Page 1

CONTROLS

Instruction Manual

Variable Speed Control

LT196 (0919)

153D-200E 153D-200E-PB

ENCLOSED 150 SERIES

A-5-4185A

Page 2

TABLE OF CONTENTS

WARRANTY ................................................................................................................................................................................ 1

WARNING ....................................................................................................................................................................................1

INTRODUCTION ......................................................................................................................................................................... 2

CONTROL FEATURES ................................................................................................................................................................ 2

150 SERIES HEATSINK DIMENSIONS.......................................................................................................................................3

MOUNTING PROCEDURE .......................................................................................................................................................... 3

MODEL SELECTION ................................................................................................................................................................... 3

CUSTOMER INSTALLATION, WIRING, & FUSING REQUIREMENTS ......................................................................................4

TYPICAL MOTOR CURRENTS ................................................................................................................................................... 4

150 HOOK-UP DIAGRAM ............................................................................................................................................................5

SETUP AND WIRING INSTRUCTIONS ....................................................................................................................................... 5

CONTROL START-UP .................................................................................................................................................................6

TRIMPOT ADJUSTMENT PROCEDURE .................................................................................................................................... 7

CONTROL HOOK-UP and SETUP MODIFICATIONS ................................................................................................................ 8

OPTION DESCRIPTIONS ............................................................................................................................................................ 9

-PB options ............................................................................................................................................................................ 9

-29B option ......................................................................................................................................................................... 10

-56H3 option ....................................................................................................................................................................... 11

IN CASE OF DIFFICULTY ......................................................................................................................................................... 12

SPECIFICATIONS ......................................................................................................................................................................12

WARRANTY

Dart Controls, Inc. (DCI) warrants its products to be free from defects in material and workmanship. The exclusive remedy for this

warranty is DCI factory replacement of any part or parts of such product which shall within 12 months after delivery to the purchaser

be returned to DCI factory with all transportation charges prepaid and which DCI determines to its satisfaction to be defective.

This warranty shall not extend to defects in assembly by other than DCI or to any article which has been repaired or altered by

other than DCI or to any article which DCI determines has been subjected to improper use. DCI assumes no responsibility for the

design characteristics of any unit or its operation in any circuit or assembly. This warranty is in lieu of all other warranties, express

or implied; all other liabilities or obligations on the part of DCI, including consequential damages, are hereby expressly excluded.

NOTE: Carefully check the control for shipping damage. Report any damage to the carrier immediately. Do not attempt to operate

the drive if visible damage is evident to either the circuit or to the electronic components.

All information contained in this manual is intended to be correct, however information and data in this manual are subject to change

without notice. DCI makes no warranty of any kind with regard to this information or data. Further, DCI is not responsible for any

omissions or errors or consequential damage caused by the user of the product. DCI reserves the right to make manufacturing

changes which may not be included in this manual.

WARNING

Improper installation or operation of this control may cause injury to personnel or control failure. The control must be

installed in accordance with local, state, and national safety codes. Make certain that the power supply is disconnected

before attempting to service or remove any components!!! If the power disconnect point is out of sight, lock it in

disconnected position and tag to prevent unexpected application of power. Only a qualified electrician or service

personnel should perform any electrical troubleshooting or maintenance. At no time should circuit continuity be checked

by shorting terminals with a screwdriver or other metal device.

AVERTISSEMENT

Toute installation ou exploitation irrégulière de cette commande peut causer des blessures au personnel ou une panne

à la commande. La commande doit être installée en respectant les codes de sécurité locaux, fédéraux et nationaux.

Assurez-vous que l’alimentation est coupée avant de maintenir ou d’enlever des composants !!! Si le point de coupure

de courant n’est pas visible, bloquez-le à la position de déconnexion et étiquetez-le pour éviter tout mise sous tension

imprévue. Toute localisation de panne électrique ou maintenance devrait être effectuée par un électricien qualifié. La

continuité du circuit ne devrait en aucun cas être vérifiée en court-circuitant les bornes avec un tournevis ou tout autre

objet métallique.

1

Page 3

INTRODUCTION

• The 150 series enclosed controls are to be used with DC motors from 1/50 - 1 HP (90VDC) and 1/25 - 2 HP (180VDC)

• The 150 series models are available for dual voltage input requirements of 120/240 Vac. Dual voltage models, via

jumper setting, will output 90Vdc (using 120 or 240Vac supply) or 180Vdc (240Vac supply only)

• Model selections are available in two feature sets. The full featured 150D models include adjustable Accel & Decel,

LED indicators for Power ON & Current Limit, and a wide range of available options. The 150L models are built for

cost sensitive applications and OEM specials.

• The control is designed to operate DC Permanent Magnet, Shunt Wound (150D models only), and some Universal

(AC/DC) motors in the above horsepower ranges.

• Incoming AC voltage is converted to adjustable full wave rectified DC voltage to operate the DC motor. Also, a

full wave field voltage is provided for shunt wound motors on the 150D models.

• All models incorporate transient voltage protection, adjustable current limit, adjustable minimum and maximum

speeds, adjustable IR compensation and an inhibit function.

• All models come standard with fixed terminal blocks.

