Page 1

7A300007 Rev. 2

APEX & ANDES Series

Printer Command Language Developer’s Manual

Page 2

Page 3

Copyrights

Datamax-O’Neil is a registered trademark of Datamax-O’Neil

Bluetooth is registered trademark of Bluetooth SIG, Inc.

Wi-Fi is a registered trademark of the Wi-Fi Alliance

Windows is a registered trademark of Microsoft Corporation

Zebra and Comtec are registered trademarks of Zebra Technologies

All other trademarks are the property of their respective owners.

Specifications subject to change without notice.

Copyright © 2013, Datamax-O’Neil. All rights reserved.

www.datamax-oneil.com

Page 4

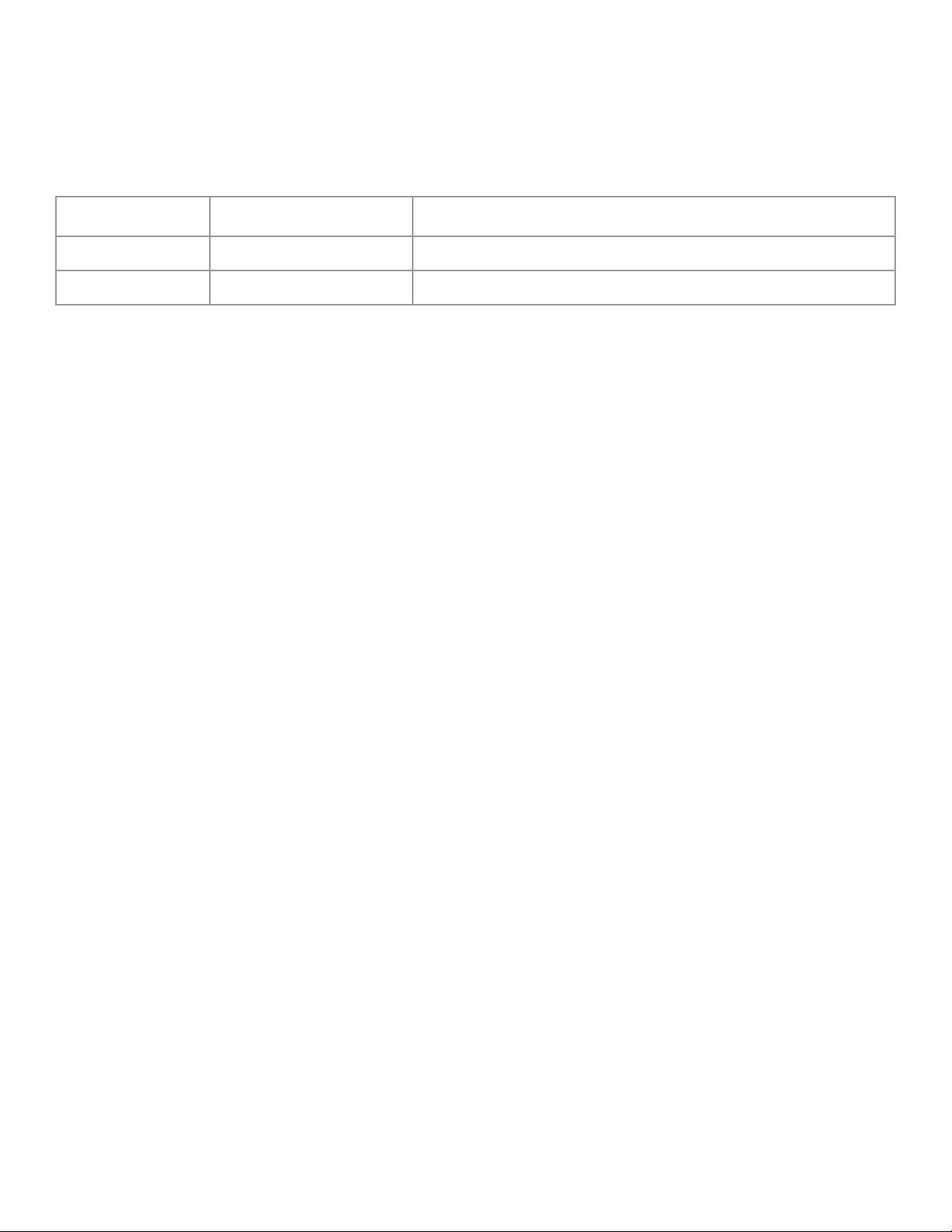

Document Revision History

Document Title: APEX and ANDES Series Printer Command Language Developer’s Manual

Revision Date Revision History Revisions Since Last Issue

7/25/2008 Revision 1 Original Release

01/08/2013 Revision 2 Added QR Code and GS1 DataBar Barcode Symbologies

Page 5

CONTENTS

Introduction..............................................................................................................................1

Datamax-O’Neil Printer Command Language (ExPCL).....................................................1

Communications ......................................................................................................................2

Character Sets..........................................................................................................................3

Character Size and Line Spacing ...........................................................................................3

Character Size and Line Spacing – Width and Height ........................................................5

Character Attributes ...............................................................................................................6

Horizontal Position..................................................................................................................8

Vertical Position.......................................................................................................................9

Bar Codes................................................................................................................................10

Code 39 Specifications ..........................................................................................................................11

Code 128 Specifications ........................................................................................................................12

UCC/EAN-128 Specifications ................................................................................................................13

Interleaved 2 of 5 Specifications ............................................................................................................14

UPC/EAN/JAN Specifications ................................................................................................................14

Codabar Specifications ..........................................................................................................................15

GS1 DataBar Specifications ..................................................................................................................16

QR CODE Specifications .......................................................................................................................21

PDF 417 Specifications..........................................................................................................................22

Graphics..................................................................................................................................24

Printer Controls – Data Processing......................................................................................26

Printer Controls – Printed Output Adjust ..........................................................................27

Printer Controls - Reset.........................................................................................................28

Printer Controls – Power ......................................................................................................28

Printer Status Commands.....................................................................................................30

Magnetic Card Reader..........................................................................................................31

Black Mark Sensing Control Commands............................................................................33

Black Mark Sensing Command Mode.................................................................................34

Black Mark Sensing Auto Mode...........................................................................................34

Page Print Commands - Configuration ...............................................................................36

Page Print Commands – Draw Commands.........................................................................37

TM

Form Fiesta

........................................................................................................................40

Form Fiesta

TM

........................................................................................................................40

Download - Printer Default Setup........................................................................................41

Download – Self test Message Hardware Information.......................................................42

i

Page 6

Download – Logo....................................................................................................................43

Download – Fonts...................................................................................................................44

Important Font Downloading Notes:...................................................................................47

Bluetooth™ & WiFi Setup Command.................................................................................49

Emulation................................................................................................................................50

O’Neil Line Print mode ...........................................................................................................................50

Communications Settings......................................................................................................52

Dip Switch Settings ................................................................................................................................52

Serial Communication (RS232C) .........................................................................................53

USB Communication (USB)..................................................................................................54

Bluetooth™ Communications...............................................................................................55

Infrared Communications (Option).....................................................................................56

Wi-Fi Communication (Option)...........................................................................................57

Printer Status Indicator LED Panel.....................................................................................57

Appendix A: Flash Font Tables............................................................................................59

ii

Page 7

Introduction

This manual is intended to be used by software developers and system integrators with the purpose of developing applications

that can print output results using Datamax-O’Neil wide range of mobile thermal printers. This section of the manual describes

the various printer models, their main technical specifications and the communication interfaces available for each model. For

specific information about the operation of each printer refer to the User’s Guide.

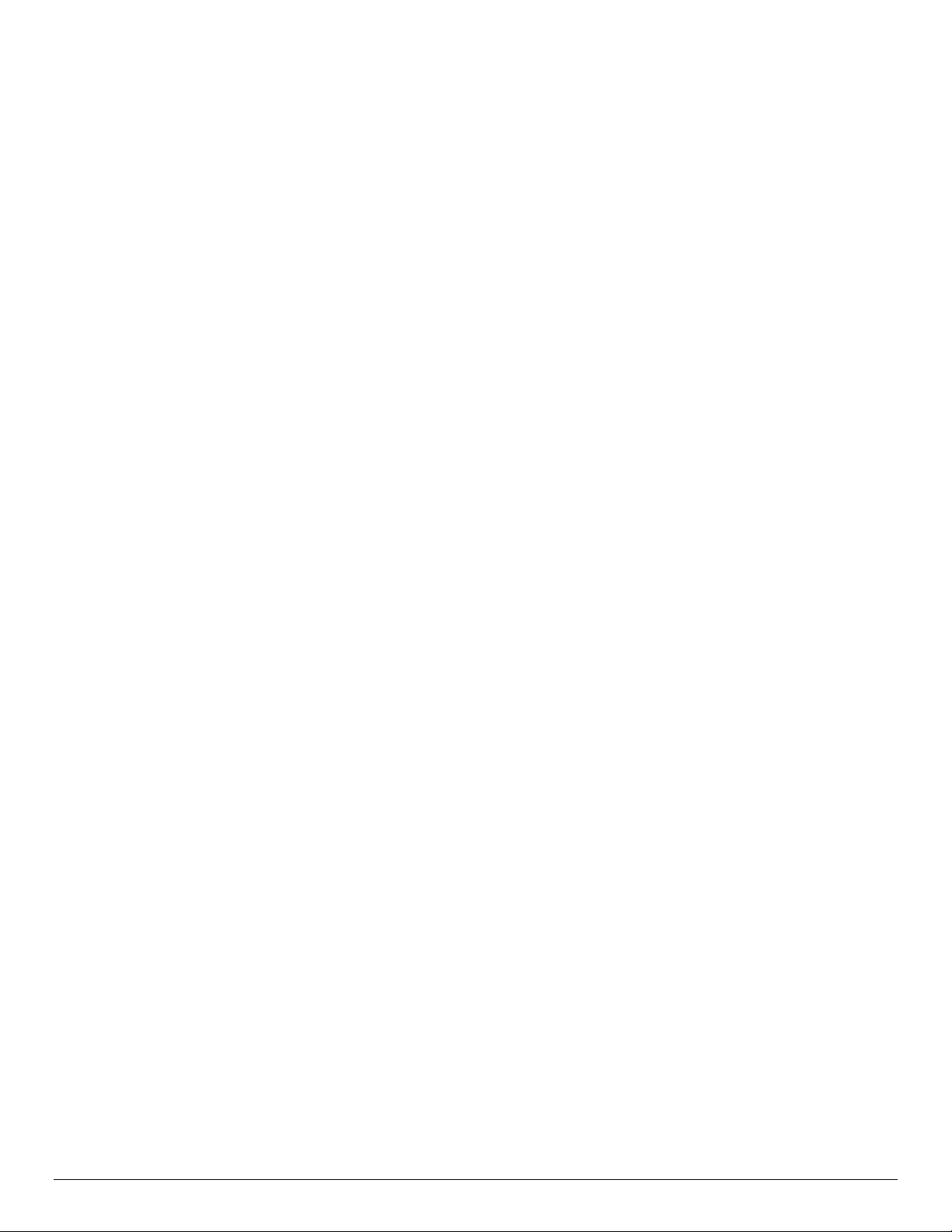

Printer Models and Supported Features

The Datamax-O’Neil series of thermal printers offer a wide variety of solutions for printing applications. Communication

interfaces and supporting flexible paper widths are shown in the table below. For additional information, please refer to the

printer’s User Guide.

