Datalogic Scanning DS6500-100-012, DS6500-100-011, DS6500, DS6500-100-015, DS6500-100-010 User Manual

...Page 1

DS6500

INSTALLATION QUICK REFERENCE

Page 2

CONTENTS

DS6500-100-010 MASTER/SLAVE MODEL ...........................................................................................................1

DS6500-100-011 PROFIBUS MODEL .....................................................................................................................8

DS6500-100-012 ETHERNET MODEL .................................................................................................................. 13

DS6500-100-015 DEVICENET MODEL .................................................................................................................18

DS6500-105-0XX OSCILLATING MIRROR MODEL.............................................................................................23

COMMON FEATURES ..........................................................................................................................................25

NOTE

For further details on product installation, see the complete Reference Manual available on the

configuration CD-ROM included with this product.

Page 3

DS6500-100-010 MASTER/SLAVE MODEL

1

1

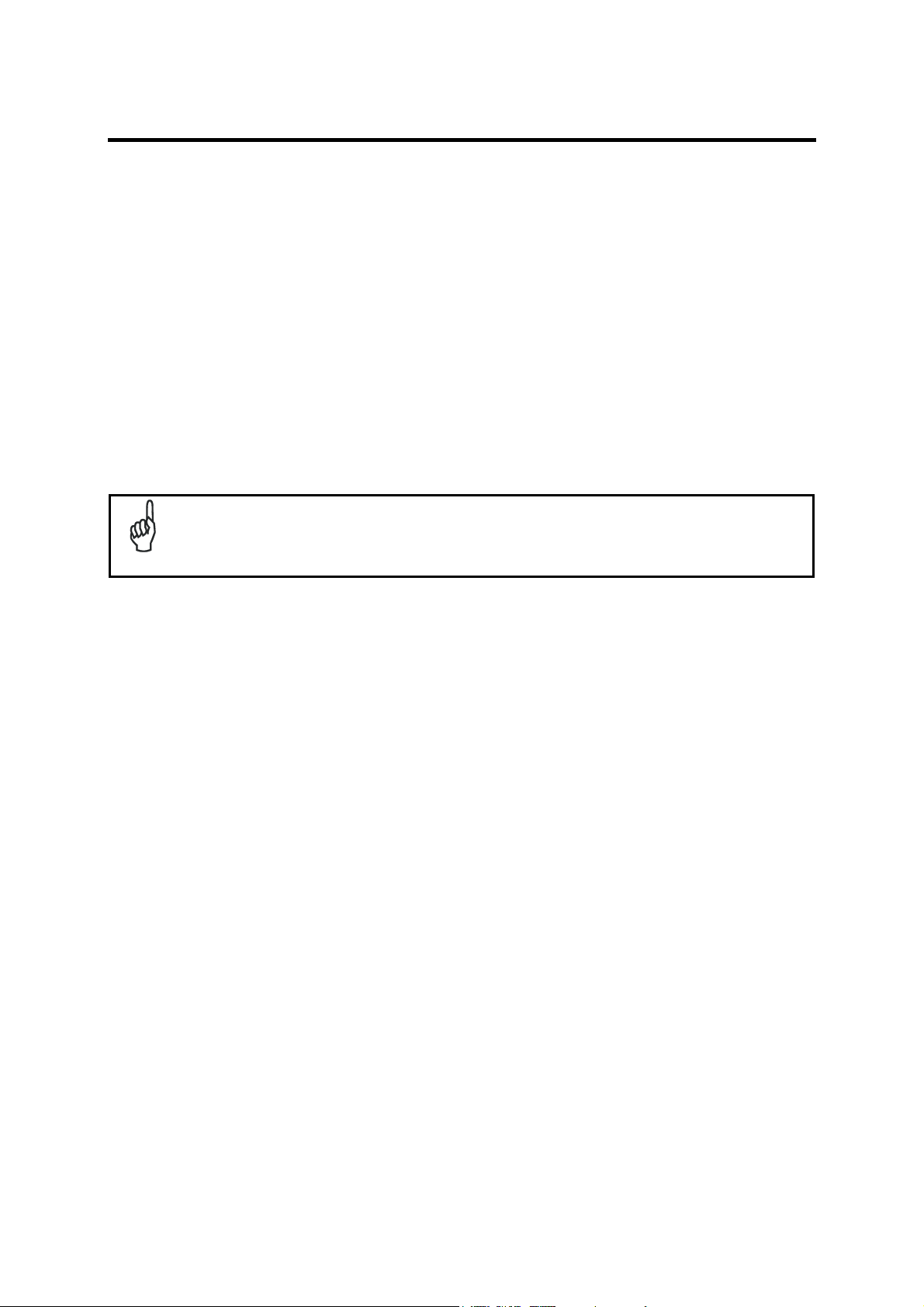

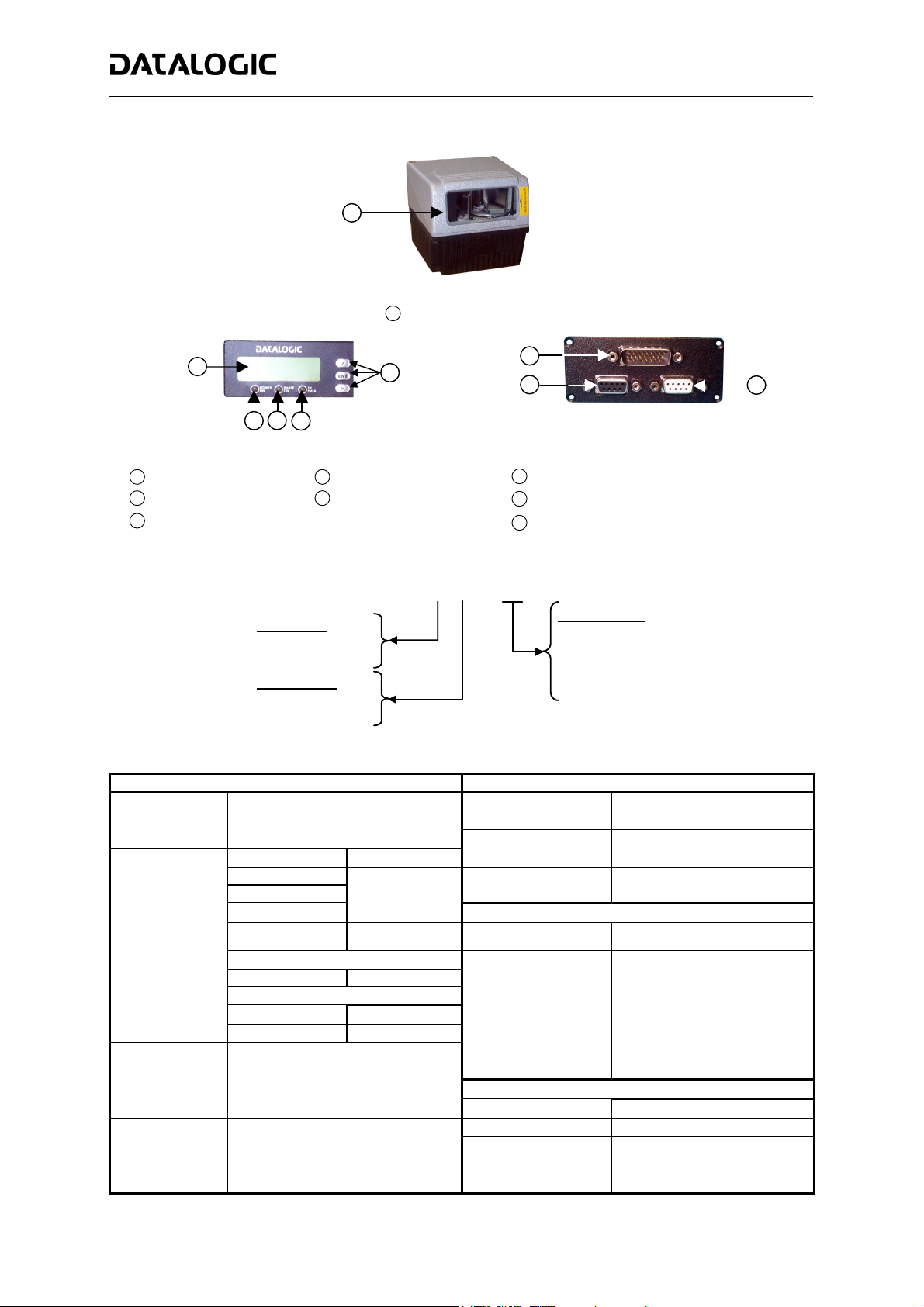

Figure A

Laser Beam Output Window

DS6500 MASTER/SLAVE MODEL

5

Programming Keypad

1

TX Data LED (Green)

2

Phase On LED (Yellow)

3

3

4

Figure B

2

Power On LED (Red)

4

LCD Display

5

1

3

Main/Aux. Interface 25-pin D-sub Male Connector

1

Lonworks 9-pin Male Connector

2

Lonworks 9-pin Female Connector

3

Available Models:

DS6500 - X0X - 0YY

Focalization

1 = Medium Version

2 = Long Version

Optical Model

0 = Standard

5 = Oscillating Mirror

Decoder Model

10 = Master/Slave

11 = Profibus

12 = Ethernet

15 = Devicenet

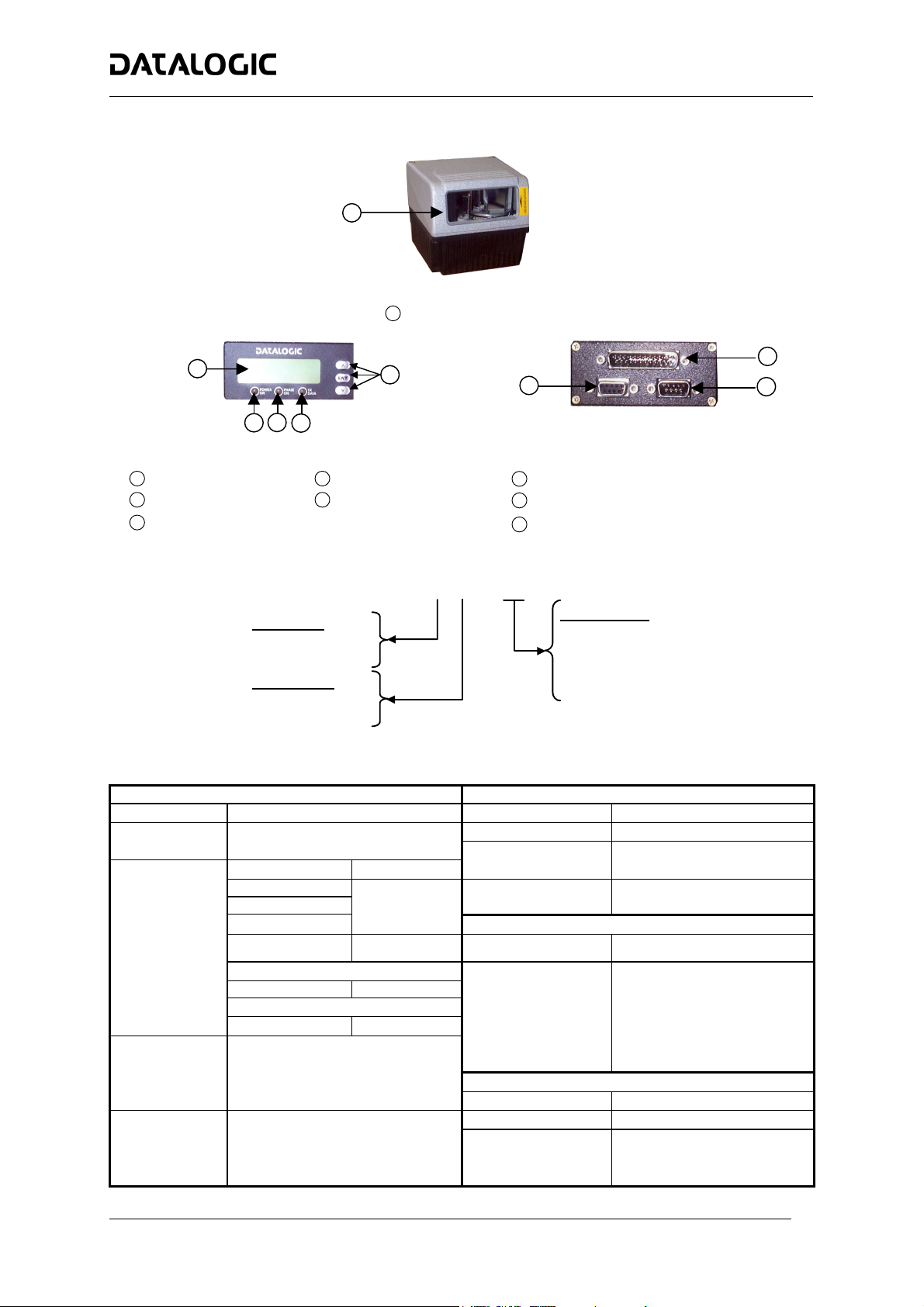

Technical Features:

ELECTRICAL FEATURES OPTICAL FEATURES

Supply Voltage

Power

Consumption

Communication

Interfaces

Inputs

Ext. Trigger 1,

3 aux. digital

inputs

Outputs

3 software

programmable

digital outputs

15 - 30 Vdc

15 W typical

20 W Max. (including startup current)

Main (isolated) Baud Rate

RS232

RS485 full-duplex

RS485 half-duplex

20 mA C.L. (INT-30

with C-BOX 100 only)

Auxiliary

RS232

1200 to 115200

19200

1200 to 115200

Other

Lonworks

1,25 Mb/s

(opt coupled NPN or PNP)

(optocoupled)

Light Receiver

Wavelength

Safety Class

Laser Control

READING FEATURES

Scan Rate

Max. Resolution

Max. Read. Distance

Max. Read. Width

Max. Depth of Field

USER INTERFACE

LCD Display

Keypad

LED Indicators

1

2

Figure C

Avalanche photodiode

630 to 680 nm

Class 2-EN 60825-1;

Class II-CDRH

Security system to turn laser

off in case of motor slow down

600-1200 scans/s

(see reading diagram)

2 lines by 16 characters LCD

3 keys

Power ON (red color)

Phase ON (yellow color)

TX Data (green color)

1

Page 4

DS6500 MASTER/SLAVE MODEL

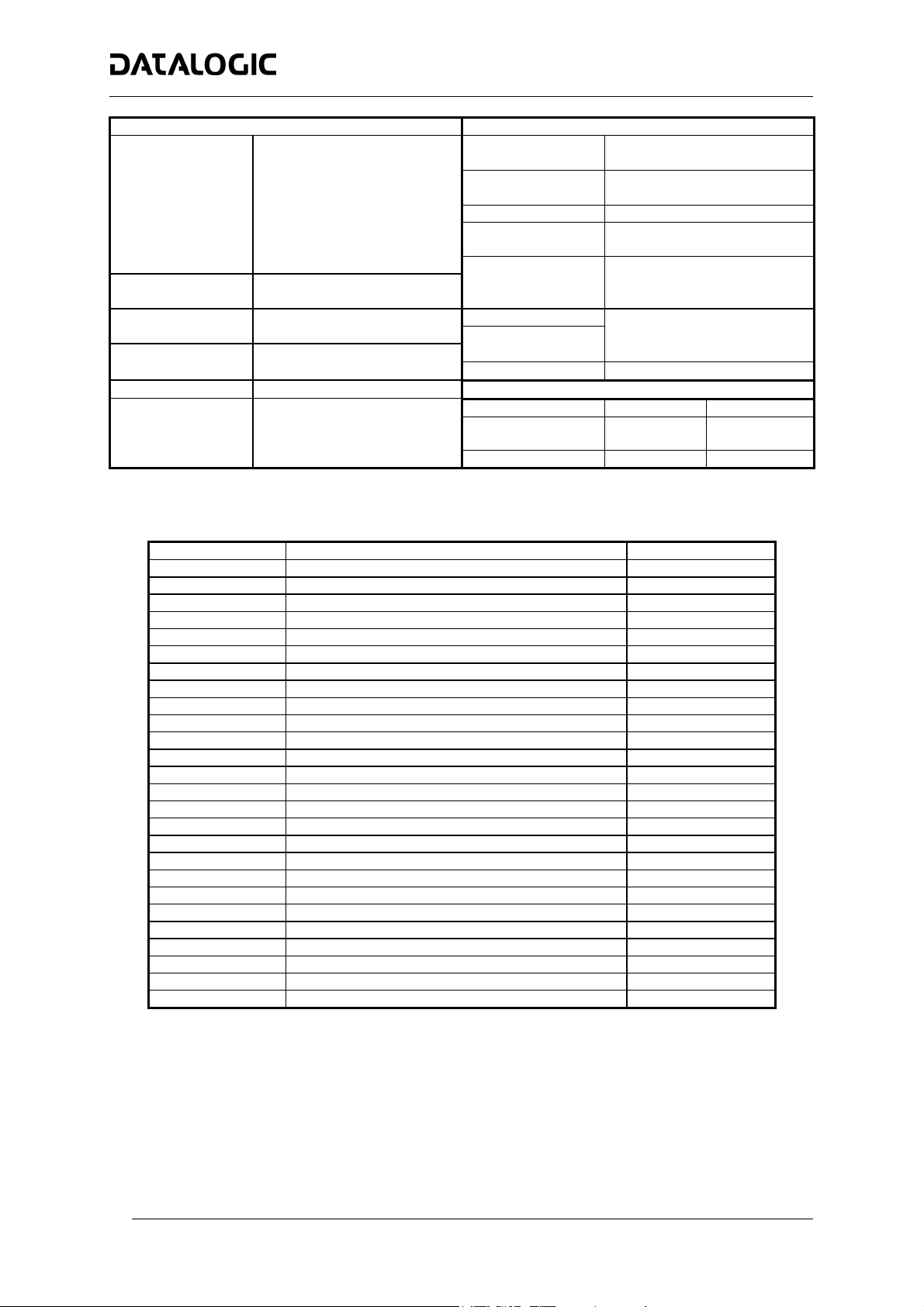

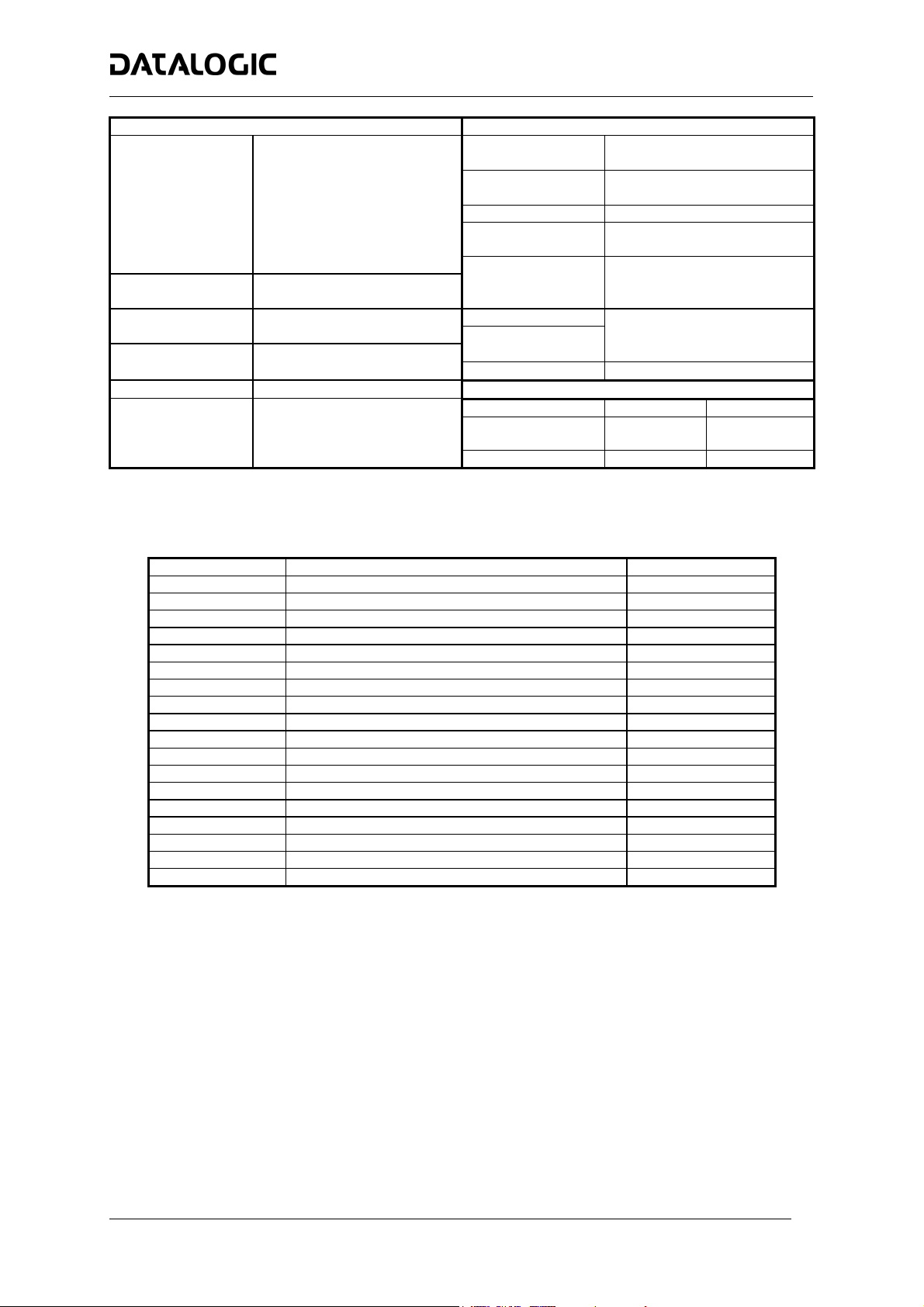

SOFTWARE FEATURES ENVIRONMENTAL FEATURES

Readable Codes

Code Selection

Headers and Shock Resistance

Terminators

Operating Modes

Config. Mode

Parameter Storage

Interleaved 2/5

Code 39 standard

Codabar

Code 128

EAN 128

Code 93 (Standard & Full ASCII)

EAN/UPC (including Add-on 2

And Add-on 5)

Up to 10 codes during one

reading phase

Up to 128-byte headers and

128-byte terminators

On Line, Automatic, Test, 3 shocks on each axis

PackTrack™

Genius™ utility program

Non-volatile internal FLASH

Operating

Temperature

Storage

Temperature

Humidity

Ambient Light

Immunity

Vibration Resistance

IEC 68-2-6 test FC 1.5 mm @ 13 to 55 Hz

2 hours on each axis 2 g @ 70 to 200 Hz

IEC 68-2-27 test EA

Protection Class

PHYSICAL FEATURES

Dimensions mm

(inch)

Weight

0° to +40 °C (+32 to +104 °F)

-20° to +70 °C (-4° to +158 °F)

90% non condensing

3500 lux

14 mm @ 2 to 10 Hz

30 g; 11 ms

IP64

Std Models Oscill. Mirror

110x113x99

(4.33x4.45x3.9)

1.5 kg (3.3 lb) 2.0 kg (4.4 lb)

113x180x104.5

(4.45x7.08x4.11)

Accessories:

Name Description Part Number

CAB-6001 Cable to C-BOX100 1 m 93A051190

CAB-6002 Cable to C-BOX100 2 m 93A051200

CAB-6005 Cable to C-BOX100 5 m 93A051210

CAB-6010 Cable to C-BOX100 10 m 93A051271

CAB-6101 Cable master/slave 1 m 93A051220

CAB-6102 Cable master/slave 2 m 93A051230

CAB-6105 Cable master/slave 5 m 93A051240

CAB-6112 Cable master/slave no power 2 m 93A051224

CAB-6115 Cable master/slave no power 5 m 93A051225

CAB-6305 Power cable Fam 6k 5 m 93ACC1768

CAB-6310 Power cable Fam 6k 10 m 93ACC1752

C-BOX 100 Passive connection box 93ACC1510

INT-30 20 mA C.L. interface board for C-BOX 100 93A151022

GFC-60 90° mirror 93A201100

GFC-600 90° mirror close distance 93A201102

PWR-120 Power unit 110/230 V AC - 24 V DC 93ACC1530

BTK-6000 Terminator kit (5 pcs) 93ACC1710

PG6002 Single unit power supply – US 93ACC1718

PG6001 Single unit power supply – UK 93ACC1719

PG6000 Single unit power supply – EU 93ACC1720

FBK-6000 Fast bracket kit (2 pcs) 93ACC1721

US-60 Mounting bracket kit (5 pcs) for multisided stations 890001020

MEP-542 Photocell kit – PNP 93ACC1727

MEP-543 Photocell kit – NPN 93ACC1728

OEK-2 Optical encoder (10 m cable + spring) 93ACC1770

OEK-1 Optical encoder kit + 10 m cable 93ACC1600

Electrical Connections:

The DS6500 reader provides a 25-pin male D-sub connector for connection to power supply, Host interface (Main

and Aux), and input/output signals.