• Digital display with push button potentiometer and manual reversing models are available

CONTROL FEATURES

MIN SPEED (Minimum Speed) - Allows adjustment of the motor speed when the speedpot is set at minimum (CCW). This

permits the user to eliminate "Deadband" on the main speed control, for zero calibration. Clockwise rotation of "MIN" trimpot

increases speed.

MAX SPEED (Maximum Speed) - Allows the user to set the maximum output voltage and speed required for the application with

the speedpot at maximum rotation. Rotation of the "MAX" trimpot in the clockwise direction increases the maximum motor speed.

IR COMP (Speed Regulation) - This allows for adjustment of the output voltage gain needed to overcome speed losses during

increased motor load. The circuitry controls armature speed by changing the armature voltage to compensate for increased or

decreased motor loading. Clockwise rotation of the "IR COMP" trimpot will increase gain compensation.

CUR. LIM. (Current Limit) - Provides protection from excessive armature current by limiting the maximum continuous armature

current the control can provide. Current Limit should be set at 125% of rated motor torque (current) based on horsepower.

Clockwise rotation of the "CUR. LIM." trimpot increases the current that the control will provide.

INHIBIT TERMINAL PINS - Allows the user to (hard) quickly stop and start the control output via a SPST switch. Using the

inhibit inputs will bypass Accel and Decel ramps.

ACCEL & DECEL – 150D models have adjustable accel and decel with a setting range of 0.5-8 seconds for accel and 0.5-6 seconds

for decel. CW rotation increases the accel and decel ramp times. The 150L models come with fixed 0.5 second accel and decel.

INPUT & OUTPUT SELECTION PINS – All 153D and 153L models come standard with selectable input voltage pins for 120 or

240 Vac operation, and selectable output voltage pins for 90 or 180 Vdc motors. NOTE: 90Vdc outputs can be achieved from

120 or 240Vac inputs however a 180Vdc output can only be achieved from a 240Vac input supply.

POWER ON & INDICATOR – On 150 Enclosed models with optional -PB digital display.

TRANSIENT PROTECTION – All models come with MOV and X2 rated line capacitors for transient and noise protection.

