Page 1

MX-E90

Industrial Vision Processor

DESCRIPTION

This guide covers MX-E90 Industrial Vision Processor models. The MX-E90

series Industrial Vision Processors oer the most powerful and exible way to

solve even complex machine vision applications.

• Rugged IP20 housing

• Low Maintenance

• 16 Inputs and 16 Outputs

• Up to 8 GigE cameras

• Easily Accessed connectors

SYSTEM SPECIFICATIONS

Processor

Intel Core i7

Storage

32 GB RAM – 128 GB SSD

GigE camera ports

For MX-E90-8: 8 (all are PoE capable)

For MX-E90-4: 4 (all are PoE capable)

All MX-E90 Industrial Vision Processors have the following specications:

• HD graphics (1920x1200)

• 2 x 10/100/1000 Mbps Base-T Network Interface

• Ethernet/IP, Modbus TCP, OPC, PROFINET communications supported

• 2 x RS232 Serial port

• 16 x Optically Isolated Digital In + 16 x Optically Isolated Digital Out,

congurable NPN (sink) or PNP (source) output type.

• Microsoft Windows 10 IoT Enterprise 2016 64-bit

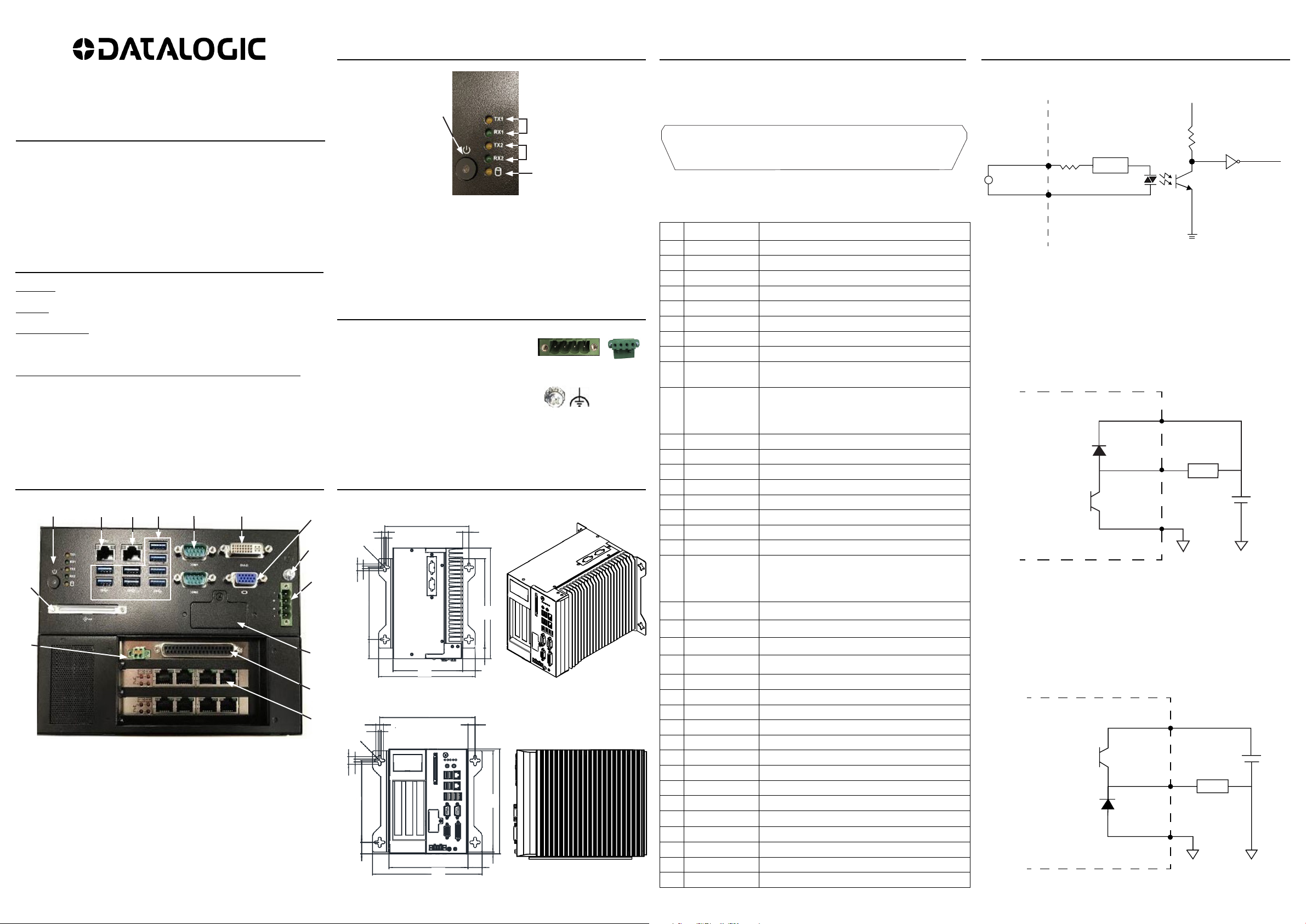

