Page 1

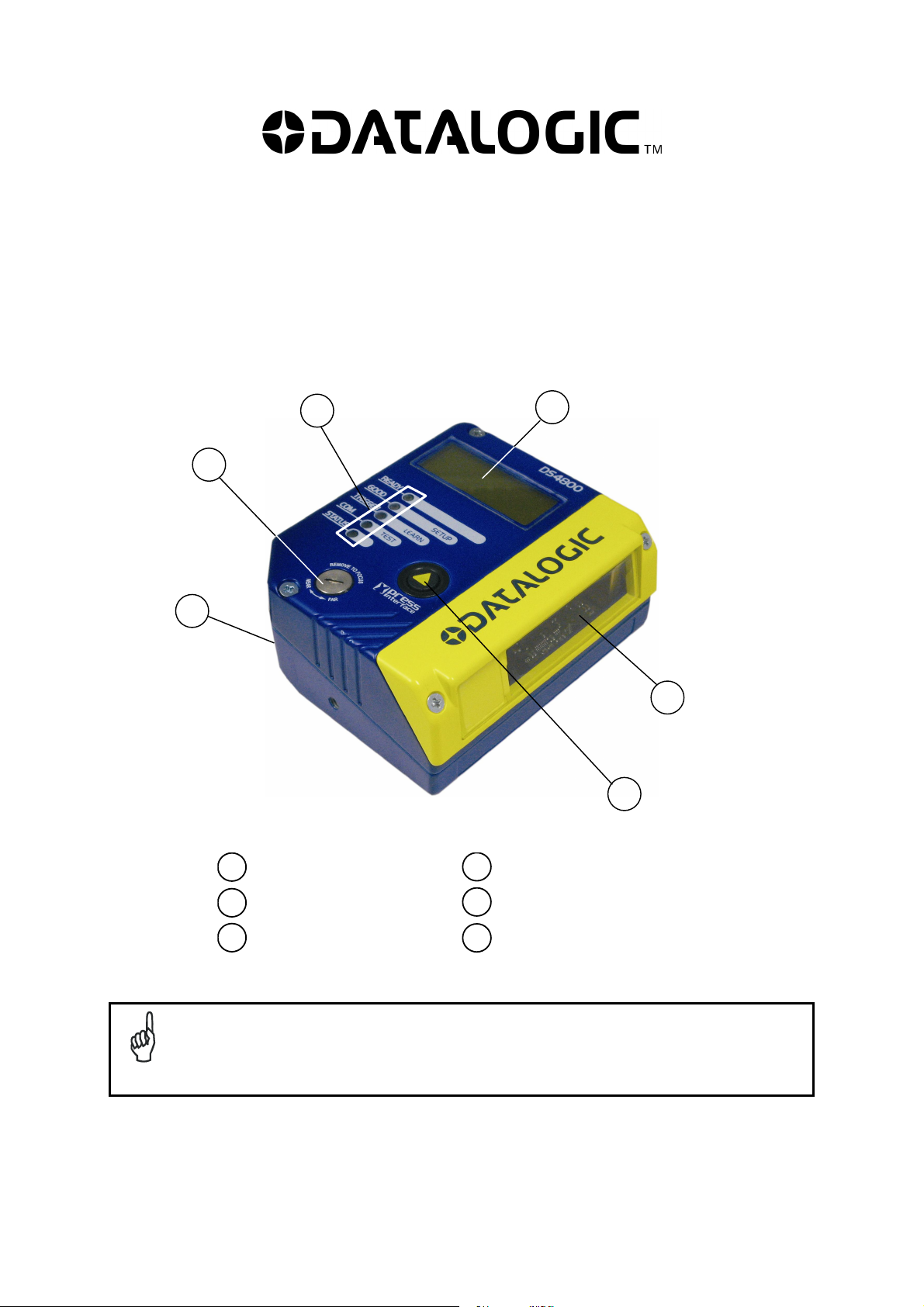

DS4800

QUICK REFERENCE GUIDE

3

2

4

NOTE

1

5

6

Figure A

"POWER ON" LED

1

Focus Adjustment

2

Indicator LEDs

3

This manual illustrates a Stand Alone application. For other types of installations, such as

ID-NET™, Pass-Through, Multiplexer Layout, etc. and for a complete scanner configuration using

Genius™ configuration program, refer to the DS4800 Reference Manual available on the CD.

This manual is also downloadable from the Web at www.automation.datalogic.com/ds4800.

Display

4

Laser Beam Output Window

5

Push Button

6

Page 2

DS4800 QUICK GUIDE

UPDATES AND LANGUAGE AVAILABILITY

UK/US

The latest drivers and documentation updates for this product are available on Internet.

Log on to: www.automation.datalogic.com

I

Su Internet sono disponibili le versioni aggiornate di driver e documentazione di questo prodotto. Questo manuale

è disponibile anche nella versione italiana.

Collegarsi a: www.automation.datalogic.com

F

Les versions mises à jour de drivers et documentation de ce produit sont disponibles sur Internet. Ce manuel est

aussi disponible en version française.

Cliquez sur : www.automation.datalogic.com

D

Im Internet finden Sie die aktuellsten Versionen der Treiber und Dokumentation von diesem Produkt. Die

deutschsprachige Version dieses Handbuches ist auch verfügbar.

Adresse : www.automation.datalogic.com

E

En Internet están disponibles las versiones actualizadas de los drivers y documentación de este producto.

También está disponible la versión en español de este manual.