Two 9-pin connectors provide access to the scanner’s local Lonworks network used for both input and output

connections to build a multi-sided or omni-station system.

2

Page 5

DS6500 MASTER/SLAVE MODEL

The details of the connector pins are indicated in the following table:

25-pin D-Sub Connector Pinout

Pin Name Function

1 CHASSIS

20 RXAUX Receive data of auxiliary RS232 (referred to GND)

21 TXAUX Transmit data of auxiliary RS232 (referred to GND)

8 OUT 1+ Configurable digital output 1 – positive pin

22 OUT 1- Configurable digital output 1 – negative pin

11 OUT 2+ Configurable digital output 2 – positive pin

12 OUT 2- Configurable digital output 2 – negative pin

16 OUT 3A Configurable digital output 3 – polarity insensitive

17 OUT 3B Configurable digital output 3 – polarity insensitive

18 EXT_TRIG/PS A External trigger (polarity insensitive) for PS

19 EXT_TRIG/PS B External trigger (polarity insensitive) for PS

6 IN2/ENC A Input signal 2 (polarity insensitive) for Encoder

10 IN2/ENC B Input signal 2 (polarity insensitive) for Encoder

14 IN3A Input signal 3 (polarity insensitive)

15 IN4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

9, 13 VS Supply voltage – positive pin

23, 25 GND Supply voltage – negative pin

Pin RS232 RS485 Full-Duplex RS485 Half-Duplex

2 TX TX485+ RTX485+

3 RX RX485+

4 RTS TX485- RTX485- see INT-30 instructions

5 CTS RX485-

7 GND_ISO GND_ISO GND_ISO

* For 20 mA C.L. connections, GND is the same of the scanner power supply.

Chassis - internally connected to GND

Cable shield connected to chassis

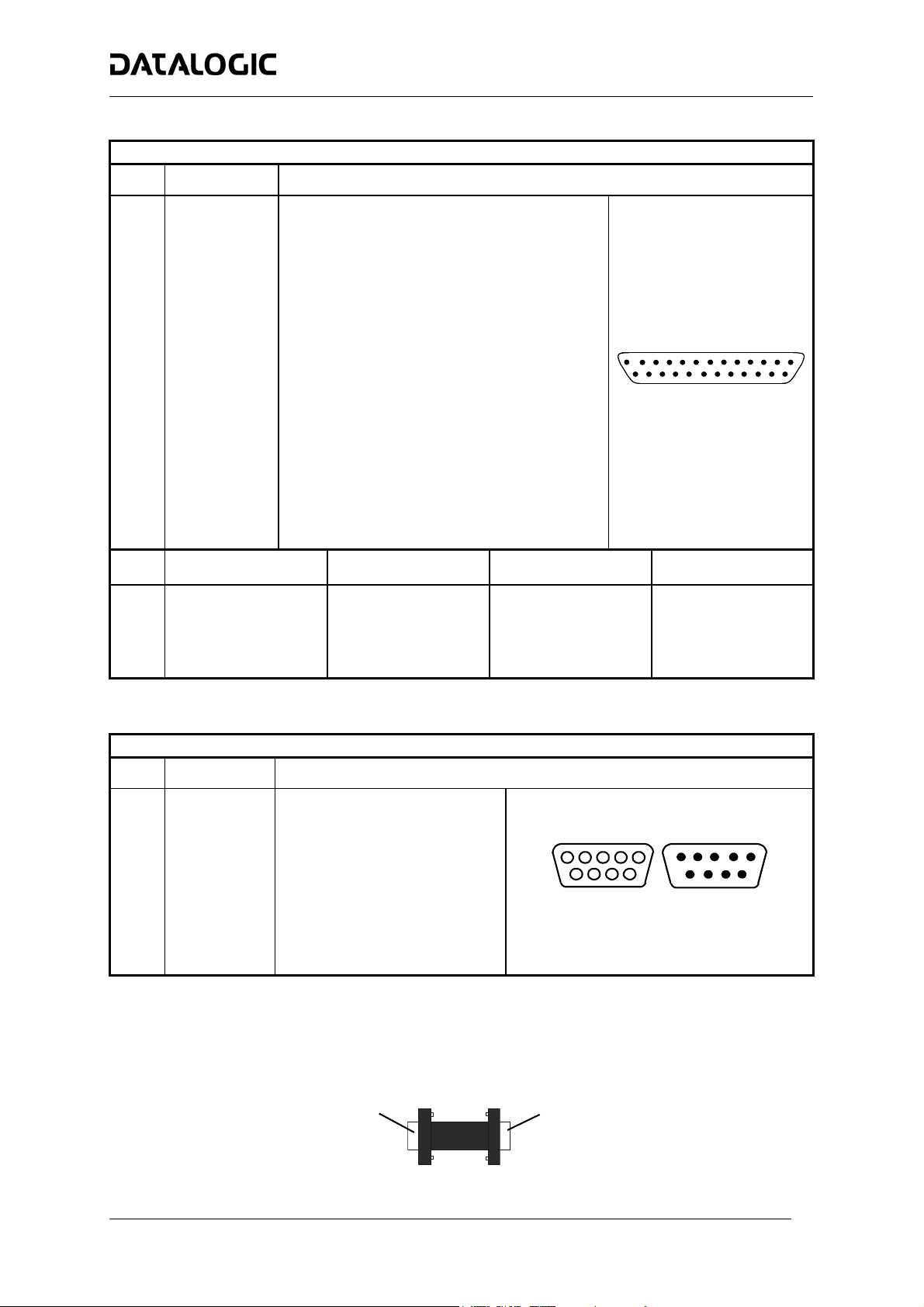

9-pin Lonworks Connector Pinout

1

14

25-pin male D-sub Connector

20 mA C.L.

(INT-30 with C-BOX 100 only)

13

25

Pin Name Function

1 CHASSIS

9 VS Supply voltage – positive pin

Cable shield internally connected

by capacitor to chassis

5

1

1

5

2 GND Supply voltage – negative pin

6 VS_I/O Supply voltage of I/O circuit

3 Ref_I/O Reference voltage of I/O circuit

4 SYS_ENC_I/O System signal

5 SYS_I/O System signal

7 LON A Lonworks line (polarity insensitive)

9

9-pin Local Lonworks Connectors

Female

6

6

Male

9

8 LON B Lonworks line (polarity insensitive)

Network Termination:

When building a local Lonworks system the network must be properly terminated by positioning a BTK-6000

terminator on the DS6500 master reader (BTK-6000 female side) and on the last slave reader (BTK-6000 male

side).

to Master

9-pin female

to Slave

9-pin male

BTK-6000 Network Terminator

3

Page 6

AUX

A

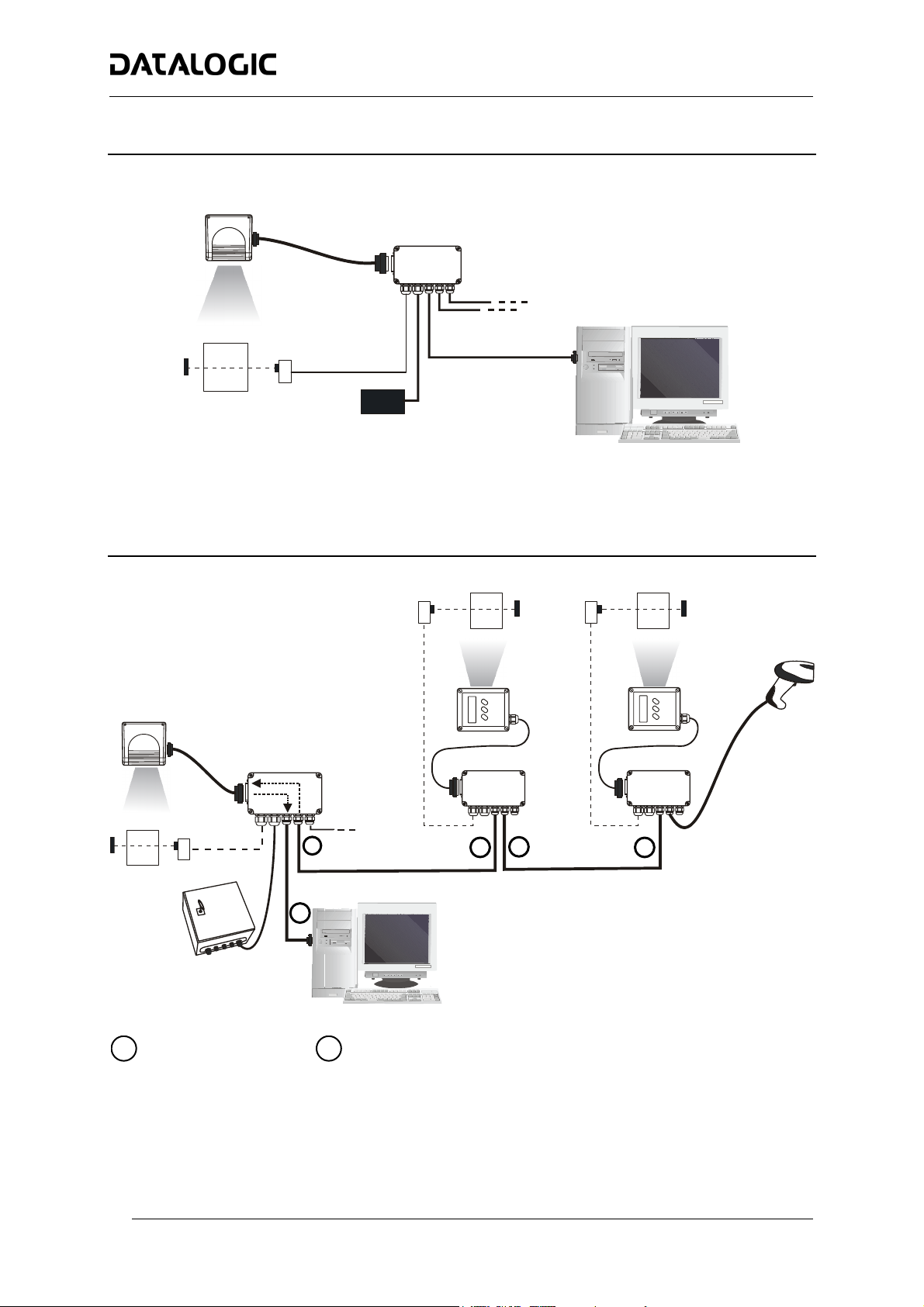

Connectivity:

DS6500

DS6500 MASTER/SLAVE MODEL

Point-to-Point Layout

CAB-600X

*P.S.

C-BOX 100

PG6000

* P.S. (Presence Sensor) connected to External Trigger/PS input.

Pass Through Layout

*P.S.

Local Host

*P.S.

Gryphon

DS6500

CAB-600X

C-BOX 100

MAIN

*P.S.

2

Local Host

<

T

N

E

<

C-BOX 100

1

1

PWR-120

1 2

Main Serial Interface

uxiliary Serial Interface

* P.S. (Presence Sensor) connected to External Trigger/PS input.

