Page 1

FAN8727

Spindle + 4-CH Motor Drive IC

www.fairchildsemi.com

Features

• Built-in Power Save Circuit

• Built-in Current Limit Circuit

• Built-in Thermal Shutdown Circuit (TSD)

• Built-in Hall Bias

• Built-in FG Signal Output Circuit

• Built-in Rotational Direction Detecting Circuit

• Built-in Protection Circuit For Reverse Rotation

• Built-in Short Brake Circuit

• Built-in Normal OP-AMP

• Built-in 4-CH Balanced Transformerless (BTL) Driver

• Built-in BTL MUTE Circuit (CH1-2, CH3 and CH4)

• Corresponds to 3.3V DSP

Description

The FAN8727 is a monolithic integrated circuit suitable for a

4-CH motor driver which drives the tracking actuator, focus

actuator, sled motor, loading motor and 3-phase BLDC

spindle motor of the MDP/CAR-MD/CAR-NAVIGATION

system.

48-QFPH-1414

Typical Applications

•Mini Disk Player

• Digital Video Disk Player

• Car Mini Disk Player

• Car Navigation System

©2002 Fairchild Semiconductor Corporation

Ordering Information

Device Package Operating Temperature

FAN8727 48-QFPH-1414 -35°C ~ +85°C

Rev. 1.0.2

Page 2

FAN8727

Pin Assignments

H3 +

48 47 46 45 44 43 42 41 40 39 38 37

H3 −

H2 +

H2 −

H1 +

H1 −

BTLSNGD

BIAS

AVM4

MUTE12

MUTE3

MUTE4

VH

FG

ECR

EC

VCC2

PC1

SIGGND

VM

CS1

SS

DIR

SB

1

2

3

4

5

6

36

35

34

33

32

31

DO4 +

DO4 −

AVM3

DO3 +

DO3 −

BTLPGND2

FAN8727

7

8

9

10

11

12

30

29

28

27

26

25

BTLPGND1

DO2 +

DO2 −

DO1 +

DO1 −

DI1

13 14 15 16 17 18 19 20 21 22 23 24

A3

A2

PWRGND

A1

OPIN+

OPIN−

OPOUT

VCC1

DI4

DI3

DI2

AVM12

2

Page 3

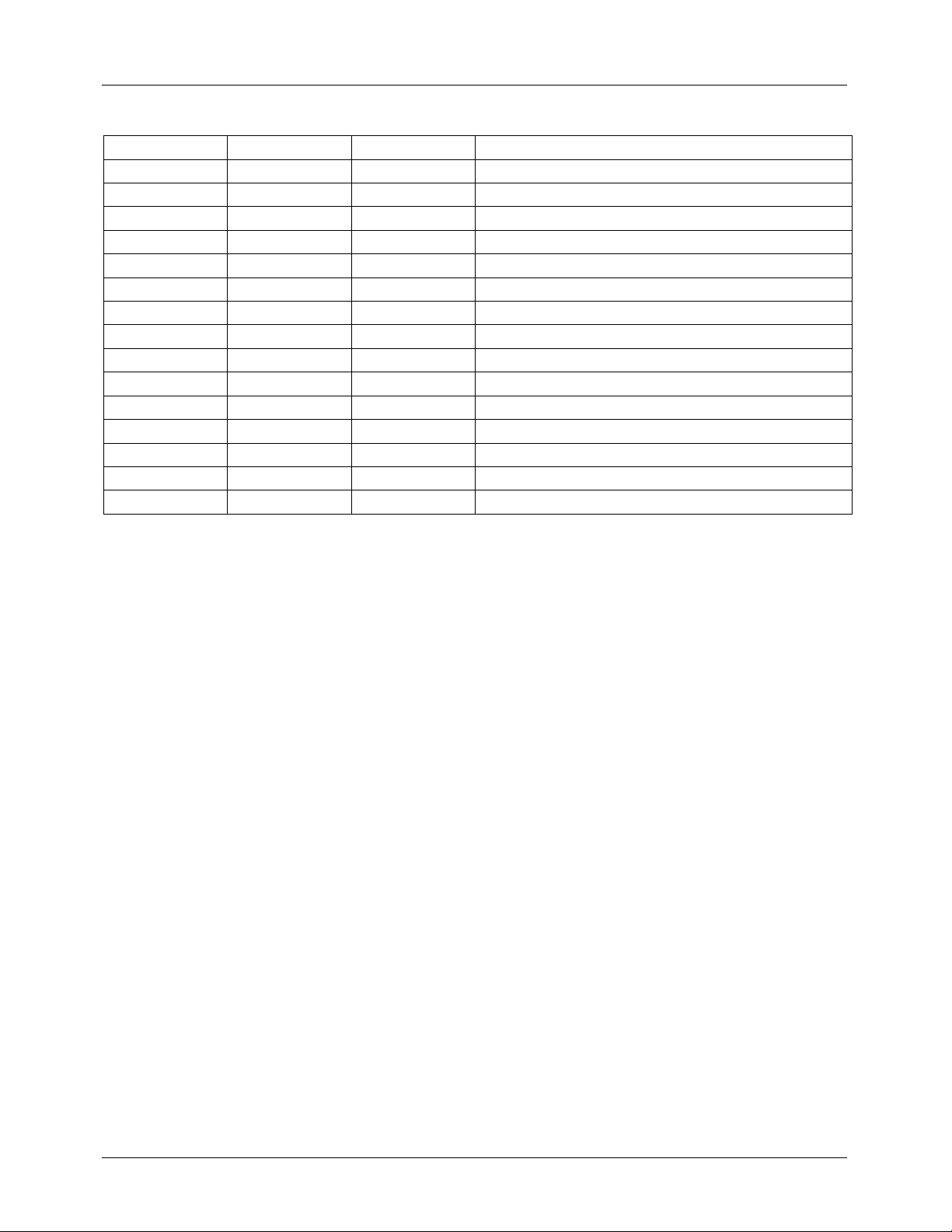