Model

APEX2

APEX3

ANDES3

APEX4

Max Paper

Width

2.28”/58m

m

3.15”/80m

m

3.15”/80m

m

4.35”/110.6

mm

Max. Print

Width

1.89”/48mm 384

2.83”/72mm 576

2.83”/72mm 576

4.09”/104m

m

Max Print

Dots

832

Sensors

Front Black

Mark

Front Black

Mark

Front & Back

Black Mark

Front Black

Mark

RS-232 USB BT IrDA WiFi MCR SCR

Std NA Std Opt Opt Opt Opt

Std NA Std Opt Opt Opt Opt

Std Std Opt* Std Opt* Opt* Opt*

Opt Std Std Opt Opt Opt Opt

Communication Interfaces

Std = Standard

NA = Not Available

Opt = Optional

Datamax-O’Neil Printer Command Language (ExPCL)

This section describes the control codes and escape sequences comprising Datamax-O’Neil Printer Command Language

(ExPCL).

Control characters defined as the set of characters encoding from 0x00 to .0x1F (ASCII values between 0 to 31)

The ExPCL defines commands that start with the ESC (Hexadecimal 1B or Decimal 27) character and then are followed for the

command and the parameters. The general structure of the commands can be defined as follows:

ESC <Command> <Param1, Param2, ....,Param n>

Where:

Character Hexadecimal 1B or Decimal 27

ESC

Command One or more ASCII characters that define a unique Datamax-O’Neil

Param1 Input parameters for the command. The commands that accept just one

Note that spaces are not part of the commands and the parameters are indicated as items typed in italics. For instance, the

command ESC k n is used to select the character size of the resident fonts in the printers. The parameter n indicates the font

type to choose with possible values between o and 9.

Printer Command Language

parameter will be defined as “n” while commands with more than one

parameter will be defined as “n1”, “n2”, etc.

1

Page 8

Parenthesis is not part of the command unless specified otherwise:

For example Esc K n CR

Escape Sequence: ESC K 1 CR

Hexadecimal: 1B 4B 31 0D

Decimal: 27 75 49 13

Note that CR means Carriage Return control character.

The following pages describe Datamax-O’Neil Command Language (ExPCL) components in more details. The commands have

been grouped based on major functions.

Communications

This section describes various methods of controlling the flow of data to and from the printer. The set of control characters

described below are used by the printer and the host while a communicating process is in place. Note that some handshaking

methods are only supported by the RS-232C Serial interface and are not supported for the USB, IrDA, Bluetooth, or Wi-Fi

interfaces.

End of Transmission EOT

The printer sends an EOT character each time the printer’s input buffer becomes empty (indicating that the printer is idle).

Control Code: EOT

Hexadecimal: 04

Decimal: 4

Note that this control character can be enabled and disabled using the command ESC P n. See detailed description of the

command in Section: “Printer Control: Data Processing”.

Transmitter On XON

When selected XON/XOFF as flow control method of serial communication, this character is transmitted by the printer to indicate

that the printer is on line and ready to receive data. After receiving this character the host computer will start sending data to the

printer.

Control Code: XON

Hexadecimal: 11

Decimal: 17

Transmitter Off XOFF

When selected XON/XOFF as flow control method of serial communication, this character is transmitted by the printer to indicate

that the printer’s buffer is nearly full and that the host computer should stop sending data. The communication process is

reestablished after the printer transmits XON character to the host.

Control Code: XOFF

Hexadecimal: 13

Decimal: 19

2

Page 9

Character Sets

Select Character Set Esc F n

This command will select the character set that will be used when printing extended characters (Hexadecimal: 80 to FF;

Decimal: 128 to 255).

n Character Set

1 International Character Set

2 PC Line Drawing Character Set

A 16 bit font (Asian tables)

Example1: The following escape sequence will select the International character set.

Escape Sequence: ESC F 1

Hexadecimal: 1B 46 31

Decimal: 27 70 49

Refer to Appendices Section for complete list of characters contained in each character set.

Note that printers are set to International Character Set by default. When using the PC Line Drawing Character Set, the text line

spacing should be set to zero in order to create continuous vertical lines.

This command is used in conjunction with the command ESC k n (or Esc K n, refer to Character Size and Line Spacing).

Character Size and Line Spacing

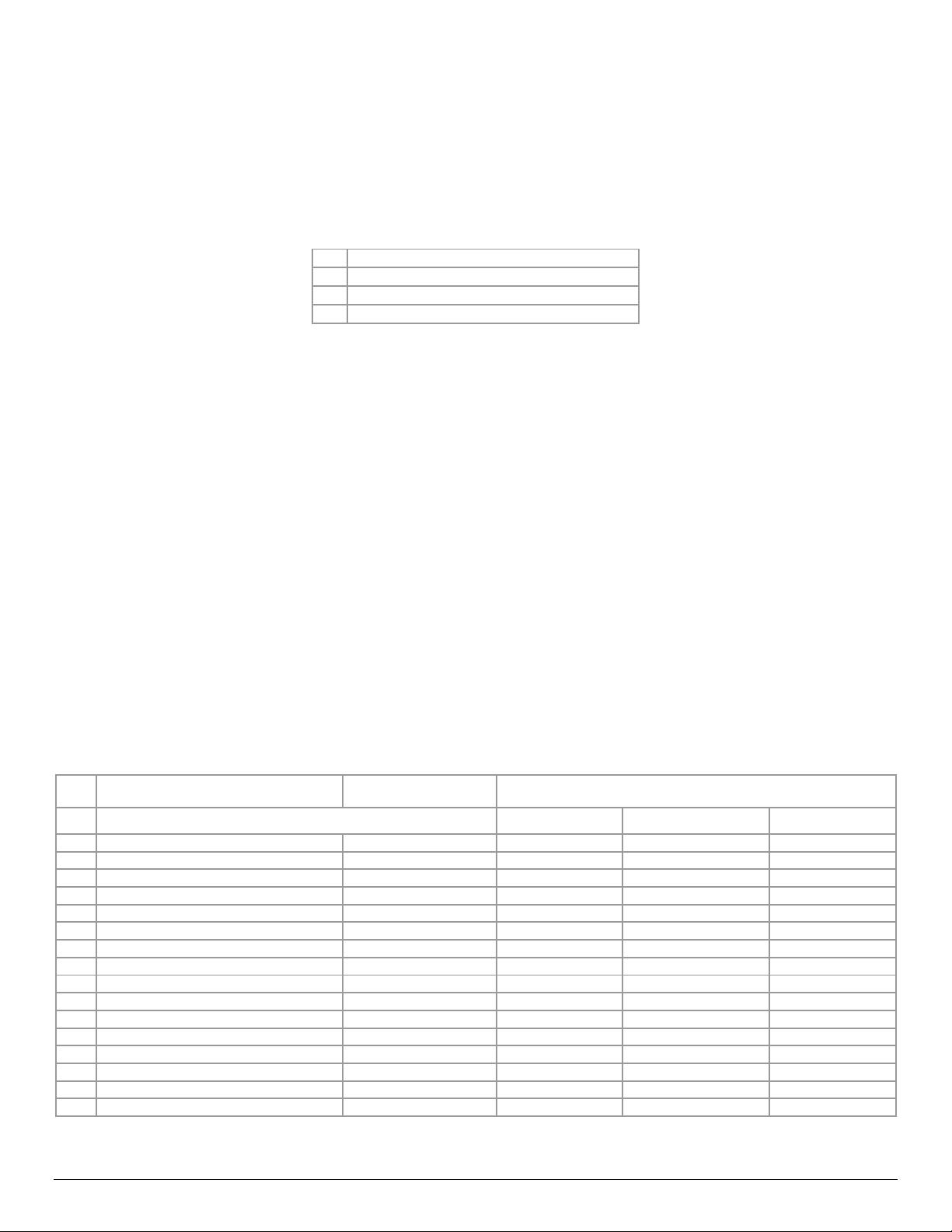

Select Character Pitch: Mode 1 ESC K n CR

This command sets the font size based on the number of character per inch. The parameter n can have the following values:

Character Pitch/Font Character size Columns Per Line

n

APEX2 APEX3 / Andes3 APEX4

0 ~13 cpi Rotated / Courier mode 0 16 x 14 24 (rows/line) 36 (rows/line) 52 (rows/line)

1 ~12 cpi Normal / Courier mode 1 16 x 23 24 36 52

2 ~16 cpi Normal / Courier mode 2 12 x 23 32 48 69

3 ~19 cpi Normal / Courier mode 3 10 x 23 38 57 83

4 ~21 cpi Normal / Courier mode 4 09 x 23 42 64 92

5 ~24 cpi Normal / Courier mode 5 08 x 23 48 72 104

6 ~10 cpi Normal / Monospace 821BT 20 x 23 19 28 40

7 ~20 cpi Normal / Monospace 821BT 10 x 23 38 57 80

8 ~20 cpi Bold / Monospace 821BT 10 x 23 38 57 80

9 ~20 cpi Short / Monospace 821BT 10 x 18 38 57 80

10 ~4 cpi Bold 48 x 80 8 12 17

11 ~25 cpi Verin 08 x 23 48 72 104

12 ~22 cpi Verin 09 x 23 42 64 92

13 ~20 cpi Verin 10 x 23 38 57 83

14 ~16 cpi Verin 12 x 23 32 48 69

15 ~12 cpi Verin 16 x 23 24 36 52

3

Page 10

This command (ESC K n CR) must be sent prior to any printable characters on the line in order to take effect.

