Page 1

USER’S MANUAL

> Arex

TM

30W – 50W

Page 2

ii

Datalogic S.r.l.

Via S. Vitalino 13

40012 – Calderara di Reno

Italy

ArexTM 30W - 50W User’s Manual

Ed.: 05/2017

Helpful links at www.datalogic. c om: Contact Us, Terms and Conditions, Support.

© 2015 - 2017 Datalogic S.p.A. and/or its affiliates ALL RIGHTS RESERVED. Without

limiting the rights under copyright, no part of this documentation may be reproduced,

stored in or introduced into a retrieval system, or transmitted in any form or by any means,

or for any purpose, without the express written permission of Datalogic S.p.A. and/or its

affiliates. Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in

many countries, including the U.S.A. and the E.U.

Arex, Lighter Suite are trademarks of Datalogic S.p.A. and/or affiliates. All other

trademarks and brands are property of their respective owners.

Datalogic reserves the right to make modifications and improvements without prior

notification.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein,

nor for incidental or consequential damages resulting from the use of this material.

821004083 rev. E

Page 3

iii

SYMBOLS

Symbols used in this m anual along with their meaning are show n below. Symbols and signs are repeated

within the chapters and/or sections and have the following meaning:

Generic Warning:

This symbol indicates the need to read the manual carefully or the necessity of an important

maneuver or maintenance operation

.

Electricity Warning:

This symbol indicates d angerous voltage associated with t he laser product, or po werful enough to

constitute an electrical risk. This symbol may also appear on the marking system at the risk area

Laser Warning:

This symbol indicates the danger of exposure t o visible or invisible las er radiation. T his symbol may

also appear on the marking system at the risk area

.

.

Fire Warning:

This symbol indicates the d anger of a fire w hen proce ssing flam mable m aterials. Because th ere is a

danger of fire, it is indispensable to follow the instructions provided by the manufacturer when

commissioning the marking system

.

Notice:

Notes, usage tips, or additional information.

Note:

Carefully read the user’s manual before using the marking system.

Page 4

iv

REVISION INDEX

Revision Date

Number of added or edited

pages

821004080 30/10/2015 Release

821004081 03/02/2016 General Review

821004082 rev.D 05/05/2016 16, Appendix C

821004083 rev.E 22/05/2017 ii, Appendix F

NOTE:

We sometimes update the documentation after original publication. Therefore, you should also

review the documentation at www.datalogic.com for updates.

Page 5

v

FOREWORD

Information included in this manual is intended for a qualified inst aller able to integrate the marking

system into a system, complying with all the protection features required by international rules and

local legislations. Refer to the Appendices for further information.

Following manual refers to ArexTM Fiber 130X-TLS2 and 150X-TLS2 marking systems in Class 4

configuration.

In addition to being pr ofessionally trained in their ro le, personnel assigned to w ork on the marking system

must be informed and m ade acquainted with the risks inherent to invisible and visib le laser radiation. The

operator is required to caref ully read the section of the m anual concerning safet y instructions as well as the

sections related to matters falling under her/his responsibility.

The workers assigned to the marking system can be identified as:

• OPERATOR

responsible for loading elements to be processed, visually checking the work cycle, removing the

finished product and cleaning the marking system.

• MAINTENANCE WORKER

responsible for the electrical, mechanical and optical m aintenance and adjustment of the marking

system.

WARNING!

Datalogic shall not be held responsible for any non-conforming use of marking system of its

manufacture

.

NOTE:

BEFORE INSTALLING AND USING THE LASER, READ CAREFULLY THE APPENDICES.

Page 6

vi

OVERVIEW

The Fiber Laser marking system developed and manufactured by Datalogic employs the most advanced

technologies with regards to the mechanical-optical part, the electronic control of laser beam power,

communication and the overall safety of the entire system.

OPERATION OF A LASER SYSTEM WITH GALVANOMETRIC SCANNING

In pulsed or continuous operation mode, the laser generates an invisible, high-energy infrared beam.

In order t o obtain a mor e accur ate focus, t he laser beam is fir st enlarged using a n optica l expansi on s ystem

and then deflected by a scanning system consisting of two mirrors mounted on galvanometric motors.

These mirrors deflect the beam in a controlled beam along the X and Y axes; processing of the product

surface occurs by coordinating the movement of the two motors with the turning on/off of the laser beam.

The deflected laser beam is focused by an F-Theta scan lens before it hits the surface of the product.

Generally speaking, the marking is carried out within the focus of the beam.

LASER SOURCE

On ArexTM marking system it is used a sealed fiber laser source.

This source is based on the new fiber solid state technology.

It guaranties high stability, lower sensi ti vit y on optical misalignment and a longer product lif etime.

GALVANOMETRIC SCANNING HEAD

The scanning head feat ures two def lection m irrors that deflec t the beam in an X and Y d irection, dep ending

on the graphics/pattern to be reproduced.

MARKING SOFTWARE

The marking software Lighter is preinstalled on the system.

NOTE:

Consult Lighter software user’s manual for a proper use of the same.

NOTE:

Consult the proper Appendix to upgrade the preinstalled software if necessary.

WARNING!

Marking system installation in secure environment is responsibility of the system integrator!

Page 7

vii

The ArexTM marking system features a po wer supply unit whose size is compatible with the standard 19”

2,5U in varnished steel, a n d a s c an head whose compact dimensions m ake it eas y to integrate into a system

that comprises saf ety systems required by applicable regulations , the management of mark ing signals and

the customer’s complementary modules, if any.

All marking system connections are found on the rear of the rack: mains power supply, safety, electrical

signals, communication ports, patch cord to the scanner head, while the front features key and enable

command devices, status LED i n ad dit ion t o a USB connector for c om munication with the internal embedded

controller.

Figure 1: Control Rack and Scan Head.

WARNING!

Laser marking m ay strongly inter act with m aterials through a ther mal carboniza tion process with t he

emission of fumes and vapours.

Adequate fume extractor and fume treatment must be provided for, especially when working on

plastic materials such PVC.

IMPORTANT WARNINGS

Access to the interna l part s of the marking system is al lo wed o nly to authorized pe rs onnel, du ly qualified and

trained with regards to risks of optical and electrical nature.

Datalogic d eclines any and al l responsibility for work carried out on live parts by untrained or unauthorized

personnel.

WARNING!

It is forbidden to change the intended use for which the system was designed and developed.

Datalogic declines any and all responsibility for improper use of its marking system.

WARNING!

These marking system actuation is demanded to the system integrator.

Page 8

viii

TABLE OF CONTENTS

SYMBOLS III

REVISION INDEX IV

FOREWORD V

OVERVIEW VI

OPERATION OF A LASER SYSTEM WITH GALVANOMETRIC SCANNING vi

LASER SOURCE vi

GALVANOMETRIC SCANNING HEAD vi

MARKING SOFTWARE vi

IMPORTANT WARNINGS vii

TABLE OF CONTENTS VIII

1 CONTENTS OF THE PACKAGING 10

1.1 UNPACKING 10

1.2 MAIN HARDWARE 11

1.3 CABLE AND ACCESSORIES 11

1.4 TRANSPORT 12

1.5 ON MOISTURE CONDENSATION 12

1.6 FIXING AND POSITIONING 13

1.7 INSTALLATION ENVIRONMENT 15

1.8 FUME / DUST EXTRACTOR 15

2 TECHNICAL SPECIFICATIONS 16

2.1 TECHNICAL CHARACTERISTICS 16

2.2 DESCRIPTION OF THE LASER

2.2.1 SCAN HEAD 18

2.2.2 CONTROL RACK 19

2.3 MARKING AREA SPEC IF I C AT I ON 20

2.4 CONNECTORS SPECIFICATIONS 22

2.4.1 INTERLOCK CONNECTOR 22

2.4.2 COMMAND BOX CONNECTOR (LASER CONTROL) 24

2.4.3 AXES CONNECTOR (I/O CONTROL) 29

2.4.4 RS232 CONNECTOR (COM2) 30

2.4.5 ENCODER CONNECTOR 31

2.4.6 PHOTOCELL CONNECTOR 31

2.5 INPUT/OUTPUT SIGNAL SPECIFICATIONS 32

2.6 CONNECTION EXAMPLE 33

3 INSTALLATION AND SET UP 34

3.1 CONNECTIONS 34

3.1.1 COMMAND BOX CONNECTOR CONNECTION 34

3.1.2 INTERLOCK CONNECTOR CONNECTION 35

3.1.3 POWER SUPPLY CABLE CONNECTION 36

3.1.4 GROUND CONNECTION 36

3.1.5 LOCAL MODE CONNECTION 37

3.1.6 REMOTE MODE CONNECTION 38

3.1.7 F-THETA LENS PROTECTION CAP REMOVAL 39

MODULES 18

4 USE AND OPERATION 40

4.1 TURNING ON SEQUENCE 40

4.1.1 ADVICE ON USING THE SYSTEM 43

4.2 LOCAL MODE OPERATIONS 44

4.3 REMOTE MODE OPERATIONS 44

4.4 OPERATING IN LOCAL MODE 46

4.4.1 HOW TO CREATE AND EDIT YOUR FIRST GRAPHIC DOCUMENT 47

Page 9

ix

4.4.2 HOW TO TEST AND ENGRAVE YOUR DOCUMENT 50

4.4.3 HOW TO USE EXTERNAL SIGNALS TO ENGRAVE YOUR DOCUMENT 52

5 CUSTOMIZE THE SYSTEM’S SOFTWARE 54

5.1 CHANGE O.S. LANGUAGE AND KEYBOARD LAYOUT 54

5.2 CHANGE THE LAN CONFIGURATION AND IP ADDRESS 57

5.3 CHANGE THE VIDEO SETTING 60

5.4 REMOTE DESKTOP CONNECTION 62

6 ACCESSORIES 64

6.1 CONTROL BOX 64

6.2 MARKING ON FLY KIT 65

6.3 RACK HANDLES 65

7 TECHNICAL SUPPORT 66

7.1 SEALS 66

7.2 MAINTENANCE 67

7.2.1 F-THETA SCAN LENS CLEANING PROCEDURE 67

7.2.2 AIR FILTER CLEANING PROCEDURE 68

7.3 PRODUCT SUPPORT AND CUSTOMER SERVICE 69

APPENDIX A: LABEL 70

POSITIONING OF EXTERNAL LABELS 71

APPENDIX B: STANDARDS 72

LASER STANDARDS 72

CE COMPLIANCE 72

FCC COMPLIANCE 72

TM

APPENDIX C: AREX

SAFETY FUNCTIONS OF AREX

SAFETY CONSIDERATION ACCORDING EN ISO 13849-1:2008 73

TM

75

APPENDIX D: NOTE ABOUT LASER 76

LASER SAFET Y 76

LASER RADIATIO N 77

ABSORPTION OF LASER RADIATION 78

CLASSIFICATION AND DANGER LEVEL 78

RADIATION VIEWING CONDITIONS 79

DIRECT VIEWING OF THE LASER BEAM 79

DIRECT VIEWING OF THE BEAM AFTER MIRROR REFLECTION 79

DIRECT VIEWING OF THE BEAM OUTPUT BY AN OPTICAL FIBER 79

DIRECT VIEWING OF THE BEAM AFTER FOCUSING 79

SCATTERED VIEWING OF THE BEAM AFTER FOCUSING 79

N.O.H.D. DETERMINATION AND O.D. OF PROTECTION GOGGLES 80

EYES AND SKIN RISKS 82

GENERAL SAFETY REGULATIONS 82

COLLATERAL RISK 82

APPENDIX E: SOFTWARE UPGRADE 84

APPENDIX F: RECOVER THE SYSTEM USING USB RECOVERY DISK 86

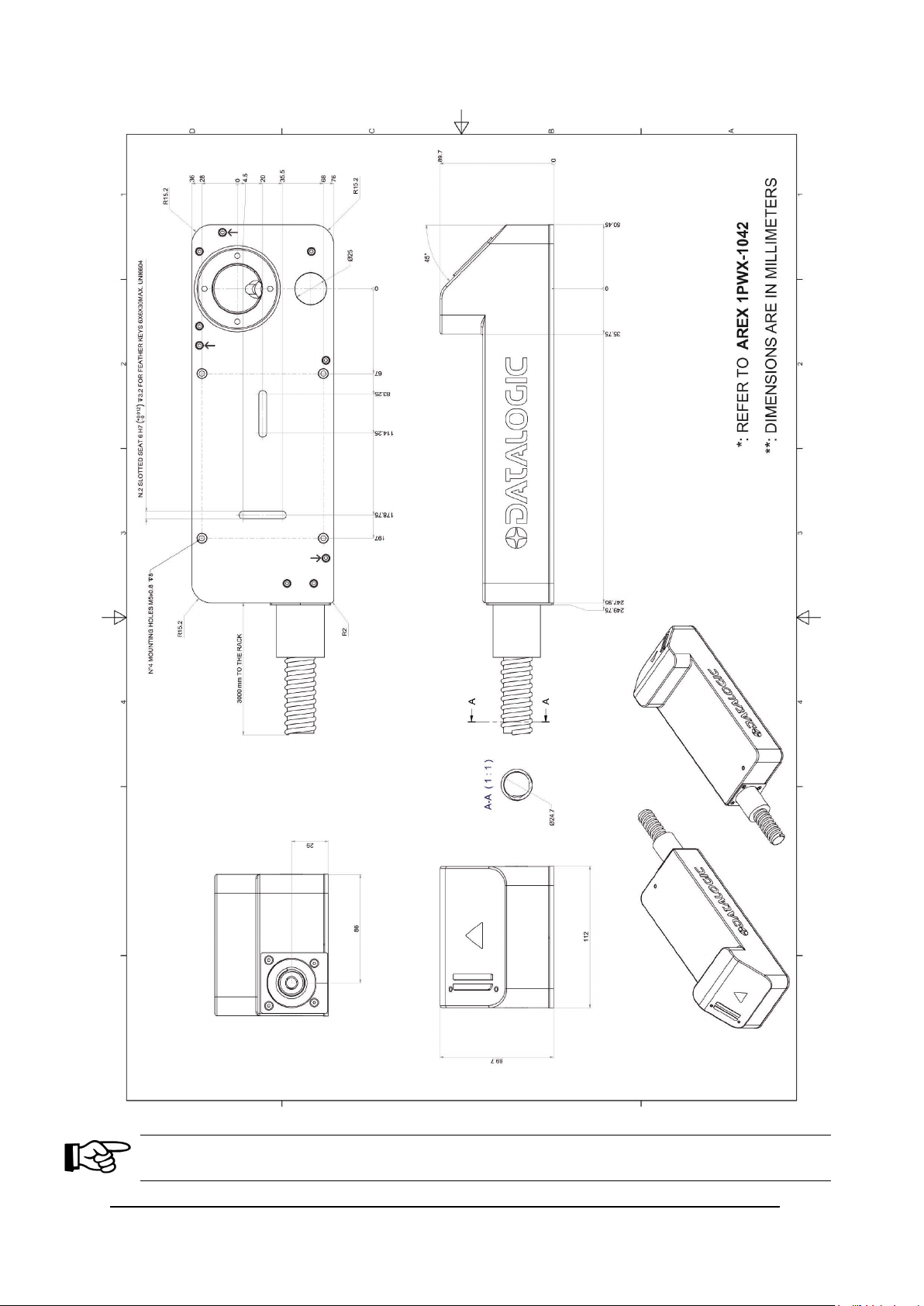

APPENDIX G: MECHANICAL DRAWINGS 92

FIGURES 94

Page 10

10

1 CONTENTS OF THE PACKAGING

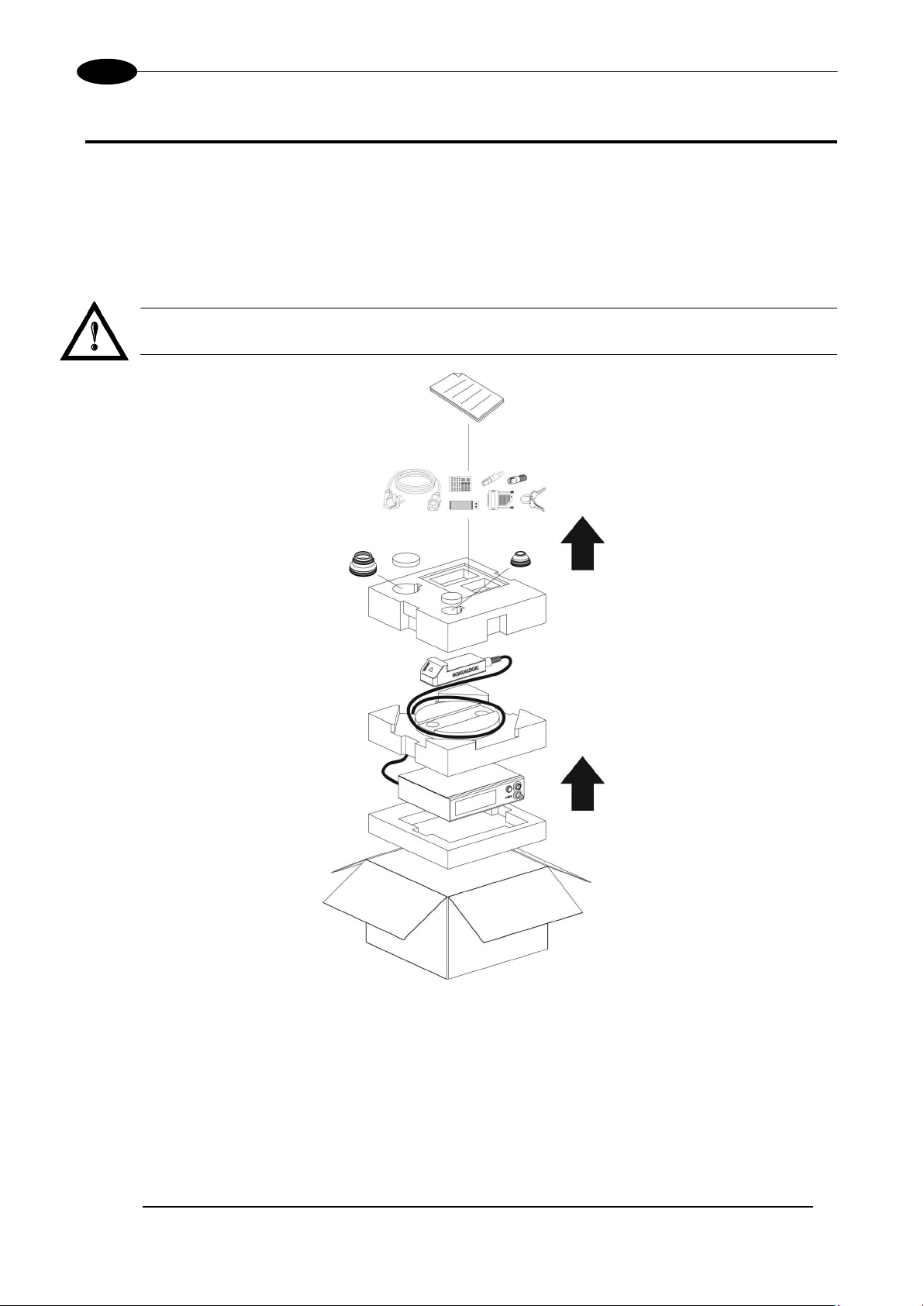

1.1 UNPACKING

When unpacking the marking system from the shipping carton you should:

• Remove the documentation from the top of the marking system

• Remove the accessories

• Carefully remove the marking system from the packaging using both hands

WARNING!