DS4600A

2

<

T

N

E

<

C-BOX 100

1

DS4600A

4

Page 7

A

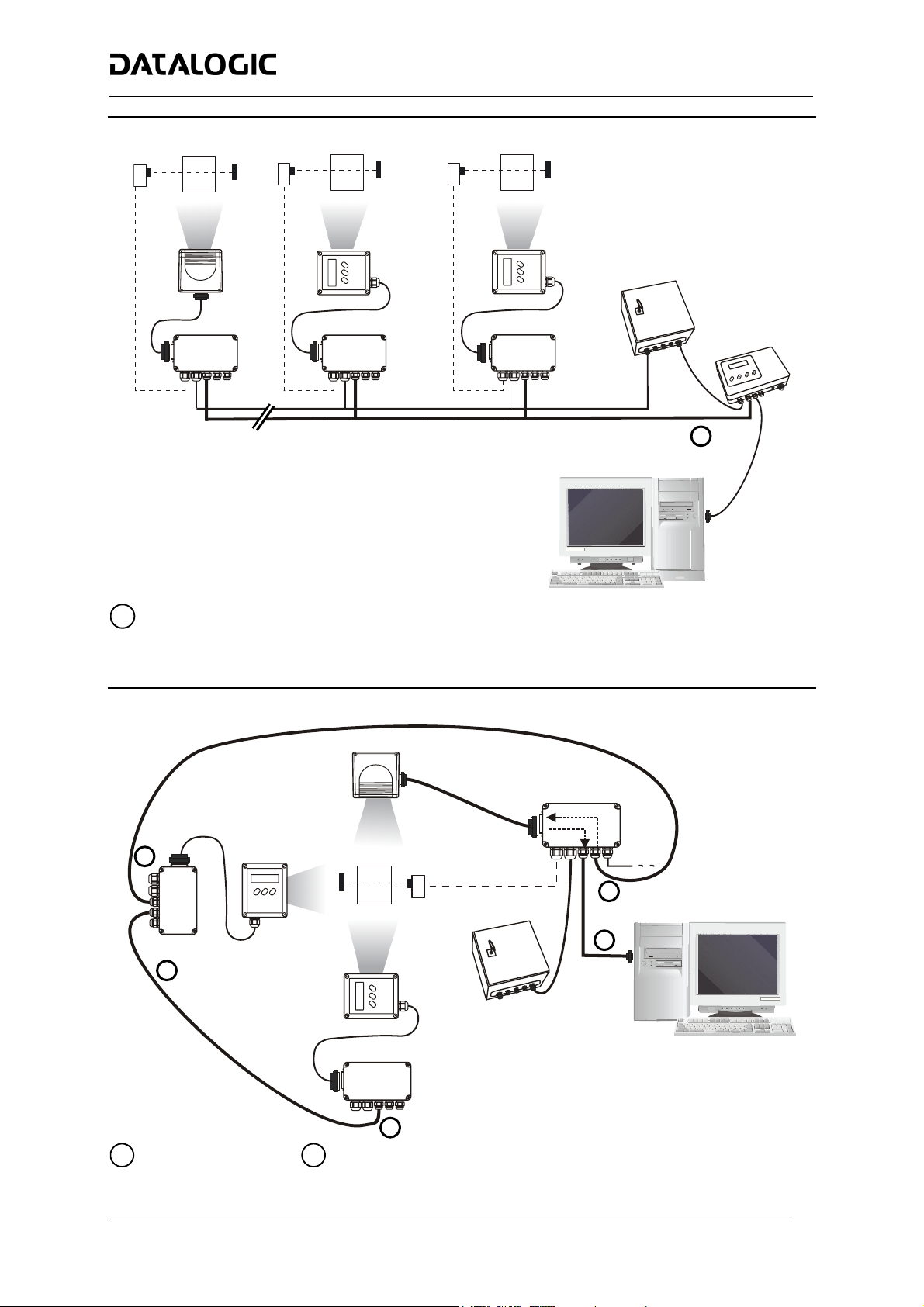

DS6500 MASTER/SLAVE MODEL

Multiplexer Layout

*P.S.

*P.S.

<

DS6500

CAB-600X

C-BOX 100

#31

DS4600A

T

N

E

<

C-BOX 100

#1

C-BOX 100

#0

1

RS485 HD Main Interface

* P.S. (Presence Sensor) connected to External Trigger/PS input.

RS232 Master/Slave Layout

<

T

N

E

<

DS4600A

Local Host

PWR-120

MX4000

1

DS6500

Master

CAB-600X

DS4600A

1

Slave 1

T

<

N

E

<

*P.S.

C-BOX 100

2

DS4600A

Slave 2

<

T

N

E

<

PWR-120

C-BOX 100

1 2

Main Serial Interface

uxiliary Serial Interface

1

* P.S. (Presence Sensor) connected to External Trigger/PS input.

C-BOX 100

2

Local Host

1

5

Page 8

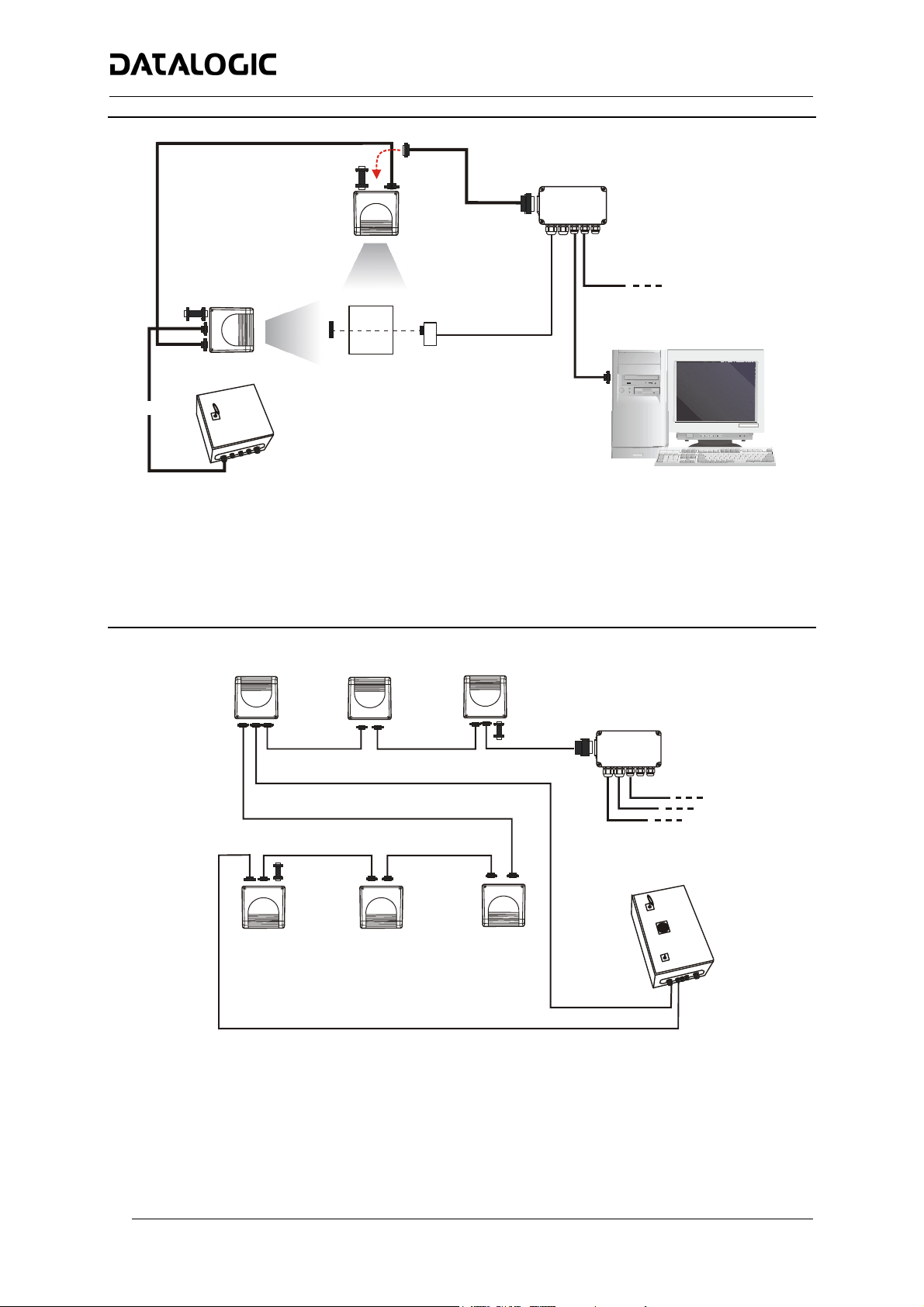

Local Lonworks Network

CAB-60XX

CAB-63XX

CAB-610X

BTK-6000

BTK-6000

Master

Slave 1

*P.S.

PWR-120

Small Synchronized Network with 2 Readers

* P.S. (Presence Sensor) connected to External Trigger/PS input.

** C-BOX 100 modified to accept scanner power.

*** Encoder connected to IN2/ENC input.

Local Lonworks Network

Slave 2

Slave 1

Master

DS6500 MASTER/SLAVE MODEL

C-BOX 100**

Encoder***

Local Host

BTK-6000

CAB-600X

Slave 3

CAB-610X

Slave 5

CAB-610X

CAB-610X

BTK-6000

CAB-610X

CAB-610X

Slave 4

CAB-63XX

Small Synchornized Network with more than 2 Readers and Single Power Unit

* P.S. (Presence Sensor) connected to External Trigger/PS input.

** C-BOX 100 modified to accept scanner power.

*** Encoder connected to IN2/ENC input.

C-BOX 100**

*P.S.

Encoder***

Host

CAB-63XX

PWR-240

6

Page 9

DS6500 MASTER/SLAVE MODEL

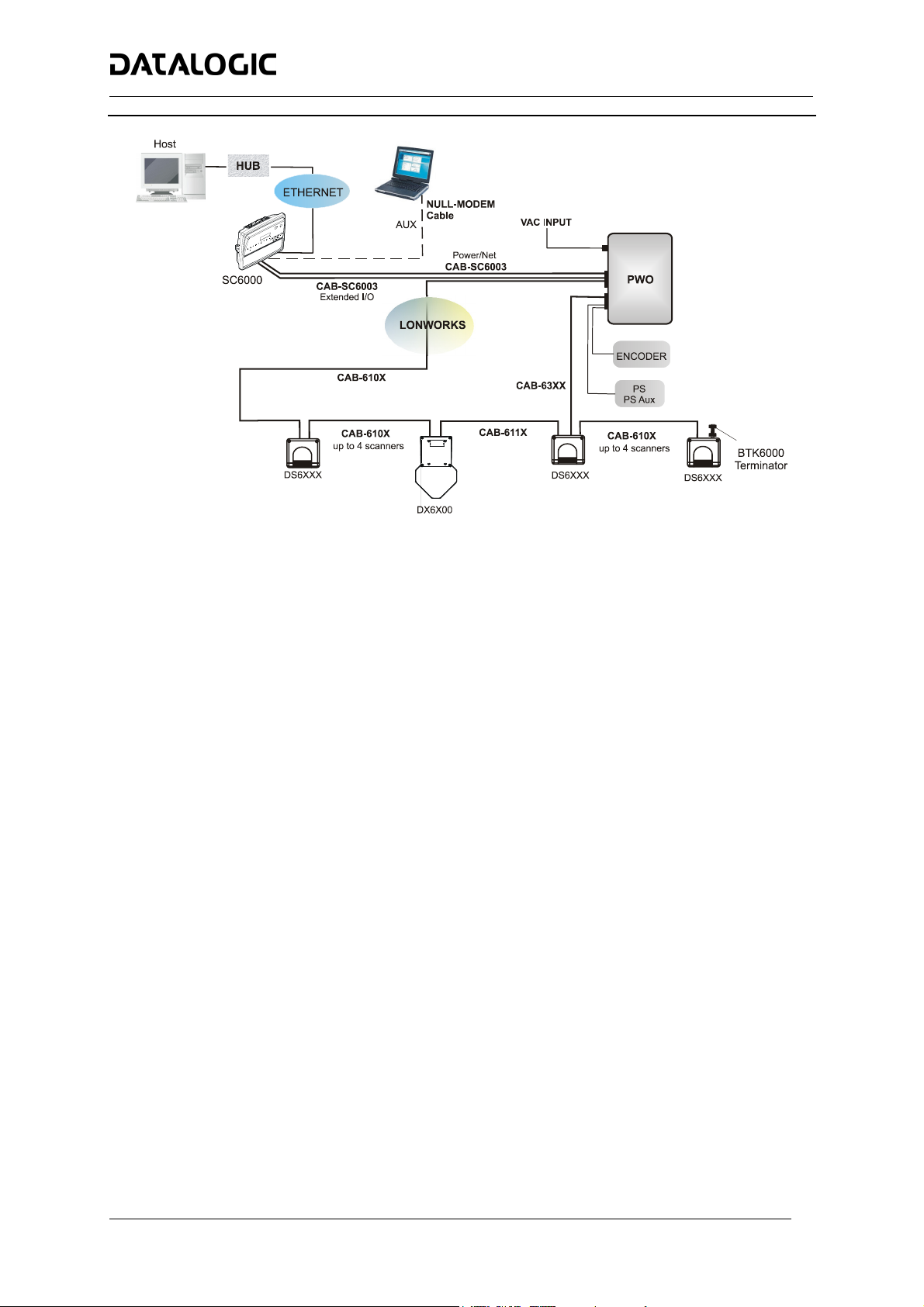

Large Synchronized Network

**

*

* P.S. (Presence Sensor) connected to External Trigger/PS input.

