Page 1

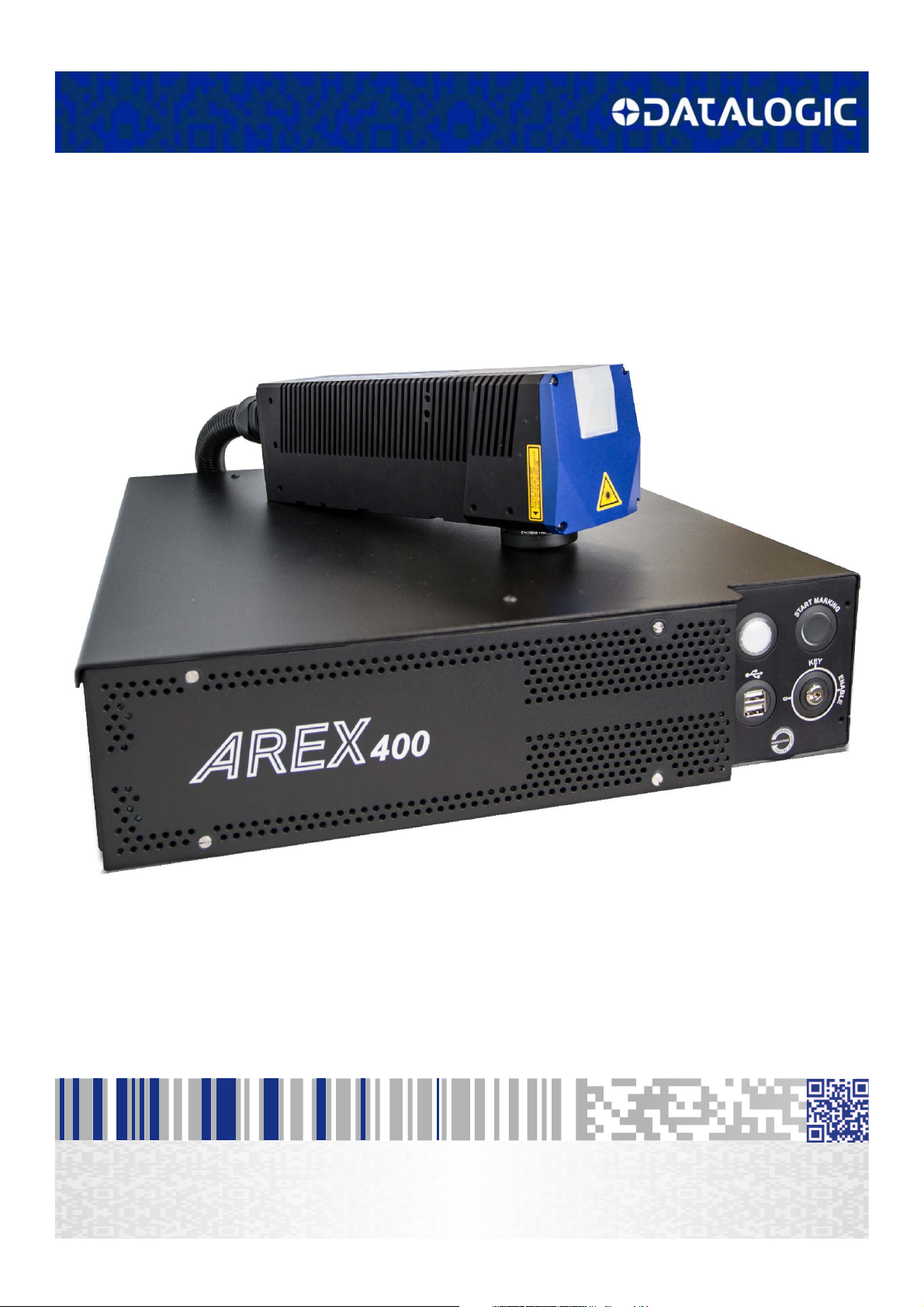

Arex™ 400

User’s Manual

Laser Marker

Page 2

Datalogic S.r.l.

Via S. Vitalino, 13

40012 Calderara di Reno — Italy

Tel. +39 051 3147011

Fax +39 051 3147205

Arex™ 400 User’s Manual

Original Instructions

Ed.: 06/2019

This manual refers to Lighter™ Suite version 7.1.0 and later.

© 2018-2019 Datalogic S.p.A. and/or its affiliates

ALL RIGHTS RESERVED. Without limiting the rights under copyright, no part of this docu-

mentation may be reproduced, stored in or introduced into a retrieval system, or transmitted

in any form or by any means, or for any purpose, without the express written permission of

Datalogic S.p.A. and/or its affiliates.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries, including the U.S.A. and the E.U.

Arex™ 400, Arex™, Lighter™ Suite, Marvis™ and Matrix™ are trademarks of Datalogic

S.p.A.and/or its affiliates. All other trademarks and bands are property of their respective

owners.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor

for incidental or consequential damages resulting from the use of this material.

Page 3

Table of Contents

PREFACE .............................................................................................................................................................................. VII

Conventions ................................................................................................................................................................................... viii

General ........................................................................................................................................................................................... viii

Model Description ............................................................................................................................................................................ix

PRO Version ..............................................................................................................................................................................ix

BASIC Version ...........................................................................................................................................................................ix

CE Compliance ...................................................................................................................................................................................x

FCC Compliance .................................................................................................................................................................................x

EAC Compliance .................................................................................................................................................................................x

UL Compliance ..................................................................................................................................................................................xi

Laser Standards ..............................................................................................................................................................................xii

Overview ..........................................................................................................................................................................................xiii

Laser Source ...........................................................................................................................................................................xiii

Galvanometric scan head ......................................................................................................................................................xiii

Operation of a laser marker with galvanometric scanning ...............................................................................................xiii

Marking Software ...................................................................................................................................................................xiii

Important Warnings ..............................................................................................................................................................xiv

INSTALLATION....................................................................................................................................................................... 1

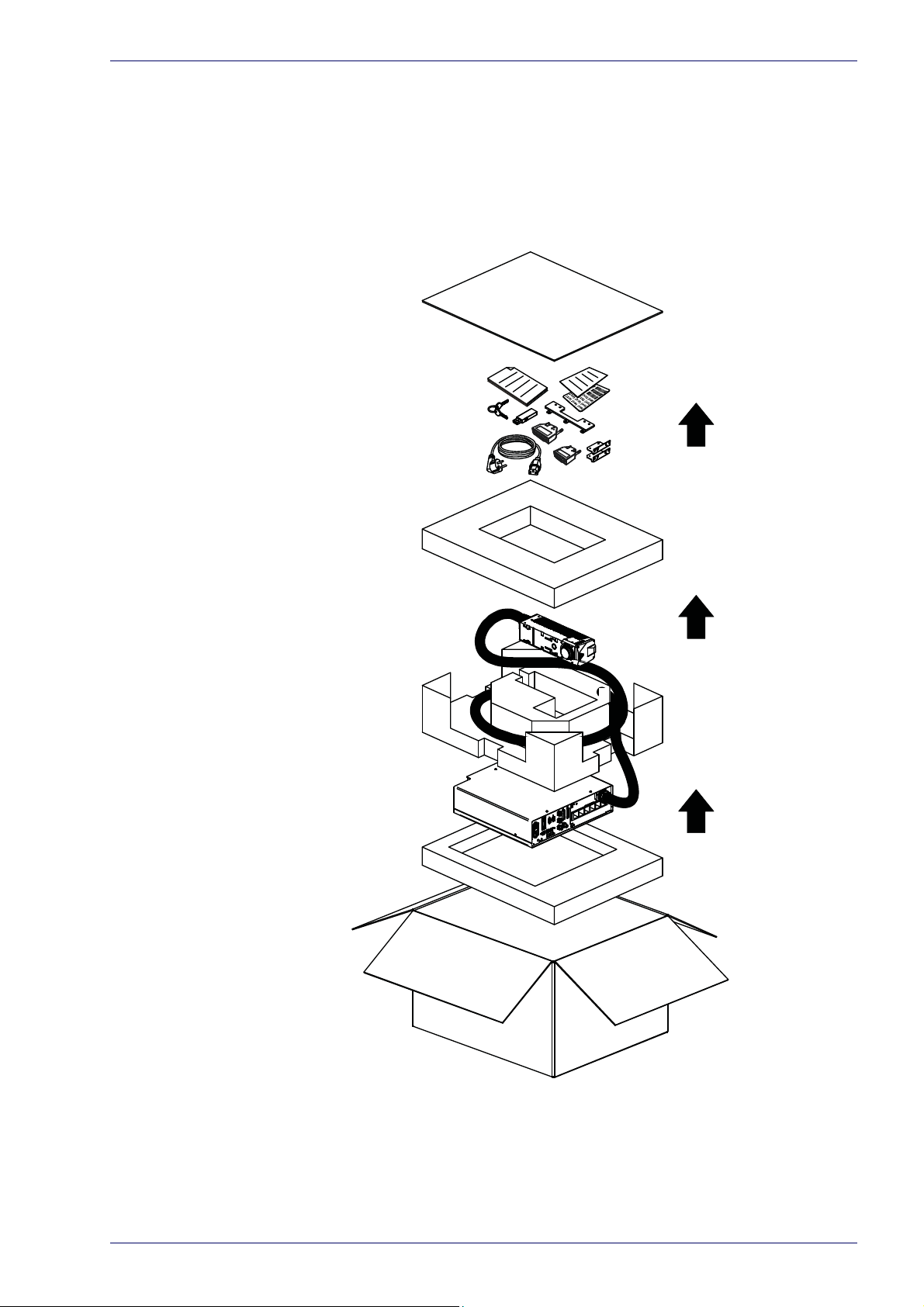

Unpacking ......................................................................................................................................................................................... 2

Contents of the packaging .............................................................................................................................................................. 4

On moisture condensation ............................................................................................................................................................. 5

Note on moisture condensation ............................................................................................................................................. 5

If moisture condensation occurs ............................................................................................................................................ 5

How to avoid moisture condensation .................................................................................................................................... 5

Fixing and positioning ..................................................................................................................................................................... 6

Control Rack installation ................................................................................................................................................................. 7

Horizontal installation ............................................................................................................................................................. 7

Vertical installation .................................................................................................................................................................. 9

Control rack mounting screws length .................................................................................................................................. 10

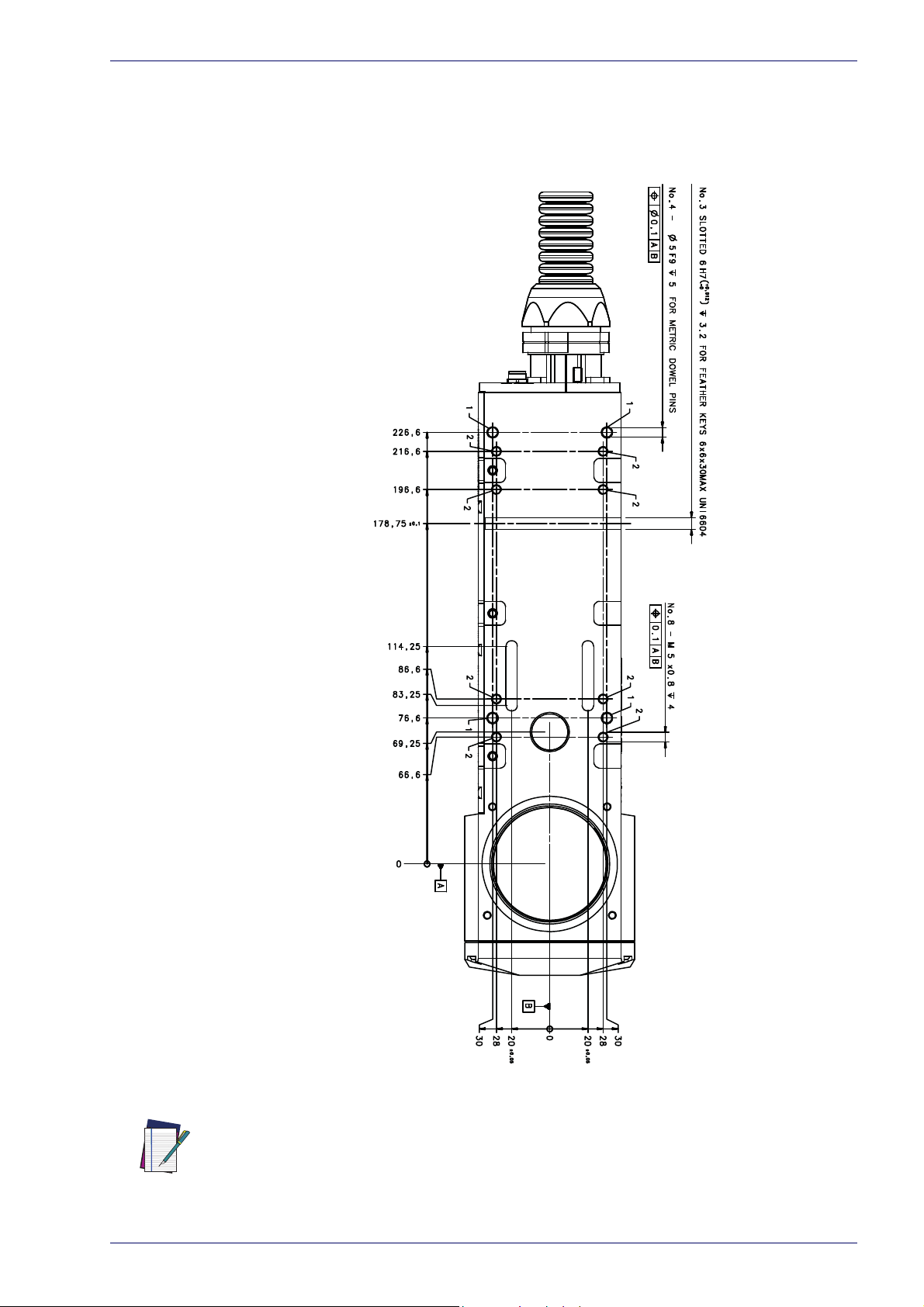

Scan Head installation .................................................................................................................................................................. 11