Be extremely careful to not damage the connection cable between Scan Head and Rack.

AREXTM 30W – 50W

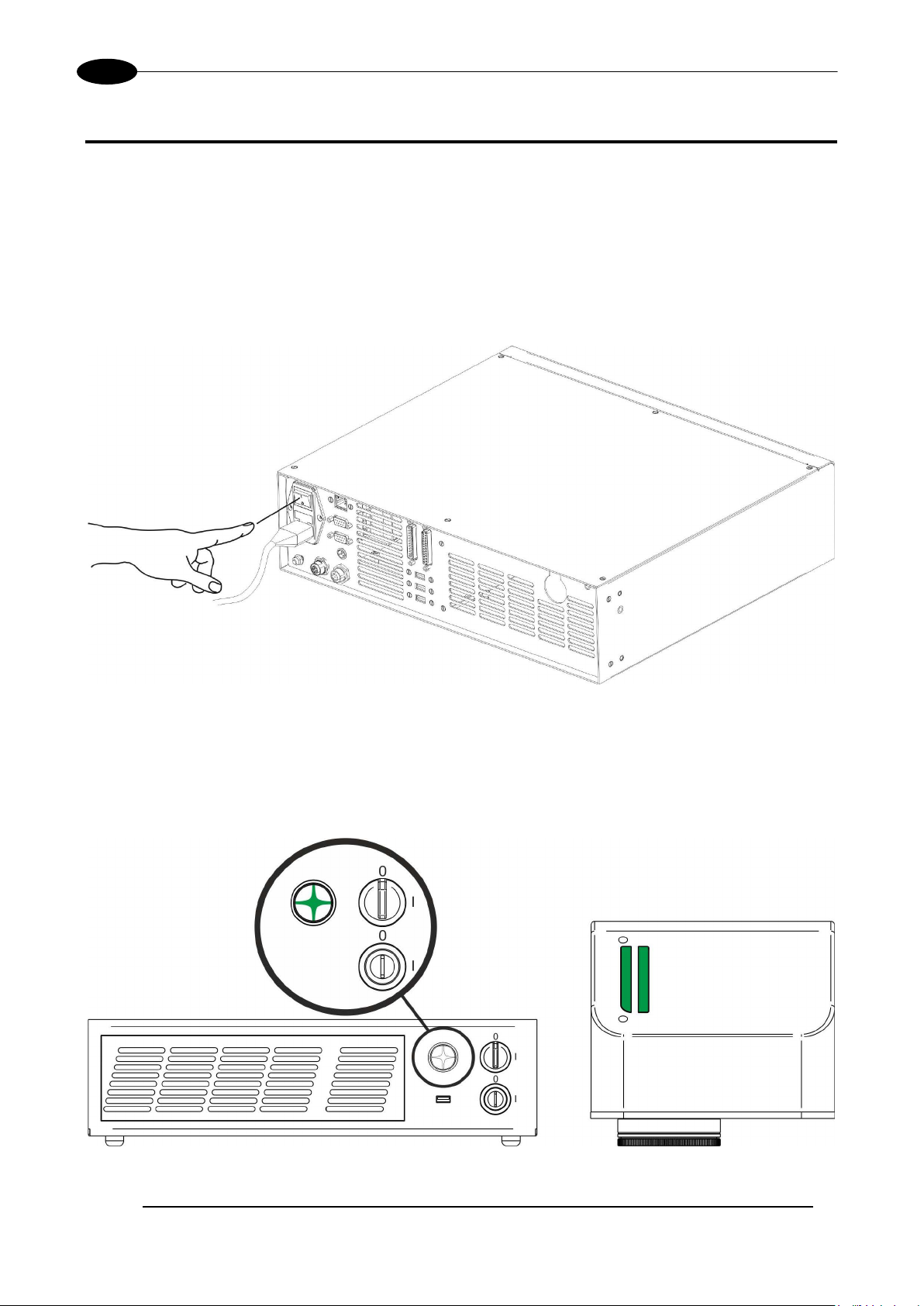

Figure 2: Unpacking.

Before installing or operating the marking system, you should:

• Inspect the shipping container for damage

• Inspect the marking system for signs of damage

• Confirm that the shipping carton contains all items on the shipping inventory list including any

accessories

Retain all packaging m aterials until th e marking s ystem has been inspected f or completenes s and damage,

and you have checked the operating performance. If anything is missing or defective, see chapter 7 for

contact details.

Page 11

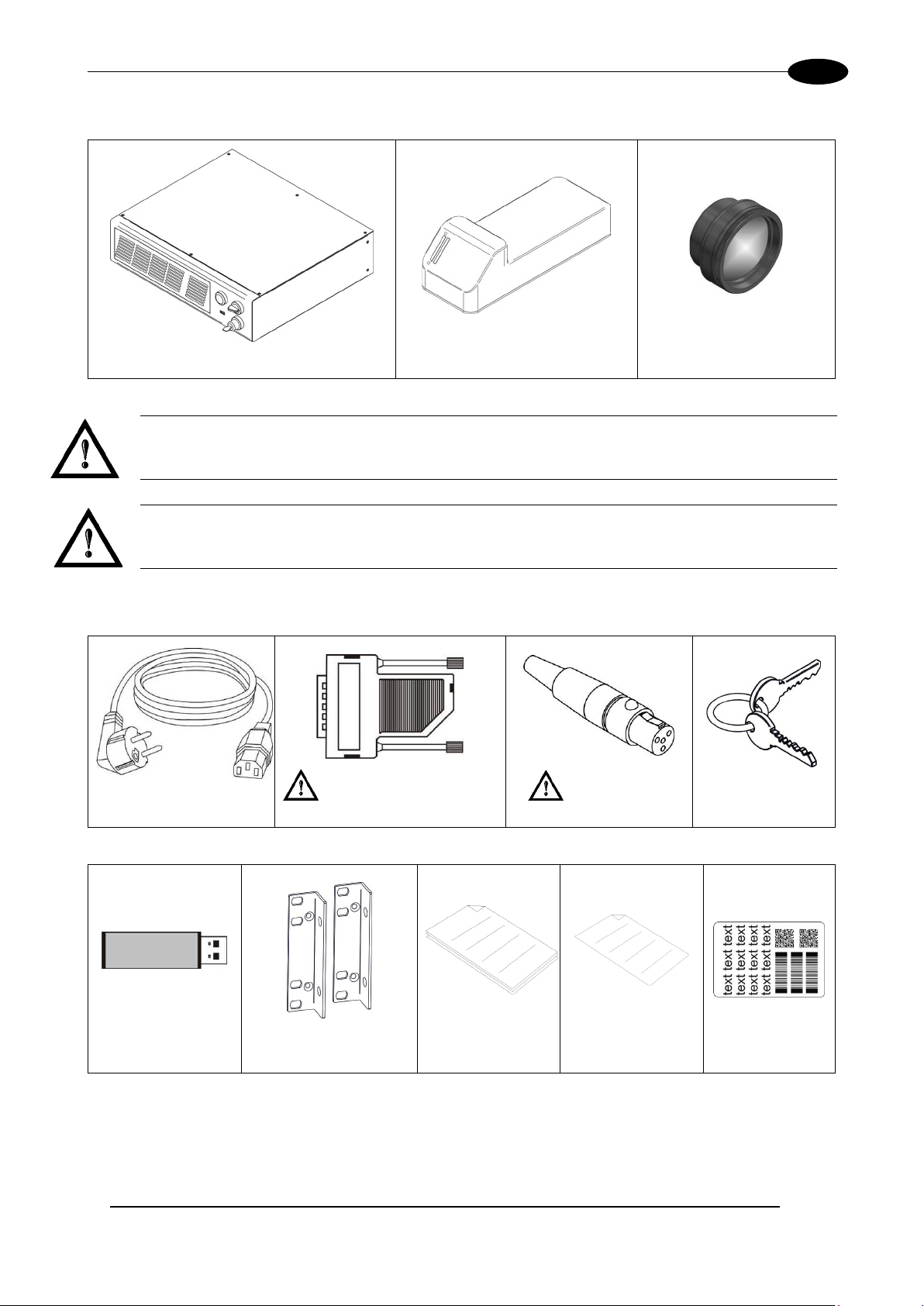

CONTENTS OF THE PACKAGING

11

Control Rack

Scan Head

F-Theta

1.2 MAIN HARDWARE

WARNING!

Rack and Scan Head are joined b y a conn ectio n cabl e 3 m et ers long, refer red a s Head Cable. Rack

and Scan Head are NOT separable.

WARNING!

To avoid damaging or break ing the optical fiber, never s ubject it to a bending radius bel ow the lim its

specified in the technical specification table.

1.3 CABLE AND ACCESSORIES

Power Supply cable Command Box Connector (*) Interlock connector (*) System Keys

USB flash drive Rack adapters Manuals Test Report Sample Test

* If this connector is used, the marking system works in DANGEROUS condition (MUTING DEVICE).

Page 12

AREXTM 30W – 50W

12

1.4 TRANSPORT

The m arking system can be easil y lifted up and moved by a single person thanks to its compact size and

reduced weight.

WARNING!

Rack and Scan Head are j o ine d b y a connec t ion cable 3 meters long. Rack and Scan Head are NOT

separable!

WARNING!

To avoid damaging or breaking the optical fiber, n ever subject it a bending rad ius below the limits

specified in the technical specification table.

Figure 3: Transport.

WARNING!

The ArexTM marking system is a delicate optical device, avoid damaging it with shock and vibrations.

WARNING!

Be extremely careful to not damage the connection cable between Scan Head and Rack.

1.5 ON MOISTURE CONDENSATION

If the marking s ystem is brought direct ly from a cold to a warm location, moisture may condens e inside or

outside the marking system. This moisture condensation may cause a malfunction of the marking system.

If moisture condensation occurs

Turn off the marking system and wait about 1 hour for the moisture to evaporate.

Note on moisture condensation

Moisture may condens e when you bring the m arking system from a cold place into a w arm place (or vice

versa) or when you use the marking system in a humid place as shown below.

How to avoid moisture condensation

When you bring the mark ing system from a cold place into a warm place, put it in a pl astic bag and seal it

tightly. Remove the bag when the air temperature inside the plastic bag has reached the ambient

temperature (after about 1 hour).

Page 13

CONTENTS OF THE PACKAGING

13

1.6 FIXING AND POSITIONING

The marking system must be positioned in a safely manner and the precautions listed below must be

followed:

Figure 4: Positioning rack.

Figure 5: Vertical positioning (need additional fixing).

WARNING!

DO NOT fix the marking system in manner not shown in figure.

Page 14

AREXTM 30W – 50W

14

The marking s ystem can be fitted inside a spec ial rack c abinet equipped with sp ecial support shou lders and

handles, available on request. The figure below shows the mounting points for mounting in rack (rack

handles available as accessory):

Figure 6: Fixing points on shrug rack (cabinet assembly).

NOTE:

In order to prevent mar king distortions, install a vibrom eter on the base of the piece to be mark ed

and check for the absence of vibrations during the marking process.

NOTE:

It is recommended to install the resonator on a micrometer positioning Z-axis system!

The Scan Head must be fixed to a suitable base (not supplied by Datalogic) using the four M5 threaded

holes and the two slotted seats:

Figure 7: Fixing points on Scan Head (vertical mount).

The Scan Head unit, just like the control rack, must be safely positioned and fixed to a stable surface,

vibration-free. The Scan Head can be fixed either vertically or horizontally. In order to prevent marking

distortions, avoid any vibration between Scan Head and piece to be marked.

WARNING!

It is very important to s ecure the laser system before you start m arking the piece since improper

securing or positioning may cause serious damage.

Do not secure the m arking system in a way other than the one described in the figure.

Page 15

CONTENTS OF THE PACKAGING

15

1.7 INSTALLATION ENVIRONMENT

The control rack must be instal led in a suitable environment in order t o allow proper air flow passage a nd

correct housing of the cables.

TM

is an air coole d marking system : an adequate air f low is necessar y to guarantee its c orrect cooling.

Arex

Installation must not slow or stop the flow of air cooling. Moreover, do not install a heat source near.

Clean air f ilter w hen it is d ir ty. If the air f ilter is dirt y, th e air -f lo w m ight b ec ome not sufficient to ensure correct

cooling and might stop marking operation. Clean or exchange air filter periodically.

Figure 8: Rack installation environme nt.

WARNING!

DO NOT place heavy objects on top of rack!

1.8 FUME / DUST EXTRACTOR

During marking proc ess, dust and/or gas may be produc ed. It is important to use ade quate fume extractor

and/or air filtration.

WARNING!

Marking PVC (or other plas tic material) can cause the release of chlorine gas which can be harmful

to the laser opera tor and to the las er system itself. Always use adequat e fum e extrac tor during PVC

and plastic marking.

Page 16

16

2 TECHNICAL SPECIFICATIONS

NOTE:

BEFORE INSTALLING AND USING THE LASER, RE AD CAREFULLY THE APPENDICES.

WARNING!

ArexTM is a CLASS 4 L ASER PRODUCT and it is the r esponsi bilit y of the O EM/s ystem integra tor t o

provide the safety completeness to be ready-to-use.

2.1 TECHNICAL CHARACTERISTICS

CONTROL RACK MECHANICAL CHARACTERISTICS

AREXTM 30W – 50W

Weight 16 Kg

Height 111 mm

Width 430 mm

Depth 370 mm

IP Rating IP21

SCAN HEAD MECHANICAL CHARACTERISTICS

Weight 3 Kg*

Height 90 mm*

Width 112 mm

Depth 300 mm

IP Rating IP54

* without F-Theta scan lens

NOTE:

Refer to Datalogic’s website for detailed drawings.

Page 17

TECHNICAL SPECIFICATIONS

17

Storage temperature

-10° to 60°C (14° to 140°F)

Package Drop Test

60 cm

30W

50W

Environmental temperature

5°C to 40°C (41° to 104°F)

5°C to 35°C (41° to 95°F)

Humidity

< 90% without condensation

Altitude

< 2000 m

Pollution Degree

2

Overvoltage Categor y

II

Input Voltage

100 to 240 V AC

100 to 240 V AC

Max Power

300W

330W

Modello 30W

50W

LASER SOURCE (specification @25°C)

Average Power W 30

50

Pulse energy (max)

mJ

1

Peak power (max)

kW

11

10

Central emission wavelength

nm

1060 - 1080

Repetition Rate

kHz

30 ÷ 200

50 ÷ 200

Laser aiming beam Class 2M ≤ 1mW @ 660nm

Cooling

Forced Air

Noise

dB(A)

< 70 at 1 meter

OTHER

HEAD CABLE

minimum bending radius

150 mm (fixed installation)

300 mm (mobile installation)

Marking head cable length

3 meters

Beam deflection

High speed galvanometer scanning system

MOF (Marking on the fly)

YES [constant speed or encoder]

Marking Control and Software

EMC embedded control and Lighter Suite

Communication

RS232, Ethernet (TCP/IP 10, 100 Mbit), digital I/O

STORAGE AND TRASPORTATION CONDITIONS

Shock and vibrations MIL 810E “CAT 1 Basic Transportation”

WARNING!

This product includes precision optical parts; avoid vibration and shocks: marking quality may deteriorate.

ENVIRONMENTAL OPERATING CONDITIONS

ELECTRICAL POWER SUPPLY

Input Current 3 to 1,25A max 3,3 to 1,4A max

PERFORMACE

Laser Type Class 4 Pulsed Fiber Laser

Laser Focus Beam Class 2 : 1 mW @ 635 nm

Marking Speed1 Up to 2000 mm/s -500 car/s

Line speed – Productivity2 Up to 75 m/min – 3 Pcs/s

1

May vary: measured with f= 160mm

2

Single line string, Roman-s font

Page 18

18

2.2 DESCRIPTION OF THE LASER MODULES

2.2.1 SCAN HEAD

A description of the main parts of the Scan Head unit is provided here below:

AREXTM 30W – 50W

Figure 9: Scan Head overview

1) Main connection Rack-Scan Head 3) Status LED bar

2) F-Theta Scan Lens 4) Focusing Beam output

Page 19

TECHNICAL SPECIFICATIONS

19

2.2.2 CONTROL RACK

The control rack is described here below in order to provide the right information for proper installation:

Figure 10: Control rack overview.

