Page 1

CONTROLS

Instruction Manual

Field Programmable Closed Loop DC Speed Control

LT61 (0508)

P.O. Box 10

5000 W. 106th Street

MDP CONTROL SERIES

Zionsville, Indiana 46077

www.dartcontrols.com

Phone (317) 873-5211

Fax (317) 873-1105

A-5-3241J

Page 2

Quick Jump

What models and options are available?

See page 3.

Looking for detailed specifi cations?

See page 3 & 4.

Want to get started fast?

See basic electrical hook-up details on page 8.

See mechanical installation details on page 4 & 5.

See some sample applications starting on page 24.

Need Help?

See troubleshooting on page 29.

Warranty

Dart Controls, Inc. (DCI) warrants its products to be free from defects in material and workmanship. The exclusive remedy

for this warranty is DCI factory replacement of any part or parts of such product which shall within 12 months after delivery

to the purchaser be returned to DCI factory with all transportation charges prepaid and which DCI determines to its satisfaction to be defective. This warranty shall not extend to defects in assembly by other than DCI or to any article which has

been repaired or altered by other than DCI or to any article which DCI determines has been subjected to improper use. DCI

assumes no responsibility for the design characteristics of any unit or its operation in any circuit or assembly. This warranty is

in lieu of all other warranties, express or implied; all other liabilities or obligations on the part of DCI, including consequential

damages, are hereby expressly excluded.

NOTE: Carefully check the control for shipping damage. Report any damage to the carrier immediately. Do not attempt to

operate the drive if visible damage is evident to either the circuit or to the electronic components.

All information contained in this manual is intended to be correct, however information and data in this manual are subject

to change without notice. DCI makes no warranty of any kind with regard to this information or data. Further, DCI is not

responsible for any omissions or errors or consequential damage caused by the user of the product. DCI reserves the right

to make manufacturing changes which may not be included in this manual.

WARNING

Improper installation or operation of this control may cause injury to personnel or control failure. The control must

be installed in accordance with local, state, and national safety codes. Make certain that the power supply is disconnected before attempting to service or remove any components!!! If the power disconnect point is out of sight,

lock it in disconnected position and tag to prevent unexpected application of power. Only a qualifi ed electrician or

service personnel should perform any electrical troubleshooting or maintenance. At no time should circuit continuity be checked by shorting terminals with a screwdriver or other metal device.

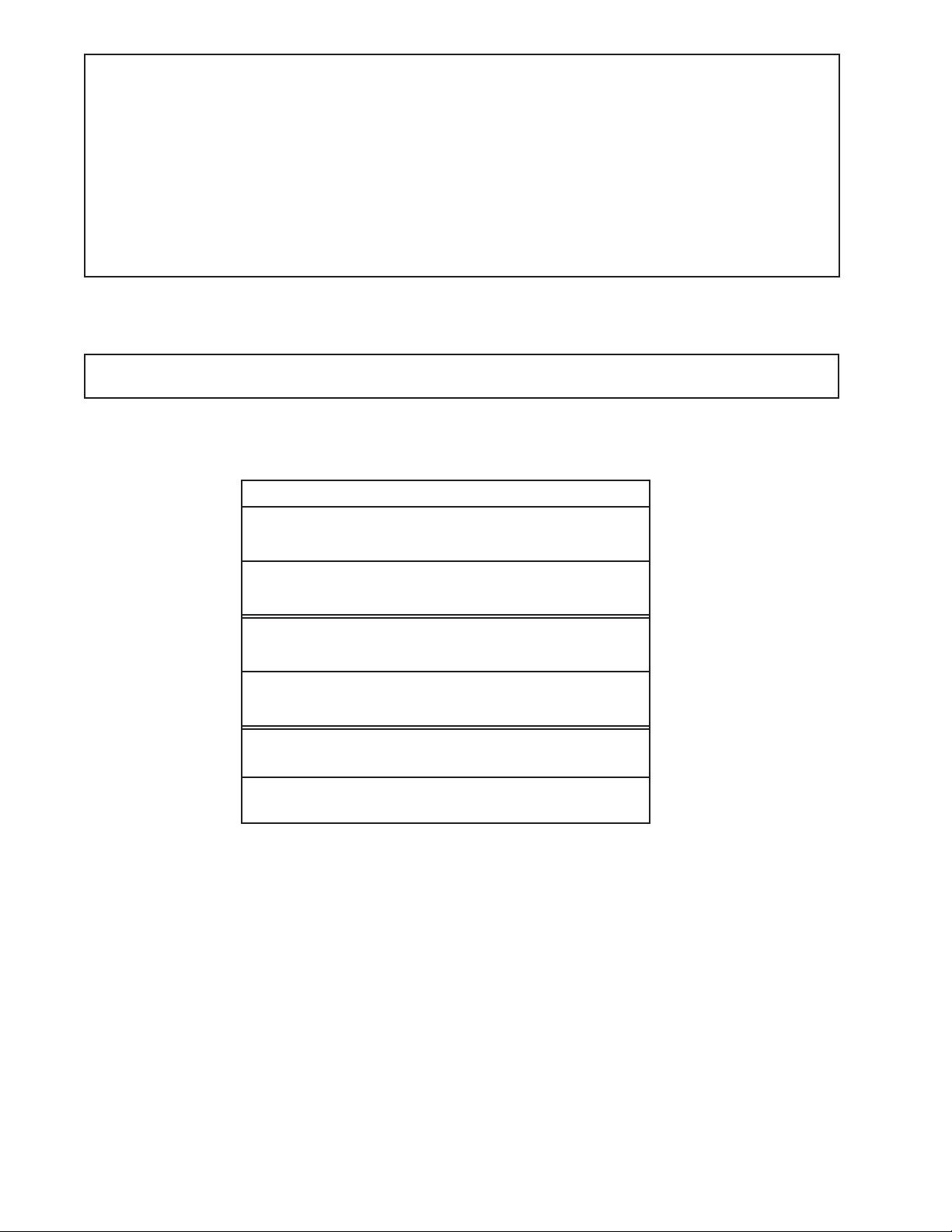

Page 3

Table of Contents

Introduction ....................................................................................................................................... 2

General Features .............................................................................................................................. 2

Models & Options ............................................................................................................................. 3

Model Table ................................................................................................................................... 3

Available Options .......................................................................................................................... 3

Recommended Accessories ......................................................................................................... 3

Agency Approvals ......................................................................................................................... 3

Specifi cations ................................................................................................................................... 3

Electrical ....................................................................................................................................... 3

Mechanical ................................................................................................................................... 4

Environmental ............................................................................................................................... 4

Dimension Chart ........................................................................................................................... 4

Installation and Mechanical Dimensions ....................................................................................... 5

Exploded Panel View .................................................................................................................... 5

Cut-out and Mounting Dimensions ............................................................................................... 6

PU-E Series Pickup Installation .................................................................................................... 7

Electrical Installation & Diagrams ................................................................................................... 8

P1 Terminal Block Hook-Up Diagrams .......................................................................................... 8

P1 Terminal Block Descriptions .................................................................................................... 9

-1 Option Wiring .......................................................................................................................... 10

Basic Operating Instructions ........................................................................................................ 10

Control Algorithm Discussion ..................................................................................................... 10

Pulse-Accumulation Loop PI Tuning .......................................................................................... 10

Master (Rate and Time) and Follower (Ratio) Modes Explained ................................................ 11

Visual Reference ........................................................................................................................ 12

How to Change a Parameter's Value (The Short Story) ............................................................. 12

Operating the User Interface (The Long Story) .......................................................................... 12

Detailed Confi guration Instructions ............................................................................................. 13

Default Confi guration .................................................................................................................. 13

Resetting the Unit to Factory Defaults ........................................................................................ 13

JP1 (Program Enable Jumper) .................................................................................................. 13

Software Parameters .................................................................................................................. 14

Parameter Descriptions .............................................................................................................. 16

Application Examples .................................................................................................................... 24

Pump Controller with Audible and Visual Alarm ......................................................................... 24

Conveyor Oven Controller with Two Preset Process Times ........................................................ 25

Synchronized Conveyor Controller with Jog Switch ................................................................... 26

Troubleshooting .............................................................................................................................. 29

Technical Support Options .......................................................................................................... 29

What's Special About www.dartcontrols.com? ........................................................................... 29

1

Page 4

Introduction

The MDP series motor controls are compact, microprocessor-based units capable of being either fi eld

or factory confi gured for a number of industry's motion control needs. These controls are designed

around a pulse-accumulation PI algorithm. They can be easily confi gured to operate as a digital speed

controller, time-based process controller, or a ratiometric follower controller in master-slave systems.

Utilizing Dart's new modular bus design techniques, the MDP series is ideal for volume OEM applications

requiring specialized inputs and outputs. Contact Dart Controls' Sales Department for details. This

fl exibility makes the MDP series ideal for applications such as:

Water and Waste Treatment Systems

Conveyor Oven Controllers

Synchronized Conveyor Lines

Its durable 1/8 and 1/4 DIN aluminum housings can be easily mounted in a panel or control cabinet.

New optional pluggable terminal block allows the installer to quickly install or replace units without the

hassle of physically removing and reattaching wires. The units can be ordered with either standard

European-style terminal block or optional “pluggable” connector.

General Features

- Microprocessor-based design combines the ultimate in responsiveness and accuracy in one package

- Digital closed-loop algorithm ensures long-term accuracy of +/-1/2 RPM of set speed or equiv.

- Non-volatile memory stores adjustable parameters even when power has been removed

- Factory or fi eld programmable via front-panel keypad

- Adjustable parameters include min, max, accel, decel, display options, alarm options, etc.

- Internal program-enable jumper selectively prevents tampering with unit’s confi guration

- Universal power supply accepts line voltages inputs from 85-265VAC @ 50-60Hz without switches

or jumpers. The unit automatically adjusts as needed.

- Transient voltage protection prolongs unit's life in harsh industrial environments

- Compatible with a variety of signal input types including: Hall-Effect Pickups, Photoelectric, TTL, etc.

Note: Open collector devices must be capable of sinking 3mA.

- Self-contained power supply for external sensor, limited to 5V @ 50mA

- Programmable alarm output with Form C contacts rated to 250VAC @ 5A

- Flexible user inputs support inhibit, emergency stop, and jog functionality.

- 1/8 and 1/4 DIN durable aluminum housing for panel mounting the MD10P and MD3P, respectively.

- Large 4 digit, 1/2” LED display

- G.E. Lexan membrane and gasket (which are included) meet NEMA 4X standards when used with

NEMA 4X enclosures

- European terminal block or pluggable terminal block available

- Recognized, fi le #E78180 (MD10P, MD3P & MD3E)

- Wide operating ambient temperature range of -10C to 45C (14F to 113F)

- Multiple operating modes including:

• Master, Rate Mode – Controls in rate unit such as RPM, Gallons per Second, etc.