2

Page 4

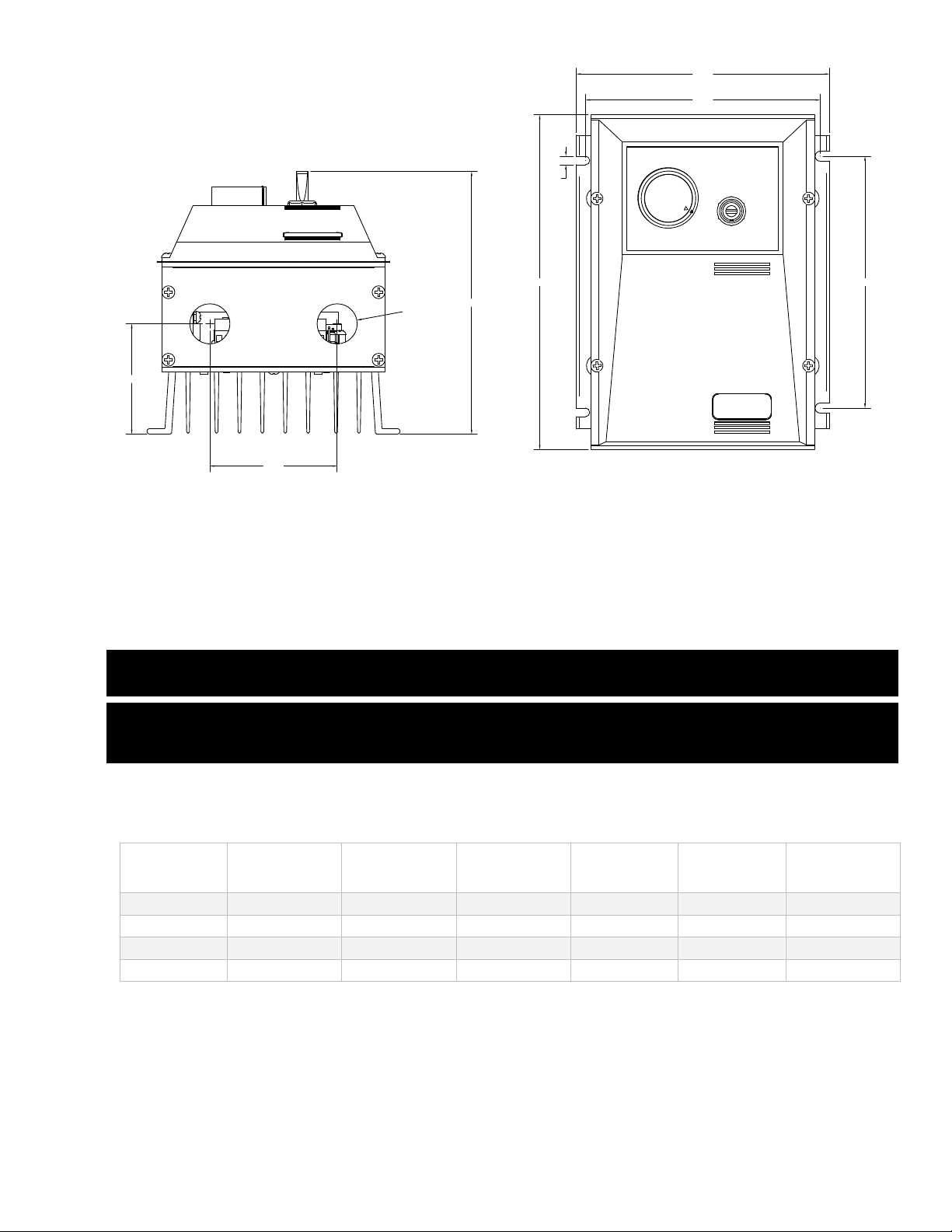

150 SERIES HEATSINK DIMENSIONS

INPUT

VOLTAGE

OUTPUT

VOLTAGE

OUTPUT

AMPS DC

HP

RANGE

ADJ

ACC/DEC

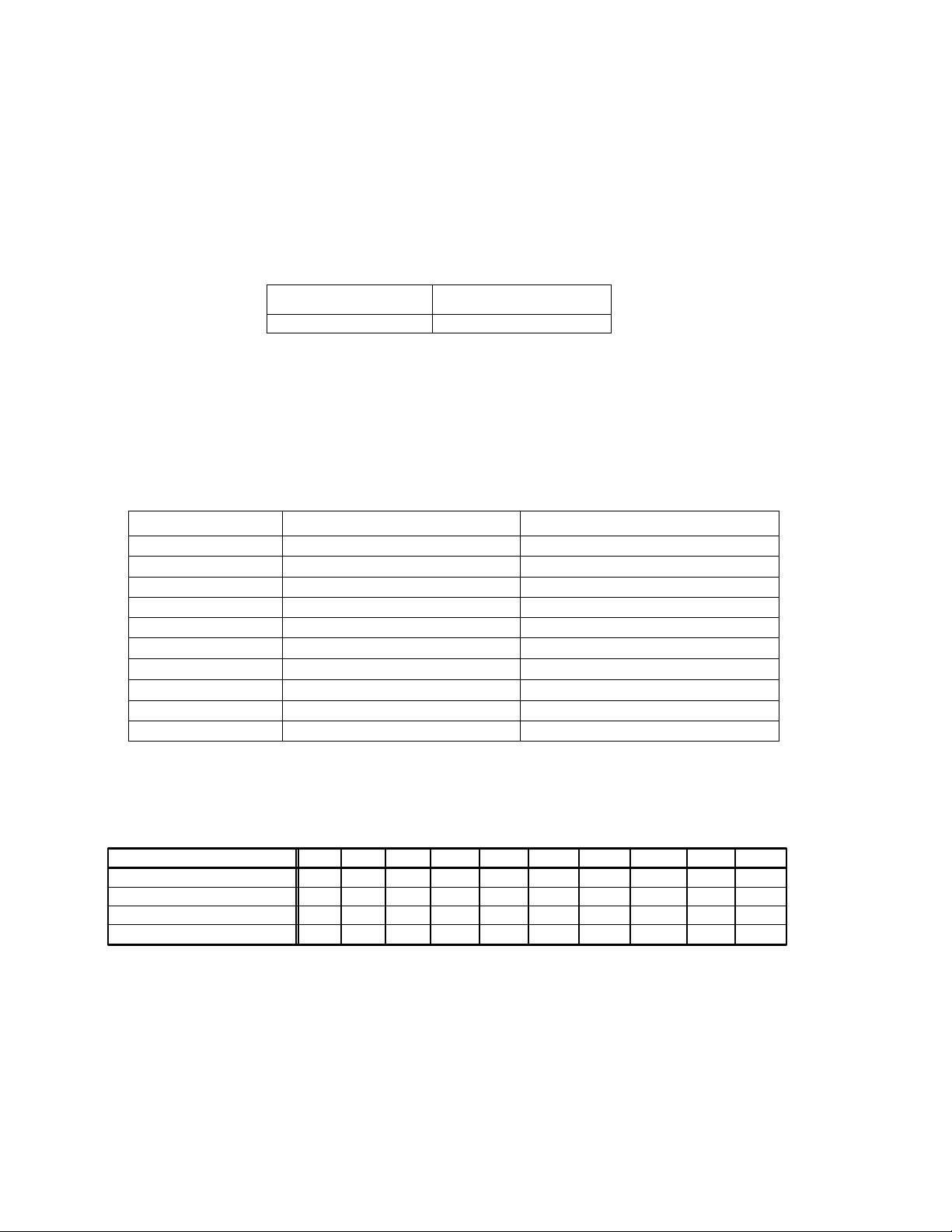

153L-25E

120/240

0-90/180

150mA – 2A

1/50 – ¼

N

N

153L-200E

120/240

0-90/180

2A – 10A

1/8 – 2

N

N

153D-25E

120/240

0-90/180

150mA – 2A

1/50 – ¼

Y

Y

153D-200E

120/240

0-90/180

2A – 10A

1/8 - 2

Y

Y

5.530

5.125

.188

2.410

2.780

Ø.875

5.739

ENCLOSED MODEL

7.300

5.500

MOUNTING PROCEDURE

1. Controls provided with .188" wide slots for mounting.

2. Control can be used as a template.

3. Use up to size 10 standard hardware for mount.

CAUTION:

DO NOT MOUNT WHERE AMBIENT TEMPERATURE IS OUTSIDE THE RANGE OF -10o C (14o F) TO 40o C (104o F)

NE MONTEZ PAS LA COMMANDE À UN EMPLACEMENT OÙ LA TEMPÉRATURE AMBIANTE SE TROUVE EN DEHORS

DE LA PLAGE ALLANT DE -10oC (15oF) À 40oC (104oF).