Scan head mounting screws length ..................................................................................................................................... 14

Installation environment .............................................................................................................................................................. 15

Control rack ............................................................................................................................................................................. 15

Scan Head ............................................................................................................................................................................... 16

Fume / Dust extractor ................................................................................................................................................................... 17

TECHNICAL SPECIFICATIONS.............................................................................................................................................. 18

Technical Characteristics .............................................................................................................................................................. 19

Product Description ....................................................................................................................................................................... 20

Control rack ............................................................................................................................................................................. 20

Scan head ................................................................................................................................................................................ 21

Marking Area Specification ........................................................................................................................................................... 22

F-Theta Scan Lens for Arex™ 110-XXX, 120-XXX and A20-X6X ........................................................................................ 22

F-Theta Scan Lens for Arex™ 130-X6X and 150-X6X ......................................................................................................... 23

Green Spot ....................................................................................................................................................................................... 24

Connectors Specifications ............................................................................................................................................................. 25

Safety Circuit ........................................................................................................................................................................... 25

Control rack back panel connector ............................................................................................................................... 25

Muting Device ................................................................................................................................................................. 27

Command Box (Laser Control) .............................................................................................................................................. 28

User Manual iii

Page 4

Contents

Control rack back panel connector ................................................................................................................................28

Muting Device .................................................................................................................................................................29

Axes (I/O Control) ....................................................................................................................................................................30

Control rack back panel connector ................................................................................................................................30

Encoder ....................................................................................................................................................................................31

Control rack back panel connector ................................................................................................................................31

Photocell ..................................................................................................................................................................................31

Control rack back panel connector ................................................................................................................................31

Device Port 1 ...........................................................................................................................................................................32

Control rack back panel connector ................................................................................................................................32

Device Port 2 ...........................................................................................................................................................................32

Control rack back panel connector ................................................................................................................................32

RS232 (COM3) ..........................................................................................................................................................................33

Control rack back panel connector ................................................................................................................................33

Ext Focus .................................................................................................................................................................................33

Scan head connector ......................................................................................................................................................33

Input/Output specifications ..........................................................................................................................................................34

Digital Input .............................................................................................................................................................................34

Digital Output ..........................................................................................................................................................................34

Laser Marker States .......................................................................................................................................................................35

Normal Operation States .......................................................................................................................................................35

Error States .............................................................................................................................................................................35

Warning State .........................................................................................................................................................................35

Control the Laser Marker States ...........................................................................................................................................36

Key Selector mode ..........................................................................................................................................................36

Command Box mode ......................................................................................................................................................36

Timing Diagrams .............................................................................................................................................................................37

Turning On sequence ..............................................................................................................................................................37

Marking control signals behavior ..........................................................................................................................................37

SW_Ready output signal (Ready to Mark mode) .................................................................................................................38

Good\Bad output signal ........................................................................................................................................................38

System_Alarm output signal .................................................................................................................................................38

MARVIS™ I/O signals behavior ..............................................................................................................................................39

Safety functions behavior ......................................................................................................................................................39

Interlock behavior ...........................................................................................................................................................39

Laser_Stop behavior .......................................................................................................................................................39

Green Spot behavior ...............................................................................................................................................................40

System Ready to Mark mode ........................................................................................................................................40

Marking Confirmation mode .........................................................................................................................................40

MARVIS Verification mode .............................................................................................................................................40

Axes I/O signals behavior ......................................................................................................................................................41

Lighter™ Suite marking software ..................................................................................................................................................42

INSTALLATION AND SET UP............................................................................................................................................... 44

Connections .....................................................................................................................................................................................45

Connecting Command Box connector ..................................................................................................................................45

Connecting Safety Circuit connector .....................................................................................................................................46

Connecting Power Supply cable ............................................................................................................................................47

Connecting the Earth Ground ................................................................................................................................................47

Local Mode Control connections ...........................................................................................................................................48

Remote Mode Control connection ........................................................................................................................................49

F-Theta scan lens protection cap removal ..................................................................................................................................49

USE AND OPERATION......................................................................................................................................................... 50

First time boot .................................................................................................................................................................................51

Turning On sequence ......................................................................................................................................................................52

Sequence using Key Selector .................................................................................................................................................52

Sequence Using Command Box .............................................................................................................................................55

CUSTOMIZE THE LASER MARKER SOFTWARE ................................................................................................................ 56

Change O.S. language and keyboard layout ................................................................................................................................57

Change the LAN configuration and IP address ...........................................................................................................................60

Change the video setting ...............................................................................................................................................................63

iv

Arex™ 400

Page 5

Contents

Remote desktop connection ......................................................................................................................................................... 65

ACCESSORIES....................................................................................................................................................................... 66

Control Box ...................................................................................................................................................................................... 67

Remote Start Foot Switch ............................................................................................................................................................. 67

I/O interface ................................................................................................................................................................................... 68

DB25-to-Free Leads Cable ............................................................................................................................................................ 68

MARVIS™ Add-on ............................................................................................................................................................................ 69

MARVIS™ Mounting Bracket ................................................................................................................................................. 69

MARVIS™ LED Ring Light ID 50mm - White ........................................................................................................................ 69

Micrometric distance sensor kit ................................................................................................................................................... 70

M39 F-Theta protective cap .......................................................................................................................................................... 70

Starter Kit for Marking On the Fly (MOF) ..................................................................................................................................... 71

Rack Handles .................................................................................................................................................................................. 71

Fume Extractor ............................................................................................................................................................................... 71

TECHNICAL SUPPORT ......................................................................................................................................................... 72

Seals ................................................................................................................................................................................................ 73

Maintenance ................................................................................................................................................................................... 74

F-Theta scan lens cleaning procedure ................................................................................................................................. 74

Air filter cleaning procedure .................................................................................................................................................. 75

Troubleshooting ............................................................................................................................................................................. 76

Service Interface ..................................................................................................................................................................... 76

List of warning and error states ........................................................................................................................................... 77

List of problems related to laser marker states ................................................................................................................. 77

List of most common problems ........................................................................................................................................... 78

Remote Assistance ........................................................................................................................................................................ 79

Product Support and Customer Service ....................................................................................................................................... 79

LABELS ............................................................................................................................................................. 80

Labels .............................................................................................................................................................................................. 81

Positioning of external labels ....................................................................................................................................................... 82

Positioning of labels on the control rack: ............................................................................................................................ 82

Positioning of labels on the scan head: ............................................................................................................................... 82

Safety labels in local languages ................................................................................................................................................... 83

UNDERSTANDING SLO: SAFE LASER OFF..................................................................................................... 84

Machine Safety ............................................................................................................................................................................... 85

Risk Assessment ............................................................................................................................................................................ 86

Performance Level (PL) .................................................................................................................................................................. 87

Datalogic Laser Markers ............................................................................................................................................................... 87

SLO connection diagram ............................................................................................................................................................... 88

Safety Functions Of Arex™ 400 ..................................................................................................................................................... 89

Arex™ XXX-X5X ....................................................................................................................................................................... 89

Arex™ XXX-X6X ....................................................................................................................................................................... 89

Example 1 ................................................................................................................................................................................ 90

Example 2 ................................................................................................................................................................................ 91

Example 3 ................................................................................................................................................................................ 92

LASER SAFETY................................................................................................................................................. 93

Laser radiation ............................................................................................................................................................................... 95

Absorption of laser radiation ........................................................................................................................................................ 96

Classification and danger level .................................................................................................................................................... 97

Degree of risk with radiation viewing conditions ...................................................................................................................... 97

Direct viewing of the laser beam .......................................................................................................................................... 97

Viewing of a laser reflected beam ........................................................................................................................................ 98

Viewing of direct laser beam from a fiber output .............................................................................................................. 98

Viewing of scattered laser beam .......................................................................................................................................... 98

N.O.H.D. determination and O.D. of protection goggles ............................................................................................................ 99

Accidental vision of the reflected laser radiation ............................................................................................................. 100

Filter scale index of the protection goggles ...................................................................................................................... 100

Eyes and skin risks ......................................................................................................................................................................100

General safety regulations ..........................................................................................................................................................100

Other risks ....................................................................................................................................................................................101

User Manual v

Page 6

Contents

USING MARKING SOFTWARE....................................................................................................................... 102

How to create and edit graphics layout .................................................................................................................................... 103

How to test and mark layout ...................................................................................................................................................... 106

How to use Command Box signals to mark layout .................................................................................................................. 108

MOPA FIBER LASER ...................................................................................................................................... 110

Laser marker operations ............................................................................................................................................................. 111

Pulse Profile ......................................................................................................................................................................... 113

Lighter™ Pulse Profile Configuration ......................................................................................................................................... 115

Creating a document with multiple objects using a single pulse profile ...................................................................... 115

Creating a document with multiple objects using different pulse profiles ................................................................... 116

MARKING SOFTWARE UPGRADE................................................................................................................. 118

How to update the marking software ....................................................................................................................................... 119

RECOVER THE LASER MARKER.................................................................................................................... 124

Overview ....................................................................................................................................................................................... 125

How to recover the laser marker ............................................................................................................................................... 125

Recover the system: ............................................................................................................................................................ 125

Initialize the Hardware ........................................................................................................................................................ 128

Customize the marking software ...................................................................................................................................... 129

MECHANICAL DRAWINGS............................................................................................................................. 130

Control Rack ................................................................................................................................................................................. 131

Scan Head ..................................................................................................................................................................................... 132

vi

Arex™ 400

Page 7

CONVENTIONS starting on page viii

GENERAL starting on page viii

MODEL DESCRIPTION starting on page ix

CE COMPLIANCE starting on page x

FCC COMPLIANCE starting on page x

EAC COMPLIANCE starting on page x

UL COMPLIANCE starting on page xi

LASER STA ND AR DS starting on page xii

OVERVIEW starting on page xiii

Preface

User Manual vii

Page 8

Preface

Conventions

Warnings

High Voltage

Laser Caution

ESD

Notes

This symbol identifies a hazard or procedure that, if incorrectly performed, could cause personal injury or result in

equipment damage. It is also used to bring the user’s attention to details that are considered IMPORTANT.

This symbol alerts the user they are about

action involving, either a dangerous level of voltage, or to warn

against an action that could result in damage to devices or

electrical shock.

This symbol alerts the user they are about

action involving possible exposure to laser light radiation.

This symbol identifies a procedure that requires you take

measures

ESD wrist strap. Circuit boards are most at risk. Please follow

ESD procedures.

This symbol draws attention to details or procedures that may

be useful in improving,

mance of the hardware or software being discussed.

to prevent Electrostatic Discharge (ESD) e.g., use an

maintaining, or enhancing the perfor-

to perform an

to perform an

General

W

ARNING

NOTE

Information included in this manual is intended for a qualified installer able to

integrate the laser marker into a system, complying with all the protection features required by international rules and local legislations. Refer to the following

ctions for further information.

se

This manual refers to Arex™ 400 Fiber laser markers, that is a Class 4 Laser

oduct.

Pr

In addition to being professi

work with laser marker must be informed and made acquainted with the risks

inherent to invisible and visible laser radiation. The operator is required to carefully read the section of the manual concerni

sections related to matters falling under her/his responsibility.

