Page 1

M-Series

Quick Reference Guide

Publication Number 821003573 Rev C

Page 2

Compliance

Datalogic S.r.l. makes no representations or warranties for merchantability or fitness for any particular purpose, regarding Datalogic’s software or hardware. Datalogic S.r.l. shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or use of

this publication or its contents.

Datalogic S.r.l. reserves the right to revise this publication from time to time and to make changes in the content hereof without obligation to notify any person of such revision or changes.

Datalogic S.r.l.

Via S. Vitalino 13

40012 Calderara di Reno - Italy

http://www.datalogic.com

mvsupport@datalogic.com

© 2014 - 2017

under copyright, no part of this documentation may be reproduced, stored in or introduced into a retrieval

system, or transmitted in any form or by any means, or for any purpose, without the express written permission of Datalogic S.p.A. and/or its affiliates. Datalogic and the Datalogic logo are registered trademarks of

Datalogic S.p.A. in many countries, including the U.S. and the E.U. Impact, P-Series, Vision Program

Manager (VPM), Pinpoint Pattern Find, and Control Panel Manager (CPM) are trademarks of Datalogic

S.p.A. and/or its affiliates, registered in many countries, including the U.S. and the E.U. All other trademarks and brands are property of their respective owners.

Datalogic S.p.A. and/or its affiliates All rights reserved. Without limiting the rights

Patent

See www.patents.datalogic.com for patent list.

This product is covered by one or more of the following patents: Utility patents: US6,512,218 B1;

US6,616,039 B1; US6,808,114 B1; US6,997,385 B2; US7,053,954 B1; US7,387,246 B2; US8,058,600 B2;

EP996,284 B1; EP999,514 B1; EP1,014,292 B1; EP1,128,315 B1; EP1,396,811 B1; EP1,413,971 B1;

JP4,435,343 B2; JP4,571,258 B2.EAC COMPLIANCE

EAC COMPLIANCE

Customs Union:

The CU Conformity certification has been achieved; this allows the Product to bear the Eurasian mark of

conformity.

CE Compliance

CE marking states the compliance of the product with essential requirements listed in the applicable European directive. Since the directives and applicable standards are subject to continuous updates, and since

Datalogic promptly adopts these updates, therefore the EU declaration of conformity is a living document.

The EU declaration of conformity is available for competent authorities and customers through Datalogic

commercial reference contacts. Since April 20th, 2016 the main European directives applicable to Datalogic

products require inclusion of an adequate analysis and assessment of the risk(s). This evaluation was carried

out in relation to the applicable points of the standards listed in the Declaration of Conformity. Datalogic

S.r.l. products are mainly designed for integration purposes into more complex systems. For this reason it is

under the responsibility of the system integrator to do a new risk assessment regarding the final installation.

Page 3

Warning

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Support Through The Website

Datalogic provides several services as well as technical support through its website. Log on to www.datalogic.com and click on the SUPPORT > Machine Vision category link. From this page you can select your

product model from the dropdown list which gives you access to:

• Downloads including Data Sheets, Manuals, Software & Utilities, and Drawings;

• Repair Program for On-Line Return Material Authorizations (RMAs) plus Repair Center contact information;

• Service Program containing details about Maintenance Agreements;

• Technical Support through email or phone.

Page 4

Page 5

M-Series Quick Reference Guide Introduction

Introduction

Thank you for using Datalogic M-Series vision system. This guide provides a brief overview to help you get started with

your new system. For more detailed instructions, please refer to the Reference Guide (843-0093) and the M-Series Processor and Camera Guide (843-0148). It is important that you note the cautions and warnings in these manuals.

Safety Precautions

Warning: There are no user-serviceable parts inside the Datalogic hardware. To avoid electrical shock, never open

the case. Opening the case or removing the tamper-proof sticker will void the product warranty.

Avertissement: Il n'y a aucune partie utilisateur-utile à l'intérieur du matériel d'Datalogic. Pour éviter le choc électrique, n'ouvrez jamais la valise. L'ouverture de la valise ou l'élimination de l'autocollant inaltérable videra la garantie de produit.

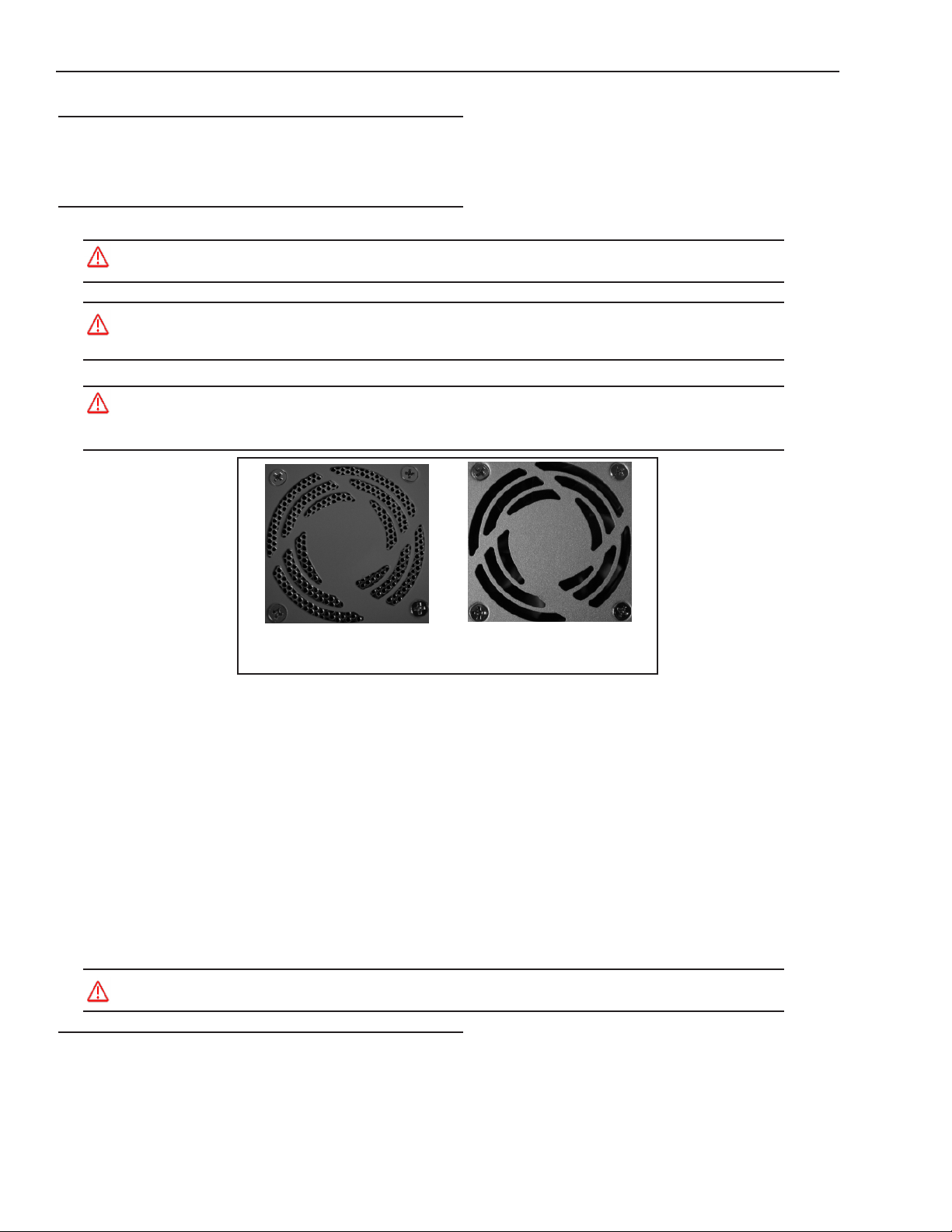

Mounting Warning: Mount the processor with the front or back of the unit facing down. For safety, do NOT

mount the processor with the filter side down. Mounting with the fan side down is acceptable only if approved

metal screen filters have been installed in all fan exhausts.

Metal Screen Filter Installed

Metal Screen Filter NOT Installed.

Do NOT mount fan side down

• Read all of the following instructions before setting up your system. Save this document for later use.

• Follow all warnings and instructions in this manual and in other user guides shipped with your hardware compo-

nents.

• To avoid damage to the vision system and its components, never plug in or unplug a cable when the power is on.

Always turn off the power supply before you make cable changes.

• Never use the system if a power cable has been damaged. Do not allow anything to rest on a power cable and keep

them away from traffic.

• The air inlets and exhausts on the top and sides of the unit are for ventilation. Do not block or cover these openings

or insert anything into these openings. Metal screen filters may be installed in the fan exhausts.

• Do not expose the vision system to moisture, rain, or snow, and do not use it near water. If a component gets wet

unplug it.

• To avoid injury, never open the case. Opening the case or removing the tamper-proof sticker will void the product

warranty.

Service Personnel Only - Caution: Risk of explosion if battery is replaced by an incorrect type. Dispose of used

batteries according to battery maker’s instructions.

Unpack the M-Series Hardware

When your system arrives, check the shipping cartons for wrinkled or damaged corners, holes through the cardboard, or

other signs of rough handling or abuse. If you find any signs of damage, ask the delivery service to make a note on the

delivery receipt describing the damage.

Page 1 Datalogic S.r.l..

Page 6

Processor Specifications M-Series Quick Reference Guide

Carefully remove the system unit, cameras, cabling, and accessories from the shipping package. Place all equipment you

unpack on a table and inspect each item. Report any damage to the carrier immediately. Save all packing materials so you

can repack the shipment in case you need to move or ship it.

Temperature precautions: If your system arrives in very cold or hot weather, allow all the equipment to reach room temperature before plugging it in. Exposing a cold device to a warm room causes condensation that could damage the system

if power is applied too soon. If condensation forms, wait for it to dry completely.