• Master, Time Mode – Controls in time unit such as HH:MM, MM:SS, SS:TT, or other unit

• Follower Mode – Controls in percentage of master rate. This mode allows the MDP control to

precisely follow the actions of a master process without any long-term loss of position

2

Page 5

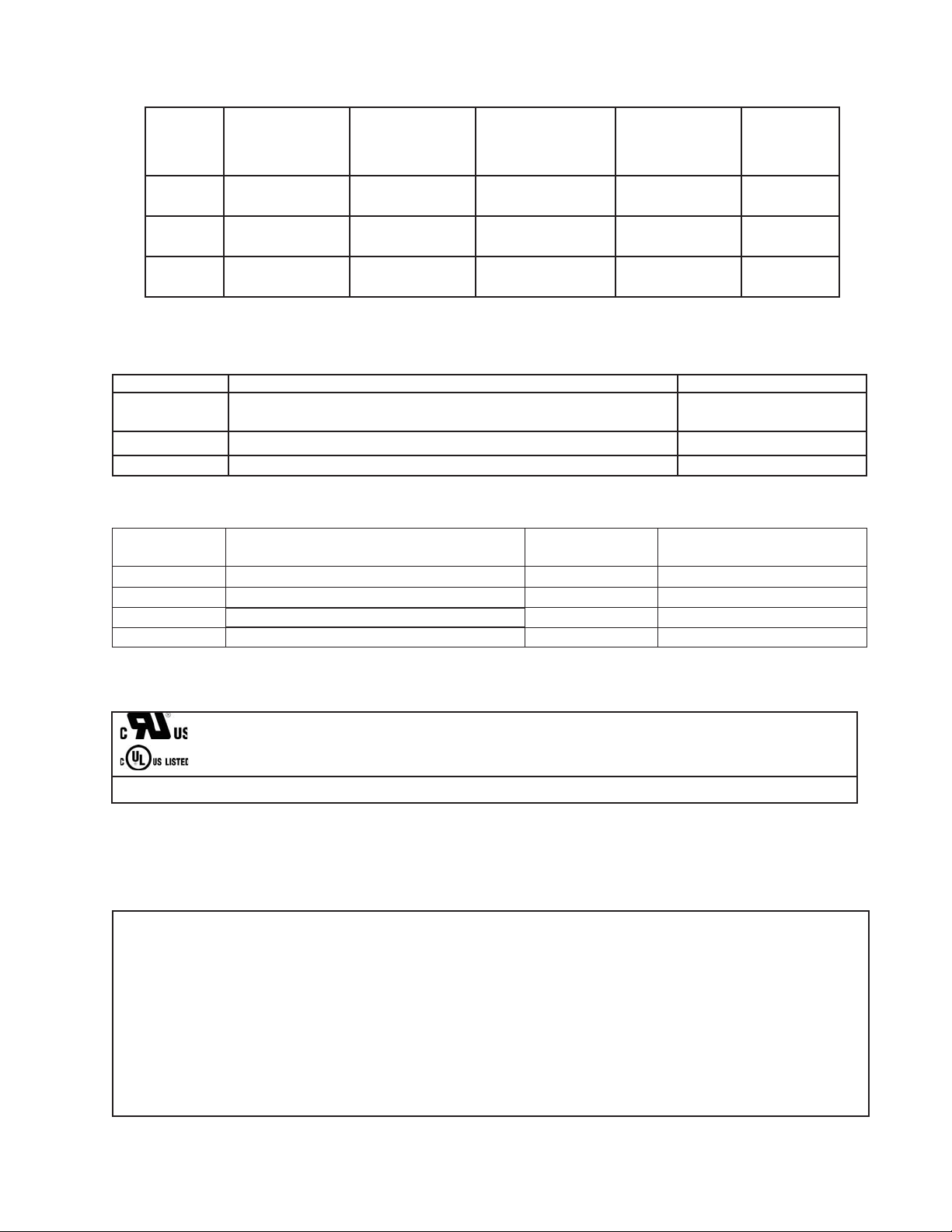

Model Table

Models & Options

Model

MD10P

MD3P 85-265VAC

MD3E 85-265VAC

Input Voltage

@ 50 - 60Hz

85-265VAC

Output Voltage

@ 120VAC

(@ 240VAC)

90VDC

(180VDC)

90VDC

(180VDC)

90VDC

(180VDC)

Max. Output H.P.

@ 120VAC

(@240VAC)

1/2

1

1

2

1

2

Max Continuous

Armature DC

Amps

5

5

10

10

10

10

Pickup or

Encoder

Required?

Yes

Yes

Yes

Available Options

Option Suffi x Description Example

-1 Expansion board which adds support for remote push button wiring via a

European-style terminal block.

-P Optional pluggable European-style terminal block

-9 Blank Lexan

MD10P-1, MD3P-1

MD10P-P, MD3P-1-P

MD10P-9

Recommended Accessories

Model Description

PU-2E Hall-Effect Pickup, Single Channel 1 1.0 – 50,000 RPM

PU-4E Hall-Effect Pickup, Single Channel 2 0.5 – 25,000 RPM

PU-20E

PU-40E Hall-Effect Pickup, Single Channel 20 0.05 – 2,500 RPM

Hall-Effect Pickup, Single Channel

Pulses per

Revolution

10 0.1 – 5,000 RPM

RPM Range When Used With

MD10P & MD3P

Agency Approvals

Recognized Component MD10P, MD3P ........................................................................................... E78180

MD3E ....................................................................................................................................................34M5

NEMA 4X ....................................................................................................................................MD10P / MD3P / MD3E

Specifi cations

Electrical

Line Input Voltage ........................................................................................................Any Voltage from 85-265 VAC

Line Input Frequency ...................................................................................................... Any Freq. from 48-62 Hertz

Signal Input Voltage Range .................................................................................. 0-5VDC to 0-24VDC square wave

Signal Input Frequency Range .................................................................................... 0 – 50,000 Pulses per Minute

(Higher frequencies are possible when using internal frequency divisor / prescaler)

Display Range ....................................................................................................................................0.001 – 99,990

Units of Operation ..................................................................................................... User Programmable, any Unit

Sensor / Pickup Power Supply ............................................................................................................... 5V @ 50mA

Isolated Alarm Relay Output Ratings ..................................................................................................250VAC @ 5A

Average Armature Output Voltage ................................................. Line Input Voltage Dependent (See model table)

Design Overload Capacity .............................................................................................................200% for 1 minute

3

Page 6

Mechanical

Display Type ................................................................................................................LED, Red, 4 Digit, ½” Height

Housing Type MD10P & MD3P (with supplied gasket) ..............................................................................NEMA 4X

MD3E NEMA 4

Connector Style (pluggable connector optional) ...................................................12-position 5mm European Style

Terminal Block Torque Setting ............................................................................................... 4.4 in. lb. Max or .5Nm

Faceplate Material .........................................................................................Polycarbonate with GE Lexan Overlay

Housing Material ........................................................................................................................................Aluminum

Length MD10P & MD3P(Required Panel Depth) ..........................................................................4.625”, 117.48mm

Faceplate Width ...........................................................................................................................4.539”, 115.29mm

Weight MD10P .............................................................................................................0.8425 lb, 13.48 oz, 382.14g

MD3P ...................................................................................................................1.52 lb, 24.32 oz, 689.44g

MD3E...................................................................................................................1.64 lb, 26.24 oz, 743.88g

Environmental

Operating Temperature Range ----------------------------------------------------------------------------- -10C to 45C (15F to 115F)

Operating Humidity Range ----------------------------------------------------------------------------------------- 95%, non-condensing

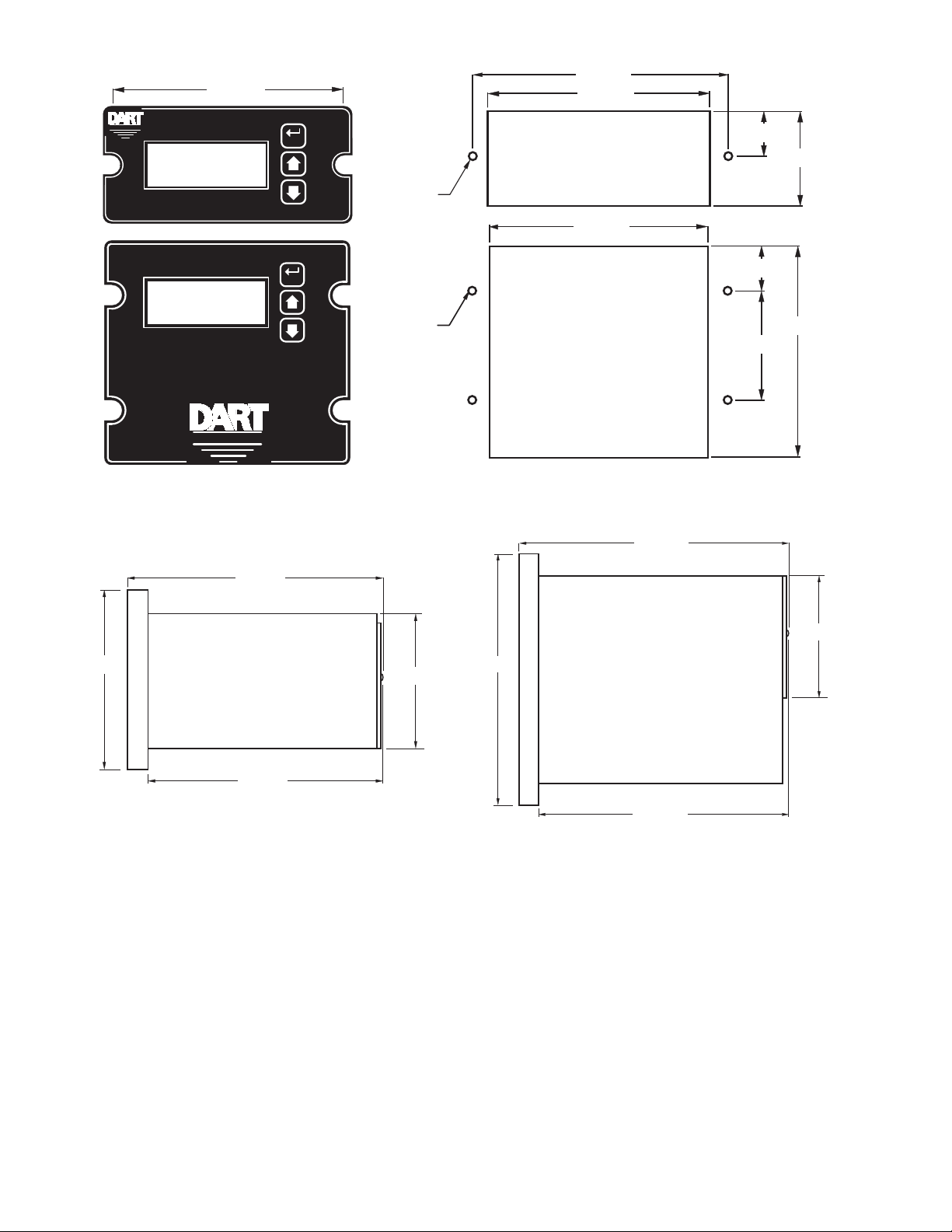

Dimension Chart

Model Width Height Depth

MD10P English (inches)

