Page 1

DS6400

Reference Manual

Page 2

Datalogic Automation S.r.l.

Via S. Vitalino 13

40012 - Lippo di Calderara di Reno

Bologna - Italy

DS6400 Reference Manual

Ed.: 10/2007

ALL RIGHTS RESERVED

Datalogic reserves the right to make modifications or improvements without prior notification.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for

incidental or consequential damages resulting from the use of this material.

Product names mentioned herein are for identification purposes only and may be trademarks and or

registered trademarks of their respective companies.

© Datalogic Automation S.r.l. 2003 - 2007

03/10/2007

Page 3

CONTENTS

REFERENCES ............................................................................................................vi

Reference Documentation........................................................................................... vi

Services and Support .................................................................................................. vi

Patents......................................................................................................................... vi

COMPLIANCE............................................................................................................vii

Electrical Safety...........................................................................................................vii

Laser Safety.................................................................................................................vii

Power Supply..............................................................................................................viii

CE Compliance...........................................................................................................viii

WEEE Compliance .....................................................................................................viii

GENERAL VIEW..........................................................................................................x

GUIDE TO INSTALLATION ...................................................................................... xiii

Point-to-Point Installation............................................................................................xiii

Master/Slave Lonworks Installation ............................................................................xiv

1 INTRODUCTION ..........................................................................................................1

1.1 Product Description ......................................................................................................1

1.2 Model Description.........................................................................................................2

1.3 Oscillating Mirror Models ..............................................................................................3

1.4 Indicators ......................................................................................................................5

1.5 Accessories ..................................................................................................................6

2 INSTALLATION ...........................................................................................................7

2.1 Package Contents ........................................................................................................7

2.2 Mechanical Mounting....................................................................................................8

2.2.1 Mounting the Scanner...................................................................................................8

2.2.2 Mounting the Scanner with Accessories.....................................................................11

2.3 Electrical Connections ................................................................................................13

2.3.1 Main/Aux. Serial Interface and I/O Connector ............................................................15

Main Interface.............................................................................................................16

Auxiliary Interface .......................................................................................................19

Inputs..........................................................................................................................20

Outputs .......................................................................................................................22

2.3.2 Lonworks Connectors.................................................................................................24

Network Termination...................................................................................................25

Lonworks Interface .....................................................................................................26

2.3.3 Ethernet Connector.....................................................................................................28

Ethernet Interface .......................................................................................................29

2.3.4 DeviceNet Connector..................................................................................................30

2.3.5 Profibus Connector.....................................................................................................31

Profibus Interface........................................................................................................31

2.3.6 Power Supply..............................................................................................................32

2.4 User Interface .............................................................................................................32

2.5 Positioning the Scanner..............................................................................................33

2.6 Typical Installations ....................................................................................................35

2.6.1 Standard Installation...................................................................................................35

2.6.2 “45° Skew” Installation................................................................................................35

2.7 Typical Layouts...........................................................................................................36

iii

Page 4

2.7.1 Point-to-Point..............................................................................................................36

2.7.2 Pass Through .............................................................................................................38

2.7.3 RS232 Master/Slave...................................................................................................39

2.7.4 Multiplexer ..................................................................................................................41

2.7.5 Local Lonworks Network.............................................................................................42

Small Synchronized Network......................................................................................43

Large Synchronized Network...................................................................................... 45

Multidata Network.......................................................................................................46

2.7.6 Fieldbus Network........................................................................................................47

2.8 FLASH™ Dynamic Focus...........................................................................................48

2.8.1 Fixed Mode.................................................................................................................48

2.8.2 Continuous Mode........................................................................................................ 48

2.8.3 Triggered Mode ..........................................................................................................49

2.8.4 D-FLASH™ Mode.......................................................................................................49

2.9 Keypad and Display....................................................................................................50

2.9.1 Internal Net .................................................................................................................50

2.9.2 Test Mode...................................................................................................................51

3 SOFTWARE CONFIGURATION................................................................................52

3.1 Genius™ Installation...................................................................................................52

3.2 Guide to Rapid Configuration .....................................................................................52

3.2.1 Wizard for Quick Reader Setup..................................................................................52

Test Operating Mode..................................................................................................53

On Line Operating Mode ............................................................................................54

Automatic Operating Mode.........................................................................................54

3.2.2 Genius™ Network Setup Through Master..................................................................55

Net-Autoset.................................................................................................................57

Express Network Setup ..............................................................................................57

Network Wizard ..........................................................................................................58

3.2.3 Alternative Slave Address Assignment.......................................................................60

3.3 Advanced Genius™ Configuration .............................................................................60

3.4 Parameter Default Values...........................................................................................61

4 READING FEATURES...............................................................................................65

4.1 Advanced Code Reconstruction (ACR™ 4)................................................................ 65

4.1.1 Tilt Angle for Advanced Code Reconstruction............................................................65

4.2 PackTrack™ ...............................................................................................................66

4.2.1 PackTrack™ Calibration for DS6400..........................................................................68

4.2.2 PackTrack™ Calibration for DS6400 Oscillating Mirror Models .................................70

4.3 Performance ...............................................................................................................70

4.3.1 Reading Conditions ....................................................................................................70

4.4 Reading Diagrams......................................................................................................72

4.4.1 DS6400 Standard Model ............................................................................................73

4.4.2 DS6400 Oscillating Mirror Model ................................................................................ 83

5 MAINTENANCE .........................................................................................................93

5.1 Cleaning......................................................................................................................93

5.2 Automatic Scanner Replacement (ASR) ....................................................................93

5.2.1 ASR Network Configuration........................................................................................93

5.2.2 Scanner Replacement Procedure............................................................................... 94

6 TROUBLESHOOTING ...............................................................................................95

7 TECHNICAL FEATURES........................................................................................... 98

iv

Page 5

GLOSSARY.............................................................................................................. 100

INDEX.......................................................................................................................103

v

Page 6

REFERENCES

REFERENCE DOCUMENTATION

The documentation related to the DS6400 management is listed below:

• C-BOX100 Installation Manual

• INT-30 20 mA Current Loop Interface Board for C-BOX 100

• PWR-120 power supply unit

• GFC-60 90° deflecting mirror

• GFC-600 90° deg. mirror close distance

• Document about the Ethernet connectivity

• Document about the Profibus connectivity

• Help On-Line in PDF format

SERVICES AND SUPPORT

Datalogic provides several services as well as technical support through its website. Log on

to www.automation.datalogic.com and click on the

including:

•

PRODUCTS

links indicated for further information

Search through the links to arrive at your product page where you can download specific

Manuals and Software & Utilities including:

- Genius™ a utility program, which allows device configuration using a PC. It provides

RS232 interface configuration.

•

SERVICES & SUPPORT

-

Datalogic Services - Warranty Extensions and Maintenance Agreements

-

Authorised Repair Centres

• CONTACT US

E-mail form and listing of Datalogic Subsidiaries

PATENTS

This product is covered by one or more of the following patents:

U.S. patents: 5,483,051; Re. 36,251; 6,049,406; 5,992,740; 6,347,740B1; 6,629,639B2;

6,394,352B1; 6,742,710B2; 7,161,685B1; 6,688,524B1; 6,443,360 B1; 7,195,162B2.

European patents: 652,530B1; 786,734B1; 789,315B1; 851,376B1; 1,363,228B1;

959,426B9; 1,300,798B1.

Additional patents pending.

vi

Page 7

COMPLIANCE

ELECTRICAL SAFETY

This product conforms to the applicable requirements contained in the European Standard for

electrical safety EN-60950-1 at the date of manufacture.

LASER SAFETY

The following information is provided to comply with the rules imposed by international

authorities and refers to the correct use of the DS6400 reader.

Standard Regulations

This scanner utilizes a low-power laser diode. Although staring directly at the laser beam

momentarily causes no known biological damage, avoid staring at the beam as one would

with any very strong light source, such as the sun.

Avoid that the laser beam hits the eye of an observer, even through reflective surfaces such

as mirrors, etc.

This product conforms to the applicable requirements of both EN60825-1 and

CDRH 21 CFR1040 at the date of manufacture. The reader is classified as a Class 2 laser

product according to EN60825-1 regulations and as a Class II laser product according to

CDRH regulations.

Disconnect the power supply when opening the device during maintenance or installation to

avoid exposure to hazardous laser light.

There is a safety device which allows the laser to be switched on only if the motor is rotating

above the threshold for its correct scanning speed.

Use of controls or adjustments or performance of procedures other than those

specified herein may result in exposure to hazardous visible laser light.

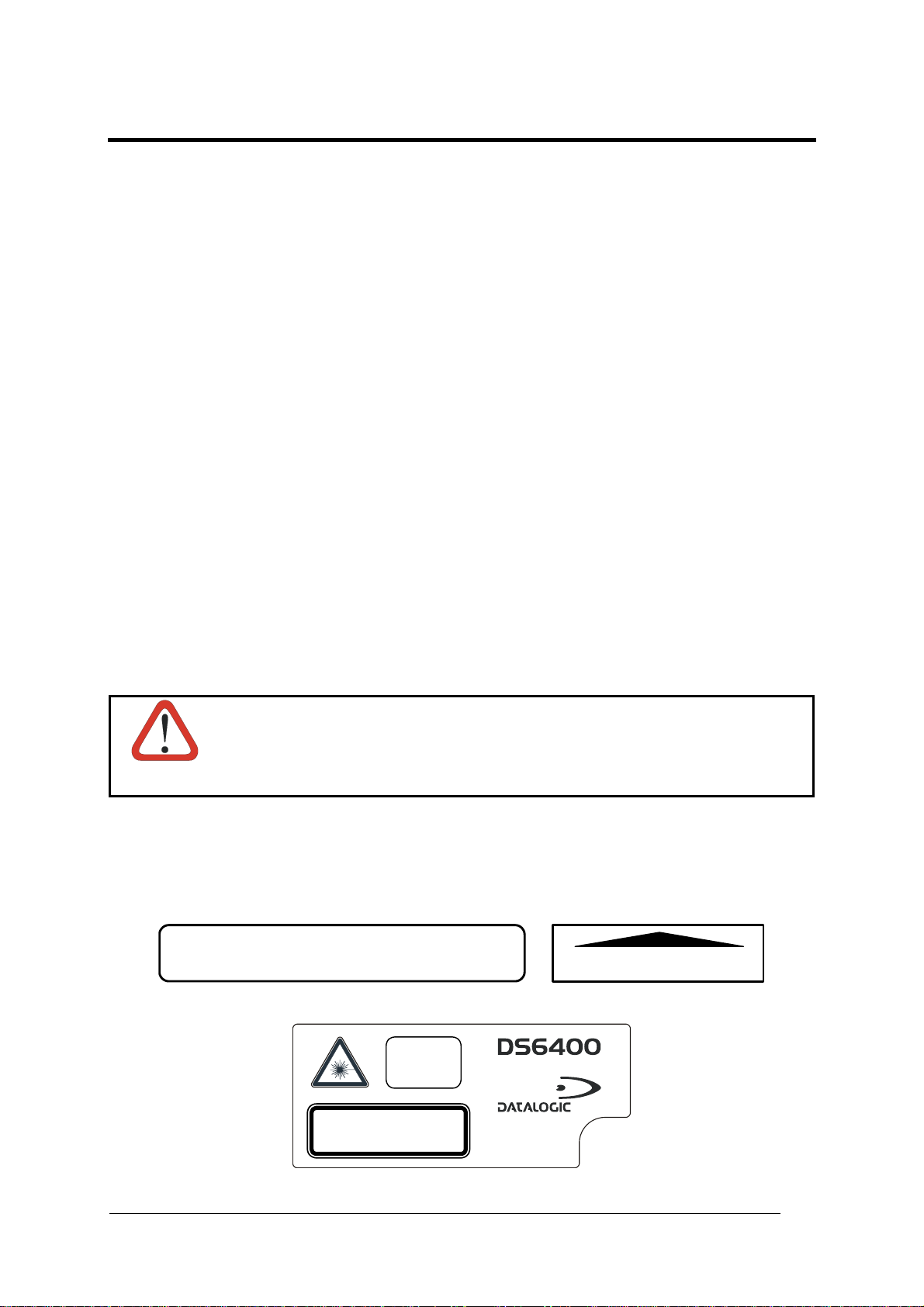

WARNING

The laser light is visible to the human eye and is emitted from the window on the head of the

reader (Figure A, 7).

Warning labels indicating exposure to laser light and the device classification are applied

onto the head of the reader (Figure A, 1, 3):

LASER RADIATION IS EMITTED FROM THIS APERTURE

AVOID EXPOSURE

AVOID EXPOSURE – LASER LIGHT

IS EMITTED FROM THIS APERTURE

Laser Safety Label for Oscillating Mirror and Standard Models

CAUTION-CLASS 3B

LASER LIGHT

WHEN OPEN

AVOID EXPOSURE

TO BEAM

LASER LIGHT – DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

MAX. OUTPUT RADIATION 1 m W

EMITTED WAVE LENGTH 630 ~ 680 nm

EN60825-1:2001

Warning and Device Class Label

vii

Page 8

The identification label is applied onto the bottom part of the scanner (Figure A, 2):

DATALOGIC S.p.A. Via Candini, 2

40012 LIPPO DI CALDERARA DI RENO (BO) ITALY

MANUFACTURED VOLT Amp.

JANUARY 2002 15-30 DC 1.5-0.7

MODEL No.

SERIAL No.

This product conforms to the applicable requirements

of 21CFR 1040 at the date of manufacture.

Device Identification Label

N2468

The laser diode used in this device is classified as a Class 3B laser product according to

EN60825-1 regulations and as a Class IIIb laser product according to CDRH regulations. Any

violation of the optic parts in particular can cause radiation up to the maximum level of the

laser diode (35 mW at 630~680 nm).

POWER SUPPLY

- This product is intended to be installed by Qualified Personnel only.

- All DS6400 Models:

This device is intended to be supplied by a UL Listed Power Unit marked “Class 2” or LPS

power source which supplies power directly to the scanner via the 25/26-pin connector.

CE COMPLIANCE

Warning:

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

WEEE COMPLIANCE

ENGLISH

Information for the user in accordance with the European Commission Directive 2002/96/EC

t the end of its useful life, the prA

separately from urban waste.

Disposin

or consu

g of the product according to this Directive:

avoids potentially negative conse• quences to the environment and human health which o

be caused by incorrect disposal

• enables the recovery of materials to obtain a significant savings of energy and resources.

or more detailed information about disposal, contact the supplier that providedF

lt the dedicated section at the website www.automation.datalogic.com.

oduct marked with the crossed out wheeled wastebin must be disposed of

therwise could

you with the product in question

viii

Page 9

ITALIANO

Informazione degli utenti ai sensi della Direttiva Europea 2002/96/EC

L’apparecchiatura che riporta il simbolo del bidone barrato deve essere smaltita, alla fine della sua vita utile,

separatamente dai rifiuti urbani.

Smaltire l’apparecchiatura in conformità alla presente Direttiva consente di:

• evitare possibili conseguenze negative per l’ambiente e per la salute umana che potrebbero invece

essere causati dall’errato smaltimento dello stesso;

• recuperare materiali di cui è composto al fine di ottenere un importante risparmio di energia e di risorse.

Per maggiori dettagli sulle modalità di smaltimento, contattare il Fornitore dal quale è stata acquistata

l’apparecchiatura o consultare la sezione dedicata sul sito www.automation.datalogic.com.

DEUTSCH

Benutzerinformation bezüglich Richtlinie 2002/96/EC der europäischen Kommission

Am Ende des Gerätelebenszyklus darf das Produkt nicht über den städtischen Hausmüll entsorgt werden. Eine

entsprechende Mülltrennung ist erforderlich.

Beseitigung des Produkts entsprechend der Richtlinie:

• verhindert negative Auswirkungen für die Umwelt und die Gesundheit der Menschen

• ermöglicht die Wiederverwendung der Materialien und spart somit Energie und Resourcen

Weitere Informationen zu dieser Richtlinie erhalten Sie von Ihrem Lieferanten, über den Sie das Produkt

erworben haben, oder besuchen Sie unsere Homepage unter www.automation.datalogic.com.