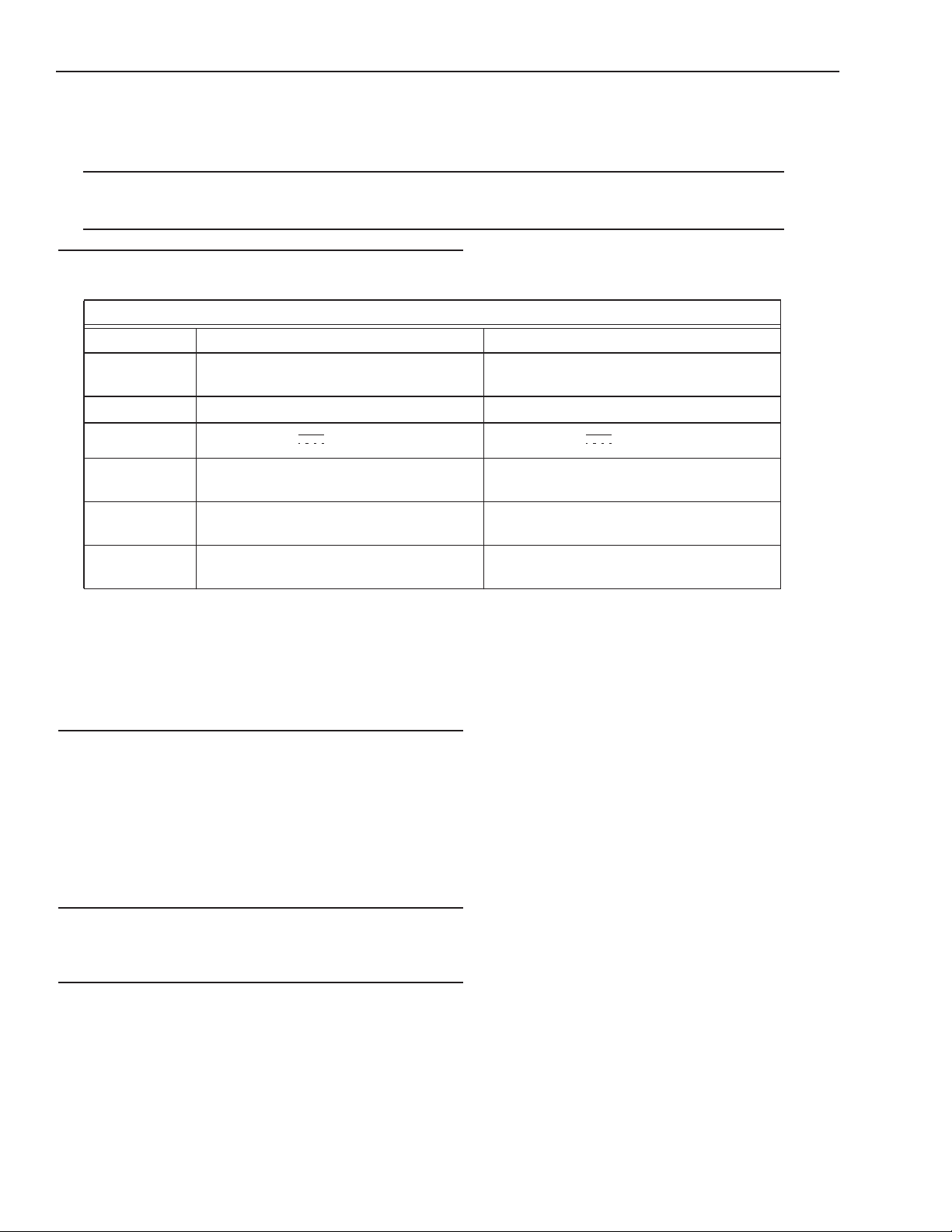

Processor Specifications

This section lists the general operating specifications for the M-Series Processors.

Processor Operating Environment

Model MX20** and MX40 MX80

Dimensions 7.8 w x 3.3 h x 6.5 d (in)

200 w x 85 h x 165 d (mm)

Weight 4.8 lb. (2.16 kg) 6.61 lb. (3 kg)

Input Power*

Temperature

Humidity

Safety

Compliance

Minimum Software Version

10 to 30VDC , Max. 10A; Min 3.5A 10 to 30VDC , Min 5A

0° to +55° C (+32° to +131° F)

0% to 90% (non-condensing)

CE/FCC, RoHs, IP30, UL

(MX20 UL Pending)

MX20 - 10.5.0

MX40 - 10.0.0

9.06 w x 3.23 h x 8.11 d (in)

230 w x 82 h X 206 d (mm)

0° to +55° C (+32° to +131° F)

0% to 90% (non-condensing)

CE/FCC, RoHs, IP30, UL

10.4.0

*NOTE: The MX20 and MX40 processors require approximately 3.5A @ 24VDC. Datalogic recommends using a 24

VDC power supply capable of providing 3.5A current. The M-Series processors run most efficiently at this voltage which

is commonly used in many manufacturing environments.

The MX80 processor requires approximately 5A @ 24VDC. Datalogic recommends using a 24 VDC power supply capable of providing 5A current. This voltage is commonly used in many manufacturing environments.

**The MX20 processor can accommodate a maximum of two cameras. The maximum image size of each camera is two

Megapixels. (The calculation is: maximum width in pixels * maximum height in pixels < 2,500,000.)

Installing Impact Software

NOTE: The M Device Software is intended for installation only on a Datalogic M-Series processor. You must install it

directly on the processor you intend to use. You cannot install it remotely.

When a new processor is powered on the first time, a monitor, keyboard, and mouse must be connected to the processor to

approve the license agreement.

All the required software was installed on the M-Series processor at the factory. If you want to change the system configuration, you will need to connect an optional monitor, mouse, and keyboard to the processor. For more details, refer to the

M-Series Hardware Guide and Impact Reference Guide. If your system does not work when you are finished with the

setup, review the instructions and diagrams to make sure you made all connections properly.

Resetting the M-Series Processor

To reset the M-Series Processor, press the Reset button on the processor’s front panel. See “MX20 and MX40 Front Panel

Connections” on page 8 and “MX80 Front Panel Connections” on page 9.

Changing the Camera’s IP Address

1. Connect to the device with VPM.

2. Select the Settings tab.

3. Click the General System Object.

4. Select the General radio button.

5. Enter the desired IP address in the IP Address field.

Datalogic S.r.l. Page 2

Page 7

M-Series Quick Reference Guide Changing the M-Series Processor’s IP Address (Windows XP)

6. Press the Tab key.

7. When the Reboot dialog is displayed, click OK.

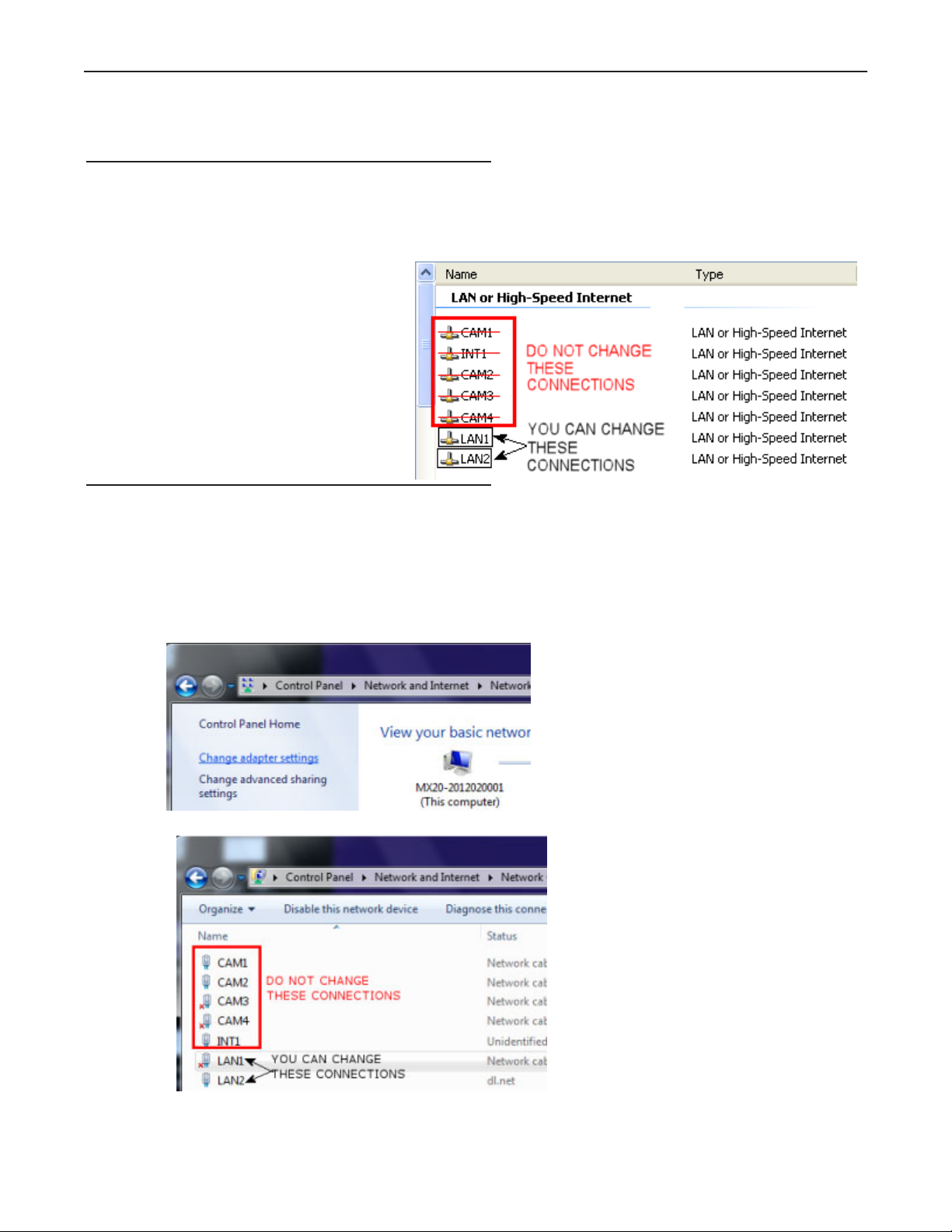

Changing the M-Series Processor’s IP Address (Windows XP)

IMPORTANT NOTE: Change only the Local Area Connection named LAN1 or LAN2. These correspond to Ethernet

Ports 1 and 2 on the front of the processor.

DO NOT change any of the other Local Area Connections. Changing any other connection can cause the M-Series cameras to stop functioning.

1. In the Start menu, right click on My

Network Places and select Properties.

2. Right click Local Area Connection

LAN1 or LAN2 and select Properties.

3. On the General tab, select Internet

Protocol (TCP/IP) and click Properties.

4. On the General tab, select Use the following IP address.

5. Enter the desired IP address.

6. Click OK to close all the open dialog

windows.