Housing 3.62 1.66 4.625

Lens 4.539 2.289 0.375

MD10P Metric (millimeters)

Housing 91.94 42.16 117.27

Lens 115.28 58.14 9.53

MD3P English (inches)

Housing 3.60 3.497 4.625

Lens 4.539 4.179 0.375

MD3P Metric (millimeters)

Housing 91.44 88.82 117.27

Lens 115.28 106.15 9.53

MD3E English (inches)

Assembly 5.53 7.40 3.90

MD3E Metric (millimeters)

Assembly 140.46 187.96 99.06

4

Page 7

Installation and Mechanical Dimensions

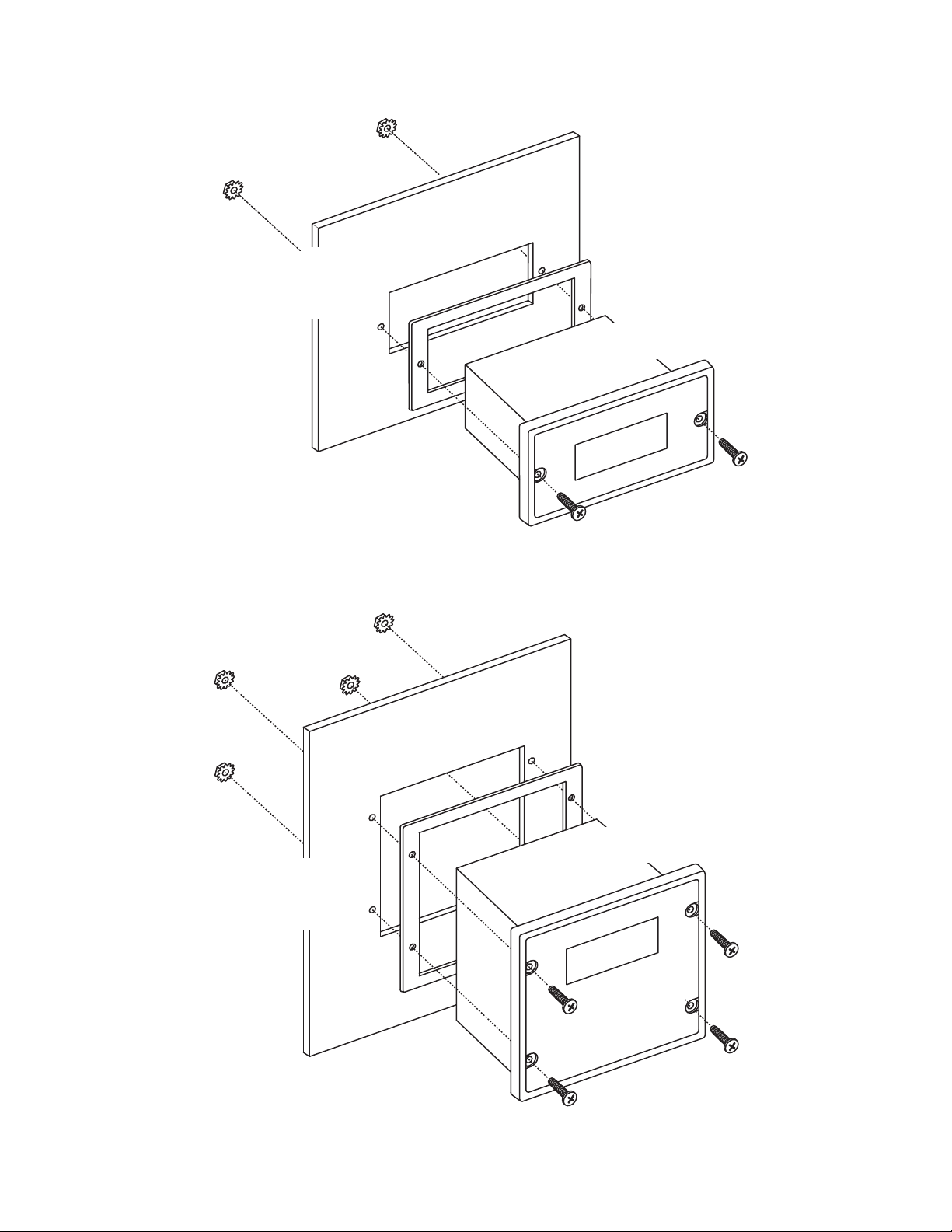

Exploded Panel View

CUSTOMER

MOUNTING PANEL

(HOLE CUT-OUT FOR CONTROL

HOUSING APPROXIMATELY

3.622" WIDE BY 1.770" HIGH)

PANEL MOUNTING GASKET

(WITH THE ADHESIVE SIDE OF

GASKET FACING THE CUSTOMER

MOUNTING PANEL)

MD10P

CONTROL

1) GASKET

2) (2) 6-32 X 3/4 PANHEAD BLACK OXIDE STAINLESS SCREWS

3) (2) #6 NUT WITH LOCKWASHER

CUSTOMER

MOUNTING PANEL

(HOLE CUT-OUT FOR CONTROL

HOUSING APPROXIMATELY

3.622" WIDE BY 3.622" HIGH)

SUPPLIED WITH EACH CONTROL:

PANEL MOUNTING GASKET

(WITH THE ADHESIVE SIDE OF

GASKET FACING THE CUSTOMER

MOUNTING PANEL)

MD3P

CONTROL

1) GASKET

2) (4) 6-32 X 3/4 PANHEAD BLACK OXIDE STAINLESS SCREWS

3) (4) #6 NUT WITH LOCKWASHER

5

SUPPLIED WITH EACH CONTROL:

Page 8

Cut-out and Mounting Dimensions

5.000"

4.625"

4.179"

1.928"

4.000"

4.000"

3.622"

CONTROLS

Ite

Ite

m

MICRO-DRIVE

MICRO-DRIVE

Tach

ValuPage

Tach

ValPage

ENTER

ENTER

MICRO-DRIVE

CONTROLS

MD10P and MD3P Dimensions

.140" x 2

.140" x 4

MD10P

HOUSING DEPTH

4.625"

PA NEL CUT-OUT

3.622

MD3P

HOUSING DEPTH

4.625"

PA NEL CUT-OUT

0.885"

1.770"

0.811"

3.622"

2.000"

2.289"

5.000"

1.656"

4.625"

6

Page 9

MD3E Mounting and Dimensions

5.530

7/32" TYP.

(4 SLOTS)

.350 DEEP

7.400

Item

CONTROLS

ValuPage

5.125 TYP.

Tach

ON

OFF

ENTER

5.500

.750

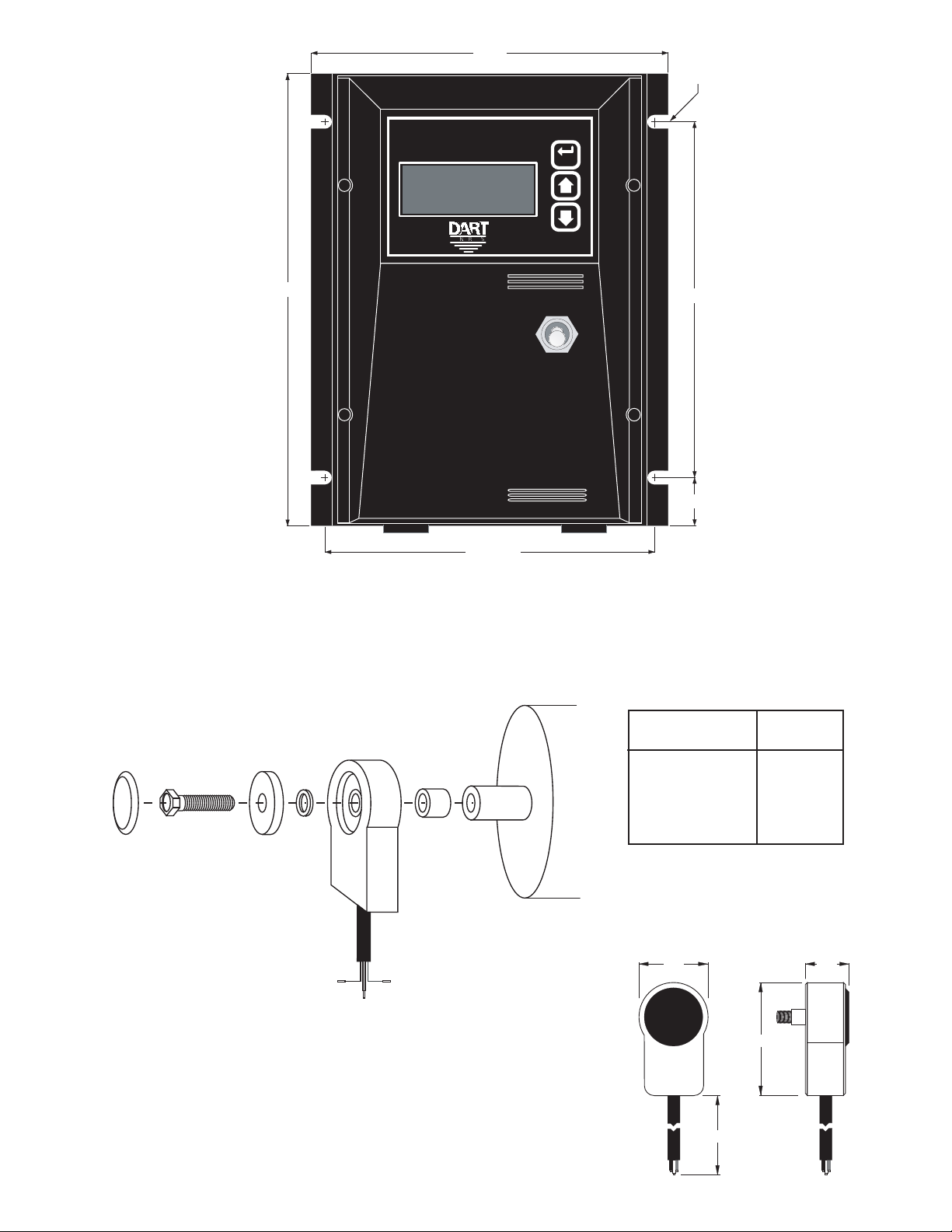

PU-E Series Pickup Installation

The PU-E series pickup is an economical way to monitor motor speed. Its patented design provides for

ease of installation in otherwise diffi cult to reach areas. The PU-E operates from a +5V power supply,

producing a 5 volt square wave whose frequency is proportional to speed. This signal is fed into the

MDP control as a speed or position reference for the microprocessor.

dust

cover

10-32

screw

magnet

disc

flat

washer

PU-E

bearing

3/16"

spacer

tapped

motor

shaft

Model

Number

PU-2E

PU-4E

PU-20E

PU-40E

Pulses per

Revolution

1

2

10

20

Dimensions

1.60 .875

2.40

signal

red wire

+5 volts

black wire

common

white wire

CAUTION:

DO NOT OVER TIGHTEN MOUNTING SCREW !!