FRANÇAIS

Information aux utilisateurs concernant la Directive Européenne 2002/96/EC

Au terme de sa vie utile, le produit qui porte le symbole d'un caisson à ordures barré ne doit pas être éliminé avec

les déchets urbains.

Éliminer ce produit selon cette Directive permet de:

• éviter les retombées négatives pour l'environnement et la santé dérivant d'une élimination incorrecte

• récupérer les matériaux dans le but d'une économie importante en termes d'énergie et de ressources

Pour obtenir des informations complémentaires concernant l'élimination, veuillez contacter le fournisseur auprès

duquel vous avez acheté le produit ou consulter la section consacrée au site Web

www.automation.datalogic.com.

ESPAÑOL

Información para el usuario de accuerdo con la Directiva Europea 2002/96/CE

Al final de su vida útil, el producto marcado con un simbolo de contenedor de bassura móvil tachado no debe

eliminarse junto a los desechos urbanos.

Eliminar este producto de accuerdo con la Directiva permite de:

• evitar posibles consecuencias negativas para el medio ambiente y la salud derivadas de una eliminación

inadecuada

• recuperar los materiales obteniendo así un ahorro importante de energía y recursos

Para obtener una información más detallada sobre la eliminación, por favor, póngase en contacto con el

proveedor donde lo compró o consultar la sección dedicada en el Web site www.automation.datalogic.com.

ix

Page 10

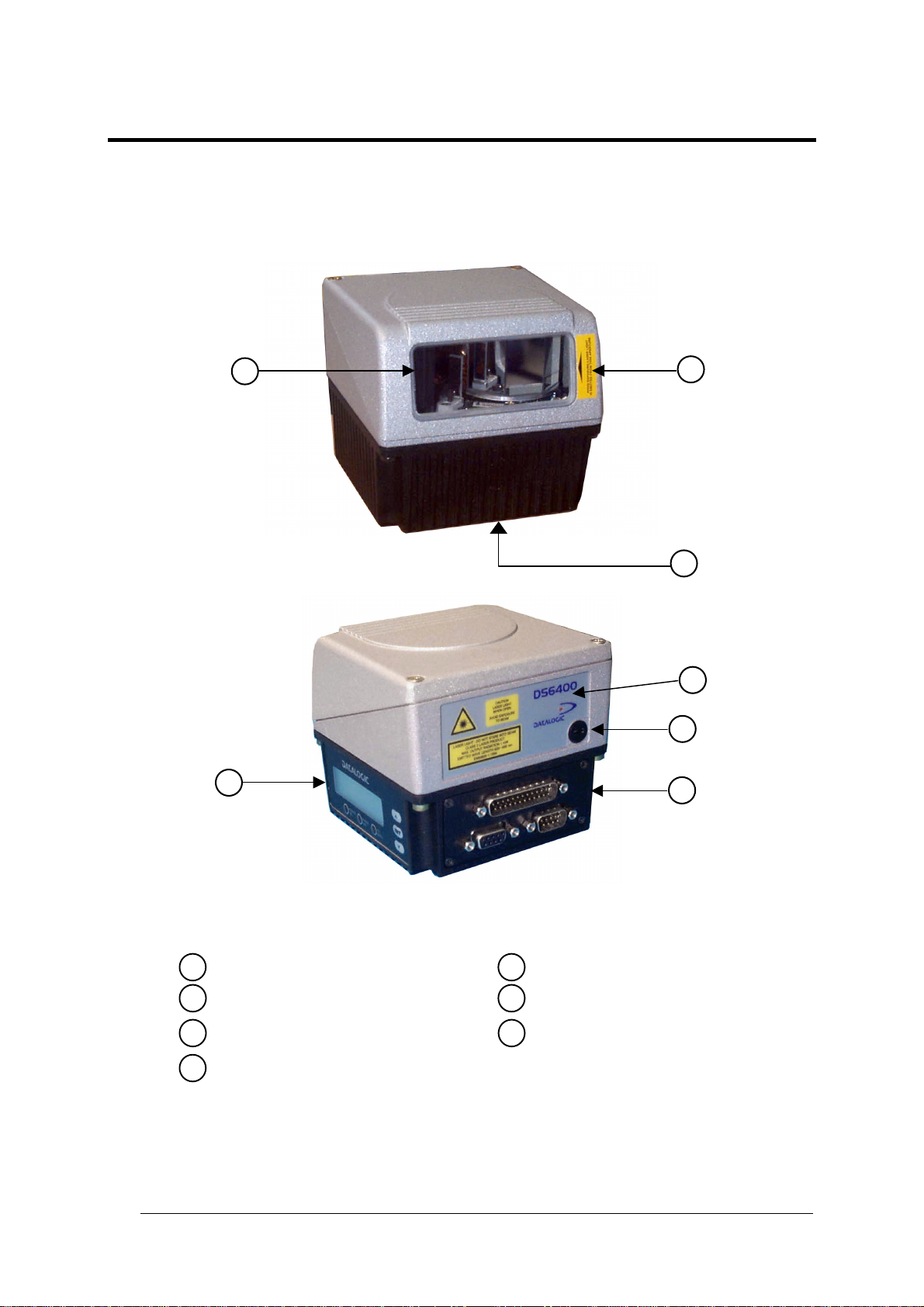

GENERAL VIEW

DS6400

7

6

1

2

3

4

5

x

Figure A - DS6400

1

Laser Safety Label

Identification Label

2

Warning and Device Class Label

3

Service Cap

4

5

Connector Panel

Display and Keypad Panel

6

Laser Beam Output Window

7

Page 11

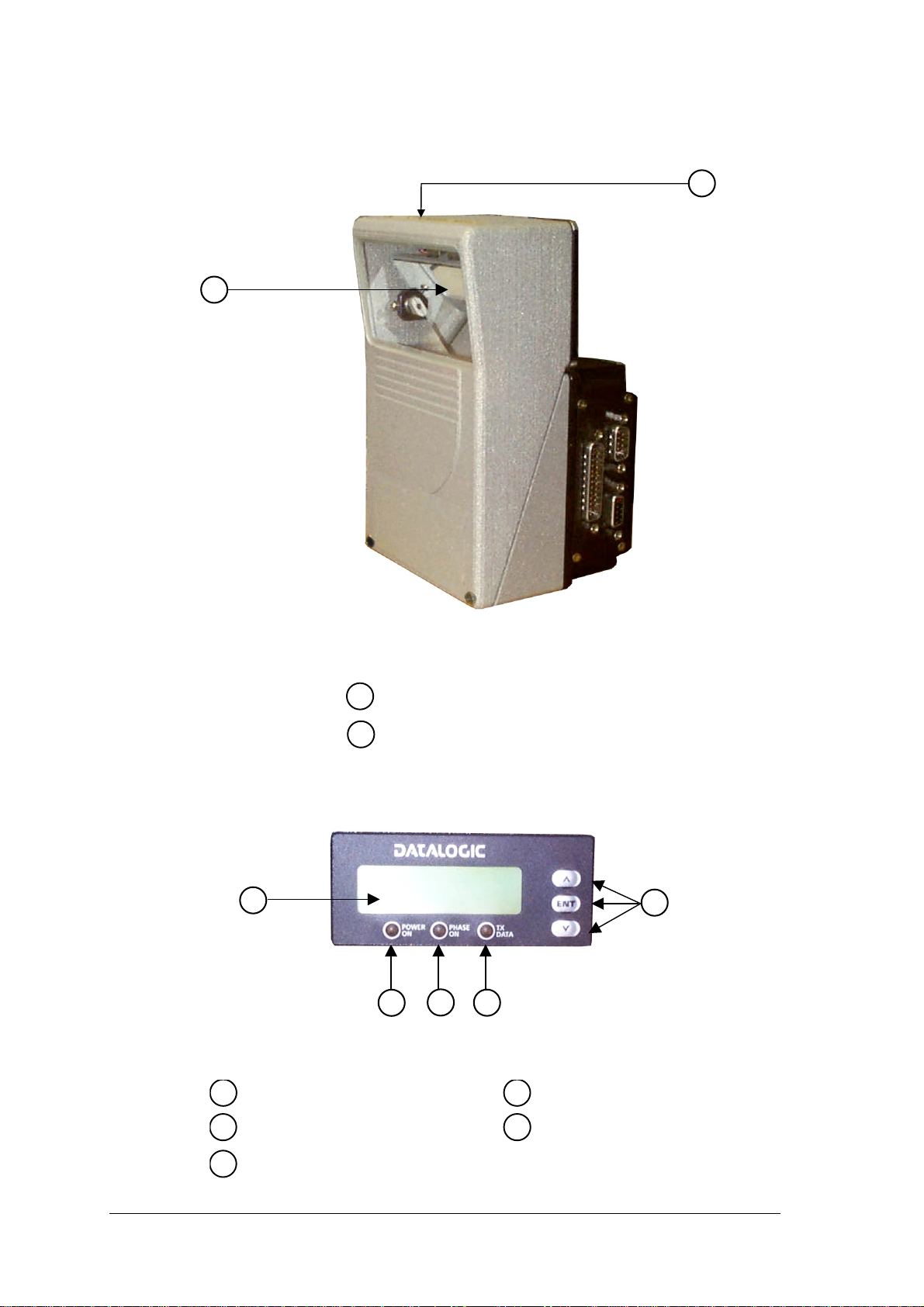

DS6400

2

1

Figure B - DS6400 Oscillating Mirror Version

5

Programming Keypad

1

Laser Safety Label

1

Laser Beam Output Window

2

3

4

Figure C - Display and Keypad Panel

2

Power On LED

4

1

2

TX Data LED

3

Phase On LED

LCD Display

5

xi

Page 12

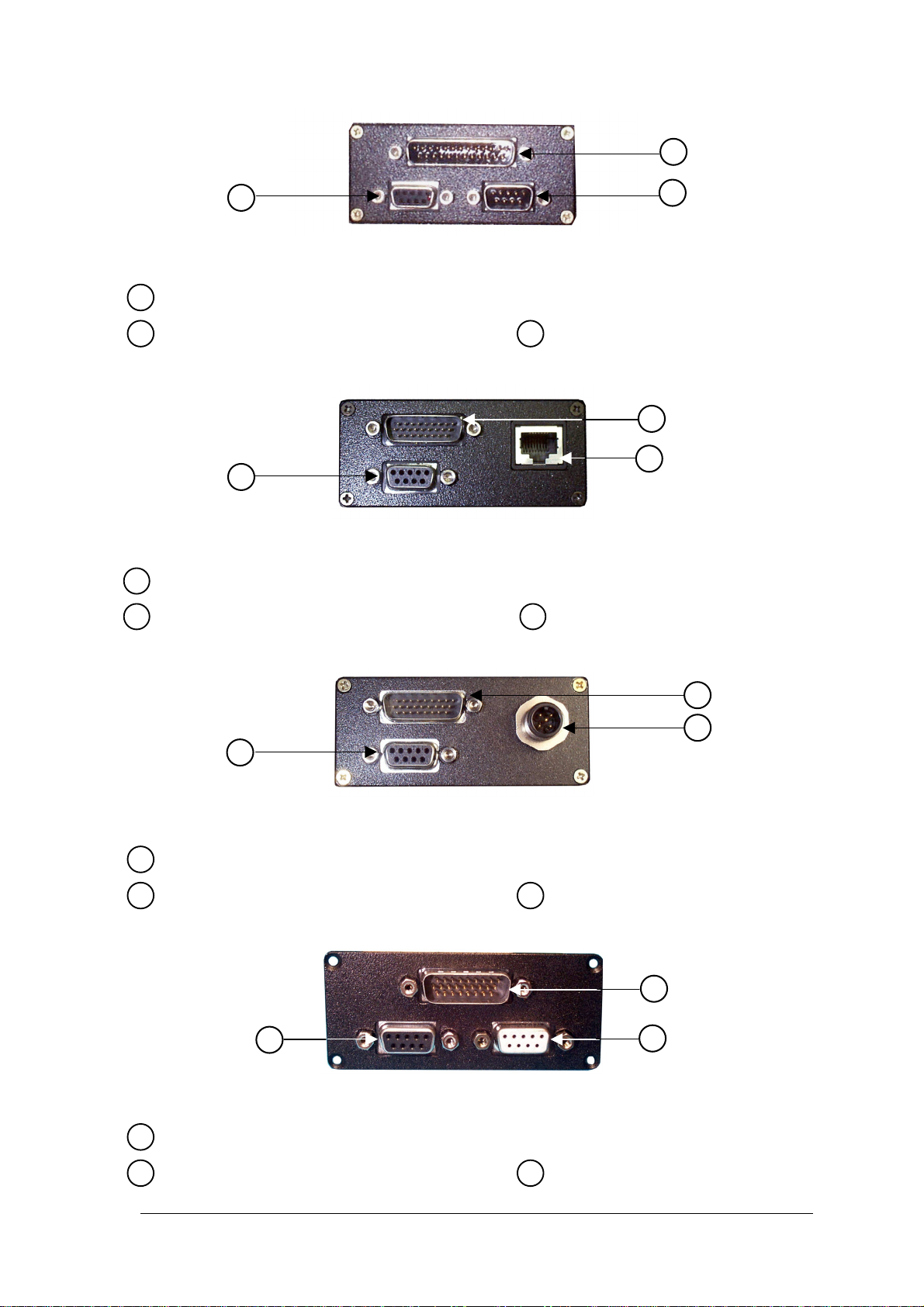

1

3

2

Figure D - Connector Panel for Master/Slave Models

1

Lonworks 9-pin maole connector

2

nnector Main/Aux. Interface 25-pin D-Sub male c

3

Lonworks 9-pin female connector

1

2

3

Figure E – Connector Panel for Ethernet Models

Main/Aux. Interface 26-pin D-Sub male connector

1

RJ45 modular connector for Ethernet Interface

2

3

Lonworks 9-pin female connector

1

2

3

Figure F – Connector Panel for DeviceNet Models

Main/Aux. Interface 26-pin D-Sub male connector

1

DeviceNet 5-pin male connector

2

3

Lonworks 9-pin female connector

1

3

2

Figure G – Connector Panel for Profibus Models

Main/Aux. Interface 26-pin D-Sub male connector

1

xii

Profibus 9-pin female connector (white)

2

3

Lonworks 9-pin female connector

Page 13

GUIDE TO INSTALLATION

POINT-TO-POINT INSTALLATION

The following can be used as a checklist to verify all the steps necessary to complete

installation of the DS6400 scanner.

1) Read all information in the section “Safety Precautions” at the beginning of this manual.

2) Correctly mount the scanner using the bracket provided according to the information in

par. 2.2.2 and position it at the correct reading distance according to your model as

shown in par. 2.5 and par. 4.4.

3) Make electrical connections to your DS6400 scanner by:

a) Connecting the DS6400 scanner to the C-BOX 100 by means of one of the cables

provided as accessory (see par. 1.5).

b) Providing correct and complete system cabling through the C-BOX 100 according to

the signals (trigger, inputs, outputs) necessary for the layout of your application.

• Layout: Point-to-Point, Pass Through, RS232 Master/Slave, Lonworks, Fieldbus.

See sub-paragraphs under 2.7 for reference.

• Cabling: Power, Main Serial Interface – RS232, RS485 Half Duplex, RS485 Full

Duplex, 20 mA Current Loop, Auxiliary Interface, Inputs, Outputs, etc -. For further

details, see all sub-paragraphs under par. 2.3.

4) Configure the DS6400 scanner by installing and running the Genius™ configuration

program from the CD-ROM provided. The main steps are:

• Select the codes to be read

• Set-up the communication parameters

• When PackTrack™ is required, set the PS Offset and Position parameters

• Define data formatting parameters

Fine tuning of the scanner position for barcode reading can be

NOTE

accomplished

in Genius™.

by performing a test through the SPY configuration tool

5) Exit the configuration program and run your application.

he installation is now complete.

T

xiii

Page 14

MASTER/SLAVE LONWORKS INSTALLATION

The following can be used as a checklist to verify all the steps necessary to complete

installation of the DS6400 scanner in a Master/Slave Lonworks network.

1) Read all information in the section “Safety Precautions” at the beginning of this manual.

2) Correctly mount the scanner using the bracket provided according to the information in

par. 2.2.2 and position it at the correct reading distance according to your model as

shown in par. 4.4.

