Page 1

Marvis™

Application Note

Marking and Reading System

Page 2

Datalogic S.r.l.

Via S. Vitalino, 13

40012 Calderara di Reno — Italy

Tel. +39 051 3147011

Fax +39 051 3147205

Marvis™ Application Manual

Original Instructions

Ed.: 04/2019

This manual refers to Lighter™ Suite version 7.1.3 and later.

© 2018-2019 Datalogic S.p.A. and/or its affiliates

ALL RIGHTS RESERVED. Without limiting the rights under copyright, no part of this docu-

mentation may be reproduced, stored in or introduced into a retrieval system, or transmitted

in any form or by any means, or for any purpose, without the express written permission of

Datalogic S.p.A. and/or its affiliates.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries, including the U.S.A. and the E.U.

Arex™ 400, Arex™, UniQ™, Vlase™, Matrix (120™, 210N™, 220™, 300N™, 410N™) and Lighter™

Suite are trademarks of Datalogic S.p.A.and/or its affiliates. All other trademarks and bands

are property of their respective owners.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor

for incidental or consequential damages resulting from the use of this material.

Page 3

Table of Contents

CONVENTIONS.......................................................................................................................................................................VI

INTRODUCTION...................................................................................................................................................................... 1

About This Document ...................................................................................................................................................................... 2

Restrictions ....................................................................................................................................................................................... 2

SUPPORTED TOPOLOGIES AND OPERATIONS.................................................................................................................... 3

Marvis™ Configuration ..................................................................................................................................................................... 4

Vlase™ and Matrix 220™/300N™/410N™ ................................................................................................................................ 4

Arex™ and Matrix 220™/300N™/410N™ .................................................................................................................................. 5

UniQ™ and Matrix 220™/300N™/410N™ ................................................................................................................................. 6

Arex™ 400 and Matrix 220™/300N™/410N™ .......................................................................................................................... 7

HARDWARE INSTALLATION ................................................................................................................................................. 9

Mounting Instructions for Matrix ................................................................................................................................................. 10

Mechanical assembly on Arex™ laser marker ..................................................................................................................... 10

Mechanical assembly on UniQ™ laser marker .................................................................................................................... 13

Mechanical assembly on Arex™ 400 laser marker .............................................................................................................. 16

Fixing the Matrix 300N™, 410N™ to the bracket .................................................................................................................. 19

Fixing the Matrix 220™ to the bracket .................................................................................................................................. 20

Connecting Matrix 220™, 300N™ and 410N™ ................................................................................................................................ 21

Connecting Matrix to the Ethernet ...................................................................................................................................... 21

Connecting to Matrix ..................................................................................................................................................... 21

Connecting to Vlase™ ..................................................................................................................................................... 21

Connecting to Arex™ ....................................................................................................................................................... 22

Connecting to UniQ™ ...................................................................................................................................................... 22

Connecting to Arex™ 400 ............................................................................................................................................... 23

Connecting Matrix to power supply ..................................................................................................................................... 24

Connecting to Matrix ..................................................................................................................................................... 24

Connecting to Vlase™, Arex™ and UniQ™ laser markers ............................................................................................. 24

Connecting to Arex™ 400 laser marker ........................................................................................................................ 24

Connecting LED Ring Light ID (optional) .............................................................................................................................. 25

Vlase™, Arex™ and UniQ™ laser markers ...................................................................................................................... 25

Arex™ 400 laser marker ................................................................................................................................................. 26

SOFTWARE CONFIGURATION............................................................................................................................................. 27

How To Configure Your Marvis™ System ..................................................................................................................................... 28

How To Test, Mark and Validate Your Document ....................................................................................................................... 34

Marking and Validation Statistics ................................................................................................................................................ 36

Troubleshooting ............................................................................................................................................................................. 38

HELP................................................................................................................................................................. 41

Photometric Adjustment ............................................................................................................................................................... 42

Setting ..................................................................................................................................................................................... 42

Results .................................................................................................................................................................................... 43

Quality Grade Training ................................................................................................................................................................... 45

Industrial traceability ............................................................................................................................................................. 45

The Code Grading process ..................................................................................................................................................... 45

Quality parameters of metrics .............................................................................................................................................. 46

CC - Cell Contrast ........................................................................................................................................................... 46

CM - Cell Modulation ..................................................................................................................................................... 46

FPD - Fixed Pattern Damage ........................................................................................................................................ 46

UEC - Unused Error Correction ..................................................................................................................................... 46

Application Note iii

Page 4

Contents

PG - Print Growth ...........................................................................................................................................................46

ANU - Axial Non-Uniformity ..........................................................................................................................................46

MR - Minimum Reflectance ..........................................................................................................................................46

GNU - Grid Non-Uniformity (GNU) ................................................................................................................................47

Verification process ................................................................................................................................................................47

Verification in production environments .............................................................................................................................47

In-line validation: a real example ..........................................................................................................................................48

MARVIS™ advantages: training on real sample ...................................................................................................................49

MARVIS™ advantages: single metric quality grade analysis ..............................................................................................49

MARVIS™ advantages: statistic threshold ............................................................................................................................50

ABOUT LED RING LIGHT ID.............................................................................................................................. 51

General Specification ......................................................................................................................................................................52

IEC62471-1 Compliance .................................................................................................................................................................52

iv

Marvis™

Page 5

Contents

Application Note v

Page 6

Conventions

Warnings

High Voltage

Laser Caution

ESD

Notes

This symbol identifies a hazard or procedure that, if incorrectly performed, could cause personal injury or result in

equipment damage. It is also used to bring the user’s attention to details that are considered IMPORTANT.

This symbol alerts the user they are about to perform an

action involving,

against an action that could result in damage to devices or

electrical shock.

This symbol alerts the user they are about to perform an

action involving possible exposure to laser light radiation.

This symbol identifies a procedure

measures to prevent Electrostatic Discharge (ESD) e.g., use an

ESD wrist strap. Circuit boards are most at risk. Please follow

ESD procedures.

This symbol draws attention to details or procedures that may

be useful in

mance of the hardware or software being discussed.

either a dangerous level of voltage, or to warn

that requires you take

improving, maintaining, or enhancing the perfor-

vi

Marvis™

Page 7

Application Note vii

Page 8

ABOUT THIS DOCUMENT starting on page 2

RESTRICTIONS starting on page 2

Chapter 1

Introduction

1

Marvis™

Page 9

About This Document

This document describes the implementation of a laser marker with a reading

system. The result of this system is defined as MARVIS™.

Refer to the associated reference manuals for additional information about setup,

maintenance and troubleshooting. Other related manuals are:

Vlase™ User’s Manual; Arex™ User's Manual; UniQ™ User's Manual; Arex™ 400 User’s

NOTE

Manual; Matrix 120™ User's Manual; Matrix 210N™ User's Manual; Matrix 220™ User's

Manual; Matrix 300N™ User's Manual; Matrix 410N™ User's Manual; Lighter™ Suite software User's Manual

Restrictions

The MARVIS™ solution is available for retrofit of existing Datalogic Laser Markers

and Readers as shown in the following table:

FAMILY DESCRIPTION MODELS NOTES

Arex™ Arex™ XX00-1X42 2015

Vlase™ Vlase™ 1X09-1X42 2016

Arex™ 20MW Arex™ A200-XX53

UniQ™ UniQ™ 1150-1X40

Arex™ 400 Arex™ XXX-XX4

Matrix 120™ Matrix 120™ X1X-01X YAG filter

Matrix 210N™ Matrix 210N™ 2XX-X1X

Matrix 220™ Matrix 220™ 3XX-010

Matrix 300N™ Matrix 300N™ 4XX-01X 472-012, 473-012, 482-012, 483-013 YAG filter

Matrix 300N™ Matrix 300N™ 4XX-01X

Matrix 410N™ Matrix 410N™ XXX-X1X

About This Document

472-010, 472-011, 473-010, 473-011,482-010, 482-011,

483-010, 483-011

→

→

NO YAG filter

W

ARNING

W

ARNING

The DPM illuminator is always recommended.

If application codes must be read which are produced

by Laser Marking in real time,

use Matrix models incorporating YAG Filters in order to avoid burning the CMOS sensor.