No other mounting screws are necessary, as the cord

will keep the unit from rotating.

7

72.00

Page 10

Caution: The PU-E cord should not be grouped with other wires or cords. For applications with PU-E

wire over 6 feet long, or noisy environments, a shielded cable is recommended. Connect the shield to

the common terminal on the MDP, leaving the shield on the PU-E end fl oating.

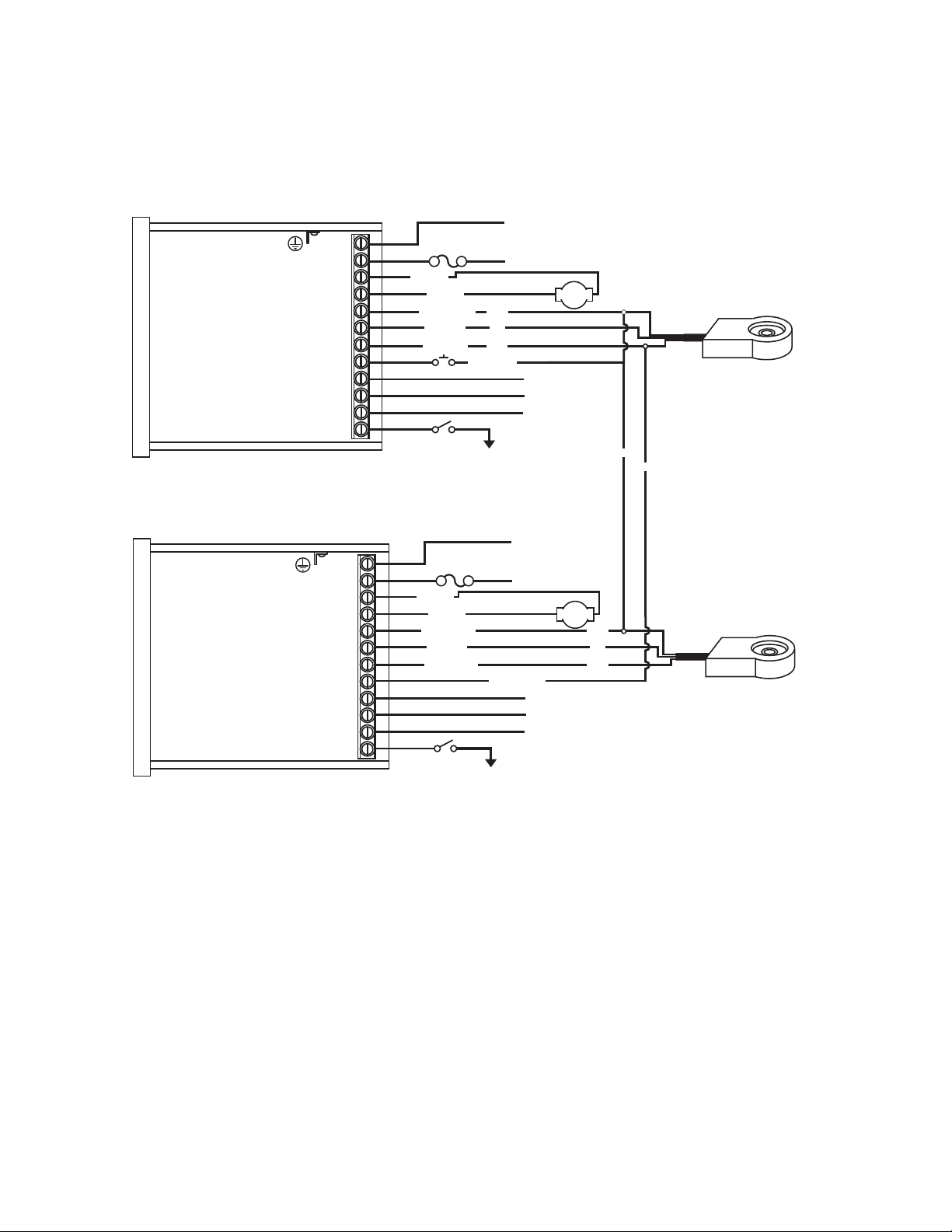

Electrical Installation & Diagrams

P1 Terminal Block Hook-Up Diagrams

MDP

MASTER

MDP

FOLLOWER

black

red

white

**

Jog Input

COM (P1-5)

SIGNAL 2

COM (P1-5)

AC INPUT

AC INPUT

Form C

Relay Output

(Programmable)

}

AC INPUT

AC INPUT

Form C

Relay Output

(Programmable)

}

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

N

L

-A

+A

COM

+5V

S1

S2

NO

C

NC

IN1

* For AC inputs utilizing two hot lines, both inputs should be

protected with appropriately sized fuses or circuit breakers.

** P1-8 & P1-12 user input may be programmed

for a number of functions. Including (jog, inhibit, etc.)

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

* For AC inputs utilizing two hot lines, both inputs should be

protected with appropriately sized fuses or circuit breakers.

** P1-8 & P1-12 user input may be programmed

for a number of functions. Including (jog, inhibit, etc.)

FUSE

MD10P = 7.5 Amp*

MD3P = 15 Amp*

-ARM

+ARM

COMMON

+5VDC

SIGNAL

Alarm Output - Normally Open

Alarm Output - Common

Alarm Output - Normally Closed

User Input 1

**INHIBIT

N

L

-A

+A

COM

+5V

S1

S2

NO

C

NC

IN1

FUSE

MD10P = 7.5 Amp*

MD3P = 15 Amp*

-ARM

+ARM

COMMON

+5VDC

SIGNAL 1

Alarm Output - Normally Open

Alarm Output - Common

Alarm Output - Normally Closed

User Input 1

**

INHIBIT

85-265VAC

}

MOTOR

}

MOTOR

85-265VAC

black

red

white

black

white

PICK-UP MOUNTED

TO MOTOR SHAFT

(Mounts on rotating

end shaft with 10-32

tapped hole, 1/2" deep)

FOLLOWER PICK-UP

MOUNTED TO

MOTOR SHAFT

(Mounts on rotating

end shaft with 10-32

tapped hole, 1/2" deep)

8

Page 11

COM

+5V

N

L

-A

+A

S1

S2

NO

C

NC

IN1

-ARM

+ARM

COMMON

+5VDC

SIGNAL

*

Jog Input

Ground Lug

AC INPUT

AC INPUT

black

red

white

Alarm Output - Normally Open

Alarm Output - Common

Alarm Output - Normally Closed

*INHIBIT

User Input 1

COM (P1-5)

85-265VAC

}

MOTOR

Form C

Relay Output

(Programmable)

}

PICK-UP MOUNTED

TO MOTOR SHAFT

(Mounts on rotating

end shaft with 10-32

tapped hole, 1/2" deep)

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

MD3E

* P1-8 & P1-12 user input may be programmed

for a number of functions. Including (jog, inhibit, etc.)

P1 Terminal Block Descriptions

P1-1 (AC / N) – For single phase AC lines connect the Neutral side of your AC line to this terminal.

For systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P1-2 (AC / L) – For single phase AC lines connect the Hot side of your AC line to this terminal. For

systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P1-3 (-A) - This is the -Armature terminal. For normal rotation of your motor you should connect

the -Armature lead of your motor to this terminal. The +Armature lead of your motor will be

connected here when a reverse directional rotation of the armature is desired.

P1-4 (+A) - This is the +Armature terminal. For normal rotation of your motor you should connect

the +Armature lead of your motor to this terminal. The -Armature lead of your motor will be

connected here when a reverse directional rotation of the armature is desired.

P1-5 (COM) – This is the common point for the control logic. The speed sensor common lead as

well as any other source needing to reference the control common will be connected to this

terminal.

P1-6 (+5V) – This is a self-contained +5VDC power supply capable of up to 50mA. The speed sensor

supply lead can be connected to this terminal for its power source.

P1-7 (S1) – This is the signal input terminal for the motor's digital pickup or encoder.

P1-8 (S2) – This input can be programmed to perform a number of advanced functions. In Follower

Mode, this input is the signal input terminal for the master's digital pickup or encoder. In Master

modes (Rate and Time), this input can be confi gured to function as an emergency stop, inhibit,

or jog command.

P1-9 (NO) – This is the normally-open contact of the user assignable relay output.

P1-10 (C) – This is the common contact of the user assignable relay.

P1-11 (NC) – This is the normally-closed contact of the user assignable relay output.

P1-12 (IN1) – This input can be programmed to perform a number of advanced functions. It can be

confi gured to function as an emergency stop, inhibit, or jog command.

9

Page 12

-1 Option Wiring

The -1 option board is a module which allows external up and down push buttons to be wired to the

unit. These buttons operate exactly like the Up and Down buttons on the user interface. This module

is commonly used to allow PLCs or hand-held pendants to operate the front-panel remotely. Wire for

the external buttons are attached via a 3mm European terminal block on the -1 option board. The

buttons are activated by shorting the terminal labeled Com to either the Up or Down terminal.

REMOTE SWITCHING

MICROPROCESSOR

DOWN UP

SERIES PC BOARD

-1 OPTION

BOARD

-3

COMMON

-2

DOWN

-1

UP

Basic Operating Instructions

Control Algorithm Discussion

The MDP series controls are based on a pulse-accumulation algorithm. The advantage to this type of

algorithm is that it allows the control to follow a master process with exceptional long-term accuracy.

The MD10P and MD3P controls have three parameters which allow the user to adjust how aggressively

the units drive the motor to achieve the target speed. These 3 parameters are as follows:

P Gain - This is the proportional gain for the control loop. In pure pulse-accumulation algorithms, there

is no loop error to base a 'P' factor on; therefore, these units must estimate error based on several

control loop factors. Those who are familiar with PID control tuning should be aware that the MD10P

and MD3P control's P Gain is somewhat different than that of standard velocity-form PID algorithms.