** Encoder connected to IN2/ENC input.

Large Synchronized Network with DX6X00 and DS6XXX Scanners

.

7

Page 10

DS6500-100-011 PROFIBUS MODEL

1

1

Figure A

Laser Beam Output Window

DS6500 PROFIBUS MODEL

5

3

4

2

1

3

2

Figure B

Programming Keypad

1

TX Data LED (Green)

2

Phase On LED (Yellow)

3

Power On LED (Red)

4

LCD Display

5

Profibus 9-pin Female Connector (white)

1

Lonworks 9-pin Female Connector

2

Main/Aux. Interface 26-pin D-Sub Male Connector

3

Available Models:

DS6500 - X0X - 0YY

Focalization

1 = Medium Version

2 = Long Version

Optical Model

0 = Standard

5 = Oscillating Mirror

Decoder Model

10 = Master/Slave

11 = Profibus

12 = Ethernet

15 = Devicenet

Technical Features:

ELECTRICAL FEATURES OPTICAL FEATURES

Supply Voltage

Power

Consumption

Communication

Interfaces

Inputs

Ext. Trigger 1,

3 aux. digital

inputs

Outputs

3 software

programmable

digital outputs

15 - 30 Vdc

15 W typical

20 W Max. (including startup current)

Main (isolated) Baud Rate

RS232

RS485 full-duplex

RS485 half-duplex

20 mA C.L. (INT-30

with C-BOX 100 only)

Auxiliary

RS232 1200 to 115200

Other

Lonworks 1,25 Mb/s

Profibus 12 Mb/s

1200 to 115200

19200

(optocoupled NPN or PNP)

(optocoupled)

Light Receiver

Wavelength

Safety Class

Laser Control

READING FEATURES

Scan Rate

Max. Resolution

Max. Read. Distance

Max. Read. Width

Max. Depth of Field

USER INTERFACE

LCD Display

Keypad

LED Indicators

1

Figure C

Avalanche photodiode

630 to 680 nm

Class 2-EN 60825-1;

Class II-CDRH

Security system to turn laser

off in case of motor slow down

600-1200 scans/s

(see reading diagram)

2 lines by 16 characters LCD

3 keys

Power ON (red color)

Phase ON (yellow color)

TX Data (green color)

8

Page 11

DS6500 PROFIBUS MODEL

SOFTWARE FEATURES ENVIRONMENTAL FEATURES

Readable Codes

Code Selection

Headers and Shock Resistance

Terminators

Operating Modes

Config. Mode

Parameter Storage

Interleaved 2/5

Code 39 standard

Codabar

Code 128

EAN 128

Code 93 (Standard & Full ASCII)

EAN/UPC (including Add-on 2

And Add-on 5)

Up to 10 codes during one

reading phase

Up to 128-byte headers and

128-byte terminators

On Line, Automatic, Test, 3 shocks on each axis

PackTrack™

Genius™ utility program

Non-volatile internal FLASH

Operating

Temperature

Storage

Temperature

Humidity

Ambient Light

Immunity

Vibration Resistance

IEC 68-2-6 test FC 1.5 mm @ 13 to 55 Hz

2 hours on each axis 2 g @ 70 to 200 Hz

IEC 68-2-27 test EA

Protection Class

PHYSICAL FEATURES

Dimensions mm

(inch)

Weight

0° to +40 °C (+32 to +104 °F)

-20° to +70 °C (-4° to +158 °F)

90% non condensing

3500 lux

14 mm @ 2 to 10 Hz

30 g; 11 ms

IP64

Std Models Oscill. Mirror

110x113x99

(4.33x4.45x3.9)

1.5 kg (3.3 lb) 2.0 kg (4.4 lb)

113x180x104.5

(4.45x7.08x4.11)

Accessories:

Name Description Part Number

CAB-6011 Cable to C-BOX100 1 m 93A051221

CAB-6012 Cable to C-BOX100 2 m 93A051222

CAB-6015 Cable to C-BOX100 5 m 93A051223

C-BOX 100 Passive connection box 93ACC1510

INT-30 20 mA C.L. interface board for C-BOX 100 93A151022

GFC-60 90° mirror 93A201100

GFC-600 90° mirror close distance 93A201102

PWR-120 Power unit 110/230 V AC - 24 V DC 93ACC1530

BTK-6000 Terminator kit (5 pcs) 93ACC1710

PG6002 Single unit power supply – US 93ACC1718

PG6001 Single unit power supply – UK 93ACC1719

PG6000 Single unit power supply – EU 93ACC1720

FBK-6000 Fast bracket kit (2 pcs) 93ACC1721

US-60 Mounting bracket kit (5 pcs) for multisided stations 890001020

MEP-542 Photocell kit – PNP 93ACC1727

MEP-543 Photocell kit – NPN 93ACC1728

OEK-2 Optical encoder (10 m cable + spring) 93ACC1770

OEK-1 Optical encoder kit + 10 m cable 93ACC1600

Electrical Connections:

The DS6500 Ethernet reader provides a 26-pin male D-sub connector for connection to power supply and

input/output signals.

An Ethernet connector is used for connection to the remote Host (for ex. Remote PC connected via Internet),

while a local Lonworks 9-pin female connector connects the Ethernet master to the first slave reader of the

system.

The details of the connector pins are indicated in the following table:

9

Page 12

DS6500 PROFIBUS MODEL

26-pin D-Sub Connector Pinout

Pin Name Function

1 CHASSIS

20 RXAUX Receive data of auxiliary RS232 (referred to GND)

21 TXAUX Transmit data of auxiliary RS232 (referred to GND)

8 OUT 1+ Configurable digital output 1 – positive pin

22 OUT 1- Configurable digital output 1 – negative pin

11 OUT 2+ Configurable digital output 2 – positive pin

12 OUT 2- Configurable digital output 2 – negative pin

16 OUT 3A Configurable digital output 3 – polarity insensitive

17 OUT 3B Configurable digital output 3 – polarity insensitive

18 EXT_TRIG/PS A External trigger (polarity insensitive) for PS

19 EXT_TRIG/PS B External trigger (polarity insensitive) for PS

6 IN2/ENC A Input signal 2 (polarity insensitive) for Encoder

10 IN2/ENC B Input signal 2 (polarity insensitive) for Encoder

14 IN3A Input signal 3 (polarity insensitive)

15 IN4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

9, 13 VS Supply voltage – positive pin

23, 25, 26 GND Supply voltage – negative pin

Pin RS232 RS485 Full-Duplex RS485 Half-Duplex

2 TX TX485+ RTX485+

3 RX RX485+

4 RTS TX485- RTX485- see INT-30 instructions

5 CTS RX485-

7 GND_ISO GND_ISO GND_ISO

Chassis - internally connected to GND

Cable shield connected to chassis

1

10

19

26-pin male D-sub Connector

20 mA C.L.

(INT-30 with C-BOX 100 only)

9

18

26

* For 20 mA C.L. connections, GND is the same of the scanner power supply.

9-pin Lonworks Connector Pinout

Pin Name Function

1 CHASSIS

Cable shield internally connected

by capacitor to chassis

9 VS Supply voltage – positive pin

2 GND Supply voltage – negative pin

6 VS_I/O Supply voltage of I/O circuit

3 Ref_I/O Reference voltage of I/O circuit

4 SYS_ENC_I/O System signal

5 SYS_I/O System signal

9-pin female Local Lonworks Connector

7 LON A Lonworks line (polarity insensitive)

8 LON B Lonworks line (polarity insensitive)

9-pin Profibus Connector

Pin Name Function

1 Shield Shield, Protective Ground resp. (optional)

2 Free

3 B-LINE (RxD/TxD-P) Received/Transmitted Data-P

4 CNTR-P Repeater Control Signal (optional, RS485 level)

5 DGND Data Ground (M5V)

6 +5 V Voltage Plus (P5V)

7 Free

8 A-LINE (RxD/TxD-N) Received/Transmitted Data

9 CNTR-N Repeater Control Signal

5

9

9-pin female Profibus Connector

1

6

5

9

(white)

1

6

10

Page 13

X

A

Connectivity:

DS6500

DS6500 PROFIBUS MODEL

Point-to-Point Layout

Remote Host

Fieldbus

Network

CAB-601X

*P.S.

C-BOX 100

* P.S. (Presence Sensor) connected to External Trigger/PS input.

Pass Through Layout

Remote Host

*P.S.

Fieldbus

Network

DS6500

CAB-601

C-BOX 100

AUX

C-BOX 100

<

T

N

E

<

PG6000

DS4600A

*P.S.

<

T

N

E

<

C-BOX 100

Gryphon

DS4600A

*P.S.

2

PWR-120

1 2

Main Serial Interface

uxiliary Serial Interface

* P.S. (Presence Sensor) connected to External Trigger/PS input.

2

1

1

11

Page 14

DS6500 PROFIBUS MODEL

Local Lonworks Network

Remote Host

Fieldbus

Network

Slave 2***

CAB-610X

CAB-610X

CAB-610X

BTK-6000

Slave 5*** Slave 4***

Slave 1***

CAB-610X

CAB-610X

Fieldbus Small Synchronized Network

Master

Slave 3***

CAB-63XX

C-BOX 100**

CAB-60XX

P.S.*

Encoder****

CAB-63XX

PWR-240

* P.S. (Presence Sensor) connected to External Trigger/PS input.

** C-BOX 100 modified to accept scanner power.

*** The Slave scanners are Master/Slave models, which allow Lonworks network propagation.

**** Encoder connected to IN2/ENC input.

12

Page 15

DS6500-100-012 ETHERNET MODEL

1

1

Figure A

Laser Beam Output Window

DS6500 ETHERNET MODEL

3

2

RJ45 Modular Connector for Ethernet Interface

1

Lonworks 9-pin Female Connector

2

Main/Aux. Interface 26-pin D-Sub Male Connector

3

Programming Keypad

1

TX Data LED (Green)

2

Phase On LED (Yellow)

3

5

3

4

2

Figure B

Power On LED (Red)

4

LCD Display

5

1

Available Models:

DS6500 - X0X - 0YY

Focalization

1 = Medium Version

2 = Long Version

Optical Model

0 = Standard

5 = Oscillating Mirror

Decoder Model

10 = Master/Slave

11 = Profibus

12 = Ethernet

15 = Devicenet

Technical Features:

ELECTRICAL FEATURES OPTICAL FEATURES

Supply Voltage

Power

Consumption

Communication

Interfaces

Inputs

Ext. Trigger 1,

3 aux. digital

inputs

Outputs

3 software

programmable

digital outputs

15 - 30 Vdc

15 W typical

20 W Max. (including startup current)

Main (isolated) Baud Rate

RS232

RS485 full-duplex

RS485 half-duplex

20 mA C.L. (INT-30

with C-BOX 100 only)

Auxiliary

RS232 1200 to 115200

Other

Lonworks 1,25 Mb/s

Ethernet 10 or 100 Mb/s

1200 to 115200

19200

(optocoupled NPN or PNP)

(optocoupled)

Light Receiver

Wavelength

Safety Class

Laser Control

READING FEATURES

Scan Rate

Max. Resolution

Max. Read. Distance

Max. Read. Width

Max. Depth of Field

USER INTERFACE

LCD Display

Keypad

LED Indicators

1

Figure C

Avalanche photodiode

630 to 680 nm

Class 2-EN 60825-1;

Class II-CDRH

Security system to turn laser

off in case of motor slow down

600-1200 scans/s

(see reading diagram)

2 lines by 16 characters LCD

3 keys

Power ON (red color)

Phase ON (yellow color)

TX Data (green color)

13

Page 16

DS6500 ETHERNET MODEL

SOFTWARE FEATURES ENVIRONMENTAL FEATURES

Readable Codes

Code Selection

Headers and Shock Resistance

Terminators

Operating Modes

Config. Mode

Parameter Storage

Interleaved 2/5

Code 39 standard

Codabar

Code 128

EAN 128

Code 93 (Standard & Full ASCII)