1) Status LED 9) I/O connector (Axes Control)

2) Enable selector 10) Main connection to Scan Head

3) Key selector 11) 3x USB connectors

4) USB connector 12) RS232 connector

5) Mains power supply connection 13) Interlock connector

6) LAN connector 14) Photocell connector

7) VGA connector 15) Encoder connector

8) Command Box connector (Laser Control) 16) Earth ground

Page 20

AREXTM 30W – 50W

20

F-Theta Scan Lens

ƒ = 160S

ƒ = 254S

Working Distance

mm

183 ± 5

280 ± 4

Fixing Distanc e

mm

197 ± 6

300 ± 5

Marking Area

mm2

85 x 85

100 x 100

F-Theta Scan Lens

ƒ = 160L

ƒ = 254L

ƒ = 330L

Working Distance

mm

176 ± 2

296 ± 5

388 ± 6

Fixing Distanc e

mm

212 ± 3

367 ± 6

471 ± 7

Marking Area

mm2

100 x 100

170 x 170

210 x 210

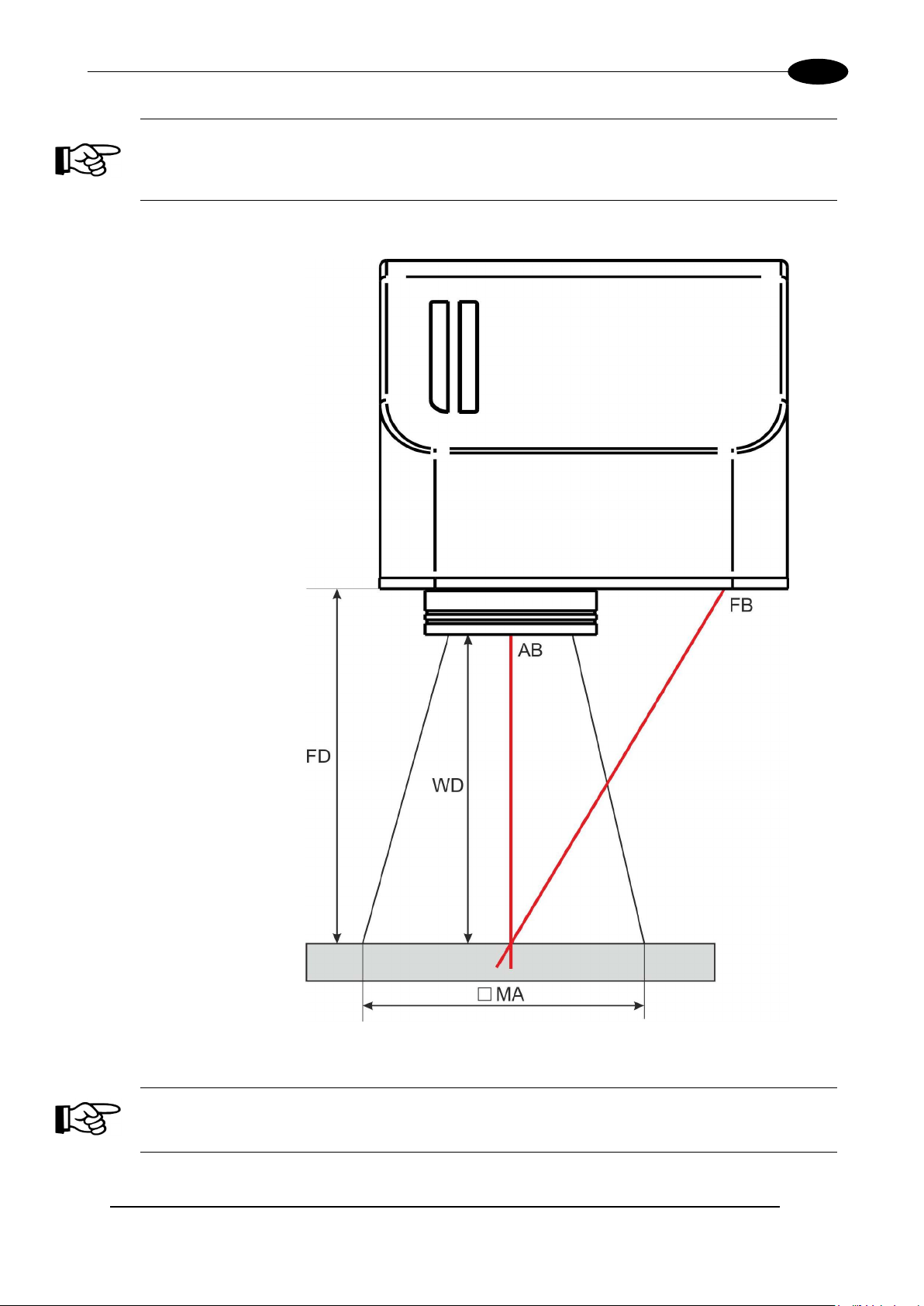

2.3 MARKING AREA SPECIFICATION

Datalogic provides a wide range of F-Theta sc an lenses to be attached to the scanning he ad to focus the

laser beam in flat Marking Field, in order to achieve high-resolution marking results.

These F-Theta scan lense s are available to best-match the object (i.e. : logo; string; 2D matr ix; etc.) to be

marked with custom er need, over the material processing, an d fit the standard Datalogic Scanning H ead;

further solutions about different models of lenses and scanning heads will be considered upon request.

The table below lists the standard F-Theta scan lenses currently availabl e:

F-Theta Scan Lens diameter: M39

F-Theta Scan Lens diameter: M85

NOTE:

Definition of Mark ing Area: square marking field within which power is > 95% respect to power in

center.

WARNING!

This product was d esigned to use only certain conf igurations of F-Theta lens and mark ing field. If

your needs are not satisfied by current available F-Theta lens configurations please contact

Datalogic for a solution. T he use of other F-Theta lenses or operation outs ide the specified m arking

field for a certain F-Theta l ens configuration can lea d to damage of F-Theta lens, scanning head or

laser source. Such damage is not covered by warranty!

WARNING!

For each F-Theta lens conf iguration Datalo gic recomm ends the use of c ertain adapter. This adapter

ensures that residual back ref lections cause d by F-T heta lens do not dam age optics of the scanni ng

head. The removal of such adapter or its incorrect use (for example inc omplete threading, use of

another F-Theta lens a dapter, etc .) can lead to damage of the F-Theta le ns, scannin g head or las er

source. Such damage is not covered by warranty!

Page 21

TECHNICAL SPECIFICATIONS

21

NOTE:

Working Distance is defined as the distance between the center of the marking area (defined

in the focal plane) and the last mechanical edge of the F-Theta Scan Lens. Refer to the

following figure.

WD: Working Distance

FD: Fixing Distance

MA: Marking Area

AB: Aiming beam

FB: Focusing beam

Figure 11: Marking area.

NOTE:

For systems equipped with standard Small F-Theta Scan Lens (M39) the focus condition is

obtained by matching the Aiming Beam with the Focusing beam.

Page 22

AREXTM 30W – 50W

22

2.4 CONNECTORS SPECIFICATIONS

2.4.1 INTERLOCK CONNECTOR

Interlock disables the Class 4 laser sour ce inside the laser s ystem. Interlock internal circ uit is designed to

comply with the single fault conditio n.

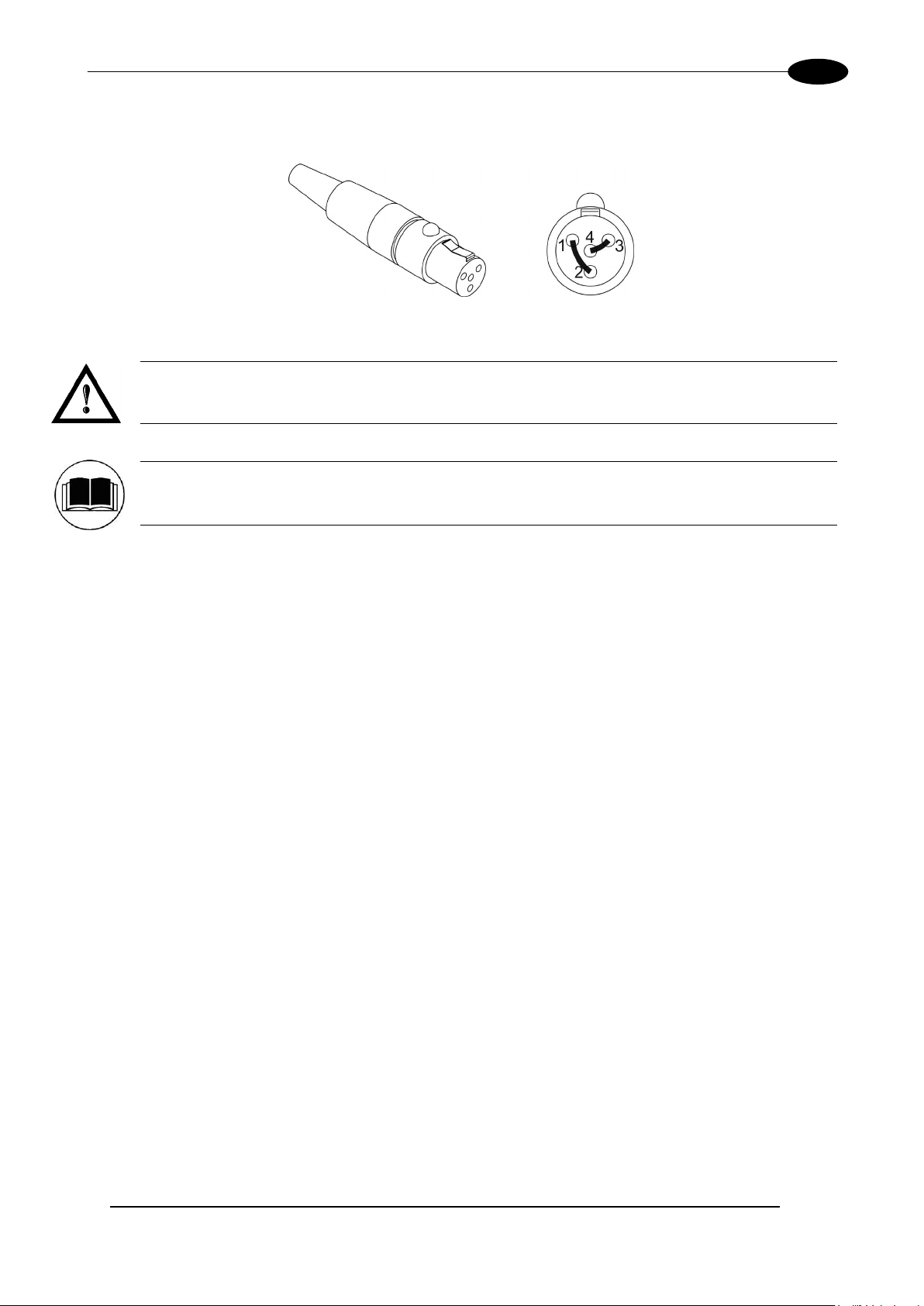

PANEL CONNECTOR

Type SWITCHCRAFT TB Series male Tini Q-G (Mini XLR) panel mount connector, 4 positions.

Figure 12: Male panel plug cod. TB4M (front view).

NOTE:

See appendix D about the compliance to EN ISO 13849-1:2008.

PIN SIGNAL TYPE DESCRIPTION FUNCTIONAL DIAGRAM

1 VCC_INT_A OUTPUT

2 INTERLOCK_A INPUT

3 GND GND

4 INTERLOCK_B INPUT

24V DC reference for

INTERLOCK IN signal A

INTERLOCK IN signal A

Ground reference for

INTERLOCK IN signal B

INTERLOCK IN signal B

PIN 1- PIN 2 PIN 3- PIN 4 MARKING FUNCTIONALITY CONDITION

CONTACT OPEN CONTACT OPEN NOT POSSIBLE SAFE

CONTACT CLOSED CONTACT OPEN NOT POSSIBLE DANGEROUS

CONTACT OPEN CONTACT CLOSED NOT POSSIBLE DANGEROUS

CONTACT CLOSED CONTACT CLOSED POSSIBLE DANGEROUS

WARNING!

In order to NO T D AM AG E the i nterlock cir cuitry, we recomm ended using “dry circuit” ( zero voltage)

switches or relay circuitry.

Page 23

TECHNICAL SPECIFICATIONS

23

PLUG CONNECTOR

Connector type SWITCHCRAFT TA Series Tini Q-G (Mini XLR) female cable mount connectors, 4 positions.

Figure 13: Female cable mount connector cod. TA4FX (solder view).

WARNING!

If the interlock gold connec tor is used, the marking system is in DANGEROUS condition (MUTI NG

DEVICE).

NOTE:

To restore the marking system it is necessary to repeat the “Turning on sequenc e” without shutting

down the system. See chapter 4.1

for more details.

Page 24

24

Secondary external ENABLE signal (see par. 2.4.2.1)

- LOW level or disconnected: contact opened

Auxiliary 12V DC power supply available for drive input

Auxiliary 12V DC power supply available for drive input

Auxiliary 12V DC power supply available for drive input

This signal is used to start to the marking process when a

- HIGH level pulsed signal start the marking process

External KEY signal (see paragraph 2.4.2.2)

- LOW level or disconnected: contact opened

This signal is used to stop the marking process (see

- HIGH level pulsed signal stop the marking process

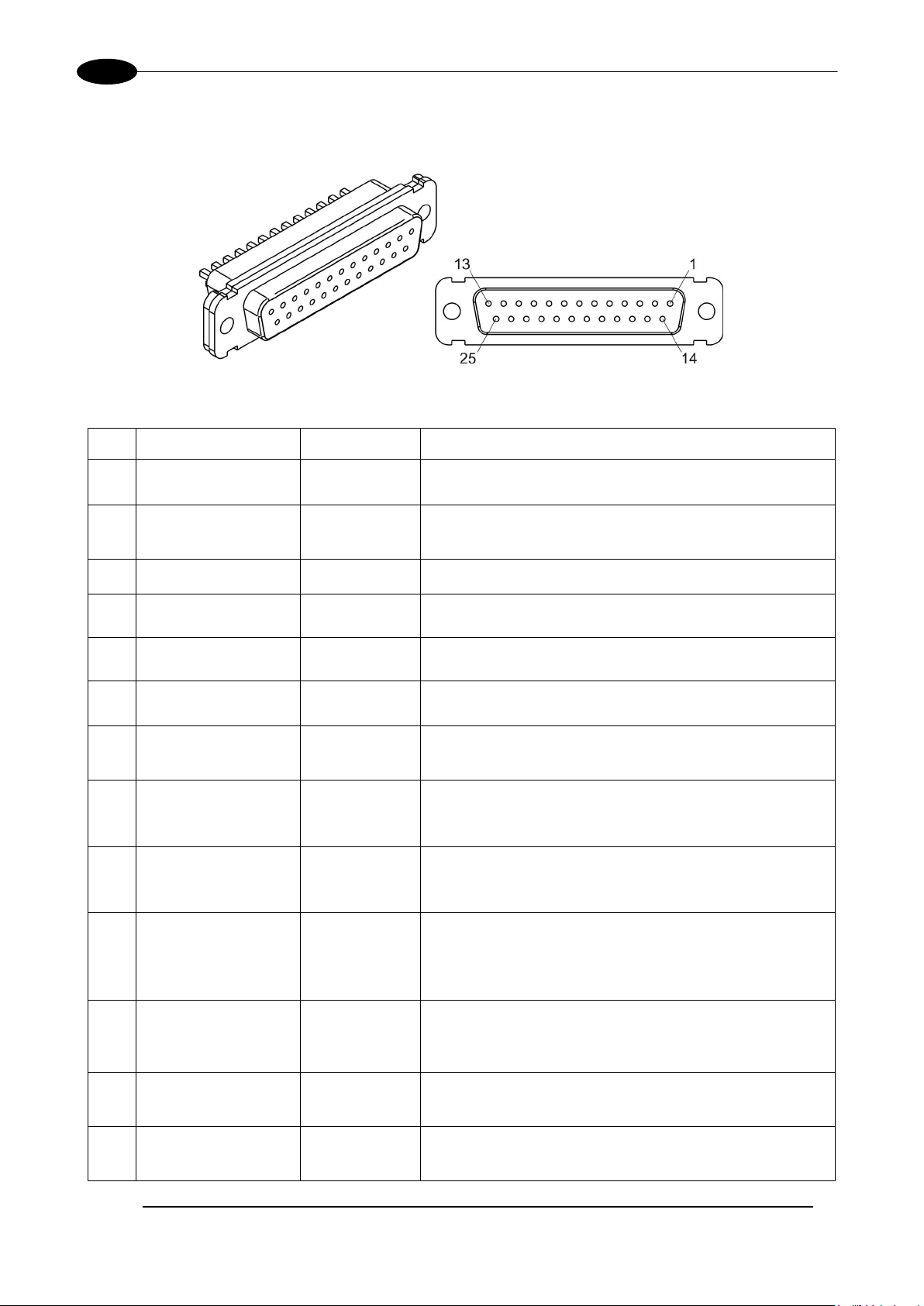

2.4.2 COMMAND BOX CONNECTOR (LASER CONTROL)

Panel socket Sub-D, 25 positions, female.

Figure 14: Female panel socket Sub-D 25 (front view).