ATTENTION:

MODELS

MODEL SELECTION

FIELD V

3

Page 5

CUSTOMER INSTALLATION, WIRING, & FUSING

REQUIREMENTS

• Do not mount DC drive where ambient temperature is outside the range of -10 to 40°C (14 to 104°F).

• Installations in unventalated enclosures must be 1.5 times the controller dimensions or more and the air temperature

inside the enclosure and around the controller must remain between 10 to 40°C (14 to 104°F).

• Keep signal wires separate from the armature and AC lines when routed in conduit or wire trays.

• These drives do not provide motor over-temperature sensing or motor overload shutdown. The need for additional motor

overload shutdown and motor over-temperature protection shall be determined based on conditions in the end installation

in accordance with the NEC.

• Size all wires that carry armature or line currents as specified by applicable national, state, and/or local codes. All other

wires may be 18AWG or smaller as permitted by code.

Type

Customer Terminal Wiring 300V, 75oC(167oF) minimum

• Fusing - The motor and control are protected against overloads by the current limit circuit and a factory installed fuse in

the AC1(L) line. THIS PROTECTION ALREADY MAY BE PROVIDED BY THE CUSTOMER WITH CIRCUIT BREAKERS

OR FUSES IN BOTH MAIN LINES. IF NOT:

FOR 120 Vac INPUT - fuse protection has been factory installed in the (Hot) AC Line 1 (see following chart)

FOR 240 Vac INPUT - fuse protection should be added by the customer for (Hot) AC Line 2 (see following chart)

FUSING ADDED BY CUSTOMER (Bussman ABC or Little Fuse 314 Series ceramic fuses)

Customer Wiring Temp

Rating

HORSEPOWER 120 VAC INPUT 240 VAC INPUT

1/50 2 AMP ---------1/20 2 AMP 1 AMP

1/8 3 AMP 2 AMP

1/4

4 AMP 3 AMP

1/3 6 AMP 3 AMP

21/

43 /

8 AMP 4 AMP

12 AMP 6 AMP

1.0 15 AMP 8 AMP

1.5 ---------- 12 AMP

2.0 ---------- 15 AMP

TYPICAL MOTOR CURRENTS

Horsepower

Typical AC Amps (120VAC)

Typical Arm Amps (120VAC)

Typical AC Amps (240VAC)

Typical Arm Amps (240VAC)

1/50 1/20 1/81/4

0.50

0.42

-----

-----

1.00

0.81

0.80

0.40

2.00

1.60

1.20

0.60

3.50

2.70

1.80

1.40

1/3

4.40

3.40

2.20

1.70

1/2

6.50

5.00

3.30

2.50

3/4

9.30

8.20

4.80

3.70

1.0

13.20

10.00

6.50

5.00

1.5

-----

-----

9.70

8.20

2.0

-----

-----

13.60

10.00

4

Page 6

150 ENCLOSED HOOK-UP DIAGRAM

120/240

INPUT

VOLTAGE

JUMPER

0-90/180

OUTPUT

VOLTAGE

JUMPER

JP2

}

}

240120

JP1

}

}

180

90

Shown as a 153D-200E

+F

TB1

-1

IRMINMAX

CL

-F

P9

P10

P8

-2

-3

DECACC

P11

-4

P14

Inhibit

Common

P13

Inhibit

Input

OPTIONAL

INHIBIT

SWITCH

Closed = Stop

Open = Run

AC1

(L)

AC2

(N)

+A -A

MOTOR

SETUP AND WIRING INSTRUCTIONS

JP1 90/180 Vdc Set this jumper selection to 90 for 90Vdc motors or 180 for 180Vdc or 130Vdc motors.

JP2 120/240Vac Although a JP2 setting of 240V will allow the control to function adequately on lower 120V

inputs for most applications, it is recommended that JP2 be set for the appropriate incoming

AC line voltage. AC inputs of 108 through 140 Volts should use a jumper position of 120. AC

inputs of 208 through 240 should use a jumper position setting of 240. NOTE 1: NEVER USE

A JP2 120V SETTING FOR INPUT VOLTAGES ABOVE 140Vac. PERMANENT CONTROL

DAMAGE MAY OCCUR.

TB1-1, TB1-2 (AC or L) 120 Vac - Connect incoming hot AC1/L1 (black wire) to TB1-1 and neutral AC2/N

(AC or N) (white wire) to TB1-2. Connect ground (green wire) to CHASSIS of control.

240 Vac - Connect incoming hot AC1/L1 to terminal TB1-1 and incoming hot AC2/L2

to terminal TB1-2. Connect ground wire to CHASSIS of control.