EAN/UPC (including Add-on 2

And Add-on 5)

Up to 10 codes during one

reading phase

Up to 128-byte headers and

128-byte terminators

On Line, Automatic, Test, 3 shocks on each axis

PackTrack™

Genius™ utility program

Non-volatile internal FLASH

Operating

Temperature

Storage

Temperature

Humidity

Ambient Light

Immunity

Vibration Resistance

IEC 68-2-6 test FC 1.5 mm @ 13 to 55 Hz

2 hours on each axis 2 g @ 70 to 200 Hz

IEC 68-2-27 test EA

Protection Class

PHYSICAL FEATURES

Dimensions mm

(inch)

Weight

0° to +40 °C (+32 to +104 °F)

-20° to +70 °C (-4° to +158 °F)

90% non condensing

3500 lux

14 mm @ 2 to 10 Hz

30 g; 11 ms

IP50

Std Models Oscill. Mirror

110x113x99

(4.33x4.45x3.9)

1.5 kg (3.3 lb) 2.0 kg (4.4 lb)

113x180x104.5

(4.45x7.08x4.11)

Accessories:

Name Description Part Number

CAB-6011 Cable to C-BOX100 1 m 93A051221

CAB-6012 Cable to C-BOX100 2 m 93A051222

CAB-6015 Cable to C-BOX100 5 m 93A051223

C-BOX 100 Passive connection box 93ACC1510

INT-30 20 mA C.L. interface board for C-BOX 100 93A151022

GFC-60 90° mirror 93A201100

GFC-600 90° mirror close distance 93A201102

PWR-120 Power unit 110/230 V AC - 24 V DC 93ACC1530

BTK-6000 Terminator kit (5 pcs) 93ACC1710

PG6002 Single unit power supply – US 93ACC1718

PG6001 Single unit power supply – UK 93ACC1719

PG6000 Single unit power supply – EU 93ACC1720

FBK-6000 Fast bracket kit (2 pcs) 93ACC1721

US-60 Mounting bracket kit (5 pcs) for multisided stations 890001020

MEP-542 Photocell kit – PNP 93ACC1727

MEP-543 Photocell kit – NPN 93ACC1728

OEK-2 Optical encoder (10 m cable + spring) 93ACC1770

OEK-1 Optical encoder kit + 10 m cable 93ACC1600

Electrical Connections:

The DS6500 Ethernet reader provides a 26-pin male D-sub connector for connection to power supply and

input/output signals.

An Ethernet connector is used for connection to the remote Host (for ex. Remote PC connected via Internet),

while a local Lonworks 9-pin female connector connects the Ethernet master to the first slave reader of the

system.

The details of the connector pins are indicated in the following table:

14

Page 17

DS6500 ETHERNET MODEL

26-pin D-Sub Connector Pinout

Pin Name Function

1 CHASSIS

20 RXAUX Receive data of auxiliary RS232 (referred to GND)

21 TXAUX Transmit data of auxiliary RS232 (referred to GND)

8 OUT 1+ Configurable digital output 1 – positive pin

22 OUT 1- Configurable digital output 1 – negative pin

11 OUT 2+ Configurable digital output 2 – positive pin

12 OUT 2- Configurable digital output 2 – negative pin

16 OUT 3A Configurable digital output 3 – polarity insensitive

17 OUT 3B Configurable digital output 3 – polarity insensitive

18 EXT_TRIG/PS A External trigger (polarity insensitive) for PS

19 EXT_TRIG/PS B External trigger (polarity insensitive) for PS

6 IN2/ENC A Input signal 2 (polarity insensitive) for Encoder

10 IN2/ENC B Input signal 2 (polarity insensitive) for Encoder

14 IN3A Input signal 3 (polarity insensitive)

15 IN4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

9, 13 VS Supply voltage – positive pin

23, 25, 26 GND Supply voltage – negative pin

Pin RS232 RS485 Full-Duplex RS485 Half-Duplex

2 TX TX485+ RTX485+

3 RX RX485+

4 RTS TX485- RTX485- see INT-30 instructions

5 CTS RX485-

7 GND_ISO GND_ISO GND_ISO

Chassis - internally connected to GND

Cable shield connected to chassis

1

10

19

26-pin male D-sub Connector

20 mA C.L.

(INT-30 with C-BOX 100 only)

9

18

26

* For 20 mA C.L. connections, GND is the same of the scanner power supply.

9-pin Lonworks Connector Pinout

Pin Name Function

1 CHASSIS

Cable shield internally connected

by capacitor to chassis

9 VS Supply voltage – positive pin

2 GND Supply voltage – negative pin

6 VS_I/O Supply voltage of I/O circuit

3 Ref_I/O Reference voltage of I/O circuit

4 SYS_ENC_I/O System signal

5 SYS_I/O System signal

9-pin female Local Lonworks Connector

7 LON A Lonworks line (polarity insensitive)

8 LON B Lonworks line (polarity insensitive)

RJ45 Modular Connector

DS6500

TX+

TX-

RX+

n. c.

n. c.

RX-

n. c.

n. c.

n. c. = not connected

1

2

3

4

5

6

7

8

HUB / SWITCH

1

2

3

4

5

6

7

8

RJ45 Modular Connector

5

9

1

6

1

8

15

Page 18

A

Connectivity:

DS6500

DS6500 ETHERNET MODEL

Point-to-Point Layout

Remote Host

Fieldbus

Network

C-BOX 100

CAB-601X

*P.S.

* P.S. (Presence Sensor) connected to External Trigger/PS input.

Remote Host

Fieldbus

Network

DS6500

CAB-601X

AUX

*P.S.

Pass Through Layout

*P.S.

C-BOX 100

C-BOX 100

2

PG6000

*P.S.

Gryphon

<

DS4600A

T

N

E

<

2

1

<

T

N

E

<

C-BOX 100

1

DS4600A

PWR-120

1 2

Main Serial Interface

uxiliary Serial Interface

* P.S. (Presence Sensor) connected to External Trigger/PS input.

16

Page 19

DS6500 ETHERNET MODEL

Local Lonworks Network

Remote Host

Fieldbus

Network

Slave 2***

CAB-610X

CAB-610X

CAB-610X

BTK-6000

Slave 5*** Slave 4***

Slave 1***

CAB-610X

CAB-610X

Master

Slave 3***

CAB-63XX

C-BOX 100**

CAB-60XX

P.S.*

Encoder****

CAB-63XX

PWR-240

Fieldbus Small Synchronized Network

* P.S. (Presence Sensor) connected to External Trigger/PS input.

** C-BOX 100 modified to accept scanner power.

*** The Slave scanners are Master/Slave models, which allow Lonworks network propagation.

**** Encoder connected to IN2/ENC input.

17

Page 20

DS6500-100-015 DEVICENET MODEL

1

Figure A

Laser Beam Output Window

1

DS6500 DEVICENET MODEL

1

Programming Keypad

1

TX Data LED (Green)

2

Phase On LED (Yellow)

3

5

3

4

2

Figure B

Power On LED (Red)

4

LCD Display

5

1

1

2

3

2

Main/Aux. Interface 26-pin D-sub Male Connector

Lonworks 9-pin Female Connector

DeviceNet 5-pin Male Connector

Available Models:

DS6500 - X0X - 0YY

Focalization

1 = Medium Version

2 = Long Version

Optical Model

0 = Standard

5 = Oscillating Mirror

Decoder Model

10 = Master/Slave

11 = Profibus

12 = Ethernet

15 = Devicenet

Technical Features:

ELECTRICAL FEATURES OPTICAL FEATURES

Supply Voltage

Power

Consumption

Communication

Interfaces

Inputs

Ext. Trigger 1,

3 aux. digital

inputs

Outputs

3 software

programmable

digital outputs

15 - 30 Vdc

15 W typical

20 W Max. (including startup current)

Main (isolated) Baud Rate

RS232

RS485 full-duplex

RS485 half-duplex

20 mA C.L. (INT-30

with C-BOX 100 only)

Auxiliary

RS232 1200 to 115200

Other

Lonworks 1,25 Mb/s

Ethernet 10 or 100 Mb/s

1200 to 115200

19200

(optocoupled NPN or PNP)

(optocoupled)

Light Receiver

Wavelength

Safety Class

Laser Control

READING FEATURES

Scan Rate

Max. Resolution

Max. Read. Distance

Max. Read. Width

Max. Depth of Field

USER INTERFACE

LCD Display

Keypad

LED Indicators

3

Figure C

Avalanche photodiode

630 to 680 nm

Class 2-EN 60825-1;

Class II-CDRH

Security system to turn laser

off in case of motor slow down

600-1200 scans/s

(see reading diagram)

2 lines by 16 characters LCD

3 keys

Power ON (red color)

Phase ON (yellow color)

TX Data (green color)

18

Page 21

DS6500 DEVICENET MODEL

SOFTWARE FEATURES ENVIRONMENTAL FEATURES

Readable Codes

Code Selection

Headers and Shock Resistance

Terminators

Operating Modes

Config. Mode

Parameter Storage

Interleaved 2/5

Code 39 standard

Codabar

Code 128

EAN 128

Code 93 (Standard & Full ASCII)

EAN/UPC (including Add-on 2

And Add-on 5)

Up to 10 codes during one

reading phase

Up to 128-byte headers and

128-byte terminators

On Line, Automatic, Test, 3 shocks on each axis

PackTrack™

Genius™ utility program

Non-volatile internal FLASH

Operating

Temperature

Storage

Temperature

Humidity

Ambient Light

Immunity

Vibration Resistance

IEC 68-2-6 test FC 1.5 mm @ 13 to 55 Hz

2 hours on each axis 2 g @ 70 to 200 Hz

IEC 68-2-27 test EA

Protection Class

PHYSICAL FEATURES

Dimensions mm

(inch)

Weight

0° to +40 °C (+32 to +104 °F)

-20° to +70 °C (-4° to +158 °F)

90% non condensing

3500 lux

14 mm @ 2 to 10 Hz

30 g; 11 ms

IP64

Std Models Oscill. Mirror

110x113x99

(4.33x4.45x3.9)

1.5 kg (3.3 lb) 2.0 kg (4.4 lb)

113x180x104.5

(4.45x7.08x4.11)

Accessories:

Name Description Part Number

CAB-6011 Cable to C-BOX100 1 m 93A051221

CAB-6012 Cable to C-BOX100 2 m 93A051222

CAB-6015 Cable to C-BOX100 5 m 93A051223

C-BOX 100 Passive connection box 93ACC1510

INT-30 20 mA C.L. interface board for C-BOX 100 93A151022

GFC-60 90° mirror 93A201100

GFC-600 90° mirror close distance 93A201102

PWR-120 Power unit 110/230 V AC - 24 V DC 93ACC1530

BTK-6000 Terminator kit (5 pcs) 93ACC1710

PG6002 Single unit power supply – US 93ACC1718

PG6001 Single unit power supply – UK 93ACC1719

PG6000 Single unit power supply – EU 93ACC1720

FBK-6000 Fast bracket kit (2 pcs) 93ACC1721

US-60 Mounting bracket kit (5 pcs) for multisided stations 890001020

MEP-542 Photocell kit – PNP 93ACC1727

MEP-543 Photocell kit – NPN 93ACC1728

OEK-2 Optical encoder (10 m cable + spring) 93ACC1770

OEK-1 Optical encoder kit + 10 m cable 93ACC1600

Electrical Connections:

The DS6500 DeviceNet reader provides a 26-pin male D-sub connector for connection to power supply and

input/output signals.

A DeviceNet connector is used for connection to the remote Host, while a local Lonworks 9-pin female connector

connects the DeviceNet master to the first slave reader of the system.

NOTE

When using DeviceNet, the Main serial interface is disabled and must not be physically

connected.