Dirección Internet : www.automation.datalogic.com

SERVICES AND SUPPORT

Datalogic provides several services as well as technical support through its website. Log on to

www.automation.datalogic.com and click on the links

indicated for further information including:

• PRODUCTS

Search through the links to arrive at your product page where you can download specific Manuals and

Software & Utilities

- Genius™ a utility program, which allows device configuration using a PC. It provides RS232 interface

configuration.

including:

• SERVICES & SUPPORT

- Datalogic Services - Warranty Extensions and Maintenance Agreements

- Authorised Repair Centres

• CONTACT US

E-mail form and listing of Datalogic Subsidiaries

2

Page 3

DS4800 QUICK GUIDE

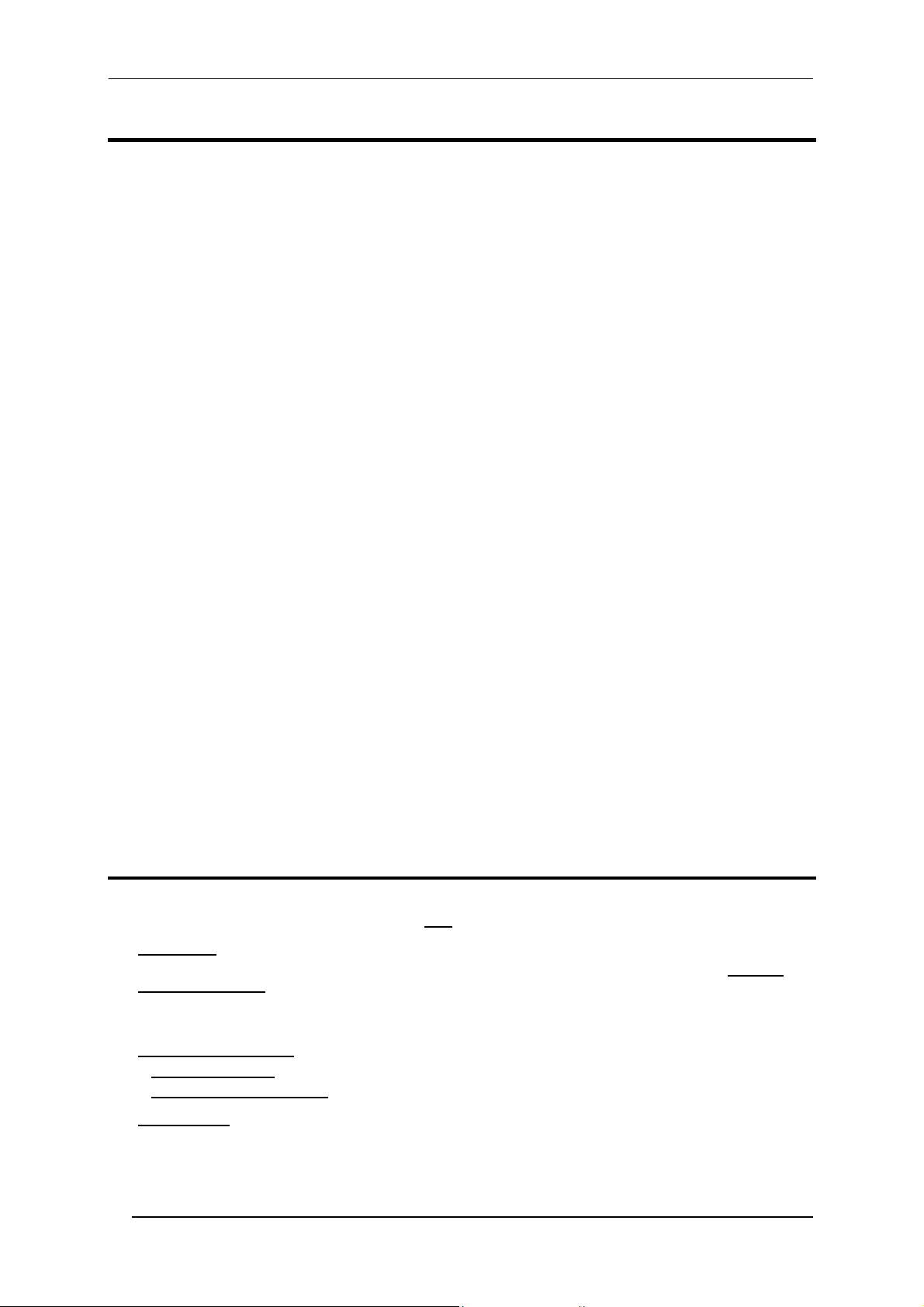

STEP 1 – CONNECT THE SYSTEM

To connect the system in a Stand Alone configuration, you need the hardware indicated in Figure 1. In this layout

the data is transmitted to the Host on the main serial interface. In Local Echo communication mode, the RS232

auxiliary interface can be used to transmit data independently from the main interface selection. When On-Line

Operating mode is used, the scanner is activated by an External Trigger (photoelectric sensor) when the object

enters its reading zone.

PG 6000

MAIN

DS4800

P.S.*

Figure 1 – DS4800 in Stand Alone Layout

CBX100/500

I/O, AUX

Host

* Presence Sensor

(for On-Line mode)

CBX100/500 Pinout for DS4800

The table below gives the pinout of the CBX100/500 terminal block connectors. Use this pinout when the DS4800

reader is connected by means of the CBX100/500:

CBX100/500 Terminal Block Connectors

Power Outputs

Vdc Power Supply Input Voltage + +V Power Source - Outputs

GND Power Supply Input Voltage - -V Power Reference - Outputs

Earth Protection Earth Ground O1+ Output 1 +

O1- Output 1 -

Inputs

+V Power Source – External Trigger O2- Output 2 I1A External Trigger A (polarity insensitive)

I1B External Trigger B (polarity insensitive) TX Auxiliary Interface TX

-V Power Reference – External Trigger RX Auxiliary Interface RX

+V Power Source – Inputs SGND Auxiliary Interface Reference

I2A Input 2 A (polarity insensitive)

I2B Input 2 B (polarity insensitive) REF Network Reference

-V Power Reference – Inputs ID+ ID-NET™ network +

Shield

Shield Network Cable Shield

Main Interface

RS232 RS485 Full-Duplex RS485 Half-Duplex

TX TX+ RTX+

RTS TX- RTX RX

CTS

SGND SGND SGND

O2+ Output 2 +

Auxiliary Interface

ID-NET™

ID- ID-NET™ network -

*RX+

*RX-

* Do not leave floating, see Reference Manual for connection details.