3) Make electrical connections to your DS6400 scanner by:

a) Connecting the DS6400

Master scanner to the C-BOX 100 by means of one of the

cables provided as accessory (see par. 1.5).

b) Correctly inserting the BTK-6000 terminator in the DS6400 Master reader according

to the information given under “Local Lonworks Network” in par. 2.3.2 and par. 2.7.5.

c) Completing the system wiring adding as much slave scanners as required by your

system layout (refer to par. 2.7).

d) Correctly inserting the BTK-6000 terminator in the last DS6400 Slave reader of the

network according to the information given under “Local Lonworks Network” in par.

2.3.2 and par. 2.7.5.

4) Install and run the Genius™ configuration program from the CD-ROM provided.

Configure the Local Lonworks Network using one of the procedures given below:

a) Configure the entire network through the Master as described in par.

b) Configure the Master as described in par. 3.2.2 and locally define each slave scanner

address as described in par. 3.2.3.

c) Define each scanner, master and slaves (with their addresses), by using the scanner

keypad according to the information given in par. 2.9.1.

5) Configure the Master scanner through the Genius™ program. The main steps are:

• Select the codes to be read

• Set-up the communication parameters

• When PackTrack™ is required, perform PackTrack™ calibration, see par. 4.2.1

• Define data formatting parameters

6) Configure each Slave scanner through the Master scanner using Genius™. The main

steps are:

• Select the codes to be read

• When PackTrack™ is required, perform PackTrack™ calibration, see par. 4.2.1

Fine tuning of the scanner position for barcode reading can be

accomplished by performing a test through the SPY configuration tool

NOTE

in Genius™.

7) Send the configuration to the Master.

xiv

Page 15

8) Optionally, perform the ASR Network Configuration procedure for system backup

purposes (see par. 5.2.1).

9) Exit the configuration program and run your application.

The installation is now complete.

xv

Page 16

xvi

Page 17

INTRODUCTION

1

1 INTRODUCTION

1.1 PRODUCT DESCRIPTION

The DS6400 is a high performance laser scanner in a complete range of industrial bar code

readers offering an innovative and modular solution in terms of reading performance,

connectivity and maintenance, in addition to a completely new hardware and software

platform.

The DS6400 has been specifically designed for simple installation, easy use and flexibility.

An innovative mechanical design together with the Datalogic patent pending Step-a-Head

feature make it possible to rotate the reader head and the decoder base independently from

each other. Step-a-Head

TM

enables the DS6400 to always be installed in the ideal position,

by modifying the orientation of the connector panel while leaving the laser window in the

desired position. The need for space is minimized and installation is easier.

The DS6400 has an innovative linear motor designed to control the focus position of the

scanner via software. This dynamic system, called FLASH

TM,

is able to move the focus

position rail to rail, from the minimum position to the maximum position, in less than 10 msec.

In typical applications, where a DOF <1 meter is required, the focus position is adjusted in 4

msec.

The DS6400 can read all most popular bar codes even in the most difficult conditions, thanks

to a new generation decoder with Intel Xscale CPU and code reconstruction technology

(ACR™ 4).

This reader is also offered in a model with an integrated SW programmable oscillating mirror.

Great attention has been given to built-in connectivity for all market standards. Lonworks,

Profibus, DeviceNet and Ethernet bus have been integrated in dedicated versions of the

decoder base.

Some of the main features of DS6400 are listed below:

• scanning speed up to 1200 scans/sec;

• 2 serial communication interfaces

• reading all popular codes;

• supply voltage from 15 to 30 Vdc;

• electrical connection through connectors;

• high speed Lonworks connectivity for Master/Slave layout;

• built-in connectivity for Profibus, DeviceNet and Ethernet;

• programmable in 5 different operating modes to suit the most various barcode reading

system requirements;

• light source: solid state laser diode; the light emitted has a wavelength between

630~680nm.

• IP64 protection class of the enclosure (not yet available for Ethernet models).

Manufacturing is the traditional industry for Auto-ID applications, with a market becoming

mature, standardized reading solutions and a tough competition. Manufacturing has been the

target industry since the very beginning of the new 6000 family with the DS6300. The

DS6400 makes possible to enlarge the market applications including Transportation &

Logistics industry, making wider the Business Opportunities scenario.

TM

1

Page 18

1

Feature

Modular solution with separated

head and base and Step-A-

TM

Head

feature

Benefit

• Possibility to select the combination of head and

base that best fits the needs of the application;

• Great scalability of the offer;

• Down time cost reduction, since the decoder base

DS6400

works even if the head has been removed;

• Easy maintenance. In case of replacement of the

head, all the configuration parameters are stored

in the base, and the scanner is automatically

configured;

Reading on pallets or big objects

• Easy installation with the minimum room needed.

• DS6400 with FLASH

TM

dynamic focusing system.

where a large reading distance /

wide reading field are needed

Reading parcels on conveyors • DS6400 implements the Packtrack

TM

functionality

which leads to an increase of the plant production

as a result of the augmented system throughput.

Master working as a multiplexer

on a high speed Lonworks bus

• Great competitiveness of the offer, since the cost

of an external multiplexer is saved;

• High data transfer on a industrial, reliable bus

running at 1,2 Mbit/sec.

GENIUSTM Configurator SW • Reduced learning time, with an easy wizard

approach;

• Multilanguage platform;

• All the configuration parameters stored into the

scanner;

• Not dependent on the Physical interface.

1.2 MODEL DESCRIPTION

The DS6400 scanner is available in versions that differ in regard to the following

characteristics:

• Optical Model (Head)

2

• Decoder Model (Base)

DS6400 - 10X - 0YY

Decoder Model (Base)

Optical Model (Head)

0 = Standard

5 = Oscillating Mirror

10 = Master/Slave

11 = Profibus

12 = Ethernet

15 = Devicenet

Page 19

INTRODUCTION

1

1.3 OSCILLATING MIRROR MODELS

Oscillating mirror models are used when coverage of a large reading area is required, mainly

in picket fence applications.

The DS6400 scanner mounts a dedicated optic head with integrated oscillating mirror driven

by a linear motor. The speed, the precision, the repeatability, and the reliability of this driving

technology assure high level performance.

The new oscillating mirror is completely software controlled and software programmable. The

Genius™ software tool allows adjusting the linear motor speed (oscillating frequency) and

the upper and lower limits of the oscillation by defining the top and bottom line limit angles.

When the oscillating mirror is programmed to read barcode labels at very small angles,

position the reader to assure at least 10° for the Skew angle (see par. 2.4). This angle refers

to the most inclined or external laser line, so that all other laser lines assure more than 10°

Skew. This avoids the direct reflection of the laser light emitted by the reader.

1

0

°

Figure 1 – Oscillating Mirror Skew Angle

Otherwise, the scanner can be mounted at an angle of inclination of 17.5° in order to attain

symmetrical deflection ranges.

1

7

.

5

°

°

5

.

7

0

1

Figure 2 - Oscillating Mirror Reading Position

In the above case, the zone where the scan line is perpendicular to the reflecting surface

corresponds to a neutral zone at the center of the reading field.

3

Page 20

1

DS6400

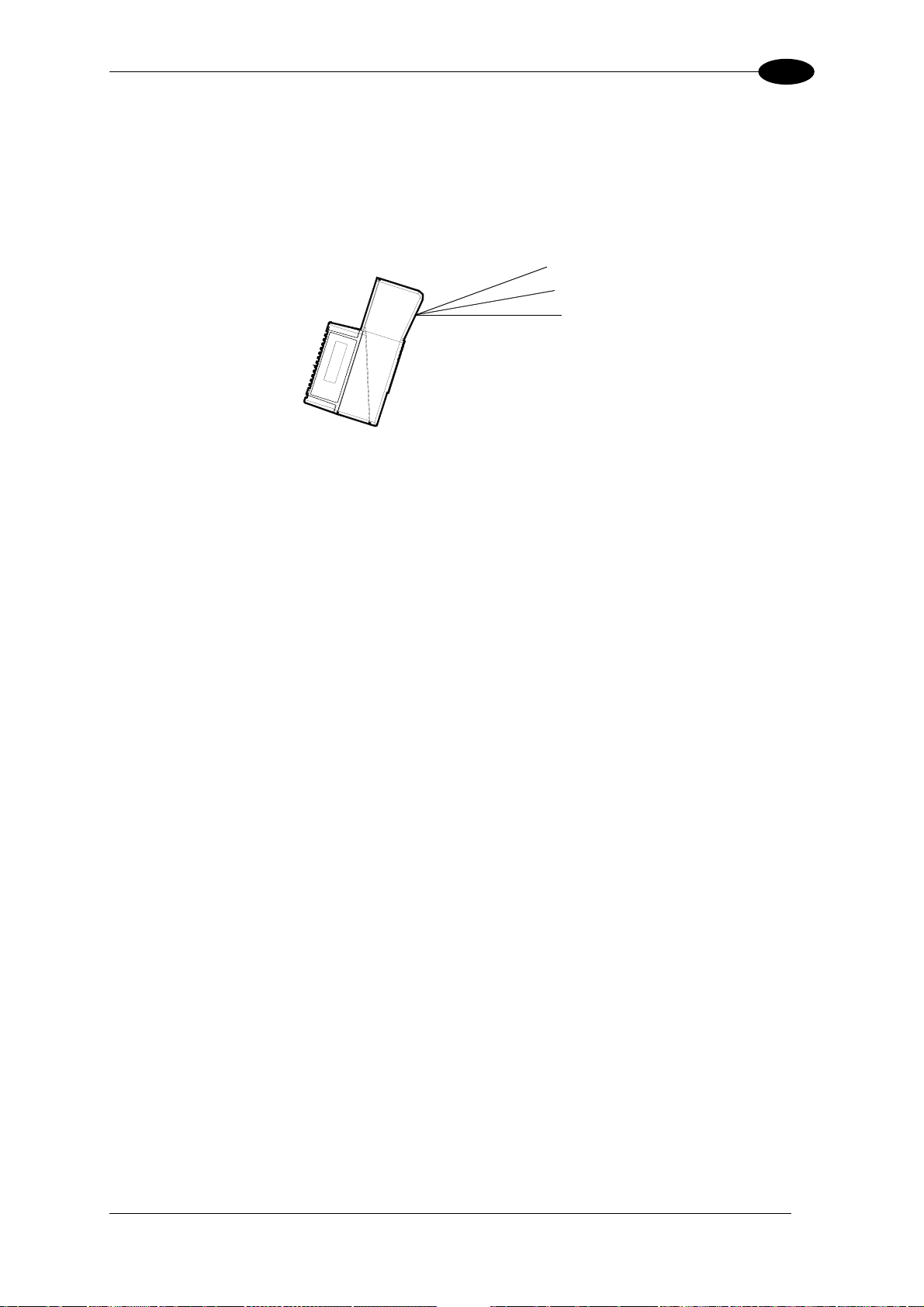

The mirror can be deflected up to 40°. Oscillation with respect to the output window median

axis is asymmetrical ( see figure below).

3

40°

7

.

5

°

0°

-

2.

5

°

Figure 3 - Oscillating Mirror Maximum Aperture and Asymmetry

By configuring the oscillating speed up to the maximum value of 19 Hz, raster emulation can

e performed for reading fast moving objects. b

Hz Max. Aperture

0-5 40°

6-10 30°

11-15 20°

16-19 10°

By limiting the raster width to the minimum necessary, the number of

NOTE

scans on the reading surface is increased.

Oscillating angles are selected in software where the minimum and maximum angles

orrespond to –2.c 5° and +37.5°.

he scanner can be tilted in order for the 17.5° software setting to correspond with the 0°

T

horizontal plane.

4

+37.5°

+17.5°

-2.5°

Figure 4 - Oscillating Mirror Extreme Angle Positions

Page 21

INTRODUCTION

These models provide higher scanning speed (1200 scans/sec) compared to standard

models and the reading performance is not adversely effected by the oscillating mirror.

The following example represents the selection of an angle of +10° for the bottom line and an

angle of +20° for the top line (see figure below).

1

+37.5°

+27.5°

+17.5°

Figure 5 - Oscillating Mode

Refer to par. 2.2.1 for deta

ils about oscillating mirror mounting.

1.4 INDICATORS

T dec se

he DS6400 oder ba provides an LCD display for system messages and configuration

menus. The three keys present on the side of the display allow configuration menu

avigation (Figure C, 1).

n

he three LED indicators have the following functions:

T

POWE

PHASE ON

TX DATA

R ON

(red) Indicates the reader is turned on (Figure C, 4)

(yellow) Indicates the presence sensor is turned on (Figure C, 3).

(green) Indicates the main serial interface is operating correctly during

data transmission (Figure C, 2).

5

Page 22

1

DS6400

1.5 ACCESSORIES

The following accessories are available on request for DS6400:

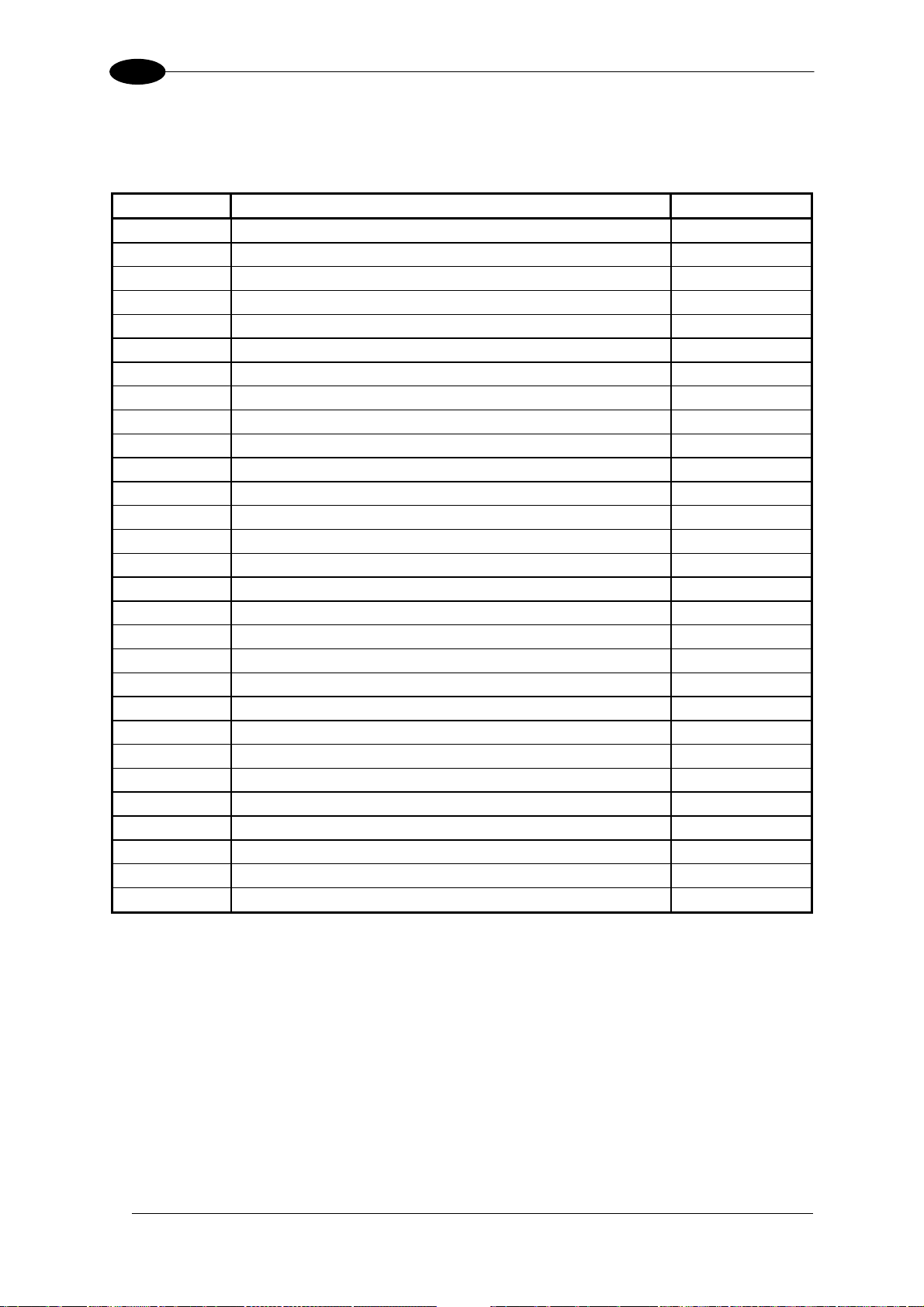

Name Description Part Number

CAB-6001 cable to C-BOX100 1 m 93A051190

CAB-6002 cable to C-BOX100 2 m 93A051200

CAB-6005 cable to C-BOX100 5 m 93A051210

CAB-6010 cable to C-BOX100 10 m 93A051271

CAB-6011 cable to C-BOX100 1 m (DS6400 Fieldbus version) 93A051221

CAB-6012 cable to C-BOX100 2 m (DS6400 Fieldbus version) 93A051222

CAB-6015 cable to C-BOX100 5 m (DS6400 Fieldbus version) 93A051223

CAB-6101 cable master/slave 1 m 93A051220

CAB-6102 cable master/slave 2 m

CAB-6105 cable master/slave 5 m 93A051240

CAB-6112 cable master/slave no power 2 m 93A051224

CAB-6115 cable master/slave no power 5 m 93A051225

CAB-6305 Power cable Fam 6k 5 m 93ACC1768

CAB-6310 Power cable Fam 6k 10 m 93ACC1752

C-BOX 100

passive connection box 93ACC1510

INT-30 20 m.A. C.L. interface board for C-BOX 100 93A151022

PWR-120 power unit 110/230 V AC 24 V 93ACC1530

BTK-6000 terminator kit (5 pcs)

