Loading...