The P Gain is a function of instantaneous error, a measure of the difference between the target (desired)

speed and the current speed of the motor.

I Gain -This is the integral gain for the control loop. The I Gain is a function of accumulated error, a

measure of the difference between the target (desired) speed and the current speed of the motor.

Pulse Accumulation Limit - This parameter allows the user to limit the maximum number of pulses

the drive will accumulate prior to intentionally losing count and therefore long-term accuracy. See the

details for parameter 29 in the Parameter Description section.

Pulse-Accumulation Loop PI Tuning

Many applications do not require tuning of the P and I Gain parameters beyond the supplied factory

default settings. If more responsiveness is desired or if the motor oscillates an unacceptable amount when

changing speeds, it may be necessary to adjust the P and I gains to obtain optimal performance.

Increasing the P and/or I gains will cause the control to drive the motor more aggressively. Decreasing

the P and/or I gains will cause the control to perform more sluggishly. Properly tuning the P and I

gains encompasses more than independently adjusting the P and I. The ratio between the two is

very important as well. Although initial tuning can be a time-consuming task, here is a basic outline

of how to proceed:

10

Page 13

Test Procedure: Adjust the target (displayed) speed as expected during normal operation, including

testing inhibit and jog transitions if applicable.

Tuning Method:

Step 1 - Connect control to loaded motor with application's anticipated load for realistic

tuning

Step 2 - Perform test procedure

Step 3 - If control performs adequately, stop tuning and record settings

Step 4 - If control is too sluggish or takes too long to reach the target speed, then try

increasing I Gain slightly (add 250). Perform the test procedure again. Continue

increasing I Gain until motor starts to slightly oscillate or become unstable. At this

point, decrease the I Gain by 250.

Step 5 - If control is too aggressive or is causing the motor to oscillate or become unstable,

then try decreasing I Gain slightly (subtract 250). Perform the test procedure again.

Continue decreasing I Gain until motor starts to stabilize and regulate more accurately.

Step 6 - Once I is set, adjust P Gain and perform test procedure. In this control, additional P

Gain may or may not improve response or stability. Experimentation will be required.

Accel and decel settings have a small impact on PI tuning as well. Specifi cally, when accel and decel

settings are extremely fast, they can cause the control loop to perform more sluggishly. Another thing

to keep in mind is that PI tuning also affects accel and decel times. For instance, a sluggishly tuned PI

control loop may take longer than the programmed accel and decel times to reach the target; whereas,

an aggressively tuned PI control loop will reach the target faster.

Master (Rate and Time) and Follower (Ratio) Modes Explained

The MDP controls have two basic modes of operation, master and follower. In the Master modes, the

controls are capable of operating independently; whereas, in the Follower Mode, the control requires a

signal from a master to operate. The Follower Mode is used in applications which require the MDP to

closely follow a master process. For example, if a factory has ten conveyors which must be synchronized

over long periods of time, an industrial engineer could use one MDP as a master control for the fi rst

conveyor and nine MDPs as slaves or followers which would receive their speed commands from the

fi rst conveyor's master control or pickup.

In Master Rate Mode, the MDP controls the rate of the motor by tracking the motor's pickup pulses

which are applied to signal input 1 (S1). In this mode, the display indicates in rate units such as

Gallons-per-minute, feet-per-second, and RPM.

In Master Time Mode, the MDP controls the process time by tracking the motor's pickup pulses which

are applied to signal input 1 (S1). In this mode, the display indicates in time units such as HH:MM or

MM:SS, where HH is hours, MM is minutes, and SS is seconds. This mode is most-commonly used

in time-sensitive processes such as conveyor ovens and plating applications.

In Follower Mode, the MDP tracks the number of pulses which are applied to the master signal input

(S2). From these pulses, it calculates the rate of the master process. This rate is then multiplied by

the percentage which is displayed on the user interface. The display is in 0.1% of master units. For

example, 675 = 67.5 percent of master speed. A master running at 1350 RPM, would cause the

follower to run its motor at 67.5% * 1350 RPM or 911.25 RPM. Typical follower applications include

synchronized rotation, synchronized conveyors, and some web-material processes.

11

Page 14

Visual Reference

Display Window

Display Window

CONTROLS

Ite

m

MICRO-DRIVE

MICRO-DRIVE

Tac h

ValuPage

CONTROLS

ENTER

ENTER

ENTER (Select) Button

Up & Down Buttons

ENTER (Select) Button

Up & Down Buttons

Display Window

ENTER (Select) Button

Item

ValuPage

CONTROLS

Tac h

ENTER

Up & Down Buttons

How to Change a Parameter's Value (The Short Story)

1. Hold down the Enter button until Parameter-Selection Mode is entered

2. Using the Up and Down buttons, select the desired parameter number to view or edit

3. Press the Enter button to change the value of the parameter

4. Using the Up and Down buttons, change the parameter's value as desired

5. Press the Enter button to permanently save the changes (Return to Parameter-Selection Mode)

6. Select parameter zero and press the Enter button to return to Running Mode

Operating the User Interface (The Long Story)

Although the MDP user interface is very versatile, it is also simple to setup and operate. With just

a few button presses, it allows the user to confi gure a number of adjustable parameters. The LED

display has three basic operating modes: Running Mode, Parameter-Selection Mode, and Value Mode.

Each of the three modes have specifi c visual indicators that allow the user to immediately determine

the current state or mode of the user interface. Parameter-Selection Mode and Value Mode can

only be entered if the Program Enable jumper is in the “On” position.

Running Mode is the default display of the unit when power is applied. The MDP will spend the majority

of its time in this mode. In Running Mode, the display shows the target value in the appropriate userdefi ned format of rate, time, or percentage. The control will continuously attempt to drive the motor at

the requested target rate. In this display mode, the Up and Down buttons increase or decrease the

displayed target value until either the display minimum or display maximum limit is reached. Depending

on the alarm confi guration, these buttons may also serve as an alarm-silence or alarm-reset button.

Example displays for rate, time, and follower operating modes are 13.60, 45:30, and 1000.

12

Page 15

Parameter-Selection Mode can be entered by simply pressing and holding the Enter button down for

three seconds. Once in Parameter-Selection Mode, the far left of the display will be a ‘P’. The right side

of the display will indicate the currently selected parameter number for editing purposes. Pressing the

Up or Down button will increase or decrease the selected parameter number on the display. Although

the parameter numbers are in numerical order, some numbers are skipped. These numbers represent

reserved parameters that are not yet implemented and are not displayed. Once the desired parameter

number is displayed, a press of the Enter button will change the display to the Value Mode. When

in Parameter-Selection Mode, pressing the Enter button with parameter 0 selected will cause

the unit to return to Running Mode. Example displays for Parameter-Selection Mode are P 1, P

13, and P 54. See the Software Parameters for a list of available parameters.

Value Mode is used to modify the value of the selected parameter. When in Value Mode, the two

dots which form the colon, between digits two and three, will alternately fl ash (one, then the other) to

inform the user that a parameter’s value is being edited. Pressing the Up or Down button increases or

decreases the selected parameter’s value. See the Software Parameters for a list of allowable values

and ranges. Value changes take effect immediately. For example, when scrolling through the alarm

output conditions, the relay will activate as the always-active selection is passed. Once the desired

value is showing in the display window, pressing the Enter button again will return to ParameterSelection Mode. The new value is not saved in permanent memory until the Enter button is pressed.

Removing power from the unit while in Value Mode may result in the specifi ed new value being lost.

Detailed Confi guration Instructions

Default Confi guration

When shipped from the factory, the following basic settings are in place:

Rate Mode Operation in RPM

S1 and S2 Signal Input Pulses per Revolution: 1

Decimal Point Display: Off

Display Range: 0 - 2400

Speed Range: 0 - 2400 RPM

Accel and Decel: 2500 RPM per second

Signal Input 2 (S2) Mode: Jog @ 1000 RPM when Low

User Input 1 (UIN1) Mode: Emergency Stop when Low

Alarm Output: Disabled

Resetting the Unit to Factory Defaults

The factory-default settings can be easily restored using either of two methods. Both methods require

the Program Enable jumper to be in the “On” position. The fi rst is to apply power to the unit with both

the Enter and Down buttons pressed for 3 seconds. The second is to change the value of parameter

95 to 5.

JP1 (Program Enable Jumper)

The JP1 jumper is located under the dust cover on the back end of the upper board. When the jumper

is set to the "Off" position, all programming features are locked out to the front panel user. When the

jumper is in the "On" position, the programming parameters are open to change. JP1 is shipped from

the factory set in the "On" position.

13

Page 16

Software Parameters

Parameter Description

Value Range

(units)

Factory

Default

0 Selecting this item exits to Running Mode n/a n/a

Read-Only Parameters

1 Model Number 10 – MD10P Unit

11 – MD3P Unit

13 – MD3E Unit

10, 11, or

13

2 Software Build 1 – 9999 n/a

3 Hardware Version 1 – 9999 n/a

4 Serial Number – Major (reserved) n/a n/a

5 Serial Number – Minor (reserved) n/a n/a

General Setup

10 Operating Mode 1 – Rate Mode

2 – Time Mode

3 – Follower Mode

1

11 Display Intensity 0 – 31 (Dim – Bright) 20

13 Decimal Point Position 0 – DP Disabled (XXXX)

1 – X.XXX

2 – XX.XX

3 – XXX.X

4 – XXXX.

0

14 Keypad Mode 1 – Linear, Constant Rate

2 – Non-linear, Accelerating Rate

2

15 Keypad Scroll Delay 0 – 30 (Fast – Slow) 10

16 S1 / S2 Input Edge & Prescaler Configuration 0 – S1 is Rising/1 S2 is Rising/1

1 – S1 is Falling/1 S2 is Rising/1

2 – S1 is Falling/4 S2 is Rising/1

3 – S1 is Falling/16 S2 is Rising/1

4 – S1 is Rising/1 S2 is Falling/1

5 – S1 is Falling/1 S2 is Falling/1

6 – S1 is Falling/4 S2 is Falling/1

7 – S1 is Falling/16 S2 is Falling/1

8 – S1 is Rising/1 S2 is Falling/4

9 – S1 is Falling/1 S2 is Falling/4

10 – S1 is Falling/4 S2 is Falling/4

11 – S1 is Falling/16 S2 is Falling/4

12 – S1 is Rising/1 S2 is Falling/16

13 – S1 is Falling/1 S2 is Falling/16

14 – S1 is Falling/4 S2 is Falling/16

15 – S1 is Falling/16 S2 is Falling/16

0

18 Power-up Mode 1 – Default to Zero Display

2 – Default to Power-up Value

3 – Default to Previous Running Val.