PIN SIGNAL TYPE (***) DESCRIPTION

AREXTM 30W – 50W

1 12V_ENABLE_B

2 EXT_ENABLE_B Digital Input

3 RESERVED Digital Output DO NOT CONNECT

4 EXT_12V

5 EXT_12V

6 EXT_12V

7 12V_ENABLE_A

8 EXT_ENABLE_A Digital Input

9 BUSY (*) Digital Output

Output power

supply

Output power

supply

Output power

supply

Output power

supply

Output power

supply

12V DC power supply available for EXT_ENABLE_B

(max 250mA)

- HIGH level: contact closed

logical HIGH (max 250mA)

logical HIGH (max 250mA)

logical HIGH (max 250mA)

12V DC power supply available for EXT_ENABLE_A

(max 250mA)

Primary external ENABLE signal (see paragraph 2.4.2.1)

- HIGH level: contact closed;

- LOW level or disconnected: contact opened

This signal is used to know if the current spooler is

executing (marking in progress) (see paragraph 2.4.2.4)

- ON during marking process

CONNECTOR

10

PRESENCE

11 START MARKING (*) Digital Input

12 EXT_KEY Digital Input

13 STOP MARKING (*) Digital Input

Digital Input

This signal is used to check the presence of the

command box connector (see paragraph 2.6)

- HIGH level: normal operation;

- LOW level or disconnected: laser source faulty

document or a sequence is running in AUTO MODE (**)

or WORK MODE (**): (see paragraph

- HIGH level: contact closed;

paragraph 2.4.2.4)

2.4.2.4)

Page 25

TECHNICAL SPECIFICATIONS

25

14 RESERVED Digital Input DO NOT CONNECT

15 RESERVED Digital Input DO NOT CONNECT

16 RESERVED Digital Input DO NOT CONNECT

This signal is used to know if the marking process is

17 END Digital Output

18 POWER_ON Digital Output

19 GND Ground Ground reference

20 SYSTEM_ALARM Digital Output

21 GND Ground Ground reference

22 ENABLE_OUT Digital Output

finished: (see paragraph 2.4.2.4):

- ON at the end of marking process

This signal is used to know if the system is already

warmed up: (see paragraph 2.4.2.3)

- ON when the laser is in STAND_BY or READY state

This signal is used to know if the system is in booting up

state or in error state: (see paragraph 2.4.2.3)

- ON during BOOTING UP

- ON in case of system error

This signal is used to know if the system is ready to emit

laser radiation: (see paragraph 2.4.2.3)

- ON when the system is in READY state

This signal is used to know if a document, sequence or

script is loaded and ready to be executed:

- ON when a document or a sequence is running in

AUTO MODE (**) or WORK MODE (**) (SW_READY

23 SW_READY (*) Digital Output

COMPATIBILITY (**) = true)

- ON when a document or a sequence is running in

AUTO MODE (**) and laser in READY state

(SW_READY COMPATIBILITY (**) = false)

- ON when a script is running n AUTO MODE (**) and

“IoPort.setReady (true)” function is used

24 GND Ground Ground reference

25 GND Ground Ground reference

(*) refers to Lighter user’s manual “Setting I/O parameters” paragraph to set the signal properties

(**) refers to Lighter user’s manual

(***) refer to paragraph 2.5

NOTE:

Connection example in paragraph 2.6.

Page 26

AREXTM 30W – 50W

26

2.4.2.1 ENABLE SIGNAL’S SCHEME (COMMAND BOX CONNECTOR)

Figure 15: ENABLE signal’s scheme.

Page 27

TECHNICAL SPECIFICATIONS

27

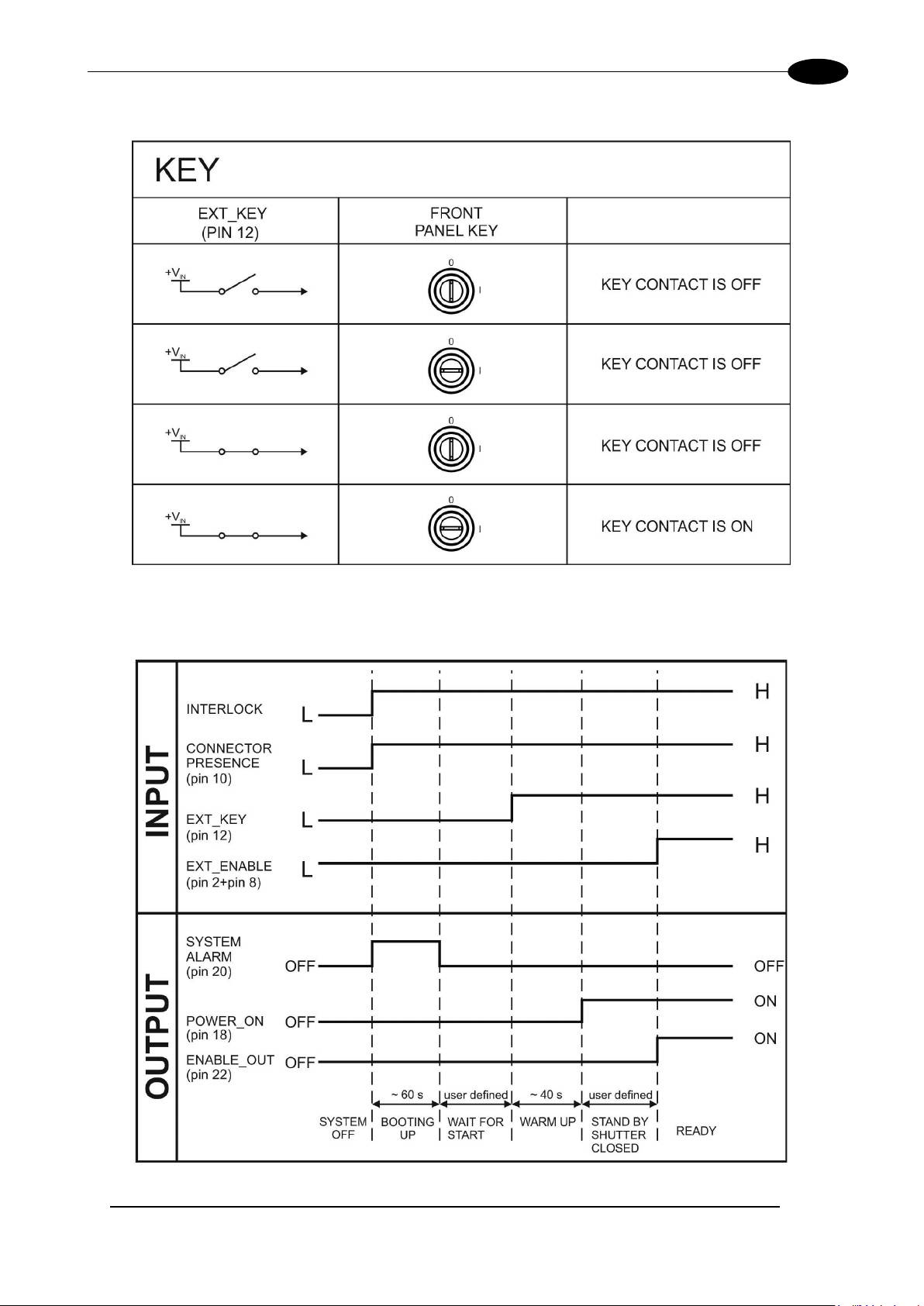

2.4.2.2 KEY SIGNAL’S SCHEME (COMMAND BOX CONNECTOR)

Figure 16: KEY signal’s scheme.

2.4.2.3 LASER CONTROL SIGNALS TIMING

Figure 17: Timing control signals.

Page 28

28

2.4.2.4 MARKING PROCESS SIGNALS TIMING

The following diagram illustrates the possible timings and settings of these signals:

AREXTM 30W – 50W

Figure 18: Timing signals

The time intervals in the diagram can all be programmed with a resolution of 1 ms

Start Time For setting the minimum acceptable time for the START_MARKING signal

T

1

Start Delay For delaying the start of marking process

T

2

Bus y Adva nc e BUSY signal corresponding to marking progress

T

3

T

Stop Time The minimum time for stop signal to stop the marking process

4

Busy Delay For delaying the Laser END signal with respect to laser emission

T

5

End Time For setting the Laser END activation time

T

6

(*) Refer to Lighter user’s manual “Setting I/O parameters” to set the signal’s properties.

(*).

Page 29

TECHNICAL SPECIFICATIONS

29

Generic input or X-Axis disable signal. When HIGH,

prior to activation

Generic input or Y-Axis disable signal. When HIGH,

prior to activation

Generic input or Z-Axis disable signal. When HIGH,

prior to activation

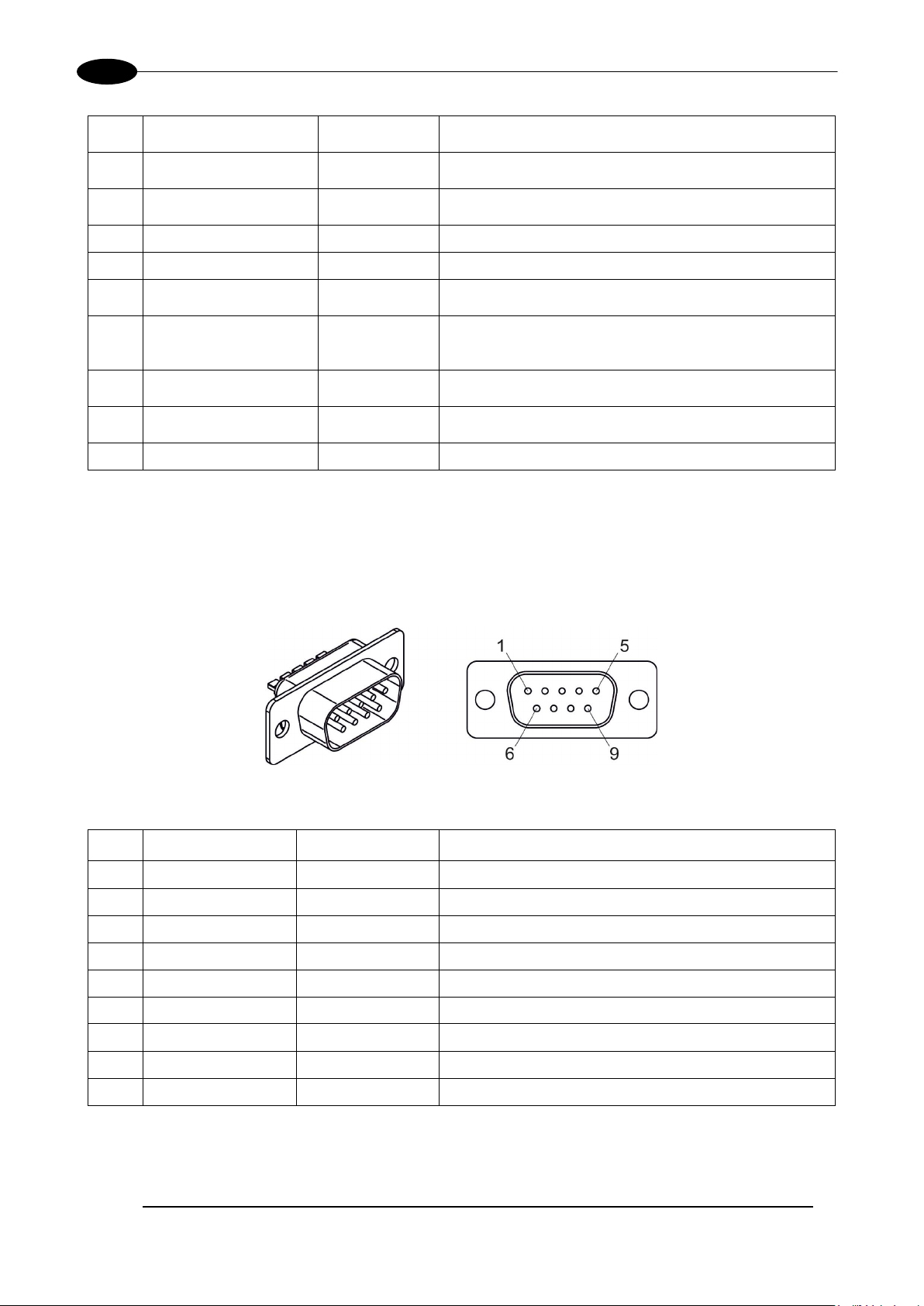

2.4.3 AXES CONNECTOR (I/O CONTROL)

Panel socket Sub-D, 25 positions, male.

Figure 19: Male panel socket Sub-D 25 (front view).

PIN SIGNAL TYPE (**) DESCRIPTION

1 EXT_12V

OUTPUT_0 (*) or

2

STEP_Y

OUTPUT_2 (*) or

3

STEP_Z

OUTPUT_4 (*) or

4

BRAKE X

OUTPUT_6 (*) or

5

BRAKE Y

OUTPUT_8 (*) or

6

BRAKE Z

INPUT_0 (*) or

7

ZERO X

INPUT_1 (*) or

8

ZERO Y

INPUT_2 (*) or

9

ZERO Z

INPUT_3 (*) or

10

DISABLE X

Output Power

supply

Digital Output

Digital Output

Digital Output

Digital Output

Digital Output

Digital Input

Digital Input

Digital Input

Digital Input

Auxiliary 12V DC power supply available for drive

input logical HIGH (max 250mA)

Generic output or Y-Axis drive step signal (Clock) for

axis control (**)

Generic output or Z-Axis drive step signal (Clock) for

axis control (**)

Generic output or X-Axis electromechanical brake

release signal. ON during drive motion

Generic output or Y-Axis electromechanical brake

release signal. ON during drive motion

Generic output or Z-Axis electromechanical brake

release signal. ON during drive motion

Generic input or X-Axis home sensor input. The home

search is stopped when this signal goes HIGH

Generic input or Y-Axis home sensor input. The home

search is stopped when this signal goes HIGH

Generic input or Z-Axis home sensor input. The home

search is stopped when this signal goes HIGH

the corresponding step signal remains in the status

INPUT_4 (*) or

11

DISABLE Y

INPUT_5 (*) or

12

DISABLE Z

13 GND Ground Ground reference

OUTPUT_12 (*) or

14

STEP R

OUTPUT_1 (*) or

15

STEP X

Digital Input

Digital Input

Digital Output

Digital Output

the corresponding step signal remains in the status

the corresponding step signal remains in the status

Generic output or R-Axis drive step signal (Clock) for

axis control

Generic output or X-Axis drive step signal (Clock) for

axis control

Page 30

AREXTM 30W – 50W

30

OUTPUT_3 (*) or

DIR Z

OUTPUT_5 (*) or

DIR Y

OUTPUT_7 (*) or

DIR X

INPUT_7 (*) or

ZERO R

Generic input or R-Axis home sensor input. The home

search is stopped when this signal goes HIGH

Generic input or R-Axis disable signal. When HIGH,

prior to activation

OUTPUT_9 (*) or

BRAKE R

Generic output or R-Axis electromechanical brake

release signal. ON during drive motion

OUTPUT_11 (*) or

DIR R

16

Digital Output Generic output or Z-Axis drive direction signal

17

18

19 INPUT 9 Digital Input Generic Input

20 INPUT 8 Digital Input Generic Input

21

INPUT_6 (*) or

22

DISABLE R

23

24

25 GND Ground Ground reference

(*) enable an axis cause that the correspondi ng signals will no longer be available as generic inputs/output. Refer to Lighter us er’s

manual, “Setting the X, Y, Z, and Rotor Axes parameters” to enable/disable Axes and set the Axes properties

(**) see paragraph 2.5

Digital Output Generic output or Y-Axis drive direction signal

Digital Output Generic output or X-Axis drive direction signal

Digital Input

Digital Input

Digital Output

Digital Output Generic output or R-Axis drive direction signal

the corresponding step signal remains in the status

2.4.4 RS232 CONNECTO R (COM2)

Panel socket Sub-D, 9 positions, male.

Figure 20: Male panel socket Sub-D 9 (front view).

PIN SIGNAL TYPE DESCRIPTION

1 DCD Input Data Carrier Detect

2 RXD Input Receive Data

3 TXD Output Transmit Data

4 DTR Output Data Terminal Ready

5 GND Ground Ground reference

6 DSR Input Data Set Ready

7 RTS Output Request to Send

8 CTS Input Clear to Send

9 RI Input Ringing Indicator

Page 31

TECHNICAL SPECIFICATIONS

31

2.4.5 ENCODER CONNECTOR

Panel socket BINDER, M12, 8 positions fem ale, 763 series. Recomm ended encoder : Datalo gic ENC58-S10XXXX-M12 (ENC58-S10-5000-M12).

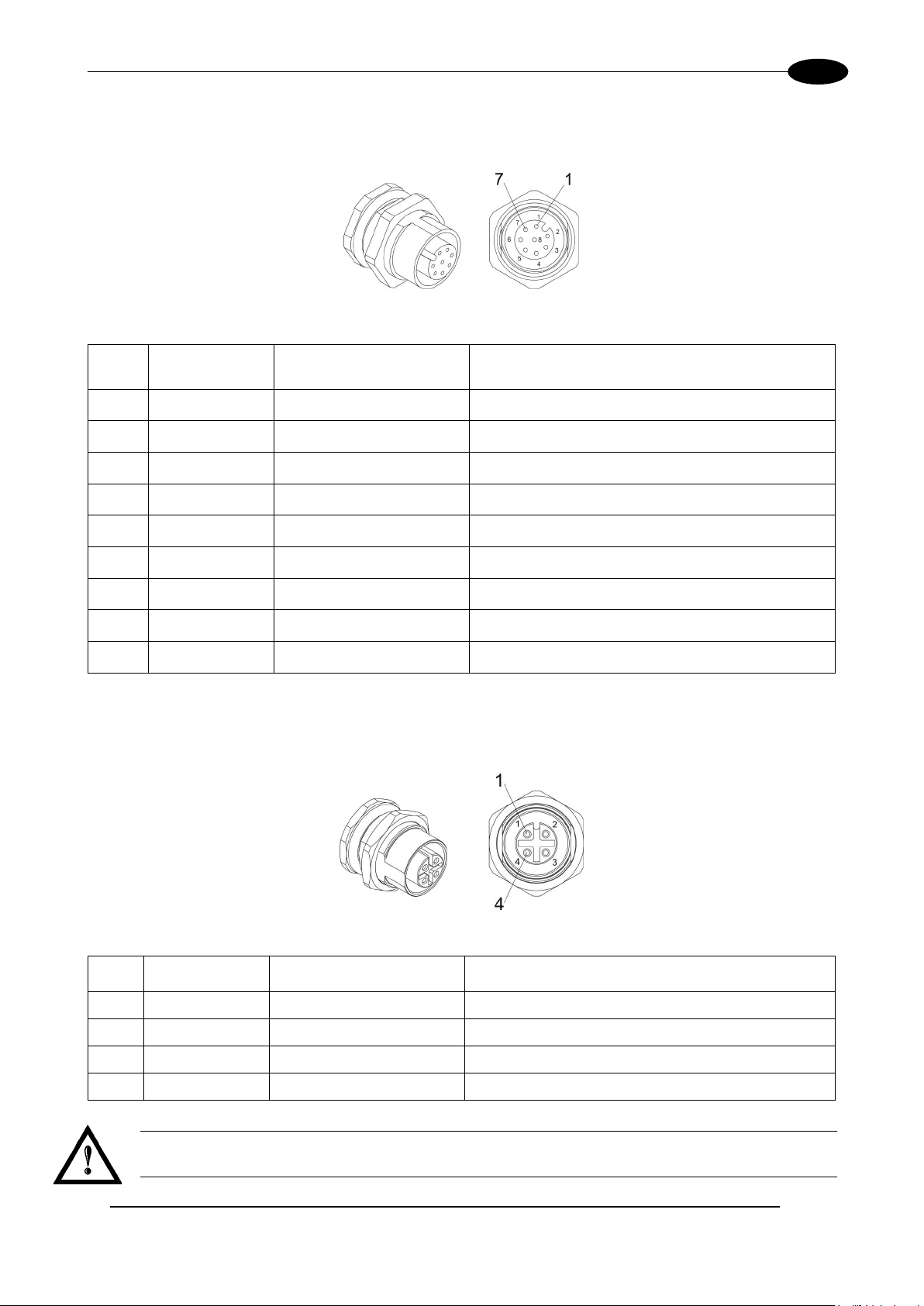

Figure 21: Female panel socket cod. 09-3482-87-08 (front view).