Pin Definitions

Pin Number Pin Name I/O Pin Function Description

1VHIHall Bias

2 FG O FG Signal Output

3 ECR I Torque Control Reference

4 EC I Torque Control Signal

5 VCC2 - Supply Voltage

6 PC1 - Phase Compensation Capacitor

7 SIGGND - Signal Ground

8 VM - Motor Supply Voltage

9 CS1 I Current Sensor

10 S/S I Start/stop

11 DIR O 3-Phase Rotational Direction Output

12 SB I Short Brake

13 PWRGND - Power Ground

14 A3 O 3-Phase Output 3

15 A2 O 3-Phase Output 2

16 A1 O 3-Phase Output 1

17 OPIN+ I OP-AMP Input (+)

18 OPIN- I OP-AMP Input (-)

19 OPOUT O OP-AMP Output

20 VCC1 - Supply Voltage

21 AVM12 - BTL CH1, 2 Motor Supply Voltage

22 DI4 I BTL Drive Input 4

23 DI3 I BTL Drive Input 3

24 DI2 I BTL Drive Input 2

25 DI1 I BTL Drive Input 1

26 DO1- O B TL Drive 1 Output (-)

27 DO1+ O BTL Drive 1 Output (+)

28 DO2- O B TL Drive 2 Output (-)

29 DO2+ O BTL Drive 2 Output (+)

30 BTLPGND1 - BTL Power Ground 1

31 BTLPGND2 - BTL Power Ground 2

32 DO3- O B TL Drive 3 Output (-)

33 DO3+ O BTL Drive 3 Output (+)

FAN8727

3

Page 4

FAN8727

Pin Definitions

Pin Number Pin Name I/O Pin Function Description

34 AVM3 - BTL CH3 Motor Supply Voltage

35 DO4- O B TL Drive 4 Output (-)

36 DO4+ O BTL Drive 4 Output (+)

37 MUTE4 I BTL Drive Mute CH4

38 MUTE3 I BTL Drive Mute CH3

39 MUTE12 I BTL Drive Mute CH1, 2

40 AVM4 - BTL CH4 Motor Supply Voltage

41 BIAS - BTL Bias Voltage

42 BTLSGND - BTL Drive Signal Ground

43 H1- I Hall1(-) Input

44 H1+ I Hall1(+) Input

45 H2- I Hall2(-) Input

46 H2+ I Hall2(+) Input

47 H3- I Hall3(-) Input

48 H3+ I Hall3(+) Input

(Continued)