PG6002

PG6001

single unit power supply (US) 93ACC1718

single unit power supply (UK) 93ACC1719

PG6000 single unit power supply (EU) 93ACC1720

FBK-6000 fast bracket kit (2 pcs) 93ACC1721

GFC-60 90° mirror 93A201100

GFC-600 90° deg. mirror close distance 93A201102

US-60 mounting bracket kit (5 pcs) for multisided stations 890001020

PH-1 Photocell kit – PNP 93ACC1791

MEP-543 Photocell kit - NPN 93ACC1728

OEK-2 Optical encoder (10 m cable + spring) 93ACC1770

OEK-1 Optical encoder kit + 10 m cable 93ACC1600

93A051230

93ACC1710

6

Page 23

INSTALLATION

2 INSTALLATION

To install the system follow the given procedure:

• Select the mounting location for DS6400;

• Mount the DS6400 scanner;

• Position the scanner with respect of the barcode;

• Proceed with system electrical connection;

• Install the Genius™ program on the PC and configure the scanner;

• Set the Flash™ dynamic focus by means of the Genius™ software tool.

When installing several scanners, take care to position them correctly so

that no laser beam enters the reading window perpendicularly and at the

same level of the output beam of the other scanners. This condition could

occur more frequently for side mounted applications. If these precautions

are not followed, it may occur that the laser of the blinded scanner starts

WARNING

blinking due to an internal circuit which temporarily turns the laser off

when detecting a power anomaly. To resolve this problem, it is sufficient

to slightly change the inclination and position of one of the two scanners

involved.

2

Refer to the Reference Documentation for details on connecting

NOTE

DS6400 reader to other devices in the system (i.e. C-BOX 100, etc ).

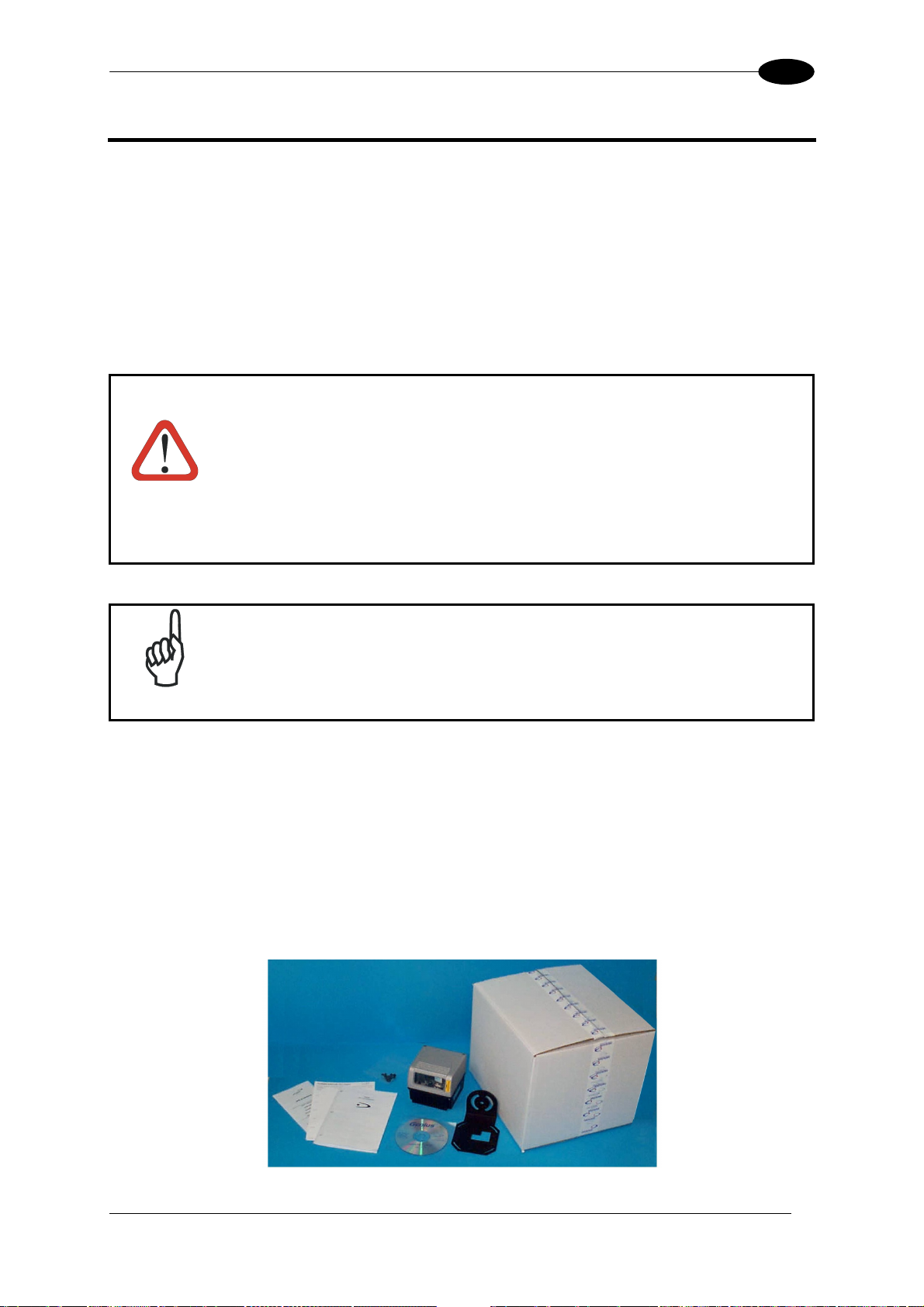

2.1 PACKAGE CONTENTS

Verify that the DS6400 reader and all the parts suppl

intact when opening the packaging; the list of parts inc

• DS6400 reader

• Installation Quick Reference +

• DS6400 configuration CD-ROM

• Mounting bracket and screws

barcode test chart

your

ied with the equipment are present and

ludes:

Figure 6 - DS6400 Package Contents

7

Page 24

2

DS6400

2.2 MECHANICAL MOUNTING

2.2.1 Mounting the Scanner

The DS6400 reader can be positioned and installed in the best way possible as a result of

the Step-a-Head™ feature. Thanks to the separation between Head and Base, you can

modify the orientation of the decoder base, and therefore display-keypad and connector

panels, while keeping the optic head in the correct reading position. The reading head and

the decoder base can be rotated independently from each other allowing the installation even

in the most critical locations.

Head Screws

Fixing Screw (4)

Figure 7 - Step-A-Head™ Feature

To rotate the head follow the given procedure:

. detach the head from the base by unscrewing the four fixing screws;

1

. rotate the head in the desired position;

2

loosen but don't remove the two screws on top of the head;

3.

4. affix the head onto the base carefully aligning the four fixing screws and progressively

tightening them about half-way;

5. completely tighten the two screws on top of the head;

6. completely tighten the four fixing screws.

8

Page 25

INSTALLATION

2

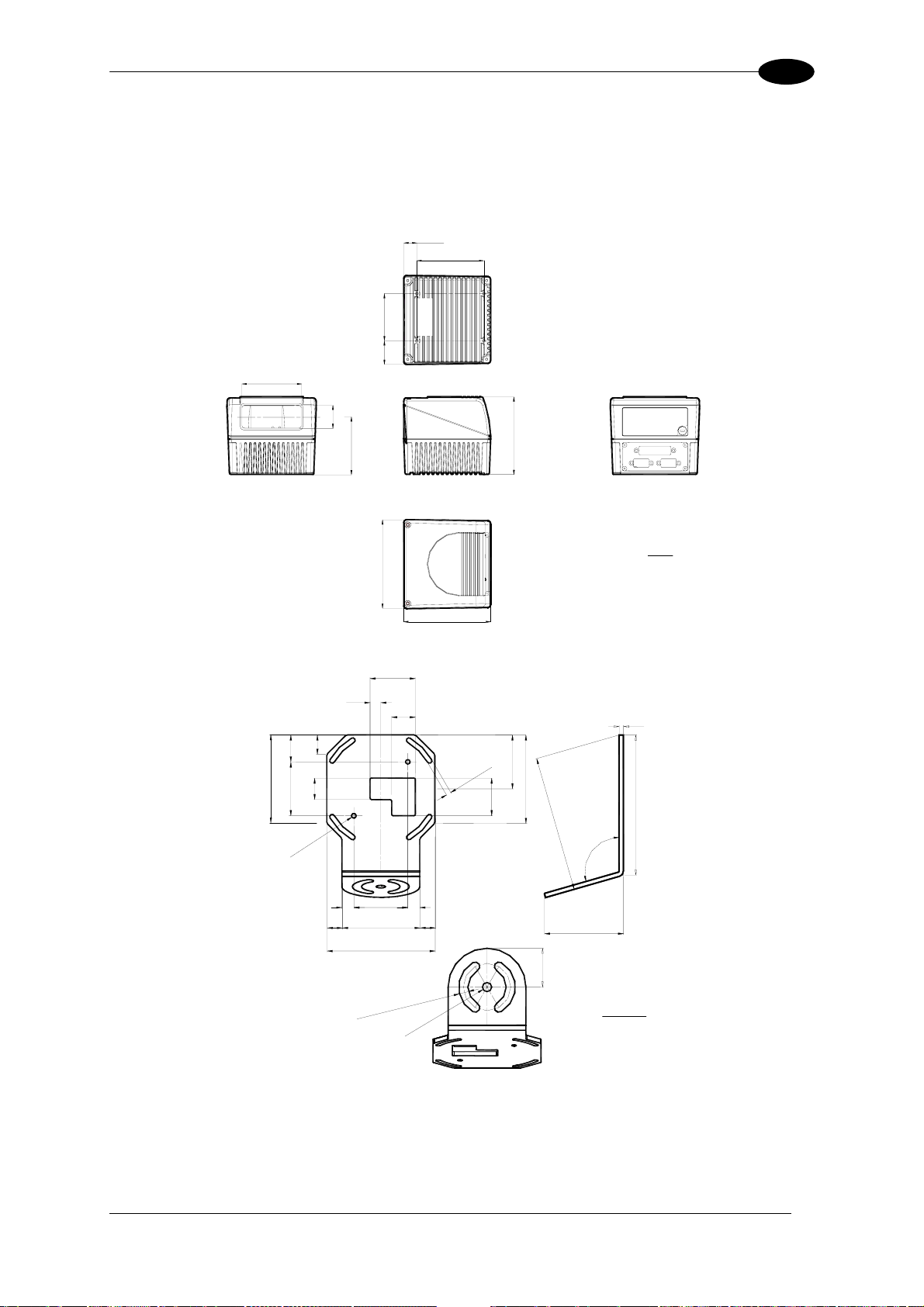

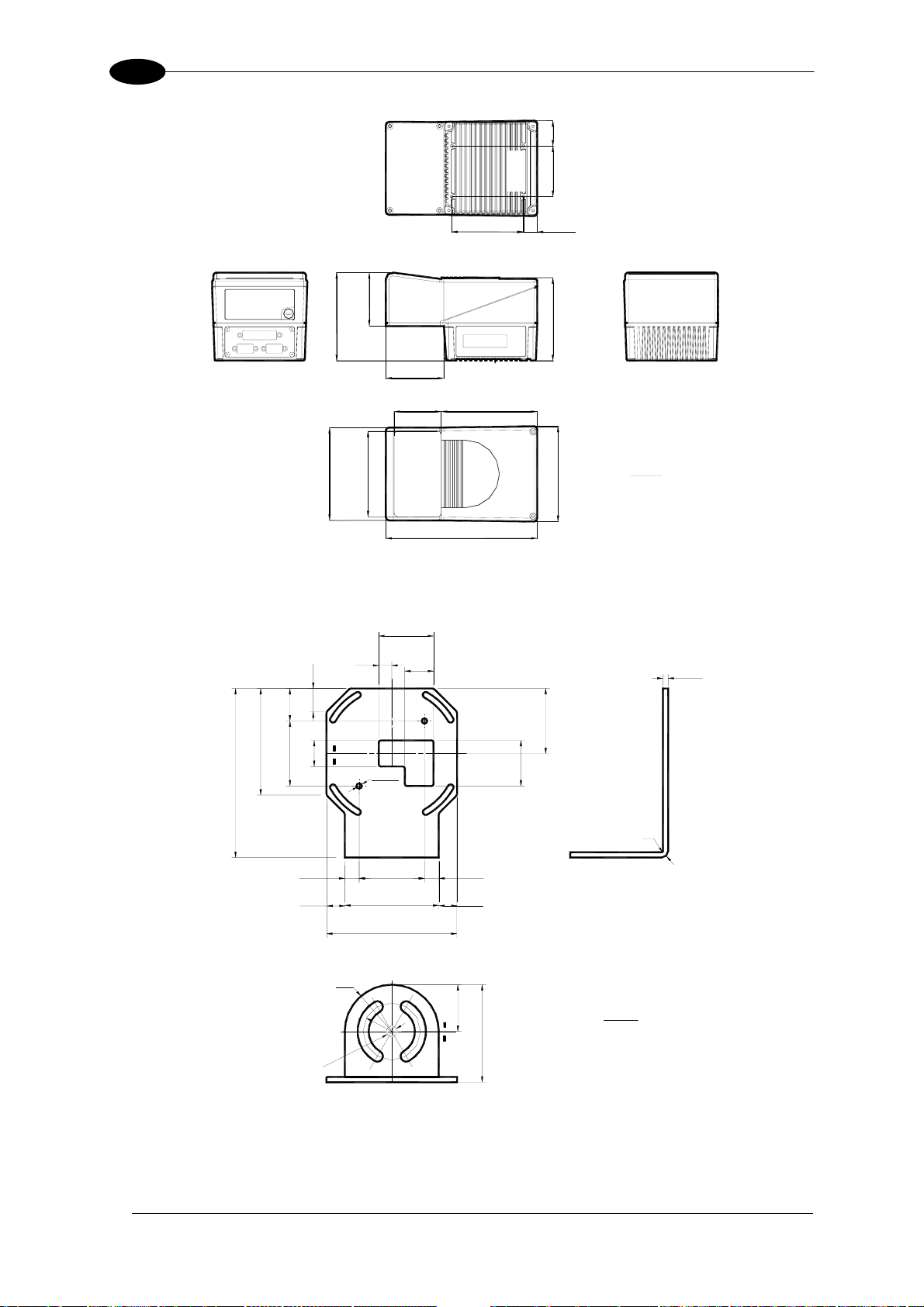

The following diagrams give the overall dimensions of the reader standard model, oscillating

mirror model and mounting brackets. They may be used for their installation. Refer to par.

2.4 for correct positioning of the scanner with respect to the code passage zone.