Datalogic shall not be held responsible for any no

its manufacture.

BEFORE INSTALLING AND USING THE LASER, CAREFULLY READ THIS MANUAL.

onally trained in their role, personnel assigned to

ng safety instructions as well as the

n-conforming use of laser marker of

viii

Arex™ 400

Page 9

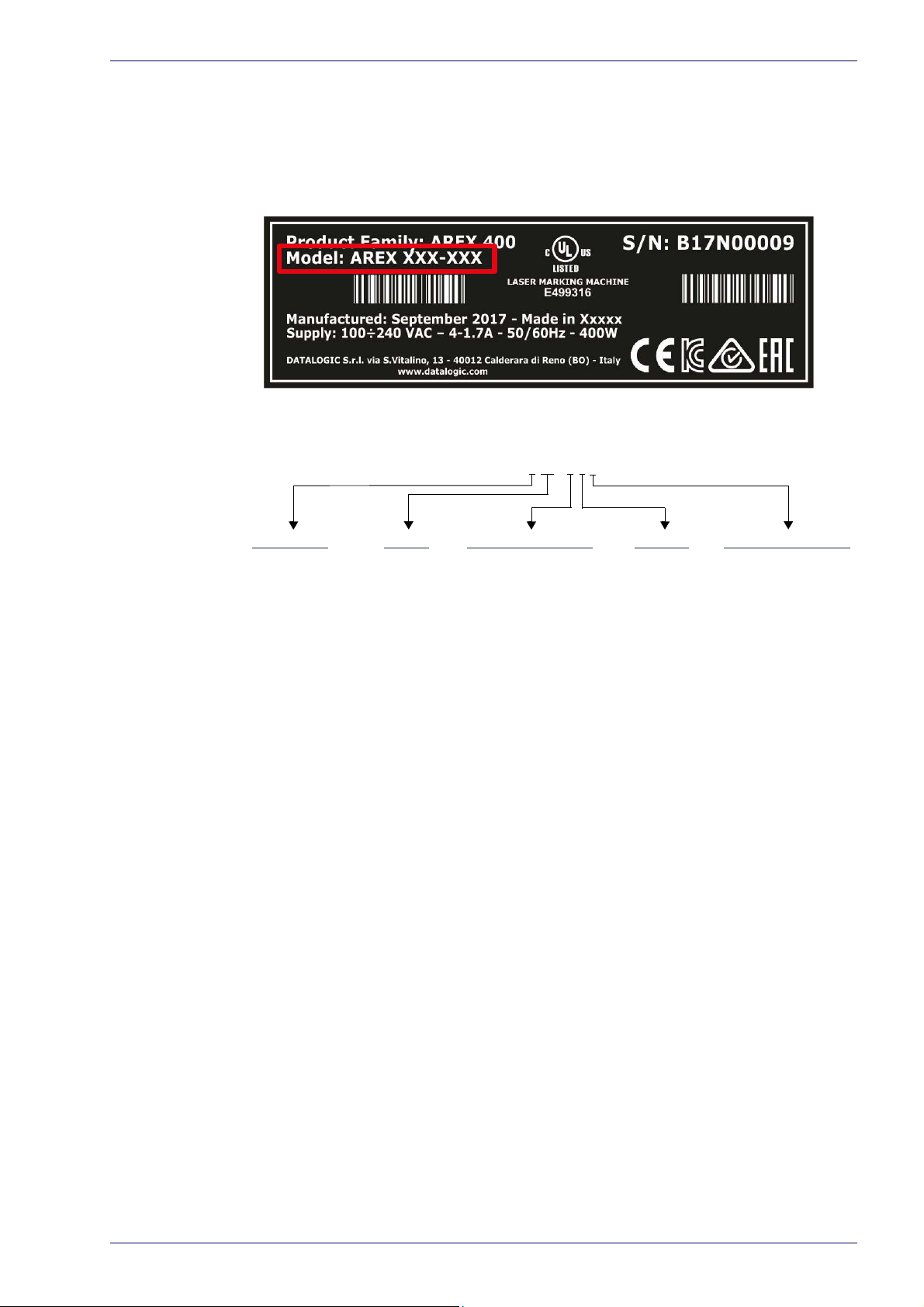

Model Description

Arex™ 400 laser markers are described by their model number which indicates

the characteristics listed in the diagram below. Not all combinations are available. For a complete list of combinations see the Models tab on the Product page

the website.

of

Model Description

AREX XXX-XXX

PRO Version

• Wider power range selection

• Wider F-Theta scan lens selection

• High performance level for safety features

• High PC performance (powered by Intel® Celeron®)

• 3x Ethernet ports 10/100/1000 Mbps

• High Precision Marking Field Center specifications

• Advanced software features

Laser Type Power F-Theta scan lens Version Operating System

1 = Pulsed Fiber 10 = 10W 3 = 160 S 5 = BASIC 4= Windows® 7

A = Fiber MOPA 20 = 20W 4 = 160L 6 = PRO

30 = 30W 6 = 254 S

50 = 50W 7 = 254 L

9 = 100 L

A = 330 L

B = 420 L

BASIC Version

• Models with power level 10W & 20W

• Basic performance level for safety features

• Basic PC performance (powered by Intel® Atom®)

• 1x Ethernet port 10/100/1000 Mbps

• Basic Precision Marking Field Center specifications

• Basic software features

User Manual ix

Page 10

Preface

CE Compliance

CE marking states the compliance of the product with essential requirements

listed in the applicable European directive. Since the directives and applicable

standards are subject to continuous updates, and since Datalogic promptly

adopts these updates, therefore the EU declaration of conformity is a living document. The EU declaration of conformity is available for competent authorities

d customers through Datalogic commercial reference contacts. Since April

an

20th, 2016 the main European directives applicable to Datalogic products

require inclusion of an adequate analysis and assessment of the risk(s). This

evaluation was carried out in relation to the applicable points of the standards

listed in the Declaration of Conformity. Datalogic products are mainly designed

for integration purposes into more complex systems. For this reason it is under

the responsibility of the customer to do a new risk assessment regarding the

final installation.

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

W

ARNING

FCC Compliance

Modifications or changes to this equipment without the expressed written

approval of Datalogic could void the permission to use the equipment.

This laser marker complies with PART 15 of the FCC Rules. Operation is subject

the following two conditions: (1) this laser marker may not cause harmful

to

interference, and (2) this laser marker must accept any interference received,

including interference which may cause undesired operation.

This laser marker has been tested and found to

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This laser marker generates,

and can radiate radio frequency energy and, if not installed and used in

uses,

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this laser marker in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his/her own expense.

EAC Compliance

Customs Union: this laser marker complies with CU Conformity certification; this

allows the Product to bear the Eurasian Mark of conformity.

comply with the limits for a Class

x

Arex™ 400

Page 11

UL Compliance

Reading this manual prevents the operator from carrying out operations that

could cause damage to himself or others.

UL Compliance

Follow-Up Service Procedure issued on 2019-03-26.

User Manual xi

Page 12

Preface

Laser Standards

This laser marker is classified as Class 4 Laser Product according to the following:

EU: EN60825-1

USA: 21 CFR 1040.10

China: GB7247-1

Datalogic, as manufacturer of laser products, provides a laser marker which is

NOT

intended for immediate use, but it must be connected, by others, to other

devices which have the final aim of creating a laser processing system.

The final system manufacturer MUST ensure

machine according to its standards including the risk-analysis, implementation

of safety measures, certification and testing of safety measures and the production of adequate information for use of the machine.

Datalogic is available for providing to the customers all the information in its

ession to help in complying with applicable standards.

poss

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

CAUTION

the safety of the laser processing

xii

Arex™ 400

Page 13

Overview

The Fiber laser marker developed and manufactured by Datalogic employs the

most advanced technologies with regards to the opto-mechanical parts, the

electronic control of laser beam power, communication and the overall safety of

the entire marker.

The Arex™ 400 laser marker features a contro

rack size is standard 19" 2.5U. The scan head compact dimensions make it easy

to integrate.

All product connections are on the rear or front of the control rack.

Laser Source

On Arex™ 400 laser marker it is used a sealed fiber laser source. This source is

based on the new fiber solid state technology. It guaranties high stability, lower

sensitivity to optical misalignment and a longer product lifetime.

Galvanometric scan head

The scan head features two deflection mirrors that deflect the beam in X and Y

directions, depending on the graphics/pattern to be reproduced.

Overview

l rack and a scan head. The control

Operation of a laser marker with galvanometric scanning

During the marking the laser generates an invisible, high-energy infrared beam.

In order to obtain a more accurate focus, the laser beam is first enlarged using

an optical expansion system and then deflected by a scanning system consisting

of two mirrors mounted on galvanometric motors.

These mirrors deflect the beam in a controlled path along the

cessing of the product surface occurs by coordinating the movement of the two

irrors and the turning on/off of the laser beam.

m

The deflected laser beam is focused by an F-Th

the product.

Generally speaking, the marking is carried out within the focus plane of the F-

eta scan lens.

Th

eta scan lens on the surface of

Marking Software

The Ligther™ marking software is preinstalled on the product.

Consult Lighter™ software user's manual for a proper use of the same.

NOTE

X and Y axes; pro-

If necessary, consult “How to update the marking soft

preinstalled software.

NOTE

ware” on page 97, to upgrade the

User Manual xiii

Page 14

Preface

Important Warnings

Access to the internal parts of the laser marker is allowed only to authorized

personnel, duly qualified and trained with regards to risks of optical and electrical nature.

Datalogic declines any and all responsibility for work carried out on active parts

by

untrained or unauthorized personnel.

It is forbidden to change the intended use for which the product was designed and

developed.

W

ARNING

Datalogic declines any and all responsibility for improper use of its laser product.

W

ARNING

W

ARNING

W

ARNING

W

ARNING

The integration and use of this laser marker is custo

Never expose reflecting surface

The reflected laser beam may cause damage to laser marker.

Laser marking interacts with materials through,

process which may lead to the emission of fumes, dust and vapors.

Adequate fume/dust extractor and treatment must be provided by customer!

Marking PVC (or other plastic material) can cause the re

be harmful to the laser operator and to the laser marker itself. Always use adequate

fume extractor during PVC and plastic marking.

s to laser radiation!

mer responsibility.

for example, a thermal carbonization

lease of chlorine gas which can

xiv

W

ARNING

It is the responsibility of the customer to inst

dition!

all the laser marker in proper safety con-

Arex™ 400

Page 15

UNPACKING starting on page 2

CONTENTS OF THE PAC KA GING starting on page 4

ON MOISTURE CONDENSATION starting on page 5

FIXING AND POSITIONING starting on page 6

CONTROL RACK INSTALLATION starting on page 7

SCAN HEAD INSTALLATION starting on page 11

INSTALLATION ENVIRONMENT starting on page 15

FUME / DUST EXTRACTOR starting on page 17

Chapter 1

Installation

User Manual 1

Page 16

Installation

Unpacking

Control rack and scan head are joined by a connection cable 3 meters long, referred as

Head Cable. Control rack and scan head are NOT separable.

W

ARNING

W

ARNING

W

ARNING

W

ARNING

Be extremely careful to not damage the connection c

trol rack.

To avoid damaging or breaking the optical fibe

bending radius below the limits specified in the technical specification table (see

“Technical Characteristics” on page 19).

The Arex™ 400 laser marker is a delicate optical device, that can be damage by shock

and vibrations.

able between scan head and con-

r, never subject the Head Cable to a

2

Arex™ 400

Page 17

Before installing or operating the laser marker, you should:

- Inspect the shipping container for damage

- Inspect the laser marker for signs of damage

- Confirm that the shipping box contains all items on the shipping inventory list

including any accessories

When unpacking the laser marker from the shipping box you should:

- Remove the accessories and documentations

- Carefully remove the laser marker from the packaging using both hands

Unpacking

Figure 1: Unpacking

Keep all packing materials until the laser has been inspected for completeness

and damage. If something is missing or defective, call Datalogic (see

Support and Customer Service” on page 79 for contact details).