3

19 Power-up Value 0 – 9999 (Display Units) 0

Display & Control Loop Setup

20 Display Minimum 0 – 9998 (Display Units) 0

21 Display Maximum 1 – 9999 (Display Units) 2400

23 Accel Setting 1 – 9999 (Display Units) 2500

24 Decel Setting 1 – 9999 (Display Units) 2500

26 Proportional Gain 0 – 9999 (Not Unit-specific) 0

27 Integral Gain 1 – 9999 (Not Unit-specific) 5000

29 Pulse Accumulation Limit 2 – 5000 (Not Unit-specific) 15

Signal Input #1 (S1) Setup

30 S1 Display Reference 0 – 9999 (Display Units) 2400

31 S1 Reference RPM 0 – 9999 (RPM) 2400

32 S1 Pulses per Revolution 1 – 2048 (PPR) 1

33 S1 Deadband (Follower Mode Only) 0 – 1000 (Seconds) 0

User

Settings

14

Page 17

Software Parameters, cont'd

Parameter

Signal Input #2 (S2) Setup

35 S2 Input Configuration 1 – Disabled (Follower Mode)

36 S2 Setpoint 1 – 9999 (Display Units) 1000

37 S2 Pulses per Revolution 1 – 2048 (PPR) 1

38 Front Panel DoubleClick Mode 0 – Hardware Inhibit

User Input #1 (UIN1) Setup

40 UIN1 Input Configuration 1 – Disabled

41 UIN1 Setpoint for Jog 1 – 9999 (Display Units) 1000

Alarm Output #1 Configuration

50 Alarm Activation Conditions 0 – Always Off

51 Output Style & Reset Mode 1 – Constant & Auto Reset

52 Reset Configuration 1 – No Sil., Reset on Key

53 Display Flash On Active Alarm 0 – Alarm Flash Disabled

54 Pulse on Time 1 – 3600 (seconds) 1

55 Pulse off Time 1 – 3600 (seconds) 1

56 Pulse Count 0 – 9999 (pulses) 0

57 Lower Limit 0 – 9999 (display units) 0

58 Upper Limit 0 – 9999 (display units) 9999

Parameter Memory Commands

95 Restore Settings to Factory

Default

98 Save to User Default Area 0 – Do Nothing & Exit

99 Restore from User Default Area 0 – Do Nothing & Exit

Description

Value Range

(units)

2 – E-Stop When S2 High

3 – E-Stop When S2 Low

4 – Inhibit When S2 High

5 – Inhibit When S2 Low

6 – Jog When S2 High

7 – Jog When S2 Low

1 – DoubleClick Toggles Inhibit

2 – E-Stop When UIN1 High

3 – E-Stop When UIN1 Low

4 – Inhibit When UIN1 High

5 – Inhibit When UIN1 Low

6 – Jog When UIN1 High

7 – Jog When UIN1 Low

1 – Always On

2 – Active when Above upper limit

3 – Active when Below lower limit

4 – Active inside Range

5 – Active outside Range

6 – Active when Target = 0

7 – Active when no Pickup Pulses

detected

8 – Active when at Max. Conduction

2 – Constant & Manual Reset

3 – Pulsed & Auto Reset

4 – Pulsed & Manual Reset

2 – No Sil., Reset on S2 High

3 – No Sil., Reset on S2 Low

4 – Sil., Reset on Key

5 – Sil., Reset on S2 High

6 – Sil., Reset on S2 Low

1 – Alarm Flash Enabled

0 – Do Nothing & Exit

5 – Restore Factory Defaults

5 – Save Setting

1 – Restore Settings

Factory

Default

7

0

3

0

1

1

0

0

0

0

User

Settings

15

Page 18

Parameter Descriptions

Parameter 0 – Exit to Running Mode

When parameter 0 is selected in Parameter-Selection Mode, the unit will return to Running

Mode and display the running value. This should be selected once changes to parameters are

completed.

Parameter 1 – Model Number (Read Only)

This is a number which represents the base model number for the product. The model codes

for the MD10P ,MD3P, and MD3E are 10 ,11, and 13 respectively.

Parameter 2 – Software Build (Read Only)

The software build is a code which identifi es the software version of the unit.

Parameter 3 – Hardware Version (Read Only)

The hardware version is a code which identifi es which hardware was used to build the unit.

Parameter 4 & 5 – Serial Number, Major & Minor (Read Only)

These parameters are reserved for future use as an electronic serial number and are unique

to each manufactured unit.

Parameter 10 – Operating Mode

This parameter defi nes the operating mode for the entire unit. There are two basic modes of

operation, master and follower. In master modes, the unit controls the load using either rate

or time units. In follower mode, the unit controls the load in percentage of master rate. The

following modes are available for the MDP:

Mode 1 – Master, Rate Mode

In Rate Mode, the MDP displays in user-defi ned rate units such as RPM, Gallons per

Hour, or Feet per Second. See applications for examples.

Mode 2 – Master, Time Mode

In Time Mode, the MDP displays in time units using the format AA:BB. By default AA:BB

represents minutes (AA) and seconds (BB). Optionally, it can be confi gured to represent

hours (AA) and minutes (BB) or other user-defi ned units with a 1:60 relationship. When

setting parameters which are confi gured in display units, the programmed value is the

determined by the formula (AA * 60) + BB. In HH:MM displays, this is the total number

of minutes. In MM:SS displays, this is the total number of seconds. See applications

for examples.

Mode 3 – Follower Mode

In Follower Mode, the MDP displays in percentage units, where 1000 equals 100.0 percent

of the master rate. For example, if the display indicates 985, 98.5, or 9.85, the MDP will

attempt to run at exactly 98.5 percent of the master rate. Display settings are always

entered ignoring the decimal point's position. See applications for more examples.

Parameter 11 – Display Intensity

This parameter adjusts the intensity of the LED display digits in the front panel of the unit. The

values of 0 – 31 correspond to a gradual change from very dim to very bright. This is often useful

when the MDP is used in the same panel as other pieces of equipment with LED displays and

a uniform display brightness is desired. Simply adjust the MDP to match its surroundings.

Parameter 13 – Decimal Point (DP) Position

This selects the format of the display with respect to the decimal point’s position. This parameter

does not effect the value entry for other parameters. For example, if the user desires to display

10.00 at 300RPM, then parameter 30 would be set to 1000, parameter 31 would be set to 300,

and parameter 13 would be set to 2.

Mode 0: Fixed XXXX

Mode 1: Fixed X.XXX

Mode 2: Fixed XX.XX

Mode 3: Fixed XXX.X

Mode 4: Fixed XXXX.

16

Page 19

Parameter 14 – Keypad Mode

This parameter selects the operating mode of the front-panel push buttons. In some

applications, increasing or decreasing the scroll rate provides the user more controllability

when entering settings. Parameters 14 and 15 affect only the Up and Down buttons when

the user interface is in Running Mode. These settings also apply to remote Up / Down

buttons which are attached via the -1 option board.

Mode 1: Linear, Constant Rate

In linear mode, pressing and holding the Up or Down buttons will cause the display to

continuously change value in the requested direction until either the Display Minimum

or Display Maximum is reached. The displayed value will scroll at a constant rate which

is specifi ed using parameter 15.

Mode 2: Non-linear, Accelerating Rate

In non-linear mode, pressing and holding the Up or Down buttons will cause the

display to continuously change value in the requested direction until either the Display

Minimum or Display Maximum is reached. The displayed value will initially scroll at a

slow rate and increase in speed until the maximum scroll rate is achieved. The initial

scroll rate is specifi ed using parameter 15.

Parameter 15 – Keypad Scroll Mode

This parameter sets the scroll speed for the front-panel push buttons. The function of this

parameter varies slightly depending on the Keypad Mode. See parameter 14 for more

details.

Parameter 16 – S1 / S2 Input Edge & Prescaler Confi guration

This parameter determines how the MDP processes the S1 and S2 signal inputs. It specifi es

which signal edge is used for measurements and the value of the internal frequency dividers

or prescalers. Modes with prescalers greater than 1 should only be used if the input pulse

rate on S1 or S2 exceeds the unit's maximum native pulse rate (see specifi cations for details);

otherwise, the control loop may become sluggish and unnecessarily inaccurate. Use the

following chart to confi gure this parameter. As an example, assume an application requires

input pulse rates on S1 of 120,000 pulses-per-minute and S2 of 35,000 pulses-per-minute.

According to the electrical specifi cations, the unit can only accept 50,000 pulses-per-minute

on each the S1 and S2 inputs. With this in mind, the S1 and S2 prescalers should be selected

as Falling / 4 and Rising / 1, respectively. In this case, parameter 16 would be set to 2.

Parameter 18 – Power-up Mode

This parameter defi nes the mode which determines the default Running Value when power

is initially applied to the MDP.

Mode 1: Default to Zero

When in this mode, the unit will default to zero (display units).

Mode 2: Default to Power-Up Value

When in this mode, the unit will default to the Power-up Value, parameter 19.

Mode 3: Default to Previously Running Value

When in this mode, the unit will default to the previous running value before power

was removed. A previous running value must have been active for at least 3 seconds

to be recalled after power has been disconnected and reapplied.

17

Page 20

Parameter 19 – Power-up Value

When Power-up Mode is set to 2, this parameter will designate the default display value at

power-up in display units.

Parameter 20 – Display Minimum

This parameter defi nes the lower end of the display range. This is the value which limits how

low the user is able to scroll the displayed value in Running Mode. In Rate and Time modes,

this value is set in display units. In Follower Mode, this is set in percentage of the master rate.

For example, in Follower Mode, 1250 represents 125.0 percent of the master rate.

Parameter 21 – Display Maximum

This parameter defi nes the upper end of the display range. This is the value which limits how

high the user is able to scroll the displayed value in Running Mode. In Rate and Time modes,

this value is set in display units. In Follower Mode, this is set in percentage of the master rate.

For example, in Follower Mode, 150 represents 15.0 percent of the master rate.

Parameter 23 – Acceleration Setting

This parameter determines how fast the MDP will accelerate toward the displayed target setting.

This parameter is set in display units of change per second such as RPM, GPM, or feet per

second. In Follower Mode, this parameter is set in RPM units.

Parameter 24 – Deceleration Setting

This parameter determines how fast the MDP will decelerate toward the displayed target setting.

This parameter is set in display units of change per second such as RPM, GPM, or feet per

second. In Follower Mode, this parameter is set in RPM units.

Parameter 26 – Proportional (P) Gain

The Proportional Gain is the fi rst of two parameters which defi ne the responsiveness of the

control with respect to how fast it responds to changing loads. Because the MDP controls

are pulse-accumulation drives, the P Gain responds differently than the same parameter in a

standard velocity-form PID control. The higher the P Gain, the more aggressively the unit will

drive the load. See the PI Control Tuning section of the manual for more details.