PIN SIGNAL TYPE DESCRIPTION

1 GND GND Ground signal

2 VCC POWER OUTPUT 12V DC power supply

3 ENC_A DIGITAL INPUT Encoder HTL A channel signal

4 GND GND Return signal for ENC_A

5 ENC_B DIGITAL INPUT Encoder HTL B channel signal

6 GND GND Return signal for ENC_B

7 NC NC NC

8 NC NC NC

BODY SHIELD SHIELD SHIELD

2.4.6 PHOTOCELL CONNECTOR

Panel socket BINDER, M 12, 4 positions fem ale, 763 series. Recomm ended photocell: Dat alogic S51-PA-5B01-PK; Datalogic S15-PA-5-B01-PK or equivalent.

Figure 22: Female panel socket cod. 09-3482-87-04 (front view).

PIN SIGNAL TYPE DESCRIPTION

1 VCC POWER OUTPUT 12V DC power supply

2 NC NC NC

3 GND GND Ground signal

4 PHOTOCELL DIGITAL INPUT PNP photocell signal

WARNING!

For EMC compliance a RICHCO RRC-16-9-28-M2-K5B (or equivalent) must be used.

Page 32

32

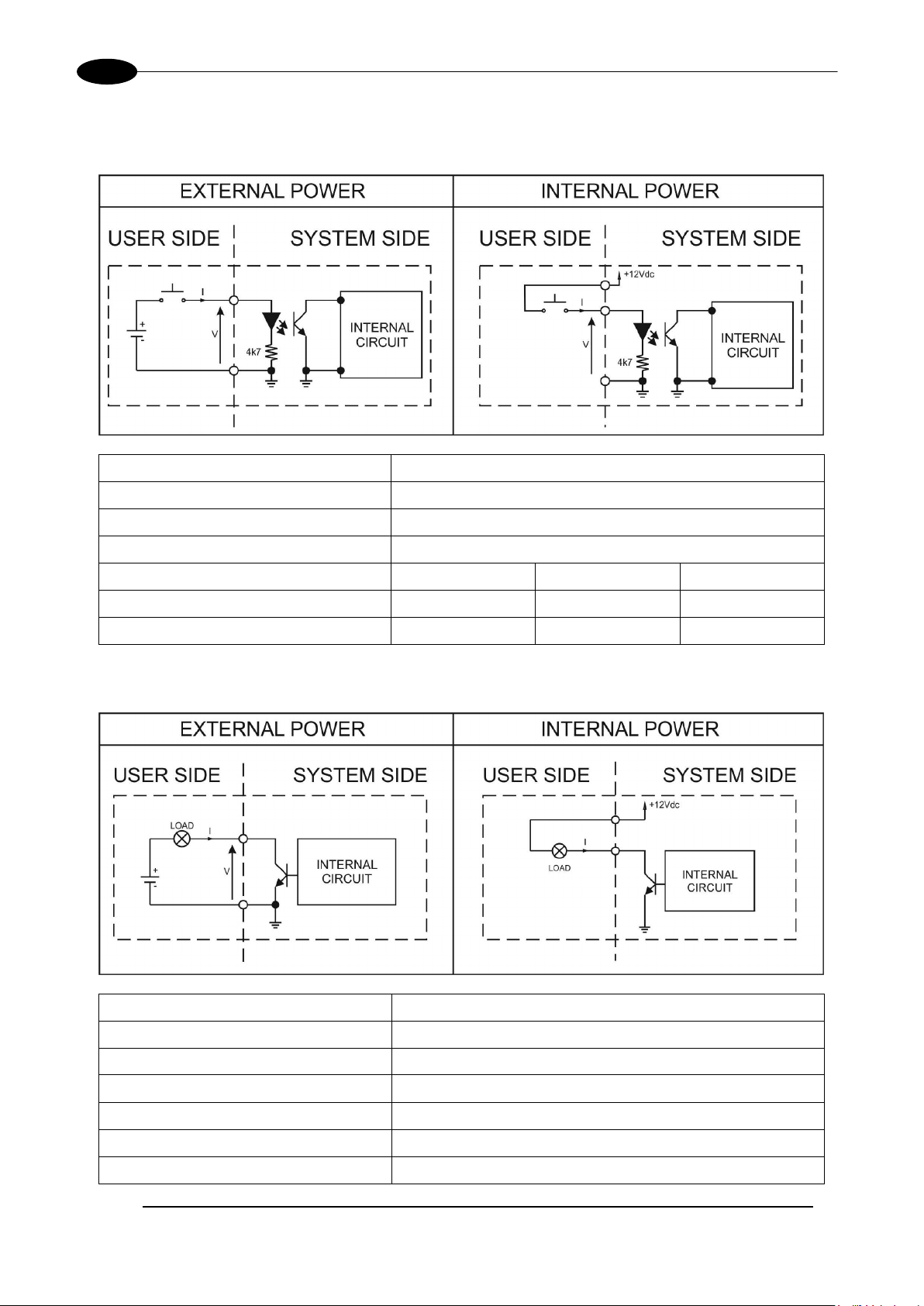

2.5 INPUT/OUTPUT SIGNAL SPECIFICATIONS

DIGITAL INPUT:

Type Optocoupler

V

24V DC

max

I

5mA @ 24V DC

max

Pulse Width ≥ 1ms (debounce)

AREXTM 30W – 50W

INPUT Logic LOW 0.0 V DC 0.0 V DC 2.0 V DC

INPUT Logic HIGH 5.0 V DC 12.0 V DC 24.0 V DC

MIN TYP MAX

DIGITAL OUTPUT:

Type Low side driver

V

24V DC

max

I

250mA

max

Vsaturation <0.5V DC

Leakage current < 5µA

OUTPUT State ON V ≤ 0.5 V DC; I ≤ 250mA

OUTPUT State OFF V ≤ 24 V DC; I ≤ 5µA

Page 33

TECHNICAL SPECIFICATIONS

33

2.6 CONNECTION EXAMPLE

Figure 23: Connection example.

NOTE:

See APP ENDIX C: AREX SAFETY CONSIDER ATION ACCORDING EN ISO 13849-1:2008 about

the compliance to EN ISO 13849-1:2008.

Page 34

AREXTM 30W – 50W

34

3 INST A LLATION A ND SET UP

3.1 CONNECTIONS

The marking system connecting is described here below. Follow the connecting operations as described.

WARNING!

Rack and Scan Head are j o ine d b y a connec t ion cable 3 meters long. Rac k and Scan Head are NOT

separable!

WARNING!

Connect the marking s ystem to other parts WITHOUT voltage in order to avoid risk s for the operat or

and for the laser source.

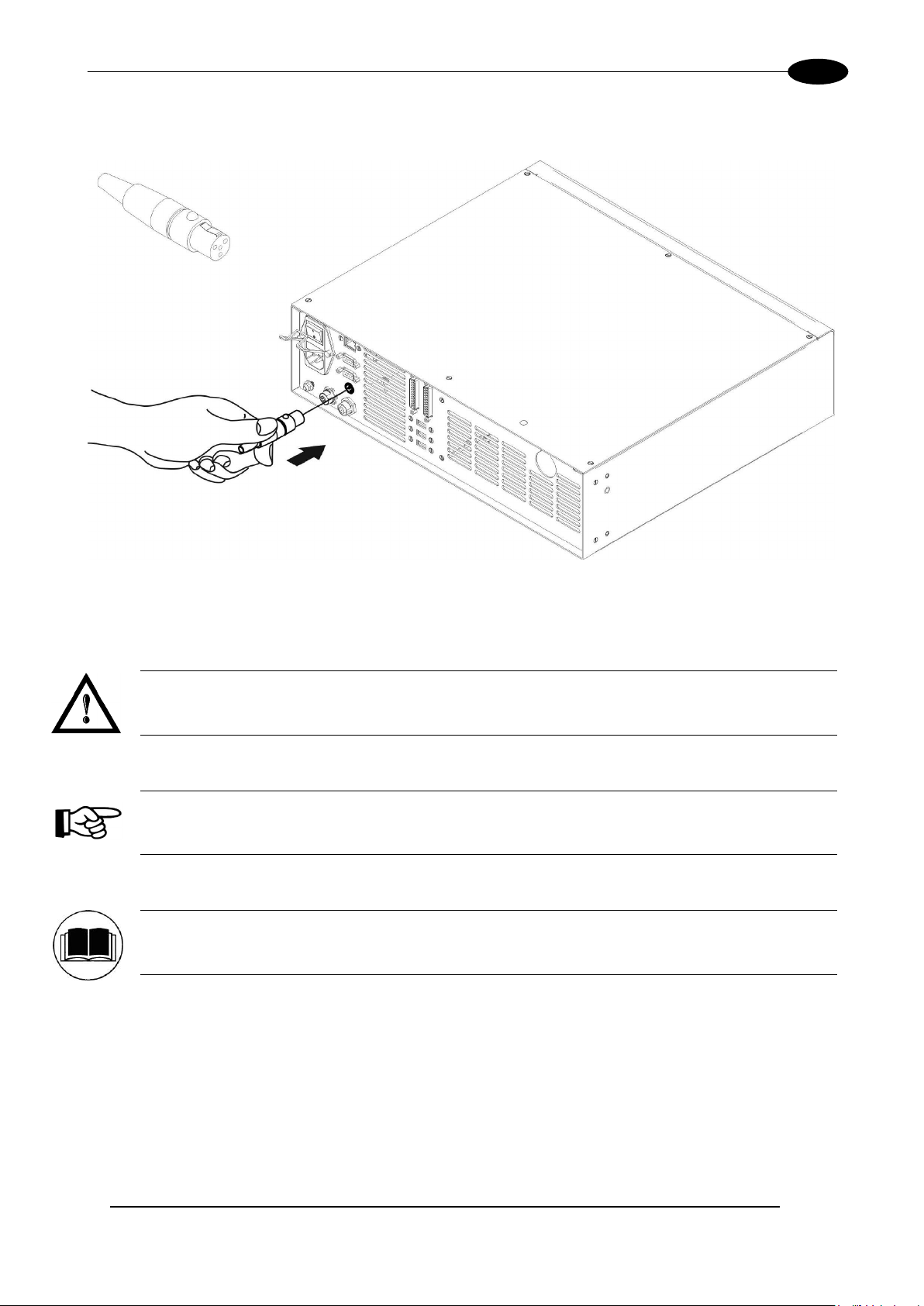

3.1.1 COMMAND BOX CONNECTOR CONNECTION

Figure 24: Connecting Command Box connector.

NOTE:

The Command Box con nector must alwa ys be inserted in ord er to use Enable and Key on the front

panel of the rack.

Page 35

INSTALLATION AND SET UP

35

3.1.2 INTERLOCK CONNECTOR CONNECTION

Figure 25: Connecting interlock connector.

WARNING!

If the interlock gold connector is used, the marking system is in DANGEROUS condition (MUTIN G

DEVICE).

NOTE:

The interlock connec tor must always be inserted in or d er to use the marking syste m. The absence of

such connector locks the marking system.

NOTE:

See APPENDIX C: AREX SAFETY CONSIDER ATION ACCORDING EN ISO 13849-1:2008 about

the compliance to EN ISO 13849-1:2008.

Page 36

36

3.1.3 POWER SUPPLY CABLE CONNECTION

Connecting power supply cable.

AREXTM 30W – 50W

Figure 26: Connecting power supply cable.

NOTE:

Lock the plug with the retaining clamp to avoid accidental disconnection.

3.1.4 GROUND CONNECTION

To ensure high electrical noise immunity it is strongly recommended to connect the chassis to earth plant.

Figure 27: Ground connection.

Page 37

INSTALLATION AND SET UP

37

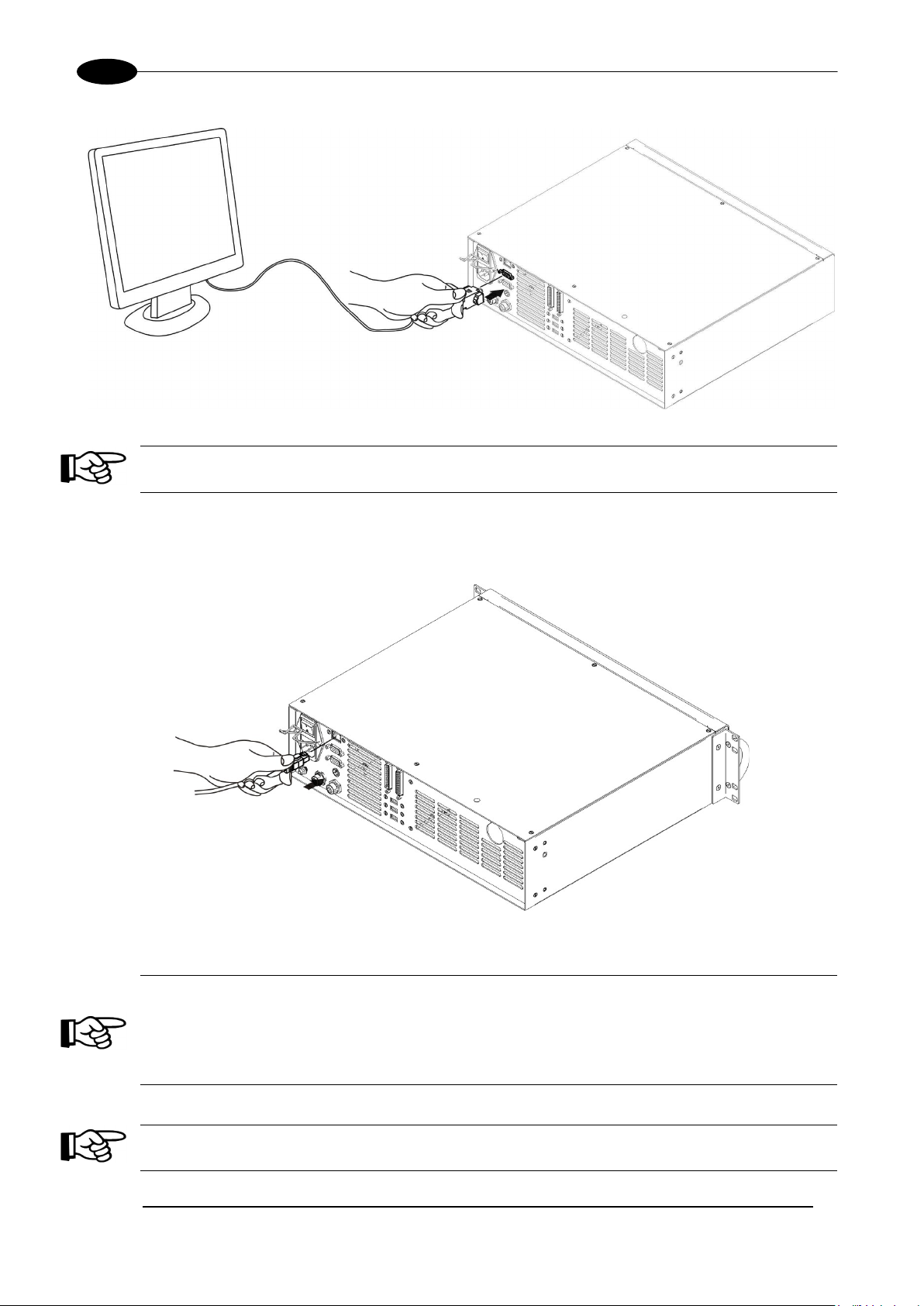

3.1.5 LOCAL MODE CONNECTION

To use the marking system in “Local Mode” it is necessary to install a mouse, keyboard and monitor.

Connect the monitor and input devices to marking system as shown below:

Figure 28: USB mouse connection.

Figure 29: USB keyboard connection.

Page 38

AREXTM 30W – 50W

38

Figure 30: VGA monitor connection.

NOTE:

Minimum resolution 800 x 600.

3.1.6 REMOTE MODE CONNECTION

To use the marking system in “Remote Control” mode it is necessary to connect a network cable:

Figure 31: RJ45 Ethernet connection.

NOTE:

The system LAN is configured by default with a fixed IP Address and Subnet Mask:

- Default IP address: 192.168.0.10

- Default Subnet Mask: 255.255. 255 .0

See chapter 5.2 in order to change LAN configuration.