Example 1: The following escape sequence set the pitch to 12 CPI (Courier Font):

Escape Sequence: ESC K 1 CR

Hexadecimal: 1B 4B 31 0D

Decimal: 27 75 49 13

Example 2: The following escape sequence set the pitch to 25 CPI Verin Font:

Escape Sequence: ESC K 1 1 CR

Hexadecimal: 1B 4B 31 31 0D

Decimal: 27 75 49 49 13

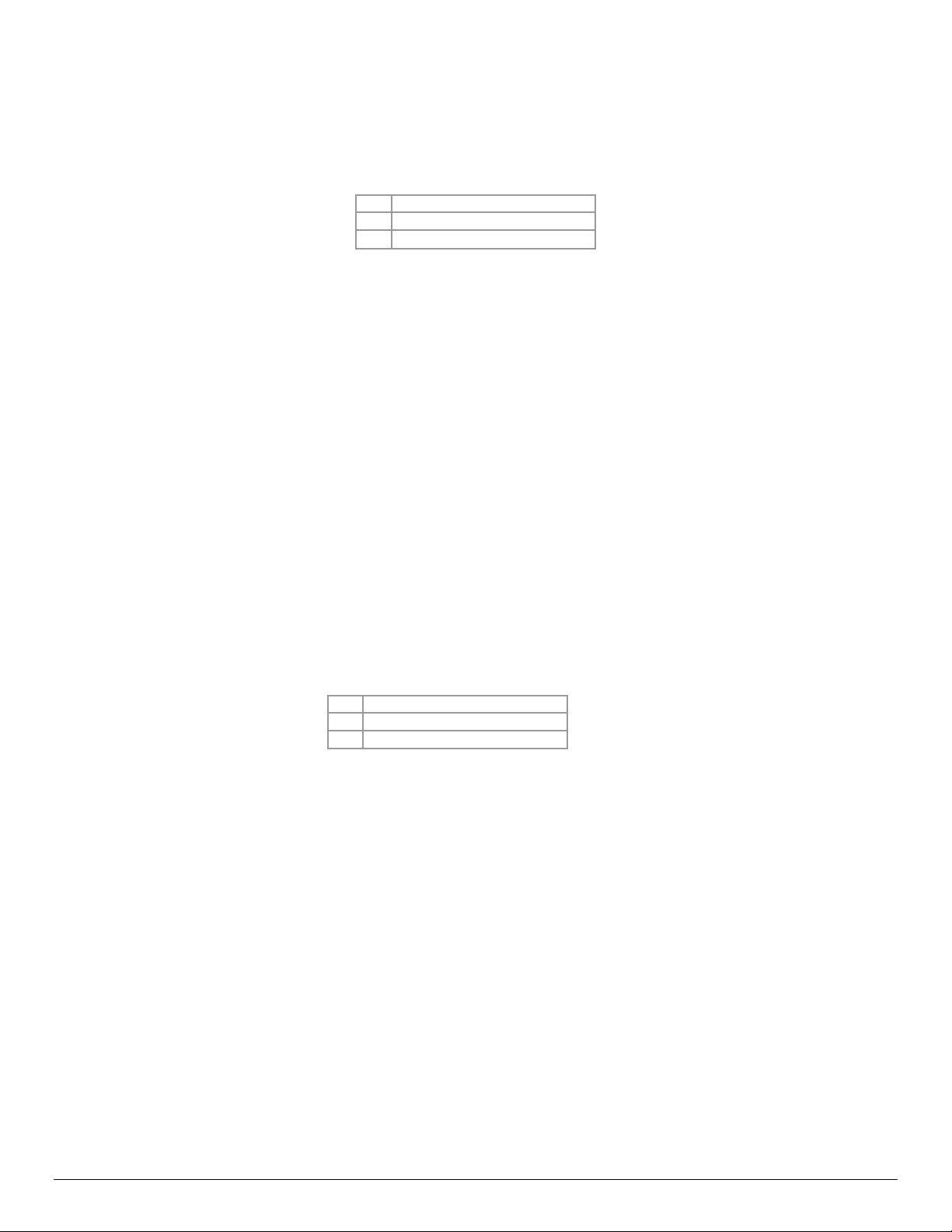

Select Character Pitch: Mode 2 ESC k n

This command is used for backward compatibility when Legacy or Factory fonts are selected. The command sets the font size

based on the number of character per inch. The parameter n can have the following values:

Character Pitch/Font Character size Columns Per Line

n

0 ~13 cpi Rotated / Courier mode 0 16 x 14 24 (rows/line) 36 (rows/line) 52 (rows/line)

APEX 2

APEX 3

Andes3

APEX4

1 ~12 cpi Normal / Courier mode 1 16 x 23 24 36 52

2 ~16 cpi Normal / Courier mode 2 12 x 23 32 48 69

3 ~19 cpi Normal / Courier mode 3 10 x 23 38 57 83

4 ~21 cpi Normal / Courier mode 4 09 x 23 42 64 92

5 ~24 cpi Normal / Courier mode 5 08 x 23 48 72 104

6 ~10 cpi Normal / Monospace 821BT 20 x 23 19 28 40

7 ~20 cpi Normal / Monospace 821BT 10 x 23 38 57 80

8 ~20 cpi Bold / Monospace 821BT 10 x 23 38 57 80

9 ~20 cpi Short / Monospace 821BT 10 x 18 38 57 80

This command (ESC k n) must be sent prior to any printable characters on the line in order to take effect.

Example: The following escape sequence set the pitch to 12 CPI (Courier font):

Escape Sequence: ESC k 1

Hexadecimal: 1B 6B 31

Decimal: 27 107 49

4

Page 11

Character Size and Line Spacing – Width and Height

Double Wide ON SO

This command sets any printed characters to double wide.

Control Code: SO

Hexadecimal: 0E

Decimal: 14

Double Wide OFF SI

This command disables the double wide feature.

Control Code: SI

Hexadecimal: 0F

Decimal: 15

Double High ON FS

This command enables double high printing. The characters printed after this control character will be printed as double height

and also the interline spacing is doubled in height. This feature will be disabled using the control character GS. Refer to the

“Double High OFF” control character for more details.

Control Code: FS

Hexadecimal: 1C

Decimal: 28

Double High OFF GS

This command disables double high printing.

Control Code: GS

Hexadecimal: 1D

Decimal: 29

Set Text Line Spacing ESC a n

This command sets the line spacing between successive printed text lines (dot row). Each dot row is 0.125mm.

0 ≤ n ≤ 40 ) decimal= . If n value is greater than 0x28 or Decimal 40, then n will be set to 0x28 )Decimal 40).

Example: The following escape sequence sets the line spacing to zero (as needed when printing line drawing characters when

the PC Line Drawing character set is selected).

Escape Sequence: ESC a NUL

Hexadecimal: 1B 61 00

Decimal: 27 97 0

Example 2: The following escape sequence sets the line spacing to 40 dot lines (0x28 and Decimal 40)

Escape Sequence: ESC a (

Hexadecimal: 1B 61 28

Decimal: 27 97 40

Note 1: Printer’s default settings are set to 3-dot line after each text line.

Note 2: Line spacing must be set to zero when printing PC Line-Draw characters, the, thus allowing graphic characters on

successive lines to be connected.

5

Page 12

Character Attributes

Emphasized Printing Mode ESC U n

The Emphasized printing mode command will cause the printer to print text with bold appearance.

n

0 Emphasized Mode Off

1

Note that on power up the printer defaults to emphasized mode off.

Example1: The following escape sequence will enable the Emphasized printing mode.

Escape Sequence: ESC U 1

Hexadecimal: 1B 55 31

Decimal: 27 85 49

All characters following this command will be emphasized. The emphasized command is terminated either by the Esc U

0 command or by cycling the printer power.

Example 2: The following escape sequence will disable the emphasized printing mode.

Escape Sequence: ESC U 0

Hexadecimal: 1B 55 30

Decimal: 27 85 48

Selection

Emphasized Mode On

Underline Printing Mode ESC U n

Underline printing mode may be used to underline text.

n

U Underline Mode ON

u Underline Mode OFF

Note that on power up the printer defaults to underline mode off.

Example1: The following escape sequence will enable the underline printing mode.

Escape Sequence: ESC U U

Hexadecimal: 1B 55 55

Decimal: 27 85 85

All characters following this command will be underlined. The underline command is terminated either by the Esc U u

command or by cycling the printer power.

Example 2: The following escape sequence will disable the underline printing mode.

Escape Sequence: ESC U u

Hexadecimal: 1B 55 75

Decimal: 27 85 117

Selection

6

Page 13

Reverse Print ESC U n

The reverse print command enables the user to print white letters on a black background .Reverse printing begins with the

characters following the command.

n

R Reverse printing ON

n Reverse printing OFF

Note that on power up the printer defaults to reverse printing off.

Example1: The following escape sequence will enable the reverse printing mode.

Escape Sequence: ESC U R

Hexadecimal: 1B 55 52

Decimal: 27 85 82

All characters following this command will be reverse printed. The reverse printing command is terminated either by the Esc U n

command or by cycling the printer power.

Example 2: The following escape sequence will disable the reverse printing mode.

Escape Sequence: ESC U n

Hexadecimal: 1B 55 6E

Decimal: 27 85 110

Selection

Right to Left and Left to Right Printing ESC F n

This command causes the printer to change the direction in which characters are printed. The printer direction default mode is

set to Left to Right.

n

R Right to Left

L Left to Right

Selection

Note that on power up the printer defaults to left to right printing mode.

Example1: The following escape sequence will enable the right to left printing mode.

Escape Sequence: ESC F R

Hexadecimal: 1B 46 52

Decimal: 27 70 82

All characters following this command will be printing right to left printed. The right to left printing command is

terminated either by the Esc F L command or by cycling the printer power.

Example 2: The following escape sequence will disable the left to right printing mode.

Escape Sequence: ESC F L

Hexadecimal: 1B 46 4C

Decimal: 27 70 76

7

Page 14

Horizontal Position

Carriage Return CR

This command prints the input buffer information and advances the paper to the next line. If the printer buffer is empty a line is

advanced.

Control Code: CR

Hexadecimal: 0D

Decimal 13

Backspace BS

This command removes the previous character from the print buffer.

Control Code: BS

Hexadecimal: 08

Decimal: 8

Horizontal Tab HT

This command advances the cursor by the number of dots specified in the Horizontal Margins command

Control Code: HT

Hexadecimal: 09

Decimal: 9

Set Horizontal Tab Width ESC T H n

This command sets the Horizontal Tab (HT) value. The parameter n has values between 0 and 255 with a default value of 100

dots..

Example: The following escape sequence sets the horizontal tab width to 50 dots.

Escape Sequence: ESC T H 2

Hexadecimal: 1B 54 48 32

Decimal: 27 84 72 50

8

Page 15

Vertical Position

Line Feed LF

This command prints the input buffer information and advances the paper to the next line.