Application Note 2

Page 10

Chapter 2

Supported Topologies and Operations

MARVIS™ CONFIGURATION starting on page 4

3

Marvis™

Page 11

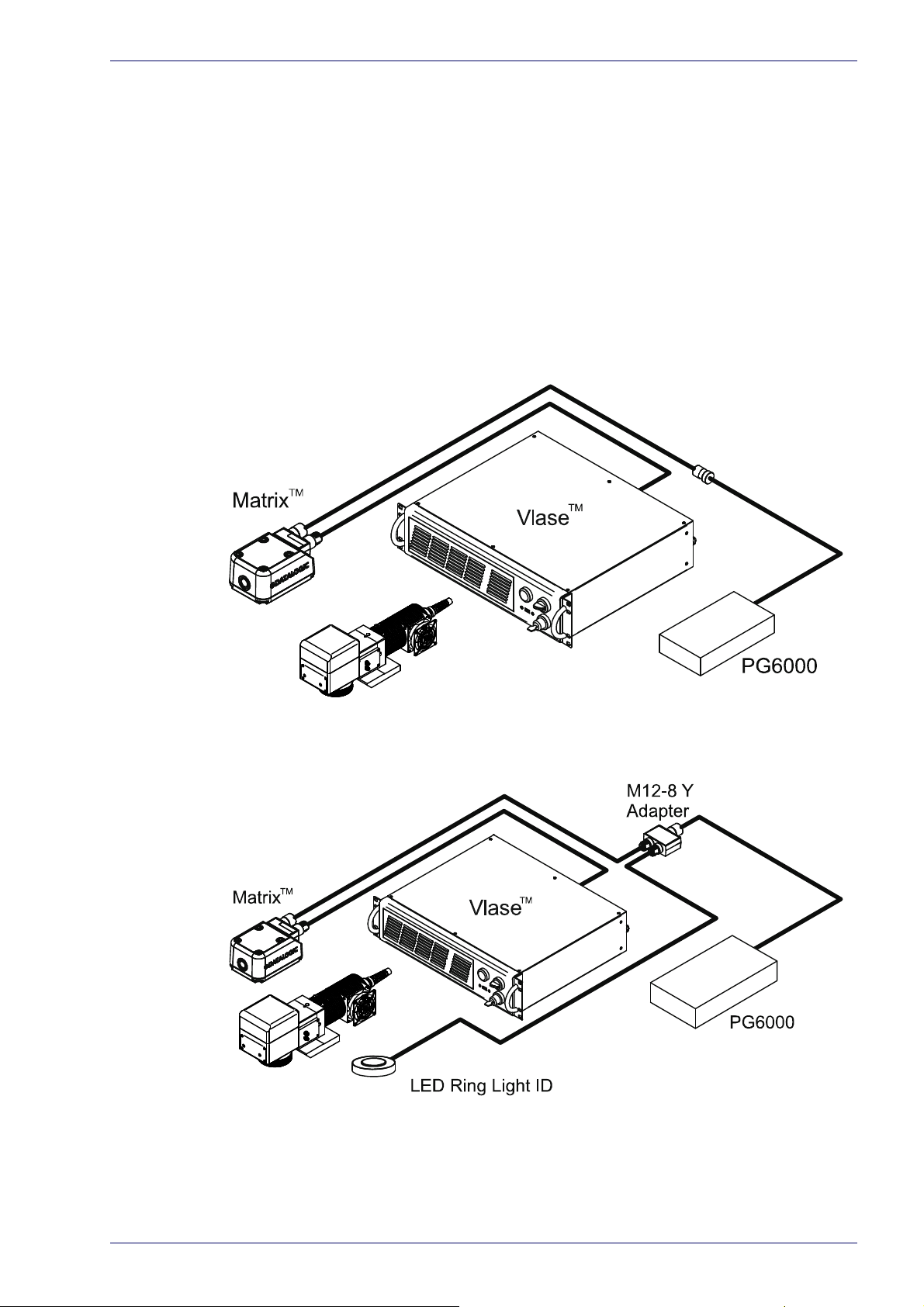

Marvis™ Configuration

Datalogic allows the integration of its products to create a complete marking and

reading verification system. To make this application possible, it is necessary to

integrate a laser marker (Vlase™, Arex™, UniQ™ or Arex™ 400) with a Matrix

reader (120™, 210N™, 220™, 300N™, 410N™).

Marvis™ Configuration

Datalogic makes available MARVIS™ ADD ON ki

between laser marker and Matrix reader easier. Currently these kits are compatible with Matrix 220™, 300N™ and 410N™. For the integration of Matrix 120N™/

0N™ with the laser marker, contact the technical support.

21

Vlase™ and Matrix 220™/300N™/410N™

ts to make the integration

Figure 1: example of integration between the Vlase™ and the Matrix™.

Figure 2: example of integration between the Vlase™ and the Matrix™ with LED Ring Light ID.

Application Note 4

Page 12

Supported Topologies and Operations

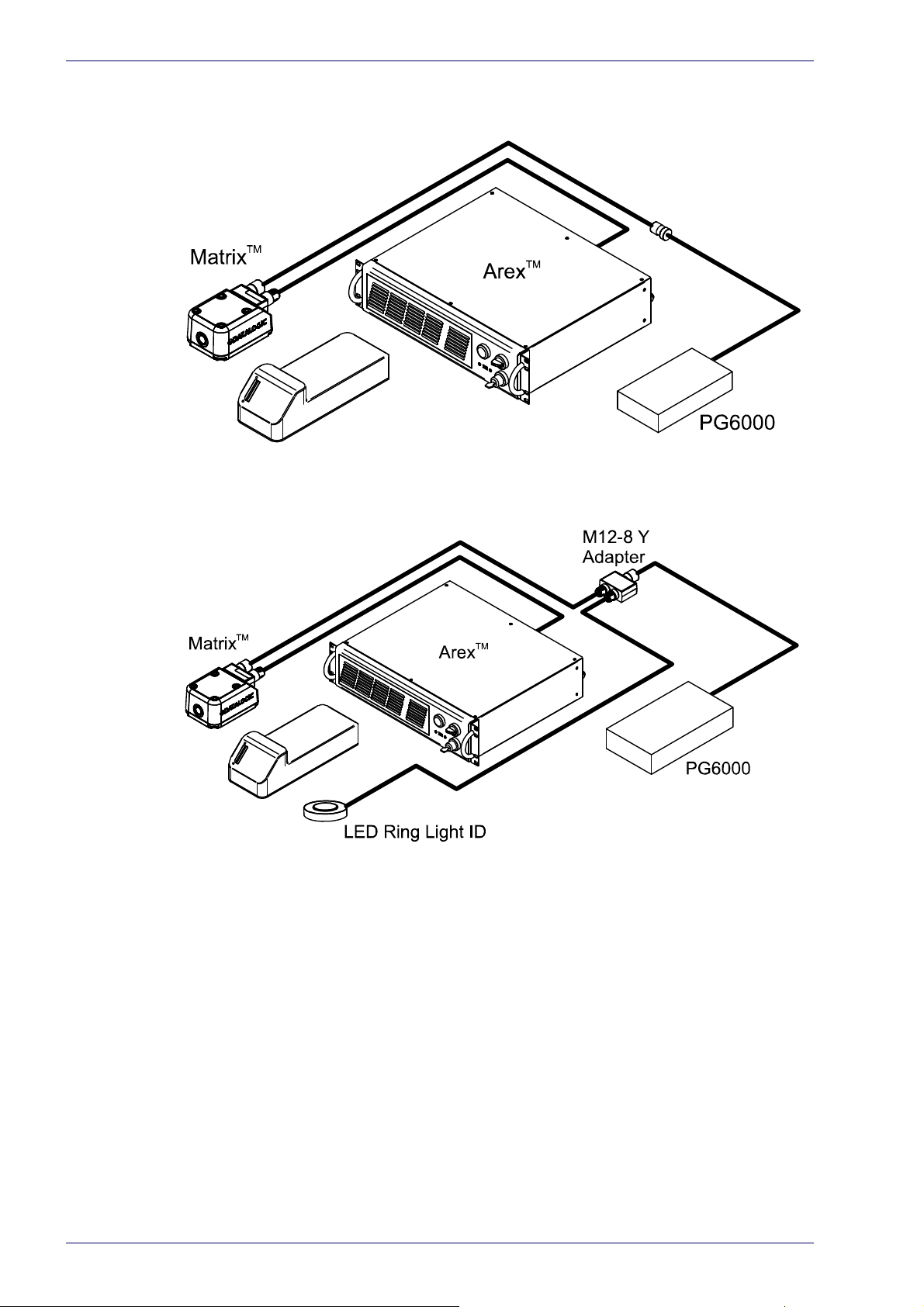

Arex™ and Matrix 220™/300N™/410N™

Figure 3: example of integration between the Arex™ and the Matrix™.