NOTE:

Ethernet TCP/IP 10, 100 M bit.

Page 39

INSTALLATION AND SET UP

39

3.1.7 F-THETA LENS PROTECTION CAP REMOVAL

Remove the F-Theta Lens protection cap before marking operation.

Figure 32: F-Theta Lens protection cap removal.

WARNING!

Marking with the lens protection cap could result in damage to the lens.

Page 40

AREXTM 30W – 50W

40

4 USE AND OPERATION

4.1 TURNING ON SEQUENCE

Before turning on the marking system, be sure that the devices are connected as previously described.

Check presence of voltage power supply connection, interlock connector and Command Box connection.

Check that “KEY” and “ENABLE” comm ands on the rack front pane l are disabled (see Figure 15 and Figure

16).

ST

: turn on the main switch in the back of the control rack:

1

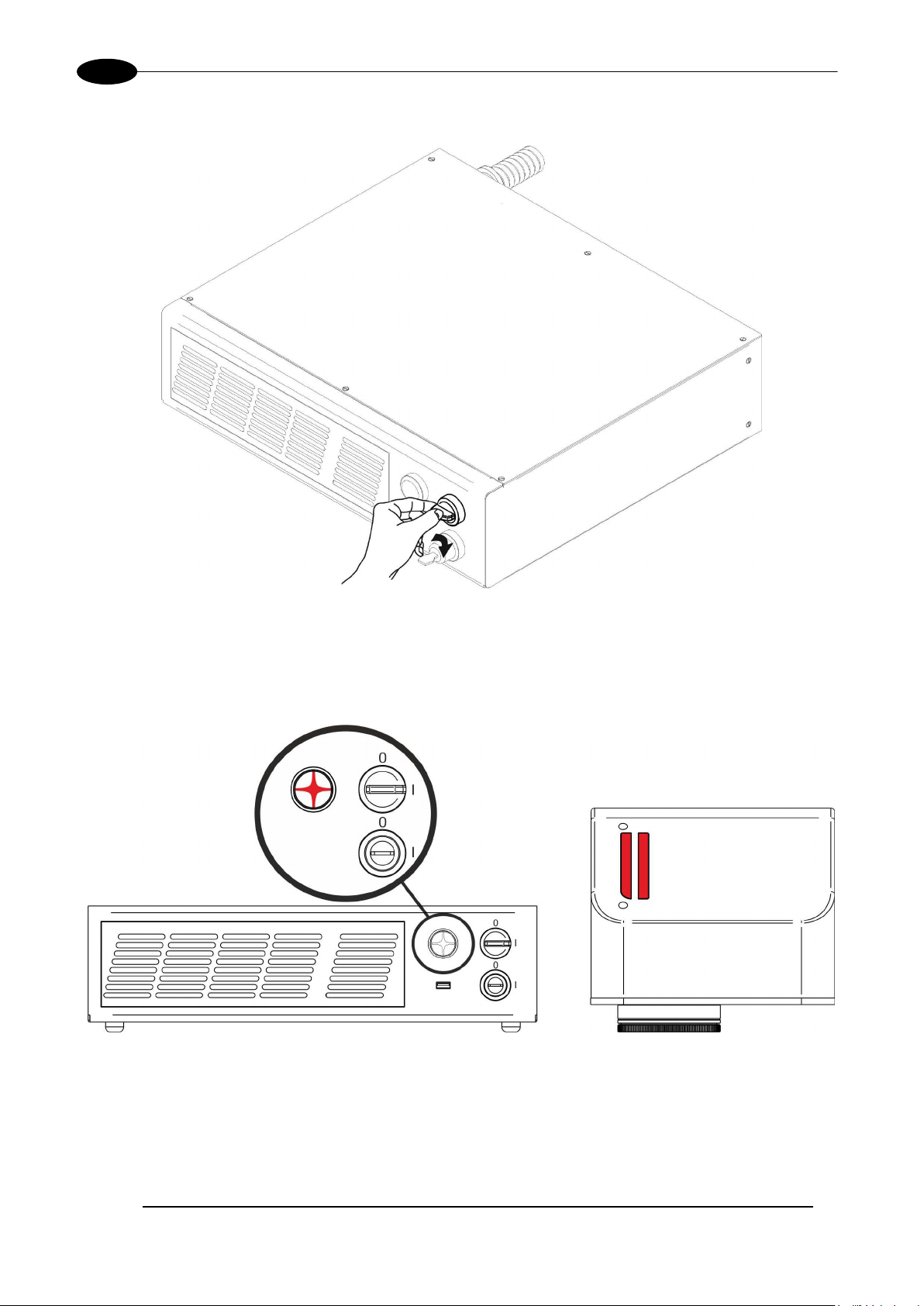

Figure 33: Power on.

During booting-up, status LED on the rack front panel and the LED bar on Scan Head will be blinking green.

Wait the end of the booting-up. The status LED on the rack and the LED bar on the Scan Head will be

steady green.

Figure 34: Status LED display.

Page 41

USE AND OPERATION

41

2ND: activate the command “KEY”, by rotating it clockwise:

Figure 35: Enable command KEY.

When the “KEY” comm and is enabled, t he status LED on the r ack and the status LED bar on the Scan Head

will be blinking orange for about 20 seconds (laser source warm-up).

Wait the end of the laser source war m-up. The s tatus LED on the rac k and the LED bar on the Scan Hea d

will be steady orange.

Figure 36: Status LED display.

Page 42

42

3RD: activate the “ENABLE” command by rotating it clockwise:

AREXTM 30W – 50W

Figure 37: Enable command ENABLE.

The marking system is rea d y to mark. The status LED on the rack and LED status bar o n the Scan Head will

turn red.

Figure 38: Status LED display.

Page 43

USE AND OPERATION

43

KEY

LOW

ENABLE

LOW

SYSTEM ALARM

ON

POWER ON

OFF

ENABLE OUT

OFF

KEY

LOW

ENABLE

LOW

SYSTEM ALARM

OFF

POWER ON

OFF

ENABLE OUT

OFF

KEY

HIGH

ENABLE

LOW

SYSTEM ALARM

OFF

POWER ON

OFF

ENABLE OUT

OFF

KEY

HIGH

ENABLE

LOW

SYSTEM ALARM

OFF

POWER ON

ON

ENABLE OUT

OFF

KEY

HIGH

ENABLE

HIGH

SYSTEM ALARM

OFF

POWER ON

ON

ENABLE OUT

ON

STATUS

STATUS LED

OUTPUT STATUS

(*)

SYSTEM ALARM

OFF

POWER_ON

OFF

ENABLE_OUT

OFF

SYSTEM ALARM

ON

POWER_ON

OFF

ENABLE_OUT

OFF

RESUME TABLE

STATUS STATUS LED INPUT STATUS

SYSTEM

BOOTING UP

WAIT FOR START STEADY GREEN

WARMING UP

STANDBY

SHUTTER CLOSED

READY STEADY RED

BLINKING GREEN (1Hz)

BLINKING ORANGE

(1Hz)

STEADY ORANGE

(*)

OUTPUT STATUS

(*)

WARNING

INVALID START SEQUENCE

BLINKING ORANGE (2Hz)

SYSTEM ERROR BLINKING RED (2Hz)

(*) See paragraph 2.4.2 for more information.

4.1.1 ADVICE ON USING THE SYSTEM

If the marking system is used in manua l mode you need t o connect Com mand Box connect or as described

before. In this way you are able to control the marking system directly on rack front panel.

If the marking system is used in autom atic mode it is recomm ended to enable pe rmanently Key and Enable

commands positioned on rack front panel and to use remote signals (EXT_KEY and EXT_ENABLE)

available on Comm and Box connector. T his part is supplied with the product an d you can connect exter nal

controls wiring connector contacts following pins description on paragraph 2.6.

Page 44

AREXTM 30W – 50W

44

Remote Active-X

4.2 LOCAL MODE OPERATIONS

The local mode (with monit or, k eyboard and m ouse co nnected) is optim al to ful ly benef it of the ALL-IN-ONE

Rack architecture characteristics.

SW Editor

SW Engine

+

Correction Matrix

=

Laser Control

Galvo Control

4.3 REMOTE MODE OPERATIONS

Keyboard, mouse and monitor are not necessary in this configuration.

LAN

SW Editor

Remote SW Engine

SW Engine

Correction Matrix

Laser Control

Galvo Control

Page 45

USE AND OPERATION

45

New IP ActiveX allows OEM integrators and end-users to create customized Applications and User

Interfaces via Ethernet.

Local or remote Activ eX control inter face is a vailable with the same c ommands to allow the us e of the sam e

application developed for both local and remote configurations.

LAN

Remote ActiveX

SW Engine

Correction Matrix

Laser Control

Galvo Control

Page 46

AREXTM 30W – 50W

46

Laser Editor is a software that allows to easily mark or engrave product identification

numeric serial n umbers, date

up that allows to oper ate on th e

select a saved docum ent, display limits using a r ed las er poi nter, w atc h th e marking

switch between Manua l/Auto mode (engra ving operations controlled b y operator or

Laser Engine Tray Icon

4.4 OPERATING IN LOCAL MODE

Connecting m onitor, mouse and keyboard to the s ystem (see paragraph 3.1.5) allo ws the oper ator to acc ess

the console which contains the instrum ents to operate with las er.

information such as 2 D matrix codes, barcodes, text, al phacodes, part numbers, graphics and logos in any production environment.

With Laser Editor you can:

o edit graphic layouts

o set laser parameters

o set marking system configuration

o control the integrated I/O module for axis management

o create automated procedures

o create programs using Lighter programming language

Laser Engine is an ap plicat ion aut om aticall y loaded at s tartmarking system. Laser Engine is present in the tray icon.

With Laser Engine you can:

o monitor the system status

o

preview and do marking tests

o

external signals)

Page 47

USE AND OPERATION

47

4.4.1 HOW TO CREATE AND EDIT YOUR FIRST GRAPHIC DOCUMENT

SIGNAL STATUS

EXT_KEY OFF

EXT_ENABLE_A OFF

EXT_ENABLE_B OFF

In “WAIT FOR START” status, double click on Laser Editor icon to start the layout editor application

Click on the document type selector and choose Layer:

Page 48

48

Click on the Text String icon in the Object toolbar to add a string object to the layer:

AREXTM 30W – 50W

Edit String properties such as value, font, style, etc. using the Properties browser:

Page 49

USE AND OPERATION

49

Edit Filling properties such as filling type, interline, etc. using the Properties browser:

Page 50

50

4.4.2 HOW TO TEST AND ENGRAVE YOUR DOCUMENT

SIGNAL STATUS

AREXTM 30W – 50W

EXT_KEY ON

EXT_ENABLE_A OFF

EXT_ENABLE_B OFF

In “STANDBY SHUTTER CLO SED” status , press L imits All butt on in the Laser Toolbar to a dj us t the obj ec t

position in the marking field:

Page 51

USE AND OPERATION

51

In “READY” status, adjust the Laser parameters using the Properties browser:

SIGNAL STATUS

EXT_KEY ON

EXT_ENABLE_A ON

EXT_ENABLE_B ON

Press Send Marking button in the La ser Toolbar to start the marking process:

Page 52

AREXTM 30W – 50W

52

4.4.3 HOW TO USE EXTERNAL SIGNALS TO ENGRAVE YOUR DOCUMENT

Automate the marking process allowing documents to be marked using external START_MARKING and

STOP_MARKING signals, that can be generated by PLC or other external devices.

Click on Save to Device button to save the layout in the device memory:

Click on Show Laser Engine button to display Laser Engine window:

AUTO/MANUAL Mode button allows switching between the two available working modes:

o Auto mode: the engraving operations are executed automatically using external signals.

o Manual mode: used for displaying the margins of the graphic objects to be marked and testing

layouts.

Page 53

USE AND OPERATION

53

Select the document from the list and click on To Auto Mode button:

The marking system is ready to mark document using external START_MARKING and STOP_MARKING

signals:

Page 54

AREXTM 30W – 50W

54

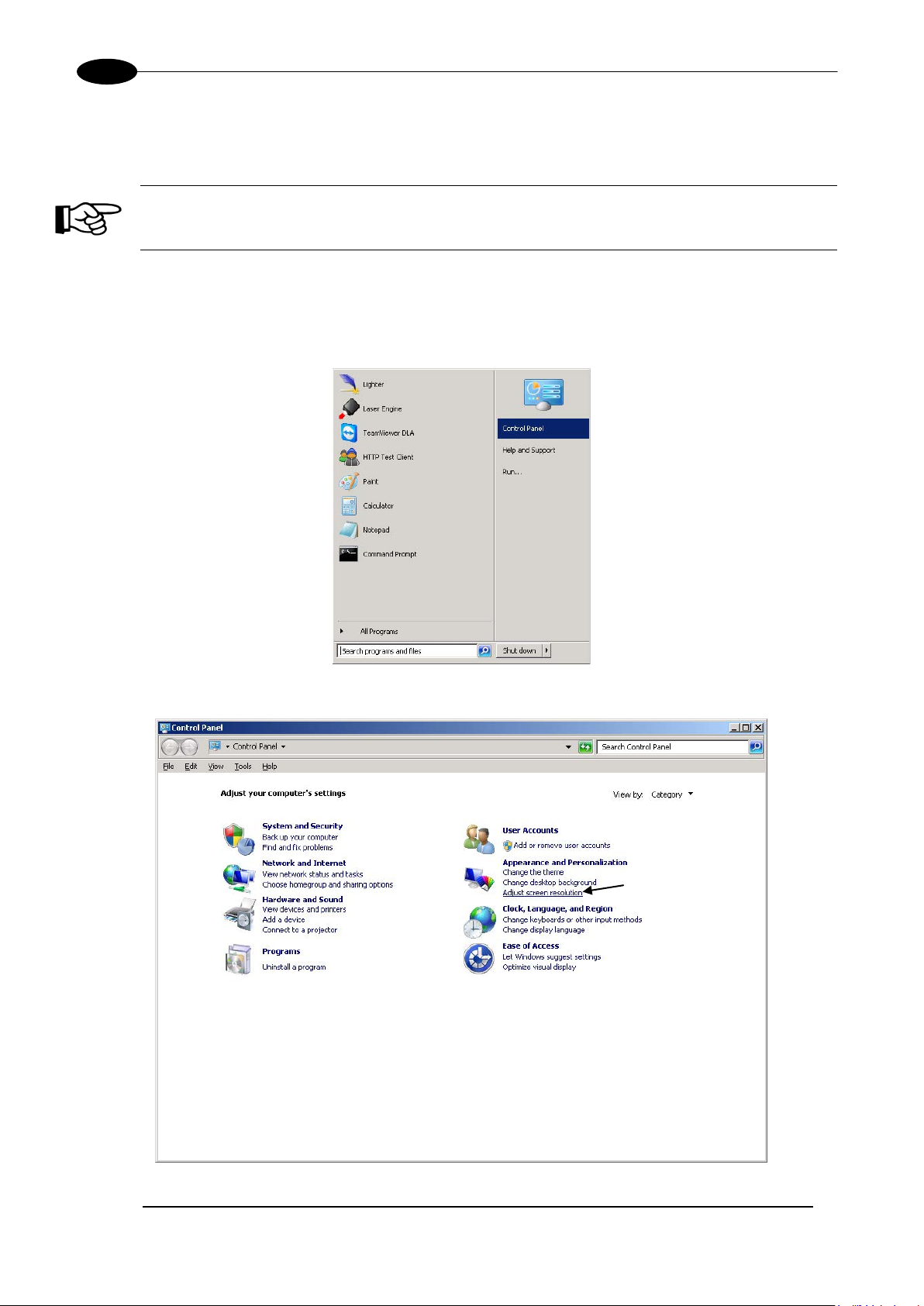

5 CUSTOMIZE THE SYSTEM’S SOFTWARE

5.1 CHANGE O.S. LANGUAGE AND KEYBOARD LAYOUT

The marking system allows you to personalize the op erating system changing t he language used in m enus

and dialogs, languages you can use to enter text and keyboard layout.

NOTE:

In order to perform this setting it is necessary to connect mouse, keyboard and monitor to the

marking system (see paragraph 3.1.5)

o Turn OFF and ON th e marking s ystem and wait the end of the boot ing-up (the status LED on th e

rack and on the scan head must be steady green)

o From the main screen click on Star t > Control Panel

.

o Select Change display language:

Page 55

CUSTOMIZE THE SYSTEM’S SOFTWARE

55

o In Keyboards and Languages select and choose the desired la ngu age.

o Select Change keyboards to change your keyboard or input language:

Page 56

56

o Select now input languages and press OK:

AREXTM 30W – 50W

o Close all the open s c reens and double clic k on the shortcut to save-data.bat icon in the Desk top

screen.

o A message advise you to restart or s hutdown the s ystem in order to perm anently save data. Press

OK:

o Shut down the system in order to save the new settings:

WARNING!