Total Feed Length = Vertical size of the current font + Text Line Spacing

A Carriage Return (CR) is also performed to place the current print position at the beginning of the next line.

Control Code: LF

Hexadecimal: 0A

Decimal : 10

Variable Size Line Feed ESC J n

This command moves the paper forward as per the distance specified by the parameter n x 0.125mm. 0 ≤ n ≤ 255.

A Carriage Return (CR) is also performed to place the current print position at the beginning of the next line.

Example: The following escape sequence advances the paper ten millimeters. Each dot is 0.125mm so to advance the paper

10mm, the n parameter is 80 (10 / 0.125).

Escape Sequence: ESC J P

Hexadecimal: 1B 4A 50

Decimal: 27 74 80

Variable Size Reverse Line Feed ESC Q J n

This command moves the paper in reverse direction as per the distance specified by the parameter n x 0.125mm. 0 ≤ n ≤ 255.

A Carriage Return (CR) is also performed to place the current print position at the beginning of the next line.

Example: The following escape sequence moves the paper in the reverse direction ten millimeters. Each dot is 0.125mm so to

reverse the paper 10mm, the n parameter is 80 (10 / 0.125).

Escape Sequence: ESC Q J P

Hexadecimal: 1B 51 4A 50

Decimal: 27 81 74 80

Vertical Tab VT

This command advances the cursor the number of dot lines specified in the Vertical Margin command (below).

A Carriage Return (CR) is also performed to place the current print position at the beginning of the next line.

Control Code: VT

Hexadecimal: 0B

9

Page 16

Set Vertical Tab Height ESC T V n

This command sets the vertical tab length in dot lines. 0 ≤ n ≤ 255.

The default value of the vertical tab is 203 dot lines.

Example: The following escape sequence sets the vertical tab to ten millimeters. Each dot is 0.125mm so to fixed the vertical

distance of 10mm, the n parameter is 80 (10 / 0.125).

Escape Sequence: ESC T V P

Hexadecimal: 1B 54 56 50

Decimal: 27 84 86 80

Form Feed FF

This command advances the paper by the number of lines specified in the Set Form Feed length in dot lines (below).

A Carriage Return (CR) is also performed to place the current print position at the beginning of the next line.

Control Code: FF

Hexadecimal: 0C

Decimal 12

Set Form Feed Length in Dot Lines ESC T F n1 n2

This command sets the Form Feed Length in Dot Lines. The total Form Feed distance is computed using the following formula:

(n2 * 256 + n1). 0 ≤ n1 ≤ 255. 0 ≤ n2 ≤ 255. The default value is 1030 dot lines.

Note that the height of the font in dot lines will be subtracted from the total dot lines specified in the command.

Example: For a font 23 dot lines high and with an Esc T V 200 (0xC8) command sent, the actual VT value will be 200 – 23 = 177

dots.

Bar Codes

The Datamax-O’Neil printer series print several barcode symbologies including Linear and 2D barcodes. The following

commands are used to print barcodes.

Print Bar Code ESC z t n h data CR LF

This command will print a barcode without human readable text. The following table describes the Bar Code command

structure.

Parameters:

t Barcode

1 Code 39

2 Code 128,UCC/EAN-128

3 Interleaved 2 of 5

4 UPC/EAN/JAN

5 Codabar

9 PDF417 *

10

Page 17

z bar code is non-human readable

t barcode type.

n number of character bytes in data array. 1 ≤ n ≤ 255

h height of bar code printed in increments of 0.125mm

data n characters to be encoded in the barcode.

*The parameters for the PDF417 barcode differ from the Linear Barcodes. See PDF-417 specifications for more detail.

Note that all barcodes are printed with the minimum bar width (“x-dimension”) of 0.250mm, in compliance with the respective

official specification.

Print Bar Code with Human Readable Text ESC Z t n h data CR LF

This command prints a barcode with Human Readable Text below the barcode. Refer to the parameters of the prior command.

Z Indicates human readable

Code 39 Specifications

Description

Character set

Elements per symbol:

Character density

Bar width

Characters per line

Example: The following command will print human readable barcode “CODE 39” of 1mm high (0.125*8= 1mm).

Escape Sequence: Esc Z 1 7 8 C O D E - 3 9 CR LF

Hexadecimal: 1B 5A 31 07 08 43 4F 44 45 2D 33 39 0D 0A

Decimal: 27 90 49 7 8 67 79 68 69 45 51 57 13 10

Each symbol starts with Leading Quiet Zone, followed with Start Symbol, Data Symbols, ending with

Stop Symbol and Trailing Quiet Zone

36 alphanumeric (0-9, A-Z) and '-' 'space' '$' '/' '+' '%'

Note: Only capital letters are supported.

9 (5 bars, 4 spaces)

6.25 CPI

0.25mm (narrow to wide ratio of 1:3).

2 Inch printer

3 Inch printer

4 Inch printer

: 9 alphanumeric with auto center (maximum)

: 12 alphanumeric with auto center (maximum)

: 22 alphanumeric with auto center (maximum)

11

Page 18

Code 128 Specifications

Description

Character set

Elements per

Each symbol starts with Leading Quiet Zone, followed with Start Symbol, Data Symbols, ending with

Stop Symbol and Trailing Quiet Zone

Support for full 256 ASCII set among three subsets

6 (3 bars, 3 spaces)

symbol

Character density

Bar width

Characters per line

9.1 CPI

0.25mm

2 Inch printer

3 Inch printer

4 Inch printer

: 13 alphanumeric characters or 26 numeric only (maximum) - automatically centered

: 18 alphanumeric characters or 36 numeric only (maximum) - automatically centered

: 32 alphanumeric characters or 36 numeric only (maximum) - automatically centered

Code 128 Start Character:

<start character> = {0x87, 0x88, 0x89} determines the character set to be printed

Start Character Characters Sent to Printer Characters Read by Bar Code Reader

IF <start character> is 0x87 CODE A

IF <start character> is 0x88 CODE B 0x020 through 0x07F ASCII

IF <start character> is 0x89 CODE C

(Each number must be paired with another)

0x020 through 0x03F ASCII

(#32 - #63)

0x040 through 0x07F ASCII

(#64 - #127)

(#32 - #127)

PAIRS 0x030 through 0x039 ASCII

(#48 - #57)

0x020 through 0x03F ASCII

(#32 - #63)

0x00 through 0x07F ASCII

(#0 - #31)

0x020 through 0x07F ASCII

(#32 - #127)

PAIRS 0x030 through 0x039 ASCII

(#48 - #57)

Code 128 Data Bytes:

<DATA>

The data bytes are defined by which character set is defined. The printer accepts all characters 0x20h - 0x7Fh with the

translations defined above.

Also, characters 0x080 - 0x86 may be used as Code 128 control characters:

HEX DEC CODE A CODE B CODE C

0x080 128 FNC 3 FNC 3

0x081 129 FNC 2 FNC 2

0x082 130 SHIFT SHIFT

0x083 131 change to C change to C

0x084 132 change to B FNC 4 change to B

0x085 133 FNC 4 change to A change to A

0x086 134 FNC 1 FNC 1 FNC 1

FNC 1: Reserved CODE 128 character (used for UCC/EAN128)

FNC 2: Message append (not supported by all bar code readers)

FNC 3: Initialize bar code reader

FNC 4: Extend characters (bar code reader reads character + 128)

For example: 'a' is changed from #97 to #97+128 = #225

Note that it is possible to switch code sets in the middle of the bar code. This is useful with heavily numeric alphanumeric bar

codes (see example below).

12

Page 19

Example 1: The following escape sequence prints alphanumeric bar code "A2a", 12.5mm high, with human readable text:

n = 3 printed characters + 1 start character = 4

L = 12.5mm / 0.125mm = #100

start character = START B (full ASCII alpha numeric) = #136

Escape Sequence: Esc Z 2 4 d 88 A 2 a CR LF

Hexadecimal: 1B 5A 32 04 64 88 41 32 60 0D 0A

Decimal: 27 90 50 4 100 136 65 50 97 13 10

Example 2: The following escape sequence print all-numeric bar code "1234", 5mm high, non-human readable text:

n1 = 4 printed characters + 1 start character = 5

L = 5mm / 0.125mm = #40

start character = START C (numeric pairs) = #137

Escape Sequence: Esc z 2 5 ( 89 1 2 3 4 CR LF

Hexadecimal: 1B 7A 32 05 28 89 31 32 33 34 0D 0A

Decimal: 27 122 50 5 40 137 49 50 51 52 13 10

UCC/EAN-128 Specifications

Description

Example: The following escape sequence print all-numeric bar code "1234", 5mm high, with human readable text in EAN-128

format:

n1 = 1 start character + EAN specified + 4 printed characters = 6

L = 5mm / 0.125mm = #40

start character = START C (numeric pairs) = #137

Escape Sequence: Esc Z 2 6 ( 89 FNC1 1 2 3 4 CR LF

Hexadecimal: 1B 5A 32 06 28 89 86 31 32 33 34 0D 0A

Decimal: 27 90 50 6 40 137 134 49 50 51 52 13 10

The UCC/EAN-128 specification is an internationally recognized format for application identifiers in

code 128 bar codes. The bar code symbology is identical to Code 128. These identifiers are not

intended for point-of-sale applications. Only recognized bodies of the UCC or EAN may assign

application identifiers. More information may be found at:

http://www.ean.be/ for the EAN and

http://www.uc-council.org/ for the UCC

13

Page 20

Interleaved 2 of 5 Specifications

Description

Character set

Elements per

symbol

Character density

Bar width

Characters per line

Example: The following escape sequence prints an Interleaved 2 of 5 barcode, encoding “12345678” with 10 mm high,

human readable.

Escape Sequence: Esc Z 3 8 2 1 2 3 4 5 6 7 8 CR LF

Hexadecimal: 1B 5A 33 08 32 31 32 33 34 35 36 37 38 0D 0A

Decimal: 27 90 51 8 50 49 50 51 52 53 54 55 56 13 10

Each symbol starts with Leading Quiet Zone, followed with Start Symbol, Data Symbols, ending with

Stop Symbol and Trailing Quiet Zone

numeric pairs

10 (5 bars, 5 spaces)

1.11 CPI

25mm

2 inch printer

3 inch printer

4 inch printer

: 16 numeric (maximum), automatically centered

: 24 numeric (maximum), automatically centered

: 35 numeric (maximum), automatically centered

UPC/EAN/JAN Specifications

Description

Character set

Elements per symbol

Character density

Bar width

Characters per line

Example 1: The following escape sequence will print a UPC-A bar code with the following: human readable, 30 mm high,

containing “123456789012” where 2 is the check digit. Due to limited spacing CR LF are not shown at the end of this command.