Do not connect GND, SGND and REF to different (external) ground references. GND, SGND

and REF are internally connected through filtering circuitry which can be permanently

CAUTION

damaged if subjected to voltage drops over 0.8 Vdc.

3

Page 4

DS4800 QUICK GUIDE

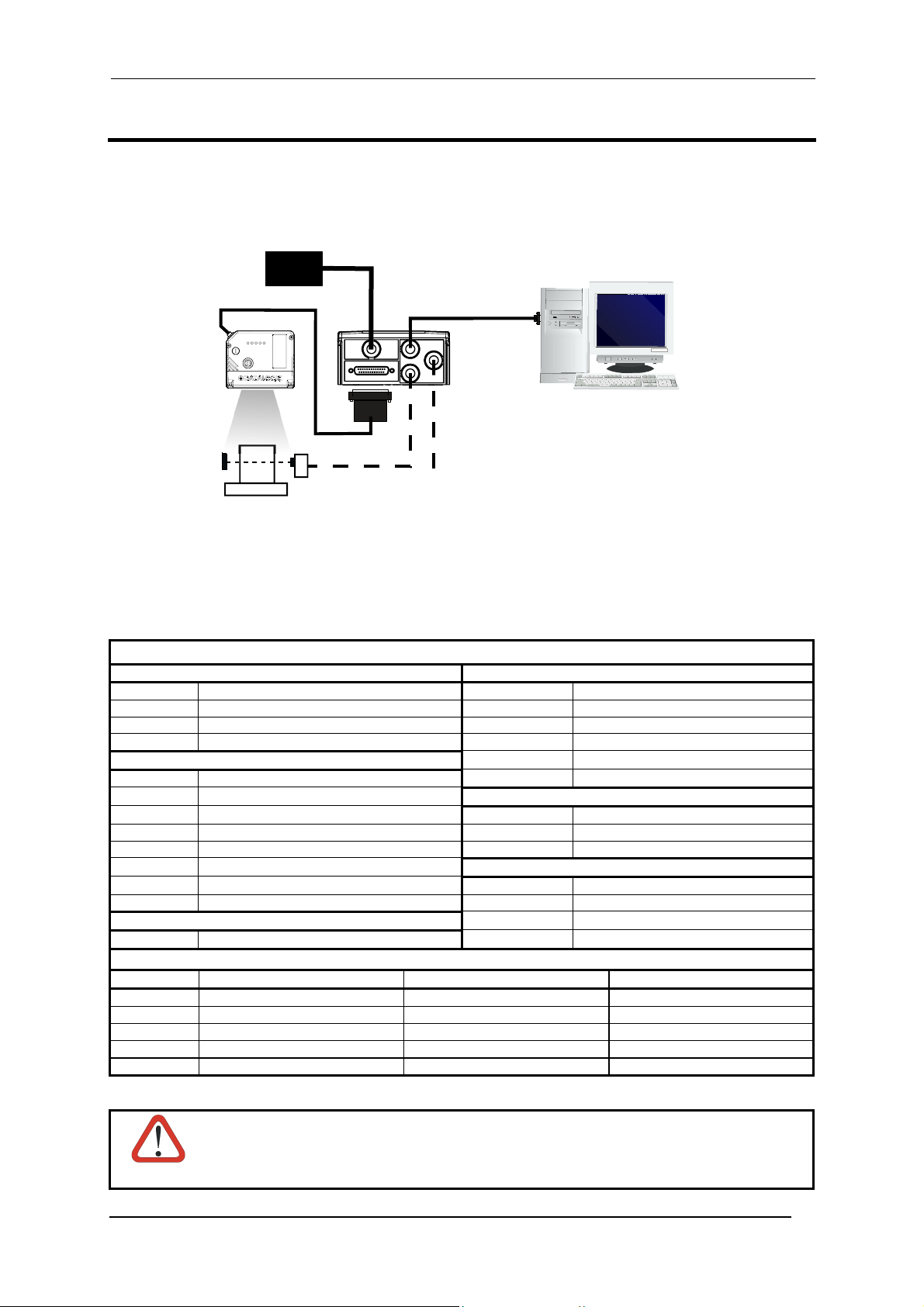

25-pin Connector Pinout for DS4800

The table below gives the pinout of the 25-pin male D-sub connector for connection to the power supply and

input/output signals. Use this pinout when the DS4800 reader is connected by means of the 25-pin connector:

Pin Name Function

13, 9 Vdc Power supply input voltage +

25, 7 GND Power supply input voltage -

1 CHASSIS Cable shield connected to chassis

18 I1A External Trigger A (polarity insensitive)

19 I1B External Trigger B (polarity insensitive)

6 I2A Input 2 A (polarity insensitive)

10 I2B Input 2 B (polarity insensitive)

8 O1+ Output 1 +

22 O1- Output 1 11 O2+ Output 2 +

12 O2- Output 2 20 RX Auxiliary RS232 RX

21 TX Auxiliary RS232 TX

23 ID+ ID-NET™ network +

24 ID- ID-NET™ network -

14, 15, 16, 17 NC Not Connected

Pin Name RS232

2 TX TX+ RTX+

3 RX

4 RTS TX- RTX-

5

* Do not leave floating, see Reference Manual for connection details.