GENERAL VIEW

①

③ ④ ⑥

②

⑤

⑦

⑧

g

o

f

a

s

d

1 Status lights and buttons 8 Chassis Grounding

2 LAN 1 9 Supply Voltage Connection

3 LAN 2 10

4 USB 3.0: x8 11 37-pin D-Sub Digital I/O

COM1 + COM 2

5

2x RS-232 Serial port

6 DVI for Monitor 13 Extra Digital Output Grounding

7 VGA 14 CFast card for extended storage

USB 2.0 Port for USB Hardware

Key

Camera connectors Cam 1 through

12

Cam 8 (for MX-E90-8), Cam 1

through CAM 4 (for MX-E90-4)

STATUS LEDS AND BUTTONS (1

)

①

②

③

④

1 Power Button, Green 3

COM1: TX1/RX1 for

2

data transmission, status

monitoring.

Power Button: Press and release to turn on the unit or shut down the OS and

switch o the unit. Press and hold to switch o without the OS shutdown.

SUPPLY VOLTAGE CONNECTION (9

Power Connector

+ 24VDC Supply Plus

- 24VDC Supply Minus

Chassis Grounding:

Connect to ground using a conductor with

minimum 2.5 mm² cross-section.

IMPORTANT NOTE: It is advised to use all 4 pins for power connection.