TB1-3 (+Arm) Connect to PLUS (+) Armature wire on motor. 0-90 VDC for 120 Vac input or 0-90/180 VDC for

240 Vac input. See “SPECIFICATIONS” for output rating.

TB1-4 (-Arm) Connects to NEG (-) Armature wire on motor.

P5 (Speedpot Hi) (Factory Wired) Connects to high side (white wire) of Speedpot (CW end). This is internal +12

volts. INPUT MUST NOT BE GROUNDED!

5

Page 7

P6 (Speedpot Wiper) (Factory Wired) Connects to wiper (red wire) of Speedpot (center lead). For Start-Stop

applications requiring soft start and soft stop (Accel and Decel ramps), the connection between

this terminal and Speedpot Wiper can be opened and closed by a SPST switch. For Voltage

Follower applications, this INPUT MUST NOT BE GREATER THAN +12V MAXIMUM AND MUST

NOT BE GROUNDED!

P7 (Speedpot Lo) (Factory Wired) Connects to Low side (orange wire) of Speedpot (CCW end). This input is raised

and lowered by the MIN trimpot. Electronic speed input (voltage follower) may be referenced to

Speedpot LO if the MIN trimpot adjustments are to be active. Otherwise, inputs may be

referenced to -ARM, which will bypass the MIN trimpot. INPUT MUST NOT BE GROUNDED!

P8 (+Field) DO NOT use for Permanent Magnet Motor. This supplies +Field voltage for a SHUNT WOUND

(150D Models ONLY) MOTOR. For motors with dual voltage field (ie. 50/100V or 100/200V), make certain highest

value is connected.

P9 (-Field) Connects to Negative (-) Field wire of a SHUNT WOUND MOTOR. This connection is also circuit

(150D Models ONLY) common but must never be connected to earth or chassis gnd. Doing so will result in damage

to the control.

P13 (Inhibit Input) Connecting this input to the Inhibit Common pin will result in a fast stop. Opening this

connection will result in a quick acceleration of the motor to the wiper input set point.

Stopping and starting via the Inhibit pins bypasses all accel and decel ramps.

P14 (Inhibit Connecting this input to the Inhibit pin willl result in a fast stop. Opening this connection

Common) will result in a quick acceleration of the motor to the wiper input set point. Stopping and

starting via the Inhibit pins bypasses all accel and decel ramps.

Warning:

1. Be sure the control housing is properly grounded.

2. Armature connections must not be switched or broken while the control is on. Serious control damage may result.

3. For non-speedpot applications, the input connection to the LO, WIPER, and HI terminals must not be grounded!

Serious control damage may result from a grounded input.

1. Assurez-vous que le coffrage du système de commande est correctement mis à la terre.

2. Les raccordements ARM ne doivent pas être commutés ou interrompus pendant que la commande est sazous ten

sion. De sérieux dégâts peuvent en découler.

3. Pour les applications sans potentiomètre : les connexions d’entrée vers les fils Lo-Curseur-Hi ne doivent pas être

mises à la terre. Une entrée mise à la terre peut gravement endommager la commande.

Do not attempt to perform Hi-pot test across AC lines with control in circuit.

This will result in immediate or long term damage to the control.

N’essayez pas d’effectuer d’essai diélectrique à travers les lignes CA lorsque la commande

est dans le circuit. La commande sera immédiatement et irrémédiablement endommagée.

Avertissement

Warning:

Avertissement:

CONTROL START-UP

WARNING: ALL POWER MUST BE TURNED OFF BEFORE PROCEEDING!

AVERTISSEMENT : L’ALIMENTATION DOIT ÊTRE COUPÉE AVANT DE DÉMARRER !!!

1. Recheck all wiring. Accidental grounds cause by, loose or pinched wires on the armature or speedpot may damage the control

when power is applied.

2. Check to see that incoming service is of correct voltage.

3. Check to make sure the input line voltage jumper selection (JP2) is set to the correct incoming service.

4. Check to make sure the 90/180 volt motor jumper selection (JP1) is set to the correct armature motor voltage required.

5. Turn speedpot to zero (fully CCW).

6. Turn power on, and advance speedpot while observing motor rotation. If motor rotation is correct, proceed to step 8. Power

must be off before step 7 can be accomplished!

7. If motor rotation is incorrect, turn power off at external disconnect and reverse +ARM and -ARM connections.

8. Check for satisfactory operation throughout the speed range.

9. If operation is satisfactory, no readjustments are needed.

10. If additional control tuning and setup are needed, see the following "TRIMPOT ADJUSTMENT PROCEDURE".

11. For other problems, consult section, “IN CASE OF DIFFICULTY”.

6

Page 8

TRIMPOT ADJUSTMENT PROCEDURE

TRIMPOT FUNCTION ADJUSTMENT

MIN

IR COMP

MAX

CUR.LIM

ACCEL

DECEL

Sets minimum motor speed or eliminates

deadband when speedpot is set at zero. CW

rotation will eliminate deadband and increase

minimum motor speed.