MAIN INTERFACE

(SW SELECTABLE)

1

Figure 2 - 25-pin Male D-sub Connector

25-pin D-sub male connector pinout

CTS

13

2514

RS485

Full-Duplex

*RX+

*RX-

RS485

Half-Duplex

4

Page 5

DS4800 QUICK GUIDE

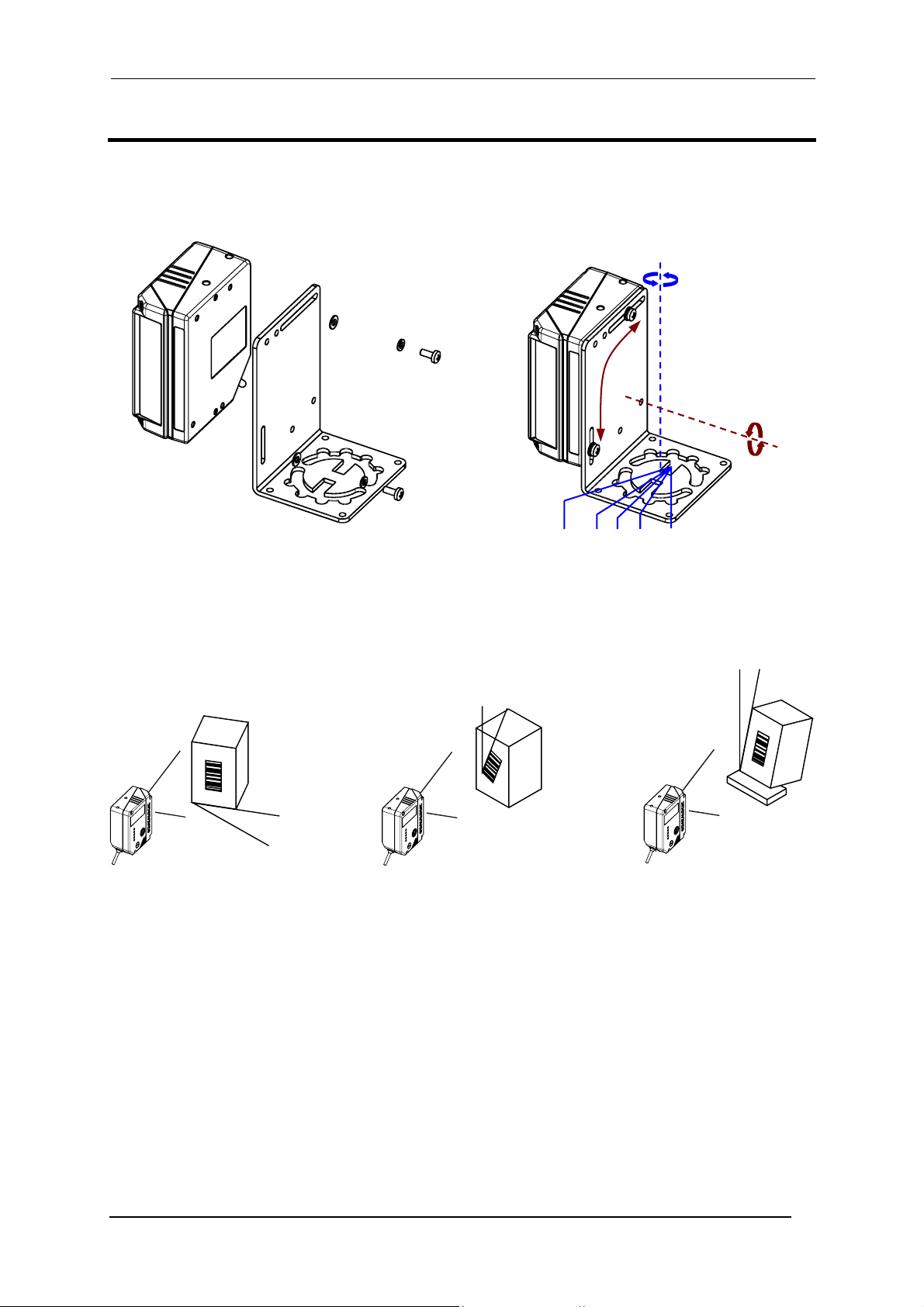

STEP 2 – MOUNT AND POSITION THE SCANNER

1. To mount the DS4800, use the mounting bracket to obtain the most suitable position for the reader as shown

in the figures below.

Skew

Pitch

Figure 3 - Positioning with Mounting Bracket

2. When mounting the DS4800 take into consideration these three ideal label position angles: Skew 15° to 30°,

Tilt 0° and Pitch 0°.

S

Assure at least 15° Minimize Minimize

Figure 4 –Skew, Tilt and Pitch Angles

3. Refer to the Reading Diagrams in the Appendix of this Quick Reference Guide to decide the distance your

scanner should be positioned at.