Figure 4: example of integration between the Arex™ and the Matrix™ with LED Ring Light ID.

5

Marvis™

Page 13

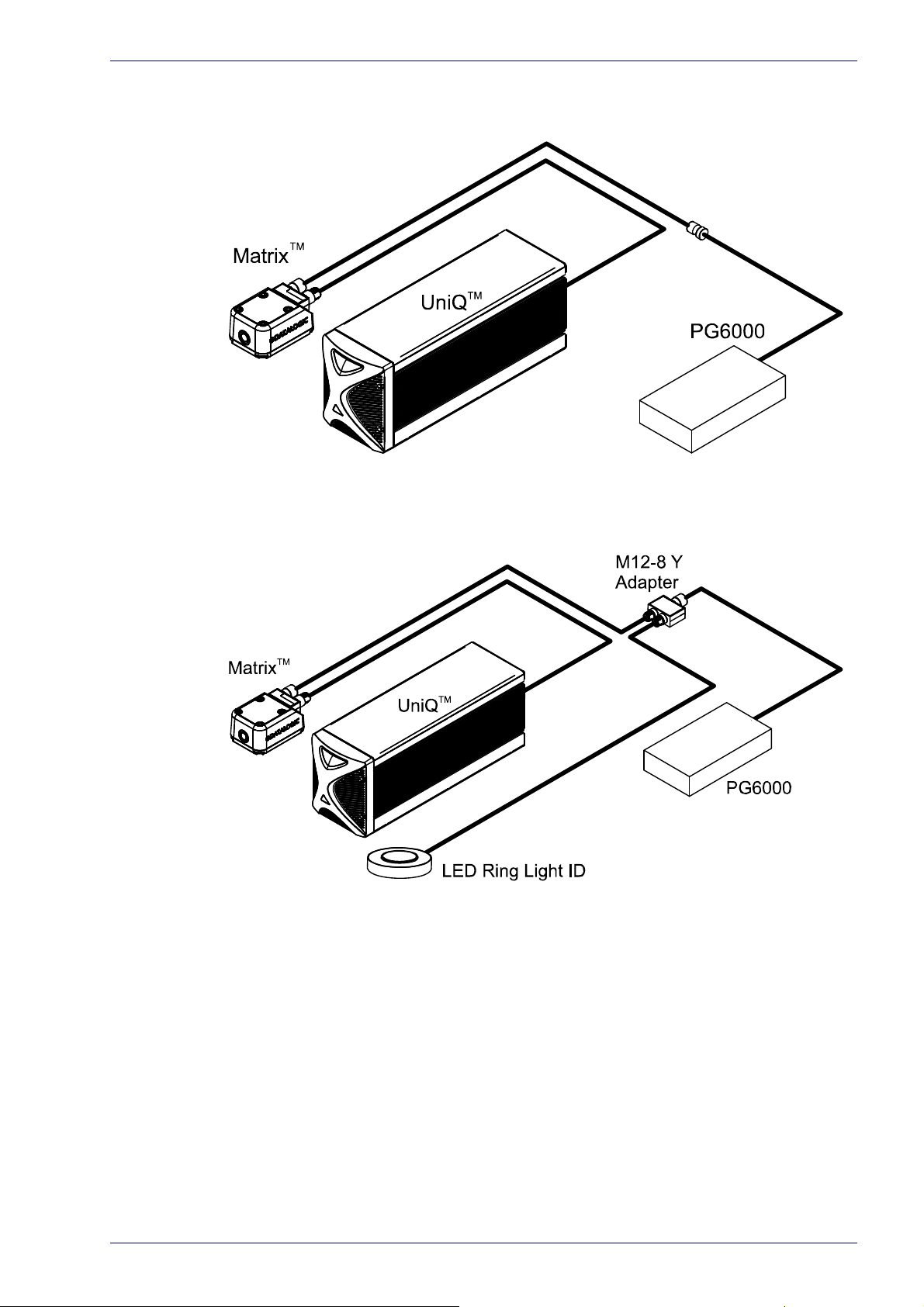

UniQ™ and Matrix 220™/300N™/410N™

Figure 5: example of integration between the UniQ™ and the Matrix™.

Marvis™ Configuration

Figure 6: example of integration between the UniQ™ and the Matrix™ with LED Ring Light ID.

Application Note 6

Page 14

Supported Topologies and Operations

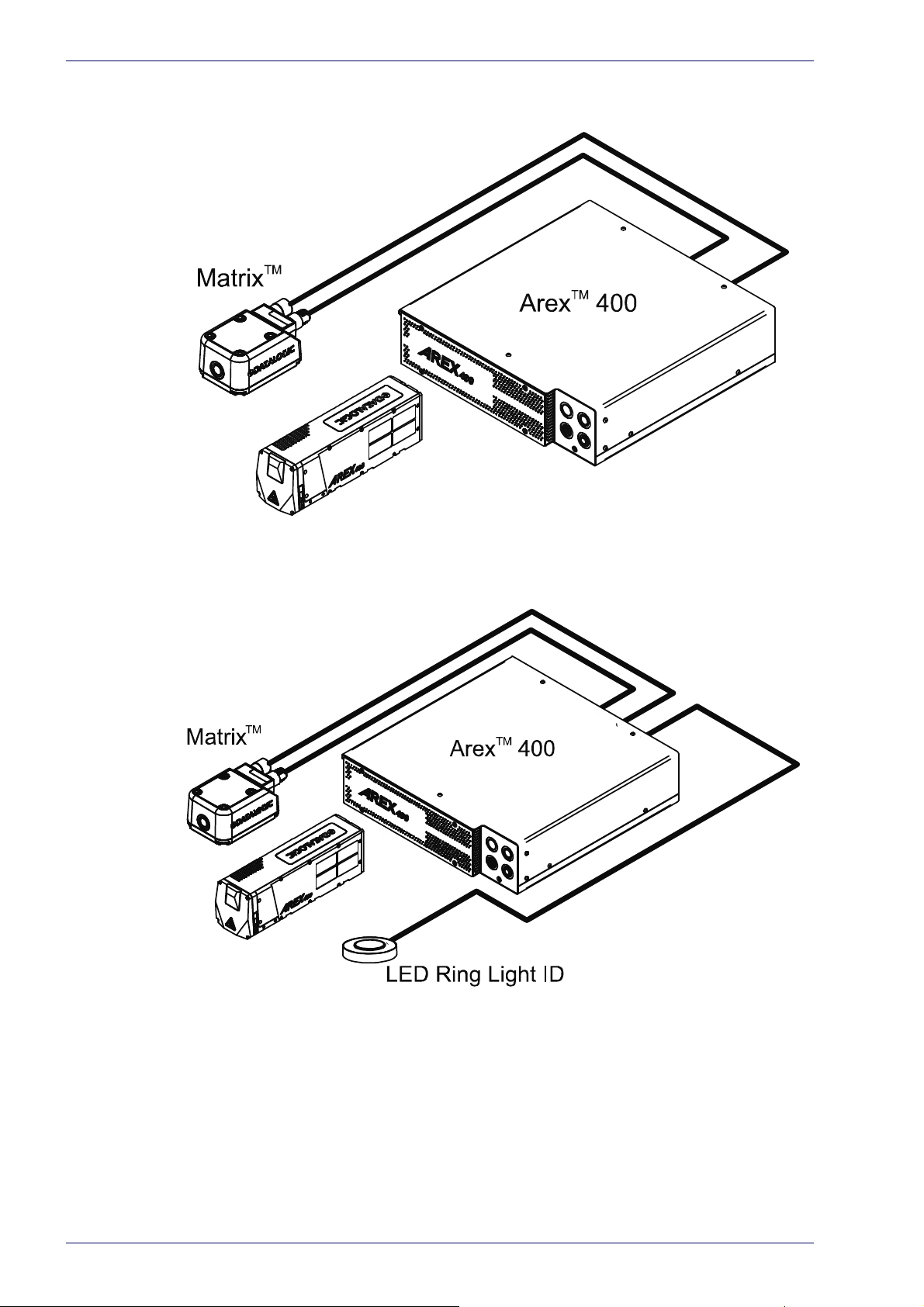

Arex™ 400 and Matrix 220™/300N™/410N™

Figure 7: example of integration between the Arec™ 400 and the Matrix 300N™.