4

Page 5

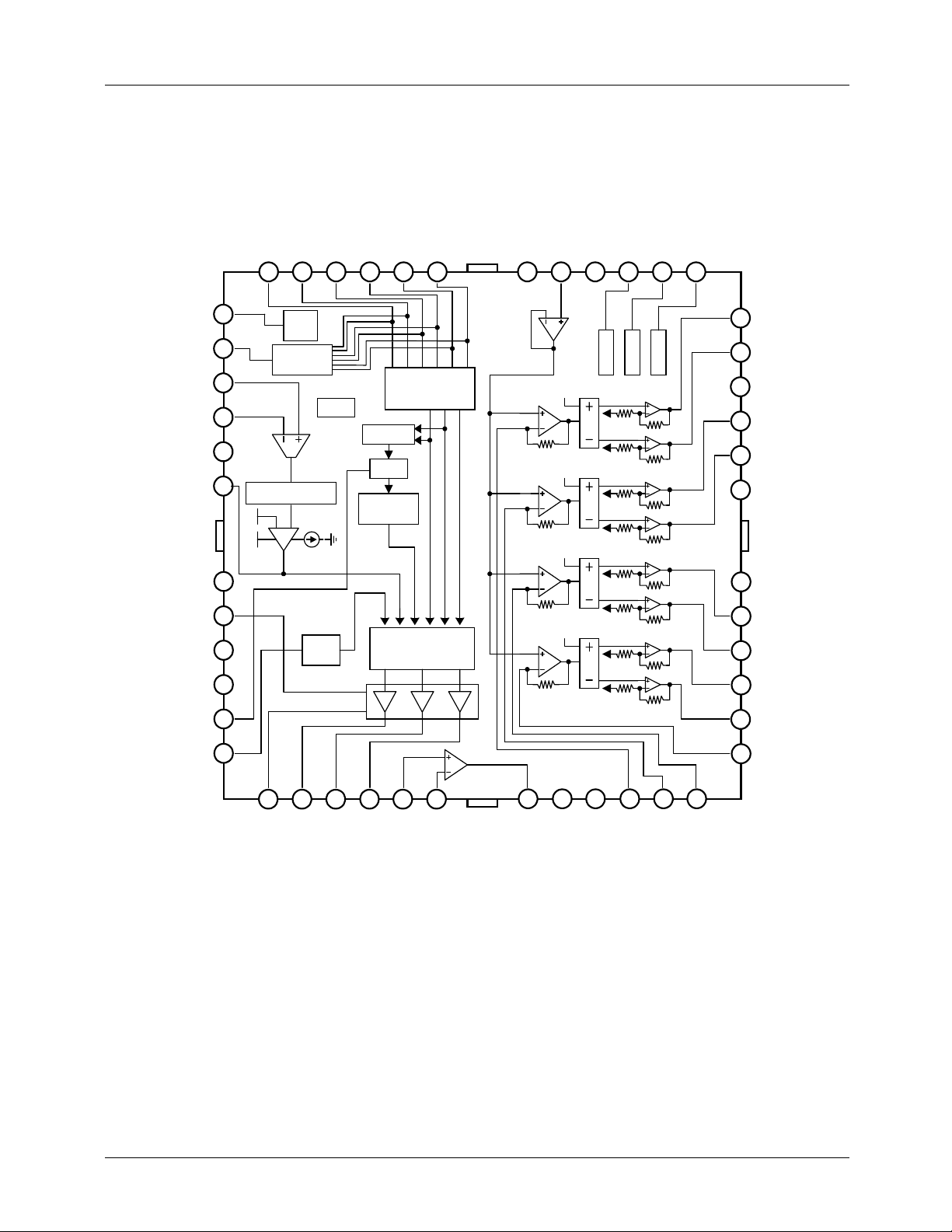

Internal Block Diagram

H3+

H3-

H2+

H2-

H1+

H1-

BIAS

BTLSGND

AVM4

MUTE12

MUTE3

FAN8727

MUTE4

37383940414248 47 46 45 44 43

VH

FG

ECR

EC

VCC2

PC1

SIGGND

VM

CS1

SS

DIR

SB

1

2

3

4

5

6

Absolute Values

CS1VM

7

8

9

10

11

12

Hall

Bias

FG

Generator

Current

Sense Amp

Output

Current Limit

Short

Brake

TSD

Hall Amp

Detection

Logic

Reverse

Rotation

Distributor

AVM4

AVM3

AVM12

AVM12

MUTE12

MUTE3

MUTE4

36

35

34

33

32

31

BTLPGND2

30

BTLPGND1

29

28

27

26

25

DO4+

DO4-

AVM3

DO3+

DO3-

DO2+

DO2-

DO1+