DO NOT turn OFF or UNPLUG the system while Windows® is shutting down.

o WAIT until system shuts down automatically (black screen)

o Power off the system to complete installation

Page 57

CUSTOMIZE THE SYSTEM’S SOFTWARE

57

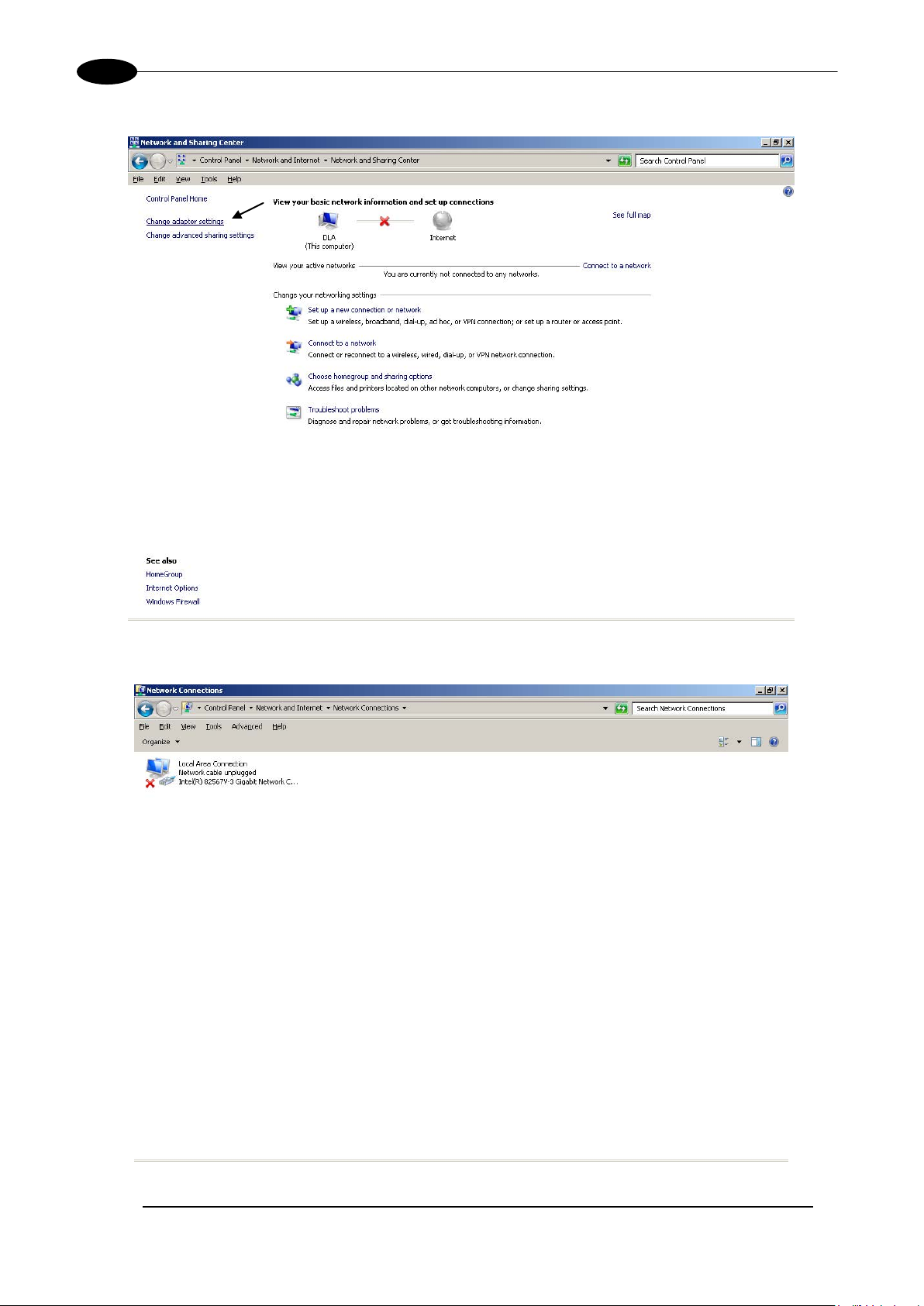

5.2 CHANGE THE LAN CONFIGURATION AND IP ADDRESS

The system allows you to change the LAN configuration and IP address.

NOTE:

In order to perform this setting it is necessary to connect mouse, keyboard and monitor to the

marking system (see paragraph 3.1.5)

o Turn OFF and ON th e marking s ystem and wait the end of the boot ing-up (the status LED on the

rack and on the scan head must be steady green)

o From the main screen click on Star t > Control Panel

.

o Select View network status and task:

Page 58

AREXTM 30W – 50W

58

o In the Network and Sharing Center screen select Change adapter settings:

o In the Network Connections screen double click on Local Area Connection icon

Page 59

CUSTOMIZE THE SYSTEM’S SOFTWARE

59

o In the Local Area Connection Properties screen double click on Internet Protocol Version 4

(TCP/IPv4)

o In the Internet Protocol Version 4 (TCP/IPv4) Properties you can change the IP address and

configuration

o Close all the open s c reens and double clic k on the shortcut to save-data.bat icon in the Desktop

screen.

o A message advise you to restart or s hutdown the s ystem in order to perm anently save data. Press

OK:

o Shut down the system in order to save the new settings:

WARNING!

DO NOT turn OFF or UNPLUG the system while Windows® is shutting down.

o WAIT until system shuts down automatically (black screen)

o Power off the system to complete installation

Page 60

AREXTM 30W – 50W

60

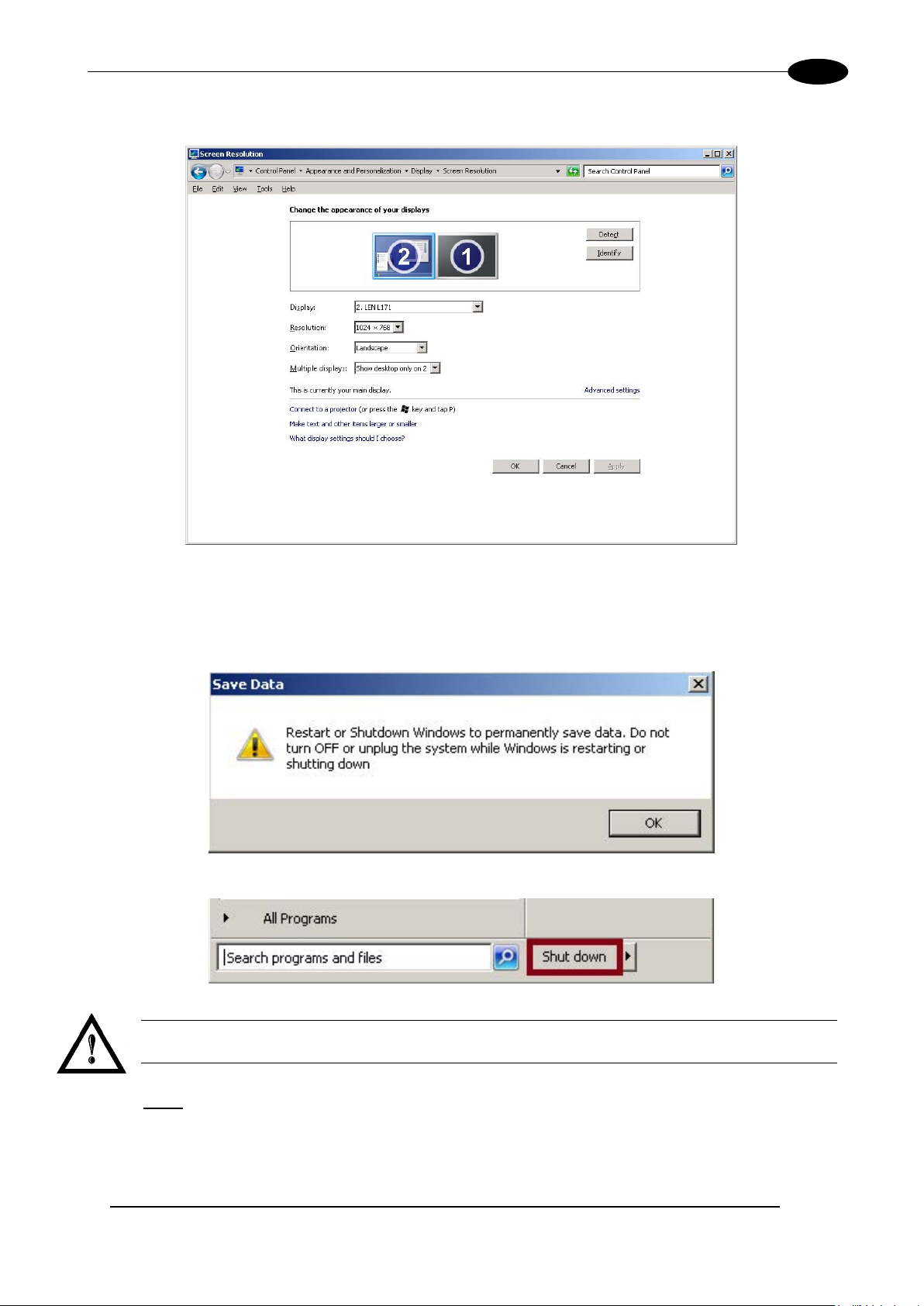

5.3 CHANGE THE VIDEO SETTING

The system allows you to change the Video setting.

NOTE:

In order to perform this setting it is necessary to connect mouse, keyboard and monitor to the

marking system (see paragraph 3.1.5)

o Turn OFF and ON th e marking s ystem and wait the end of the boot ing-up (the status LED on the

rack and on the scan head must be steady green)

o From the main screen click on Star t > Control Panel

.

o Select Adjust screen resolution:

Page 61

CUSTOMIZE THE SYSTEM’S SOFTWARE

61

o In the Screen Resolution window select the desired Screen resolution and Color quality:

o Close all the open screens and double click on shortcut to save-data.bat icon in the Desktop

screen.

o A message advise you to restart or s hutdown the s ystem in order to perm anently save data. Press

OK:

o Shut down the system in order to save the new settings:

WARNING!

DO NOT turn OFF or UNPLUG the system while Windows® is shutting down.

o WAIT until system shuts down automatically (black screen)

o Power off the system to complete installation

Page 62

AREXTM 30W – 50W

62

5.4 REMOTE DESKTOP CONNECTION

To connect the marking system to a remote Windows based computer, follow these steps:

o Turn on marking system

o Make sure that both marking system and remote computer are connected to the LAN

o Click Start > All Programs > Accessories and then click Remote Desktop Connection

o Click Options

o In the Computer list, t ype the host name or the IP addr ess of the computer to which you want to

connect

o Type the user nam e, pass word, and domain ( if applic able) of an accoun t to which you have al lowed

remote access into the corresponding boxes, and then click Connect

Page 63

CUSTOMIZE THE SYSTEM’S SOFTWARE

63

o In the Log On to Windows® dialog box that appear s, t ype the pass word of the a ccount with rem ote

access privileges into the Password box:

User name: DLA

Password: dla

o In the Log on to list, if applica ble, select the domain or remote c omputer that you want, and then

click OK

The remote desktop is displa yed in a wind ow on the d esk top. The rem ote computer is locked dur ing

this session

o To disconnect the sess ion, click the Close button in the session w indow, and then click OK when

you are prompted to disconnect the Windows

session.

Page 64

AREXTM 30W – 50W

64

Key selec tor

Selector switch for EXT_KEY control signal

Enable selector / ENABLE indicator

Selector switch for both EXT_ENABLE_A and EXT_ENABLE_B control sig nals with LED indicator

for ENABLE_OUT control signal

ALARM indicator

LED indicator for SYSTEM_ALARM control signal

START button / BUSY indicator

Pushbutton for START_MARKING control signal with LED indicator for BUSY control signal

STOP button / END indicator

Pushbutton for STOP_MARKING control signal with LED indicator for END control signal

READY indicator

External connector

Connection to Command Box connector

6 ACCESSORIES

The accessories listed here below are described for information purposes only, and are not necessarily

included in the pack aging. The minimum contents of the packaging include the main hardware, cables and

keys. For additional information, please refer to paragraph 1.2.

6.1 CONTROL BOX

Control and command device able to manage:

• Warmup the system

• Open the shutter and enable laser emission

• Start and Stop the marking process

• Show the marking process status

• Show the system error status

Figure 39: Control Box (Ordering no: 985330031).

1

2

3

4

5

6

LED indicator for SW_READY control signal

7

* Refer to Command Box connector (see paragraph 2.4.2) for detailed control signal’s description.

WARNING!

If the Control Box is used, the marking system works in DANGEROUS condition.

Page 65

ACCESSORIES

65

6.2 MARKING ON FLY KIT

The marking on fly kit is available on request. Kit includes: encoder, photocell, cables and plastic reflectors.

Figure 40: Kit MOF (Ordering no: 985330027).

6.3 RACK HANDLES

Handles for rack fastening are available on request.

Figure 41: Handles rack.

Page 66

AREXTM 30W – 50W

66

7 TECHNICAL SUPPORT

7.1 SEALS

The marking system has seals in some areas. The seals m us t not be br oken or removed for any reason. The

sealed parts ma y be open ed on ly and ex clus ivel y by Datalogic. Break age of these seals b y a c ustom er s hall

result in immediate cancellation of the warranty on the entire marking system.

WARNING!

If a customer breaks or remo ves th e seals p lac ed by th e m anufac turer on t he marking system the

warranty on the entire marking system will immediately become “null and void”

WARNING!

The manufacturer shall not be held liable for any non-conforming use of marking system of its

manufacture.

It is forbidden to operate the marking system before the machine it is intended for, has been

declared in conformance with statutory Directives

.

.

WARNING!

Access to the internal parts of the control rack is only permitted for authorized personnel, who have

been trained and instructed on the electrical risks.

Datalogic shall not be held liable for work on electrically charged parts by inadequately trained

personnel!

WARNING!

Access to the internal parts of the scan head is on ly permitted f or authorized personnel, who have

been trained and instructed on the optical risks!

Datalogic shall not be held liable for work on parts by inadequately trained personnel

!

Page 67

TECHNICAL SUPPORT

67

Every 3 months (according to the

7.2 MAINTENANCE

The ordinary maintenance program foresees only simple operations. Some operations consist in a mere

“check” of the operating condition.

The maintenance activiti es must be done in com pliance with the la w prescriptions r egarding the safet y rules

during the operations.

The following parts/functions have to be controlled:

MAINTENANCE PR O G RAM

COMPONENT OR FUNCTION TYPE OF OPERATION INTERVALS

Weekly: wipe gently with a dry cloth (or

F-Theta Scan Lens Check / Clean

soaked in high purity iso propyl alcohol) or

clean it with air blowing

Rack Air filters Clean / Replace

environment and frequency of use)

7.2.1 F-THETA SCAN LENS CLEANING PROCEDURE

WARNING!

Before cleaning the F-Theta scan lens, the marking system MUST be in set SAFE mode:

1- Disable EXT_ENABLE_A and EXT_ENABLE_B signals.

2- Disable INTERLOCK_A and INTERLOCK_B signals.

Figure 42: Cleaning F-Theta lens.

Page 68

68

7.2.2 AIR FILTER CLEANING PROCEDURE

AREXTM 30W – 50W

Figure 43: Removal of air filter.

WARNING!

In order to set the marking system in SAFE mode, disconnect AC power cable before starting

this operation!

1. Turn off key switch on controller unit

2. Disconnect AC power cable

3. Loosen screws of front panel and remove them

4. Remove filter

5. Clean filter with air blow or with neutral detergent and air-dr y i t

6. Reinstall the filter and protective cover

WARNING!

DO NOT install wet filter!

7. If filter cannot be cleaned, replace the filter

8. Suitable filters are available as spare parts

Page 69

TECHNICAL SUPPORT

69

7.3 PRODUCT SUPPORT AND CUSTOMER SE RV ICE

Warranty Information

Datalogic reser ves t he r i ght to c han ge t he inf or mation and specification c ont ai ner in this manual with out pr ior

notice.

Product Support

In the unlikely event that the marking system does not function normally and that it requires attention, contact

Datalogic for advice on further on-site fault diagnosis and/or module return.

If the marking s ystem is to be returned t o D atalog ic, e nsure th at al l rele vant r etur n doc um entation is in p lace

before shipment. Det ails of documentation requirem ents and copies can be obtained where requir ed from

Datalogic.

Pack the marking s ystem in the original packing a nd include all original acces sories and documentati on as

detailed in the original inventory. It is advised that the correct and original packaging is used to prevent

transit damage t o the marking s ystem. If part or all of the original pack aging is unavailable, pl ease contact

Datalogic for replacement items. Please take time to complete all return documentation. This can be

obtained from Datalogic and accurate details, diagnosis and comments in the documentation can help

reduce turnaround time for module repair at Datalogic.

Customer Service Contacts

Product Support

support-dla-lasermarking@datalogic.com

Tel: +39 051-3147011

Customer Services

service-dla-lasermarking@datalogic.com

Tel: +39 0331-918001

Company Web Site

www.datalogic.com

For further contact information see the Contact Us link at www.datalogic.com or contact your local distributor.

Page 70

70

APPENDIX A: LABEL

LABEL DESCRIPTION

Identification label 30W

Identification label 50W

Warning logotype (Laser)

Laser Label (Scan Head)3

Aperture Label

Label for non-interlock protective housing

Caution, possibility of electric shock

Generic Warning

USB plug

MAC Address

0 - I KEY/ENABLE Positions

COMMAND BOX Command Box connector

AXES (I/O) Control Axes connector

INTERLOCK Interlock connector

LAN LAN connector

RS232 RS232 connector

VGA VGA connector

PHOT Photocell connector

ENC Encoder connector

2xT5A Fuses

3

Maximum output of laser radiation as per definition 3.55 of IEC60825-1 considering single fault conditions.

Page 71

71

POSITIONING OF EXTERNAL LABELS

Positioning of labels on the control rack:

Figure 44: External labels rack location.

Positioning of labels on the Scan Head:

Figure 45: External labels Scan Head location.

Page 72

72

APPENDIX B: STANDARDS

LASER STANDARDS

The marking system is designed to comply with the applicable sections of these laser standards:

EU : EN60825-1

USA : 21 CFR 1040.10

The marking system is classified as Class 4 Laser Product.

Datalogic, as m anufacturer of marking system, provides a laser which is NOT intended for im mediate use,

but it must be connec ted, by ot hers, t o other de vices whic h have the final a im of c reating a laser proc essing

system.

The final system manufacturer MUST ensure the safety of the laser processing machine according to its

standards including the ris k-analysis, implementation of safety measures, certification and tes ting of safety

measures and the production of adequate information for use of the machine.

Datalogic is available f or providing to the s ystem integrator/O EM all the inform ation in its possessio n to help

in complying with applicable standards.

CE COMPLIANCE

CE marking states the compliance of the product with essential requirements listed in the applicable

European directive.

Since the directives and applicable standards are subject to continuous updates, and since Datalogic

promptly adopts these updates, therefore the EU declaration of conformity is a living document.