Escape Sequence: ESC Z 4 12 240 1 2 3 4 5 6 7 8 9 0 1

Hexadecimal: 1B 5A 34 0C F0 31 32 33 34 35 36 37 38 39 30 31

Decimal: 27 90 52 12 240 49 50 51 52 53 54 55 56 57 48 49

Each symbol starts with Leading Quiet Zone, followed with Left Guard Bars, Left Data Symbols,

Center Bar Pattern, Right Data Symbols, Check Character, ending with Right Guard Bars and

Trailing Quiet Zone.

The UPC, EAN/JAN-8, EAN/JAN-13 specifications comprise an internationally recognized format for

application identifiers. Unlike the UCC/EAN-128 specification, these identifiers are intended for pointof-sale applications. Only recognized bodies of the UCC and EAN may assign application identifiers.

More information may be found at:

http://www.ean.be/ for the EAN and

http://www.uc-council.org/ for the UCC

Numeric - fixed length

4 (2 bars, 2 spaces)

14.5 CPI

0.25mm

UPC-A: 11 - plus check digit (automatically centered)

UPC-E: 6 - plus check digit (automatically centered)

EAN/JAN-8: 7 - plus check digit (automatically centered)

EAN/JAN-13: 12 - plus check digit (automatically centered)

14

Page 21

Example 2: The following escape sequence will print a UPC-E bar code with the following: human readable, 30 mm high,

containing “1234565” where 5 is the check digit.

Escape Sequence: ESC Z 4 7 240 1 2 3 4 5 6 CR LF

Hexadecimal: 1B 5A 34 07 F0 31 32 33 34 35 36 0D 0A

Decimal: 27 90 52 7 240 49 50 51 52 53 54 13 10

Example 3: The following escape sequence will print an EAN/JAN-8 bar code with the following: human readable, 30 mm high,

containing “12345670” where 0 is the check digit.

Escape Sequence: ESC Z 4 8 240 1 2 3 4 5 6 7 CR LF

Hexadecimal: 1B 5A 34 08 F0 31 32 33 34 35 36 37 0D 0A

Decimal: 27 90 52 8 240 49 50 51 52 53 54 55 13 10

Example 4: The following escape sequence will print an EAN/JAN-13 bar code with the following: human readable, 30 mm high,

containing “1234567890128” where 8 is the check digit. Due to limited spacing CR LF are not shown at the end of this

command.

Escape Sequence:ESC Z 4 13 240 1 2 3 4 5 6 7 8 9 0 1 2

Hexadecimal: 1B 5A 34 0D F0 31 32 33 34 35 36 37 38 39 30 31 32

Decimal: 27 90 52 13 240 49 50 51 52 53 54 55 56 57 48 49 50

Note that all heights are total height, including a 1.23mm drop bar pattern printed after the bar code pattern.

Codabar Specifications

Description

Character set

Elements per

symbol

Character density

Bar width

Characters per line

Example 1: The following escape command prints a Codabar barcode with the following: Encoding “123456”, human readable,

20 mm high, start character A and stop character T

Escape Sequence: ESC Z 5 8 160 A 1 2 3 4 5 6 T CR LF

Hexadecimal: 1B 5A 35 08 A0 41 31 32 33 34 35 36 54 0D 0A

Decimal: 27 90 53 8 160 65 49 50 51 52 53 54 84 13 10

Example 2: The following escape command prints Codabar barcode with the following: Encoding “2468”, human readable, 10

mm high, start character C and stop character *. .

Escape Sequence: ESC Z 5 6 P C 2 4 6 8 * CR LF

Hexadecimal: 1B 5A 35 06 50 43 32 34 36 38 2A 0D 0A

Decimal: 27 90 53 6 80 67 50 52 54 56 42 13 10

Each symbol starts with Leading Quiet Zone, followed with Start Symbol, Data Symbols, ending with

Stop Symbol and Trailing Quiet Zone

0-9, {$, -, :, /, ., +} and start/stop pairs {A/T, B/M, C/*, D/E}

7 (4 bars, 3 spaces)

8.1 CPI

0.25mm

2 Inch Printer

3 inch printer

4 inch printer

: 15 (maximum) plus start/stop, automatically centered

: 20 (maximum) plus start/stop, automatically centered

: 35 (maximum) plus start/stop, automatically centered

15

Page 22

GS1 DataBar Specifications

GS1 DataBar symbols can carry more information and identify small items than the current

Description

Character set

QR Code Models

Error Correction

Levels

Data Modes

Elements per

symbol

Max. Characters

EAN/UPC bar code. GS1 DataBar enables GTIN identification for hard-to-mark products like fresh

foods, jewelry and do-it-yourself hardware products and can carry GS1 Application Identifiers such as

serial numbers, lot numbers, and expiration dates.

numeric, alphanumeric, byte / binary, Kanji

Model 1 is the original specification.

Model 2 is an enhanced form of the symbology.

Ultra High Reliability Level (30% of codewords can be restored)

High Reliability Level (25% of codewords can be restored)

Standard Level (15% of codewords can be restored)

High Density Level (7% of codewords can be restored)

AUTO (do not need to specify the character mode)

MANUAL (need to specify the character mode.)

Square dot/element with the following pixel multipliers: 1(none), 2, 4(default), 8, 16

7366

QR Code Command Structure:

<ESC> – ‘z’ or ‘Z’ – ‘6’ – TYPE – DATA SIZE – ELEMENT SIZE – X UNDERCUT – Y UNDERCUT – SEP ROW HEIGHT – MAX

SEG PER ROW - [User’s Data]

Parameters:

1) ESC(0x1B)

2) "Z"(0x5A) or "z"(0x7A) - Enables\disables annotation

3) "6"(0x36) - Selects GS1 DataBar barcode family

4) 1(SOH) through 12(FF) - selects symbology type, where:

New GS1 Databar

1(SOH) RSS-14 GS1 DataBar Omnidirectional

2(STX) RSS-14 Truncated GS1 DataBar Truncated

3(ETX) RSS-14 Stacked GS1 DataBar Stacked

4(EOT) RSS-14 Stacked Omnidirectional GS1 DataBar Stacked Omnidirectional

5(ENQ) RSS Limited GS1 DataBar Limited

6(ACK) RSS Expanded GS1 DataBar

Expanded

7(BEL) UPC-A

8(BS) UPC-E

9(HT) EAN-13

10(LF) EAN-8

11(VT) UCC/EAN-128 & CC-A/B

12(FF) UCC/EAN-128 & CC-C

5) 0(NULL)-256(0xFF) - number of bytes to encode. For more information please refer to "Data input string format:" section

below.

16

Page 23

6) 1(SOH)-12(FF) - pixels per X

7) 0(NULL)-3(ETX) - X pixels to undercut

8) 0(NULL)-3(ETX) - Y pixels to undercut

9) 1(SOH)-12(FF) * 2 - separator row height

10) 2(STX)-22(SYN) - maximum segments per row (22 default). Note this entry is only applicable for RSS Expanded symbology

11) Data string

Example: The following escape commands encode the data “1234567890123” in RSS14 Linear type. Due to space limitation CR

LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <SOH> <EOT> <SOH> <NUL> <NUL> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’ ‘3’

Hexadecimal :

1b 5a 36 1 0d 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32 33

Decimal:

27 90 54 1 13 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50 51

Expected Result (not to scale):

Example: The following escape commands encode the data “1234567890123” in RSS14 Truncated Linear type. Due to space

limitation CR LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <STX> <EOT> <SOH> <NUL> <NUL> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’ ‘3’

Hexadecimal :

1b 5a 36 2 0d 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32 33

Decimal:

27 90 54 2 13 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50 51

Expected Result (not to scale):

Example: The following escape commands encode the data “1234567890123” in RSS14 Stacked Linear type. Due to space

limitation CR LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <ETX> <EOT> <SOH> <NUL> <NUL> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’ ‘3’

Hexadecimal :

1b 5a 36 3 0d 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32 33

Decimal:

17

Page 24

27 90 54 3 13 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50 51

Expected Result (not to scale):

Example: The following escape commands encode the data “1234567890123” in RSS14 Stacked Omnidirectional Linear type.

Due to space limitation CR LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <EOT> <EOT> <SOH> <NUL> <NUL> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’ ‘3’

Hexadecimal :

1b 5a 36 4 0d 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32 33

Decimal:

27 90 54 4 13 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50 51

Expected Result (not to scale):

Example: The following escape commands encode the data “1234567890123” in RSS Limited Linear type. Due to space

limitation CR LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <ENQ> <EOT> <SOH> <NUL> <NUL> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’ ‘3’

Hexadecimal :

1b 5a 36 5 0d 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32 33

Decimal:

27 90 54 5 13 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50 51

Expected Result (not to scale):

Example: The following escape commands encode the data “DATAMAX-O’NEIL” in RSS Expanded Linear type. Due to space

limitation CR LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <ACK> <SO> <SOH> <NUL> <NUL> <SOH> <SYN> ‘D’ ‘A’ ‘T’ ‘A’ ‘M’ ‘A’ ‘X’ ‘-’ ‘O’ ‘’’ ‘N’ ‘E’ ‘I’ ‘L’

Hexadecimal :

1b 5a 36 6 0e 1 0 0 1 16 44 41 54 41 4d 41 58 2d 4f 27 4e 45 49 4c

Decimal:

27 90 54 6 14 1 0 0 1 22 68 65 84 65 77 65 88 45 79 39 78 69 73 76

18

Page 25

Expected Result (not to scale):

Example: The following escape commands encode the data “12345678901” in UPC-A type. Due to space limitation CR LF are

not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <BEL> <VT> <SOH> <NUL> <NUL> <SOH> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’

Hexadecimal :

1b 5a 36 7 0b 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31

Decimal:

27 90 54 7 11 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49

Expected Result (not to scale):

Example: The following escape commands encode the data “1234500006” in UPC-E type. Due to space limitation CR LF are not

shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <BS> <LF> <SOH> <NUL> <NUL> <SOH> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘0’ ‘0’ ‘0’ ‘0’ ‘6’

Hexadecimal :

1b 5a 36 8 0a 1 0 0 1 16 31 32 33 34 35 30 30 30 30 36

Decimal:

27 90 54 8 10 1 0 0 1 22 49 50 51 52 53 48 48 48 48 54

Expected Result (not to scale):

Example: The following escape commands encode the data “123456789012” in EAN-13 type. Due to space limitation CR LF are

not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <HT> <FF> <SOH> <NUL> <NUL> <SOH> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’

Hexadecimal :

1b 5a 36 9 0c 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32

19

Page 26

Decimal:

27 90 54 9 12 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50

Expected Result (not to scale):

Example: The following escape commands encode the data “1234567” in EAN-8 type. Due to space limitation CR LF are not

shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <LF> <BEL> <SOH> <NUL> <NUL> <SOH> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’

Hexadecimal :

1b 5a 36 0a 7 1 0 0 1 16 31 32 33 34 35 36 37

Decimal:

27 90 54 10 7 1 0 0 1 22 49 50 51 52 53 54 55

Expected Result (not to scale):

Example: The following escape commands encode the data “123456789012” in UCC EAN-128 & CC-A/B type. Due to space

limitation CR LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <VT> <FF> <SOH> <NUL> <NUL> <SOH> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’

Hexadecimal :

1b 5a 36 0b 0c 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32

Decimal:

27 90 54 11 12 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50

Expected Result (not to scale):

Example: The following escape commands encode the data “123456789012” in UCC EAN-128 & CC-C type. Due to space

limitation CR LF are not shown

Escape Sequence:

<ESC> ‘z’ ‘6’ <FF> <FF> <SOH> <NUL> <NUL> <SOH> <SYN> ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’ ‘8’ ‘9’ ‘0’ ‘1’ ‘2’

Hexadecimal :

1b 5a 36 0c 0c 1 0 0 1 16 31 32 33 34 35 36 37 38 39 30 31 32

20

Page 27

Decimal:

27 90 54 12 12 1 0 0 1 22 49 50 51 52 53 54 55 56 57 48 49 50

Expected Result (not to scale):

QR CODE Specifications

The code consists of black modules (square dots) arranged in a square pattern on a white

Description

Character set

QR Code Models

Error Correction

Levels

Data Modes

Elements per

symbol

Max. Characters

background. The information encoded may be made up of four standardized types ("modes") of data

(numeric, alphanumeric, byte / binary, Kanji), or through supported extensions, virtually any type of

data.

numeric, alphanumeric, byte / binary, Kanji

Model 1 is the original specification.

Model 2 is an enhanced form of the symbology.

Ultra High Reliability Level (30% of codewords can be restored)

High Reliability Level (25% of codewords can be restored)

Standard Level (15% of codewords can be restored)

High Density Level (7% of codewords can be restored)

AUTO (do not need to specify the character mode)

MANUAL (need to specify the character mode.)

Square dot/element with the following pixel multipliers: 1(none), 2, 4(default), 8, 16

7366

QR Code Command Structure:

<ESC> – ‘z’ or ‘Z’ – ‘7’ – QR MODEL – ERROR CORRECTION – DATA MODE – MSB – LSB – PIXEL MULT - [User’s Data]

or

<ESC> – ‘z’ or ‘Z’ – ‘7’ – ‘1’ or ‘2’ – ‘H’, ‘Q’, ‘M’ or ‘L’ – ‘A’ or ‘M’ – MSB – LSB – PM - [User’s Data]

Parameters

1) ESC(0x1B)

2) 'Z'(0x5A) or 'z'(0x7A) - Enables\disables annotation

3) '7'(0x37) - Selects QR Code barcode symbology

4) '1'(0x31) or '2'(0x32) - selects model, where:

'1'(0x31) --- QR Code model 1 is the original specification while

'2'(0x32) --- QR Code model 2 is an enhanced form of the symbology (default and recommended)

5) 'L', 'M', 'Q' or 'H' - QR Code Error correction level, where:

'H' --- Ultra High Reliability Level

'Q' --- High Reliability Level

'M' --- Standard Level (default)

'L' --- High Density Level

6) 'A' or 'M' - QR Code Data Input Modes <AUTO, MANUAL>, where:

'A' --- AUTO (default)

21

Page 28

'M' --- MANUAL

If you specify AUTO you do not need to specify the character mode.

If you specify MANUAL you will need to specify the character mode.

7) 0x00(NULL)-0xFF - MSB for a message length parameter

8) 0x00(NULL)-0xFF - LSB for a message length parameter

Total Message Length = (MSB * 256) + LSB

9) '0'(0x30) - '4'(0x34) - Pixel multiplier. '2' - (default)

Multiplication factor = 2^provided value. For Example: '0' -> 2^0=1, '1' -> 2^1=2, '2' -> 2^2=4, '3' -> 2^3=8 and '4' ->

2^4=16

10) 'N', 'A', 'B' or 'K' - Character mode(for MANUAL mode only), where:

'N' --- Numeric

'A' --- Alphanumeric (default)

'B' --- Binary

'K' --- Kanji

11) Data string

Example: The following escape commands encode the data “12345678”. Due to space limitation CR LF are not shown

Escape Sequence:

<ESC> ‘Z’ ‘7’ ‘2’ ‘M’ ‘A’ <NUL> <FS> ‘2’ ‘h’ ‘t’ ‘t’ ‘p’ ‘:’ ‘/’ ‘/’ ‘w’ ‘w’ ‘w’ ‘.’ ‘d’ ‘a’ ‘t’ ‘a’ ‘m’ ‘a’ ‘x’ ‘–‘ ‘o’ ‘n’ ‘e’ ‘i’ ‘l’ ‘.’ ‘c’ ‘o’ ‘m’

Hexadecimal:

1b 5a 37 32 4d 4

1 0 1c 32 68 74 74 70 3a 2f 2f 7777772e646174616d6178 2d 6f 6e 65 696c2e636f 6d

Decimal:

1

1

1

27 90 55 50 77 6

5 0 28 50

0

4

1

6

1

1

1

6

2 58 4747

1

1

1

1

1

1

1

1

0

1

9

9

946

097

697

PDF 417 Specifications

Description

Character set

Elements per

symbol

Character/symbol

Error correction

PDF417 Command Structure:

<ESC> – ‘z’ – ‘9’ – CM – SL – SW – SH – EW – EH – MSB – LSB – [User’s Data]

Parameters

CM: Compaction Mode. Select a mode to encode the user’s data

Each PDF 417 symbol character consists of a stack of vertically aligned rows between 3 and 90. Each

row includes a start and a stop pattern, left and right row indicators and a maximum of 30 symbol

characters. The symbol shall include a quite zone on all four sides

All ASCII and extended characters, 8-Bit binary data and up to 811,800 different character sets

Height: Variable (3 to 90 rows) and Width: Variable (90X to 583X)

1850 text characters

2 to 512

1

0

997

1

2

045

1

1

1

1

1

0

1

0

1

1

0

5

1

0

84699

1

1

1

0

1

9

22

Page 29

Compaction Mode Description Encoding Capability

‘0’ (Future Use) Byte Compaction Mode (BC) All characters, (0-255)

‘1’ (Recommended) Text Compaction Mode (TC) ASCII only, (0-127) + Shift to BC Mode is implemented.

‘2’ (Future Use) Numeric Compaction Mode (NC) Digits Only, (‘0’-‘9’)

A’ (Future Use) AUTO (combinations of all modes) Mix of three compaction modes

SL: Security Level byte. This can be any digit from ‘0’ to ‘8’. Set the value of the Security Level based on

the number of user’s data to be encoded

Security Level # Error-Check Code Words

‘0’ 2

‘1’ 4

‘2’ (recommended)

‘3’ 16

‘4’ 32

‘5’ 64

‘6’ 128

‘7’ 256

‘8’ 512

8

SW: Symbol Width byte. This is the total width length of the printed PDF417 symbol. The user may specify any value here,

and the printer will calculate the actual width of the symbol & it will update this value again (Future Use).

Recommended Value: ‘0’ or 0x30

SH: Symbol Height byte. This is the total height length of the printed PDF417 symbol. The user may specify any value

here, and the printer will calculate the actual width of the symbol & it will update this value again (Future Use).

Recommended Value: ‘0’ or 0x30

EW: Element Width byte. This is the width length of a single element in the PDF417 symbol, that is, bar/space width. Can

be set to ‘1’ or ‘2’

Element Width Value Length in mil

‘1’ 4.9 mil

‘2’ (recommended)

9.8 mil

EH: Element Height byte. This is the height length of a single element in the PDf417 symbol, that is, bar/space

height. A value between 0x03 to 0x0A can be used. Recommended Value: 0x06

MSB: Most Significant Byte: This byte represents the most significant byte of how many bytes to encode of User’s

Data. Maximum is 06 in hex, that is, MSB = 06h (max).

LSB: Least Significant Byte: This byte represents the least significant byte of how many bytes to encode of user’s

Data.

User’s data: Data to be encoded in the barcode

Total number of user’s data that can be encode is [MSB][LSB] = 0x06B8 = 1720 bytes, that is, only alphanumeric with

security level set to its minimum value.

Setting the security level to a higher value, will result in less user data to be encoded, since the total number of code

words that can fit in a PDF417 symbol are 929, and if security level is set to ‘8’, then already 512 error code words are

occupied in the symbol, and (929-512 = 417), so only about (417*2) alphanumeric data can be encoded with security

level ‘8’.

If any parameter in the command line does not match the spec in this document, then an error message “Invalid

Barcode” will be sent out from the printer’s serial port.

23

Page 30

Example: The following escape commands encode the data “12345678”. Due to space limitation CR LF are not shown

Escape Sequence:

ESC z 9 1 2 0 0 2 6 0 8 1 2 3 4 5 6 7 8

Hexadecimal :

1B 7A 39 31 32 30 30 32 06 00 08 31 32 33 34 35 36 37 38

Decimal:

27 122 57 49 50 48 48 50 6 0 8 49 50 51 52 53 54 55 56

Barcode Height Multiplier ESC z h n

This command allows the user to change the height of a selected barcode using a multiplier with values 1 < n < 18

(HEX values). The multiplier command can be sent prior to or after the Print Barcode sequence (ESC z t n h data CR

LF)

Example:

The sequence below prints CODE39 barcode first of a height of 50 dots and then sets the new height to 3 x 50 dots.

To print CODE-39 of height 150 dots using the multiplier command send steps 1, 2, in the order below.

Barcode Height Multiplier

Escape Sequence: ESC z h 3

Hexadecimal: 1B 7A 68 03

Decimal: 27 122 104 3

Printing Barcode:

Escape Sequence: Esc Z 1 7 2 C O D E - 3 9 CR LF

Hexadecimal: 1B 5A 31 07 32 43 4F 44 45 2D 33 39 0D 0A

Decimal: 27 90 49 7 50 67 79 68 69 45 51 57 13 10

Graphics

The printer uses a single line thermal print head with elements spaced at 0.125mm. The 8-bit graphic commands

enable control of each heating element of the print head. The commands also advance the paper in increments of

0.125mm. The number of heating elements can vary according to your printer model. Refer to the printer’s User’s Guide

for specific information.