16.5

0.65

85

3.34

60

2.36

30

1.18

76

2.99

30

1.18

74

2.85

99

3.90

mm

113

4.45

110

4.33

inch

Figure 8 - DS6400 Overall Dimensions

42

1.65

10

0.4

18

0.71 N°2

25

0.98

82

3.22

50

20

0.78

1.96

2

°

2

°

N

N

1

.

6

4

1

.

Ø

0

Ø

1.96

2.83

100

3.93

.

8

0

22

0.86

S

50

T

O

1.96

L

S

T

S

O

4

L

°

S

N

4

5

°

.

N

4

8

1

.

0

==

50

72

5

.

==

S

T

O

L

S

2

°

S

T

N

O

L

S

2

°

N

3

3

5

.

8

3

Ø

3

.

0

Ø

82

3.22

35

1.37

1

4

2

.

6

9

6

106°

73.2

2.88

36

1.41

mm

inch

4

0.15

130

5.12

Figure 9 – ST-237 Mounting Bracket Overall Dimensions

9

Page 26

2

30

60

DS6400

1.18

2.36

104.5

110.3

85

3.35

2.50

63.5

4.11

69

2.72

56

2.20

102

4.34

4.01

180

7.08

114

4.48

16.5

0.65

99

3.90

113

4.45

mm

inch

Figure 10 - DS6400 Oscillating Mirror Model Overall Dimensions

42

1.65

130

82

5.11

3.22

25

50

0.98

1.96

18

20

1

0.7

0.78

10

0.4

Ø4.1

0.16

22

0.86

35

4

0.15

50

1.96

1.37

10

R1

R5

0.43

14

0.55

0.55

36

1111

0.43

14

1.41

75

2.95

mm

inch

50

1.96

72

2.83

100

3.93

R36

R22

5

.

8

Ø

Figure 11 – ST-210 Mounting Bracket Overall Dimensions

Page 27

INSTALLATION

2

2.2.2 Mounting the Scanner with Accessories

The following a

our network layout:

y

ST-237 mounting bracket;

-

- ST-210 mounting bracke

FBK-6000 fast bracket.

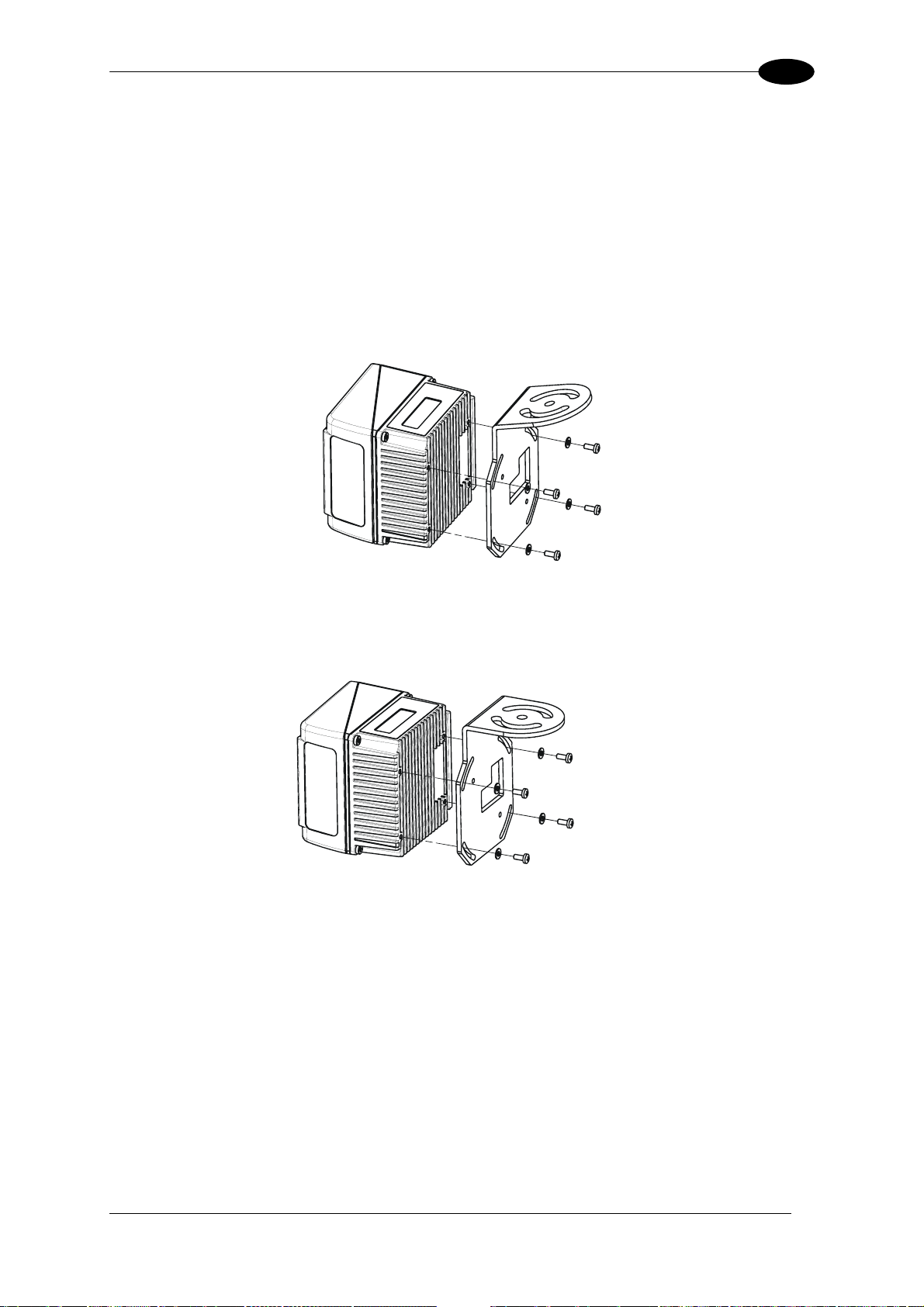

The ST-237 is a 106° mounting bracket to be mounted on the reader as displayed in the

image below:

ccessories allow installing the DS6400 reader in the most suitable position for

t;

-

Figure 12 – Mounting the ST-237 Mounting Bracket

The ST-210 is a 90° mounting bracket to be mounted on the reader as displayed in the

image below:

Figure 13 – Mounting the ST-210 Mounting Bracket

11

Page 28

2

DS6400

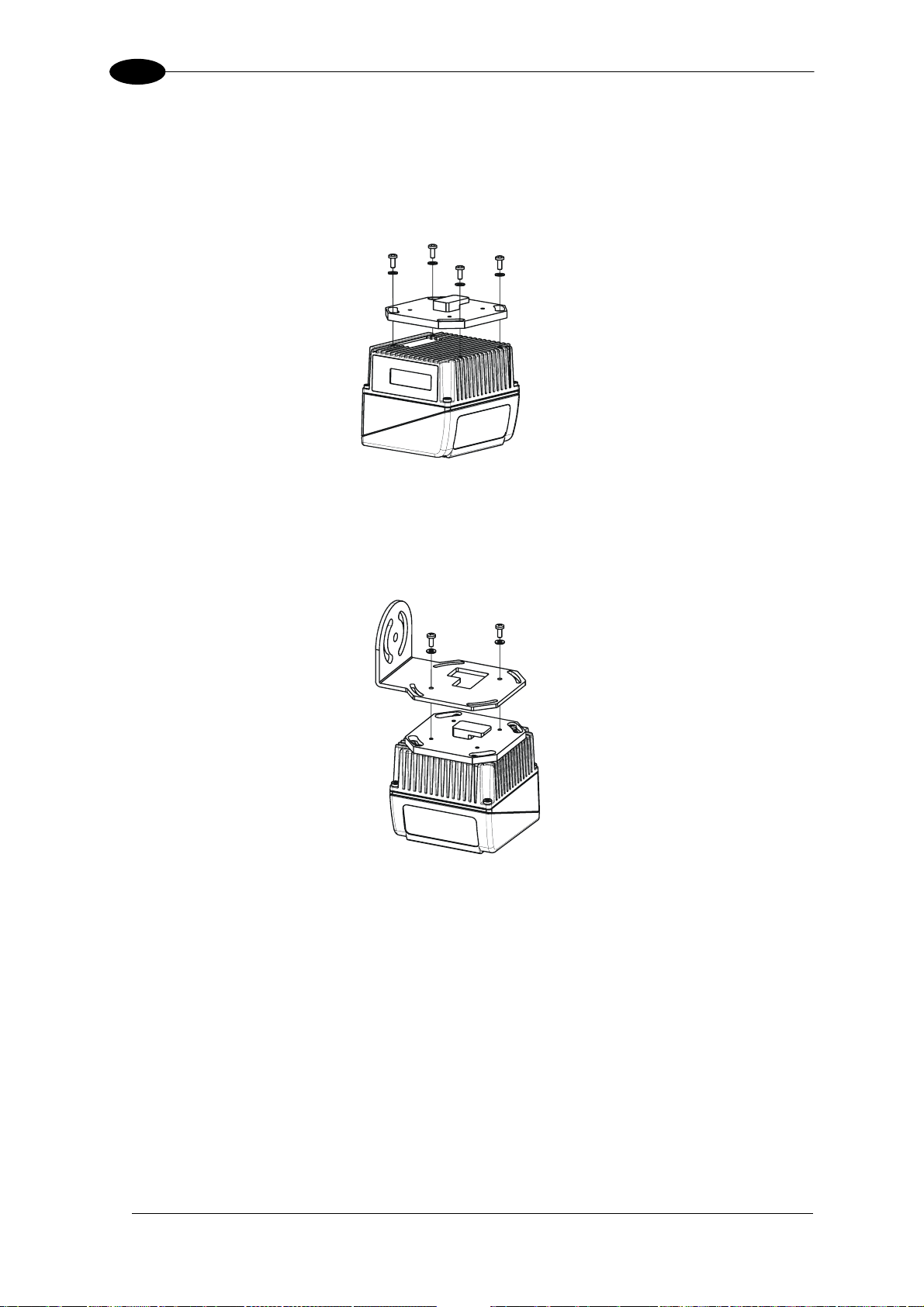

The FBK-6000 is a fast bracket kit allowing a quick and easy mounting of the scanner on

either the ST-210 or the ST-237 brackets.

First, it is necessary to fix the FBK-6000 to the DS6400 scanner by means of the mounting

screws:

Figure 14 – Mounting the FBK-6000 on the Scanner

Then, attach the assembly to the mounting bracket by slipping the hook into the bracket hole.

Finally, fix it by means of the 2 fixing screws:

12

Figure 15 – Mounting the Assembly on the Bracket

Page 29

INSTALLATION

2.3 ELECTRICAL CONNECTIONS

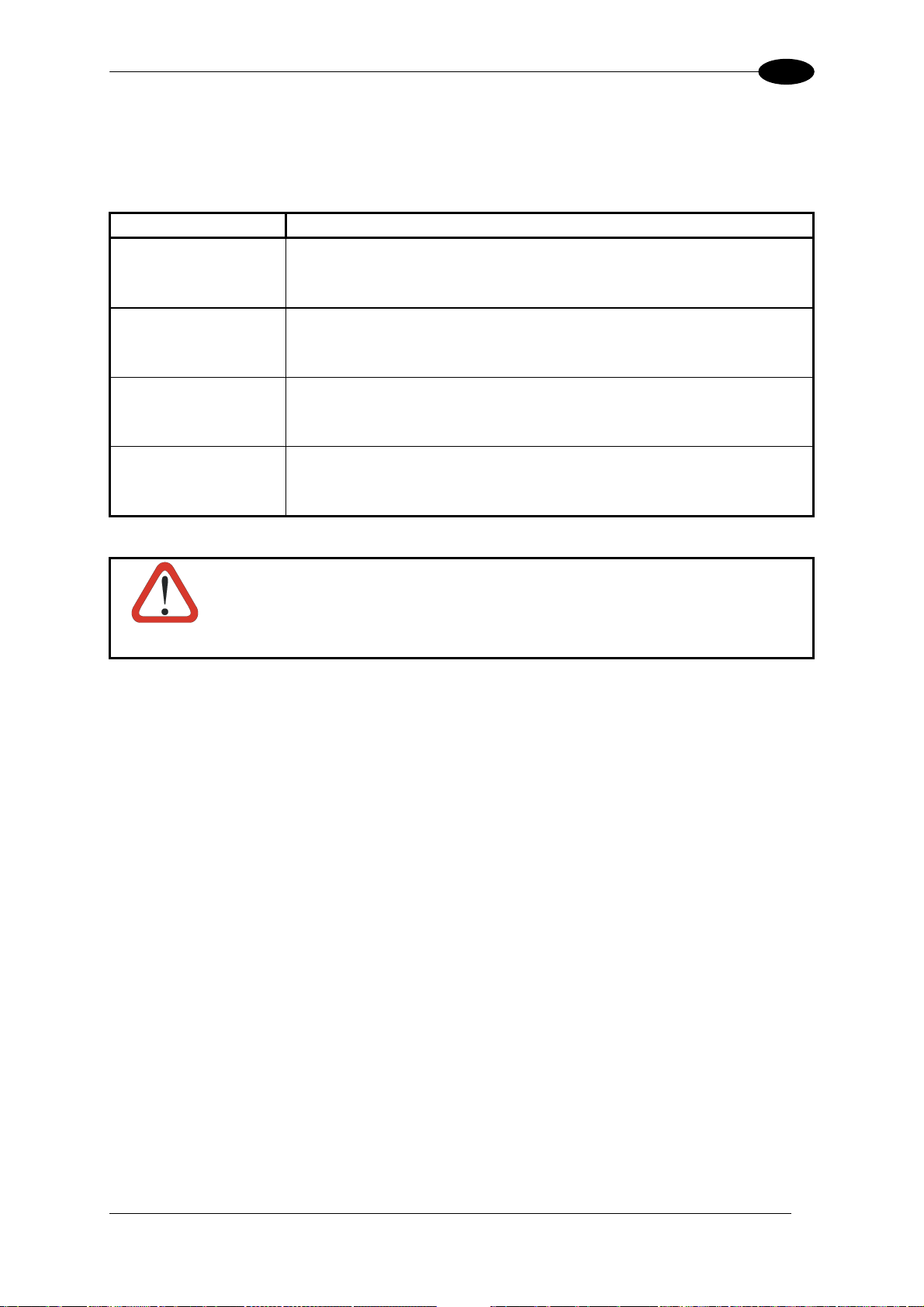

All the connectors available for each scanner model are the following:

Scanner Model Connector

Master/Slave 25-pin male serial interface and I/O connector

9-pin male Lonworks connector*

9-pin female Lonworks connector

Ethernet 26-pin male serial interface and I/O connector

9-pin female Lonworks connector

RJ45 modular connector

DeviceNet 26-pin male serial interface and I/O connector

9-pin female Lonworks connector

5-pin male connector

Profibus 26-pin male serial interface and I/O connector

9-pin female Lonworks connector

9-pin female Profibus connector

2

CAUTION

* Do not connect an RS232 port to the 9-pin Lonworks Connector. This may

damage your Laptop PC.