“Product

User Manual 3

Page 18

Installation

3x

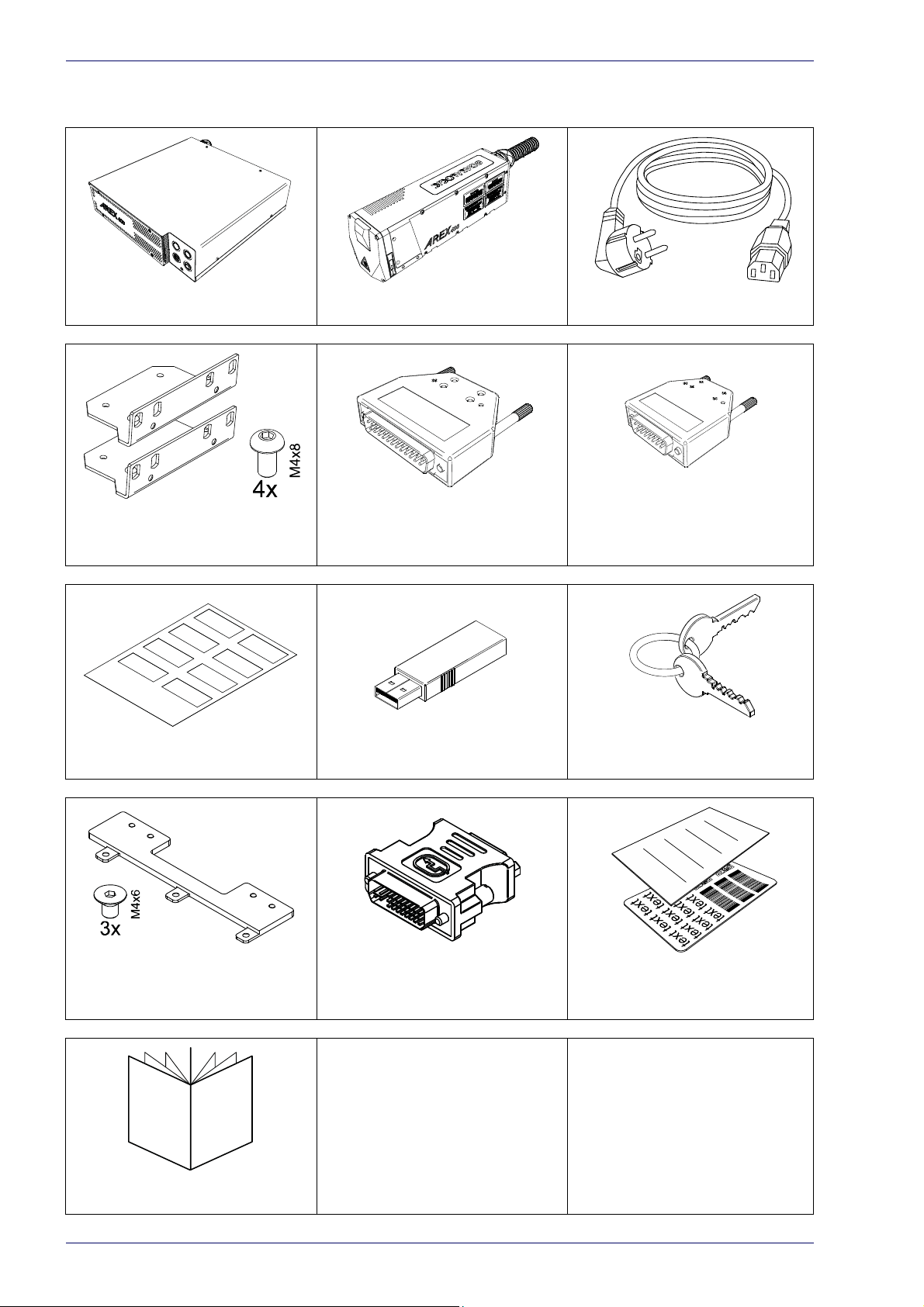

Contents of the packaging

Control Rack Scan Head Power Supply cables

Rack Fixing Brackets

(Only for XXX-X6X models)

Safety labels USB Recovery Disk Selector Keys

Command Box

MUTING DEVICE

Safety Circuit

MUTING DEVICE

Scan Head Fixing Bracket

Quick Reference Guide

4

VGA to DVI Adapter

(Only for XXX-X6X models)

Test report and sample test

plate

Arex™ 400

Page 19

On moisture condensation

If the laser marker is brought directly from a cold to a warm location, moisture

may condense inside or outside the laser product. This moisture condensation

may cause a malfunction of the laser marker.

Note on moisture condensation

Moisture may condense when you bring the laser marker from a cold place into a

warm place (or vice versa) and when you use the laser marker in a humid place.

If moisture condensation occurs

Turn off the laser marker and wait about 1 hour for the moisture to evaporate.

How to avoid moisture condensation

Before moving the laser marker from a cold place into a warm place, put it in a

plastic bag and seal it tightly. Remove the bag when the air temperature inside

the plastic bag has reached the ambient temperature (after about 1 hour).

On moisture condensation

User Manual 5

Page 20

Installation

Fixing and positioning

Fix the laser marker according to instructions shown in the figures.

W

ARNING

W

ARNING

W

ARNING

NOTE

NOTE

It is mandatory to secure the laser marker before you

securing or positioning may cause serious damage.

Do not secure the laser marker in a way other than the one described in the figure.

Introduction of optical or mechanical surfaces,

tional protective glass, between F-Theta scan lens output and marking surface may

case optical feedback into the laser marker.

Optical induced damage caused to laser marker by reflection from external surfaces is

not covered by warranty.

In order to prevent marking distortions, avoid vibrations and bumps during

ing process!

It is recommended to install the scan head on a positioning Z-axis

such as mechanical shutters or addi-

start marking, since improper

the mark-

system for accu-

rate mounting at focal distance!