Figure 8: example of integration between the Arex™ 400 and the Matrix™ with LED Ring Light ID.

Figure 9

7

Marvis™

Page 15

Marvis™ Configuration

Application Note 8

Page 16

Chapter 3

Hardware Installation

MOUNTING INSTRUCTIONS FOR MAT RI X starting on page 10

CONNECTING MAT RI X 220™, 300N™ AND 410N™ starting on

page 21

9

Marvis™

Page 17

Mounting Instructions for Matrix

Datalogic makes available MARVIS™ MOUNTING BRACKETS to make the integration between laser marker and Matrix 220™, 300N™ and 410™ readers easier.

Install the individual systems following the instructions present in the relative

stallation manuals. This manual explains what to do in order to obtain a mark

in

and read application.

Mechanical assembly on Arex™ laser marker

At first, mount the LED Ring Light ID (if present) on the bracket:

Mounting Instructions for Matrix

Figure 1: LED Ring Light ID mounting on Arex™.

Application Note 10

Page 18

Hardware Installation

The assembly of the following accessory changes the fixing distance by the value of

the base plate thickness.

W

ARNING

Fix the bracket to the adjustment plate with the supplied screws.

The bracket can be installed in two different positions:

11

Figure 2: Bracket mounting on Arex™.

Marvis™

Page 19

Mounting Instructions for Matrix

Mount the bracket between the Arex™ Scan Head and the fixing plane.

Figure 3: Fixing of Arex™ with bracket on fixing plane.

Application Note 12

Page 20

Hardware Installation

Mechanical assembly on UniQ™ laser marker

At first, mount the LED Ring Light ID (if present) on the bracket:

13

Figure 4: LED Ring Light ID mounting on UniQ™.

Marvis™

Page 21

W

ARNING

Mounting Instructions for Matrix

The assembly of the following accessory modifies the fixing points.

Fix the adjustment plate to the Uniq ™ with the supplied screws as shown:

Figure 5: Fixing adjustment plate on UniQ™.

Application Note 14

Page 22

Hardware Installation

Fix the bracket to the adjustment plate with the supplied screws.

The bracket can be installed in two different positions:

15

Figure 6: Bracket mounting on UniQ™.

Marvis™

Page 23

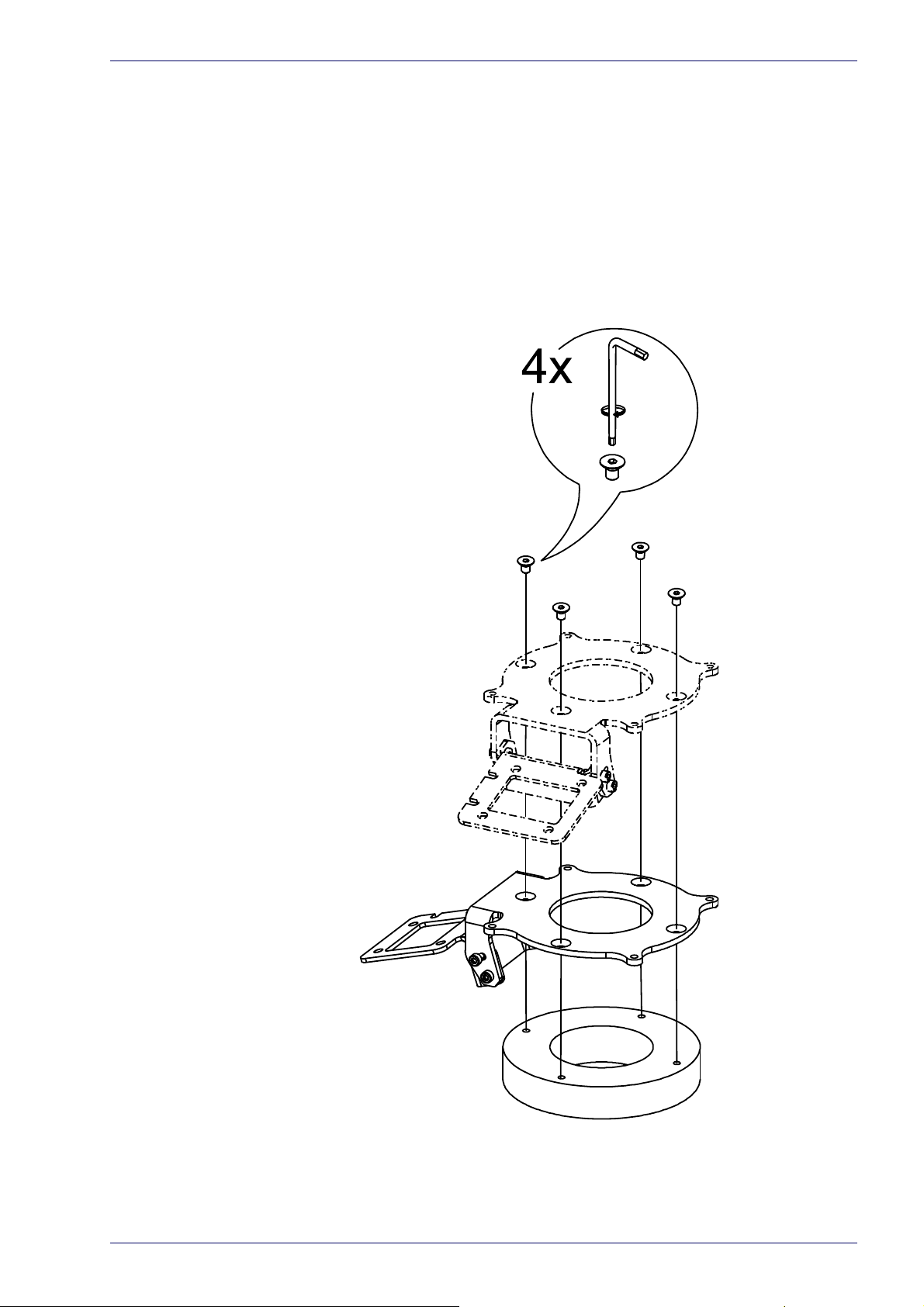

Mechanical assembly on Arex™ 400 laser marker

At first, mount the LED Ring Light ID (if present) on the bracket:

Mounting Instructions for Matrix

Figure 7: LED Ring Light ID mounting on Arex™.

Application Note 16

Page 24

Hardware Installation

Fix the adjustment plate to the Arex™ 400 with the supplied screws as shown:

17

Figure 8: Fixing adjustment plate on Arex™ 400.