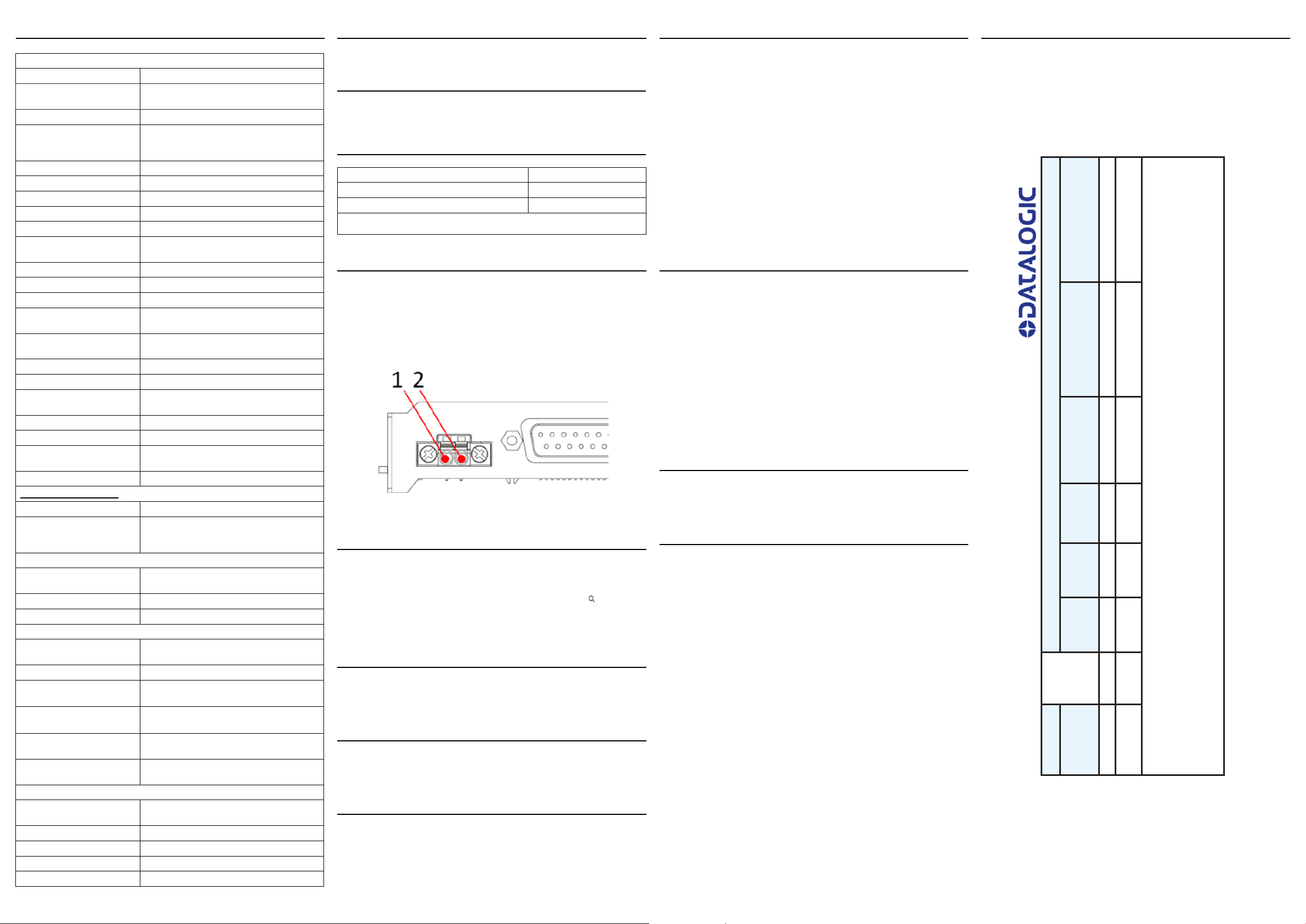

MECHANICAL DIMENSIONS

145

201

175

145

175

201

14

5

Ø10

14

5

15040

5

Ø10

14

5

150

21

COM2: RX2/TX2 for data transmission,

status monitoring.

4 HDD LED status, Yellow

)