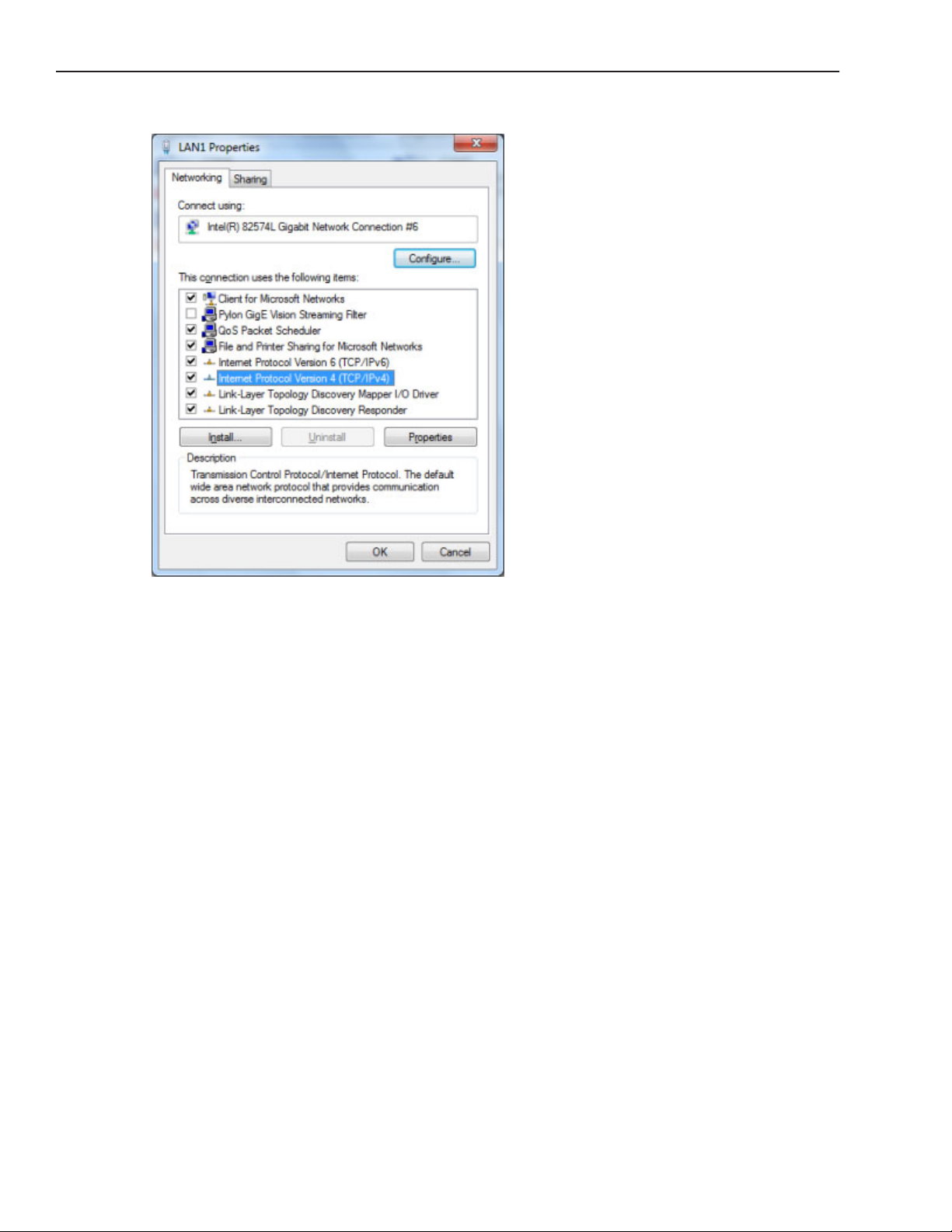

Changing the M-Series Processor’s IP Address (Windows 7)

IMPORTANT NOTE: Change only the Local Area Connection named LAN1 or LAN2. These correspond to Ethernet

Ports 1 and 2 on the front of the processor.

DO NOT change any of the other connections. Changing any other connection can cause the M-Series cameras to stop

functioning.

1. In the Start menu, click on Control Panel.

2. Under Network and Internet, click on View Network Status and Tasks.

3. On the left side of the screen, click Change Adapter Settings.

4. Right click LAN1 or LAN 2 and select Properties.

Page 3 Datalogic S.r.l.

Page 8

Changing the M-Series Processor’s IP Address (Windows 7) M-Series Quick Reference Guide

5. In the list of items, select Internet Protocol Version 4 (TCP/IPv4), then click Properties.

6. Select Use the following IP address.

7. Enter the desired IP address.

8. Click OK to close all the open dialog windows.

Datalogic S.r.l. Page 4

Page 9

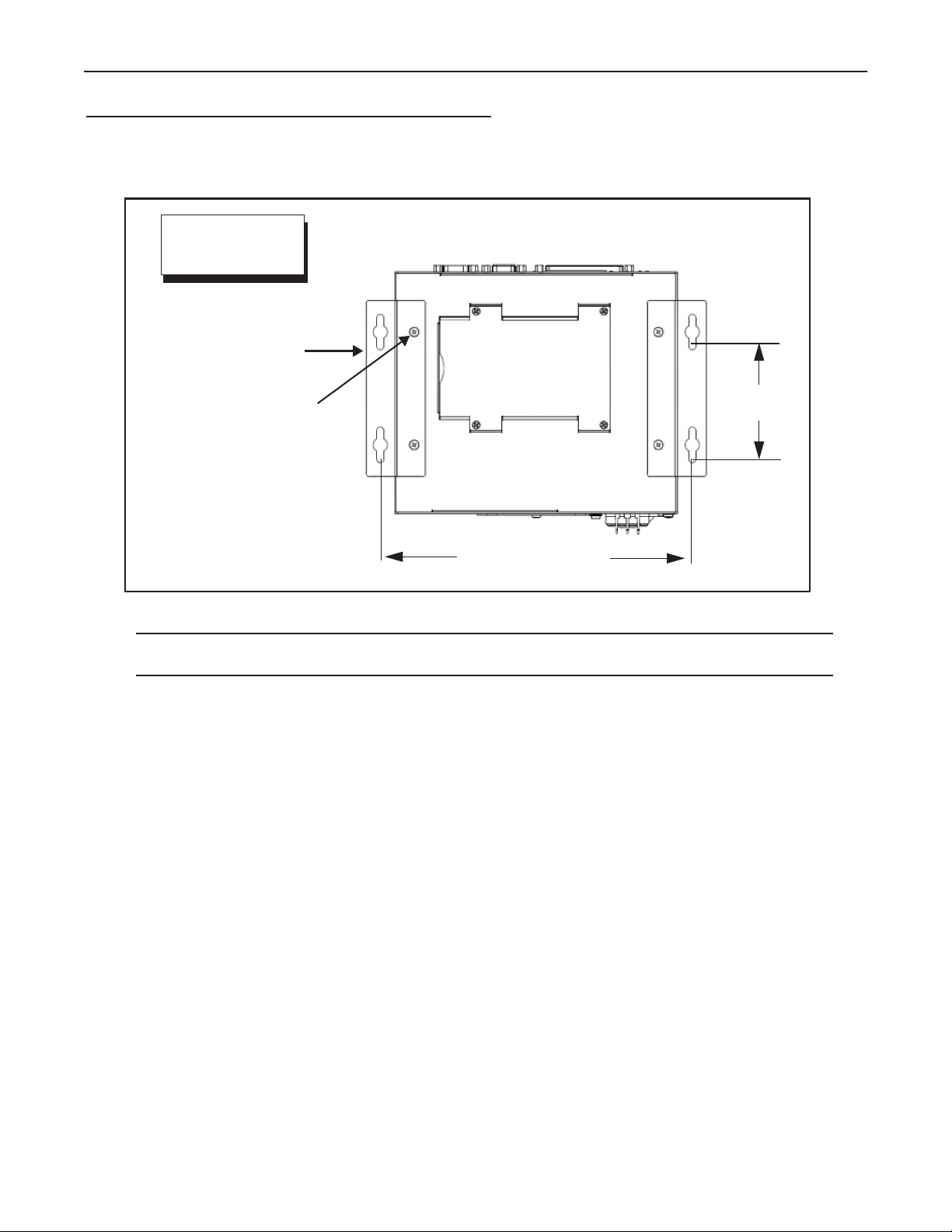

M-Series Quick Reference Guide Flat Surface Mounting

Flat Surface Mounting

The M-Series Processor may be mounted on any stable surface using the provided case mounting brackets. (Use the

appropriate bracket for the Processor model.) Allow at least 1.5 inches (38.1 mm) of clearance at the sides and top of the

unit.

IMPORTANT: See Mounting Warning on Page 1

Bottom View

Mounting Hole

Dimensions

Mounting Brackets (x2)

Provided

Processor front

Bracket Mounting Screws (x4)

M4, 0.7 mm pitch, 5 mm length -

Provided

UNITS: inch [mm.]

All models

3.2 [80.0]

Flat Surface Mounting

(Front Up)

Mounting Bracket Installation

NOTE: If the Processor uses a Compact Flash card, mount with the Processor front facing upward so the CF

card does not fall out due to vibration.

MX20; MX40=8.7 [221]

MX80 =9.92 [252]

To mount the Processor using the mounting brackets:

1. Fasten the two mounting brackets to the bottom of the Processor using the bracket mounting screws.

2. Using the mounting brackets as a template, mark the surface mounting holes in the desired location. The surface must be sufficiently sturdy to hold the unit, stable, and free of vibration.

3. Drill four surface mounting holes in the mounting surface.

4. Insert four mounting screws in the mounting holes and tighten them until approximately 0.2 inches (5 mm) is

left exposed. The mounting screws must be at least size #12 (min. 0.216 inches or 5.486 mm) and long

enough to provide sufficient support.

5. Maneuver the Processor so mounting bracket slots align with the mounting screws.

6. Place the slots over the screws and slide the Processor down until the screws fit snugly into the mounting

bracket slots.

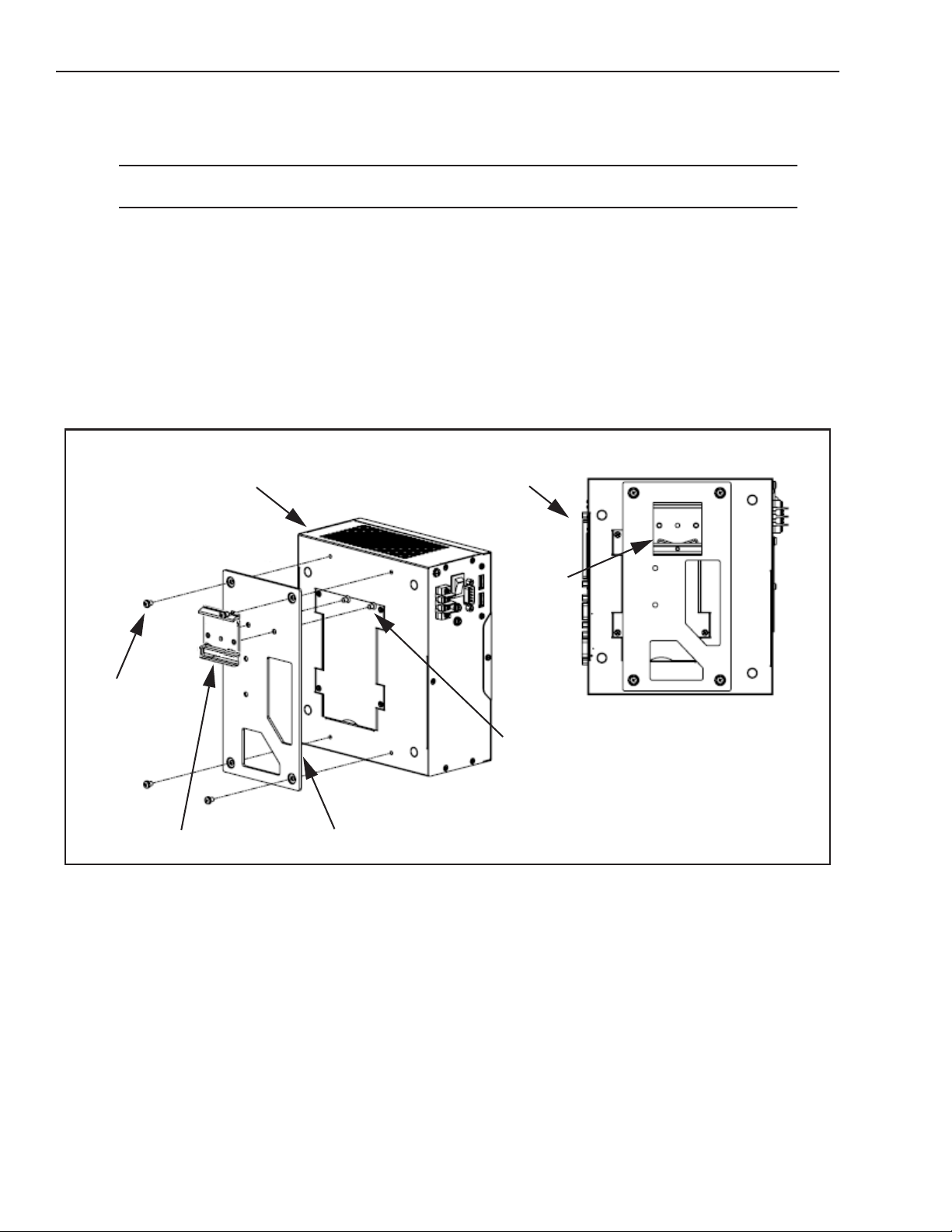

DIN Rail Mounting

The M-Series Processor may be bottom-mounted on a DIN rail using the optional DIN Rail Mount kit (MX20/MX40: Part

# 606-0683; MX80: Part # 95A906038).

Page 5 Datalogic S.r.l.