Marvis™

Page 25

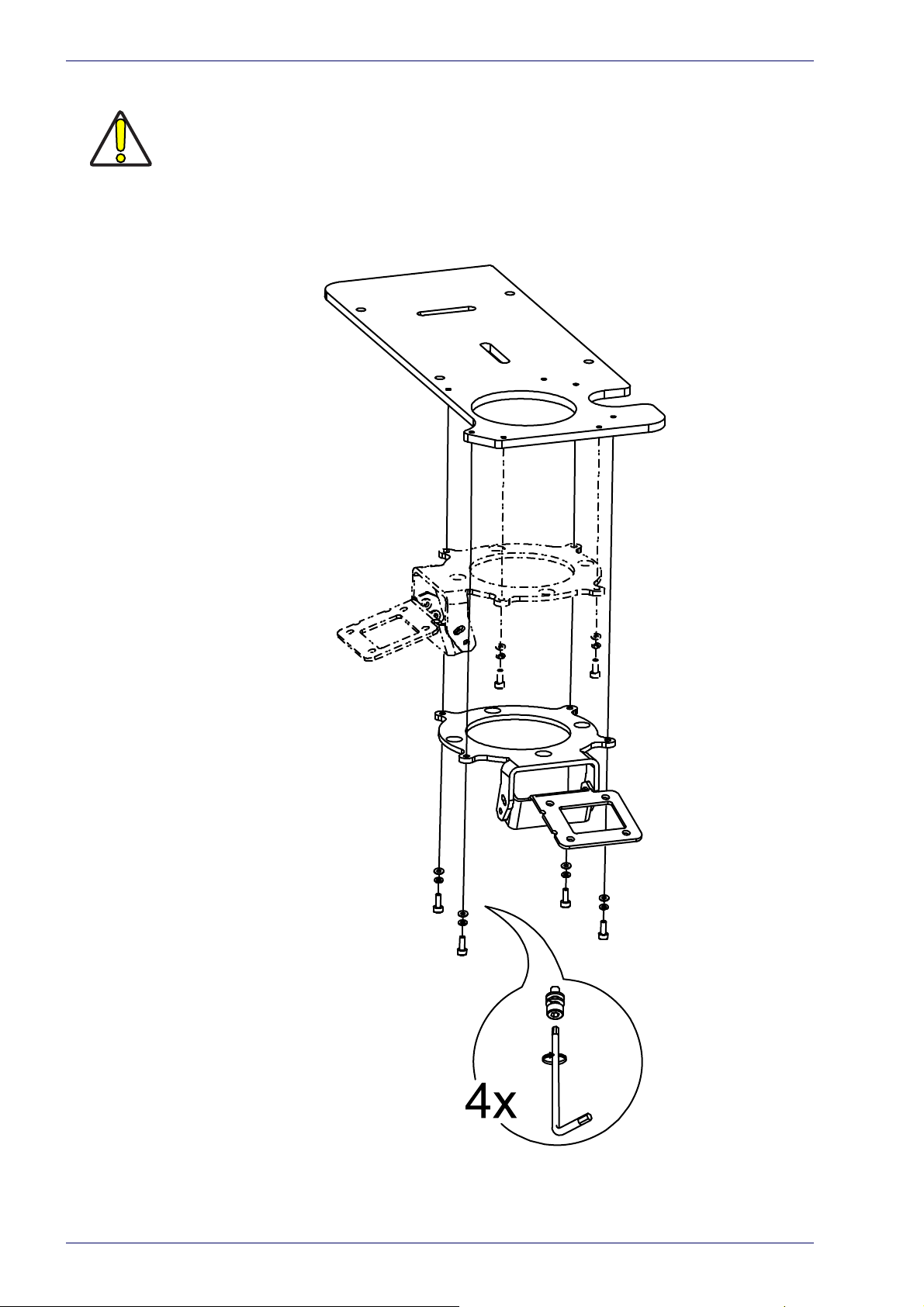

Mounting Instructions for Matrix

Fix the bracket to the adjustment plate with the supplied screws.The bracket can

be installed in three different positions:

Figure 9: Bracket mounting on Arex™ 400.

Application Note 18

Page 26

Hardware Installation

Fixing the Matrix 300N™, 410N™ to the bracket

Fix the Matrix 300N™, 410N™ to the bracket with the supplied screws.

19

Figure 10: Matrix 300N™, 410N™ mounting on bracket.

Marvis™

Page 27

Fixing the Matrix 220™ to the bracket

Fix the Matrix 220™ to the bracket with the supplied screws.

Mounting Instructions for Matrix

Figure 11: Matrix 220™ mounting on bracket.

Application Note 20

Page 28

Hardware Installation

Connecting Matrix 220™, 300N™ and 410N™

This section describes the Marvis™ system wiring. Carry out the connecting

operations as described below.

Refer to the corresponding user manual of the laser marker for the main connections.

NOTE

Connect the components of the Marvis™ system together WITHOUT voltage in order to

avoid risks to th

W

ARNING

Connecting Matrix to the Ethernet

Connecting to Matrix

Connect the M12 connector of the Ethernet cable to the M12-4F connector of the

Matrix:

e operator and to the laser marker.

Figure 12: Wiring Ethernet cable to Matrix.

Connecting to Vlase™

Connect the RJ-45 connector of the Ethernet cable to the laser marker:

21

Figure 13: Wiring Ethernet cable on Vlase™.

Marvis™

Page 29

Connecting Matrix 220™, 300N™ and 410N™

Connecting to Arex™

Connect the RJ-45 connector of the Ethernet cable to the laser marker:

Figure 14: Wiring Ethernet cable on Arex™.

Connecting to UniQ™

Connect the RJ-45 connector of the Ethernet cable to the laser marker:

Figure 15: Wiring Ethernet cable on UniQ™.

Application Note 22

Page 30

Hardware Installation

Connecting to Arex™ 400

Connect the RJ-45 connector of the Ethernet cable to the laser marker:

NOTE

W

ARNING

Figure 16: Wiring Ethernet cable on Arex™ 400.

If the laser marker is to be controlled remotely, an Ethernet switch can be used for network connections.

If the “Discovery” function does not detect

the LAN and try again.

any device, disconnect other devices from

23

Marvis™

Page 31

Connecting Matrix to power supply

Connecting to Matrix

Connect the power supply cable to Matrix (via M12-17F).

Figure 17: Wiring M12-17F connector to Matrix.

Connecting to Vlase™, Arex™ and UniQ™ laser markers

Connect the power supply cable of the Matrix to power supply PG6000 (via M128F).

Connecting Matrix 220™, 300N™ and 410N™

Figure 18: Wiring M12-8F connector to PG6000.