-45° -15° 0° 15° 45°

P

T

5

Page 6

DS4800 QUICK GUIDE

r

T

T

T

T

T

T

T

T

T

T

T

T

T

T

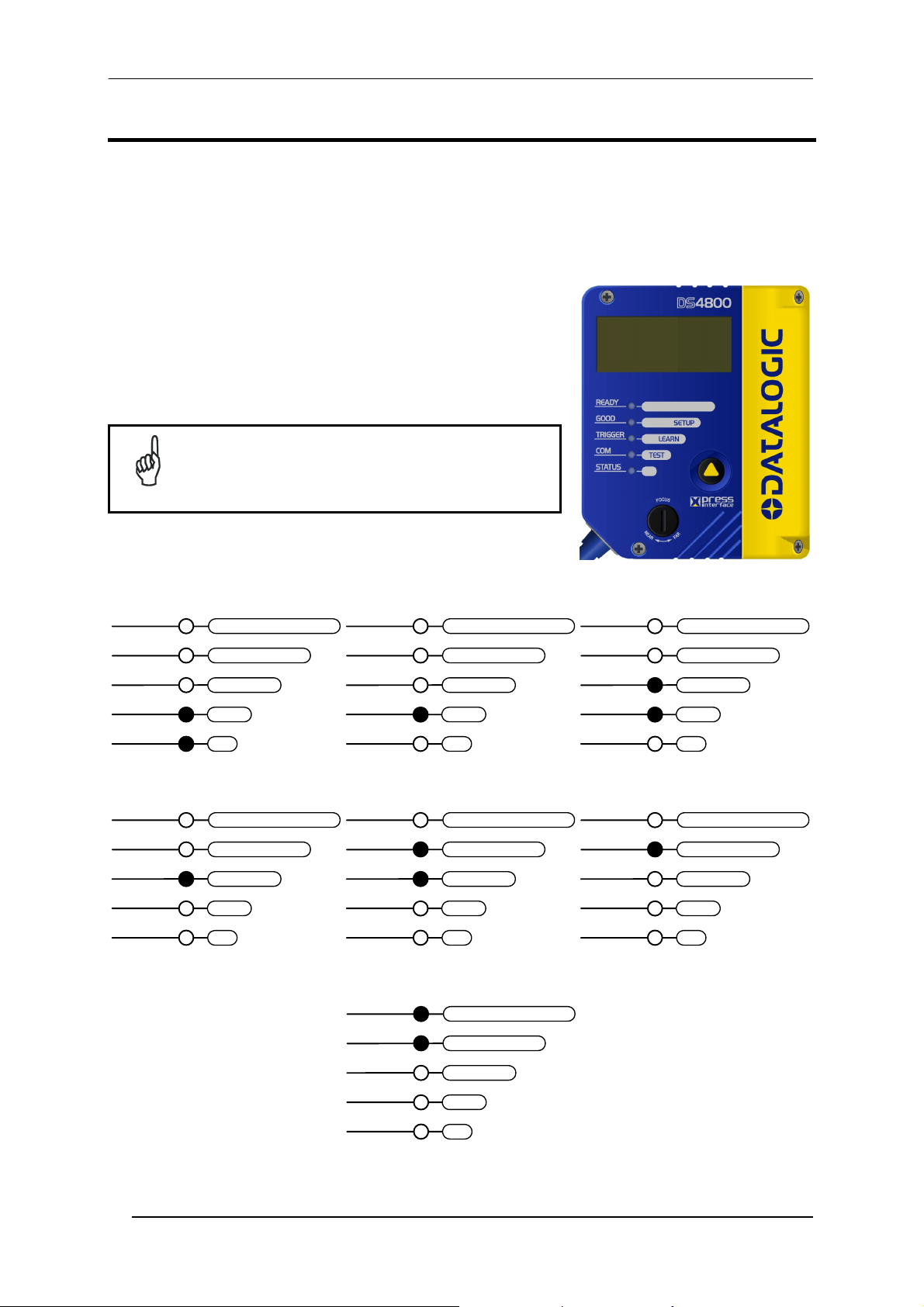

STEP 3 – FOCUS THE SCANNER

The reading distance depends on the focus distance of the scanner and should be set according to the

application requirements. The Focus Position is set directly through the focus adjustment screw on the front panel

of the scanner. This screw moves the internal lens of the scanner to change the focal length of the scanner. The

setting is continuous but should not be set beyond the limits "Too Far" or "Too Near" which appear on the display

at the extremes of the focus range. Although the scanner reads across the entire focus range, there are three

guaranteed positions which correspond to the reading diagrams in the Appendix of this Quick Reference Guide.

1. Power up the scanner and wait for the power up sequence to finish.

The alternating message on the display shows the mechanical

Focus Position.

2. Using a screwdriver turn the focus adjustment screw in the desired

direction clockwise (focus nearer to the scanner) o

counterclockwise (focus farther from the scanner). The focus

position in centimeters and inches is shown on the scanner display.

The value of the Focus Position can be stored in memory.

If the mechanical position changes with respect to the

value in memory, an alarm will be sent. See the Focus

NOTE

Lock function in step 4, X-PRESS™ Configuration.

As an additional visual aid during focusing, the indicator LEDs show the relative focus position as follows:

READY

GOOD

RIGGER

COM

STATUS

SETUP

LEARN

EST

Î

less than 30 cm

READY

GOOD

RIGGER

COM

STATUS

SETUP

LEARN

EST

Í Î

30 cm

READY

GOOD

RIGGER

COM

STATUS

SETUP

LEARN

EST

Í Î

40 cm

READY

GOOD

RIGGER

COM

STATUS

LEARN

EST

Í

Î

42-58 cm

SETUP

READY

READY

GOOD

RIGGER

COM

STATUS

READY

GOOD

RIGGER

COM

STATUS

LEARN

EST

Í

Î

32-38 cm

LEARN

EST

Í Î

60 cm

SETUP

SETUP

GOOD

RIGGER

COM

SETUP

LEARN

EST

STATUS

Í

more than 60 cm

6

Page 7

DS4800 QUICK GUIDE

T

T

STEP 4 – X-PRESS™ CONFIGURATION

X-PRESS™ is the intuitive Human Machine Interface designed to improve ease of installation and maintenance.

Status and diagnostic information are clearly presented on the display (which can be configured in various

languages) and by means of the five colored LEDs, whereas the single push button gives immediate access to

the following relevant functions:

• AutoSetup to self-optimize and auto-configure reading performance

in demanding applications

• AutoLearn to self-detect and auto-configure for reading unknown

barcodes (by type and length)

• Focus Lock to memorize the mechanical focus position

• Test Mode with bar-graph visualization to check static reading

performance

The colors and meaning of the five LEDs are illustrated in the following

table:

READY (green) This LED indicates the device is ready to operate.

GOOD (green) This LED confirms successful reading.

TRIGGER (yellow) This LED indicates the status of the reading phase.

COM (yellow) This LED indicates active communication on main serial port.

STATUS (red) This LED indicates a NO READ result.

During the reader startup (reset or restart phase), all the LEDs blink for one second.

On the back of the reader near the cable, the “POWER ON” LED indicates the laser scanner is correctly powered.