DO1-

DI1

13

PWRGND

A3

OPOUT

2019

VCC1

AVM12

22 2321

DI4

17

OPIN+

18

OPIN-

16

1514

A2

A1

DI3

24

DI2

5

Page 6

FAN8727

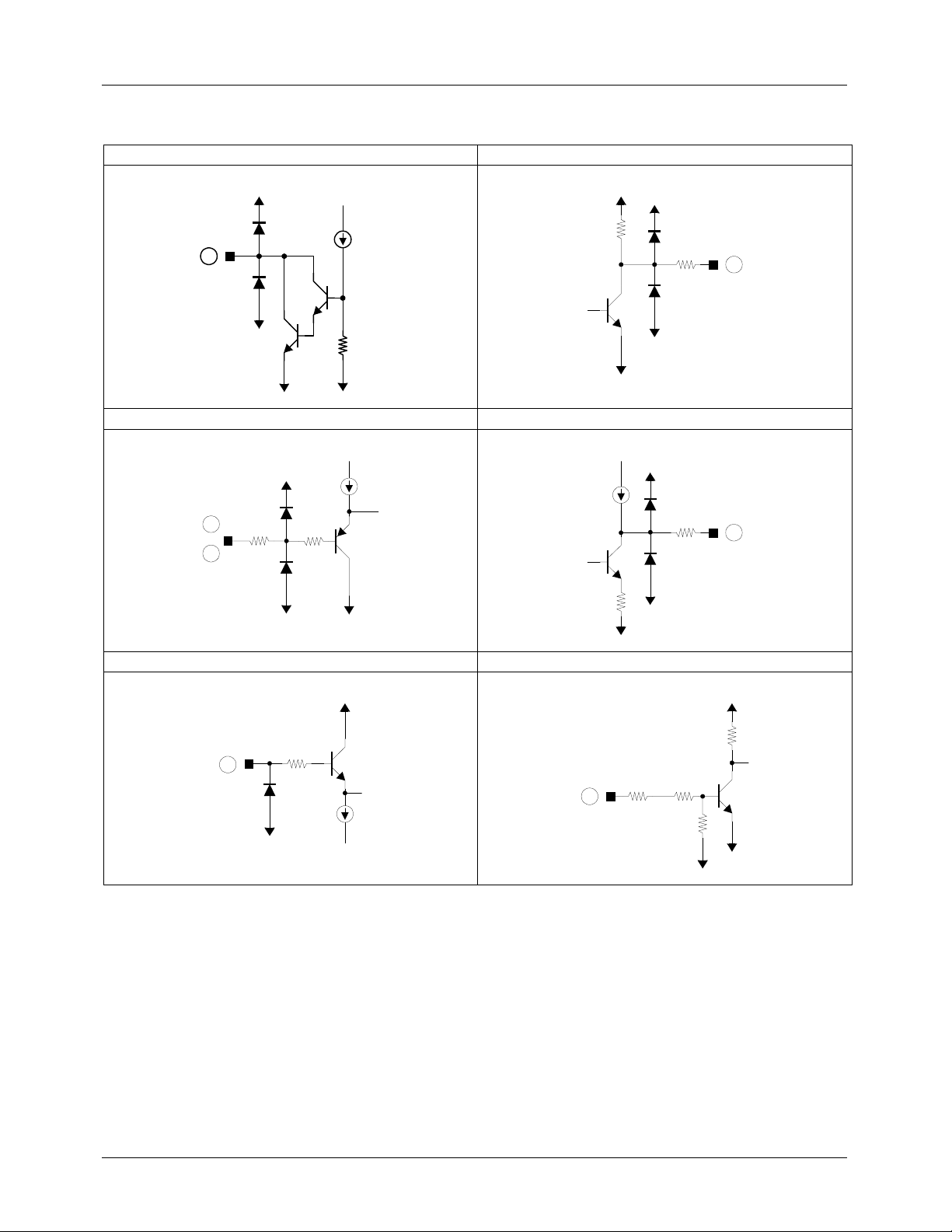

Equivalent Circuits

Hall Bias FG Signal Output

1

Torque Control Reference & Signal Phase Compensation Capacitor

100K

Ω

10K

2

Ω

25

Ω

3

Ω

25

4

Ω

1K

Ω

1K

Current Detector Start/Stop

9

Ω

5K

10

Ω

25

25

50K

30K

6

Ω

Ω

100K

Ω

Ω

6

Page 7

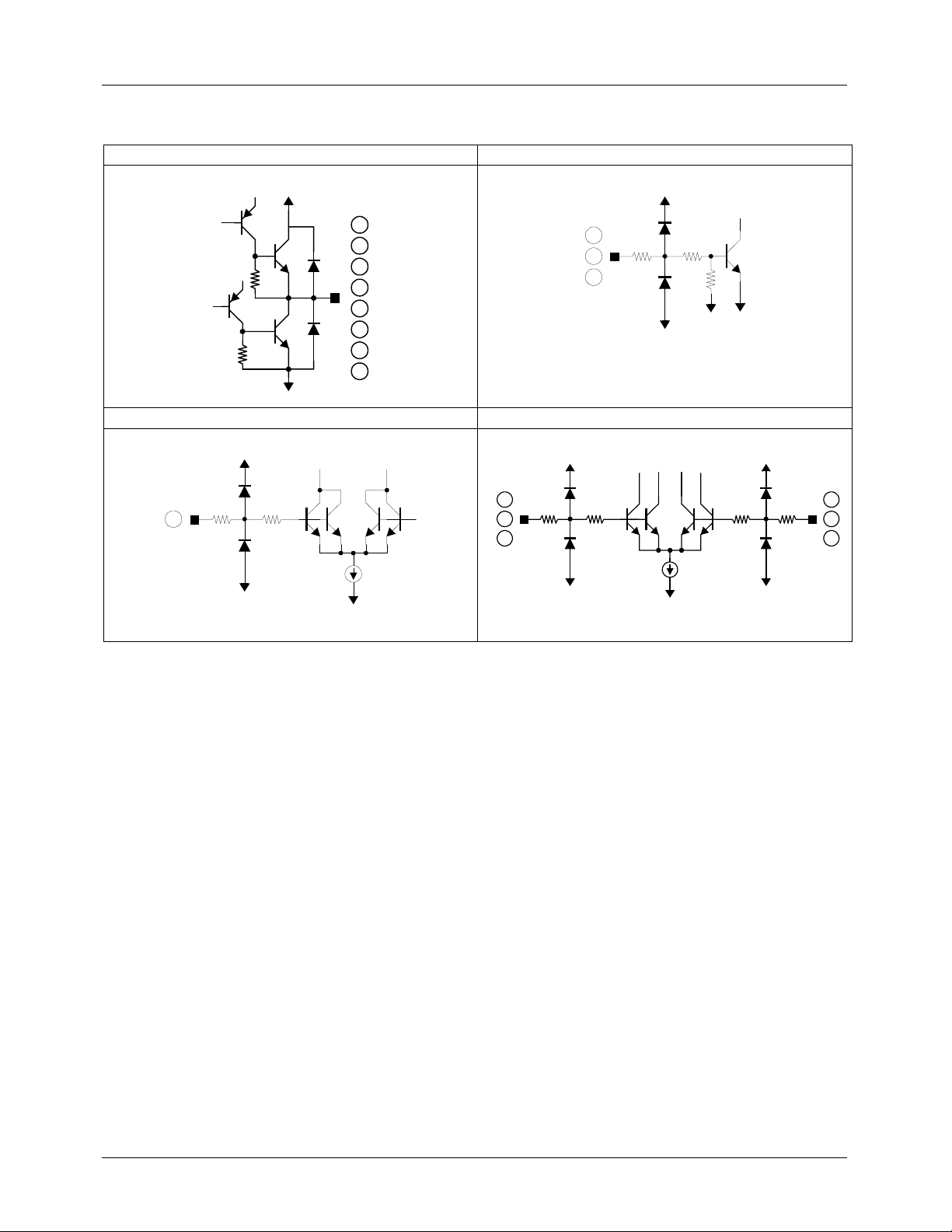

FAN8727

Equivalent Circuits

3-Phase Rotational Direction Output Short Brake

Ω

10K

3-Phase Output OP-AMP Input

Ω

15K

(Continued)