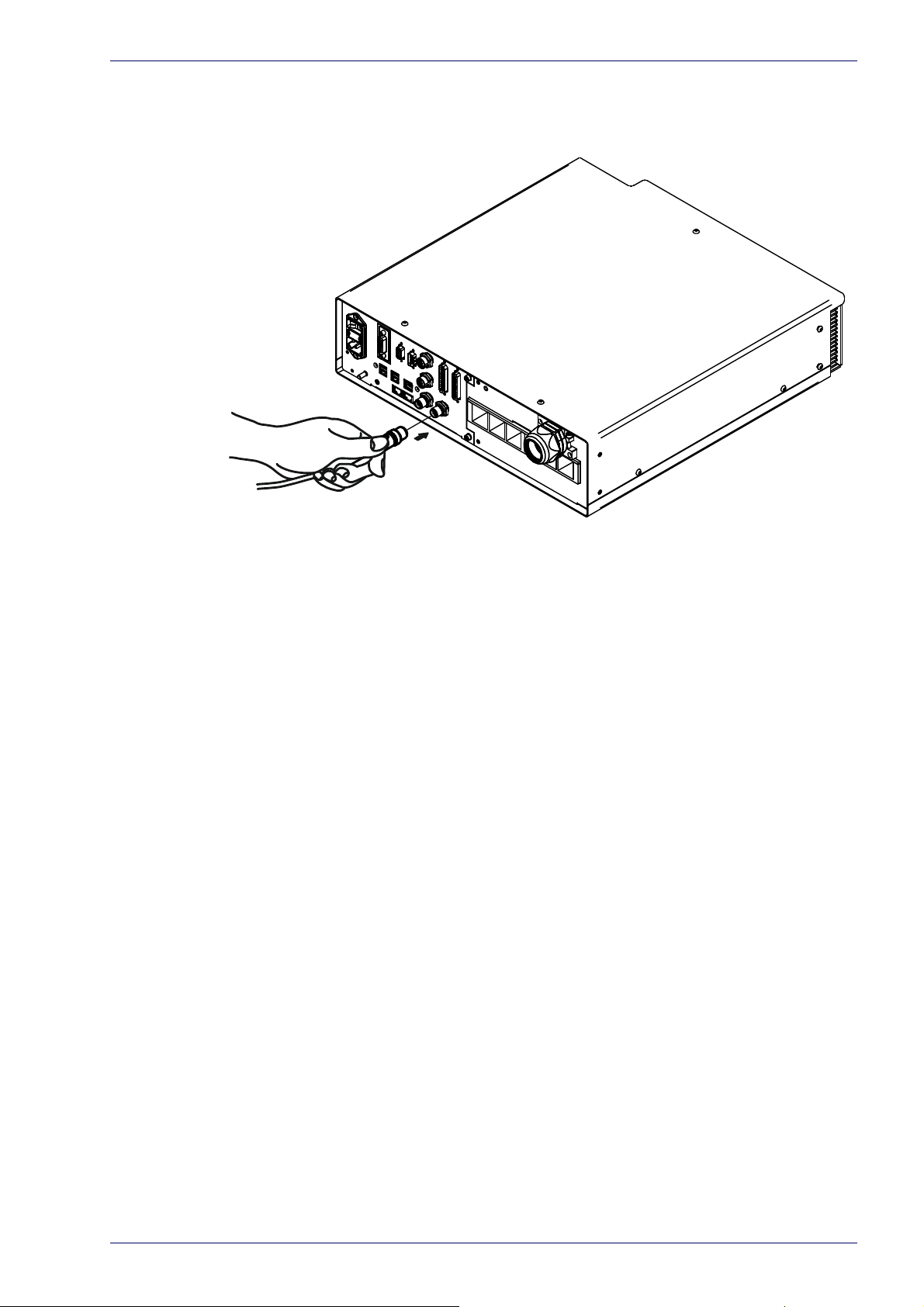

Connecting to Arex™ 400 laser marker

Connect the power supply cable of the Matrix to the Device Port 1 on the control

rack back panel:

Figure 19: Wiring M12-8F connector to the Arex™ 400 Device port 1.

Application Note 24

Page 32

Hardware Installation

Connecting LED Ring Light ID (optional)

Vlase™, Arex™ and UniQ™ laser markers

Connect the M12 connector of The LED Ring Light ID to the M12-8Y adapter on

one of the two M8-M connectors.

Figure 20: Wiring LED Ring Light ID to the adapter.

Connect the power supply cable of the Matrix to the other M8-M connector of

the M12-8Y adapter.

Figure 21: Wiring Matrix™ to the adapter.

Finally connect the PG6000 M8-8F connector to the M8-F connector on the

adapter.

25

Figure 22: Wiring PG6000 to the adapter.

Marvis™

Page 33

Connecting Matrix 220™, 300N™ and 410N™

Arex™ 400 laser marker

Connect the M12 connector of The LED Ring Light ID to the Device Port 2 on the

control rack back panel.

Figure 23Wiring LED Ring Light ID to the Arex™ 400 Device port 2.

Application Note 26

Page 34

Chapter 4

Software Configuration

HOW TO CONFIGURE YOUR MARVIS™ SYSTEM starting on page 28

HOW TO TEST, MARK AND VALIDATE YOUR DOCUMENT starting

on page 34

MARKING AND VALIDATION STAT IS TI CS starting on page 36

TROUBLESHOOTING starting on page 38

27

Marvis™

Page 35

How To Configure Your Marvis™ System

Refer to Lighter Suite software user manual for a proper use of the same.

NOTE

How To Configure Your Marvis™ System

Right-click on the Laser Engine icon in the Icon Tray and select the Laser configuration item.

In the Laser Configuration window, go to the MARVIS section and choose Discovery.

If the laser marker is to be controlled remotely, an Ethernet switc

work connections.

h can be used for net-

NOTE

Application Note 28

Page 36

Software Configuration

Select the reader to connect and press Manage Device.

Set the IP address to assign to the reader and press Change.

29

NOTE

W

ARNING

W

ARNING

The IP address to be assigned must belong to the same subnet as the laser marker.

If the “Discovery” function does not detect

the LAN and try again.

The DHCP option is to be used only for advanced users.

any device, disconnect other devices from

Marvis™

Page 37

How To Configure Your Marvis™ System

Press Test to verify the correct connection of the laser marker to the reader.

When the test is complete, press Apply and then OK to proceed with the configuration.

Start Lighter Suite, create a layer, add a code (for example a Datamatrix) and

Photometric Adjustment.

press

The features “Extended Layer” and “Ring Document” are not supported by MARVIS™

application.

W

ARNING

Application Note 30

Page 38

Software Configuration

In the new window, press Auto Setup to automatically configure the photometric

parameters of the reader.

NOTE

If the Auto setup is completed correctly the decoding is successful:

Auto Setup estimates the exposure time and gain parameters based on the luminosity

and contrast observed in the captured image but it doesn't always correspond to the

optimum results for Quality Grading. We recommend therefore to consider the Auto

Setup results as a starting point to obtain the optimum working conditions. If you don't

obtain the expected grading results from your reference samples, you should adjust

the photometry parameters manually and observe the statistical behavior of the grading until the desired results are obtained. Refer to “Help” on page 41 for more information.

In Results tabs copy (CTRL+C) the text of the decoding result and press Save to

save the parameters and continue.

31

Marvis™

Page 39

How To Configure Your Marvis™ System

Now paste (CTRL+V) the text of the decoding result in the property of the symbol and proceed with the l

Grade Training button.

earning of the quality grade by selecting the Quality

Type the acquisition number to be executed and start the learning by pressing

Start Training.

Refer to “Help” on page 41 for more information about the quality grade.

NOTE

Application Note 32

Page 40

Software Configuration

At the end of the learning the percentages and degree of reading quality will be

displayed.

Select Apply Custom Metric to apply the individual metrics learned to the project.

33

You can set a single degree of Overall desired for all metrics by selecting it in the

item Overall grade.

Marvis™

Page 41

How To Test, Mark and Validate Your Document

How To Test, Mark and Validate Your Document

You can simulate marking and validation by pressing the Send Marking button.

The result of the simulation is visible on the Lighter icon tray.

It is now possible to save the document by

pressing the Save to Device button.

Application Note 34

Page 42

Software Configuration

Open Laser Engine, select the document you just saved and perform the marking

by pressing Start marking button.

The result of the marking and validation is visible on the Laser Engine icon tray.

For automatic processing it is possible to execute a sequence. In Laser Engine

h to Auto Mode, select the sequence document and start marking by press-

switc

art marking button.

ing St

35

In the Laser Engine Documents tab, in addition to the preview of the document,

it is also possible to display the steps of the sequence.

In the Laser Engine Icon Tray, at the end of each single sequence a message

appears on the

result of the marking and validation.

Marvis™

Page 43

Marking and Validation Statistics

It is possible to consult the statistics on the marking and validation processes.

Marking and Validation Statistics

Statistics on marking processes are available in the Layouts section. The following statistics are displayed:

• OK: for the marking processes correctly performed

• ERROR: for the errors in marking processes

• STOPPED: for the marking processes s

Statistics on validation are available in the Validation se

tistics are displayed:

• MATCH: to match what is marked

• GRADE TRESHOLD: for good/bad match and good/bad grade

History: press

this button to access the results history detail.

topped by an external command

ction. The following sta-

Application Note 36

Page 44

Software Configuration

In the history window it is necessary to select the desired time period.

Start marking: set the starting time

End: s

Clear:

database and images).

When the images space and DB used space are full, the oldest data are automatically overwritten. To delete the data manually, use the clear button.

Show Match Details: this button shows the match detail (to enable this button

select the marking in the time period filed)

et the end time

this button deletes all the information of the selected period (including

Update: press this button to update the time period field (for it works, the end of

the time period must be set forward of the current time

Export Data: pre

automatic export from the drop down menu.

ss this button to export the data to a .cvs file. It is also set an

37

Marvis™

Page 45

Troubleshooting

To access the troubleshooting windows right-click on the Laser Engine icon in

the Icon Tray and select the Troubleshooting item.

Troubleshooting

•In Errors Tab errors of the Current Session or the History are displayed.

In the drop-down Level menu select the type of messages to display:

- ALL: display all messages

- ERRORS: display error messages

- WARNINGS: display warning messages

- INFO: display information messages

Application Note 38

Page 46

Software Configuration

Click on the Update button to updates (select the Live Update box for an

automatic and continuous update):

- the results of the Current Session

- the results of the History whenever the period has changed

Click on Clear button to delete data of the Current Session or select period.

Click Export button to export the data of the Current Session or select

period to a .cvs file.

•In Event Tracking Tab errors of the Current Session or the History are displayed.