Parameter 27 – Integral (I) Gain

The Integral Gain is the second of two parameters which defi ne the responsiveness of the

control with respect to how fast it responds to changing loads. The higher the I Gain, the more

aggressively the unit will drive the load. When using high PPR pickups or encoders, it will be

necessary to decrease the I Gain to prevent unwanted oscillation and instabilities. See the PI

Control Tuning section of the manual for more details.

Parameter 29 – Pulse Accumulation Limit

This parameter sets the limit for the maximum number of pulses the drive will accumulate prior

to intentionally losing count and therefore long-term accuracy. Because the MDP controls are

pulse-accumulation drives, they are able to accurately track a master (in Follower Mode) pulseby-pulse. That is, they are able to run for days, weeks, or months and remain completely in

sync with a master drive or process; unfortunately, this functionality comes at a small cost.

By default, if the main pickup signal were lost and then reattached, the unit may run at high

speeds for many seconds while attempting to make-up what would have been lost pulses.

Once it catches up, it returns to normal operation. In some applications, this is a nuisance. In

these cases, the Pulse Accumulation Limit, parameter 29, can be lowered to limit the maximum

number of pulses the drive will remember.

This parameter is set from 0 to 9999, where 0 is no accumulation and 9999 is maximum

accumulation. As this value approaches zero, the unit will gradually lose its ability to drive the

motor and eventually stop the motor completely. It may be necessary to increase the value of

this parameter for application which demand higher long-term accuracy.

18

Page 21

Parameter 30 – Signal Input 1 (S1) Display Reference

This is the number to be displayed when at the user-specifi ed motor Reference RPM. In Rate

Mode, this value represents rate units such as feet, ounces, or revolutions. In Time Mode, this

value represents the reference time measured in seconds or minutes. If the desired display

is HH:MM, then all values should be entered in minutes. If MM:SS is desired, then all values

should be entered in seconds. In Follower Mode, this value is the percentage of the master rate

in 0.1% units. For example, 1000 equates to 100%. See applications for more examples.

Parameter 31 – Signal Input 1 (S1) Reference RPM

This is the reference RPM at which the Display Reference value should be displayed. In Rate

and Time Modes, this value represents the RPM of the encoder to which the Display Reference

corresponds. In Follower Modes, this value is not used. See applications for examples.

Parameter 32 – Signal Input 1 (S1) Pulses per Revolution

This is the number of pulses per revolution for the signal input 1 (S1). The MDP supports pickups

and encoders from 1 to 2048 pulses per revolution.

Parameter 33 – Signal Input 1 (S1) Deadband (Follower Mode Only)

When in Follower Mode, it is often desirable for the follower unit to continue to slowly makeup the small pickup pulse differential between the master and follower's position. In some

applications, it is not necessary for the follower to continue to slowly seek the master's exact

pulse position when the master rate is at zero. In these cases, the Deadband parameter can

be set above zero to force the MDP to stop driving the motor slowly and cause it to inhibit until

the master starts rotating again. At that point, the follower will automatically make-up the pulse

differential as it starts to rotate. The deadband is disabled by setting it to zero seconds.

Parameter 35 – Signal Input 2 (S2) Input Confi guration

This parameter determines the operating mode of signal input 2 (S2).

Mode 1: Disabled (Follower Mode)

The S2 input is inactive. This is the required setting for Follower Mode.

Mode 2: Emergency Stop When S2 High (Not Wired To Common)

When the S2 input is at an electrically high (+5V) state or allowed to fl oat disconnected,

the MDP will enter emergency-stop mode. While in this mode, the armature output will

immediately be turned off. Once the S2 input returns to an electrically low state or wired

to the unit's common, the output will become active.

Mode 3: Emergency Stop When S2 Low (Wired To Common)

When the S2 input is at an electrically low state or wired to the unit's common, the MDP

will enter emergency-stop mode. While in this mode, the armature output will immediately

be turned off. Once the S2 input returns to an electrically high (+5V) state or allowed to

fl oat disconnected, the output will become active.

Mode 4: Inhibit When S2 High (Not Wired To Common)

When the S2 input is at an electrically high (+5V) state or allowed to fl oat disconnected,

the MDP will enter inhibit mode. While inhibited, the armature output will decrease

according to the decel setting until zero output is reached. Once the S2 input returns to

an electrically low state or is wired to the unit's common, the output will start to accelerate

toward the previous running value.

Mode 5: Inhibit When S2 Low (Wired To Common)

When the S2 input is at an electrically low state or wired to the unit's common, the MDP

will enter inhibit mode. While inhibited, the armature output will decrease according to

the decel setting until zero output is reached. Once the S2 input returns to an electrically

high (+5V) state or allowed to fl oat disconnected, the output will start to accelerate toward

the previous running value.

19

Page 22

Mode 6: Jog When S2 High (Not Wired To Common)

When the S2 input is at an electrically high (+5V) state or allowed to fl oat disconnected,

the MDP will enter jog mode. While in jog mode, the display will immediately change to

the programmed jog setpoint, parameter 36. The unit will start accelerating or decelerating

toward the jog setting at the confi gured accel and decel rates. Once the S2 input returns to

an electrically low state or is wired to the unit's common, the output will start to accelerate

or decelerate toward the previous running value. In Follower Mode, the unit will operate

as its own master. This allows an application to jog by overriding a stopped master.

Mode 7: Jog When S2 Low (Wired To Common)

When the S2 input is at an electrically low state or wired to the unit's common, the

MDP will enter jog mode. While in jog mode, the display will immediately change to the

programmed jog setpoint, parameter 36. The unit will start accelerating or decelerating

toward the jog setting at the confi gured accel and decel rates. Once the S2 input returns

to an electrically high (+5V) state or allowed to fl oat disconnected, the output will start to

accelerate or decelerate toward the previous running value. In Follower Mode, the unit

will operate as its own master. This allows an application to jog by overriding a stopped

master.

Parameter 36 – Signal Input 2 (S2) Setpoint

When the S2 confi guration, parameter 35, is set to one of the jog modes, this parameter defi nes

the jog setpoint in display units. If the MDP operating mode is set to Follower Mode, then this

parameter is set in RPM units. This allows a follower control to be jogged when the master is

stopped.

Parameter 37 – Signal Input 2 (S2) Pulses per Revolution

This is the number of pulses per revolution for the signal input 2 (S2). The MDP supports pickups

and encoders from 1 to 2048 pulses per revolution.

Parameter 38 - Front Panel DoubleClick Mode

When set to a value of 1, the setting of Parameter 35 and/or Parameter 40, particularly Modes

4 and 5 (Inhibit), have no effect; instead, "clicking" the ENTER Button twice in rapid succession

("Double-Clicking") will TOGGLE the MD10P/3P in and out of "Inhibit" mode. When in DoubleClick

mode, the Motor will decelerate to a stop, and the Display will show 4 dashes

"----" DoubleClicking again will cause the motor to accelerate up to the Target speed/time, and

the Display to return to its normal condition. When set to a value of Zero, the Inhibit function

is controlled exclusively by the signal level on the S2 and/or UIN1 Input(s), and the setting of

Parameters 35 and/or 40, and the "DoubleClick" function will have no effect. Note also that

the DoubleClick Inhibit is only honored in "Run" mode.

Parameter 40 – User Input 1 (UIN1) Confi guration

This parameter determines the operating mode of user input 1 (UIN1).

Mode 1: Disabled

The UIN1 input is inactive.

Mode 2: Emergency Stop When UIN1 High (Not Wired To Common)

When the UIN1 input is at an electrically high (+5V) state or allowed to fl oat disconnected,

the MDP will enter emergency-stop mode. While in this mode, the armature output will

immediately be turned off. Once the UIN1 input returns to an electrically low state or

wired to the unit's common, the output will become active.

Mode 3: Emergency Stop When UIN1 Low (Wired To Common)

When the UIN1 input is at an electrically low state or wired to the unit's common, the MDP

will enter emergency-stop mode. While in this mode, the armature output will immediately

be turned off. Once the UIN1 input returns to an electrically high (+5V) state or allowed

to fl oat disconnected, the output will become active.

20

Page 23

Mode 4: Inhibit When UIN1 High (Not Wired To Common)

When the UIN1 input is at an electrically high (+5V) state or allowed to fl oat disconnected,

the MDP will enter inhibit mode. While inhibited, the armature output will decrease

according to the decel setting until zero output is reached. Once the UIN1 input returns to

an electrically low state or is wired to the unit's common, the output will start to accelerate

toward the previous running value.

Mode 5: Inhibit When UIN1 Low (Wired To Common)

When the UIN1 input is at an electrically low state or wired to the unit's common, the MDP

will enter inhibit mode. While inhibited, the armature output will decrease according to the

decel setting until zero output is reached. Once the UIN1 input returns to an electrically

high (+5V) state or allowed to fl oat disconnected, the output will start to accelerate toward

the previous running value.

Mode 6: Jog When UIN1 High (Not Wired To Common)

When the UIN1 input is at an electrically high (+5V) state or allowed to fl oat disconnected,

the MDP will enter jog mode. While in jog mode, the display will immediately change to

the programmed jog setpoint, parameter 41. The unit will start accelerating or decelerating

toward the jog setting at the confi gured accel and decel rates. Once the UIN1 input

returns to an electrically low state or is wired to the unit's common, the output will start

to accelerate or decelerate toward the previous running value. In Follower Mode, the unit

will operate as its own master. This allows an application to jog by overriding a stopped

master.

Mode 7: Jog When UIN1 Low (Wired To Common)

When the UIN1 input is at an electrically low state or wired to the unit's common, the

MDP will enter jog mode. While in jog mode, the display will immediately change to the

programmed jog setpoint, parameter 41. The unit will start accelerating or decelerating

toward the jog setting at the confi gured accel and decel rates. Once the UIN1 input

returns to an electrically high (+5V) state or allowed to fl oat disconnected, the output will

start to accelerate or decelerate toward the previous running value. In Follower Mode,

the unit will operate as its own master. This allows an application to jog by overriding a

stopped master.

Parameter 41 – User Input 1 (UIN1) Setpoint

When the UIN1 confi guration, parameter 40, is set to one of the jog modes, this parameter

defi nes the jog setpoint in display units. If the MDP operating mode is set to Follower Mode,

then this parameter is set in RPM units. This allows a follower control to be jogged when the

master is stopped.

Parameter 50 – Alarm 1 Conditions

This defi nes which conditions will result in the alarm 1 output being activated.

Mode 0: Always Inactive

The alarm output will remain in an inactive state. In this state, the NC and C contacts

will be internally electrically connected.