11

Ω

25

14

15

16

12

Ω

1k

Ω

20k

Ω

2K

17

Ω

25

Ω

1K

Ω

25

Ω

2K

18

Ω

Ω

25

1K

Ω

2K

Ω

2K

OP-AMP Ouput BTL Drive Input

22

18

23

24

Ω

25

Ω

50

25

7

Page 8

FAN8727

Equivalent Circuits

BTL Drive Output BTL Drive Mute

Ω

20K

Ω

30K

BTL Bias Voltage Hall Input

41

Ω

25

0.5K

Ω

(Continued)

26

27

28

29

32

33

35

36

37

38

39

43

45

47

Ω

25

1K

Ω

25

50K

30K

Ω

Ω

44

Ω

Ω

1K

25

46

Ω

48

8

Page 9

Absolute Maximum Ratings ( Ta=25°°°°C)

Parameter Symbol Value Unit

Supply Voltage (BTL Signal)

Supply Voltage (Spindle Signal)

Supply Voltage (Motor)

Supply Voltage (BTL Motor)

Power Dissipation

Operating Temperature Range

Storge Temperature Range

Maximum Output Current (Spindle Part)

Maximum Output Current (BTL Part)

Note:

When mounted on 70mm × 70 mm × 1.6mm PCB (Phenolic resin material)

1.

Power dissipation is reduced 24 mW/°C for using above Ta=25°C

2.

Do not exceed Pd and SOA.

3.

V

CC1max

V

CC2max

V

Mmax

V

MBTLmax

Pd

Topr

Tstg

I

OMAXS

I

OMAXB

Pd [mW]

3,000

15

7

15

15

note

3.0

-35 ~ +85

-55 ~ +150

1.3

1

FAN8727

V

V

V

V

W

°°°°C

°°°°C

A

A

2,000

1,000

0

0

175150125100755025

Ambient Temperature, Ta [°C]

Recommended Operating Conditions ( Ta=25°°°°C)

Parameter Symbol Min. Typ. Max. Unit

Operating Supply Voltage (BTL Signal) V

Operating Supply Voltage (Spindle Signal) V

Operating Supply Voltage ( Spindle Motor) V

Operating Supply Voltage (BTL Motor) V

Note: The VM should be turn on before the VCC2.

CC1

CC2

note

M

MBTL

4.5 - 13.2 V

4.5 - 5.5 V

4.5 - 13.2 V

4.5 - V

CC1

V

9

Page 10

FAN8727

Electrical Characteristics

(Ta=25°C, V

=5V, VM=12V)

CC2

Parameter Symbol Condition Min. Typ. Max. Unit

Circuit Current 1 I

Circuit Current 2 I

CC 1

CC2

Power Save=0V - 0.3 1 mA

Power Save=5V - 4.5 6 mA

START/STOP

On Voltage Range V

Off Voltage Range V

PSON

PSOFF

L-H Circuit On 2.5 - - V

H-L Circuit Off - - 0.5 V

HALL BIAS

Hall Bias Voltage V

HB

IHB= 20mA - 1.2 1.8 V

HALL AMP

Hall Bias Current I

In-Phase in Voltage Range V

Minimum in Level

note

V

HA

HAR

INH

- -15uA

- 1.5 - 4.0 V

-60--mVpp

TORQUE CONTROL

In Voltage Range E

Offset Voltage (-)

note

Offset Voltage (+) E

E

COFF-

COFF+

In Current E

In/Output Gain G

C

CIN

EC

ECR= 2.5V -100 -50 -20 mV

ECR= 2.5V 20 50 100 mV

EC= ECR= 2.5V -5 -1 - uA

ECR= 2.5V, RCS= 0.5Ω 0.41 0.51 0.61 A / V

- 0.5 - 3.3 V

FG

FG Output Voltage (H) V

FG Output Voltage (L) V

Input Voltage Range

note

V

FGH

FHL

FGR

IFG= -10uA 3.0 - V

CC

IFG= 10uA - - 0.5 V

Hn+, Hn- input D-range 1.5 - 4.0 V

OUTPUT BLOCK

Saturation Voltage (Upper TR) V

Saturation Voltage (Lower TR) V

Torque Limit Current I

OH

OL

TL

IO= -300mA - 0.9 1.6 V

IO= 300mA - 0.2 0.6 V

RCS= 0.5Ω 560 700 840 mA

DIRECTION DETECTOR

Dir Output Voltage (H) V

Dir Output Voltage (L) V

DIRH

DIRL

IFG= -10uA 3.0 - V

CC

IFG= 10uA - - 0.5 V

SHORT BRAKE

On Voltage Range V

Off Voltage Range V

Note: Guaranteed field ( No EDS / Final test )

SBON

SBOFF

-2.5-V

CC

-0-1.0V

V

V

V

10

Page 11

FAN8727

=12V, V

(Continued)

=12V, RL=24Ω)