AUTO LEARN

If you are configuring your scanner using X-PRESS™, you must start with the Auto Learn procedure.

1. Enter the Auto Learn function by holding the X-PRESS™ push button pressed until the LEARN LED is on.

2. Release the button to enter the Auto Learn function.

Once entered, the reader starts a procedure to automatically detect and recognize barcodes (by type and

length), which are presented to it (*). The laser turns on and the LEARN LED blinks to indicate the ongoing

process.

READY

GOOD

RIGGER

COM

STATUS

Figure 5 – X-PRESS™ Interface: Auto Learn Function

LEARN

EST

SETUP

green

green

yellow

yellow

red

The procedure is as follows:

A) place the desired barcode on the scanline.

B) wait until the LEARN LED stays steady on

(indicating the reader has detected the barcode).

C) repeat, if needed, the above two steps to

program up to 10 different barcodes (either by

length or by symbology). If more than one

barcode is detected, the Multi Label mode is

enabled (refer to the “2K/4K Family Software

Configuration Parameter Guide” Help file).

3. Exit the process by pressing the X-PRESS™ push button once. The scanner will restart at the end of the

process, and then the detected barcodes are automatically configured in scanner memory.

If the barcode cannot be read because of low contrast or excessive ambient light, you can

perform the AutoSetup function to optimize the optical parameters. Then you can perform

AutoLearn to recognize the barcode symbology.

NOTE

* In case of Programming Barcodes, refer to the “ID-NET™ Programming Barcodes And Setup Procedure” document in the

product CD.

7

Page 8

DS4800 QUICK GUIDE

T

T

T

T

AUTO SETUP (OPTIONAL)

At the end of the Auto Learn procedure, you can perform the Auto Setup procedure to set up the reading

parameters.

1. Enter the Auto Setup function by holding the X-PRESS™ push button pressed until the SETUP LED is on.

2. Release the button to enter the Auto Setup function.

Once entered, if a barcode label is positioned in front of the scanline, the scanner automatically performs the

optimal setup of the reading parameters for that specific barcode.

READY

GOOD

RIGGER

COM

STATUS

Figure 6 – X-PRESS™ Interface: Auto Setup Function

SETUP

LEARN

EST

green

green

yellow

yellow

red

The procedure is as follows:

A) place the desired barcode on the scanline.

B) enter the AutoSetup function (the laser turns on

and the SETUP LED blinks to indicate the

ongoing process)

C) wait until the SETUP LED stays steady on

(indicating the reader has detected the

barcode)

This procedure ends either when the barcode is successfully decoded or after a timeout of about 7 (seven) seconds.

The scanner will restart at the end of the process, and then the optimized reading parameters for that barcode are

automatically configured in scanner memory.

FOCUS LOCK/UNLOCK (OPTIONAL)

You can perform the Focus Lock procedure to save the mechanical focus position to memory. If the mechanical

focus position is changed with respect to the memorized value (by more than the Max. Focus Displacement

value), a diagnostic alarm will be sent to the display.

1. Enter the Focus Lock function by holding the X-PRESS™ push button pressed until the FOCUS LOCK LED is on.

2. Release the button to enter the Focus Lock function.

Once entered, the scanner automatically performs the Lock (saving) or Unlock procedure depending on the

previous state of the Locked Position parameter.

READY

GOOD

RIGGER

COM

STATUS

Figure 7 – X-PRESS™ Interface: Focus Lock/Unlock Function

LEARN

EST

SETUP

green

green

yellow

yellow

red

The scanner will restart at the end of the process.

The procedure is as follows:

A) enter the Focus Lock function

B) wait until the "Focus locked at..." message

appears on the display (indicating the focus

position has been saved to memory). The

following parameters are set:

• Locked Position = your mechanical setting

• Max. Displacement = ± 2 cm (default)

• Focus Displacement (Alarm) = set (default to

display only)

If your application has been configured using X-PRESS™, go to STEP 6.

NOTE

RESET SCANNER TO FACTORY DEFAULT (OPTIONAL)

If it ever becomes necessary to reset the scanner to the factory default values, you can perform this procedure by

holding the X-PRESS™ push button pressed while powering up the scanner. At the end of the procedure (about

5-6 seconds), the Configuration and Environmental parameters are reset, all LEDs blink simultaneously 3 times

and the message "Default Set" is shown on the display.

8

Page 9

DS4800 QUICK GUIDE

STEP 5 – INSTALL GENIUS™ CONFIGURATION PROGRAM

Genius™ is a Datalogic scanner configuration tool providing several important advantages:

• Wizard approach for new users;

• Multi-language version;

• Defined configuration directly stored in the reader;

• Communication protocol independent from the physical interface allowing to consider the reader as a remote

object to be configured and monitored.

To install Genius™, turn on the PC that will be used for the configuration, running Windows 98, 2000/NT or

XP, then insert the Genius™ CD-ROM, wait for the CD to autorun and follow the installation procedure.

This configuration procedure assumes scanner connection to a CBX100/500. Genius™, running on a laptop

computer, is connected to the scanner auxiliary port through the CBX100/500 9-pin connector.

WIZARD FOR QUICK READER SETUP

After installing the Genius™ software program the following window appears asking the user to choose the

desired configuration level.

Figure 8 - Genius™ Wizard Opening Window

The Wizard option is advised for rapid configuration or for new users, since it shows a step-by-step scanner

configuration.

1. Select the Create a new configuration button.

You will be guided through the configuration being asked to define the following parameters:

9

Page 10

DS4800 QUICK GUIDE

a. Barcode selection and definition b. Operating mode selection and definition

c. Digital Outputs configuration d. Hardware interface selection

e. Output data format configuration

The On Line operating Mode requires the reader to be connected to an External Trigger/Presence Sensor

using I1A and I1B inputs.