19

Page 22

5-p

ecto

DS6500 DEVICENET MODEL

The details of the connector pins are indicated in the following table:

26-pin D-Sub Connector Pinout

Pin Name Function

1 CHASSIS

20 RXAUX Receive data of auxiliary RS232 (referred to GND)

21 TXAUX Transmit data of auxiliary RS232 (referred to GND)

8 OUT 1+ Configurable digital output 1 – positive pin

22 OUT 1- Configurable digital output 1 – negative pin

11 OUT 2+ Configurable digital output 2 – positive pin

12 OUT 2- Configurable digital output 2 – negative pin

16 OUT 3A Configurable digital output 3 – polarity insensitive

17 OUT 3B Configurable digital output 3 – polarity insensitive

18 EXT_TRIG/PS A External trigger (polarity insensitive) for PS

19 EXT_TRIG/PS B External trigger (polarity insensitive) for PS

6 IN2/ENC A Input signal 2 (polarity insensitive) for Encoder

10 IN2/ENC B Input signal 2 (polarity insensitive) for Encoder

14 IN3A Input signal 3 (polarity insensitive)

15 IN4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

9, 13 VS Supply voltage – positive pin

23, 25, 26 GND Supply voltage – negative pin

Pin RS232 RS485 Full-Duplex RS485 Half-Duplex

2 TX TX485+ RTX485+

3 RX RX485+

4 RTS TX485- RTX485- see INT-30 instructions

5 CTS RX485-

7 GND_ISO GND_ISO GND_ISO

* For 20 mA C.L. connections, GND is the same of the scanner power supply.

Pin Name Function

1 CHASSIS

9 VS Supply voltage – positive pin

2 GND Supply voltage – negative pin

6 VS_I/O Supply voltage of I/O circuit

3 Ref_I/O Reference voltage of I/O circuit

4 SYS_ENC_I/O System signal

5 SYS_I/O System signal

7 LON A Lonworks line (polarity insensitive)

8 LON B Lonworks line (polarity insensitive)

Pin Name Function

2 V+ Supply voltage – positive pin

5 CAN_L CAN bus data line – L

1 SHIELD Shield

4 CAN_H CAN bus data line – H

3 V- Supply voltage – negative pin

Chassis - internally connected to GND

Cable shield connected to chassis

9-pin Lonworks Connector Pinout

Cable shield internally connected

by capacitor to chassis

5-pin DeviceNet Connector Pinout

1

10

19

26-pin male D-sub Connector

20 mA C.L

(INT-30 with C-BOX 100 only)

5

9

9-pin female Local Lonworks Connector

4

5

1

in male DeviceNet Conn

1

6

3

2

r

9

18

26

The power supplied on pin V+ and V- is used only to propagate power to the section of the

DeviceNet board directly connected to the Bus. It is completely isolated from the DS6500 power

NOTE

which must be supplied on pin 9, 13 and pin 23, 25 of the 26-pin Main/Aux connector.

20

Page 23

A

Connectivity:

Point-to-Point Layout

Fieldbus

DS6500

* P.S. (Presence Sensor) connected to External Trigger/PS input.

Remote Host

Network

C-BOX 100

CAB-601X

*P.S.

Pass Through Layout

DS6500 DEVICENET MODEL

Remote Host

PG6000

*P.S.

Fieldbus

Network

DS6500

PWR-120

*P.S.

CAB 601X

AUX

C-BOX 100

2

C-BOX 100

1

1 2

Main Serial Interface

uxiliary Serial Interface

* P.S. (Presence Sensor) connected to External Trigger/PS input.

<

T

N

E

<

DS4600A

2

*P.S.

<

T

N

E

<

C-BOX 100

1

Gryphon

DS4600A

21

Page 24

DS6500 DEVICENET MODEL

Local Lonworks Network

Remote Host

Fieldbus

Network

Slave 2***

CAB-610X

CAB-610X

CAB-610X

BTK-6000

Slave 5*** Slave 4***

Slave 1***

CAB-610X

CAB-610X

Master

Slave 3***

CAB-63XX

C-BOX 100**

CAB-60XX

P.S.*

Encoder****

CAB-63XX

PWR-240

Fieldbus Small Synchronized Network

* P.S. (Presence Sensor) connected to External Trigger/PS input.

** C-BOX 100 modified to accept scanner power.

*** The Slave scanners are Master/Slave models, which allow Lonworks network propagation.

**** Encoder connected to IN2/ENC input.

22

Page 25

DS6500 OSCILLATING MIRROR MODEL

DS6500-105-0XX OSCILLATING MIRROR MODEL

1

1

Oscillating mirror models are used when coverage of a large reading area is required, mainly in picket fence

applications.

The DS6500 scanner mounts a dedicated optic head with integrated oscillating mirror driven by a linear motor.

The speed, precision, repeatability, and reliability of this driving technology assure high level performance.

The new oscillating mirror is completely software controlled and software programmable. The Genius™ software

tool allows adjusting the linear motor speed (oscillating frequency) and the upper and lower limits of the oscillation

by defining the top and bottom line limit angles.

When the oscillating mirror is programmed to read barcode labels at very small angles, position the reader to

assure at least 10° for the Skew angle (see DS6500 Reference Manual). This angle refers to the most inclined or

external laser line, so that all other laser lines assure more than 10° Skew. This avoids the direct reflection of the

laser light emitted by the reader.

Figure A

Laser Beam Output Window

1

0

°

Oscillating Mirror Skew Angle

Otherwise, the scanner can be mounted at an angle of inclination of 17.5° in order to attain symmetrical deflection

ranges.

1

7

.

5

°

°

5

.

7

0

1

Oscillating Mirror Reading Position

23

Page 26

DS6500 OSCILLATING MIRROR MODEL

In the above case, the zone where the scan line is perpendicular to the reflecting surface corresponds to a neutral

zone at the center of the reading field.

The mirror can be deflected up to 40°. Oscillation with respect to the output window median axis is asymmetrical

(see figure below).

3

40°

7

.

5

°

0°

-

2

.

5

°

Oscillating Mirror Maximum Aperture and Asymmetry

By configuring the oscillating speed up to the maximum value of 19 Hz, raster emulation can be performed for

reading fast moving objects.

By limiting the raster width to the minimum necessary, the number of scans on the reading

surface is increased.

NOTE

Oscillating angles are selected in software where the

minimum and maximum angles correspond to –2.5° and

+37.5°.

The scanner can be tilted in order for the 17.5° software

setting to correspond with the 0° horizontal plane.

Hz Max. Aperture

0-5 40°

6-10 30°

11-15 20°

16-19 10°

+37.5°

-2.5°

+17.5°

These models provide higher scanning speed (1200 scans/sec) compared to standard models and the reading

performance is not adversely effected by the oscillating mirror.

The example represents the selection of an angle of

+10° for the bottom line and an angle of +20° for the top

line (see figure beside).

Oscillating Mirror Extreme Angle Positions

+37.5°

+27.5°

+17.5°

24

Oscillating Mode

Page 27

COMMON FEATURES

COMMON FEATURES

C-BOX 100 Pinout for DS6500:

The table below gives the pinout of the C-BOX 100 terminal block connectors. Use this pinout when the DS6500

reader is connected in a network by means of the C-BOX 100:

C-BOX 100 Terminal Block Connectors

Power

1, 3, 5 VS

2, 4, 6 GND

7, 8 EARTH GROUND

20, 40 Reserved

Inputs

27 EXT TRIG/PS A (polarity insensitive) for PS

28 EXT TRIG/PS B (polarity insensitive) for PS

29 IN 2/ENC A (polarity insensitive) for Encoder

30 IN 2/ENC B (polarity insensitive) for Encoder

31, 33 IN 3A (polarity insensitive)

32, 34 IN 4A (polarity insensitive)

36 IN 3B/IN 4B Reference (polarity insensitive)

Outputs

21 OUT 1+

22 OUT 1-

23 OUT 2+

24 OUT 2-

25 OUT 3A (polarity insensitive)

26 OUT 3B (polarity insensitive)

Auxiliary Interface

35 TX AUX

37 RX AUX

38, 39 GND

Main Interface

RS232 RS485 Full-Duplex RS485 Half-Duplex

11, 15 TX 232 TX 485+ RTX 485+

12, 16 RTS 232 TX 485- RTX 485-

17 RX 232 RX 485+ see INT-30

18 CTS 232 RX 485- instructions

10, 14, 19 SGND Main Isolated SGND Main Isolated SGND Main Isolated

9, 13 RS485 Cable Shield RS485 Cable Shield

20 mA C.L.

(with INT-30 only)

25

Page 28

5

COMMON FEATURES

Mechanical Installation:

The DS6500 reader can be positioned and installed in the best way possible as a result of the Step-A-Head

feature. Thanks to the separation between Head and Base, you can modify the orientation of the decoder base,

and therefore display-keypad and connector panels, while keeping the optic head in the correct reading position.

The reading head and the decoder base can be rotated independently from each other allowing the installation

even in the most critical locations.

To rotate the head follow the given procedure:

Head Screws

1. detach the head from the base by unscrewing the four fixing screws;

2. rotate the head in the desired position;

3. loosen but don't remove the two screws on top of the head;

4. affix the head onto the base carefully aligning the four fixing screws and

progressively tightening them about half-way;

5. completely tighten the two screws on top of the head;

6. completely tighten the four fixing screws.

Step-A-Head™ Feature

16.5

0.65

85

3.34

18

25

0.98

82

3.22

50

20

0.78

1.96

2

°

N

N

1

.

6

4

1

.

Ø

0

Ø

2.99

60

2.36

30

1.18

76

30

1.18

74

2.85

113

4.45

110

4.33

99

3.90

mm

inch

DS6500 Overall Dimensions ST-237 Mounting Bracket Overall Dimensions

42

1.65

10

0.4

22

0.86

0.71 N°2

2

°

==

50

1.96

==

72

2.83

100

3.93

S

T

O

L

S

2

°

N

O

5

.

L

8

S

2

°

N

3

3

5

.

.

0

8

Ø

3

.

0

Ø

S

50

T

O

1.96

L

S

T

S

O

4

L

°

S

N

4

5

°

.

4

N

82

8

1

.

0

S

T

3

3.22

35

1.37

1

4

2

.

6

9

6

106°

73.2

2.88

36

1.41

Fixing

Screw (4)

4

0.1

130

mm

inch

TM

5.12

42

3060

1.18

2.36

85

3.35 0.65

2.50

63.5

4.11

104.5

69

2.72

56

2.20

102

4.34

4.01

110.3

180

7.08

114

4.48

16.5

99

113

3.90

130

mm

4.45

inch

18

25

0.98

82

3.22

20

50

1.96

5.11

0.43

14

0.55

Ø

1.65

10

22

0.4

Ø4.1

0.16

1.96

72

2.83

100

3.93

0.86

35

1.37

36

0.55

1111

0.43

14

1.41

75

2.95

50

0.71

0.78

R36

R22

5

.

8

DS6500 Oscillating Mirror Model Overall Dimensions ST-210 Mounting Bracket Overall Dimensions

26

4

0.15

50

1.96

R1

R5

mm

inch

Page 29

COMMON FEATURES

Typical Installations:

Standard Installation

The DS6500 scanner is mounted on the ST-237 106° mounting bracket which guarantees a built-in Skew angle

(S in the figure below) of 16° with respect to the frame plane (typically the Skew angle should be between

10° - 20°). This avoids the direct reflection of the laser light emitted by the scanner. Furthermore, the bracket

guides allow adjusting the Tilt angle (T in the figure below, which is typically 0°) for the best scanner orientation:

T

S

Conveyor Direction

“45° Skew” Installation

The DS6500 scanner is mounted on the ST-210 90° mounting bracket. By adjusting the mounting bracket guides,

reach 45° for the Skew angle (S in the figure below) to avoid the direct reflection of the laser light emitted by the

scanner:

45°

S

If using the “45° Skew” installation, it is not guaranteed that the scanner reading performances

(see reading diagram section) will match those measured for the standard installation with

ATTENTION

Skew angle between 10° - 20°.

The ST-210 mounting bracket is an accessory of the DS6500 standard model available in the

US-60 kit (order no. 890001020).

NOTE

When installing several scanners, take care to position them correctly so that no laser beam

enters the reading window perpendicularly and at the same level of the output beam of the

other scanners. This condition could occur more frequently for side mounted applications. If

these precautions are not followed, it may occur that the laser of the blinded scanner starts

WARNING

blinking due to an internal circuit which temporarily turns the laser off when detecting a power

anomaly. To resolve this problem, it is sufficient to slightly change the inclination and position

of one of the two scanners involved.

Reading Conditions:

• ANSI Grade B minimum

• 800 scans/sec

The following tables describe the requirements for standard applications.