The EU declaration of conformity is available for competent authorities and customers by Datalogic

commercial reference contacts.

Since 20th April 2016 the m ain European directives applicable to Datalog ic products require to include an

adequate analysis and ass essm ent of the risk(s ). This evaluat ion was c arried out in relatio n to the appl icab le

points of the standards listed in the Declaration of Conformity.

Datalogic products are mainly designed for integration purposes, into more complex systems. For this reason

it is under the responsibility of the system integrator to do a new risk assessment regarding the final

installation.

WARNING!

This is a Class A produc t. In a Class B environment this product m ay cause radio interference in

which case the user may be required to take adequate measures.

FCC COMPLIANCE

Modifications or changes to this marking system with out the expressed written approval of Datalogic coul d

void the authority to use the system.

This system complies with PART 15 of the FCC Rules. Operation is subject to t he following t wo conditions:

(1) This system may not cause harmful interference, and (2) this system must accept any interference

received, including interference which may cause undesired operation.

This marking system has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the F CC Rules. These limits are designed to provide r easonable protection against

harmful interference when the system is operated in a commercial environment. This marking system

generates, uses, an d can radiate radio frequenc y energy and, if not install ed and used in accordance with

the instruction manual, may cause harmful interf erence to radio comm unications. Operation of this marking

system in a residentia l area is likely to cause harm ful interference in whic h case the user will be required t o

correct the interference at his own expense.

Page 73

73

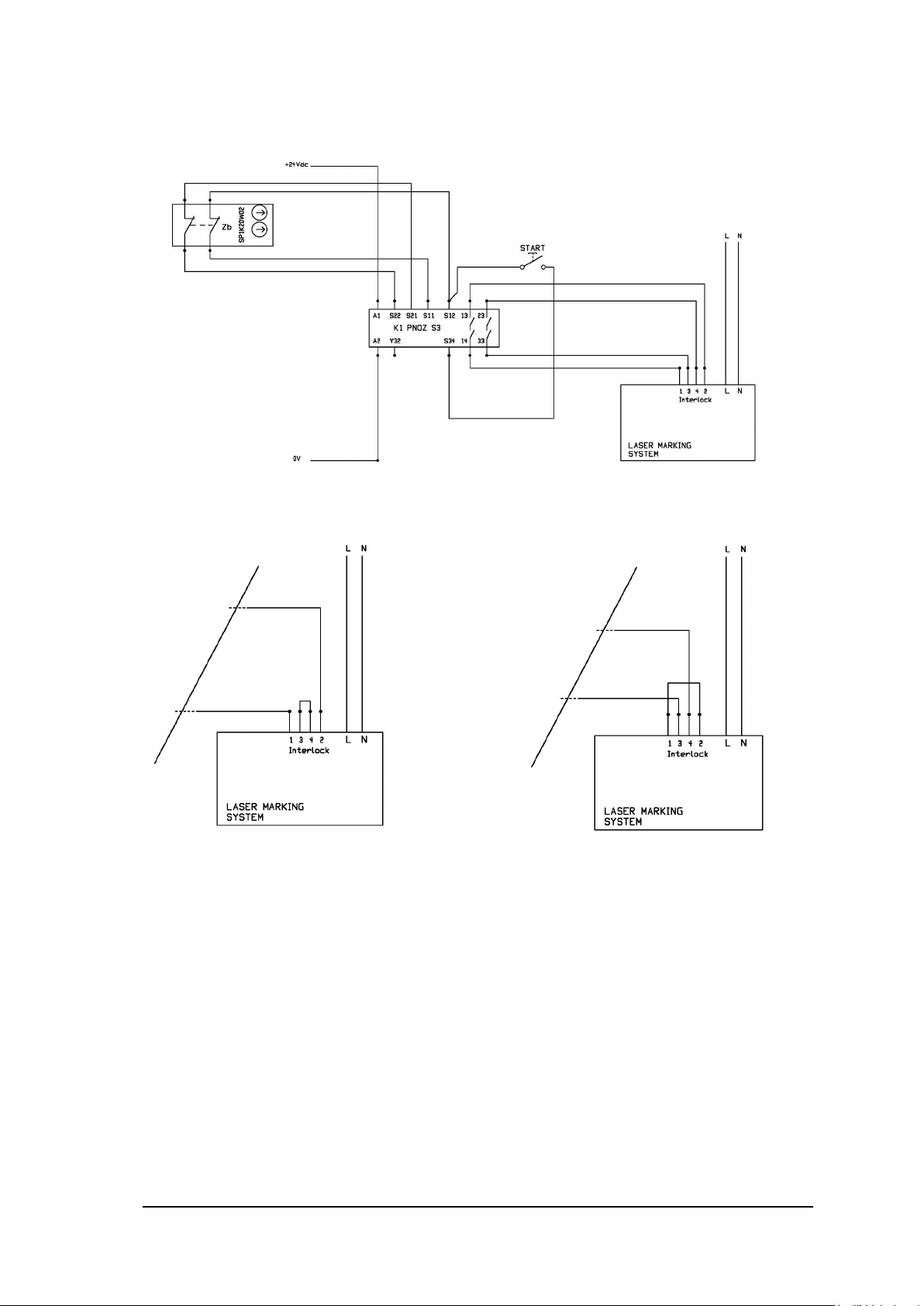

APPENDIX C: AREXTM SAFETY CONSIDERATION ACCORDING EN ISO 13849-1:2008

The interlock connector located to t he rear of the ArexTM laser m arking system is the interface of the internal

safety-related parts of control system (SRP/CS).

With appropriate use of safety external components AND the application of the suggested

maintenance, the SRP/CS of the machine that uses Arex

Category 3, PL c.

Interlock is used t o put the marking system in a saf e operating mode because the action is to rem ove the

power to the laser source.

According to Categ ory 3, Arex

INTERLOCK B. For a normal operation INTERLOCK A signal must be short circuited to its reference

VCC_INT_A and INTERLOCK B signal must be short circuited to its reference GND.

The opening of at le ast o ne c hannel causes the p ower rem oval fr om the interna l laser sourc e. T he respo nse

time from full laser emission to zero emission is < 5ms.

TM

as components will result in Safety

TM

interlock is made by two separate c han nels , referred as INTERLOC K A and

The connector’s pin-out description is:

PIN SIGNAL TYPE DESCRIPTION

1 VCC_INT_A OUTPUT

2 INTERLOCK_A INPUT

3 GND GND

4 INTERLOCK_B INPUT

24V DC reference for INTERLOCK signal A

INTERLOCK signal A

Ground reference for INTERLOCK signal B

INTERLOCK signal B

Page 74

74

YES

NO

NO

The following diagram is a n example of the c orrect co nnection between th e inter lock connector and a safet y

relay:

The minimum requirement for safety relay is Cat.3 PL d.

Do not by-pass one of the two interlock channel:

Maintenance:

The functionality of each interlock channel should be checked every 100 working hours following this

procedure:

1 – set the system in laser “READY” status

2 – open only INTERLOCK_A channel

3 – check of INTERLOCK_A channel is OK if the system goes into “interlock error status” and t he noise

produced by the fans is lower

4 – do the same for INTERLOCK_B channel

5 – final check is OK if both interlock channels are O K. If Final Ch eck is not OK , and the ro ot cause is due

to Arex

issue, please contact your supplier of the system.

TM

, the unit should be return ed to the manufactur er or authorized repair center. To manage this

General information:

Safety MUST be a part of our conscience.

The safety devices fulfill their safety function only if they are correctly installed, in accordance with the

Standards in force.

If you are not certain to have the expertise necessary to install the marking system in the correct way,

Datalogic Technical Support is at your disposal to carry out the installation.

Page 75

75

SAFETY FUNCTIONS OF AREXTM

ArexTM provides inputs and actuators to implement the following safety functions:

- SF.1 ENABLE (e.g. no IR laser output if "EXT_ENABLE_A" or "EXT_ENABLE_B" are disabled,

where "disabled" means contacts open)

- SF.2 INTERLOCK (e.g. no IR laser output if "INTERLOCK_A" or "INTERLOCK_B" are disabled,

where "disabled" means contacts open)

These functions has been evaluated according to UNI EN ISO 13849-1. The results are:

- SF.1:

- Category: B

- MTTFd <10 years

- DC: none according category

- SF.2:

- Category: 3

- MTTFd = 113 years (dop=365days, hop=24h, Tcycle=1800s)

- DC: because Arex

the process. The estim ate for DC is 0% t o 99% depen ding on the applicat ion. Thi s measure alone

is not sufficient for the PL "e". If it is executed a test every 100 working hours, then DC=60%.

- Response time: 5ms

TM

doesn't provide f eedbacks, a measure of fault detection must be included in

Page 76

76

APPENDIX D: NOTE ABOUT LASER

LASER SAFETY

The following inform ation is provided in compliance with regulat ions set by International Authorities, and it

refers to proper use of the marking system.

WARNING!

It is crucial that you protect yourself against beams of reflected or direct light as they cause

permanent damage to your skin

.

WARNING!

Staring directly at a laser beam may cause irreversible damage to your eyes.

WARNING!

Wear safety goggles while using the marking system!

NOTE:

BEFORE INSTALLING AND USING THE LASER, READ CAREFULLY THE APPENDIX

CONCERNING LASER SAFETY.

Page 77

77

LASER RADIATION

Laser radiation is an electromagnetic emission with a micrometric wa velength which ranges from the long

infrared (CO

(excimer laser).

It should be considered non-Ionizing Radiation. In Arex

stimulated by “optical pum ping” generat ed by a Diode Las er. The continuous ref lection of Photons , between

a front mirror and rear mirror, c reates a positive reaction so that their number continues to incre ase, until

reaching the concentr at ion nec ess ary to produce a beam which projects f rom t he semi-reflecting front mirror.

The radiation (whic h we can imagine as a “Beam of in visible light”) is then Collimated a nd Focalized with

Lenses at a point where the intensity becomes high enough to be able to react with various materials

producing an alteration in them due to thermal effect.

The radiation of Arex

the natural defense pro vided b y pupil ref lex! Added to t his is the f act that it is generally very intense , with t he

result that it can be very harmful to the eye and present vision problems.

To prevent permanent damage to vision, a few precautions must be taken.

All individuals who m ay be exposed to da ngero us l evels of laser rad iation , m ust k now that th e laser is ac tive

and wear protective goggles if necessary.

Las er), close infrared (Yd fiber , Nd:YAG, Nd:YVO4), visible (He:Ne or Argon) and ultr aviolet

2

TM

marking system, the emission of a light is

TM

marking system is invisible and the Eye receives it alm os t in its e nt ir et y wi tho ut us ing

WARNING!

Directly viewing a las er bea m can cause irreversible damage to vision.

Due to its high power, the laser integrated in the Datalogic system provokes reflected laser light from flat

surfaces. Reflected light is potentially dangerous for the eyes and skin. Electromagnetic emission with a

micrometric wavelength is placed in long infrared, and is therefore invisible, thus it is not clear where

reflected beams are aimed.

WARNING!

It is indispensable to protect yourself from reflected light beams, because they can be

sufficiently intense to create permanent injury to the eyes or skin

In addition to possible injur y to the e yes or sk in, direc t laser em ission can c ause flam m able materials to burn

like organic solvents (alcohol, acetone) or gasoline and cause fabric and clothing to burn.

.

WARNING!

This marking system is classified as Class 4. Class 4 includes lasers which can produce r isks, not

only from direct or reflected radiation, but also fr om scattered radiat ion! T he laser sour ces m ay be

a significant risk for the skin and risk of burning flammable materials

.

Page 78

78

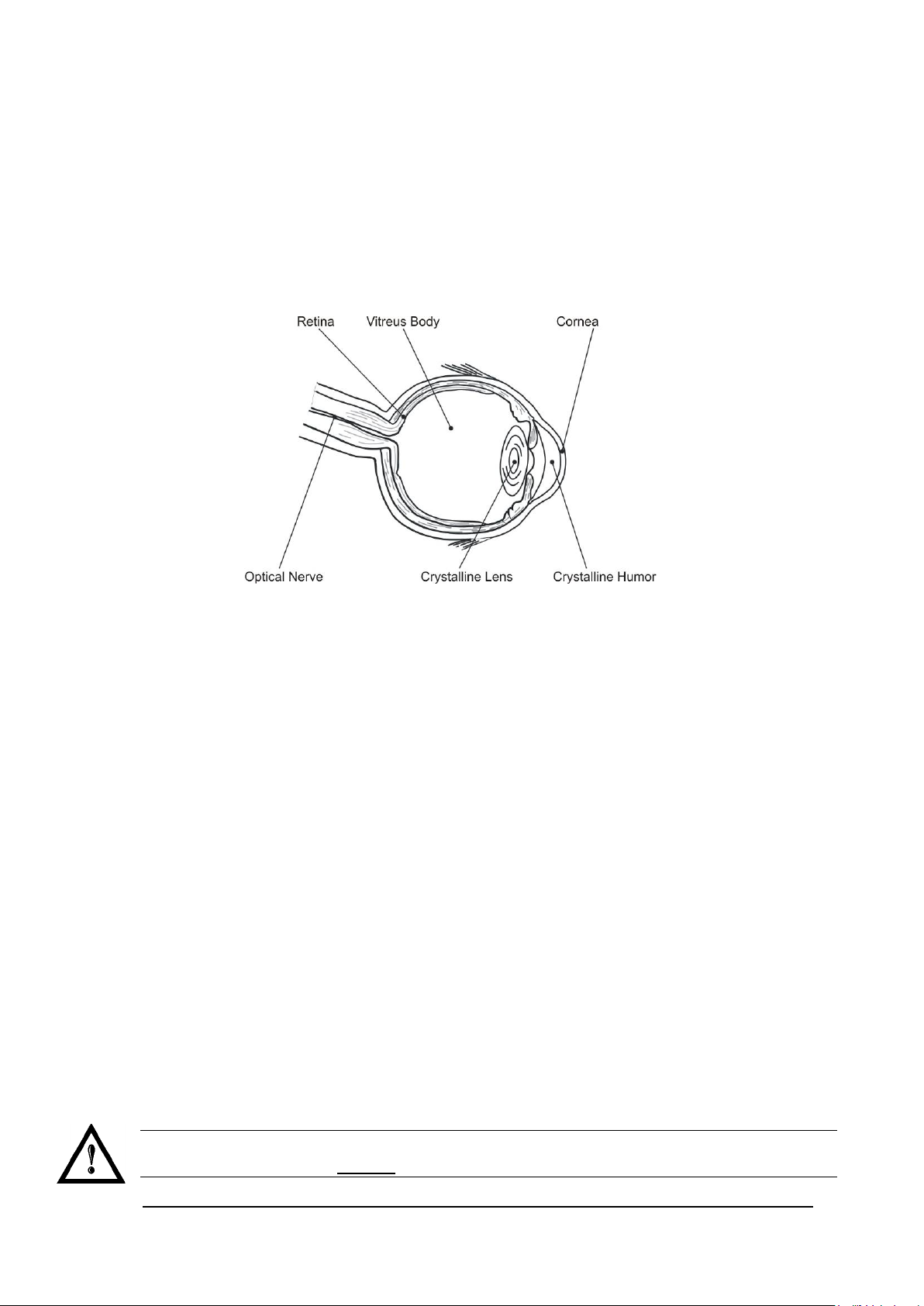

ABSORPTION OF LASER RADIATION

Human skin absorbs electromagnetic radiation in different ways depending on the wave length of the

radiation. Both the e ye and skin have a “predisposition” f or accepting certain wave lengths, and are more

unresponsive to absorbin g others. In the spec ific case of the E ye, the Cornea and Cr ystalline lens let al l the

wave lengths from 400 to 1 400 nm pass and reach t he Retin a, even with vari ous atte nuations. T hey inc lude

the range from visible light to IRA infrared. T hus Arex

this range and leads to direct Retina exposure!

In terms of the Skin, the “biological window” has different absorption percentages but is not dissimilar in

terms of wave length. The maximum exposure values for Skin are much different compared to those

tolerated by the Eye.

TM

laser radiation (1070 nm wavelength) is included i n

Figure 46: Eyeball section.

In terms of the damage m echanism that absorbed ra diation can cause, it also depends on the wave length.

Short lengths (ultraviolet: UV-C 18 0-280nm; UV-B 280-315 nm , UV-A 315-400 nm) generall y cause photochemical effects:

• cataract, or opacification of the crystalline lens

• melanic coloring, or reddening of the skin

Greater wavelengths (inf rared: I R-A 780-1 400 nm ; I R-B 1400 3000 nm; IR-C 300 0-10

thermal effects:

• detachment or photocoagulation of the retina

• burning of the skin

The degree of injury obviously depends on the amount of absorbed radiation and the instantaneous

power of the radiation source.

E6

nm) gener all y cause

CLASSIFICATION AND DANGER LEVEL

Regulations have esta blished different classes of Las er danger based on the ability to injur e people, from

Laser Class 1 (basically safe in all conditions) to Laser Class 4 dangerous in various conditions .

Lasers which can produce risks, not only for direct or reflected radiation, but also for scattered radiation

belong to Class 4. These Laser sources can also have a significant risk for the Skin and fire risk for

flammable material. For these reasons, the User m ust put into effect all measures aim ed at containing the

radiation to make sur e that it is term inated at the end of its useful path. The oper ator mus t also be inform ed

of the risks from exposure to Laser radiation and mus t wear specific I.P.D. (individual pr otection devices)

including goggles that protect against radiation and are certified as suitable for this use.

WARNING!

The ArexTM marking system contains a Class 4 invisible laser source.

Page 79

79

RADIATION VIEWING CONDITIONS

The Laser output by the Sc an Head is to be considered as a hig hly collimated and intense m onochromatic

light source. Due to these char acteristics it can be seen as a “point source” of high lum inosity. This means

that its image is then focal ized on the Retina in a v ery small spot with a dang erously high power dens ity! If

the beam becom es divergent and scatters to a no n-reflecting screen, then there is an “extended visi on” of