MBTL

Electrical Characteristics

BTL Drive Part (Ta=25°C, V

CC1

Parameter Symbol Condition Min. Typ. Max. Unit

Quiescent Circuit Current I

Output Offset Voltage V

Maximum Output

Amplitude Voltage

V

Voltage Gain G

Ripple Rejection Ratio

Slew Rate

note

CH Mute off Voltage V

CH Mute On Voltage V

note

MOFFCH

MONCH

CC

OO

OM

VC

VIN=0.1Vrms, 1kHz 10.5 12.0 13.5 dB

RR VIN=0.1Vrms, 120kHz - 60 - dB

SR 120Hz, 2Vpp - 1.0 - V/us

Pin37, 38, 39 = Variation - - 1.0 V

Pin37, 38, 39 = Variation 2.5 - - V

- - 18 25 mA

--40-40mV

- 9.5 10.5 - V

NORMAL OP- AMP

Input Offset Voltage V

Input Bias Current I

High Level Output Voltage V

Low Level Output Voltage V

Output Sink Current I

Output Source Current I

note

note

note

G

CMRR1 f=1kHz, VIN= -20dB - 80 - dB

Open Loop Voltage Gain

Ripple Rejection Ratio

Slew Rate

note

Common Mode Rejection Ratio

OF

B1

OH1

OL1

SINK

SOU1

VO1

f=1kHz, VIN= -75dB - 75 - dB

RR1 f=120Hz, VIN= -20dB - 65 - dB

SR1 f=120Hz, 2Vp-p - 1 - V/us

- -20 - +20 mV

- - - 600 nA

-11--V

---0.1V

-1025-mA

-58-mA

Note: Guaranteed field ( No EDS / Final test )

11

Page 12

FAN8727

Calculation of Gain & Torque Limit Current

VM VM

Current / Voltage

EC

ECR

Convertor

+

Gm

−

Absolute

Values

−

Vin

R1

+

VM

Max. output current limiting

+

Vmax

−

0.255 which is made from GM times R1 is fixed value within IC.

Gain

0.255

-------------- -=

R

S

Vmax (see above block diagram) is setted to 350mV.

Itl mA[]

Vmax

--------------- -

R

S

350 mV[]

----------------------- -==

R

S

Negative

Feedback loop

−

+

Driver

+

I

O

R

Power

Transistors

Commutation

Distributor

H1

−

V

S

S

+

CS1 (Pin 9)

H2

H3

Output

Current sense

I

O

U

V

W

12

Page 13

FAN8727

Application Information

1. Mute Function

1) Mute Control Voltage Condition

When using the mute function, the applied control voltage condition is as follows.

MUTE ON Voltage 2.5[V] Above Mute Function Operation

MUTE OFF Voltage OPEN or 0.5[V] Below Normal Operation

2) Separated Channel Mute Function

These pins are used for individual channel mute operation.

- When the mute pins (pin 37, 38 and 39) are OPEN or the voltage of the mute pins are below 0.5[V], the mute circuit is

stopped and BTL output cir cui t s ope r at e norm al l y.

- When the mute pins (pin 37, 38 and 39) are above 2.5[V], the mute circuits are activ ated so that the BTL output circu its

will be muted.

- If the junction temperature rises above 175°C, then the thermal shutdown (TSD) circuit is activated and all the output

circuits (4-CH BTL Drivers and 3-phase BLDC Driver) are muted.

2. 4-CH Balanced Transformerless (Btl) Driver

VCC

Vbias

Vin

Rextern

41

22 23

24 25

DRIVE

AMP

X2

+

AMP1

−

10k

Q1

Q3

27

29

33

36

M

LEVEL

SHIFT

GND

Q2

26

28

32

Q4

35

DRIVE

AMP

X2

- The voltage, Vbias, is the reference voltage given by the external bias voltage of pin 41.

- The input signals, Vin, through t he pin s (pi n 22, 23 , 24 and 2 5) are amp lified 1 0K/Re xtern t ime s and th en f ed to the l evel

shift.

- The level shift produces the current due to the difference between the input signal (Vin) and the arbitrary reference

voltage (Vbia s). The current produced as + ∆I and - ∆I are fed into the drive buffers.

- The drive buffer operates the power TR of the output stage according to the state of the input signal(Vin).

- The output stage is the BTL driver, and the motor (or actuator) is rotating in forward direction by operating TR Q1 and

TR Q4. On the other hand, if TR Q2 and TR Q3 are operating, the motor (or actuator) is rotating in reverse direction.

- When the input signal Vin, through the pin (pin 22, 23, 24 and 25) is below the Vbias, then the motor (actuator) is in

forward direction.

13

Page 14

FAN8727

- When the input signal Vin, through the pin (pin 22, 23, 24 and 25) is above the Vbias, then the motor (actuator) is in

reverse direction.

- If you want to change the gain, then modify the external resistor's value (Rextern )

3. T o rque & Output Current Control

Torque Control & Output Current Control

V

M

+

−

Torque sense amp

V

AMP

E

C

+

−

E

CR

−

+

- By amplifying the voltage difference between E

(V

) for the current sense AMP.

AMP

and ECR from the Servo IC, the torque sense AMP produces the input

C

Current sen s e a m p

TSD

Gain

Controller

- The current sense AMP produces the input for the Gain controller to allo w the output cu rrent (I

controlled by the input voltage (V

converted into V

RNF

.

), where the output current (IO) is detected by the sense resistor (RNF) and is

AMP

V

M

R

NF

V

RNF

I

O

Driver

) of the driver to be

O

- In the end, the signals of the Servo IC control the velocity of the motor by controlling the output current (I

driver.