Mode 1: Always Active (When Power Is Applied)

The alarm output will become active when the power is applied to the unit. In this state,

the NO and C contacts will be internally electrically connected.

Mode 2: Active When Display Value Above Limit

The alarm output will activate when the displayed value is above the upper limit setting,

parameter 58.

Mode 3: Active When Display Value Below Limit

The alarm output will activate when the displayed value is below the lower limit setting,

parameter 57.

Mode 4: Active When Display Value Inside Range

The alarm output will activate when the displayed value is greater than or equal to lower

limit settings and less than or equal to the upper limit setting.

21

Page 24

Mode 5: Active When Display Value Outside Range

The alarm output will activate when the displayed value is less than the lower limit setting

or greater than upper limit setting.

Mode 6: Active When Target (Display) = Zero

The alarm output will activate when the displayed value is equal to zero. This allows the

alarm output to be used to drive a mechanical brake to decrease stopping time or to

provide holding torque at zero speed.

Mode 7: Active When Main Pickup Signal (S1) Stalled or stopped

The alarm output will activate when the main pickup signal input (S1) has stalled or

stopped. The alarm lower limit (Parameter 57) is used to specify the stall timeout, in

seconds, under a motor stall condition. When using the lower limit to set the stall timeout,

an inhibit command or zero speed command will not be recognized as a stall condition.

The pickup is considered to have stalled if the timeout passes with no pickup pulses when

the target (displayed) value is greater than zero and the control has not been given an

inhibit command. The alarm upper limit (Parameter 58) is used to specify a zero speed or

stopped timeout condition in seconds. When using the upper limit to set a zero speed or

stopped timeout, an inhibit command, a zero speed command or a motor stall condition

will all be recognized as a stopped condition. The pickup is considered to have stopped

after the timeout passes with no pickup pulses.

Note: When using the upper limit to set a stopped timeout the lower limit should

be set to zero.

Mode 8: Active When Driving At Maximum Conduction Angle

The alarm output will activate when the control is driving the motor at the maximum

conduction angle. This can be used to determine if the control is running away due to a

broken pickup signal wire when stall-detection is not desired.

Parameter 51 – Alarm 1 Output Style & Reset Confi guration

This setting confi gures the output mode and reset method for the alarm output.

Mode 1: Constant & Auto Reset

In this mode, the alarm output will remain active until the alarm condition ceases to exist.

The alarm will automatically reset when the conditions return to normal.

Mode 2: Constant & Manual Reset

In this mode, the alarm output will remain active until the alarm is reset manually. See

parameter 52 for details.

Mode 3: Pulse & Auto Reset

In this mode, the alarm output will pulse on and off until the alarm condition ceases to

exist. The pulsed modes are commonly used for audible alarms where a constant output

would be considered distracting or awkward. The alarm will automatically reset when the

conditions return to normal.

Mode 4: Pulse & Manual Reset

In this mode, the alarm output will pulse on and off until the alarm is reset manually. See

parameter 52 for reset details. The pulsed modes are commonly used for audible alarms

where a constant output would be considered distracting or awkward.

Parameter 52 – Alarm 1 Reset Confi guration

This setting determines which actions will cause an active alarm to be silenced or reset.

Mode 1: No Silencing, Reset On Any Button Press

In this mode, an active alarm cannot be silenced. Once the alarm condition ceases to

exist, however, any user-interface button may be pressed to cause a manual reset.

Mode 2: No Silencing, Reset On S2 Input High (Not Wired To Common)

Similar to Mode 1. Once the alarm condition ceases to exist, setting the S2 input to a

high (+5V) state or allowing it to fl oat disconnected will cause a manual reset.

Mode 3: No Silencing, Reset On S2 Input Low (Wired To Common)

Similar to Mode 1. Once the alarm condition ceases to exist, setting the S2 input to a

low (COM) state or wiring it to common will cause a manual reset.

22

Page 25

Mode 4: Silencing Enabled, Reset On Any Button Press

When the conditions for an active alarm persist, pressing any user-interface button will

result in the alarm being silenced or deactivated, but not reset. A second attempt to reset

the alarm must be made after the condition cease to exist to clear the alarm.

Mode 5: Silencing Enabled, Reset On S2 Input High (Not Wired To Common)

Similar to Mode 4. Setting the S2 input to a high (+5V) state or allowing it to fl oat

disconnected will cause the alarm to be silenced or reset depending on the current state

of the alarm conditions.

Mode 6: Silencing Enabled, Reset On S2 Input Low (Wired To Common)

Similar to Mode 4. Setting the S2 input to a low (COM) state or wiring it to common

will cause the alarm to be silenced or reset depending on the current state of the alarm

conditions.

Parameter 53 – Alarm 1 Display Flash On Alarm

This will cause the display to fl ash when an alarm condition is active.

Parameter 54 – Alarm 1 Pulse on Time

This parameter defi nes the number of seconds the output should be enabled during the ‘on’

phase of an active pulsing alarm’s output.

Parameter 55 – Alarm 1 Pulse off Time

This parameter defi nes the number of seconds the output should be disabled during the ‘off’

phase of an active pulsing alarm’s output.

Parameter 56 – Alarm 1 Pulse Count

This setting determines how many pulses are output when the alarm is activated and is confi gured

in pulse output style. When 0 is entered, the unit will be set for continuous pulses while the

alarm is active.

Parameter 57 – Alarm 1 Lower Limit

This setting defi nes either the lower limit, the lower end of a range for the alarm region or a stall

timeout. Alarm limits are set in display units without regard to decimal point or colon position.

In Rate and Follower Modes, a limit of 123 could represent a display value of 123, 12.3, 1.23, or

0.123. When in Time Mode, a limit of 123 would represent 1:23 on the display. When the lower

limit is being used to set a stall timeout for parameter 50 mode 7, the setting is in seconds.

Parameter 58 – Alarm 1 Upper Limit

This setting defi nes either the upper limit, the upper end of a range for the alarm region or a stop

timeout. Alarm limits are set in display units without regard to decimal point or colon position.

In Rate and Follower Modes, a limit of 123 could represent a display value of 123, 12.3, 1.23, or

0.123. When in Time Mode, a limit of 123 would represent 1:23 on the display. When the upper

limit is being used to set a stop timeout for parameter 50 mode 7, the setting is in seconds.

Parameter 95 – Factory Default Command

When set to a value of 5, the unit will be reset to factory default settings. This can also be

achieved by applying power to the unit with both the Enter and Down buttons depressed. The

programming jumper must be in the "On" position for this method to function.

Parameter 98 – Save to User Default Area Command

When set to a value of 5, the unit will store all adjustable parameters to the user default area.

The user default area is intended to be a location where an OEM or integrator can store settings

specifi c to their application. Using this, an OEM can easily refresh their custom settings in the

fi eld if an end-user accidentally reconfi gures the unit unsuccessfully. Another common use for

this area is testing and initial setup. The user can store known-good settings here and easily

experiment without the fear of losing the optimal confi guration.

Parameter 99 – Restore from User Default Area Command

When set to a value of 1, the unit will restore the all adjustable parameters from the user default

area. See parameter 98 for additional information.

23

Page 26

Pump Controller with Audible and Visual Alarm

Description:

A waste pump control which displays the pump rate in liters per minute with an audible and

visual alarm output which will warn the operator if the waste fl ow has stopped. The alarm

should not be able to be silenced and should automatically reset when fl ow rates have returned

to normal. The display should indicate in the format "xxx.x" (LPM).

Application Diagram:

Dart MD10P, MD3P, or MD3E

Motor Control

CONTROLS

ValuPa ge

Ite

m

153.0

MICRO-DRIVE

Application Examples

Tach

ENTER

Audible

Annunciator

Wiring Diagram:

DC Motor

MD10P

MD3P

or

MD3E

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

Pump

Pump Specs:

19 Shaft Rotations = 2 Liters

N

L

A-

A+

COM

+5V

S1

S2

NOT USED

NO

C

NC

NOT USED

IN1

NOT USED

Flow Transducer

(73 Pulses per Liter)

*FUSE

}

GND

+V

SIGNAL OUT

Fluid

Outlet

Fluid

Inlet

AC Line Input 85-265VAC, 50-60 Hz

MOTOR

FLOW TRANSDUCER

(Frequency Output)

240VAC

Audible

Annunciator

* Size fuse according to unit and application. See

electrical specifications for maximums.

24

Page 27

Parameter Confi guration:

Parameter Value Notes

10 1 Master, Rate Mode Setting (LPM is a rate-based unit)

13 3 Decimal point position set to XXX.X on display

30 10 Display should indicate 1.0 LPM (10) when pickup at Reference RPM, parameter 31

31 73 This is the RPM at which the Display Reference, parameter 30, should be displayed

32 1 Pulses per revolution of shaft encoder or pickup is 1 PPR

50 7 Alarm active when pickup stalled

53 1 Flash display when alarm is active

57 10 Lower limit setting for pickup stall timeout. Set for 10 seconds.

Conveyor Oven Controller with Two Preset Process Times

Description:

An oven monitor displaying the “tunnel” time in minutes and seconds. The tunnel time is

defi ned as the time it takes for the heated object on the conveyor to travel from point A to point

B in the application diagram below. An external time-select switch should allow the user to

choose between the displayed process time or a second fi xed process time. The time should

be displayed in MM:SS (minutes:seconds) format. The process time should only be allowed

to be adjusted between 6:30 and 12:15.

Application Diagram:

AB

Heat Source

Tunnel Oven

CONTROLS

Ite

ValuPage

m

6:30

MICRO-DRIVE

Dart MD10P, MD3P, or MD3E

Motor Control

Oven Speed Select Switch

SPEED 1 SPEED 2

Connect to

Coupling

Non-Reduced

Shaft

Dart PU-2E

or equivalent

Tach

ENTER

Gear Motor

Drive Train Specs:

1380 RPM at non-reduced

motor shaft equates to

6 minutes and 40 seconds

of tunnel time

Coupling to

Chain Drive

Wiring Diagram:

25

Page 28

Parameter Confi guration:

Parameter Value Notes

10 2 Time Mode Setting (MM:SS is a time-based unit)

20 390 Display minimum set to 6:30 (MM:SS)

For example: (6 minutes * 60 seconds-per-minute) + 30 seconds = 390 seconds

21 735 Display maximum set to 12:12 (MM:SS)

For example: (12 minutes * 60 seconds-per-minute) + 15 seconds = 735 seconds

30 400 Display should indicate 6:40 (MM:SS) when motor at Reference RPM, parameter 31

For example: (6 minutes * 60 seconds-per-minute) + 40 seconds = 400 seconds

31 1380 This is the RPM at which the Display Reference, parameter 30, should be displayed

32 1 Pulses per revolution of shaft encoder or pickup is 1 PPR

35 7 Set S2 input mode to jog when low