6

Arex™ 400

Page 21

Control Rack installation

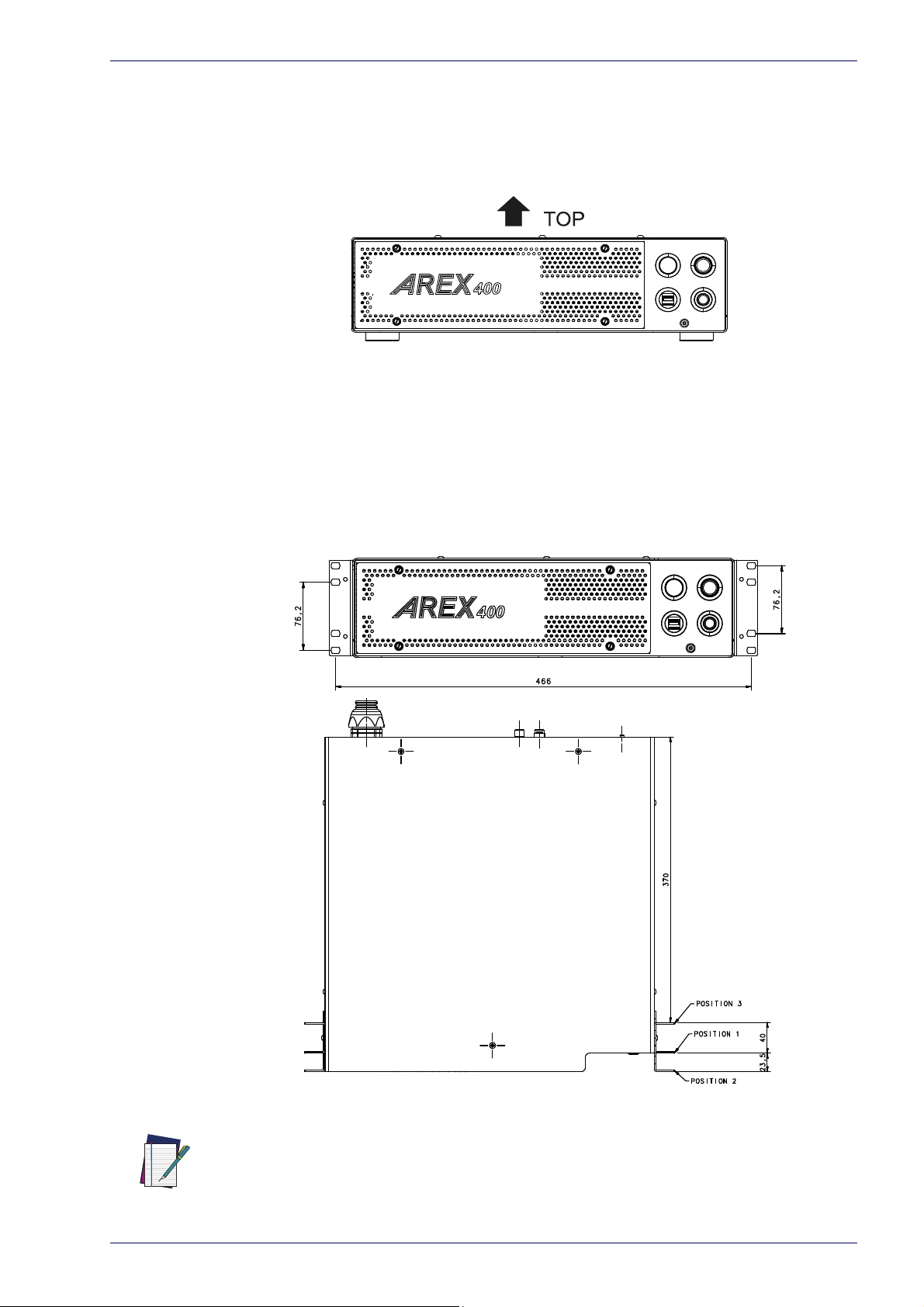

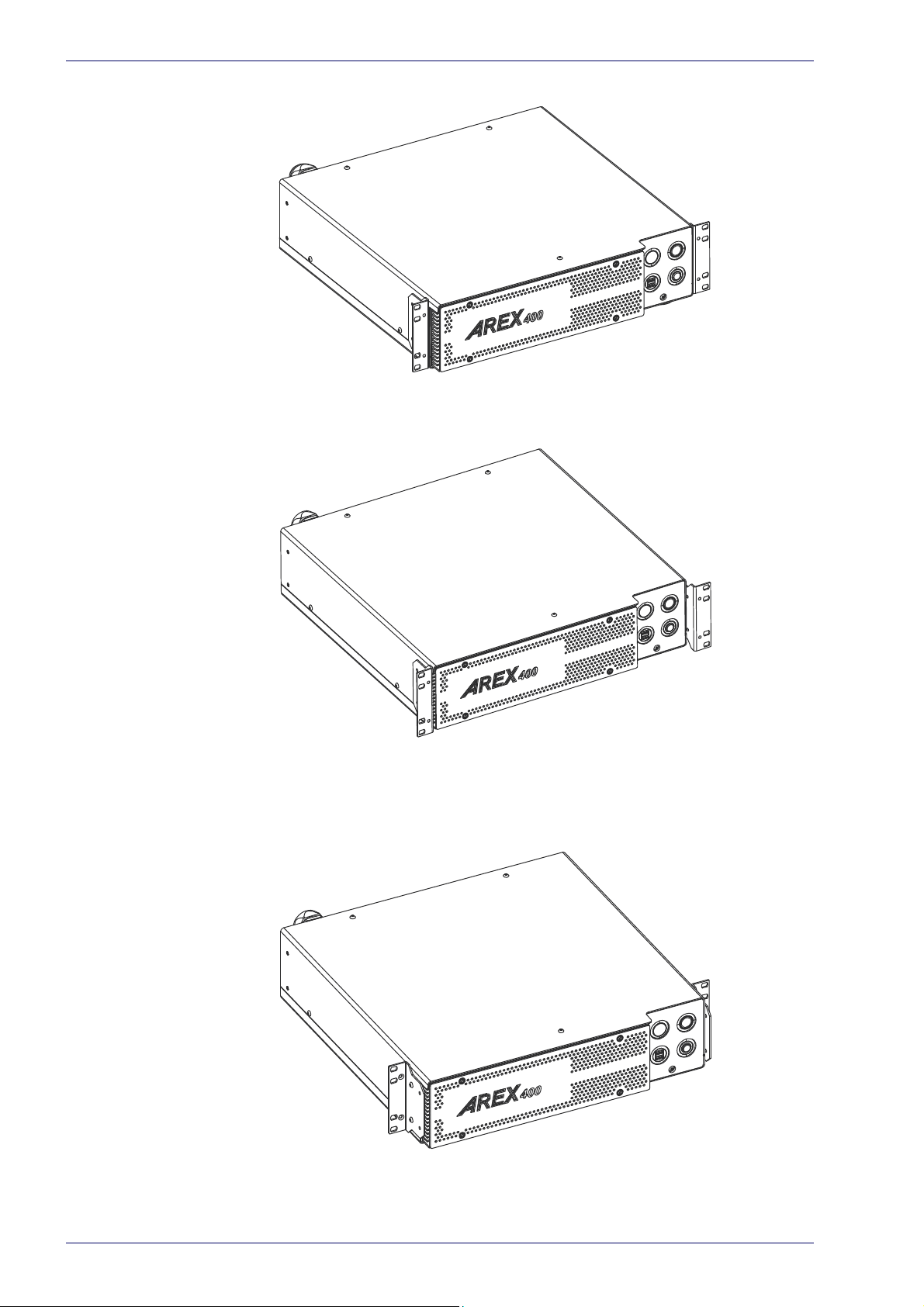

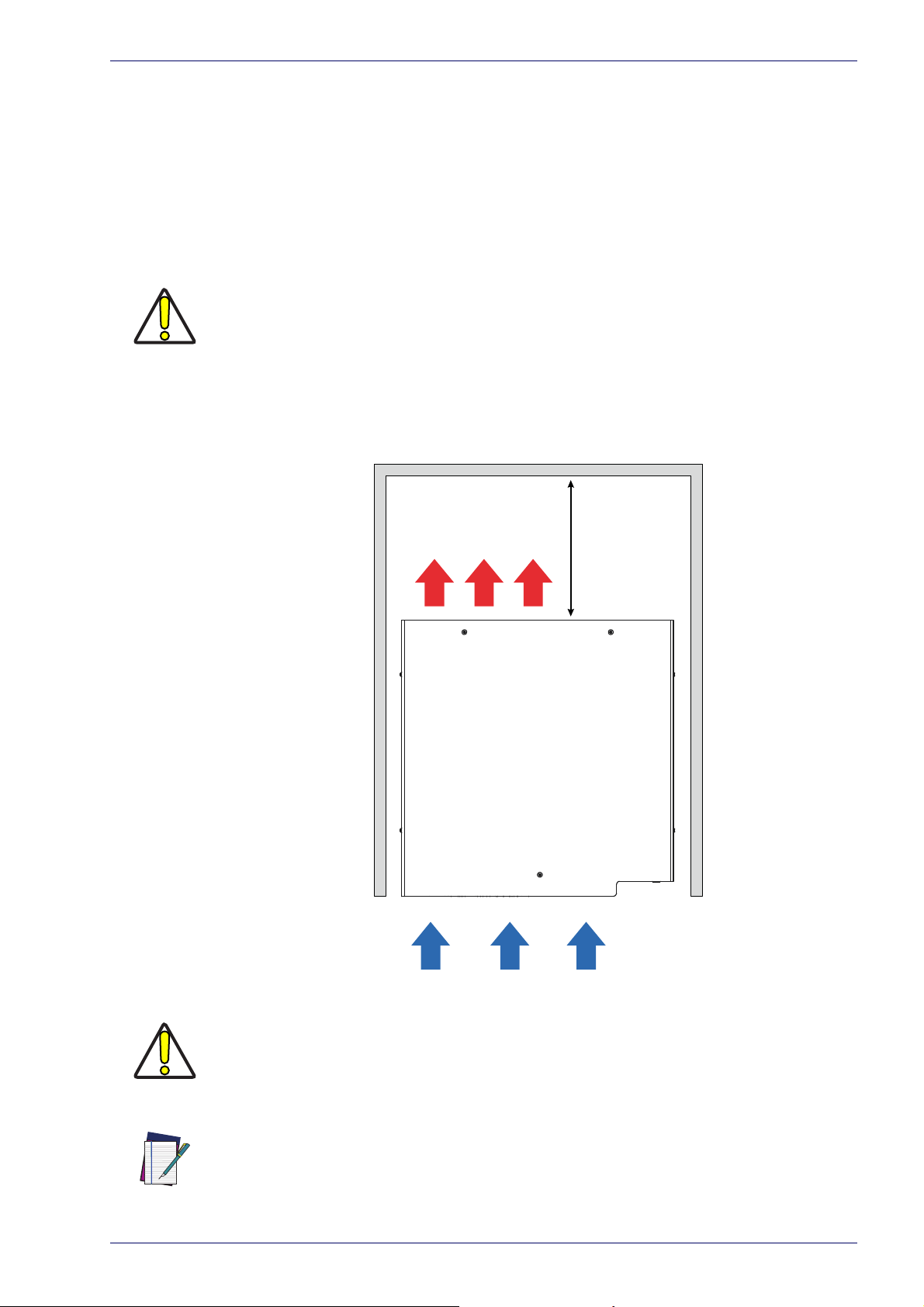

Horizontal installation

The control rack must be positioned in a safe manner, following the recommendations below:

Figure 2: Control rack horizontal positioning

The control rack can be installed on a standard 19" rack cabinet using the fixing

brackets supplied as a standard equipment with XXX-X6X models and as an

accessory for XXX-X5X models (see "Ra

The figure below shows the fixing points for installation in a rack cabinet. Rack

ha

ndles for an easier installation are available as an accessory (see "Ra

dles" on page 71).

Using the fixing brackets is possible to install the control rack in three different

positions

inside the cabinet:

Control Rack installation

ck Handles" on page 71).

ck Han-

Figure 3: Control rack fixing bracket mounting configuration

All dimensions are in millimeters.

NOTE

User Manual 7

Page 22

Installation

Using this position the fixing brackets are aligned with the console.

Figure 4: Control rack fixing brackets mounting position 1

Using this position the fixing brackets are aligned with the frontal grid panel.

Figure 5: Control rack fixing brackets mounting position 2

Use this position if you want to use a pre-existing integration for AREX™ 3 and it

is required that the back panel of AREX™ 400 is in the same position as the back

panel of AREX™ 3 inside the cabinet.

Figure 6: Control rack fixing brackets mounting position 3

8

Arex™ 400

Page 23

Vertical installation

The control rack must be positioned in a safe manner, following the recommendations below.

The feet must be removed from the bottom of the control rack and installed on the left

side of the control rack using the appropriate fixing points. Tightening torque = 0.5 Nm.

NOTE

Control Rack installation

W

ARNING

Figure 7: Control rack vertical positioning

The control rack MUST be fixed to a side wall using the appropriate fixing points placed

on the bottom of the

control rack.

Figure 8: Control rack fixing points for vertical installation

User Manual 9

Page 24

Installation

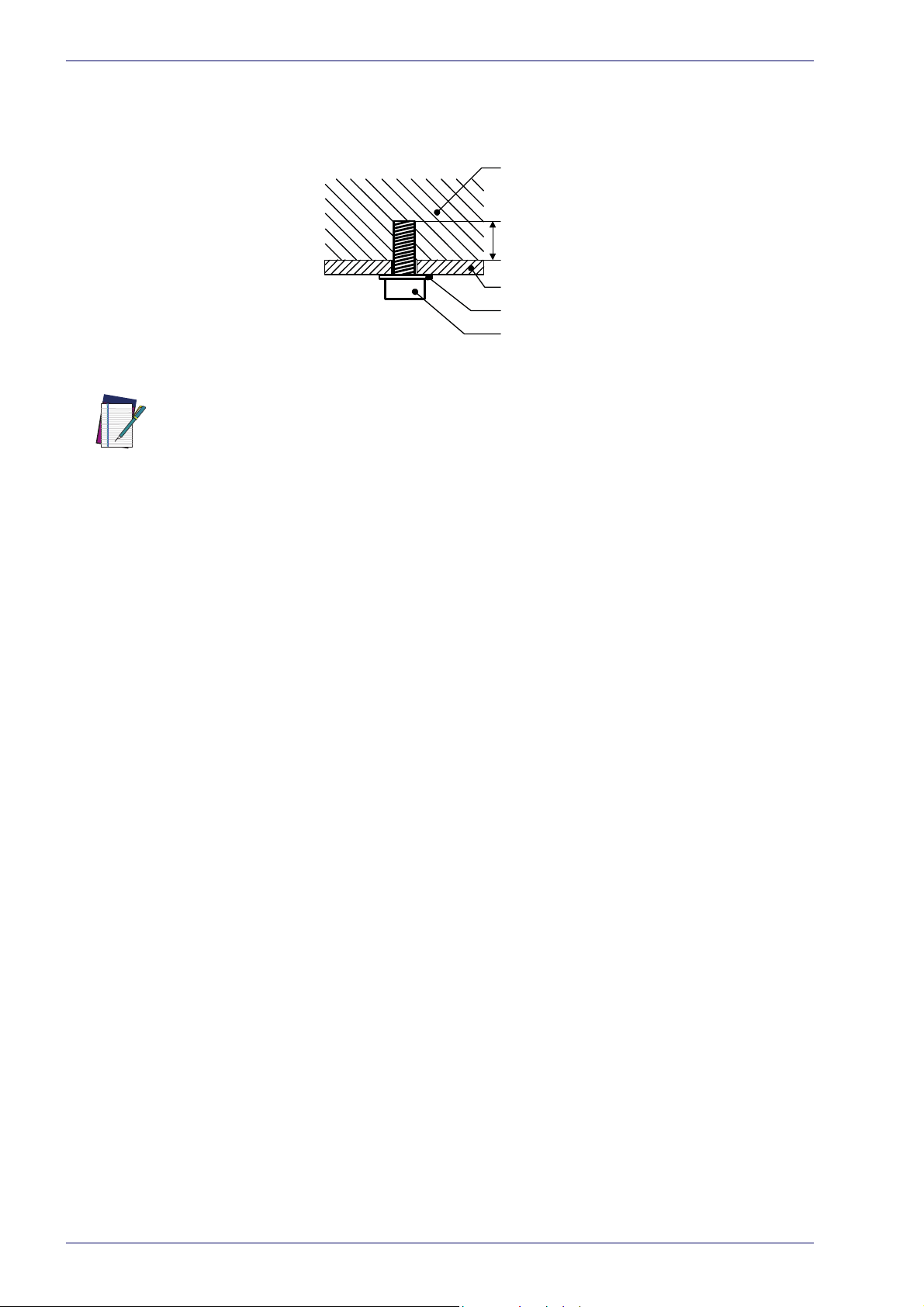

Control rack

7 mm

Mounting plate thickness

Washer thickness

M4 screw

Control rack mounting screws length

To determine the length of the mounting screws, consider the thickness of the

mounting plate and the thickness of the washer.

Figure 9: Length of mounting screws

Mounting holes depth is =7mm. Tightening torque = 2 Nm.

NOTE

10

Arex™ 400

Page 25

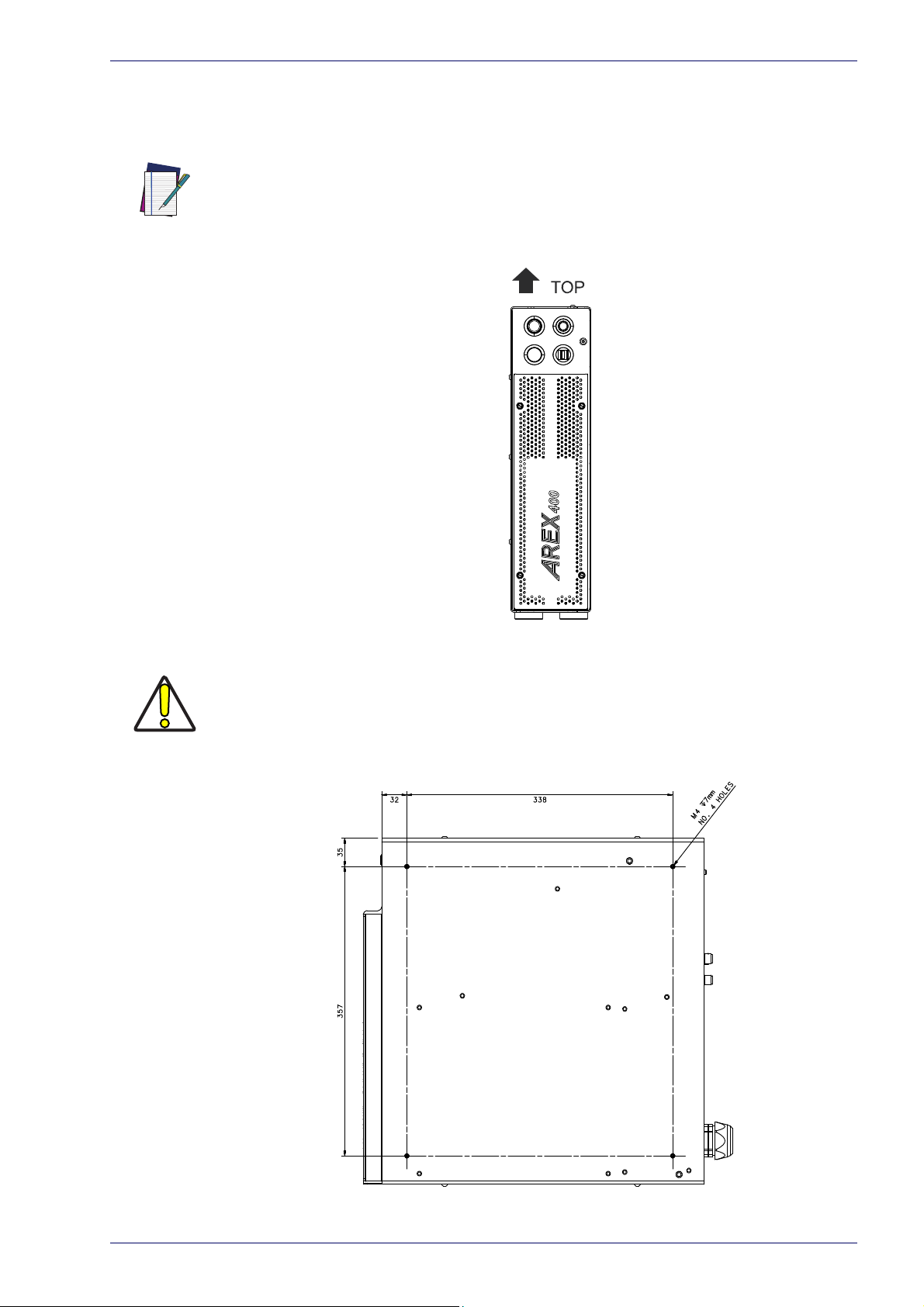

Scan Head installation

The scan head can be installed in any orientation and must be fixed to a suitable

base (not supplied by Datalogic) using the dedicated threaded holes and the high

precisions slotted seats:

Scan Head installation

Figure 10: Fixing points on scan head (bottom view)

All dimensions are in millimeters.