The Automatic operating mode does not require connection to an external Presence Sensor. When

working in this mode the reader is continuously scanning, while the reading phase is activated each time a

barcode enters the reader reading zone. The reader stops reading after an N number of scans without a

code. Barcode characters are transmitted on the serial interface. In case of a failed reading phase no

message is sent to the host computer.

10

Page 11

DS4800 QUICK GUIDE

2. After defining the parameter values the following window appears allowing to complete the reader

configuration as follows:

• Saving the configuration to disk;

• Switching to Advanced mode;

• Sending the configuration to the scanner.

3. After sending the configuration to the scanner you have completed the configuration process.

4. By clicking Finish, the System Information window will be displayed with specific information concerning the

scanner.

11

Page 12

DS4800 QUICK GUIDE

T

T

STEP 6 – TEST MODE

Use a code suitable to your application to test the system. Alternatively, you can use the Datalogic Test Chart

(Code 128).

1. Enter the Test mode function by holding the X-PRESS™ push button pressed until the TEST LED is on.

2. Release the button to enter the Test mode function.

Once entered, the Bar-Graph on the five LEDs is activated and if the scanner starts reading barcodes the

Bar-Graph shows the Good Read Rate. In case of no read condition, only the STATUS LED is on and blinks.

READY

GOOD

RIGGER

COM

SETUP

LEARN

EST

STATUS

Figure 9 – X-PRESS™ Interface: Test Mode Function

3. To exit the Test Mode, press the X-PRESS™ push button once.

green

green

yellow

yellow

red

By default, the Test Mode exits automatically after two minutes.

NOTE

12

Page 13

DS4800 QUICK GUIDE

ADVANCED SCANNER CONFIGURATION

For further details on advanced product configuration, refer to the complete Reference Manual on the installation

CD-ROM or downloadable from the web site through this link:

The following are alternative or advanced scanner configuration methods:

HOST MODE PROGRAMMING

The scanner can also be configured from a host computer using the Host Mode programming procedure, by

commands via the serial interface. See the Host Mode Programming file on the CD-ROM.

ADVANCED GENIUS™ CONFIGURATION

The ADVANCED selection available when starting the Genius™ program is addressed to expert users being able

to complete a detailed scanner configuration. By choosing this option it is possible either to start a new scanner

configuration or to open and modify an old one. The desired parameters can be defined in the following window,

similar to the MS Explorer:

www.automation.datalogic.com/ds4800.

Figure 10 - Genius™ Parameter Explorer Window

ALTERNATIVE LAYOUTS

• The ID-NET™ network is a built-in high-speed interface dedicated for high-speed scanner interconnection.

ID-NET™ is in addition to the Main and Auxiliary serial interfaces.

If you need to install an ID-NET™ network refer to the DS4800 Reference Manual.

The scanner can also be configured by reading programming barcodes. See the ID-NET™ Setup Procedure

Using Programming Barcodes printable from the CD-ROM.

• If you need to install a Pass-Through network refer to the DS4800 Reference Manual.

• If you need to install a Multiplexer network refer to the DS4800 Reference Manual.

• If you need to install an RS232 Master/Slave (for backward compatibility) refer to the DS4800 Reference

Manual.

13

Page 14

DS4800 QUICK GUIDE

APPENDIX

READING DIAGRAMS

DS4800-1000 Focus Distance 30 cm (Near)

20

15

05 1510 30

0 10 20 30 40 50 60 70 80 90 100

50

40

20 25 35 40

(in)

(cm)

CONDITIONS

Code = Code 128

PCS = 0.90

Pitch angle = 0°

Skew angle = 15°

Tilt angle = 0°

*Scan Speed = 800 scans/sec

*Reading Conditions = Standard

*Reading Mode = Linear

* Parameter selectable in Genius™

10

5

0

5

10

15

20

(in)

30

20

10

10

20

30

40

50

(cm)

≥ 0.50 mm

(20 mils)

0

0.20 mm

(8 mils)

0.30 mm

(12 mils)

0.38 mm

(15 mils)

14

Page 15

DS4800 QUICK GUIDE

CONDITIONS

Code = Code 128

PCS = 0.90

Pitch angle = 0°

Skew angle = 15°

Tilt angle = 0°

*Scan Speed = 800 scans/sec

*Reading Conditions = Standard

*Reading Mode = Linear

* Parameter selectable in Genius™

DS4800-1000 Focus Distance 40 cm (Medium)

20

15

10

5

0

5

10

15

05 1510 30

0 10 20 30 40 50 60 70 80 90 100

50

40

30

20

10

0

10

20

30

40

20 25 35 40

≥ 0.50 mm

(20 mils)

0.30 mm

(12 mils)

0.38 mm

(15 mils)

(in)

(cm)

CONDITIONS

Code = Code 128

PCS = 0.90

Pitch angle = 0°

Skew angle = 15°

Tilt angle = 0°

*Scan Speed = 800 scans/sec

*Reading Conditions = Standard

*Reading Mode = Linear

* Parameter selectable in Genius™

50

20

(cm)

(in)

DS4800-1000 Focus Distance 60 cm (Far)

20

15

10

5

0

5

10

15

05 1510 30

0 10 20 30 40 50 60 70 80 90 100 110 120

60

50

40

30

20

10

0

10

20

30

40

20 25 35 40 45

≥ 0.50 mm

(20 mils)

0.38 mm

(15 mils)

(in)

(cm)

50

20

(in)

60

(cm)

15

Page 16

DS4800 QUICK GUIDE

READING PERFORMANCE

Version Reading Distance Max Code Resolution

mm (mils)

F = 30 20 cm (7.9 in) - 47 cm (18.5 in) on 0.50 mm (20 mils) codes 0.20 (8) 800

F = 40 25 cm (9.8 in) - 68 cm (26.8 in) on 0.50 mm (20 mils) codes 0.30 (12) 800

F = 60 40 cm (16.7 in) - 100 cm (39.4 in) on 0.50 mm (20 mils) codes 0.38 (15) 800