- + + -

Power 24

13

230

186

22

26

1314

186

192

3

26

Supplied

Power

DIGITAL I/O SPECIFICATIONS

PCOM1

19

Pin Color Code Signal Name

1 Black Input 1

2 Brown Input 3

3 Red Input 5

4 Orange Input 7

5 Yellow Input 9

6 Green Input 11

7 Blue Input 13

8 Purple Input 15

9 Gray

10 White

11 Pink Output 1

12 Light Green Output 3

13 Black/White Output 5

14 Brown/White Output 7

15 Red/White Output 9

16 Orange/White Output 11

17 Green/White Output 13

18 Blue/White Output 15

19 Purple/White

20 Red/Black Input 2

21 Orange/Black Input 4

22 Yellow/Black Input 6

23 Green/Black Input 8

24 Gray/Black Input 10

25 Pink/Black Input 12

26 Pink/Red Input 14

27 Pink/Blue Input 16

28 Pink/Green Isolated ground

29 Light Blue Isolated ground

30 Light Blue/Black Output 2

31 Light Blue/Red Output 4

32 Light Blue/Blue Output 6

33 Light Blue/Green Output 8

34 Gray/Red Output 10

35 Gray/Green Output 12

36 Purple/Black Output 14

37 Blue/Black Output 16

O 15

18

37

O 16

O 13

17

36

O 14

O 11 O 12

16

35

O 1

O 3 O 4

O 5 O 6

O 7

O 9 O 10

11

12

13

14

15

33

34

O 8

Common pin for external source or ground of Input

1 to Input 16

PCOM0

NPN: common pin for connecting inductive loads of

O 1 to O 8

PNP: common pin for external voltage of O 1 to O 8

PCOM1

NPN: common pin for connecting inductive loads of

O 9 to O 16

PNP: common pin for external voltage of O9 to O 16

30

31

32

O 2

PCOM0

10

29

GND

ECOM

9

28

GND

I 15

8

27

I 16

I 13

7

26

I 14

I 11

6

25

I 12

I 9

5

24

I 10

EXAMPLE I/O DIAGRAMS

I 1 I 2

I 3

I 5

I 7

2

3

4

23

I 8

1

21

22

20

I 4

I 6

External Internal

0

1

S Vin

ECOM

Figure 1 - Input connection

Protection

Circuit

Bi-direction

diode

Internal

PC 5V

O channels

External

PCOMx

(Sink type)

Ox

+

–

IGND

Figure 2 - Output connection (sinking)

Internal External

PCOMx

+

(Source type)

Ox

LOAD

IGND

Figure 3 - Output connection (sourcing)

–

Page 2

TECHNICAL DATA

PART

(Hg)

(Cd)

Chromium (Cr(VI)

(PBB)

ethers (PBDE)

Metal Parts

X

O

O

O

O

O

(

)

I/O CONFIGURATION

CE COMPLIANCE

CHINA ROHS TABLE OF RESTRICTED ELEMENTS

ELECTRICAL FEATURES

Supply voltage (Vs) 9 ~ 36VDC

Current Consumption

Digital Inputs 16 opto-isolated, see Digital I/O Specications.

Input Voltage

Input Resistance 3.21kΩ

On Current >3mA

O Current <1mA

Current Maximum 8.5 mA @30VDC

Isolation Protection 2500VDC

Optical isolation response

time

Overvoltage protection 70VDC

Load Voltage 5 ~ 40VDC

Load Current 350mA (max per channel)

Input current

Digital Outputs

Format Opto-coupler isolated open emitter output

Residual Voltage Output On 2V or less (output current ≤mA)

Optical isolation response

time

Camera interface GigE (x 4 or 8 depending on model)

USB Hardware Port USB 2.0 Port for USB Hardware Key

USB Ports

Graphic Interface Intel® HD (1920x1200 resolution) VGA, DVI

Host Communications:

Serial Communications 2x RS-232 Serial Port (COM 1 + COM 2)

Ethernet

PHYSICAL FEATURES

Dimensions

Weight 445000 g

Housing material Metal

ENVIRONMENTAL FEATURES

Temperature

Relative Humidity 5 to 95%, non condensing

Vibrations

(EN60068-2-64)

Vibrations

(EN60068-2-6)

Shock resistance

(EN60068-2-27)

Mechanical protection

(EN 60529)

SOFTWARE FEATURES

Minimum Impact Software

Version Required

HARDWARE FEATURES

CPU Intel® Core i7

System Memory DDR4 RAM 32GB.

Storage 128 GB SSD, 1 CFast slot.

Nominal: 5.5 A at 24VDC

Maximum: 23A at 9VDC; 6A at 36VDC

Logic 0: 3V max

Logic 1: 10V min (30V max) or dry contact.

100µsec

3.28mA @ 12VDC

6.71mA @24VDC

16 opto-isolated (congurable sink-NPN or

source-PNP), see Digital I/O Specications.

100µsec

8x USB 3.0 ports for monitor, mouse and

keyboard

10/100/1000 Mbps Ethernet x 2

Ethernet/RIP, Modbus, TCP, OPC, PROFINET

communications supported.

7.55 w x 5.74 h x 9.05 d (in)

192 w x 145 h x 230 d (mm)

Operating: 0° to +50° C (+32° to +122° F)

Storage: -20° to +70° C (-4° to +158° F)

Random: 5 to 500Hz 3g

Sine: Ramp to 2g from 5 to 15Hz

15 to 500Hz 2g

Half sine: 11ms (50g Max)

IP20

12.2.0

Camera communication uses Cat6 Ethernet cable and provides POE for M1xx

and E1xx cameras. Use only Datalogic provided cables.