- When the junction temperature rises up to about 175°C, then the output drive circuit will be shut down.

- The range of the torque control input voltage is as shown below.

V

RNF

[V]

Reverse

Forward

Rotation

M

) of the

O

3 mV

The input range (E

14

Ecoff−

) of the Torque Sense AMP is 0.5V ~ 3.3V

C

Ecoff+

0

E

CR-EC

[V]

Ec < E

Ec > E

Forward rotation

CR

Stop after detecting

CR

reverse rotation

Page 15

4. Power Save Function

FAN8727

Bias block

100k

Q1

Start

Stop

V

CC

10

30KΩ

12KΩ

- This function block operates the power saving function.

- The power save circuit is activated by operating TR Q1.

- When the SS (Start/Stop) pin 10 i s h igh (V

), the TR Q1 is turned on so that the bias circuit is enabled. On the other

CC

hand, when the SS (Start/Stop) pin 10 is Open or Low (GND), the TR Q1 is turned off so that the bias circuit is disabled.

- The power save operation controlled by SS (pin 10) input conditions is as follows;

Pin#10 FAN8727

HIGH START

OPEN/LOW STOP

5. Short Brake Function

V

M

MOTOR

ON

OFF

V

CC

12

1KΩ

80KΩ

Drive logic

Q1

OFF

ON

14

15

16

When the pick-up part moves from the inner to the outer spindle of the MD, the brake function of the reverse voltage is commonly employed to rate the rotational velocity of the spindle motor.However, if the spindle motor rotates rapidly, the brake

function of the reverse voltage may produce too much heat at the drive IC.

To remove these shortcomings and to enhance efficiency, the short brake function is added to FAN8 727. When the short brake

function is active, all upper Power transistors are turned off and the lower Power transistors turned on, so as to reduce the rotational velocity of the motor. The short brake operation controlled by SB (pin 12), and the inputs conditions are as follows.

Pin#12 SHORT BRAKE

HIGH ON

LOW OFF

15

Page 16

FAN8727

6. Thermal Shutdown (Tsd) Function

When the junction temperature rises up to about 175°C, then the output drive circuit is shut down, when the junction temperature falls off to about 160°C, the output drive circuit will be normally operated. It has the temperature hysteresis of about 15°C.

7. Rotational Direction Detecting Function

V

CC

H2+

H2−

H3+

H3−

+

D

R

Q

CK

D-F/F

−

+

−

DIR

11

< E

E

C

CR

EC > E

CR

Rotation DIR

Forward Low

Reverse High

- The forward and reverse rotations of the MD are detected by the cir cuit, as shown in the above Table.

- The rotational direction of the MD can be learned by the output waveforms of the hall sensor and/or the driver. Let the

three hall sensors be H1, H2 and H3 respectively. If the hall sensors turn on in the order, H1 → H2 → H3, of the reverse

rotation, the output waveforms of the hall sensors will be as shown below.

H1

H2

H3

( a)

Inversely, if the hall sensors turn on i n t he or de r, H3→ H2→ H1, of the forward r ota ti on , t h e ou t pu t w ave f or ms of the hall sensors will be as shown mext page.

16

Page 17

H1

H2

FAN8727

H3

( b)

In the cases above, the value of H2 at the falling edges of H3 is Low in figure <a>, while High in figure <b>. The rotational

direction detector takes advantage of this phenomenon.

8. Reverse Rotation Preventing Function

E

+

E

H2+

H2−

H3+

H3−

CR

C

−

+

−

+

−

DQ

CK

D-F/F

Current

Sense

Amp

Gain

Controller

Driver

M

- The forward and reverse rotation of the moto r are detected, as shown in the table below, by the circuit shown above.

Consequent ly at reverse rotation, the D- F/F output Q b e comes Low and cuts off the output current sense Amp, resulting

in the stoppage of the Gain controller function.

- When the MD is rotating in forward direction, E

controlling time of E

gets longer, MD slows down, stops, and then rotates in the reverse direction. To prevent the

C>ECR

is sometimes controlled to retard and/or stop the MD. As the

C>ECR

MD from rotating in the reverse direction, a reverse rotation resistant function is required. Its operational principles are

discussed below.

Rotation H2 H3 D-F/F

Reverse Rotation Preventer

E

C<ECR

EC>E

CR

Forward H H → L H Forward Brake and Stop

Reverse L H → LL - Stop

17

Page 18

FAN8727

9. FG Output Function

The FG output, which detects the number of rotations of the MD, is generated by combination zero-crossing the output waveforms of the hall sensors. The FG output circuit is as shown below.

+

H1

H2

H3

−

+

−

FG OUTPUT

+

−

10. Hall Sensor Connection

External Hall sensors are used in series or parallel connection as shown below.

V

CC

HALL 1 HALL 2

1

VH

HALL 3

V

CC

HALL 1

HALL 2

HALL 3

1

VH

18

Page 19

FAN8727

11. Hall Input Output Timming Chart

The 3-phase hall signal is amplified in the hall amplifiers and sent to the matrix section, where the signal is further amplified

and combined. After the signal is converted to a current in the amplitude control circuit, the current is supplied to the output

driver, which then provides a motor drive current. The phases of the hall input signal, output voltage, and output current are

shown below.