Page 10

DIN Rail Mounting M-Series Quick Reference Guide

DIN Rail Mount Kit Installation

NOTE: If the Processor uses a Compact Flash card, horizontal mounting is recommended (the Processor

front facing upward) so the card does not fall out due to vibration.

To mount the Processor using the DIN Rail Mount kit (see diagram):

1. To fasten the mounting bracket to the bracket holding plate, insert the bracket mounting screws from the

reverse side of the bracket holding plate.

Be sure to use the appropriate holes in the holding plate for the desired bracket orientation —horizontal or

vertical. The part of the bracket that contains the butterfly clip should be on the bottom.

2. Fasten the bracket holding plate onto the bottom of the processor using the plate mounting screws.

3. Hook the bottom of the mounting bracket in the bottom flange of the DIN rail. The butterfly clips will offer

some resistance.

4. While exerting slight upward force, clip the top of the mounting bracket over the top flange of the DIN rail.

5. Verify that the bracket is clipped securely to the rail.

IMPORTANT: See Mounting Warning on Page 1

Plate

Mounting

Screws

(x4)

Processor front

Mounting Bracket

Bracket Holding Plate

Processor front

Butterfly

Clip

Bottom View

Bracket Mounting

Screws (x2)

DIN Rail Mounting (Fan Down)

Datalogic S.r.l. Page 6

Page 11

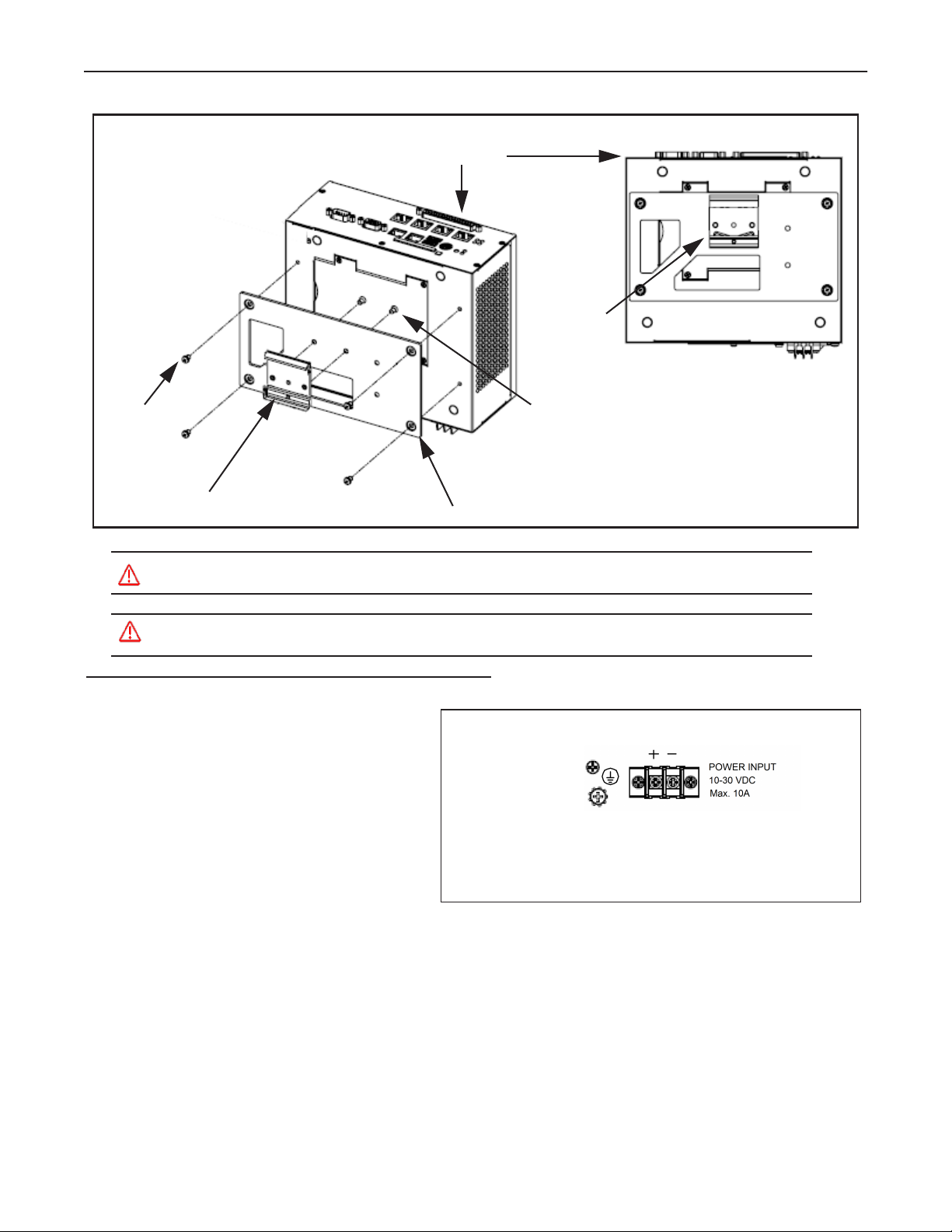

M-Series Quick Reference Guide MX20 and MX40 Processor Power Supply Connection

IMPORTANT: See Mounting Warning on Page 1

Processor front

Butterfly

Clip

Bottom View

Bracket Mounting

Plate

Mounting

Screws

(x4)

Screws (x2)

Mounting Bracket

Bracket Holding Plate

DIN Rail Mounting (Front Up)

Warning: To avoid electrical shock, disconnect all power to the power supply before working on it.

Avertissement: Pour éviter le choc électrique, débranchez toute la puissance à l'alimentation d'énergie avant de tra-

vailler à lui.

MX20 and MX40 Processor Power Supply Connection

The MX20 and MX40 power inputs use standard

spade terminals to connect the power supply. The

ground terminal on the power input must be connected to the power supply’s grounded chassis/

enclosure. This connection is needed to insure

electromagnetic compliance and proper operation.

The MX20 and MX40 processors require approximately 10A @ 10VDC; 3.5A @ 24VDC; and 3A

@ 30VDC. Datalogic recommends using a 24

VDC power supply capable of providing 3.5A

current. The M-Series processor runs most efficiently at this voltage which is commonly used in

many manufacturing environments.

Power Connector

Connect Ground terminal to Power Supply Circuit Ground

1

Connect - terminal to Power Supply Minus

2

Connect + terminal to Power Supply 10 to 30VDC*

3

123

Page 7 Datalogic S.r.l.

Page 12

MX80 Processor Power Supply Connection M-Series Quick Reference Guide

MX80 Processor Power Supply Connection

The MX80 power input uses a Datalogic-supplied

connector. Wire the power supply cable to the connector, then plug it into the power connector on the

rear of the processor. The ground terminal on the

power input must be connected to the power supply’s

grounded chassis/enclosure. This connection is

needed to insure electromagnetic compliance and

proper operation.

The MX80 processor requires approximately 5A @

24VDC. Datalogic recommends using a 24 VDC

power supply capable of providing 5A current. This

voltage is commonly used in many manufacturing

environments.

Power Connector

Connect GND terminal to Power Supply Circuit Ground

Connect V- terminal to Power Supply Minus

Connect V+ terminal to Power Supply 10 to 30VDC*

GND V-V+

POWER INPUT

10-30VDC

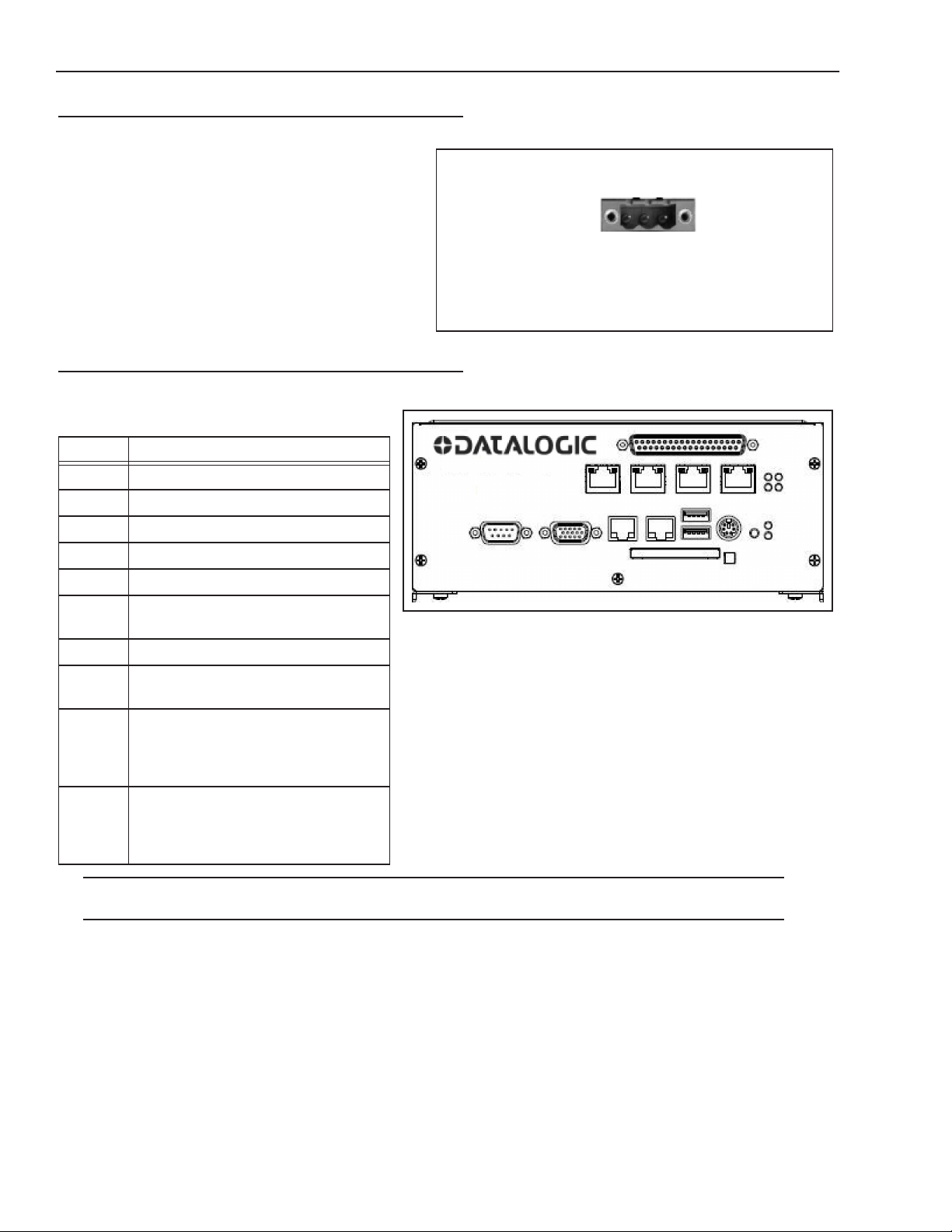

MX20 and MX40 Front Panel Connections

This is the MX20 and MX40 Processor’s front

panel.