13

Page 30

2

DS6400

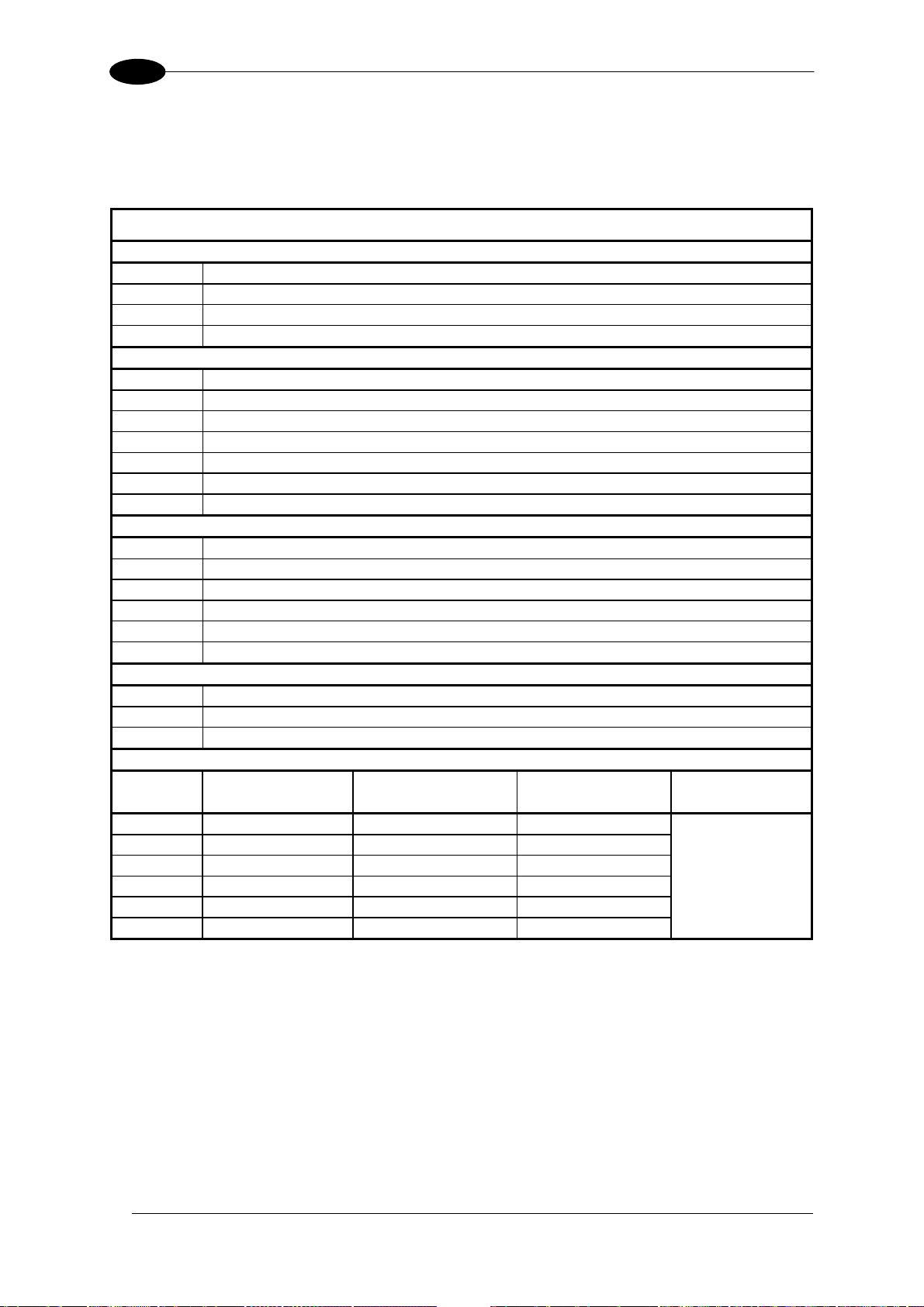

The table below gives the pinout of the C-BOX 100 terminal block connectors. Use this

pinout when the DS6400 reader is connected in a network by means of the

C-BOX 100:

C-BOX 100 Terminal Block Connectors

Power

1, 3, 5 VS

2, 4, 6 GND

7, 8 EARTH GROUND

20, 40 Reserved

Inputs

27 EXT TRIG/PS A (polarity insensitive) for PS

28 EXT TRIG/PS B (polarity insensitive) for PS

29 IN 2/ENC A (polarity insensitive) for Encoder

30 IN 2/ENC B (polarity insensitive) for Encoder

31, 33 IN 3A (polarity insensitive)

32, 34 IN 4A (polarity insensitive)

36 IN 3B/IN 4B Reference (polarity insensitive)

Outputs

21 OUT 1+

22 OUT 1-

23 OUT 2+

24 OUT 2-

25 OUT 3A (polarity insensitive)

26 OUT 3B (polarity insensitive)

Auxiliary Interface

35 TX AUX

37 RX AUX

38, 39 GND

Main Interface

Pin RS232

RS485

Full-Duplex

RS485

Half-Duplex

20 mA C.L.

(with INT-30 only)

11, 15 TX232 TX485+ RTX485+

12, 16 RTS232 TX485- RTX485-

17 RX232 * RX485+

18 CTS232 * RX485-

10, 14, 19

9, 13

SGND Main Isolated SGND Main Isolated SGND Main Isolated

RS485 Cable Shield RS485 Cable Shield

see INT-30

instructions

* Do not leave floating, see par. "RS485 Full-Duplex Interface" for connection details.

14

Page 31

INSTALLATION

2

2.3.1 Main/Aux. Serial Interface and I/O Connector

The DS6400 master/slave model is equipped with a 25-pin male D-sub connector for

connection to the host computer, power supply and input/output signals.

The DS6400 fieldbus models (Ethernet, DeviceNet, Profibus) adopt a 26-pin male connector

instead of the 25-pin one.

The details of the connector pins are indicated in the following table:

1

1

10

Figure 16 - 26-pin Connector Figure 17 - 25-pin Connector

19

26

18

9

14

DS6400 25-pin/26-pin D-sub connector pinout

25

13

Pin Name Function

1 CHASSIS

Chassis - internally connected to GND

Cable shield connected to chassis

20 RXAUX Receive data of auxiliary RS232 (referred to GND)

21 TXAUX Transmit data of auxiliary RS232 (referred to GND)

8 OUT 1+ Configurable digital output 1 - positive pin

22 OUT 1- Configurable digital output 1 - negative pin

11 OUT 2+ Configurable digital output 2 - positive pin

12 OUT 2- Configurable digital output 2 - negative pin

16 OUT 3A Configurable digital output 3 - polarity insensitive

17 OUT 3B Configurable digital output 3 - polarity insensitive

18 EXT_TRIG/PS A External trigger (polarity insensitive) for PS

19 EXT_TRIG/PS B External trigger (polarity insensitive) for PS

6 IN 2/ENC A Input signal 2 (polarity insensitive) for Encoder

10 IN 2/ENC B Input signal 2 (polarity insensitive) for Encoder

14 IN 3A Input signal 3 (polarity insensitive)

15 IN 4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

9,13 VS Supply voltage - positive pin

23,25,26 GND Supply voltage - negative pin

Main Interface Connector Pinout

Pin

RS232

RS485

Full Duplex

RS485

Half Duplex

20 mA C.L.

(INT-30 with C-BOX 100 only)

2 TX TX485 + RTX485 + see INT-30 instructions

3 RX * RX485 +

4 RTS TX485 - RTX485 -

5 CTS * RX485 -

7 GND_ISO GND_ISO GND_ISO

Pin 26 is only available for fieldbus models (Ethernet, DeviceNet, Profibus).

* Do not leave floating, see par. "RS485 Full-Duplex Interface" for connection details.

15

Page 32

2

DS6400

Main Interface

The main serial interface is compatible with the following electrical standards:

RS232

RS485 full-duplex

RS485 half-duplex

(20 mA current loop)

The 20 mA Current Loop interface is available by using the C-BOX 100 with the optional

INT-30 accessory installed in it. The scanner communicates to the C-BOX 100 through the

RS232 interface and the INT-30 converts the signals.

The main serial interface type and its relative parameters (baud rate, data bits, etc.) are

selected via software using the Genius™ utility program. For more details refer to the

section "Main Serial Port" in the Genius™ Help On Line.

Details regarding the connections and use of the main interface selection are given in the

next paragraphs.

RS232 Interface

The main serial interface is used for communication with the Host computer and allows both

transmission of code data and configuring the reader. The overall maximum cable length

should not exceed 15 m (50 ft).

The following pins of the 25-pin and 26-pin connector are used for RS232 interface

connection depending on the reader model:

Pin Name Function

2 TX Transmit

3 RX Receive

4 RTS Request to send

5 CTS Clear to send

7 GND_ISO Main signal ground

The RTS and CTS signals control data transmission and synchronize the connected devices.

If the RTS/CTS hardware protocol is enabled, the DS6400 activates the RTS output to

indicate a message can be transmitted. The receiving unit must activate the CTS input to

enable the transmission.

DS6400

TX

2

3

RX

RTS

4

CTS

5

7

GND_ISO

CHASSIS

1

Figure 18 - RS232 Connections

USER INTERFACE

RXD

TXD

SGND Main Isolated

Earth

Ground

16

Page 33

INSTALLATION

2

RS485 Full-Duplex Interface

The RS485 full-duplex interface is used for non-polled communication protocols in

point-to-point connections over longer distances than those acceptable for RS232

communications or in electrically noisy environments. The overall maximum cable length

should not exceed 1200 m (3937 ft).

The following pins of the 25-pin and 26-pin connector are used for RS485 full-duplex

interface connection:

Pin Name Function

2 TX485 + RS485 output (+)

3 RX485 + RS485 input (+)

4 TX485 - RS485 output (-)

5 RX485 - RS485 input (-)

7 GND_ISO Main signal ground

Figure 19 - RS485 Full-Duplex Interface Connections

DS6400

USER INTERFACE

2

TX485+

3

RX485+

4

TX485-

RX485-

5

7

GND_ISO

1

CHASSIS

RX485+

TX485+

RX485-

TX485-

SGND Main Isolated

Earth

Ground

For applications that do not use RX485 signals, do not leave these lines

NOTE

floating but connect them to GND_ISO as shown below.

DS6400

2

4

3

5

7

1

TX485+

TX485-

RX485+

RX485-

GND_ISO

CHASSIS

USER INTERFACE

RX485+

RX485-

SGND Main Isolated

Earth

Ground

Figure 20 - RS485 Full-Duplex Interface Connections Using Only TX Signals

17

Page 34

2

DS6400

RS485 Half-Duplex Interface

The RS485 half-duplex interface can be used for multidrop connections with a Datalogic

multiplexer or it can also be used for a master/slave layout. The overall maximum cable

length should not exceed 1200 m (3937 ft).

The following pins of the 25-pin and 26-pin connector are used for RS485 half-duplex

interface connection:

Pin Name Function

2 RTX485 + RS485 input/output (+)

4 RTX485 - RS485 input/output (-)

7 GND_ISO Main signal ground

Figure 21 – RS485 Half-Duplex Interface Connections

DS6400

MULTIPLEXER

2

RTX485+

4

RTX485-

7

GND_ISO

1

CHASSIS

RTX485+

RTX485-

RS485REF

Earth

Ground

18

Page 35

INSTALLATION

2

Auxiliary Interface

The auxiliary serial interface is equipped with RS232 full-duplex interface connections. The

interface type is exclusive and is selectable through the Genius™ configuration program. The

overall maximum cable length should not exceed 15 m (50 ft).

The following pins of the 25-pin and 26-pin connector are used for RS232 full-duplex

interface connection:

Pin Name Function

20 RXAUX Receive data

21 TXAUX Transmit data

23 SGND AUX Auxiliary signal ground

DS6400

USER INTERFACE

20

RXAUX

21

TXAUX

23

GNDAUX

1

CHASSIS

TXD

RXD

GND

Earth

Ground

Figure 22 - RS232 Auxiliary Interface Connections

19

Page 36

2

DS6400

Inputs

The inputs of the reader are on the 25-pin and 26-pin connector (Figure D, 1 and Figure E, 1)

of the DS6400.

These inputs are called EXT_TRIG/PS, IN2/ENC, IN3 and IN4.

Pin Name Function

18 EXT_TRIG/PS A External trigger (polarity insensitive) for PS

19 EXT_TRIG/PS B External trigger (polarity insensitive) for PS

6 IN2/ENC A Input signal 2 (polarity insensitive) for Encoder

10 IN2/ENC B Input signal 2 (polarity insensitive) for Encoder

14 IN3A Input signal 3 (polarity insensitive)

15 IN4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

IN2/ENC is normally used for the Encoder input. In PackTrack™ mode, it detects the

conveyor speed. The maximum Encoder frequency is 2 KHz.

EXT_TRIG/PS is the main presence sensor. When active, this input tells the scanner to scan

for a code and that decoding can take place. The yellow LED (Figure C,3) indicates the

EXT_TRIG/PS is active.

IN3 and IN4 can be used as the stop signal for the reading phase.

All inputs are optocoupled, polarity insensitive, and driven by a constant current generator;

the command signal is filtered through an anti-disturbance circuit which generates a delay

which can be set to 5 ms or 500 µs. In particular, EXT_TRIG/PS, IN3 and IN4 share the

same value which usually corresponds to 5 ms when using a photoelectric sensor, while

IN2/ENC has a different value which is set to 500 µs when this input is used for the Encoder.

+ 5V

DS6400

+

A/B

~

-

~

B/A

Vext

EXTERNAL TRIGGER/ENCODER

V

Ground

20

Figure 23 – PNP Command Input Connection using External Power

DS6400

VS

A/B

+ 5V

~

-

+

~

B/A

GND

EXTERNAL TRIGGER/ENCODER

V

Ground

Figure 24 - PNP Command Input Connection using Scanner Power

Page 37

INSTALLATION

2

DS6400

+ 5V

EXTERNAL TRIGGER/ENCODER

Vext

A/B

~

-

+

~

B/A

V

Ground

Figure 25 - NPN Command Input Connection using External Power

+ 5V

DS6400

+

VS

A/B

~

-

~

B/A

GND

EXTERNAL TRIGGER/ENCODER

V

Ground

Figure 26 - NPN Command Input Connection using Scanner Power

DS6400

Vext

EXTERNAL DEVICE

V

+ 5V

+ 5V

~

+

~

~

+

~

IN3A

-

Ground

Vext

V

IN4A

-

INREF

Ground

Figure 27 - IN3/IN4 PNP Input Command using External Power

21

Page 38

2

DS6400

+ 5V

+ 5V

DS6400

~

-

+

~

~

-

+

~

VS

INREF

IN3A

IN4A

GND

EXTERNAL DEVICE

V

Ground

EXTERNAL DEVICE

V

Ground

Figure 28 - IN3/IN4 NPN Input Command using Scanner Power

Input devices can be supplied by either scanner power (VS and GND) or external power

supplies (Vext).

Electrical isolation between the input command logic and the scanner is maintained when

powering the input devices from an external supply voltage (Vext).

The driving logic of the input signals may be powered, for convenience, with the voltage

supply between pins 9 (VS) and 23 (GND) of the 26-pin I/O connector. In this case, however,

the device is no longer electrically isolated.

The voltage available on the 26-pin I/O connector, is physically the same as used to power

the scanner.

The electrical features of these inputs are:

Maximum voltage 30 V

Maximum current 10 mA

Outputs

Three general purpose outputs are available.

Pin Name Function

8 OUT 1+ Configurable digital output 1 – positive pin

22 OUT 1- Configurable digital output 1 – negative pin

11 OUT 2+ Configurable digital output 2 – positive pin

12 OUT 2- Configurable digital output 2 – negative pin

16 OUT 3A Configurable digital output 3 – polarity insensitive

17 OUT 3B Configurable digital output 3 – polarity insensitive

The function of the three outputs OUT1, OUT2 and OUT3 can be defined by the user.

Refer to Genius™ Help On-Line for further details.

22

Page 39

INSTALLATION

2

By default, OUT1 is associated with COMPLETE READ event, which activates when the code

has been read correctly. In case the reader has been programmed to read several codes

within the same reading phase, the event activates when all codes have been read.

OUT2 is associated with NO READ event, which activates when no code has been read.

OUT3 is associated with NONE, which means that the output is always in Line State.

The OUT1 and OUT2 electrical features are given below:

Collector-emitter voltage 30 V Max.

Collector current (pulse) 130 mA Max.

Collector current (continuous) 40 mA Max.

Saturation voltage (VCE) 1 V at 10 mA Max.

Maximum power dissipation 90 mW at 50°C (Ambient temperature).

The limit requested by the maximum power dissipation is more important than that of the

maximum collector current: if one of these outputs is continuously driven, the maximum

current must not be more than 40 mA although 130 mA may be reached in pulse conditions.

DS6400

USER INTERFACE

30 Vdc max

Vext

+

-

Figure 29 – Output 1 and Output 2 Interface

When the load is powered by an external power supply, the voltage must be less than 30 V.

OUT3 has different electrical features, since it is a bi-directional solid state relay with built-in

current limit protection. If this output is continuously driven, the maximum current must be not

more than 200 mA although more than 300 mA may be reached in pulse conditions for an

ambient temperature of 25°C. At the maximum ambient temperature of 50°C the maximum

respective current is 150 mA continuous and 240 mA pulse.

The OUT3 electrical features are given below:

Maximum voltage ± 100 V

Collector current (pulse) 240 mA Max.