NOTE

User Manual 11

Page 26

Installation

Focusing Beam output

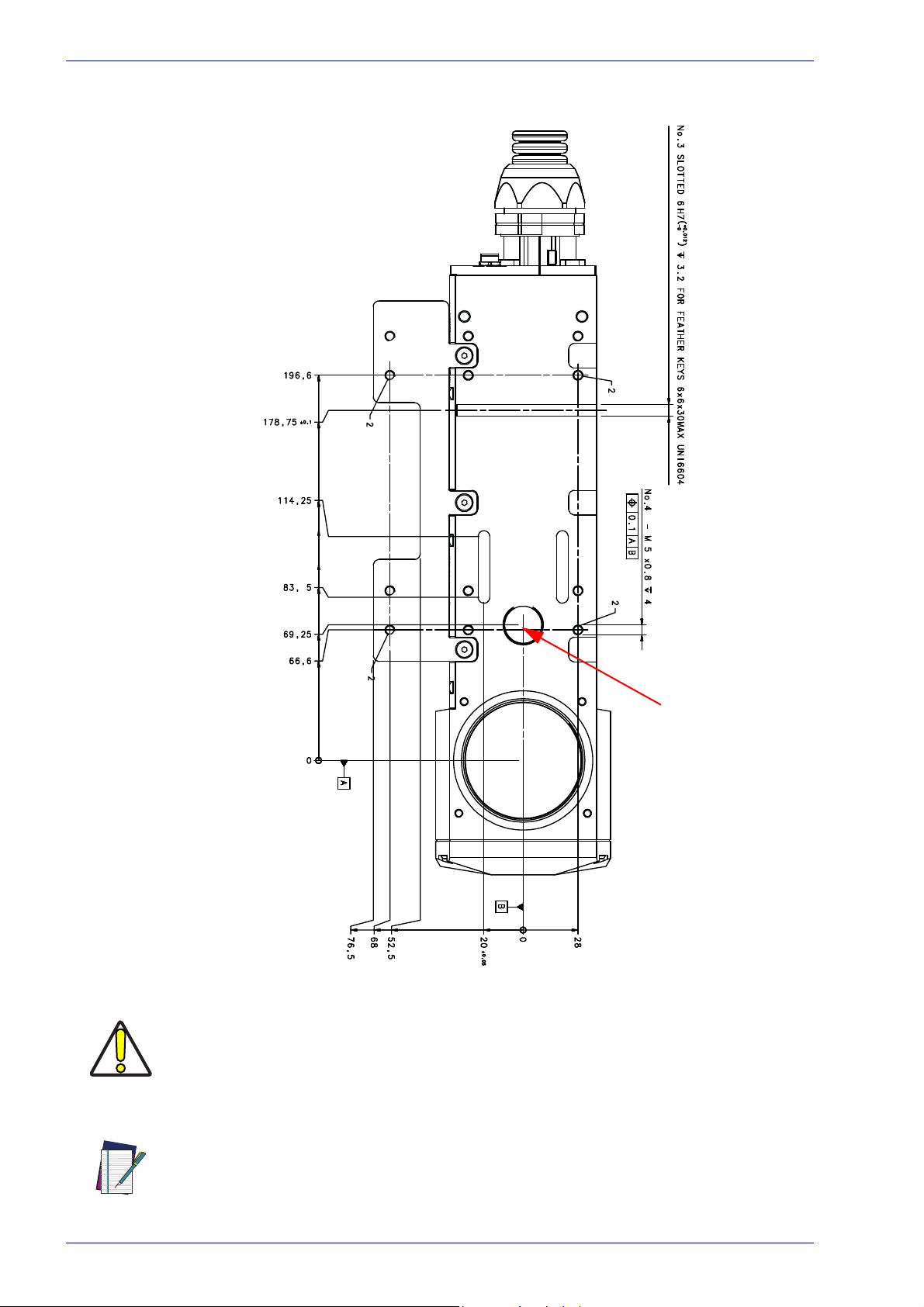

A fixing bracket for scan head is provided to offer dedicated threaded holes

designed to be fully compatible with Arex™ 3 products:

12

W

ARNING

NOTE

Figure 11: Fixing points on scan head (back compatibility with Arex™ 3)

If the scan head is mounted on an existing support suitable for Arex™ 3, the Arex™ 400

focusing beam diode may be covered.

All dimensions are in millimeters.

Arex™ 400

Page 27

Scan Head installation

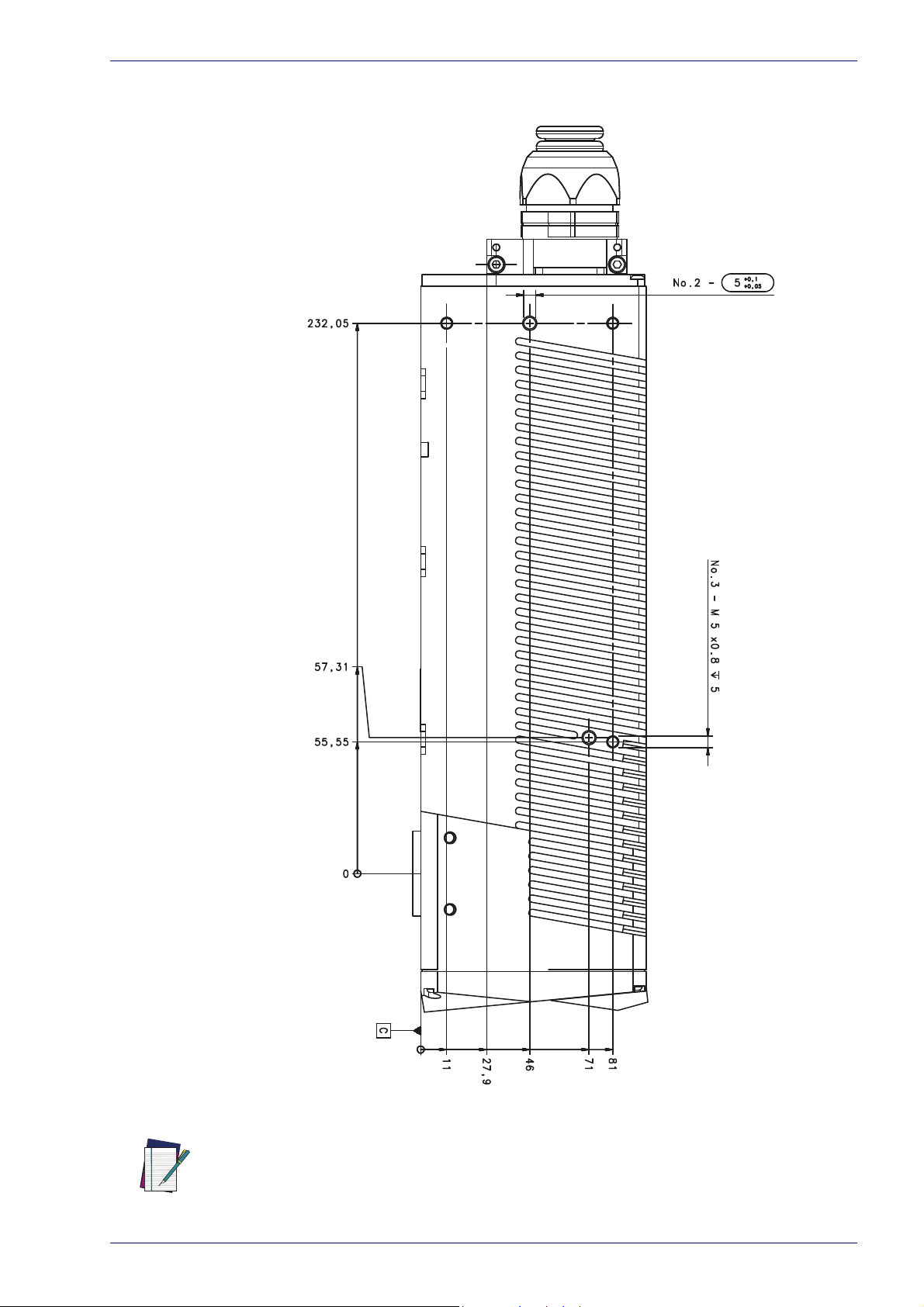

It is also possible to mount the scan head sideways using dedicated threaded

holes:

Figure 12: Fixing points on scan head side

All dimensions are in millimeters.

NOTE

User Manual 13

Page 28

Installation

Scan Head

4 mm

Mounting plate thickness

Washer thickness

M5 screw

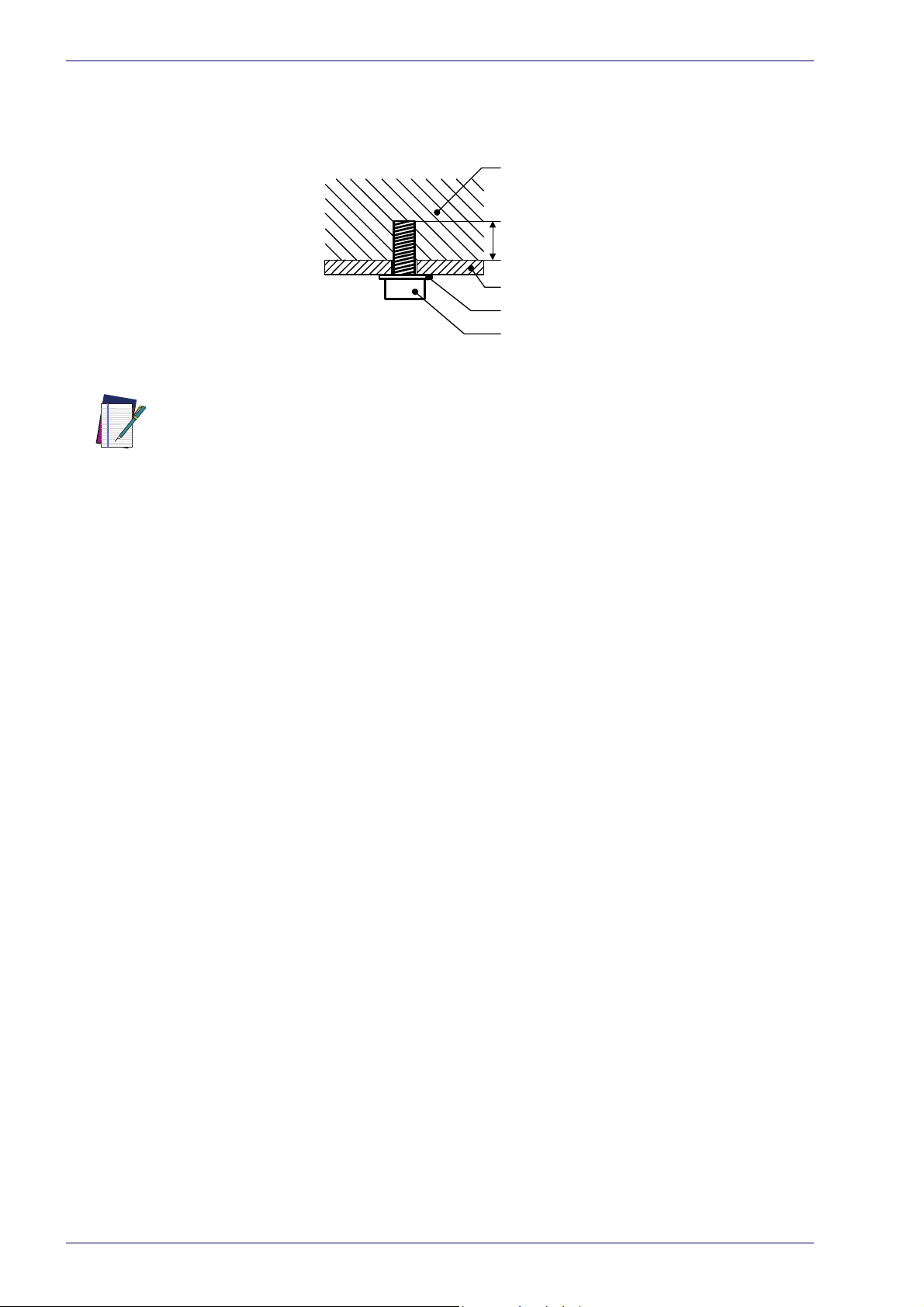

Scan head mounting screws length

To determine the length of the mounting screws, consider the thickness of the

mounting plate and the thickness of the washer.