COMMUNICATIONS

Vision Program Manager (VPM) software installed on the processor is used to

create vision programs and congure input and output response. Refer to the

Impact Reference Guide for programming details.

DIGITAL I/O CABLES TERMINALS AND CONNECTIONS

Cable Part Number

Digital I/O 37-pin to Terminal Block 248-0110 606-0675-xx

Digital I/O 37-pin to pigtail (remove one end) 606-0675-xx

Note: Do not disconnect the cable at the connector while power is on.

EXTRA DIGITAL OUTPUT GROUNDING

The spring clamp connector on the I/O Card provides two extra connections that

are equivalent to the GND/PCOM pin on the 37-pin connector and are used to

increase the current tolerance on the I/O Card. The spring clamp pins should

be connected whenever the combined total output current is higher than 3.2A.

The pin assignments are as follows:

Pin 1: PCOM, used in source type (PNP) connections

Pin 2: GND, used in sink type (NPN) connections

Spring Clamp Connector Pin Denition

SUPPORT THROUGH THE WEBSITE

Datalogic provides several services as well as technical support through its

website. Log on to www.datalogic.com.

For quick access, from the home page click on the search icon , and type in

the name of the product you’re looking for. This allows you access to download

Data Sheets, Manuals, Software & Utilities, and Drawings.

Hover over the Support & Service menu for access to Services and Technical

Support.

PATENT

See www.patents.datalogic.com for patent list.

This product is covered by one or more of the following patents:

Utility patents: EP2517148B1, EP2649555B1, US10095951, US8888003,

US8915443, US9396404, US9495607, US9798948, ZL200980163411.X

SEALS

The Industrial Vision Processor has seals in some areas. The seals must not be

broken or removed for any reason. The sealed parts may be opened only and

exclusively by Datalogic. Breakage of these seals by a customer shall result in

immediate cancellation of the warranty on the entire Industrial Vision Processor.

WARRANTY

The warranty period for this product is 24 months. See General Terms and

Conditions of Sales at www.datalogic.com for further details.

CE marking states the compliance of the product with essential requirements

listed in the applicable European directive. Since the directives and applicable

standards are subject to continuous updates, and since Datalogic promptly

adopts these updates, therefore the EU declaration of conformity is a living

document. The EU declaration of conformity is available for competent authorities

and customers through Datalogic commercial reference contacts. Since April

20th, 2016 the main European directives applicable to Datalogic products

require inclusion of an adequate analysis and assessment of the risk(s). This

evaluation was carried out in relation to the applicable points of the standards

listed in the Declaration of Conformity. Datalogic products are mainly designed

for integration purposes into more complex systems. For this reason, it is under

the responsibility of the system integrator to do a new risk assessment regarding

the nal installation.

WARNING

This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

FCC COMPLIANCE

Modications or changes to this equipment without the expressed written

approval of Datalogic could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

which may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

EAC COMPLIANCE

Customs Union:

The CU Conformity certication has been achieved; this allows the Product to

bear the Eurasian mark of conformity.

LEGAL NOTICES

© 2019 Datalogic S.p.A. and/or its aliates ♦ ALL RIGHTS RESERVED. ♦

Without limiting the rights under copyright, no part of this documentation may be

reproduced, stored in or introduced into a retrieval system, or transmitted in any

form or by any means, or for any purpose, without the express written permission

of Datalogic S.p.A. and/or its aliates.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A.

in many countries, including the U.S. and the E.U.

Datalogic shall not be liable for technical or editorial errors or omissions

contained herein, nor for incidental or consequential damages resulting from the

use of this material.

Datalogic reserves the right to make modications and improvements without

prior notication.

有毒有害物质或元素

MX-E90

多溴二苯醚

Polybrominated diphenyl

多溴联苯

Polybrominated biphenyls

六价铬

Hexavalent

镉

Cadmium

汞

Mercury

铅

Lead (Pb)

部件名称

金属部件

(821005991 Rev. B)

X O O O O O

面板

Panel (if any)

如有

本表格依据 SJ/T 11364 的规定编制。

○ 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

× 表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

Loading...

Loading...