To select the 8-bit graphic mode, the user application must issue the ESC V command. After that, the user application

must send two bytes to indicate the number of the graphic lines desired, followed with a packet of 72 bytes for each

graphic line. The printer prints the graphic line and advances to the next line automatically.

8-Bit Graphics ESC V n1 n2 data

8-bit Graphic mode is selected using the ESC V command. <n1> and <n2> is a 16 bit integer indicating the number of

graphic lines of 72 characters each to be received. Valid Graphic character sets range from 0x00 to 0xFF Hex using bits

0-7

To achieve optimized smooth printing and to extend battery life when printing graphics, a print buffer is employed. The

printer buffer accumulates a specific amount of data before actually printing the graphic data.

24

Page 31

The following 8-bit graphic command is used to print a single line of graphic

Escape Sequence: ESC V SOH NUL 72 bytes of data

Hexadecimal: 1B 56 01 00 72 bytes of data

Decimal: 27 86 1 0 72 bytes of data

8 Bit Compressed Graphics ESC v height width counter data [c data] [c data] …

This command differs from the 8 Bit Graphics command described above by reducing the number of bits (bytes) that

have to be sent to the printer. This allows for faster data transfer between the host computer and the printer.

Graphic String Component Function

height

(# of lines)

width

(# of bytes in each line)

counter

r (# of lines)

An eight bit value representing the number of dot-lines contained in the following data set

An eight bit value representing the number of bytes to be contained in each dot-line of the following

data set

An eight bit value which describes how the following data will be processed

For Signed

Values

For Unsigned

Values

{127 ≥ Counter ≥ 0} Process the next (Counter + 1) bytes of data as 8 bit

graphics.

{0 > Counter ≥ -128} Repeat the next single byte of data ((-Counter) + 1) times.

{127 ≥ Counter ≥ 0} Process the next (Counter+1) bytes of data as 8 bit graphics

{128 ≥ Counter ≤ 255} Repeat the next Singe byte of data, (( 256 – Counter)+1)

times

Example: Compressed graphic

The following graphics data is to be printed:

25

Page 32

This data may be represented in hexadecimal:

0x55 0x55 0x00 0x00 0xAA 0x11

0x55 0x00 0x55 0x55 0x55 0x55

The RLE compressed graphics command:

ESC ‘v’ height width

DEC 27 118 2 6 255 85 255 0 3 170 17 85 0 253 85

HEX 0x1B 0x76 0x02 0x06 0xFF 0x55 0xFF 0x00 0x03 0xAA 0x11 0x55 0x00 0xFD 0x55

counter data…

Printer Controls – Data Processing

The printer can be operated in two modes, Online and Buffer mode. In online mode, the characters are printed as they are

received. In buffer mode, the characters received are stored in the print buffer and printed upon receipt of the EOT character

(^D). Also if the printer is in Buffer Mode and the print buffer is full, the printer will start printing but will remain in the Buffer Mode

until the Online Mode command is sent to the printer.

Enable Buffer Mode ESC P $

This command selects the printer buffer mode.

Escape Sequence: ESC P $

Hexadecimal: 1B 50 24

Decimal: 27 80 36

Disable Buffer Mode (Select Online Mode) ESC P #

This command disables the printer buffer mode and selects the online mode. The online mode is the default mode of operation

of the printer.

Escape Sequence: ESC P #

Hexadecimal: 1B 50 23

Decimal: 27 80 35

26

Page 33

Print Buffer Contents (Buffer Mode) EOT

This command allows the printer to process all of the commands stored in the printer buffer. This command is valid only when

the printer is in the buffer mode.

Control Code: EOT

Hexadecimal: 04

Decimal 04

Enable EOT Control Character Transmission (Currently Not Available) ESC P +

When enabled, the printer transmits the EOT command character when the print buffer is empty. The End Of Text (EOT) control

character is transmitted once when the printer buffer is empty.

Escape Sequence: ESC P +

Hexadecimal: 1B 50 2B

Decimal: 27 80 43

Disable EOT Control Character Transmission (Currently Not Available) ESC P –

This command disables the EOT control character transmission. Therefore, the control character EOT is not transmitted when

the printer buffer is empty

Escape Sequence: ESC P Hexadecimal: 1B 50 2D

Decimal: 27 80 45

Printer Controls – Printed Output Adjust

Print Contrast ESC P n

This command sets the printer level of contrast or darkness of the printer.

The parameter n is the level of contrast. 1 ≤ n ≤ 9.

The printed text or graphics contrast depends on the type of thermal paper used, the printer battery voltage and the

printer contrast setting (selected by the host application).

The table below specifies recommended n values according to the media used.

Paper type Low Medium High

P390 1 2 (*) 3

P300 4 5 6

Reserved (currently P300) 7 8 9

* The printer defaults to a contrast of ‘2’.

Note that the print speed and power consumption is affected by the contrast setting.

Example: The following escape sequence set the printer contrast to “7”.

Escape Sequence: ESC P 7

Hexadecimal: 1B 50 37

Decimal: 27 80 55

27

Page 34

Printer Controls - Reset

Cancel CAN

This command deletes the entire printer buffer and resets the printer to the power-up default values.

Control Code: CAN

Hexadecimal: 18

Decimal: 24

Reset printer and load default setup ESC @

This command initializes all programmable attributes to factory default values. Custom programming, present in flash memory,

will be restored as well, overriding the factory defaults.

Note: This command does not clear the print buffer! Use the Cancel (CAN) command to clear the buffer.

This command will not restore any changes that were burned into the flash memory such as: fonts, logos, default power up

message or hardware information message. User programmable printer attributes and their factory defaults are shown in the

table below:

Attribute Factory Default

Font Courier 3

Character set International

Underline Disabled

Bold Disabled

Reverse Printing (White on Black) Disabled

Double Width Disabled

Double Height Disabled

Line spacing 3 dots

Form Feed Length 2030 dots

Vertical Tab distance 203 dots

Horizontal Tab distance 100 dots

Printing direction Left-to-right

Contrast 2

Sensor Sensitivity 255

Auto Power Down time 99 seconds

Printer Controls – Power

Auto Power Down Command ESC M n m 0 CR

This command configures the printer Auto power-down timer.

In order to conserve battery life, the printer features an auto power down timer. If the printer is in the AUTO POWER

DOWN MODE, the power down timer defaults to 99 seconds on initial power up. Refer to the printer User Manual for

appropriate dip-switch positions.

The auto power down timer may be set or disabled by sending recognized command strings. The auto power down is

re-started upon every character received.

The auto power down timer may be disabled by activating the <RTS> input line, or setting the auto power down timer to

zero, the printer lowers the CTS output line and transmits AUXOFF followed by XOFF before power down. On power

down the timer reverts to its default settings.

The parameters n1 and n2 may be set to ‘0’ through ‘9’.

28

Page 35

Example 1: The command Esc M 0 0 0 CR Disables the power out timer

Example 2: The command Esc M 9 9 0 CR Sets the timer to 99 seconds

Note that spaces are not part of the command

Extended Auto Power Down Command ESC M HH MM SS 0 CR

The ‘Set Auto Power Down’ command allows the user to program the printer to automatically shut down after a certain

length of inactivity. This command accepts the following formats: (1) seconds, (2) minutes and seconds, or (3) hours,

minutes and seconds. When used in conjunction with the Default Power-Up Setup command, this command will allow

for the power down timer value to be saved permanently in Flash.

The following table details the available formats for this command:

Command String Printer Response

Esc–‘M’–‘S1’ –‘S2’–‘0’–CR Sets the printer Auto power down timer to S1S2

seconds

Esc–‘M’–‘M1’–‘M2’–‘S1’ –‘S2’–‘0’–CR Sets the printer Auto power down timer to M1M2

minutes S

Esc–‘M’–‘H1’–‘H2’–‘M1’–‘M2’–‘S1’ –‘S2’–‘0’–CR Sets the printer Auto power down timer to H1H2

hours M

Here, H

, M1M2 and S1S2 are two decimal characters that denote hours, minutes and seconds respectively. Values

1H2

range from ‘00’ to ‘99’ with values over 59 being carried over. Up to 18 hours may be specified. The CR character at the

end of the command is mandatory.

Example 1: This escape sequence sets the Auto power down timer to 54 seconds

Escape Sequence: ESC M 5 4 0 CR

Hexadecimal: 1B 4D 35 34 30 0C

Decimal: 27 77 53 52 48 13

Example 2: This escape sequence sets the Auto power down timer to 1 hour 16 minutes 54 seconds. Note that 76

minutes was converted to 1 hour 16 minutes.

Escape Sequence: ESC M 7 6 5 4 0 CR

Hexadecimal: 1B 4D 37 36 35 34 30 0C

Decimal: 27 77 55 54 53 52 48 13

Example 3: This escape sequence sets the Auto power down timer to 18 hours. Note that 98 hours got truncated to 18

hours

Escape Sequence: ESC M 9 8 7 6 5 4 0 CR

Hexadecimal: 1B 4D 39 38 37 36 35 34 30 0C

Decimal: 27 77 57 56 55 54 53 52 48 13

seconds

1S2

minutes S1S2 seconds

1M2

29

Page 36

Printer Status Commands

Query Print Buffer & Timer-MCR Status STX

This command will cause the printer to print the battery status

Printer Response

Print Buffer Status ESC B <4 ASCII digits> CR LF

Timer-MCR Status ESC M <4 ASCII digits> CR LF

Note that the first three digits of the Timer-MCR field correspond to the printer times. The last byte indicates that the

MRC track is currently activated in the printer.

Query Print Buffer, Battery Voltage, Timer-MCR & Print Head Temperature SYN

This command will cause the printer to send the following information to the host:

Printer Response

Print Buffer Status ESC B <4 ASCII digits> CR LF

Battery Voltage Status ESC V <4 ASCII digits> CR LF

Timer-MCR Status ESC M <4 ASCII digits> CR LF

Print Head Temperature ESC T <4 ASCII digits> CR LF

Note that the first three digits of the Timer-MCR field correspond to the printer times. The last byte indicates that the

MRC track is currently activated in the printer.

Print Battery Voltage ESC P ^

This command will enable the printer to output the battery voltage reading.

Escape Sequence: ESC P ^

Hexadecimal: 1B 50 5E

Decimal: 27 80 94

Query Printer Firmware Version ESC P (

This command will cause the printer to send the Firmware Version to the host.

Escape Sequence: ESC P (

Hexadecimal: 1B 50 28

Decimal: 27 80 40

After sending the previous command, the printer will respond with the following ASCII sequence:

ASCII Sequence: <string> CR LF

The <string> field represents the firmware version.