Figure 13: Length of mounting screws

Mounting holes depth is =4mm. Tightening torque = 2 Nm.

NOTE

14

Arex™ 400

Page 29

Installation environment

≥300mm

Control rack

The control rack must be installed in a suitable environment in order to allow

proper air flow and correct housing of the cables.

The control rack uses a forced air cooling system: an adequate air flow is necessary to guarantee its correct cooling. Install the control rack so that air flow is

no

t obstructed. Moreover, do not install it near a heat source.

If not enough space is provided, the temperature inside the control rack could rise,

causing temperature error.

W

ARNING

Clean the air filter when it is dirty. If the air filter is dirty, insufficient air-flow

might not ensure correct cooling and might stop the marking operation. Clean or

replace the air filter periodically.

Installation environment

Figure 14: Control rack installation environment

DO NOT place heavy objects on top of the control rack!

W

ARNING

The control rack IP rating is IP31 in horizontal position, otherwise IP30.

NOTE

User Manual 15

Page 30

Installation

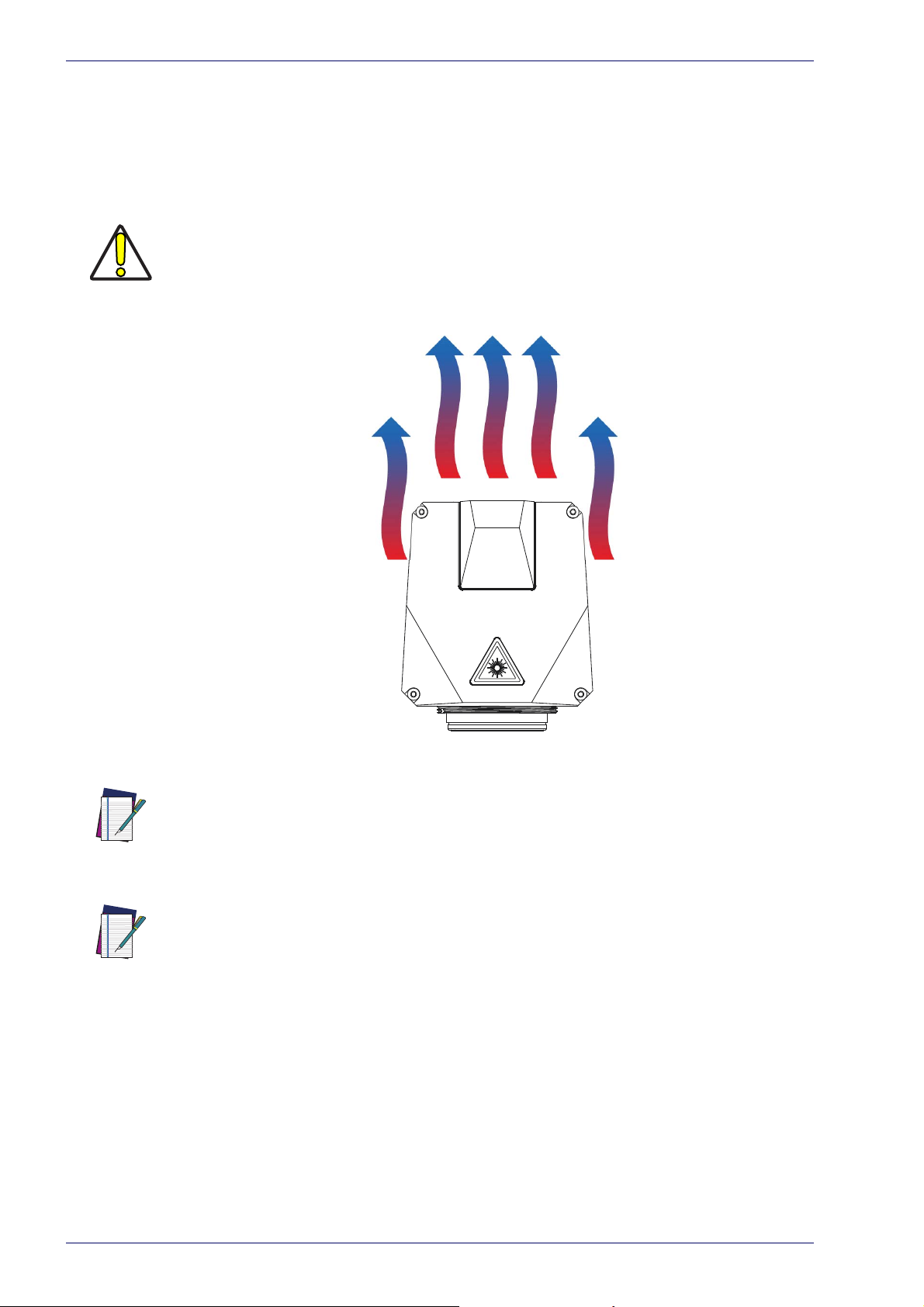

Scan Head

W

ARNING

The scan head must be installed in a suitable environment in order to allow

proper air flow and correct housing of the cables.

The scan head uses a passive air cooling syst

sary to guarantee its correct co

obstructed. Moreover, do not install it near a heat source.

If not enough space is provided, the temperature inside the control rack could rise,

causing temperature error.

oling. Install the scan head so that air flow is not

em: an adequate air flow is neces-

NOTE

NOTE

Figure 15: Scan head installation environment

The scan head IP rating is IP64 not co

To ensure a complete IP64 protection for 160S and

proper accessory (see "

M39 F-Theta protective cap" on page 70).

nsidering F-Theta scan lens.

254S F-Theta scan lenses use the

16

Arex™ 400

Page 31

Fume / Dust extractor

During the marking process, dust and/or fume may be produced. It is important

to use an adequate fume/dust extractor and/or air filtration (see “Fume

Extractor” on page 71).

Marking PVC (or other plastic material) can cause the release of chlorine gas which can

be harmful to the laser operator and to the laser marker itself. Always use adequate

fume extractor during PVC and plastic marking.

W

ARNING

Fume / Dust extractor

User Manual 17

Page 32

Chapter 2

Technical Specifications

TECHNICAL CHARACTERISTICS starting on page 19

PRODUCT DESCRIPTION starting on page 20

MARKING AREA SPECIFICATION starting on page 22

GREEN SPOT starting on page 24

CONNECTORS SPECIFICATIONS starting on page 25

INPUT/OUTPUT SPECIFICATIONS starting on page 34

LASER MARKER STAT ES starting on page 35

TIMING DIAGRAMS starting on page 37

LIGHTER™ SUITE MARKING SOFTWARE starting on page 42

18

Arex™ 400

Page 33

Technical Characteristics

Technical Characteristics

AREX™ 400 MODELS A20-X6X 110-XXX 120-XXX 130-X6X 150-X6X

Electrical specifications

Input Voltage (main power supply) V (AC) 100 to 240 @ 50-60 Hz

Max. Input Current (main power supply) A 3 - 1.25 4 - 1.7

Max power W 300 400

2

4

6

1

(HxWxD)

≥

0.75 1

≥

10 10

°C

°F

°C

°F

5 to 40

41 to 104

-10 to 60

14 to 140

< 90 without condensation

mm

in

Kg

lbs

113x432x434

4.4x17x17.1

17.5

38.5

Forced Air Cooling

Rack fans: L10@ 40°C = 70000 h

Laser source fans: L10@ 40°C = 65000 h

mm

in

Kg

lbs

96x90x326

3.7x3.5x12.8

3.5

7.7

IP64

Air Cooling

mm

in

mm

in

80 (fixed installation); 11

0 (mobile installation)

3.15 (fixed installation); 4.33 (mobile installation)

2885

113.5

High speed galvanometer scanning system

mm/s Up to 10000

char/s Up to 600

m/min

pcs/s

Up to 75

3

EMC (Embedded Marking Control) and Lighter™ Suite

5 to 35

41 to 95

Laser Source specifications

Laser Type Pulsed Fiber Laser

Nominal Average Power W 20 10 20 30 50

Pulse Energy (max.) mJ

Peak Power (max.) kW

Central Emission Wavelength nm 1050-1080 1064

Typical Nominal Pulse Width ns 4 to 250 100

Repetition Rate kHz 20 to 500 2 to 200

Laser Aiming Beam / Focus Beam Class 2: 655 nm

Environmental specifications

Operating temperature

Storage Temperature

Humidity %

Altitude m < 2000

Shock and Vibration MIL 810E ”CAT1 Basic Transportation”

Package Drop Test cm 60

Pollution Degree 2

Overvoltage Category II

Physical specifications

Control Rack dimensions (HxWxD)

Control Rack Weight

Control Rack IP Rating IP31 (in horizontal position, otherwise IP30)

Control Rack Cooling

Scan Head dimensions

Scan Head Weight

3

Scan Head IP Rating

Scan Head Cooling

Noise dB (A) < 65 at 1 meter

Head Cable minimum bending radius

Head Cable Length

Beam deflection

Other specifications

Marking Speed

5

Char Marking Speed

MOF (Marking on the fly) YES [constant speed or encoder]

Line speed - Productivity

Marking Control and Software

Communication RS232, Ethernet (TCP/IP 10, 100 Mbit), Ethernet/IP, digital I/O

1. Specification @ 25°C

2. Without F-Theta scan lens

3. Without F-Theta scan lens

4. Using M39 F-Theta protective cap

5. May vary: measured with f =160mm

6. Single line string, Roman-s font, 1mm height

User Manual 19

Page 34

Technical Specifications

Product Description

Control rack

A description of the main parts of the control rack unit is provided here below:

Figure 1: Control rack overview (front and back panels view)

Front panel:

1. Status LED

2. Start Marking button

3. Key Selector

4. 2x USB 2.0 ports

Back panel:

5. Main Power Supply connection

6. Safety Circuit connector

7. VGA port

8. RS232 port

9. Encoder connector

10. Photocell connector

11. I/O connector (Axes Control)

12. Command Box connector (Laser Control)

13. Head Cable

14. Device Port 2

15. Device Port 1

16. LAN 1 port

17. LAN 3 port (

18. LAN 2 port (

19. 4x USB 2.0 ports

20. Earth ground connection

only for XXX-X6X models

only for XXX-X6X models

)

)

20

Arex™ 400

Page 35

Scan head

Product Description

A description of the main parts of the scan head unit is provided here below:

Figure 2: Scan head overview (front, rear and bottom view)

1. Status LED

2. F-Theta Scan Lens

3. External Focus Beam connector

4. Head Cable

5. Focusing Beam output

6. IR laser beam output / Aiming laser beam output / Green Spot beam output

User Manual 21

Page 36

Technical Specifications

Marking Area Specification

Datalogic provides a wide range of laser marker models with different F-Theta

scan lenses configurations.

These configurations are provided to best match customer needs regarding

rking field size, working distance and power density.

ma

Contact Datalogic if other configurations are necessary.

NOTE

Definition of Marking Area:

• Arex™ 110-XXX/120-XXX/A20-X6X: square marking field measured on black

anodized aluminium plate.

NOTE

• Arex™ 130-X6X/150-X6X: square marking field within which power is > 95% with

resp

ect to power in center.

only certain configurations of F-Theta scan lens and

talogic provides a specific adapter. This

WARNING

W

ARNING

This product was designed to use

marking field. If your needs are not satisfied by the currently available F-Theta scan

lens configurations please contact Datalogic for a solution. The use of other F-Theta

scan lenses or operation outside the specified marking field for a certain F-Theta scan

lens configuration can lead to damage of the F-Theta scan lens, scan head or laser

source. Such damage is not covered by warranty!