Provides a means of improving motor speed

ation in the armature feedback mode. If a

regul

constant output voltage is desired, or if some

speed loss with increased load is of no concern,

then rotate this trimpot fully CCW.

Sets maximum motor speed when speedpot is set

at maximum (full CW rotation). CW rotation of

MAX trimpot increases maxim

NOTE: MAX trimpot settings that result in

output voltage greater than the motor rating

may result in unregulated speeds at full load

and higher than normal motor temperatures.

Limits DC motor armature current (torque) to

prevent damage to the motor or control. The

current limit is set for the rated motor current. CW

rotation of this trimpot increases the armature

current.

Sets the amount of time it takes the motor to go

from the minimum set speed to the maximum set

speed. The range of this setting is 0.5 to 8

seconds. CW rotation increases the Accel time.

Full CCW is 0.5 seconds.

Sets the amount of time it takes the motor to go

from the maximum set speed to the minimum set

speed. The range of this setting is 0.5 to 6

seconds. CW rotation increases the Decel time.

Full CCW is 0.5 seconds.

um motor speed.

1. Set Speedp

2. Rotate MIN trimpot CW

3. Slowly rotat

NOTE: If motor rotation is desired, rotate MIN

trimpot CW

1. Set Speedpot at 50%.

2. Observe motor spee

3. Apply full anticipated load to motor.

4. Turn IR COMP trimpot CW to obtain the same

motor spee

1. TURN DRIVE POWER OFF!!

2. Connect a

n

egative lead to -ARM.

NOTE: Meter must not be grounded!!

3. Turn power on. Set Speedpot at 100%.

4. Observe output voltage on meter and adjust the

max trimpot un

A tachometer

max output sp

1. TURN DRIVE POWER OFF!!

2. Connect a

+ARM on control. This is in se

3. Turn power on.

4. Set Speedp

Limit trimpot full CCW.

5. Apply frictio

motor stalls.

ith motor output shaft locked safely in

6. W

positio

n, set current at 125%

current by ad

ed current setting is achieved.

requir

1. Set Speedpot to zero (fully CCW).

2. Rotate Accel trimpot CW

on 0.5-8 seconds

3. Set Speedpot to full CW and time the acceleration

to full speed.

4. If a slower acceleration and longer time frame is

d then rotate Accel trimpot CW.

nee

1. Set Speedpot to full on (fully CW).

2. Rotate Decel trimpot CW to desired setting based

on 0.5-6 second range.

3. Set Speedpot to full CCW and time the deceleration

to zero speed.

4. If a slower deceleration and longer time frame is

d then rotate Decel trimpot CW.

nee

ot to zero (fully CCW

e MIN trimpot CCW until moto

until

d observed at no load.

DC Voltmeter: positive lead to +A

til desired maximum voltage is reache

may be used in lieu of a voltme

eed. Note: Do not exceed motor ratings.

DC Ammeter between A1 on

ot at the 50% rotation and turn

n braking or load to the motor

justing CUR. Limi

).

until motor starts to rotate.

r stops.

desired MIN speed is reached.

d at no load condition.

RM,

ter to set

motor and

ries with the mo

of rated motor armature

t trimpot CW until

to desired setting based

tor.

the Cur.

shaft until

a stalled

d.

7

Page 9

CONTROL HOOK-UP and SETUP MODIFICATIONS

Two speed operation can be achieved by several methods as

shown below. In all three methods, a center off switch can be

used for a Speed1 / Off / Speed2 operation.

Two Speed Operation

W

HI

LO

W

HI

LO

HI

SPDT

Two 10K Speedpots

Two speed operation using two

10K pots and a SPDT switch.

SPDT

Two 5K Speedpots

W

HI

LO

DPDT

HI

W

HI

LO

W

LO

HI

High speed and low speed operation using single 5K pot

and a SPDT switch. In this hookup diagram, the Low

speed is set via the MIN trimpot and must be less than

40% of MAX trimpot setting. The High speed is set via

the speedpot to any speed from Low speed to MAX

trimpot setting.

Two speed operation using two

5K pots and a DPDT switch.

When a Start/Stop action is required by means of a switch, the following

hook-ups may be used to achieve the necessary function. Starting and

Stopping by means of the Inhibit pin (P13) will result in a hard Start/Stop.

Use of the Inhibit input bypasses the Accel and Decel ramps. Start/Stop

actions via the Wiper input signal (P6) will result in a soft Start/Stop.

Refer to the diagrams below for several methods of starting and stopping

that may meet you application requirements.

Start, Stop & Inhibit Operation

Using a SPST switch in series witht

the Wiper input signal will give you a

“soft” Start/Stop (Closed = Run).

Using a SPST switch connected to

(P13) inhibit and (P14) COM will give

you “hard” Start/Stop (Open = Run).

Using a DPDT (On-None-On) switch

connected to (P13) inhibit and P6

Wiper input, shown in this diagram

will give you a “hard” Stop and a

“soft” Start (P13 to P14 Closed =

Hard Stop) (P6 to W Closed = Soft

Start).

SPST

W

HI

LO

SPST

W

HI

LO

DPDT SWITCH (N.C.)