NOTE

In the drop-down Level menu select the type of messages to display:

- ALL: display all messages

- ERRORS: display error messages

- WARNINGS: display warning messages

- INFO: display information messages

In the drop-down Type menu it is possible to filter one or more types of

events (Lighter, Ethernet_IP; Axis, etc…).

Only the events configured in the General panel of the Laser Configuration are displayed.

Click on the Update button to updates (select the Live Update box for an

automatic and continuous update):

- the results of the Current Session

- the results of the History whenever the period has changed

Click on Clear button to delete data of the Current Session or select period.

Click Export button to export the data of the Current Session or select

period to

a .cvs file.

39

Marvis™

Page 47

Troubleshooting

Application Note 40

Page 48

Appendix A

PHOTOMETRIC ADJUSTMENT starting on page 42

QUALITY GRADE TRAINING starting on page 45

Help

41

Marvis™

Page 49

Photometric Adjustment

Setting

Photometric adjustment manages image acquisition photometry and focusing.

For most applications, the Auto-Setup routine which automatically sets the photometry is the quickest and be

manually.

Photometric Adjustment

st solution. Otherwise these parameters can be set

Exposure Time

It defines the time during which all pixels of the CMOS image sensor synchro-

nously capture the frame. This parameter must be set according to the environmental conditions (external lighting, code c

time corresponds to a lighter image but is susceptible to blurring due to the

code movement. A shorter exposure time corresponds to a darker image.

NOTE: Th

Internal Lighting Mode parameter setting, therefore, after changes to Internal

Lighting Mode, recheck Exposure Time.

Gain

Amplifies or reduces the pixel gray level effectively increasing or decreasing the

contrast of the image.

Gain Multiplier

Multiplies the defined Gain from x2 to x10 times. If set to x1, the defined Gain is

left unchanged.

Internal Lighting

Sets the operating mode of the internal lighting system. Possible values are:

• Disabled:

• Always On:

• Power Str

NOTE: To avoid LED array overheating, for Power Strobed settings, the program

automatically limits the range of allowed values for the Exposure Time parameter. It is strongly recommended to use high lighting values for short exposure

time

e range of values and step of this parameter change according to the

the built-in LED array is turned off all the time. This option can be

useful if using an external lighting system;

the built-in LED array is turned on all the time at the lowest

power level. This option is useful if the LED-array blinking (produced by Power Strobed lighting modes and rapidly occurring reading phases) disturbs the operator.

obed: the built-in LED array is on only during the image exposure

time. Different Power Strobed lighting levels can be set.

s.

ontrast etc.). In general, a longer

Application Note 42

Page 50

Help

Results

LED Group

This parameter enables one of the two possible internal lighting system LED

groups: internal or external. The internal LED Group provides Bright Field illumination for dark absorbing backgrounds. The external LED Group provides low

gle Dark Field illumination for DPM applications or highly reflective back-

an

grounds.

Sectors

This parameter allows selecting which quadrants of the selected LED group will

be enabled.

Reading Distance

For Liquid Lens models, this parameter sets the reading distance (measured in

mm) defined as the distance from the reading window to the code surface.

In Result Table Tab the values of the reading are displayed.

43

In the Console Tab the readings of the parameters defined by the user are displayed:

Marvis™

Page 51

Photometric Adjustment

The parameters to be displayed can be selected by pressing the button Console

Configuration:

Application Note 44

Page 52

Help

Quality Grade Training

Industrial traceability

In today's industrial application DPM (direct part marking) bi-dimensional codes

like Datamatrix and QRcode have become crucial to correctly identify and automatically track part

traceability) and along the entire supply chain (external traceability) till the endof-life of the product. Laser marking is the preferred choice to enhance contrast

and to increase resolution that means larger amounts of data stored in the code.

It is obvious that the most important featu

other words, the capability to ensure fail-proof reading along the supply chain.

The Code Grading process

To ensure quantitative measurement of the code quality, specific Standards and

Technical Reports have been defined: for DPM code the verification methodology

is defined in the ISO/IEC TR 29158 (that includes the AIM DPM-1-2006 Quality

Guideline).

The scope to the ISO/IEC TR 29158

Standard is to define methodologies for the measurement of specific attributes of two-dimensional

ode symbols, defining methods

c

for evaluating and grading these

measurements and finally classify

the code into five quality classes or

grades: A, B, C; D and F.

The higher the class the higher the

reliability of the reading process, F

grade symbols are unlikely to be

read successfully in most environments.

The OVERALL quality of the code is

defined

grade within the evaluated set of

individual parameters.

To perform a reliable analysis of a

c

ode, specific measuring instru-

ments, called Certified Verifiers, are

vailable on the market. These

a

instruments embed standardized

lighting systems, lenses and certified algorithms to objectively evaluate the quality of the code,

oviding a Quality Report with

pr

quantitative information about the code properties.

Verifiers are widely used use to evaluate and certify the quality of the so called

“golden sample” or

mass production to ensure fail proof readings.

by the lowest resulting

s and components within the production process (internal

re of a code is its readability, or in

“approved quality sample” to be used as the reference in

45

Marvis™

Page 53

Quality parameters of metrics

Accordingly with ISO /IEC TR 29158 that includes the AIM DPM-1-2006, seven

quality parameters or Metrics have been defined. The knowledge of the meaning

of each quality parameter may be helpful in laser marking process tuning. Each

quality parameter is classified into grades from A to F, and OVERALL is defined

as the lowest result among all the parameters or metrics.

CC - Cell Contrast

This parameter measures the differences between the mean brightest

and the mean darkest values of the symbol.

'In laser DPM the creation of background of the code (quiet zone) with

ow power settings is extremely effective to boost the contrast.

l

CM - Cell Modulation

Cell modulation analyzes the uniformity of the contrast inside the code extension.

'In laser DPM this defect is usually refers to local non-uniformity of the material

surface (i.e.

curved marking surfaces.

finishing quality, dust, oil...) incorrect marking distance or tilted/

Quality Grade Training

FPD - Fixed Pattern Damage

This metric checks the fundamental characteristics of the

code (quiet zone around the code, “L” finder and clocking

tterns, and reference dots).

pa

Poor results on this metric may reduce the capability to

cate and read the code.

lo

As for “Cell Contrast”, the use of a smooth

reduces the risk of low grade FPD.

UEC - Unused Error Correction

Data Matrix incorporates an error correction mechanism and data

redundancy. This parameter tests and grades how much redundant

data had

fect mark that requires no error correction would achieve a UEC score

of 10

to be used during reading to decode the data content. A per-

0% that results in grade A.

PG - Print Growth

Measures the deviation of actual elements dimension from

the expected element dimension due to printing problems

.e. overprint or underprint).

(i

uniform background as a quite zone

ANU - Axial Non-Uniformity

This parameter measures and grades the modules' squareness in the

direction of each of the symbol's major axes (X-axis and Y-axis).

'In laser DPM applications this metric is typically affected by off-axis

rking (tilted surfaces vs laser marking axis) but also off- axis read-

ma

ing (skewed reader vs target surface).

MR - Minimum Reflectance

Determines the degree to which the object reflects light.

Accurate tuning of laser parameters like power, speed

matically influence this quality parameter.

Application Note 46

and repetition rate dra-

Page 54

Help

GNU - Grid Non-Uniformity (GNU)

This parameter measure and grades the module placement by comparing to a nominal evenly spaced grid.

Assuming a grid on which the ideal angle of intersection is 90°, any

angl

Verification process

A DPM verification system or Verifier is composed of an imaging sensor, optical

lens, dedicated lighting, stand and fixturing and verification software.

The verification process begins with the acqu

a standardized configuration (lighting Angle, Wavelength, and optical system

Aperture).

After a digitalization process

assesses the images on a number of quality metrics specified by the ISO/IEC

Standards.

The output of a verification process is a digital report that includes the results of

th

e quality metrics analysis and the overall grade of the code. Additional infor-

mation or customized metrics are so

This off-line process, is aimed to test output of a marking equipment to ensure

r

eliable code readability or to create the so called “Golden Sample” to be used as

a quality reference.

From a process control standpoint, DPM verification systems can quickly detect

pro

blems at the marking station by monitoring variations in the quality of a just-

applied code.

e deviation from 90° constitutes Grid Non-Uniformity.

isition of the image of the code, in

the image is evaluated by a Software Library that

metimes present in the report.