For each F-Theta scan lens configuration Da

adapter ensures that residual back reflections caused by the F-Theta scan lens do not

damage the scanning head optics. The removal of such adapter or its incorrect use (for

example incomplete threading, use of another F-Theta scan lens adapter, etc.) can lead

to damage of the F-Theta scan lens, scan head or laser source. Such damage is not

covered by warranty!

F-Theta Scan Lens for Arex™ 110-XXX, 120-XXX and A20-X6X

The table below lists the standard F-Theta scan lenses currently available for

Arex™ 110

F-Theta Scan Lens 160S 254S

Working Distance mm 183 ± 5 280 ± 4

Fixing Distance mm 197 ± 6

Marking Area mm 100 x 100 140 x 140

-XXX, 120-XXX and A20-XXX:

F-Theta Scan Lens diameter: M39

300 ± 5

22

F-Theta Scan Lens diameter: M85 (

F-Theta Scan Lens 100L 330L(*) 420L(*)

Working Distance mm 99 ± 3 388 ± 6 492 ± 6

Fixing Distance mm 141 ± 4 471 ± 7

Marking Area mm 50 x 50 220 x 220 285 x 285

(*) NOT AVAILABLE for 110-X6X

available only for XXX-X6X versions

561 ± 7

)

Arex™ 400

Page 37

F-Theta Scan Lens for Arex™ 130-X6X and 150-X6X

WD: Working Distance

FD: Fixing Distance

MA: Marking Area

AB: Aiming Beam

FB: Focusing Beam

The table below lists the standard F-Theta scan lenses currently available for

Arex™ 130-X6X and 150-X6X:

F-Theta Scan Lens diameter: M85

F-Theta Scan Lens 160L 254L 330L

Working Distance mm 176 ± 2 296 ± 5 388 ± 6

Fixing Distance mm 212 ± 3 367 ± 6

Marking Area mm 100 x 100 170 x 170 210 x 210

Working Distance is defined as the distance between the center of the marking area

(defined in the focal plane) and the closest mechanical edge of the F-Theta scan lens.

Refer to the following figure.

NOTE

Marking Area Specification

471 ± 7

NOTE

Fixing Distance is defined as the distance be

marking area. Refer to the following figure.

tween the base of the scan head and the

NOTE

User Manual 23

Figure 3

For products equipped with 160S, 254S, 160L and

position, defined at the point where the focus beam overlaps with the aiming beam, is

preset at factory.

: Marking Area

100L F-Theta scan lenses the focus

Page 38

Technical Specifications

Green Spot

The Green Spot is an indicator integrated in the scan head able to provide a

green visual feedback in the center of marking field area.

CONFIGURATION

OFF

SYSTEM READY TO MARK

MARKING CONFIRMATION

MARVIS VERIFICATION

1

Figure 4: Green Spot indicator

DESCRIPTION

The Green Spot indicator is not active (always OFF)

The Green Spot is steady ON only when all these events are verified:

- the laser marker is in READY state

- a document is in AUTO MODE or WORK MODE

- the marking process is not in progress

The Green Spot turns ON when all these events are verified:

- the laser marker is in READY state

-

a document is in AUTO MODE or WORK MODE

- the marking process was correctly executed (no errors, no

stop marking, no state changing)

The Green Spot indicator turns ON at the end of the marking process and

stay active for a configurable range of time from 0.1s to 5s

This is available only if MARVIS™ feature is enabled.

The Green Spot turns ON when all these events are verified:

- the laser marker is in READY state

a document is in AUTO MODE or WORK MODE

-

- the marking process was correctly executed (no errors, no

stop marking, no state changing)

- the verification of the marking content made by MARVIS™

device was positive

The Green Spot indicator turns ON at the end of the marking process and

s

tay active for a configurable range of time from 0.1s to 5s

24

1. refer to Lighter™ user's manual “Setting I/O parameters” paragraph to set the signal properties

Arex™ 400

Page 39

Connectors Specifications

Connectors Specifications

Safety Circuit

Control rack back panel connector

Socket Sub-D, 15 pins, female.

Figure 5: Safety Circuit connector, female panel plug (front view)

PIN SIGNAL TYPE DESCRIPTION

1 VCC Power Output Auxiliary 24V DC power supply

2 RESERVED - DO NOT CONNECT

3 VCC Power Output

4 SAFETY_FDBK+ Output Clean contact pole for monitor K relays state (Common)

5 SAFETY_FDBK- Output

6 GND Ground Ground reference

7 RESERVED 8 GND Ground Ground reference

9 INTERLOCK_A Input

10 RESERVED - DO NOT CONNECT

11 INTERLOCK_B Input

12 RESERVED - DO NOT CONNECT

13 LASER_STOP_A Input

14 RESERVED - DO NOT CONNECT

15 LASER_STOP_B Input Return signal for K2 relay coil (

Auxiliary 24V DC power supply

Return of clean contact pole for monitor

mally Closed)

DO NOT CONNECT

Interlock signal for K1 relay coil

Interlock signal for K2 relay coil (

Return signal for K1 relay coil

only for XXX-X6X models

only for XXX-X6X models

K relays state (Nor-

)

)

Table 1: Safety Circuit connector pinout

User Manual 25

Page 40

Technical Specifications

for XXX-X5X models

for XXX-X6X models

Safety Circuit Electric Diagram

Figure 6: Safety Circuit connector, electric diagram

TECHNICAL CHARACTERISTICS

Control Contacts

Inrush current max. 15 A for 20 ms

Switching current range

Contact resistance (as delivered) 100 m / 6 V / 100 mA

Standard coils for direct current

Nominal Voltage V DC 24

Min. pick-up voltage at 20°C

Drop-out voltage at 20°C

Nominal current in mA 31.5

Resistance in Ohm at 20°C 760 ± 10%

5 mA to 6 A

16.8

2.4

26

Arex™ 400

Page 41

WARNING

Connectors Specifications

Muting Device

Sub-D, 15 pins, male, with shell.

Figure 7: Safety Circuit Muting Device provided

Do not use the Safety Circuit Muting Device for external devices, since this will result in

loss of the safety function of the machine to which this product is installed.

Do not use the Safety Circuit Muting Device except for maintenance of this product.

W

ARNING

It is the customer's responsibility to provide a correct integration of the safety signals

according to applic

able regulations.

Internal electric diagram

Figure 8: Safety Circuit Muting Device electric diagram

User Manual 27

Page 42

Technical Specifications

Command Box (Laser Control)

Control rack back panel connector

Socket Sub-D, 25 pins, female.

Figure 9: Command Box connector, female panel socket (front view)

PIN SIGNAL TYPE (***) DESCRIPTION

1 24V_ENABLE_B Output power supply Auxiliary 24V DC power supply available for

Secondary external ENABLE signal:

2 EXT_ENABLE_B Digital Input

3 GOOD/BAD Digital Output

4 EXT_24V Output power supply Auxiliary 24V DC power supply available for drive input logical HIGH (max 125mA)

5 EXT_24V Output power supply

6 EXT_24V Output power supply Auxiliary 24V DC power supply available for drive input logical HIGH (max 125mA)

7 24V_ENABLE_A Output power supply

8 EXT_ENABLE_A Digital Input

9 BUSY Digital Output

10 CONNECTOR_PRESENCE Digital Input

11 START_MARKING (*) Digital Input

12 EXT_KEY Digital Input

13 STOP_MARKING (*) Digital Input

14 RESERVED - DO NOT CONNECT

15 RESERVED 16 RESERVED - DO NOT CONNECT

17 END Digital Output

18 POWER_ON Digital Output

19 GND Ground

20 SYSTEM_ALARM Digital Output

21 GND Ground

22 ENABLE_OUT Digital Output

23 SW_READY (*) Digital Output

24 GND Ground Ground reference

25 GND Ground Ground reference

- HIGH level: contact closed

- LOW level or disconnected: contact opened

This signal is used to notify a bad marking:

- ON in case of bad marking

Auxiliary 24V DC power supply available for drive input logical HIGH (max 125mA)

Auxiliary 24V DC power supply available for

Primary external ENABLE signal:

- HIGH level: contact closed

- LOW level or disconnected: contact opened

This signal is used to know if the current

- ON during marking process

This signal is used to check the presence of the Command Box connector:

- HIGH level: normal operation

- LOW level or disconnected: laser marker faulty

This signal is used to start to the marking process when a docum

ning in AUTO MODE (**) or WORK MODE (**):

- HIGH level pulsed signal start the marking process

External KEY signal:

- HIGH level: contact closed

- LOW level or disconnected: contact opened

This signal is used to stop the marking process:

- HIGH level pulsed signal stop the marking process

DO NOT CONNECT

This signal is used to know if the marking process is finished:

- ON at the end of marking process

This signal is used to know if the laser marker is already warmed up:

- ON when the laser is in STAND_BY or READY state

Ground reference

This signal is used to know if the laser marker is in booting up state or in error state:

- ON during BOOTING UP

- ON in case of system error

Ground reference

This signal is used to know if the laser marker is ready to emit laser radiation:

- ON when the laser marker is in READY state

Depending on the configuration this signal can be used in different ways:

- COMPATIBILITY: ON when a document or a sequence is running in AUTO MODE (**) or

RK MODE (**) independently from the laser marker state. The signal is ON regardless

WO

of whether the laser marker is ready to start a new marking

- STANDARD: ON when a document or a sequence is running in AUTO MODE (**) or WORK

MOD

E (**) and the laser marker state is READY. The signal is ON regardless of whether

the laser marker is ready to start a new marking

- READY TO MARK: ON only when a document or a sequence is running in AUTO MODE (**)

o

r WORK MODE (**) and the laser marker state is READY. The signal is ON only if the laser

marker is ready to accept a new START_MARKING event (loading/spooling already executed)

This signal can also be driven using Lighter™ Script engine "IoPort.setReady (true)" function

EXT_ENABLE_B

EXT_ENABLE_A

spooler is executing (marking in progress):

(max 125mA)

(max 125mA)

ent or a sequence is run-

28

Table 2: Command Box connector pinout

(*) refers to Lighter™ user's manual “Setting I/O parameters” paragraph to set the signal properties

(**) refers to Lighter™ user's manual

(***) see “Input/Output specifications” on page 34

Arex™ 400

Page 43

W

ARNING

Connectors Specifications

Muting Device

Sub-D, 25 pins, male, with shell.

Figure 10: Command Box Muting Device provided

If the Command Box Muting Device provided is connected, the laser marker enable is

bypassed.

Internal electric diagram

Figure 11: Command Box Muting Device electric diagram

User Manual 29

Page 44

Technical Specifications

Axes (I/O Control)

Control rack back panel connector

Plug Sub-D, 25 pins, male.

Figure 12: Axes connector, male panel plug (front view)

PIN SIGNAL(**) TYPE (***) DESCRIPTION

1 EXT_24V

2 OUTPUT_0 (*) or STEP_Y Digital Output Generic output or Y-Axis drive step signal (Clock) for axis control (**)

3 OUTPUT_2 (*) or STEP_Z Digital Output

4 OUTPUT_4 (*) or BRAKE X Digital Output

5 OUTPUT_6 (*) or BRAKE Y Digital Output

6 OUTPUT_8 (*) or BRAKE Z Digital Output

7 INPUT_0 (*) or ZERO X Digital Input

8 INPUT_1 (*) or ZERO Y Digital Input

9 INPUT_2 (*) or ZERO Z Digital Input

10 INPUT_3 (*) or DISABLE X Digital Input

11 INPUT_4 (*) or DISABLE Y Digital Input

12 INPUT_5 (*) or DISABLE Z Digital Input

13 GND Ground

14 OUTPUT_12 (*) or STEP R Digital Output Generic output or R-Axis drive step signal (Clock) for axis control

15 OUTPUT_1 (*) or STEP X Digital Output

16 OUTPUT_3 (*) or DIR Z Digital Output Generic output or Z-Axis drive direction signal

17 OUTPUT_5 (*) or DIR Y Digital Output

18 OUTPUT_7 (*) or DIR X Digital Output Generic output or X-Axis drive direction signal

19 INPUT 9 Digital Input

20 INPUT 8 Digital Input Generic Input

21 INPUT_7 (*) or ZERO R Digital Input

22 INPUT_6 (*) or DISABLE R Digital Input

23 OUTPUT_9 (*) or BRAKE R Digital Output

24 OUTPUT_11 (*) or DIR R Digital Output Generic output or R-Axis drive direction signal

25 GND Ground Ground reference

Output Power

supply

Auxiliary 24V DC power supply available for drive input logical HIGH

(max 125mA)

Generic output or Z-Axis drive step signal (Clock) for axis control (**)

Generic output or X-Axis electromechanical brake release signal. ON

during drive motion

Generic output or Y-Axis electromechanical brake release signal. ON

during drive motion