Symbol Function

A Status Lights (see Page 10)

B Reset Button (Resets the processor)

C Keyboard and Mouse

J

A

I

D

E

C

D USB Ports 2.0 (2)

E LAN Ethernet Ports (2)

F Compact Flash Socket (See Note

below)

G VGA Connector

H Serial Port 1 - See “MX20 and MX40

Serial Cable” on page 11

I M-Series Camera Connectors (CAM1-

CAM4) MX20 has only 2 POE ports

(CAM1-CAM2)

Cable 606-0457-x

J Digital I/O Connector - Cable 606-

0675-xx with terminal block 661-0403

or terminal block 248-0110. Use cable

431-0952-xx without terminal block.

GH

F

BA

Note: If a Compact Flash card is present in the socket, it can be used for extended storage by the MX20 and MX40 processors. Do NOT insert or remove the card while the unit is powered on.

Datalogic S.r.l. Page 8

Page 13

M-Series Quick Reference Guide MX20 and MX40 Rear Panel Connections

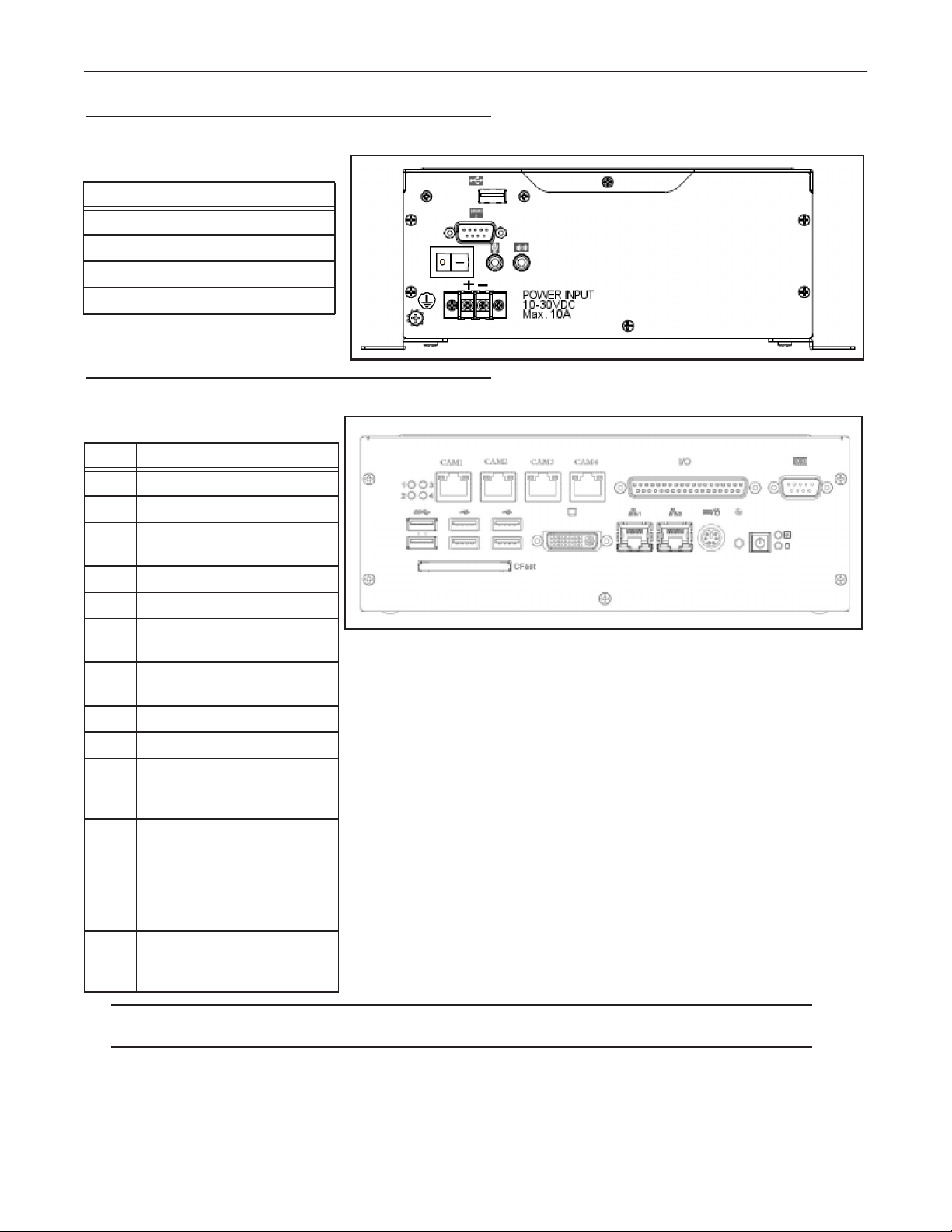

MX20 and MX40 Rear Panel Connections

This is the MX20 and MX40 Processors’ rear panel.

Symbol Function

A USB Port

A

B Serial Port 2

C Speaker and Microphone

D Power Switch

MX80 Front Panel Connections

These are the connections for the

MX80 Processor’s front panel.

Code Function

A Status Lights (see Page 11)

B Power Button

C Reset Button (Resets the

processor)

D Keyboard and Mouse

E Gigabit Ethernet Ports (2)

F DVI-I Video Connector (VGA

Capable)

G CFast Compact Flash Socket

(See Note below)

H

B

D

C

JKL

I

EF

D

C

BA

G

H USB 3.0 Ports (2)

I USB 2.0 Ports (4)

J M-Series Camera Connec-

tors (CAM1 - CAM4)

Cable 606-0457-x

K Digital I/O Connector - Cable

606-0675-xx with terminal

block 661-0403 or terminal

block 248-0110. Use cable

431-0952-xx without terminal

block.

L Serial Port 1 (Com 5) See

“MX80 Serial Cable” on page

12

Note: If a Compact Flash card is present in the socket, it can be used for extended storage by the processor. Do NOT insert

or remove the card while the unit is powered on.

Page 9 Datalogic S.r.l.

Page 14

MX80 Rear Panel Connections M-Series Quick Reference Guide

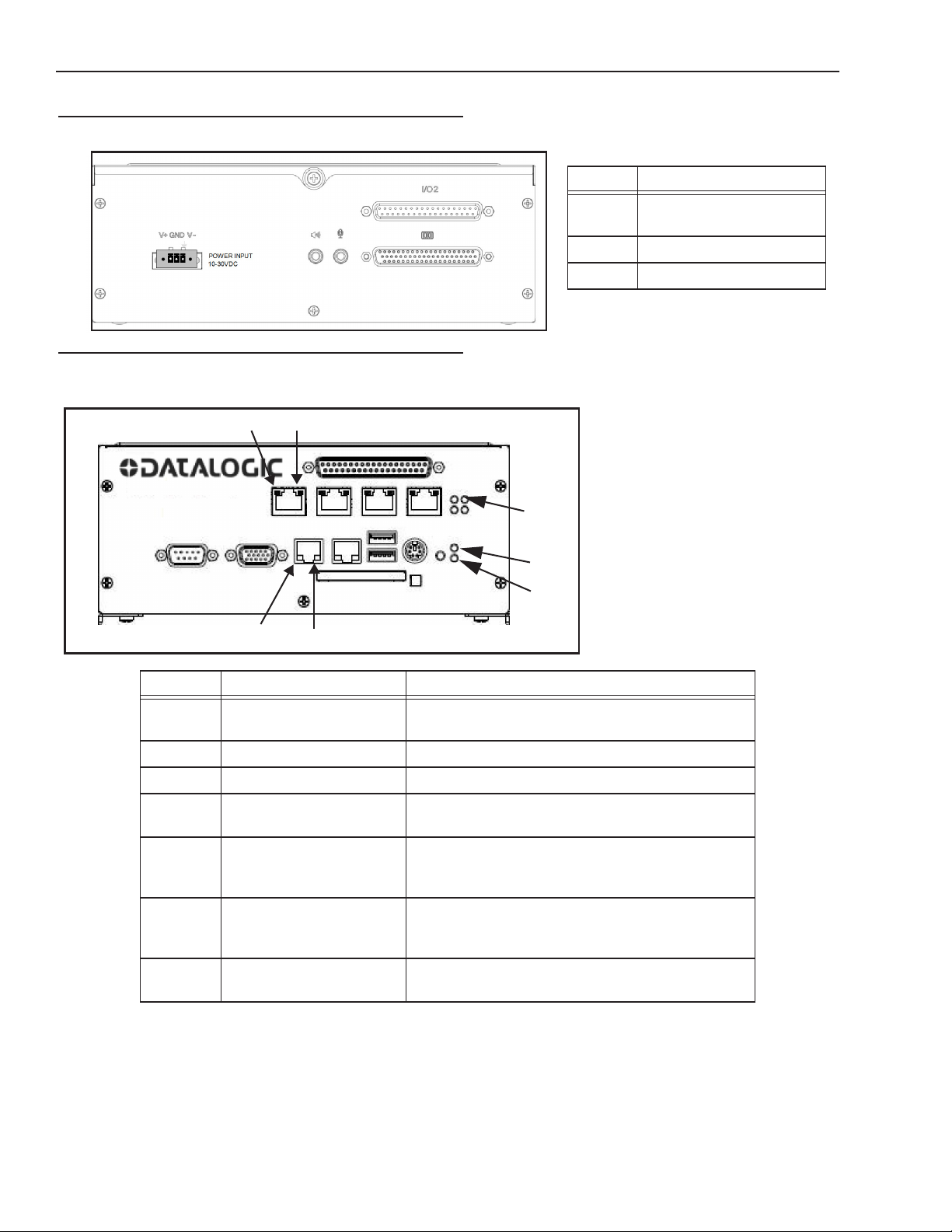

MX80 Rear Panel Connections

MX80 Processor’s rear panel connections

A

B

Symbol Function

A Do Not Use. (For future

expansion)

B Serial Ports 2-4 (COM 2-4)

C

MX20 and MX40 Status Lights

These are the status lights on the front of the MX20 and MX40 Processors.