Verification in production environments

As other standard measurement instruments, Certified Verifiers are dedicated to

operate in controlled environment, and typically are not suitable to monitor code

quality in real world production environments.

Code acquisition in a real production environment is sensitive to ambient light

v

ariation, mechanical vibration, electrical noise, degradation of the LED light

system, etc. These fluctuations are not compatible with absolute and standardized measurement of the grade and cause, for example, the grade of the same

mples measured several times to actually give different values.

sa

In automatic production processes it is important to constantly monitor in-line

th

e quality of the marking in order to scrap non -readable or poorly readable

components.

For the in-line quality check of the just-applied codes,

the Datalogic Matrix 300N™, are widely used, to perform comparative analysis of

the code quality, monitoring at high speed variation in a real harsh production

environment.

Even though the Matrix family uses a gradi

standards, it does not take into consideration the external environmental lighting parameters such as Aperture, Wavelength and Illumination Angle which can

n any case affect the Scan Grade. For this reason the Matrix family can be used

i

to monitor variations in code quality but cannot be considered as a Certified

Verifier.

MARVIS™ is the traceability solution that ensures code quality in real production

vironments and combines into one single Graphical User Interface the flexibil-

en

ity of Laser Marking and the reliability of Matrix series industrial code images.

MARVIS™ allows collecting multiple measurements and computes the statistical

ersion of each individual quality parameter, measuring and considering the

disp

contribution of each individual parameter.

industrial readers, like

ng library fully compliant with ISO/IEC

47

Marvis™

Page 55

This statistical approach allows real sample quality threshold training and a sim-

Fig.1 Validation Report from certified Verifier.

Fig.2 Results of in-line quality

inspection.

ple and immediate visualization of the qua

This fully automatic Quality Training process provides a so called “QUALITY PRO-

FILE” (Patent Pending) that always includes all the relevant quality parameters.

In-line validation: a real example

To fully understand the advantages of this approach, consider the following

example.

An OEM car manufacturer orders from a Tier1 supplier a mechanical component

hat includes a Datamatrix code.

t

To ensure reliable internal traceability, the OEM requires a QUALITY GRADE B or

tter.

be

The Tier1 manufacturer, produces a batch of

samples a

requirements, and, to evaluate the Quality Grade

o

f the 2D code, he refers to a Certified Verifier

that in the Metrologic laboratory provides a

quality report as GRADE B, fully compliant with

OEM request (Fig.1)

To ensure contract compliance, and reduce the

cost of r

Tier1 manufacturer decides to incorporate a

direct part mark reader to monitor the DPM code

quality.

ccordingly

ejecting parts due to unreadable codes,

with the customer's

Quality Grade Training

lity spread for each code parameter.

Once installed in a real production environment

beside the laser marking un

mark reader provides an overall GRADE C, even

on the same “golden sample” just certified as

GRADE B. (Fig.2)

How do they correlate these two pieces of information?

It is clear that the “golden sample” has an intrinsic quality of GRADE A, as validated by the Certifie

On the other side, the in-line code reader is really affected by measurement

e

rrors caused by installation factors like tilt, skew, not optimal reading and

lighting etc.

These errors are always present in real world environments and are usually

ated to the effectiveness of the embedded grading algorithm.

rel

d Verifier.

it, the direct part

Application Note 48

Page 56

Help

MARVIS™ advantages: training on real sample

Starting from a qualified “golden sample”, MARVIS can provide a QUALITY PROFILE (Patent Pending) that maps quality distribu

the case of non-ideal installations and environment.

This Quality Profile defines a threshold metric by metric mitigating influence of

ext

ernal factors.

Setting a Quality Profile is as simple as pressing the “START

tion on each single metric even in

TRAINING” button.

MARVIS™ advantages: single metric quality grade analysis

The use of OVERALL GRADE to validate the code quality may not detect some relevant code quality degradation.

By definition, code verification is based on

sample parts with a reference grade. Since Overall Code Grade is determined

only by the lowest grade among all the metric parameters, any fluctuation in

individual metrics that lies above the lowest grade is neglected.

In other words, verification on OVERALL GRADE = C will

single metrics between A and C.

In the following example, three samples

erified with a target quality of

are v

GRADE C.

Since for all samples the lowest grade

within the selected metrics is “C”, the

OVERALL grade of the three samples

match the requirements and all samples

are verified and validated.

Instead, a single metric analysis, shows

that the three samples are quite different.

Sample #3 has a much lower quality on

4

parameters (CM, UEC, MR, GNU) compared to other samples and to the refer-

ence.

These differences are “masked” by the poor results on Axial Non Uniformity of

the ref

erence that contribute to the OVERALL GRADE.

matching the OVERALL GRADE of the

ignore any variation on

Thanks to the QUALITY METRIC

GRADE PROFILE, MARVIS™ is able to

luate the fluctuation in quality

eva

on single metrics, independently

from the OVERALL, ensuring high

read rate along the entire supply

chain.

49

Marvis™

Page 57

MARVIS™ advantages: statistic threshold

GRADE PROFILE offers also a clear indication of the statistical threshold of a

quality grade for each metric.

In the following table it is evident that FPD for a specific sample will be GRADE B

at 65%

This statistical approach

pr

view of the distribution of

the quality.

By running CODE QUALITY

TRAINING on different

lighting conditions, it is

possible to evaluate the

influence of the external

environment on the grading analysis, and eventually compensate for

fluc

Marvis™ suggest GRADE C

(i

an excessive scrap rate. Selecting the GRADE B threshold for this metric would

statistically result in a 35% scrap rate.

and GRADE C at 35%.

ovides an immediate

tuations.

n green) for FDP to avoid

Quality Grade Training

Application Note 50

Page 58

Appendix B

GENERAL SPECIFICATION starting on page 52

IEC62471-1 COMPLIANCE starting on page 52

About LED Ring Light ID

51

Marvis™

Page 59

General Specification

General Specification

Electrical Specifications

Operating Temperature

Cable Informations 3 meters (118”) long

Compliance

IP Rating IP50

Lumen Maintenance

Working Distance

Optical Performances

Color 24V Current (A)

WHI 0.14 0.47

0° to 60° C

CE, RoHS

L70 = 50,000 hours

Illuminance

(mm)

100 46.0 136.0

300 10.8 31.4 190.5

600 3.8 8.6 355.6

(klux)

Irradiance

(W/m2)

Electrical specifications

FWHM Diameter

(mm)

114.3

IEC62471-1 Compliance

This product has been classified RISK GROUP 1 (LOW-RISK) according IEC62471-

1.

The philosophical basis for this classification is that the lamp does not pose haz-

ard due to normal behavioral limitations on exposure. This requirement is met

by lamp that

• a retinal blue-light hazard (Lb) within 100s, nor

• a retinal thermal hazard (Lr) within 10s

Only Lb and Lr are considered because the product uses white LEDs (emissions

ly in the 400-780nm range).

on

In carrying out the obligations laid down in Articles 6(3) and 9(1) of Directive 89/

1/EEC, the employer, in the case of workers exposed to artificial sources of

39

optical radiation, shall assess and, if necessary, measure and/or calculate the

levels of exposure to optical radiation to which workers are likely to be exposed

so that the measures needed to restrict exposure to the applicable limits can be

identified and put into effect. (article 4, section II, Directive 2006/25/EC of the

European Parliament and of the Council of 5 April 2006 on the minimum health

and safety requirements regarding the exposure of workers to risks arising from

physical agents (artificial optical radiation).

exceeds the limits for the Exempt Group but that does not pose.

Application Note 52

Page 60

© 2018-2019 Datalogic S.p.A. and /or its affiliates • All rights reserved. • Without

limiting the rights under copyright, no part of this documentation may be reproduced,

stored in or introduced into a retrieval system, or transmitted in any form or by any

means, or for any purpose, without the express written permission of Datalogic S.p.A.

and/or its affiliates • Datalogic and the Datalogic logo are registered trademarks of

Datalogic S.p.A. in many countries, including the U.S. and the E.U.

www.datalogic.com

Datalogic S.r.l.

Via S. Vitalino, 13 | 40012 Calderara di Reno | Bologna - Italy

Tel. +39 051 3147011 | Fax +39 051 3147205

Loading...

Loading...