30

Page 37

Query Printer Model and Hardware Revision Level ESC P )

This command will cause the printer to send the hardware model to the host.

Escape Sequence: ESC P )

Hexadecimal: 1B 50 29

Decimal: 27 80 41

After sending the previous command, the printer will respond with the ASCII sequence:

ASCII Sequence:<string> CR LF

The <string> field represents the hardware model.

Magnetic Card Reader

A three track Magnetic Card Reader is an option available on the Datamax-O’Neil printers. The MCR reader is designed

to read magnetically encoded data from cards conforming to ANSI/ISO 7810, 7811 standards.

The MC reader converts the F2F encoded signals on the magnetic card, to ISO7811 compatible ASCII format and

transmits the information to the host computer or terminal. Also, the MCR can read one, two or three tracks

simultaneously and bi-directionally.

The table below summarizes the format of the data stored on each magnetic track.

Track Position

Recording Density 210 BPI 75 BPI 210 BPI

Recording Capacity 79 characters 40 characters 107 characters

Number of data bits 7 5 7

Card Thickness .76 mm +/- 0.08 mm

Track 1

ISO1 (IATA)

Track2

ISO2 (ABA)

Track3

ISO3(MINTS)

Read Magnetic Card Data ESC M n1 n2 t (CR) or ESC m n1 n2 t (CR)

This command activates the MRC reader and waits until the user swipes a card (or until the timer times out). The

<n1><n2> parameters are used to set the MC reader’s timer. "01" through "99" are valid timer settings. “00” disables

the timer. The ‘t’ value indicates which MCR track number to read.

The printer aborts and transmits the time-out error message if the operator fails to swipe a card within the time period

set by the host application.

If the timer times out, the printer aborts the swipe process, transmits the timeout error message and switches off the

<READING> LED. A good magnetic card swipe automatically terminates the read process. The following table details

the possible combinations for this command:

Magnetic Card Command String Description

ESC M n1n2 1 CR (CR = Carriage Return) or

ESC m n1n2 1 CR (CR = Carriage Return)

ESC M n1n2 2 CR or ESC m n1n2 2 CR Read Track2 only

ESC M n1n2 3 CR or ESC m n1n2 3 CR Read Track3 only

ESC M n1n2 4 CR or ESC m n1n2 4 CR Read Track1 and Track2 simultaneously

ESC M n1n2 5 CR or ESC m n1n2 5 CR Read Track2 and Track3 simultaneously

ESC M n1n2 6 CR or ESC m n1n2 6 CR Read Tracks 1,2 and 3 simultaneously

Read Track1 only

31

Page 38

Example: The following escape sequence sets the timer to 99 seconds and activates the MRC to read the track #1.

Escape Sequence: ESC M 9 9 1 CR

Hexadecimal: 1B 4D 39 39 31 0C

Decimal: 27 77 57 57 49 13

or

Escape Sequence: ESC m 9 9 1 CR

Hexadecimal: 1B 6D 39 39 31 0C

Decimal: 27 109 57 57 49 13

Magnetic Card Data Output Format

The track data retrieved from a magnetic card is transmitted to the host in ISO7811 ASCII format as summarized in the

table below. The first four characters (“%/1/”) flag the track number, the track data follows the flag string terminated with

‘?’-CR-LF.

‘%;+’ are the track start characters, While ‘?’ is the end of track character.

If no data is available for a track then that data field will be empty. If an Error is encountered on any track, a single ‘E’

will be the output for that track’s data field. The ISO 7811 ASCII Format is detailed below:

Track1 Track 2 Track 3

%/1/ Data ?CRLF ;/2/ Data ?CRLF +/3/ Data ?CRLF

Magnetic Card Read Error Messages

The characters <%> and <E> preface all error messages. Following these two characters is a comma, two ASCII digits

representing the error number (01 through 99), another comma, English description of the error encountered, and finally

a CR-LF which terminates the <Error Message> string. The syntax is as follows:

<%><E>, nn, Error text in ASCII, <CR> <LF>

Where nn is the error number encountered

The printer may transmit three (3) types of Read Error messages. Refer to the table below for detailed description of the

error messages.

Error # Error Message Transmitted

05 Time-out Expired

07 Invalid Track Number

09 Cancel Request

Interfacing to the Magnetic Card Reader

This section details the software steps required to access the MC reader from a computer or a terminal.

(1) The Host selects the printer by activating the RTS input line or sending wake-up characters to the printer.

(2) The Printer Sends the XON command to the host to indicate that it is ready to receive data from the host.

(3) Once XON is received the host sends an ASCII serial command string to enable the magnetic card reader (e.g. Escm004-cr). The printer switches on the GREEN <READY> LED.

(4) Once the operator swipes the magnetic card, the printer transmits, in ASCII format, the track information found on

the magnetic card.

A good read automatically switches off the MC reader and the <READY> LED.

(5) The <READY> LED illuminates RED if an error is encountered while reading the magnetic card.

The printer transmits a timeout error message if the operator fails to swipe a card in the time period set by the host

application.

32

Page 39

Cancel Magnetic Card Data Read Command ESC C

This command cancels the MCR read process. The printer returns to online operation mode.

Escape Sequence: ESC C

Hexadecimal: 1B 43

Decimal: 27 67

Note that after executing this command the printer will send the message “, 09, Cancel Request” to the host.

Black Mark Sensing Control Commands

Set Paper-Out Sensitivity ESC Q Q n CR

This command sets the paper-out sensor sensitivity level. 0 ≤ n ≤ 255.

This command sets the number of 0.125mm dot rows that the printer can advance paper before the sensor detects an

out of paper error. The length of the paper sensitivity must be larger than the length of the black mark on the media to

avoid paper out error.

The value selected for the sensitivity is dependent upon the height of the pre-printed black mark located on the label or

form stock. The default power-on value n is 255 (0xFF).

Example: The following escape sequence sets the paper sensitivity to 6.25mm (50*0.125)

Escape Sequence: ESC Q Q 50

Hexadecimal: 1B 51 51 32

Decimal: 27 81 81 50

Enable Black Mark Reporting ESC Q R CR

This command enables the printer to send reporting messages to the host. Refer to “Black Mark Found” and “Black

Mark not found” commands for details of the messages that are activated.

Escape Sequence: ESC Q R CR

Hexadecimal: 1B 51 52 0D

Decimal: 27 81 82 13

Disable Black Mark Reporting ESC Q r CR

Prevents the printer from sending report messages to the host. Refer to “Black Mark Found” and “Black Mark not found”

commands for details of the messages that are deactivated

Escape Sequence: ESC Q r CR

Hexadecimal: 1B 51 72 0D

Decimal: 27 81 114 13

33

Page 40

Black Mark Sensing Command Mode

Forward Seek Black Mark ESC Q F n CR

This command sets the printer to black mark seek mode using a forward feed operation. The value of forward feed is

determined by the user in dot lines (n) where 0 ≤ n ≤ 255 dots. Each dot line corresponds to 0.250mm. If the black

mark is found, the printer responds with the command “Black Mark Found”, otherwise the printer responds with the

command “Black Mark not Found”. Both escape sequence responses are described below.

Example: The following escape sequence advances the paper 80 dot lines looking for a Black Mark.

Escape Sequence: ESC Q F P CR

Hexadecimal: 1B 51 46 50 0D

Decimal: 27 81 70 80 13

Reverse Seek Black Mark ESC Q B n CR

This command causes the printer to seek black mark using backward feed until n dot line feeds have been processed;

each dot line feed is 0.25mm.

Not the using this command can cause a paper jam since the paper is advanced in reverse mode. The results may vary

depending on the media used in the printer.

Black Mark Found (Response from printer) ESC Q ? ? n1, n2

This message is sent to the host and indicates that a black mark has been found. The numbers n1 and n2 are the high

and the low nibble, respectively, describing how many (0.25mm) dot lines were required to find black mark.

Black Mark Not Found (Response from Printer) ESC Q 0 0 n1 n2

This message is sent to the host and indicates that a black mark has not been found. The numbers n1 and n2 are the

high and the low nibble, respectively, describing how many (0.25mm) dot lines were processed before reporting black

mark not found.

Black Mark Sensing Auto Mode

Enable Front Black Mark Sensor ESC Q f e CR

This command will enable the printer’s front black mark sensor and automatically disable the BACK

side sensor.

Escape Sequence: ESC Q f e CR

Hexadecimal: 1B 51 66 65 0D

Decimal: 27 81 102 101 13

Disable Front Black Mark Sensor ESC Q f d CR

This command disables the printer’s front black mark sensor.

Escape Sequence: ESC Q f d CR

Hexadecimal: 1B 51 66 64 0D

Decimal: 27 81 102 100 13

34

Page 41

Enable Back Black Mark Sensor ESC Q b e CR

This command will cause the printer to enable the back black mark sensor and automatically disables the front side

sensor.

Escape Sequence: ESC Q b e CR

Hexadecimal: 1B 51 62 65 0D

Decimal: 27 81 98 101 13

Disable Back Black Mark Sensor ESC Q b d CR

This command will disable the printer’s back black mark sensor.

Escape Sequence: ESC Q b d CR

Hexadecimal: 1B 51 62 64 0D

Decimal: 27 81 98 100 13

Disable Both Front and Back Black Mark Sensors ESC Q f x CR or ESC Q b x CR

This command disables the printer’s front and back black mark sensors.

Escape Sequence: ESC Q f x CR

Hexadecimal: 1B 51 66 78 0D

Decimal: 27 81 102 120 13

or

This command disables the printer’s front and back black mark sensors.

Escape Sequence: ESC Q b x CR

Hexadecimal: 1B 51 66 78 0D

Decimal: 27 81 102 120 13

Printed Receipt/Label Presenter Positive Adjust ESC Q D + n

This command will cause the printer to advance the paper to the distance specified by n dots after a form or label has

been printed.

Example: The following escape sequence will feed the paper 112 dots.

Escape Sequence: ESC Q D + 112

Hexadecimal: 1B 51 44 2B 70

Decimal: 27 81 68 43 112

Printed Receipt/Label Presenter Positive Adjust ESC Q P n

This command is identical to Esc Q D + n command and will cause the printer to advance the paper to the distance

specified by n dots after a form or label has been printed.

Example: The following escape sequence will feed the paper 112 dots.

Escape Sequence: ESC Q P 112

Hexadecimal: 1B 51 50 70

Decimal: 27 81 80 112

35

Page 42

Printed Receipt/Label Presenter Negative Adjust (*) ESC Q D – n

This command will cause the printer to move the paper backwards to a distance specified by n dots after a form or label

has been printed.