D

Symbol Name When lit indicates:

A PoE: MX40 = 4

MX20 = 2

E

F

G

Power over Ethernet (PoE) is active (M1xx camera

only)

C Speaker and Microphone

A

B

C

B Power Power is On

C HDD Blinking: Solid-state hard drive is active

D PoE Activity/Link:

MX40 = 4; MX20 = 2

E PoE Speed:

MX40 = 4; MX20 = 2

F LAN 1 and 2 Speed Off: 10 Mbps

G LAN 1 and 2 Activity/Link On: Link is established

Datalogic S.r.l. Page 10

On: Link is established

Blinking: Data is being transferred

Off: 10 Mbps

Green: 100 Mbps

Orange: 1000 Mbps (Gigabit)

Green: 100 Mbps

Orange: 1000 Mbps (Gigabit)

Blinking: Data is being transferred

Page 15

M-Series Quick Reference Guide MX80 Status Lights

MX80 Status Lights

This illustration shows the status lights on the front of the MX80 Processor.

E

F

D

A

B

C

G

Symbol Name When lit indicates:

A Diagnostic Continuously: No physical storage connected

Blinking: No memory installed

B HDD Blinking: Solid-state hard drive is active

C Power Power is On

D PoE (4) Power over Ethernet (PoE) is active (M1xx camera only)

E PoE Activity/Link (4) On: Link is established

Blinking: Data is being transferred

H

F PoE Speed (4) Off: 10 Mbps

Green: 100 Mbps

Orange: 1000 Mbps (Gigabit)

G LAN 1 and 2 Speed Off: 10 Mbps

Green: 100 Mbps

Orange: 1000 Mbps (Gigabit)

H LAN 1 and 2 Activity/Link On: Link is established

Blinking: Data is being transferred

M-Series Processor Serial Outputs

MX20 and MX40 Serial Cable

The MX20 and MX40 processors provide one serial port connection. The front panel connector (Serial Port 1-COM 1)

uses a standard serial cable. CAM 1 controls this serial port.

Pin Number Signal Name

1 Carrier Detect (CD)

2 Received Data (RxD)

3 Transmitted Data (TxD)

4 Data Terminal Ready (DTR)

5 Signal Ground (GND)

6 Data Set Ready (DSR)

Page 11 Datalogic S.r.l.

Page 16

MX80 Serial Cable M-Series Quick Reference Guide

Pin Number Signal Name

7 Request To Send (RTS)

8 Clear To Send (CTS)

9 Ring Indicator (RI)

Pin 1

9 Pin Male

(Pin Side)

MX80 Serial Cable

The MX80 processor provides four serial port connections. The connector on the front panel is Serial Port 1 (COM 5)

which uses a standard serial cable. CAM 1 controls this serial port.

The rear panel connector has three serial port connections for Serial Ports 2, 3, and 4 (COM 2, 3, and 4 respectively).

CAM 2 controls Serial Port 2, CAM 3 controls Serial Port 3, and CAM 4 controls Serial Port 4. Use the Datalogic provided cable which has a DB-62P connector on one end and four standard serial port connectors (DB9) on the other end

(Part 95A906006). The connector wiring pin numbers on the DB9 connectors are the same as the MX20 and MX40.

M-Series Processor I/O Wiring

To connect Processor power and input/output signals, use cable

606-0675-xx (37 pin D-sub Male to Male) with terminal block

661-0403.

Terminal Name Signal Notes

Input Cmn (2) Input Common

Input 1 through

Input 16

Output Ground (2) Output Ground

Output +5 to +35

VCC

Output 1 through

Output 16

Outputs Sourcing

Pullups VCC

JP1 through JP16 Pullup Enable/Disable See “Pullup Jumpers to Enable Sourcing” on page 14

Input 1+ through

Input 16+

Output Control Voltage See Supply

Outputs 1 through 16

(sinking or sourcing

selectable)

Output Pullup - use if

Output needs to be

sourcing

Input Characteristics

See Input Voltage

on Page 13

Voltage on Page 13

See “Pullup Jumpers to Enable Sourcing” on page 14

+24 VDC

(Jumpers JP1 through JP16 enable/disable connection)

The diagrams and table below describe the input characteristics and how to wire a sensor to a general purpose or event

input.

Datalogic S.r.l. Page 12

Page 17

M-Series Quick Reference Guide General Purpose Input Circuit (Sinking)

Note: All connections to inputs must be made using properly grounded shielded cable.

All inputs must be wired as either sinking or sourcing, they cannot be mixed. There is only one “Input Common” connection for all the inputs.

Input Resistance

(nominal)

1.2k @ 0.5 W 0-24 Vdc >3 Vdc < 0.8 Vdc 2500 Vrms

Input

Voltage

General Purpose Input Circuit (Sinking)

General Purpose Input Circuit (Sourcing)

Turn On

Voltage

Turn Off

Voltage

Isolated

Voltage

Output Characteristics

The M-Series Processors contain sixteen general-purpose output connections.

Supply Voltage +5 VDC (minimum) to +35 VDC (maximum)

Sink Current (maximum) 1 Amp per output

Source Current (maximum) 15 Milliamperes per output (see “Pullup Jumpers” below)

NOTES: An external power source is required to power an output load. The outputs are merely switches that are open or

closed. All output connections must use properly grounded and shielded cable.

The Trigger Signal and Strobe Output for M-Series cameras are separate and not part of the M-Series Processor inputs and

outputs. See “Camera Trigger, Power, and Strobe Wiring” on page 15 for details.

Page 13 Datalogic S.r.l.

Page 18

Pullup Jumpers to Enable Sourcing M-Series Quick Reference Guide

Pullup Jumpers to Enable Sourcing

Jumpers JP1 through JP16 enable and disable the connection between their respective Output and the “Outputs Sourcing

Pullups VCC” signal on the terminal block. If a jumper is in the Enable position, the Sourcing VCC is connected to the

Output and it provides a sourcing signal (it is normally low and goes high when On). If a jumper is in the Disable position,

the Output provides a sinking signal (normally high and goes low when On). The Discrete Output tool in the vision program must be programmed to provide the desired output level. Refer to Discrete Output tool in the Impact Reference

Guide (843-0093).

Note: With the sourcing pullup jumper enabled, the maximum current per output is 15 Milliamperes.

General Purpose Output Circuit (Sinking)

This is not an output voltage source. An

external power source must be connected to VCC, as indicated.

NOTES: To prevent output damage, all inductive loads must have noise suppressors connected directly across the load, as

close to the load as possible.

The Output +5 to +35 VCC terminal is not an output voltage source. An external power source must be connected to it.

Output +5 to +35 VCC is not an

output voltage source. An external power source must be connected to VDD, as indicated.

Datalogic S.r.l. Page 14

Page 19

M-Series Quick Reference Guide General Purpose Output Circuit (Sourcing)

General Purpose Output Circuit (Sourcing)

This is not an output voltage source. An

external power source must be connected to VCC, as indicated.

Note: To turn PLC Input On,

turn M Output Off. To turn

PLC Off, turn M Output On.

Camera Trigger, Power, and Strobe Wiring

Datalogic M1xx Camera

To connect M1xx camera power, trigger signals, and strobe outputs, use cable 606-0674-xx (6

pin to DB9) with terminal block 661-0399.

Terminal Name Signal Notes

Optional Camera

Power +12VDC

Optional Camera

Power Ground

I/O Ground I/O Ground

DO NOT USE (Power is supplied by POE)

DO NOT USE

Output +5 to +35 VCC is not

an output voltage source. An

external power source must

be connected as indicated.

Page 15 Datalogic S.r.l.

Page 20

Datalogic M1xx Camera M-Series Quick Reference Guide

Terminal Name Signal Notes

Trigger In** Camera Trigger In 0 to +24 VDC recommended

Maximum +30 VDC

As sinking input

Off: 0 to +1.4 VDC

On: +2.2 to +24 VDC; 5 to 15 ma

As sourcing input (see Trigger Pullup +VCC)

Off: +2.2 to +24 VDC; 5 to 15 ma

On: 0 to +1.4 VDC

Trigger Pullup

+VCC**

Strobe Output

Pullup +VCC*

Strobe Trigger

Output*

Trigger In Pullup - use if

Trigger In needs sourcing (see Note 1 below)

Strobe Supply Voltage use if Strobe Trigger

Output needs sourcing

(see Note 2 below)

Trigger Out to Strobe

(see Note 3 below)

+24 VDC recommended

Maximum +30 VDC

(**Block contains 1.6k Ohm 1W resistor between Trigger In

and Trigger Pullup +VCC)

Based on Strobe requirement (optional)

Max: +30 VDC; 50 ma

(*Block contains 1.6k Ohm 1W resistor between Strobe Trigger Output and Strobe Output Pullup +VCC)

DO NOT APPLY ANY VOLTAGE DIRECTLY TO THIS OUTPUT. DO NOT WIRE OUTPUTS IN PARALLEL.

NOTE 1: If Camera Trigger In requires a sinking signal, set the Software Trigger Event to Rising Edge. If it requires a

sourcing signal, set the Software Trigger Event to Falling Edge.

NOTE 2: If Strobe Trigger Output requires a sinking signal, set the Strobe Trigger Output to Falling Edge. If it requires a

sourcing signal, set the Strobe Trigger Output to Rising Edge.

NOTE 3: Disconnecting the camera will turn on some strobe lights.

M1xx Trigger In Circuit

WARNING: Never wire M1xx Camera Strobe Outputs in parallel with M1xx, M2xx, or M3xx Camera Strobe Outputs.

This will damage the cameras.

Datalogic S.r.l. Page 16

Page 21

M-Series Quick Reference Guide Datalogic M1xx Camera

M1xx Strobe Trigger Output Circuit

M1xx Terminal Connections

Page 17 Datalogic S.r.l.

Page 22

Datalogic M2xx and M3xx Camera M-Series Quick Reference Guide

Datalogic M2xx and M3xx Camera

To connect M2xx and M3xx camera power, trigger signals, and strobe outputs, use cable 6060673-xx (12-pin to HD-15) with terminal block 661-0400.

Terminal Signal Name Notes

Camera Power Ground Camera Ground

I/O Ground I/O Ground

Camera Power +VDC Camera Power +12 to +24 VDC recommended

@ 500 mA Max

Maximum: +30 VDC

Output +VCC Power for Strobe Trigger Out +3.3 to +24 VDC; 50 mA Max

Maximum: +30 VDC

Input 2 Pullup +VCC DO NOT USE Not Currently Supported

Trigger Pullup +VCC Trigger In Pullup - use if Trig-

ger In needs sourcing input

Trigger In Camera Trigger In (see Note

1 below)

Input 2 DO NOT USE Not Currently Supported

Strobe Trigger Out Trigger Out to Strobe (see

Note 2 below)

Output 2 DO NOT USE Not Currently Supported

Output 3 DO NOT USE Not Currently Supported

Output 4 DO NOT USE Not Currently Supported

Recommended: +24 VDC

0 to +24 VDC recommended

Maximum +30 VDC

As sinking input

Off: 0 to +1.4 VDC

On: +2.2 to +24 VDC; 5 to 15 ma

As sourcing input (see Trigger Pullup

+VCC)

Off: +2.2 to +24 VDC; 5 to 15 ma

On: 0 to +1.4 VDC

DO NOT APPLY GROUND DIRECTLY

TO THIS OUTPUT.