H1 +

H2 +

H3 +

A1 output current

A1 output voltage

A2 output current

A2 output voltage

A3 output current

A3 output voltage

19

Page 20

FAN8727

Test Circuits 1

BTL Drive Part

1

2

3

4

5

6

7

8

9

10

11

12

VH

FG

ECR

EC

VCC2

PC1

SIGGND

VM

CS1

SS

DIR

SB

H3+

10µF

434445464748

H3−

H2+

H2−

H1+

H1−

BTLSGND

FAN8727

2.5V

BIAS

AVM4

12V

VMUTE

MUTE12

VMUTE

VMUTE

373839404142

MUTE3

BTLPGND2

BTLPGND1

DO4+

MUTE4

DO4−

AVM3

DO3+

DO3−

DO2+

DO2−

DO1+

DO1−

DI1

V

36

35

34

33

32

31

30

29

28

27

26

25

SW4

12V

10µF

SW3

SW2

SW1

RL4’

RL4

RL3’

RL3

V

V

RL2

RL1

20

PWRGNDA3A2

13 14 15 16 17 19 2218 20 21 2423

OPIN (+) OPIN (−)OPOUT

SW5

3

1

1MΩ

2

V

p1

V

V

IN1

A1

V

IN3

OPIN+

V

+

−

OPIN−

BTL SVCC

10µF

V

s1

12V

SW6

OPOUT

A

10µF

3

V

VCC1

1

IN3

10µF

12V

2

AVM12

D14

D13

D12

SERVO AMP

TRACKING

FOCUS

SLED

CONTROL TRAY

V

1.2kΩ

1MΩ

V

V

V

CC

SW7

1

2

3

Page 21

Test Circuits 2

Spindle Motor Drive Part

FAN8727

H3+

AAAAAA

VV

SW12

1

VH

2

2.5V

E

C

SW14

5V

A

SW13

FG

3

ECR

4

EC

5

VCC2

6

PC1

H3+

H3−

H2+

H3−

H2+

H2−

H1+

H1−

3738394042 41434445464748

H2−

H1+

H1−

BTLSGND

BIAS

AVM4

MUTE12

MUTE3

MUTE4

DO4+

DO4−

AVM3

DO3+

DO3−

BTLPGND2

36

35

34

33

32

31

FAN8727

SW15

IFR

SW16

7

SIGGND

8

VM

9

CS1

10

SS

11

DIR

12

SB

PWRGNDA3A2

13 14 15 16 17 19 20 21 22 23 24

A1

OPIN−

OPIN+

18

OPOUT

VCC1

BTLPGND1

AVM12

D14

D13

12V

V

V

SW17

SW18

DO2+

DO2−

DO1+

DO1−

DI1

D12

30

29

28

27

26

25

VSB

SW19

SW20

21

Page 22

FAN8727

Application Circuits

FOCUS TRACKING

MUTE

SLED MUTE

BTL BIAS

HALL3

HALL2

HALL1

VOLTAGE

+5V

TRAY MUTE

FG SIGNAL

SERVO

TORQUE

CONTROL

12V

ROTATE

DIRECTION

100pF

VCC

SYSTEM

CONTROL

SHORT

BREAK

10K

0.1µF

42

H3−

1

2

3

4

5

6

H3+

VH

FG

ECR

EC

VCC2

PC1

H2+

H2−

H1+

H1−

BIAS

BTLSGND

FAN8727

7

SIGGND

8

VM

CS1

9

SS

10

11

DIR

12

SB

PWRGNDA3A2

13 14 15 16 17 18 19 20 21 22 23 24

A1

OPIN−

OPIN+

OPOUT

VCC1

3738394041434445464748

AVM4

AVM12

MUTE12

D14

MUTE3

BTLPGND2

BTLPGND1

D13

DO4+

MUTE4

DO4−

AVM3

DO3+

DO3−

DO2+

DO2−

DO1+

DO1−

D12

DI1

36

35

34

33

32

31

30

29

28

27

26

25

+5V

TRAY

MOTOR

SLED

MOTOR

FOCUS

ACTUATOR

TRACKING

ACTUATOR

22

VCC

+5V

SERVO AMP

TRACKING

FOCUS

SLED

CONTROL TRAY

Page 23

FAN8727

23

Page 24

FAN8727

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURT HER NOTICE TO ANY

PRODUCTS HEREI N TO IMPROVE RELIABILITY, FUNCTIO N OR DESIGN. FAIRCH IL D DOES NOT ASSUME ANY

LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER

DOES IT CONVEY ANY LICENSE UNDER IT S PATENT RIGHTS, NOR THE RIGHTS OF OTHE RS.

LIFE SUPPORT POL I CY

FAIRCHILD’S PR ODUCTS ARE NOT AUTH ORIZED FOR USE AS C RITICAL COMPONENT S IN LIFE SUPPORT DE VICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPOTATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and (c) whose failure to

perform when properly used in accordance with

2. A critical component in any component of a life support

device or sy stem whose fai lure to perform can be

reasonably expec ted to cause the failur e of the life support

device or system, or to affect its safety or effec t iv ene ss .

instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury of the

user.

www.fairchildsemi.com

9/6/02 0.0m 001

2002 Fairchild Semiconductor Corporation

Stock#DSxxxxxxxx

Loading...

Loading...