Collector current (continuous) 150 mA Max.

R on 6 – 15 Ω

R off > 500 Ω

Off-state leakage current < 1 µA

Maximum power dissipation 550 mW at 50°C (Ambient temperature).

23

Page 40

2

DS6400

DS6400

A

B

USER INTERFACE

100 Vdc max

Vext

Figure 30 – Output 3 Interface

The command signal is filtered and generates a delay of about 50 µs for OUT1 and OUT2

and 1 ms for OUT3.

2.3.2 Lonworks Connectors

Do not connect an RS23

damage your Laptop PC.

CAUTION

The local network used by DS6400 exploits a Lonworks standard communication system

requiring only two wires (polarity insensitive) to enable a connection. The connector also

rovides a positive and a negative supplying wire. In this way, all the slave readers can be

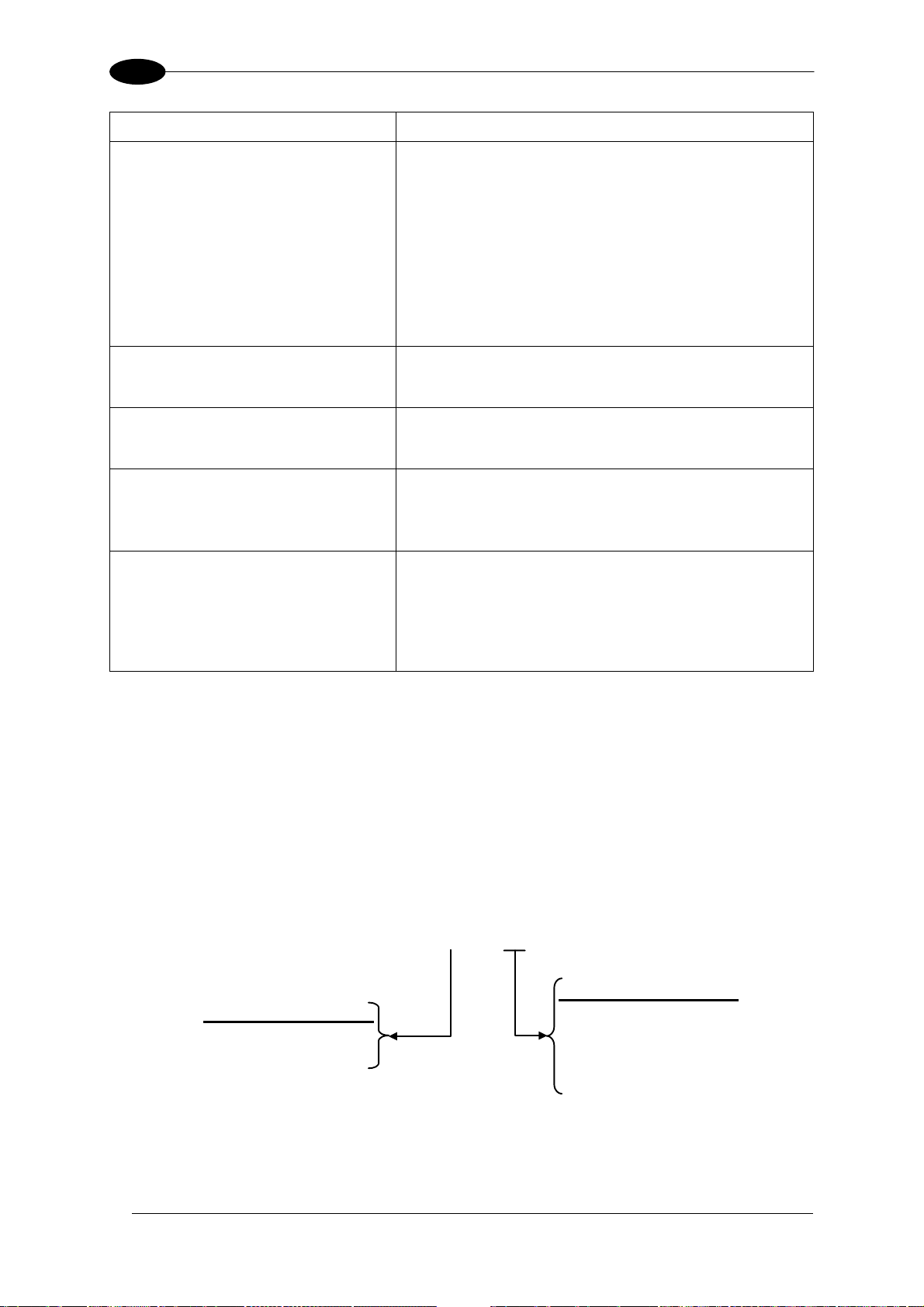

p

powered by the master through the Datalogic standard cables.

When working in applications requiring enhanced synchronization capabilities, the DS6400

master reader (output) transmits two system signals named Sys_I/O and Sys_Enc_I/O to

slave readers (input). For example, when working with applications requiring an encoder the

signal is received by the master and directly transmitted to the slaves throug

he internal circuits generating the system signals are externally supplied by means of the

T

VS_I/O and REF_I/O pins and are isolated from the reader supply voltage.

The use of these system circuits is not required in all the operating modes (see pa

etails). Anyway, for a correct system functioning it is suggested to use Datalogic cables and

d

ccessories and follow the description of the typical layout (see par. 2.7 for details).

a

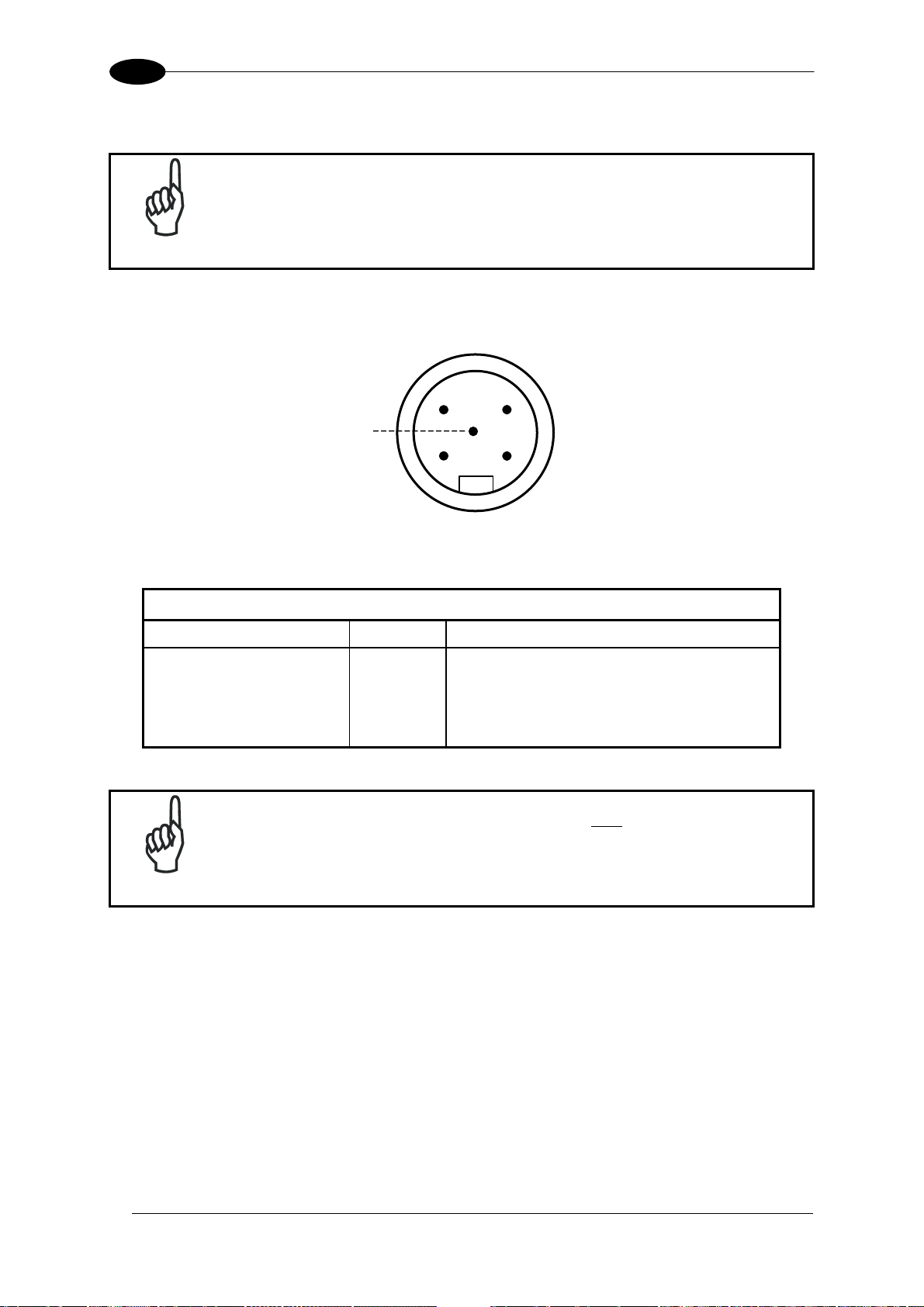

5

1

2 port to the 9-pin Lonworks Connector. This may

the

h the cable.

r. 2.7 for

1

5

24

9

Female (all mode

6

ls)

Figure 31 – 9-pin Local Lonworks Connectors

Male (Master/Slave model)

6

9

Page 41

INSTALLATION

2

DS6400 9-pin Lonworks connector pinout

Pin Name Function

1 CHASSIS cable shield internally connected by capacitor to chassis

9 VS Supply voltage - positive pin

2 GND Supply voltage - negative pin

6 VS_I/O Supply voltage of I/O circuit

3 Ref_I/O Reference voltage of I/O circuit

4 SYS_ENC_I/O System signal

5 SYS_I/O System signal

7 LON A Lonworks line (polarity insensitive)

8 LON B Lonworks line (polarity insensitive)

Network Termination

When building a Lonworks system the network must be properly terminated by positioning

BTK-6000 terminator in the DS6400 master reader and in the last DS6400 slave reader.

Each side of the terminator provides a different connector; thus, it can be inserted either into

the Lonworks 9-pin male connector of the master reader or in the Lonworks 9-pin female

connector of the last slave reader:

Slave

Master

NOTE

Female

Male

Male

Female

Figure 32 - BTK-6000 Network Terminator

For Fieldbus models no terminator must be inserted in the reader, since it

is internally integrated.

25

Page 42

2

r

r

DS6400

Lonworks Interface

The Lonworks network is used for both input and output connection to build a multi-sided or

omni-station system connecting several readers.

The DS6400 master usually employs the 9-pin female connector for output connection to the

first slave, while the 9-pin male one is terminated by inserting the BTK6000 terminator (see

par. 2.7.2 for details). If creating a T network configuration, it is necessary to use both

connectors to create the double branch line of slave readers.

Both connectors are always employed when connecting together the slave readers. In

particular, the 9-pin female connector is used for output connection and the male one for

input connection. The female connector is always terminated in the last slave reader to close

the system network.

The following diagram represents the connection between a DS6400-XXX-010 working as

master and a DS6400-XXX-010 working as a slave reader.

The cable shield for LON A/B is connected to pin 1 - CHASSIS.

Master

VS_I/O

Slave

REF_I/O

LON A

LON B

CHASSIS

VS

GND

4

5

3

7

8

1

AWG 16

9

AWG 16

2

= male connecto

= female connecto

4

5

3

7

8

CHASSIS

1

9

2

Figure 33 – DS6400-XXX-010 Master/Slave Lonworks Connection

The maximum current to be propagated to the slave readers through the

master is 2 A.

For this reason, it is suggested the use of a 24 V power supply allowing to

CAUTION

supply up to three readers (master + 2 slaves).

The following diagrams represent different network terminations using the BTK-6000

terminator. In each diagram the terminator is indicated by the

element, while the figure

elow shows its electrical circuit in details: b

Figure 34 – BTK-6000 Electrical Circuit

26

Page 43

INSTALLATION

r

r

r

r

r

r

2

The diagram below represents the termination of a DS6400-XXX-010 working as master by

means of the BTK-6000 terminator.

Master

VS

VS_I/O

LON A

LON B

GND

REF_I/O

9

6

7

8

2

3

= male connecto

= female connecto

Figure 35 – DS6400-XXX-010 Master Termination

BTK-6000 Female Side

9

6

7

8

2

3

T

The diagram below represents the termination of a DS6400-XXX-010 working as slave by

means of the BTK-6000 terminator.

Slave BTK-6000 Male Side

LON A

LON B

7

8

7

8

T

= male connecto

= female connecto

Figure 36 – DS6400-XXX-010 Slave Termination

The diagram below represents the connection between a DS6400 Fieldbus model, which

always works as master, and a DS6400-XXX-010 working as a slave reader.

Fieldbus Master

REF_I/O

VS_I/O

LON A

T

LON B

CHASSIS

VS

GND

4

5

3

7

8

1

AWG 16

9

AWG 16

2

= male connecto

= female connecto

Figure 37 – DS6400-XXX-010 Master/Slave Lonworks Connection

Slave

4

5

3

7

8

CHASSIS

1

9

2

27

Page 44

2

DS6400

2.3.3 Ethernet Connector

This connector is only available for DS6400 Ethernet models and allows the Ethernet

connection between the host and the reader.

8

1

Figure 38 – Cable RJ45 Male Modular Connector

1

Figure 39 – DS6400 RJ45 Female Modular Connector

8

This interface and the connector pinout (see the following table) are IEEE 802.3 10 BaseT

and IEEE 802.3u 100 Base Tx c

ompliant.

Modu

RJ45 lar Jack Pinout

P in Name Function

1 TX + Transmitted data (+)

2 TX - Transmitted data (-)

3 RX + Received data (+)

6 RX - Received data (-)

4, 5, 7, 8 N.C. Not connected

In order to meet EMC requirements:

• use Eth shielded cable

connect the Ethernet interface cable

• shield to the plant earth ground

The cable shield must be connected to the chassis of both connectors.

A ferrite (type Stewart 28A2029-0A0) may also be applied on the scanner

NOTE

side of the Ethernet cable to reduce electrical noise.

28

Page 45

INSTALLATION

2

Ethernet Interface

The Ethernet interface (NIC) can be used for TCP/IP communication with remote or local

host computer by connecting the scanner to a LAN as well as with a host PC directly

connected to the scanner.

The following is an example of a connection to a LAN through a Hub using a straight through

cable:

DS6400

HUB / SWITCH

TX+

1

TX-

2

RX+

3

n. c.

4

n. c.

5

RX-

6

n. c.

7

n. c.

8

n. c. = not connected

1

2

3

4

5

6

7

8

Figure 40 – Straight Through Cable

The following is an example of direct connection to a PC using an inverted cable:

DS6400

TX+

1

TX-

2

RX+

3

n. c.

4

n. c.

5

HOST PC

3

6

1

4

5

RX-

6

n. c.

7

n. c.

8

n. c. = not connected

2

7

8

Figure 41 – Inverted Cable

For further details refer to the “Ethernet Service Guide” document provided as reference

documentation.

29

Page 46

2

DS6400

2.3.4 DeviceNet Connector

When using DeviceNet, the Main serial interface is disabled and must not

NOTE

The 5-pin male connector is only available in the DS6400 DeviceNet model and allows

connection between the host and the reader:

be physically connected.

NOTE

4

5

1

3

2

Figure 42 - DeviceNet 5-pin Male Connector

DS6400 evic

5-pin D eNet connector pinout

P n in Name Functio

2 V + Supply voltage – positive pin

5 CAN_L CAN bus data line – L

1 SHIELD Shield

4 CAN_H CAN bus data line – H

3 V - Supply voltage – negative pin

The power supplied on pin V+ and V- is used only to propagate power to

the section of the DeviceNet board directly connected to the Bus. It is

completely isolated from the DS6400 power which must be supplied on

pin 9, 13 and pin 23, 25 of the 26-pin Main/Aux connector.