NOTE 1: If Camera Trigger In requires a sinking signal, set the Software Trigger Event to Rising Edge. If it requires a

sourcing signal, set the Software Trigger Event to Falling Edge.

NOTE 2: If Strobe Trigger Output requires a sinking signal, set the Strobe Trigger Output to Falling Edge. If it requires a

sourcing signal, set the Strobe Trigger Output to Rising Edge.

Datalogic S.r.l. Page 18

Page 23

M-Series Quick Reference Guide Datalogic M2xx and M3xx Camera

M2xx and M3xx Trigger In Circuit

M2xx and M3xx Strobe Trigger Out Circuit

Page 19 Datalogic S.r.l.

Page 24

Datalogic M565/M570 Camera M-Series Quick Reference Guide

M2xx and M3xx Terminal Connections

Datalogic M565/M570 Camera

To connect the M565/M570, use terminal block 661-0401 with cable 606-0673-xx (12-pin to

HD-15 camera I/O) and cable 606-0674-xx (6 pin to DB9 camera power). For details about

programming the Line Trigger, refer to the Impact Reference Guide (843-0093).

NOTE: Do NOT use the M2xx/M3xx terminal block (661-0400) or M1xx block (661-0399)

to connect this camera. They will NOT provide the correct signal levels.

Terminal Signal Name Notes

Camera Power Ground Camera Ground See Note 1 Below

I/O Ground I/O Ground See Note 1 Below

Camera Power

+12VDC

Input 1 - No Connection DO NOT USE

Datalogic S.r.l. Page 20

Camera Power +12 VDC (+-10%) @ 700 mA Max

Page 25

M-Series Quick Reference Guide Datalogic M565/M570 Camera

Terminal Signal Name Notes

Input 1 + Frame Start Trigger As sinking input

Off 0 to +0.8 VDC

On: +2.0 to +5 VDC

As sourcing input (see Input 1 Pullup)

Off: +2.0 to +5 VDC

On 0 to +0.8 VDC

Maximum: +5 VDC

Input 2 - No Connection DO NOT USE

Input 2 + Single Line Trigger

OR

Phase A Line Trigger

(Quadrature Encoder)

Input 3 - No Connection DO NOT USE

Input 3 + Phase B Line Trigger

(Quadrature Encoder)

Output 1 - Not Currently Supported DO NOT USE

Output 1 + Not Currently Supported DO NOT USE

Output 2 - Not Currently Supported DO NOT USE

Output 2 + Not Currently Supported DO NOT USE

Input 1 Pullup +5VDC Frame Start Trigger Pullup -

use if Input 1 needs sourcing

input

As sinking input

Off 0 to +0.8 VDC

On: +2.0 to +5 VDC

As sourcing input (see Input 2 Pullup)

Off: +2.0 to +5 VDC

On 0 to +0.8 VDC

Maximum: +5 VDC

As sinking input

Off 0 to +0.8 VDC

On: +2.0 to +5 VDC

As sourcing input (see Input 3 Pullup)

Off: +2.0 to +5 VDC

On 0 to +0.8 VDC

Maximum: +5 VDC

Maximum: +5 VDC

Input 2 Pullup +5VDC Line Trigger Pullup - use if

Input 2 needs sourcing input

Input 3 Pullup +5VDC Line Trigger Pullup - use if

Input 3 needs sourcing input

Maximum: +5 VDC

Maximum: +5 VDC

NOTE 1: To help prevent ground loops and possible false triggering, we recommend connecting I/O Ground to Camera

Power Ground.

Page 21 Datalogic S.r.l.

Page 26

Datalogic M565/M570 Camera M-Series Quick Reference Guide

M565/M570 Frame Trigger Circuit

M565/M570 Single Line Trigger Circuit

Datalogic S.r.l. Page 22

Page 27

M-Series Quick Reference Guide Datalogic M565/M570 Camera

M565/M570 Quadrature Encoder Line Trigger Circuit

M565/M570 Trigger Terminal Connections

Page 23 Datalogic S.r.l.

Page 28

Using Unisolated Terminal Blocks M-Series Quick Reference Guide

Using Unisolated Terminal Blocks

IMPORTANT: This section describes how to connect M-Series cameras and I/O using the unisolated, discrete style of

terminal block. To use the newer, integrated style of terminal block, see “M-Series Processor I/O Wiring” on page 1-12

and “Camera Trigger, Power, and Strobe Wiring” on page 1-15.

WARNING: Never wire M1xx Camera Strobe Outputs in parallel with M1xx, M2xx, or M3xx

Camera Strobe Outputs. This will damage the cameras.

M1xx Camera Connection (Unisolated Terminal Blocks)

Camera power, trigger signals, and strobe triggers can be connected to the camera using one of two

methods: a terminal block and cable or an unterminated cable only. To use a terminal block (248-

0140) you must also use the optional Hirose 6-pin to DB9 camera cable (606-0674-xx).

To connect the camera using an unterminated cable, use the optional Hirose 6-pin to unterminated

cable (part number 606-0672-xx).

Terminal Color Signal Name Notes

1 Blue DO NOT USE Do NOT apply power to this terminal.

Power is supplied by Power over

Ethernet (PoE)

2 Orange Camera Trigger In 0 to +24 VDC recommended

Off: 0 to +1.4 VDC

On: +2.2 to +24 VDC; 5 to 15 ma

Maximum +30 VDC

3 Green No Connection

4* Wht/

Grn

5 Wht/

Org

6 Wht/

Blu

7* None Strobe VCC Based on Strobe requirement

Strobe Trigger Out DO NOT APPLY ANY VOLTAGE DIRECTLY TO THIS OUT-

PUT. DO NOT WIRE OUTPUTS IN PARALLEL.

I/O Ground

DO NOT USE Not required. Ground is supplied by Power Over Ethernet

(PoE)

Max: +30 VDC; 50 ma

(*Block contains 1k Ohm 2W resistor between terminals 4 and

7)

NOTE: The M1xx camera's Strobe Trigger Out is normally closed (it opens to trigger the strobe). Do not wire multiple

cameras' strobe outputs in parallel to trigger a single strobe.

To connect the power cable to the camera, align the cable connector with the connector on the rear of the camera, push

gently until the cable connector seats securely, then tighten the connector collar. To disconnect it, loosen the collar completely, then grasp the connector and gently pull.

NOTE: To reduce stress on the cable and connectors, loop the cable and fasten it to the camera's mounting block. Do not

crimp or tie the cable tightly with wire ties as this may damage it internally. The cable is not intended for continuous flexing or movement. The cable's maximum bend radius is fifteen times the cable diameter.

Datalogic S.r.l. Page 24

Page 29

M-Series Quick Reference Guide M1xx Circuit Diagrams (Unisolated Terminal Blocks)

M1xx Circuit Diagrams (Unisolated Terminal Blocks)

Set Software Trigger Event to Falling Edge

M1xx Trigger Input circuit (sourcing)

Set Software Trigger Event to Rising Edge

M1xx Trigger Input circuit (sinking)

Set Software Strobe Trigger Output to Rising Edge

Note: Disconnecting the camera will turn on some strobe lights

M1xx Strobe Output circuit (sourcing)

Page 25 Datalogic S.r.l.

Page 30

M1xx Terminal Connections (Unisolated Terminal Blocks) M-Series Quick Reference Guide

Set Software Strobe Trigger Output to Falling Edge

M1xx Strobe Output circuit (sinking)

WARNING: Never wire M1xx Camera Strobe Outputs in parallel with M1xx, M2xx, or M3xx Camera Strobe Outputs.

This will damage the cameras.

M1xx Terminal Connections (Unisolated Terminal Blocks)

M1xx Terminal Block Connections

Datalogic S.r.l. Page 26

Page 31

M-Series Quick Reference Guide M1xx Unterminated Cable Connections (Unisolated Terminal Blocks)

M1xx Unterminated Cable Connections (Unisolated Terminal Blocks)

M1xx Unterminated Cable Connections

Page 27 Datalogic S.r.l.

Page 32

M2xx and M3xx Camera Connection (Unisolated Terminal Blocks) M-Series Quick Reference Guide

M2xx and M3xx Camera Connection (Unisolated Terminal Blocks)

Camera power, trigger signal, and strobe trigger can be connected to the camera using one of two

methods: a terminal block and cable or an unterminated cable only. To use a terminal block (248-

0141), you must also use the optional Hirose 12-pin to HD-15 camera cable (606-0673-xx).

To connect the camera using an unterminated cable, use the optional Hirose 12-pin to unterminated cable (part number 606-0671-xx).

Terminal Color Signal Name Notes

1

2

3 Wht/Brn Camera Trigger In 0 to +24 VDC recommended

4 Brn/Wht DO NOT USE

5 Wht/Grn Camera Trigger Ground

6* Wht/Gry Strobe Trigger Out

7 Gry/Wht DO NOT USE

8

9

10 Grn/Wht Strobe VCC Based on strobe requirement

11 Red/Blu DO NOT USE

12 Blu/Red DO NOT USE

13 None Strobe Output Ground Block contains 270 Ohm 2W resistor between terminals

Wht/Blu

Wht/Org

Blu/Wht

Org/Wht

Camera Power Ground

Camera Power Ground

Camera Power VCC

Camera Power VCC

See Note 1 below

Off: 0 to + 1.4 VDC

On: +2.2 to + 24 VDC; 5 to 15 mA

Maximum: +30 VDC

+12 to +24 VDC recommended @ 500 mA Max

Maximum: +30 VDC

See Note 1 below

Maximum: +30 VDC; 100 ma

6 and 13

NOTE 1: Pins 1 and 2 are tied together inside of the camera. Pins 8 and 9 are tied together inside of the camera. To avoid

a voltage drop when there are long wires between your power supply and the camera, we recommend that you provide

camera power VCC through separate wires between your power supply and pins 8 and 9 on the camera. We also recommend that you provide camera power ground through separate wires between your power supply and pins 1and 2 on the

camera.

To connect the power cable to the camera, align the cable connector with the connector on the rear of the camera, push

gently until the cable connector seats securely, then tighten the connector collar. To disconnect it, loosen the collar completely, then grasp the connector and gently pull.

NOTE: To reduce stress on the cable and connectors, loop the cable and fasten it to the camera's mounting block. Do not

crimp or tie the cable tightly with wire ties as this may damage it internally. The cable is not intended for continuous flexing or movement. The cable's maximum bend radius is fifteen times the cable diameter.