27

Page 30

COMMON FEATURES

Minimum Code Height for ACR Reading (mm)

45° 30°

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3 0.5 1 1.5 2 2.5 3

2/5 Interleaved

Code Resolution (mm)

Ratio 3:1

0.25

0.30

0.33

0.38

0.50

0.72

1.00

10 12 14 16 18 20 7 9 10 12 13 15

12 14 15 17 19 21 8 9 11 12 14 15

13 14 16 18 20 22 8 10 11 13 14 16

14 16 18 19 21 23 9 11 12 14 15 17

18 19 21 23 25 26 11 12 14 15 17 18

24 25 27 28 30 32 15 16 17 19 20 22

33 34 35 36 38 40 20 21 22 23 25 26

Table 1

Minimum Code Height for ACR Reading (mm)

45° 30°

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3 0.5 1 1.5 2 2.5 3

Code 39

Code Resolution (mm)

Ratio 3:1; Interdigit = Module Size

0.25

0.30

0.33

0.38

0.50

0.72

1.00

9 10 12 14 16 17 6 7 9 10 12 13

10 11 13 15 17 18 7 8 9 11 12 14

11 12 13 15 17 19 7 8 10 11 13 14

12 13 14 16 18 20 8 9 10 12 13 15

15 16 17 18 20 22 10 10 11 13 14 16

20 21 22 23 24 26 13 13 14 15 17 18

27 28 29 30 31 32 17 17 18 19 20 21

Table 2

Minimum Code Height for ACR Reading (mm)

45° 30°

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3 0.5 1 1.5 2 2.5 3

Code 128 – Ean 128

Code Resolution (mm)

0.25

0.30

0.33

0.38

0.50

0.72

1.00

8 9 11 13 15 17 5 7 8 10 11 13

8 10 12 14 16 18 6 7 9 10 12 13

9 11 13 14 16 18 6 8 9 11 12 14

10 11 13 15 17 19 7 8 10 11 13 14

12 13 15 17 19 21 8 9 11 12 14 15

16 17 19 21 22 24 10 11 13 14 16 17

22 23 24 25 27 29 13 14 15 17 18 20

Table 3

Minimum Code Height for ACR Reading (mm)

45° 30°

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3 0.5 1 1.5 2 2.5 3

Codabar

Code Resolution (mm)

Ratio 3:1; Interdigit = Module Size

0.25

0.30

0.33

0.38

0.50

0.72

1.00

8 9 11 13 15 17 5 7 8 10 11 13

9 10 12 14 16 18 6 7 9 10 12 13

9 11 13 14 16 18 6 8 9 11 12 14

10 11 13 15 17 19 7 8 10 11 13 14

13 14 15 17 19 21 8 9 11 12 14 15

17 18 19 21 22 24 11 12 13 14 16 17

23 24 25 26 27 29 14 15 16 17 18 20

Table 4

Minimum Code Height for ACR Reading (mm)

45° 30°

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3 0.5 1 1.5 2 2.5 3

EAN 8-13, UPC-A

Code Resolution (mm)

0.25

0.30

0.33

0.38

0.50

0.72

1.00

7 9 10 12 14 16 5 6 8 9 11 12

8 9 11 13 15 17 6 7 8 10 11 13

9 10 11 13 15 17 6 7 9 10 12 13

10 11 12 14 16 18 7 7 9 10 12 13

12 13 14 15 17 19 8 9 10 11 13 14

16 17 18 19 20 22 10 11 12 13 14 16

22 23 24 24 25 26 13 14 15 16 16 18

Table 5

28

Page 31

r

r

Reading Diagrams:

In the following reading diagrams (0,0) is the center of the laser beam output window.

DS6500-100-0XX

CONDITIONS

Code = Interleaved 2/5 o

Code 39

PCS = 0.90

Pitch angle = 0°

Skew angle = 10° - 20°

Tilt angle = 0°

20

16

12

8

4

0

-4

-8

0 4

0 10 20 30 40 50

50

40

30

20

10

0

-10

-20

812 16

20

0.25 mm

(10 mils)

24

28

70

60

COMMON FEATURES

32

80

36

90

0.375 mm

(15 mils)

0.3 mm

(12 mils)

40

100

(in)

(cm)

CONDITIONS

Code = Interleaved 2/5 o

Code 39

PCS = 0.90

Pitch angle = 0°

Skew angle = 10° - 20°

Tilt angle = 0°

-30

-12

-40

-16

-50

-20

(in) (cm)

20

50

16

40

12

30

8

20

4

10

0

-10

-4

-20

-8

DS6500-105-0XX

0 4

0 10 20 30 40 50

0

812 16

20

0.25 mm

(10 mils)

60

24

32

80

36

90

0.3 mm

(12 mils)

0.375 mm

(15 mils)

28

70

40

100

(in)

(cm)

-30

-12

-40

-16

-50

-20

(in) (cm)

29

Page 32

r

r

Reading Diagrams:

CONDITIONS

Code = Interleaved 2/5 o

Code 39

PCS = 0.90

Pitch angle = 0°

Skew angle = 10° - 20°

Tilt angle = 0°

30

24

18

12

0

-6

-12

-18

COMMON FEATURES

DS6500-200-0XX

0 14

0 35 50 65 80 95

75

60

45

30

6

15

0

-15

-30

-45

20 26 32

38

44

110

0.375 mm

(15 mils)

50

125

56

140

62

155

0.5 mm

(20 mils)

68

170

(in)

(cm)

CONDITIONS

Code = Interleaved 2/5 o

Code 39

PCS = 0.90

Pitch angle = 0°

Skew angle = 10° - 20°

Tilt angle = 0°

-24

-30

(in) (cm)

30

24

18

12

6

0

-6

-12

-60

-75

DS6500-205-0XX

0 14

0 35 50 65 80 95

75

60

45

30

15

0

-15

-30

20 26 32

38

44

110

0.375 mm

(15 mils)

50

125

56

140

62

155

0.5 mm

(20 mils)

68

170

(in)

(cm)

30

-45

-18

-60

-24

-75

-30

(in) (cm)

Page 33

User Interface:

1

COMMON FEATURES

RS232 PC-side connections

1

5

13

9 6

9-pin male connector

25-pin male connector

25 14

Pin Name Pin Name

2 RX 3 RX

3 TX 2 TX

5 GND 7 GND

7 RTS 4 RTS

8 CTS 5 CTS

How To Build A Simple Interface Test Cable:

The following wiring diagram shows a simple test cable including power, external (push-button) trigger and PC

RS232 COM port connections.

DS6500

25-pin D-sub female

TXAUX

21

20

RXAUX

GND

23

13

VS

25

GND

9-pin D-sub female

2

RX

3

TX

5

GND

PC

VS

9

18

EXT TRIG A

19

EXT TRIG B

Trigger

Power Supply

VS (15 – 30 VDC)

Power GND

31

Page 34

Compliance:

Laser Safety

COMMON FEATURES

1

1

2

Figure A

Laser Safety Label

1

Identification Label

2

1

Figure B

Warning and Device Class Label

1

Figure C

Laser Safety Label

1

The scanner is classified as a Class 2 laser product according to EN 60825-1 regulations and as a Class II laser

product according to CDRH regulations.

Disconnect the power supply when opening the device during maintenance or installation to avoid exposure to

hazardous laser light.

There is a safety device which allows the laser to be switched on only if the motor is rotating above the threshold

for its correct scanning speed.

The laser beam can be switched off through a software command (see also the Genius™ Help On-Line).

LASER RADIATION IS EMITTED FROM THIS APERTURE

AVOID EXPOSURE

AVOID EXPOSURE – LASER LIGHT

IS EMITTED FROM THIS APERTURE

Laser Safety Label for Oscillating Mirror and Standard Models

CAUTION-CLASS 3B

LASER LIGHT

WHEN OPEN

AVOID EXPOSURE

TO BEAM

LASER LIGHT – DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

MAX. OUTPUT RADIATION 1 m W

EMITTED WAVE LENGTH 630 ~ 680 nm

EN60825-1:2001

DATALOGIC S.p.A. Via Candini, 2

40012 LIPPO DI CALDERARA DI RENO (BO) ITALY

MANUFACTURED VOLT Amp.

JANUARY 2002 15-30 DC 1.5-0.7

MODEL No.

SERIAL No.

This product conforms to the applicable requirements

of 21CFR 1040 at the date of manufacture.

N2468

Warning and Device Class Label Device Identification Label

32

Page 35

COMMON FEATURES

The laser diode used in this device is classified as a Class 3B laser product according to EN 60825-1 regulations

and as a Class IIIb laser product according to CDRH regulations. As it is not possible to apply a classification

label on the laser diode used in this device, the following label is reproduced below:

MAXIMUM OUTPUT RADIATION 3 5 mW

EMITTED WAVE LENGTH 630~6 80 nm

TO EN60825-1 (2001)

Any violation of the optic parts in particular can cause radiation up to the maximum level of the laser diode

(35 mW at 630 ~ 680 nm).

Power Supply

- This product is intended to be installed by Qualified Personnel only.

- All DS6500 Models:

This device is intended to be supplied by a UL Listed Power Unit marked “Class 2” or LPS power source

which supplies power directly to the scanner via the 25/26-pin connector.

WEEE Compliance

LASER LIGHT

AVOID EXPOSURE TO BEAM

CLASS 3B LASER PRODUCT

Laser Diode Class Label

33

Page 36

DATALOGIC S.p.A., DATALOGIC S.p.A.,

Via Candini, 2 Via Candini, 2

40012 - Lippo di Calderara 40012 - Lippo di Calderara

Bologna - Italy Bologna - Italy

dichiara che dichiara che

declares that the declares that the

déclare que le déclare que le

bescheinigt, daß das Gerät bescheinigt, daß das Gerät

declare que el declare que el

DS6500-XXX-XXXDS6500-XXX-XXX, Laser Scanner e tutti i suoi modelli

and all its models

et tous ses modèles

und seine modelle

y todos sus modelos

sono conformi alle Direttive del Consiglio Europeo sottoelencate:

are in conformity with the requirements of the European Council Directives listed below:

sont conformes aux spécifications des Directives de l'Union Européenne ci-dessous:

der nachstehend angeführten Direktiven des Europäischen Rats:

cumple con los requisitos de las Directivas del Consejo Europeo, según la lista siguiente:

89/336/EEC EMC Directive e 92/31/EEC, 93/68/EEC emendamenti successivi

and further amendments

et ses successifs amendements

und späteren Abänderungen

y succesivas enmiendas

73/23/EEC Low Voltage Directive

Basate sulle legislazioni degli Stati membri in relazione alla compatibilità elettromagnetica ed alla sicurezza dei prodotti.

On the approximation of the laws of Member States relating to electromagnetic compatibility and product safety.

Basée sur la législation des Etats membres relative à la compatibilité électromagnétique et à la sécurité des produits.

Über die Annäherung der Gesetze der Mitgliedsstaaten in bezug auf elektromagnetische Verträglichkeit und Produktsicherheit

entsprechen.

Basado en la aproximación de las leyes de los Países Miembros respecto a la compatibilidad electromagnética y las Medidas

de seguridad relativas al producto.

Questa dichiarazione è basata sulla conformità dei prodotti alle norme seguenti:

This declaration is based upon compliance of the products to the following standards:

Cette déclaration repose sur la conformité des produits aux normes suivantes:

Diese Erklärung basiert darauf, daß das Produkt den folgenden Normen entspricht:

Esta declaración se basa en el cumplimiento de los productos con la siguientes normas:

EN 55022 (CLASS A ITE), AUGUST 1994:

A

MENDMENT A1 (CLASS A ITE), OCTOBER 2000:

IMITS AND METHODS OF MEASUREMENTS OF RADIO DISTURBANCE

L

CHARACTERISTICS OF INFORMATION TECHNOLOGY EQUIPMENT

(ITE)

EN 61000-6-2, OCTOBER 2001: ELECTROMAGNETIC COMPATIBILITY (EMC).

P

ART 6-2: GENERIC STANDARDS - IMMUNITY FOR INDUSTRIAL

ENVIRONMENTS

EN 60950-1, DECEMBER 2001: INFORMATION TECHNOLOGY EQUIPMENT – SAFETY –

P

ART 1: GENERAL REQUIREMENTS

EN 60825-1, JUNE 1994: SAFETY OF LASER PRODUCTS –

AMENDMENTS A11 (1996), A2 (2001): PART 1: EQUIPMENT CLASSIFICATION, REQUIREMENTS AND USER'S

GUIDE

Lippo di Calderara, September 8th, 2005

05

Ruggero Cacioppo

Quality Assurance Laboratory Manager

821000796 (Rev. G)

Loading...

Loading...