Speed

scans/s

TECHNICAL FEATURES

ELECTRICAL FEATURES

Power Supply 10 to 30 Vdc

Max. Consumption

Main Serial Interfaces

Baud Rate

Auxiliary Interface

Baud Rate

ID-NET™ Interface

Baud Rate

Inputs

Input 1 (External Trigger), Input 2

Voltage

Current Consumption

Minimum Pulse Duration

Outputs

Output 1, Output 2

V

CE

Collector Current

V

CE Saturation

Power Dissipation

OPTICAL FEATURES

Light Source Semiconductor laser diode

Wavelength In the range 630 to 680 nm

Safety Class Class 2 – EN 60825-1; CDRH

READING FEATURES

Scan Rate (software programmable) 600 to 900 scans/sec

Aperture Angle 50°

Maximum Reading Distance

Maximum Resolution

ENVIRONMENTAL FEATURES

Operating Temperature 0° to +50 °C (+32° to +122 °F) c

Storage Temperature -20° to +70 °C (-4° to +158 °F)

Humidity max. 90% non condensing

Vibration Resistance

EN 60068-2-6

Shock Resistance

EN 60068-2-27

Protection Class IP65

PHYSICAL FEATURES

Dimensions

Weight 570 g (20.1 oz)

USER INTERFACE

LED Indicators

Multi-function Key X-PRESS™ button

Display

c If the reader is used in high temperature environments (over 40 °C), use of the Beam Shutter is advised (see the Genius™

configuration program) and/or a thermally conductive support (such as the metal bracket provided).

0.6 to 0.2 A; 6 W

Programmable:

RS232, RS485 FD and HD

1200 to 115200

RS232

1200 to 115200

RS485 Half Duplex

Up to 1Mbaud

Optocoupled, polarity insensitive

10 to 30 Vdc

12 mA max.

5 ms

Optocoupled

30 Vdc max.

40 mA continuous max.; 130 mA pulsed max.

1V at 10 mA max.

80 mW max. at 45 °C (ambient temperature)

See reading diagrams

14 mm @ 2 to 10 Hz; 1.5 mm @ 13 to 55 Hz;

2 g @ 70 to 200 Hz; 2 hours on each axis

30 g; 11 ms;

3 shocks on each axis

85 x 101 x 42 mm (3.3 x 4 x 1.7 in)

Ready, Good, Trigger, Com, Status, Power On

2 lines x 16 characters

menu and diagnostic messages configurable in various languages

16

Page 17

DS4800 QUICK GUIDE

MECHANICAL INSTALLATION

13

M5

M5

10

[0.39]

[0.51]

42

[1.65]

M5

34

[1.34]

7.5

[0.30]

10

41.4

[0.39]

[1.63]

mm

[in]

27.9

[1.10]

85

[3.34]

101

[3.98]

41.9

[1.65]

Figure 11 – DS4800 Overall Dimensions

M4

M4

87.7

[3.45]

81

[3.19]

M4

M4

12.1

[0.48]

5.2

[0.21]

37.8

[1.49]

37

[1.46]

3

[0.12]

Ø4.2

[Ø0.17] N°4

Ø4.2

[Ø0.17] N°4

4.2

[0.17]

10

[0.39]

55

[2.17]

=

[2.76]

[3.15]

30°

80

4.2

[0.17]

120

Ø8.1

[Ø0.32] N°2

8.1

[0.32] N°8

70

=

Figure 12 – Mounting Bracket Overall Dimensions

[4.72]

70

[2.76]

mm

[in]

17

Page 18

DS4800 QUICK GUIDE

r

r

e

PATENTS

This product is covered by one or more of the following patents:

U.S. patents 5,992,740; 6,394,352 B1; 6,742,710 B2; 6,688,524 B1

European patents 789,315 B1; 959,426 B9

Additional patents pending.

COMPLIANCE

LASER SAFETY

The scanner is classified as a Class 2 laser product according to

EN 60825-1 regulations and as a Class II laser product according

to CDRH regulations.

Disconnect the power supply when opening the device during

maintenance or installation to avoid exposure to hazardous lase

light.

There is a safety device, which allows the laser to be switched on

only if the motor is rotating above the threshold for its correct

scanning speed.

The laser beam can be switched off through a software command

(see also the Genius Help On Line).

The laser diode used in this device is classified as a class 3B lase

product according to EN 60825-1 regulations and as a Class IIIb

laser product according to CDRH regulations.

Any violation of the optic parts in particular can cause radiation up

to the maximum level of the laser diode (40 mW at 630 to 680 nm).

DO NOT STARE INTO BEAM

MAX. OUTPUT RADIATION 1 mW

EMITTED WAVE LENGTH 630~680 nm

AVOID EXPOSURE

LASER LIGHT IS EMITTED

FROM THIS APERTURE

CAUTION-CLASS 3B

LASER LIGHT WHEN OPEN

AVOID EXPOSURE TO BEAM

U.S. pat. 5,992,740; 6,394,352B1; 6,742,710B2; 6,688,524B1.

Via S. Vitalino, 13 – 40012 Calderara di Reno

Figure 13 - Warning and Device Class Labels

POWER SUPPLY

This product is intended to be installed by Qualified Personnel only.

This accessory device is intended to be supplied by a UL Listed or CSA Certified Power Unit with «Class 2» or

LPS power source, which supplies power directly to the scanner via the 25-pin connector.

CE COMPLIANCE

Warning: This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

821001470 (Rev. A)

This product conforms to the

applicable requirements

of 21CFR1040 at the dat

of manufacture

LASER LIGHT

CLASS 2 LASER PRODUCT

TO EN 60825-1:2001

EP pat. 789,315B1; 959,426B9

DATALOGIC AUTOMAT ION S.r.l.

MADE IN ITALY-

www.datalogic.com

18

Loading...

Loading...