Datalogic S.r.l. Page 28

Page 33

M-Series Quick Reference Guide M2xx and M3xx Circuit Diagrams (Unisolated Terminal Blocks)

M2xx and M3xx Circuit Diagrams (Unisolated Terminal Blocks)

Set Software Trigger Event to Rising Edge

M2xx and M3xx Cameras Trigger Input circuit (sourcing)

Set Software Trigger Event to Falling Edge

M2xx and M3xx Cameras Trigger Input circuit (sinking)

Set Software Strobe Trigger Output to Falling Edge

M2xx and M3xx Cameras Strobe Output circuit (sourcing)

WARNING: Never wire M1xx Camera Strobe Outputs in parallel with M1xx, M2xx, or M3xx Camera Strobe Outputs.

This will damage the cameras.

Page 29 Datalogic S.r.l.

Page 34

M2xx and M3xx Terminal Connections (Unisolated Terminal Blocks) M-Series Quick Reference Guide

M2xx and M3xx Terminal Connections (Unisolated Terminal Blocks)

M2xx and M3xx Terminal Block Connections

Datalogic S.r.l. Page 30

Page 35

M-Series Quick Reference Guide M2xx and M3xx Unterminated Cable Connections (Unisolated Terminal Blocks)

M2xx and M3xx Unterminated Cable Connections (Unisolated Terminal Blocks)

M2xx and M3xx Unterminated Cable Connections

Page 31 Datalogic S.r.l.

Page 36

M565/M570 Camera Connection (Unisolated Terminal Blocks) M-Series Quick Reference Guide

M565/M570 Camera Connection (Unisolated Terminal Blocks)

This camera uses three cables, one for Ethernet, one for power, and one for trigger signals.

Power

To connect power, use the optional Hirose 6-pin unterminated cable (part number 606-0672-xx)

without a terminal block. Table 1 shows the power connections.

Trigger

To connect trigger signals, use a terminal block with a cable or an unterminated cable. Use a terminal block (248-0136) with the optional Hirose 12-pin to HD-15 camera cable (606-0673-xx). Without a terminal block, use the optional Hirose 12-pin to unterminated cable (part number 606-0671xx). Table 2 shows the trigger connections.

NOTE: Do NOT use the M2xx/M3xx terminal block (248-0141) to connect this camera. It will NOT provide the correct

signal levels.

Power Cable Connections

Cable Pin Color Signal Name Notes

1

2

3 Green Not Connected

4 Wht/Grn Not Connected

5

6

Blue

Orange

Wht/Org

Wht/Blu

Camera Power VCC

Camera Power VCC

Camera Power Ground

Camera Power Ground

+12 VDC (+-10%) @ 700 mA Max

See Note below

See Note 1 below

NOTE 1: Pins 1 and 2 are tied together inside of the camera. Pins 5 and 6 are tied together inside of the camera. To avoid

a voltage drop when you use long wires between the power supply and the camera, we recommend providing camera

power VCC through separate wires between the power supply and camera pins 1 and 2. We also recommend providing

camera power ground through separate wires between the power supply and pins 5and 6 on the camera.

Trigger Cable Connections

Terminal Color Signal Name Notes

1 Wht/Blu Input 1 Ground No Connection

2 Wht/Org Input 1 Plus Frame Start Trigger

Off: 0 to + 0.8 VDC

On: +2.0 to +5 VDC

Maximum: +5 VDC

3 Wht/Brn Input 3 Ground No Connection

4 Brn/Wht Input 3 Plus Phase B Line Trigger (Quadrature Encoder)

Off: 0 to + 0.8 VDC

On: +2.0 to +5 VDC

Maximum: +5 VDC

5 Wht/Grn Camera Trigger Ground See Note 2 below

6 Wht/Gry DO NOT USE

7 Gry/Wht DO NOT USE

8 Blu/Wht Input 2 Ground No Connection

Datalogic S.r.l. Page 32

Page 37

M-Series Quick Reference Guide M565/M570 Camera Connection (Unisolated Terminal Blocks)

Terminal Color Signal Name Notes

9 Org/Wht Input 2 Plus Single Line Trigger

OR

Phase A Line Trigger (Quadrature Encoder)

Off: 0 to + 0.8 VDC

On: +2.0 to +5 VDC

Maximum: +5 VDC

10 Grn/Wht Not Connected

11 Red/Blu DO NOT USE

12 Blu/Red DO NOT USE

NOTE 2: To help prevent ground loops and possible false triggering, we recommend connecting pin 5 on the Trigger

Input (Camera Trigger Ground) to the ground on the Camera Power supply cable (pins 5 and/or 6).

Page 33 Datalogic S.r.l.

Page 38

M565/M570 Camera Connection (Unisolated Terminal Blocks) M-Series Quick Reference Guide

M565/M570 Circuit Diagrams (Unisolated Terminal Blocks)

M565/M570 Camera Frame Trigger Input circuit

M565/M570 Camera Single Line Trigger Input circuit

Datalogic S.r.l. Page 34

Page 39

M-Series Quick Reference Guide M565/M570 Camera Connection (Unisolated Terminal Blocks)

M565/M570 Camera Quadrature Encoder Line Trigger Input circuit

M565/M570 Terminal Connections (Unisolated Terminal Blocks)

M565/M570 Terminal Block Connections

Page 35 Datalogic S.r.l.

Page 40

M565/M570 Camera Connection (Unisolated Terminal Blocks) M-Series Quick Reference Guide

M565/M570 Unterminated Cable Connections (Unisolated Terminal Blocks)

M565/M570 Unterminated Cable Connections

Datalogic S.r.l. Page 36

Page 41

M-Series Quick Reference Guide Processor Input/Output (Unisolated Terminal Blocks)

Processor Input/Output (Unisolated Terminal Blocks)

Two options for connecting to the Unisolated M-Series Processor I/O terminal block are listed in the table below. The

cable wire color codes are listed in the following table.

The last two digits of the part number indicate the cable length in meters.

Connector Type Part Number

Terminal Block - 37 pin D-sub to Screw Terminal 248-0110

I/O Cable - 37 pin D-sub Male to Male Cable (for use with above terminal block) 606-0675-xx

I/O Cable - 37 pin D-sub Male to Unterminated Cable (remove one end) 606-0675-xx

Page 37 Datalogic S.r.l.

Page 42

Processor Input/Output (Unisolated Terminal Blocks) M-Series Quick Reference Guide

Connector or terminal

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 Purple/White Output VDD +5 to 35 VDC external

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Color Code Signal Name

Black

Brown

Red

Orange

Yellow

Green

Blue

Purple

Gray

White

Pink

Light Green

Black/White

Brown/White

Red/White

Orange/White

Green/White

Blue/White

Red/Black

Orange/Black

Yellow/Black

Green/Black

Gray/Black

Pink/Black

Pink/Red

Pink/Blue

Pink/Green

Light Blue

Light Blue/Black

Light Blue/Red

Light Blue/Blue

Light Blue/Green

Gray/Red

Gray/Green

Purple/Black

Blue/Black

Input 1 and Event 1 +

Input 3 +

Input 5 +

Input 7 +

Input 9 +

Input 11 +

Input 13 +

Input 15 +

Input Common

Output GND

Output 1 +

Output 3 +

Output 5 +

Output 7 +

Output 9+

Output 11 +

Output 13 +

Output 15 +

supply. *Not an output voltage

Input 2 and Event 2 +

Input 4 +

Input 6 +

Input 8 +

Input 10 +

Input 12 +

Input 14 +

Input 16 +

Output GND

Output GND

Output 2 +

Output 4 +

Output 6 +

Output 8 +

Output 10 +

Output 12 +

Output 14 +

Output 16 +

Pin 1

Pin 20

J1 (37 Pin "D" Sub Male)

AMP Part 747916-4

Part 244-0287

(Solder Side)

Pin 19

Pin 37

Hood Assembly with

Screws

LEOCO Part DCHD-

37MON4

Part 248-0089

Datalogic S.r.l. Page 38

Page 43

M-Series Quick Reference Guide Processor Unisolated I/O Terminal Block

Processor Unisolated I/O Terminal Block

This diagram illustrates the 37 pin D-sub to Screw Terminal block (Part number 248-0110). This terminal block can be

mounted on a DIN rail, then connected to the unit using a 37-pin cable (Part number 606-0675-xx). You can then wire

from the terminal block to the controlled devices.

37-pin cable connector

Insert small flat screw-

driver blade here to

open connector

Terminal Block

Wire Connections

Terminal Block

Wire Connections

General Purpose Unisolated I/O Output Circuit (Sinking)

This is not an output voltage source. An

external power source must be connected to VDD, as indicated.

This is an inductive load

spike prevention filter.

NOTES: To prevent output damage, all inductive loads must have noise suppressors connected directly across the load, as

close to the load as possible.

Terminal 19 is not an output voltage source. An external power source must be connected to VDD.

Terminal 19 is not an output

voltage source. An external

power source must be connected to VDD, as indicated.

Page 39 Datalogic S.r.l.

Page 44

General Purpose Unisolated I/O Output Circuit (Sourcing) M-Series Quick Reference Guide

General Purpose Unisolated I/O Output Circuit (Sourcing)

Terminal 19 is not an output

voltage source. An external

power source must be connected to VDD, as indicated.

Unisolated Input I/O Circuit

The M-Series Processors contain sixteen general-purpose input connections.

Two inputs serve as both event and polled inputs (Inputs 1 and 2). The remaining inputs are polled. The event inputs are

interrupt-driven which means that a change of state on the input will immediately cause an action and any inspection task

that uses that input will run. Polled input means that the input’s status is checked based on conditions defined in the

inspection task.

Interrupt-driven inputs are edge-triggered and the duration of the input pulse must be longer than the debounce time. The

active trigger edge (rising, falling, or both), input pulse duration, and debounce, are all configured in the Vision Program

Manager Settings tab.

This table describes the input characteristics.

Input Resistance

(nominal)

1.2k @ 0.5 W 0-24 Vdc >3 Vdc < 0.8 Vdc 2500 Vrms

This table lists the connector/terminal numbers for the input signals.

Connector and

terminal number

Input

Voltage

Turn On

Voltage

Signal Name

1

2

3

4

5

6

7

8

Input1 and Event 1 +

Input 3 +

Input 5 +

Input 7 +

Input 9 +

Input 11 +

Input 13 +

Input 15 +

9 Input Common

Turn Off

Voltage

Isolated

Voltage

Datalogic S.r.l. Page 40

Page 45

M-Series Quick Reference Guide Input Wiring

Connector and

terminal number

20

21

22

23

24

25

26

27

Signal Name

Input 2 and Event 2 +

Input 4 +

Input 6 +

Input 8 +

Input 10 +

Input 12 +

Input 14 +

Input 16 +

Input Wiring

The diagrams below show two ways to wire a sensor to a general purpose or event input.

Note: All connections to inputs must be made using properly grounded shielded cable.

All inputs must be wired as either sinking or sourcing, they cannot be mixed. There is only one “Input Common” connection for all the inputs.

General Purpose Input Circuit (Sinking)

General Purpose Input Circuit (Sourcing)

Page 41 Datalogic S.r.l.

Page 46

General Purpose Input Circuit (Sourcing) M-Series Quick Reference Guide

Datalogic S.r.l. Page 42

Loading...

Loading...