30

Page 47

INSTALLATION

2

2.3.5 Profibus Connector

The 9-pin Profibus female connector (white) is only available in the DS6400 Profibus model

and allows connection between the host and the reader:

5

9

Figure 43 - Profibus 9-pin Female Connector

DS6400 9-pin Profibus connector pinout

Pin Name Function

1 Shield* Shield, Protective Ground resp.

2 Free

3 B-LINE (RxD/TxD-P) Received/Transmitted Data-P

4 CNTR-P** Repeater Control Signal

5 DGND Data Ground (M5V)

6 +5 V Voltage Plus (P5V)

7 Free

8 A-LINE (RxD/TxD-N) Received/Transmitted Data

9 CNTR-N** Repeater Control Signal

1

6

* signal is optional

** signal is optional; RS485 level

Profibus Interface

The Profibus interface is used for communication with an Host and allows expanding the

networking and remote diagnostic capabilities of the scanner.

For further details refer to the “Profibus_Fam6k.pdf” document provided as supplementary

documentation.

31

Page 48

2

DS6400

2.3.6 Power Supply

The supply voltage of a single scanner must be between 15 and 30 VDC.

Datalogic strongly recommends a minimum 24 VDC supply voltage when using a

master/slave configuration.

The power consumption of the different DS6400 models is slightly different.

In particular, when connecting several DS6400 readers in a master/slave connection, the

typical power consumption for each scanner is 15 W. There is a power peak of about

20 W lasting 5..10 seconds caused by the motor starting.

A security system allows the laser to activate only once the motor has reached the correct

rotational speed; consequently, the laser beam is generated after a slight delay from the

power on of the scanner.

Note that GND is internally connected to chassis. The cable shield is also connected to

pin 1 - CHASSIS.

DS6400

USER INTERFACE

Chassis

Figure 44 – Power Supply Using the 25/26-pin Connector

2.4 USER INTERFACE

1

9-pin male connector

Pin Name Pin Name

2 RX 3 RX

3 TX 2 TX

5 GND 7 GND

7 RTS 4 RTS

8 CTS 5 CTS

9/13

23/25

1

VS

GND

CHASSIS

V+ (15 – 30 Vdc)

V- (Ground)

RS232 PC-side connections

1

5

9 6

25-pin male connector

Earth Ground

13

25 14

32

Page 49

INSTALLATION

2

How To Build A Simple Interface Test Cable:

The following wiring diagram shows a simple test cable including power, external

(push-button) trigger and PC RS232 COM port connections.

DS6400

25-pin D-sub female

21

20

23

13

25

9

18

19

Trigger

TXAUX

RXAUX

GND

VS

GND

VS

EXT TRIG A

EXT TRIG B

9-pin D-sub female

Power Supply

VS (15 – 30 VDC)

Power GND

2

RX

PC

3

TX

5

GND

Test Cable for DS6400

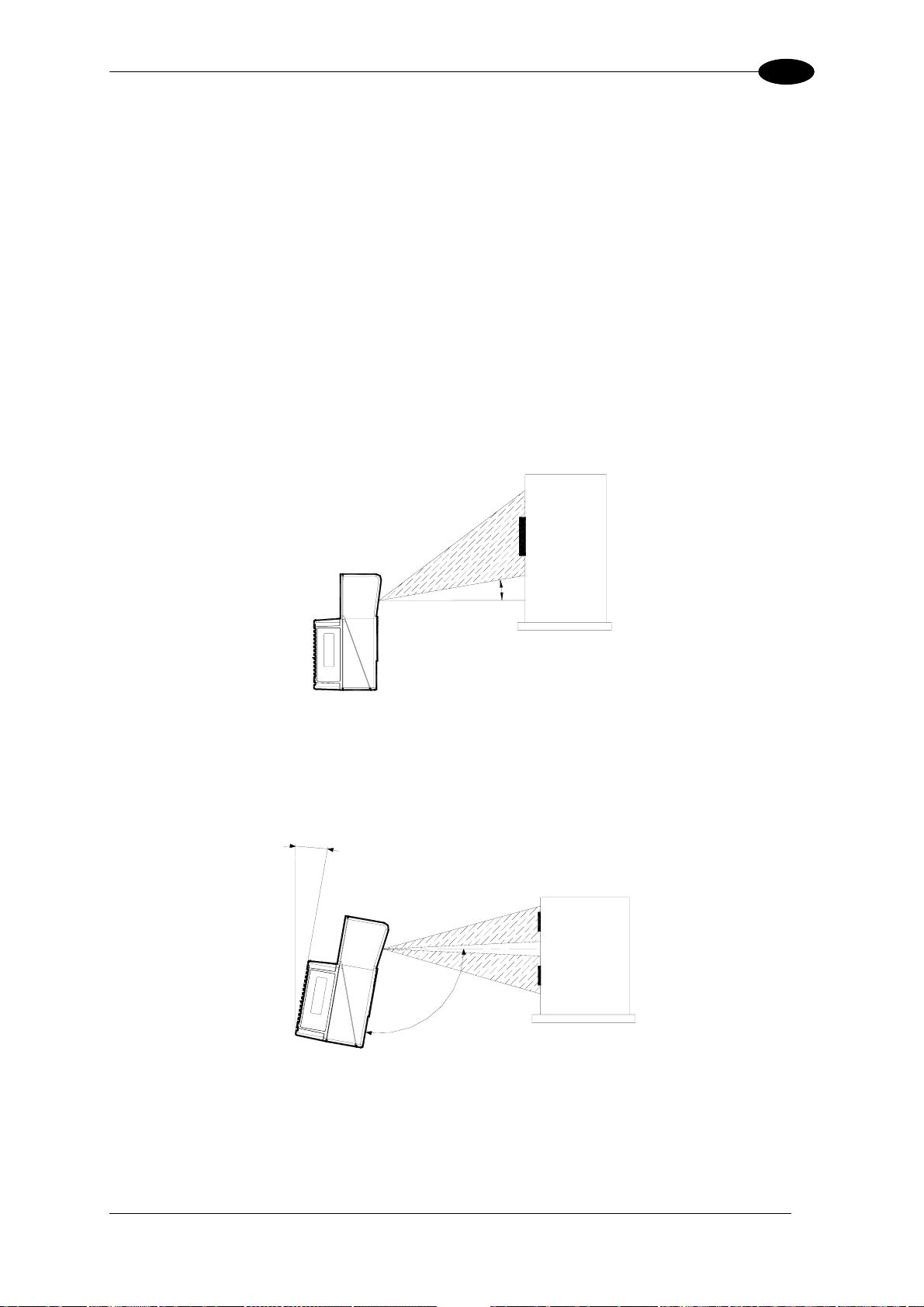

2.5 POSITIONING THE SCANNER

The DS6400 reader is able to decode moving barcode labels at a variety of angles, however

significant angular distortion may degrade reading performance.

When mounting DS6400 take into consideration these three ideal label position angles:

Pitch 0°, Skew 10° to 30° and Tilt 0°.

Follow the suggestions for the best orientation:

The Pitch angle is represented by the value P in Figure 45. Position the reader in order to

minimize the Pitch angle.

P

Figure 45 - "Pitch" Angle

33

Page 50

2

DS6400

The Skew angle is represented by the value S in Figure 46. Position the reader to assure at

least 10° for the Skew angle. This avoids the direct reflection of the laser light emitted by the

scanner.

For oscillating mirror models, this angle refers to the most inclined or external laser line, so that

all other laser lines assure more than 10° Skew.

S

Figure 46 - "Skew" Angle

The Tilt angle is represented by the value T in Figure 47.

Figure 47 - "Tilt" Angle

T

34

Page 51

INSTALLATION

2

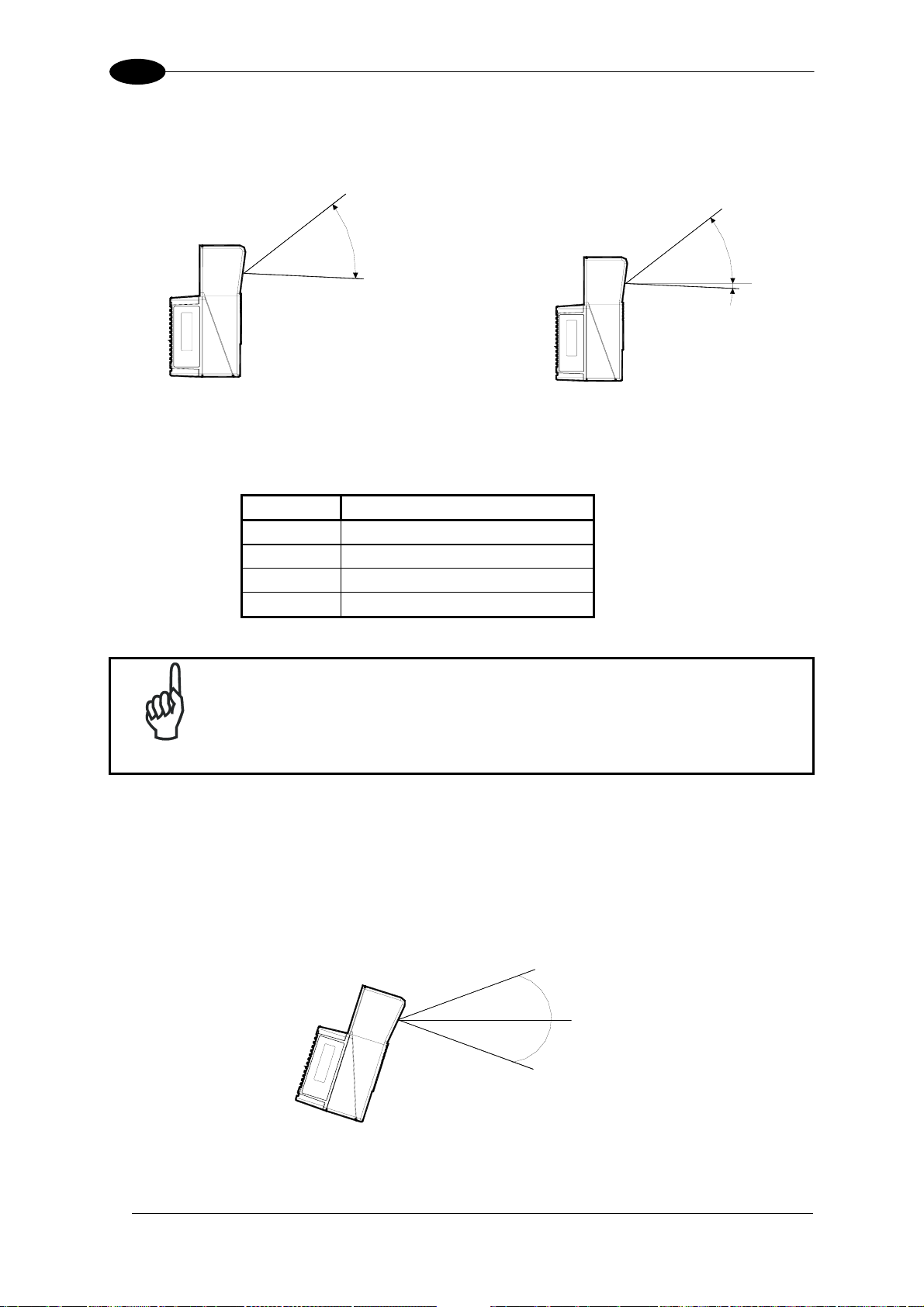

2.6 TYPICAL INSTALLATIONS

2.6.1 Standard Installation

The DS6400 scanner is mounted on the ST-237 106° mounting bracket (see Figure 9) which

guarantees a built-in Skew angle (S in the figure below) of 16° with respect to the frame

plane (typically the Skew angle should be between 10° - 20°). This avoids the direct

reflection of the laser light emitted by the scanner. Furthermore, the bracket guides allow

adjusting the Tilt angle (T in the figure below, which is typically 0°) for the best scanner

orientation:

T

S

Conveyor Direction

Figure 48 – Standard Installation

2.6.2 “45° Skew” Installation

The DS6400 scanner is mounted on the ST-210 90° mounting bracket (see Figure 11). By

adjusting the mounting bracket guides, reach 45° for the Skew angle (S in the figure below)

to avoid the direct reflection of the laser light emitted by the scanner:

45°

Figure 49 – 45° Skew Installation

S

35

Page 52

2

ATTENTION

If using the “45° Skew” installation, the scanner reading performance is

not guaranteed to match that measured for the standard installation with

Skew angle between 10° - 20° (see reading diagrams in par. 4.4.1).

DS6400

NOTE

The ST-210 mounting bracket is an accessor

model available in the US-60 kit (890001020).

y of the DS6400 standard

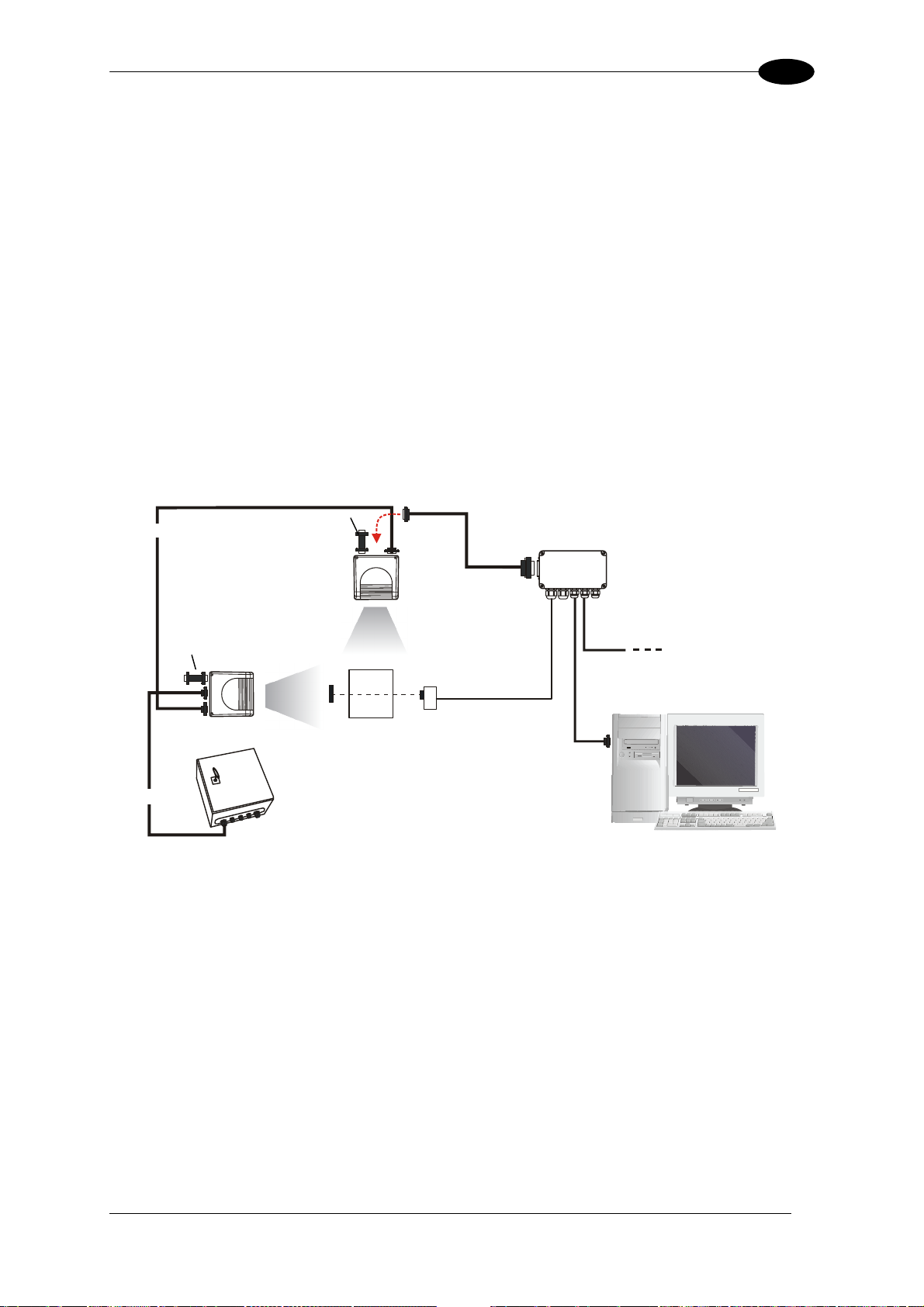

2.7 TYPICAL LAYOUTS

The DS6400 scanners can be connected in a variety of layouts depending on the number of