W

HI

LO

One 5K Speedpot

“Soft” Start/Stop

“Hard” Start/Stop

Hard Stop/Soft Start

P13

P14

P13

P14

P12

P12

P12

P12

P12

P12

MIN POT

8

Page 10

OPTION DESCRIPTIONS

-PB option

Digital Push Button Potentiometer with power on indiactor Factory Installed Only

This is a digital push button potentiometer that replaces the traditional mechanical rotary potentiometer (speed pot). Like the

standard speed pot that operates from a 0-10 dial, the digital push button potentiometer operates from 0.0-100.0% set point

that is adjusted via the front panel up and down arrow push buttons. 0.0 will always represent what the min trimpot control

setting is and 100.0 will always represent the max trimpot setting. The display adjustment between those two points will always

be a linear scale between the min and max settings of the control.

ENTER (Select) Button

Power Indicator

CONTROLS

PWR

% OUTPUT

ENTER

Up & Down Buttons

ON

Display Window

OFF

Power ON/OFF Switch

DIGITAL SCR

SPEED CONTROL

Setting Up and Operating the -PB Option

Set up of a control with the -PB option is accomplished in the same manor as a standard control using the mechanical speed

pot except the display setting replaces the dial position setting of the speed pot. A 0.0 display setting is equivalent to a full

CCW or 0 dial position setting, and a 100.0 display setting is equivalent to a full CW or 10 dial position setting. With that in

mind, follow the CONTROL START-UP and the TRIMPOT ADJUSTMENT PROCEEDURE sections of this manual for proper

setup and tuning of the control for your application.

Optional Display Startup Setting

The -PB option has one parameter setting that can be changed depending on the end use application. The factory default is for

the display to always start at a min setting of 0.0 at power up. This is for safety reasons so the motor doesn't start running after

a power up. If you want the control to always return to the last user setting then follow this setup instruction.

1) With power applied press and hold the ENTER key until the display shows P0. Then release.

2) Press the up arrow until you reach P18.

3) Press and release the ENTER key and the display should display a 1 if the parameter is still at factory default.

4) Use the up and down arrows to select 1 if you want the control display to reset to 0.0 at power up, or 2 if you want the

display to always return to the last set point at power up.

5) Press and release the ENTER key to return to P18 on the display.

6) Press the down arrow until you reach P0.

7) Press and release the ENTER key to return to your display set point.

9

Page 11

-29B option

Manual Forward-Off-Reverse Switch Factory Installed Only

Permits reversing of the motor. This is accomplished using a 4PDT anti-plug reverse center blocked switch. When switching

between the forward/reverse positions, a mechanically blocked center position protects against plug reversing the motor by not

allowing the switch to transition past the center off position until pressure is removed from the toggle.

Warning:

THE MOTOR MUST COME TO A COMPLETE STOP BEFORE CHANGING DIRECTIONS. IF THE MOTOR DOES

NOT COME TO A COMPLETE STOP, SERIOUS DAMAGE TO THE MOTOR, CONTROLLER, OR SWITCH MAY

RESULT.

Avertissement:

LE MOTEUR DOIT VENIR A UN ARRET COMPLET AVANT DE CHANGER LES INSTRUCTIONS. SI LE MOTEUR

NE ARRIVE PAS À UN ARRÊT COMPLET, DES DÉGATS GRAVES POUR LE MOTEUR, LE CONTRÔLEUR OU

LE COMMUTATEUR PEUVENT EN RÉSULTER.

-29 SWITCH 4PDT BLOCKED CENTER OFF

TB1-4 TB1-3 TB1-2 TB1-1

-A +A AC1 (L)AC2 (N)

150 CONTROL

AC2 (N)

AC1 (L)

-A

+A

-29 4PDT SWITCH

-4

-3

-2

-1

FUSE

TB1

10

Page 12

-56H3 option

Isolated Signal Input

with Auto/Manual Hook-Up Factory Installed

NOTE 1: This option is factory installed only.

NOTE 2: Use of this option eliminates the availability of the + and – field pins for use with DC Shunt Wound Motors.

NOTE 3: This option changes the function of the cover switch to 'Auto-Off-Manual', where Auto is following input

signal for motor speed, Off is AC power off to the control, and Manual is motor speed set by pot / digi-pot in cover.

This option card allows for the use of either a grounded or non-grounded remote DC signal such as 0 to 5 through

0 to 250Vdc, 4-20mA current, or a remote speed pot. The DC input signal type can be selected for voltage (Vin) or

current (4-20mA) via the JP2 jumper clip. There is a Hi/Lo range jumper selection that should be set to the (Lo) setting

when using a 4-20mA signal, or voltage ranges of 0-5 through 0-25Vdc. When using voltage ranges of 0-25 through

0-250 this jumper must be set to (Hi). The GAIN trimpot is used to set full linear output in reference to the input signal

range. The output of this remote signal isolation board is a linear signal that is proportional to the remote input signal

being supplied.

CAUTION: DO NOT use TRIMPOT ADJUSTMENT CHART. Set pots using directions in the previous SET-UP

PROCEDURE.

INPUT

TYPE

SELECTOR

GAIN

(Vin OR 4-20in)

POT

- ARM

0-90/180

OUTPUT

VOLTAGE

JUMPER

120/240

INPUT

VOLTAGE

JUMPER

VOLTAGE

RANGE

JUMPER

CONNECTOR

SIG

+5V

COM

JP2

Vin 4-20

JP1

HI

-

+

LO

+ ARM

AC2(N)

AC1(L)

SIGNAL

GROUND

CUSTOMER WIRING

SETUP PROCEDURE FOR -56H3 OPTION

1. With NO power to control, connect a DC Voltmeter to control the output as follows: Meter COMMON to the -ARM terminal,

and meter POSITIVE to the +ARM terminal. Select correct meter range (for 90Vdc or 180Vdc if needed).

2. Preset GAIN pot on the remote signal board fully CCW.

3. Place the JP2 jumper clip in the proper position based on the input signal being used.

4. Place the P4 jumper clip in the (LO) position for 4-20mA signals or voltage signals less than 25Vdc. Place the P4 jumper

clip in the (HI) position for voltage signals greater than 25Vdc. (NOTE: Never exceed input signals greater than 250Vdc)

5. Make sure all connections and jumper settings are properly made per the hookup connection diagram and then apply AC

power to the controller.

6. Set the remote input signal to its lowest setting. Adjust the MIN trimpot to deadband (the point just before an increase

causes an output).

7. Apply the maximum remote input signal. Motor should start to run. Adjust the GAIN pot CW until no further increase in control output voltage occurs and then decrease the gain pot slowly until output voltage to the motor drops approximately 5Vdc.

8. Set the MAX trimpot on the control to the correct motor voltage.

9. Some interaction between trimpots may occur. Recheck the Min trimpot setting and repeat steps 6 through 8 as needed.

11

Page 13

IN CASE OF DIFFICULTY

- Worn motor brushes

Replace brushes

- MAX SPEED set incorrectly

- Max set too high

See ADJUSTMENT PROCEDURE

- Defective electrical components

PROBLEM POSSIBLE CAUSE(S) CORRECTIVE ACTION(S)

Motor doesn’t operate - Blown Fuse or Breaker

- Incorrect or no power source

- Speedpot set at zero

Replace Fuse or reset breaker

Install proper service

Adjust Speedpot CW to start

Armature output voltage

cannot be adjusted, output

is a constant DC level

Motor stalls, or runs very

slowly with speed control

turned fully CW

Motor hunts - Motor current less than 150mA

Repeated fuse blowing - Low Voltage

- No motor or load connected

- Speedpot low connection open

- Low Voltage

- Overload Condition

- Worn motor brushes

- Too much IR COMP

- Motor is in current limit

- Motor speed is above rated speed

- Overload Condition

- Worn motor brushes

- Defective motor bearings

Check that motor or load is connected to

armature terminals

Check that speedpot low wire is connected

Check that Vac is above 100Vac

Reduce load or increase motor size and/or

Cur. Lim. setting.

Replace brushes

See ADJUSTMENT PROCEDURE

Motor current must be greater than 150mA

D.C.

See ADJUSTMENT PROCEDURE

See ADJUSTMENT PROCEDURE

Reduce Speed

Check that VAC is above 100Vac

Reduce load

Replace

Replace

Call Dart Distributor or Representative

SPECIFICATIONS

AC input voltage .................................................................................................................................. 120 or 240 Vac +10V/-12V

Acceleration ............................................................................................................................... (150L Models) 0.5 seconds fixed

Amps - DC output ............................................................................................................................................... 150mA to 10Adc

Controller overload capacity ......................................................................................................................... 200% for one minute

Current limit trimpot range ............................................................................. (150 Models followed by -12C/-25C) 0.3 to 2.5Adc

Deceleration .............................................................................................................................. (150L Models) 0.5 seconds fixed

Dimensions and weights:

WIDTH LENGTH DEPTH WEIGHT

ENGLISH

METRIC

Drive service factor ................................................................................................................................................................... 1.0

Efficiency ..................................................................................................................................................................... 85% typical

Input frequency ....................................................................................................................................................... 50 or 60 Hertz

Max. trimpot speed range ................................................................................................................. 60% to 110% of base speed

Min. trimpot speed range .............................................................................................................. 0% to 30% of maximum speed

Power devices ............................................................................................................................................ SCR isolated case tab

Shunt field voltage .................. (Available on 150D Models only) 100Vdc @ 120Vac input; 200Vdc @ 240Vac input; .7Adc MAX

Speed control ....................................................................................... via 5kW 1/2W potentiometer or 0-10Vdc isolated signal

Speed range ........................................................................................................................................................................... 30:1

Speed regulation ............................................................................................................................................ ±1% of base speed

Temperature range ............................................................................................................. -10o to 40o C. ambient (15o to 104o F. )

Transient protection ................................................................................................................... MOV and X2 rated line capacitor

Trigger ........................................................................................................................................................................ opto-coupler

Type of accel/decel ramp ...................................................................................................................... 150D models only - linear

5.530"

140.4mm

7.300"

185.4mm

5.739"

145.8mm

(150D Models) 0.5 - 8 seconds adjustable

(150 Models followed by -100C/-200C) 1 to 15Adc

(150D Models) 0.5 - 6 seconds adjustable

WEIGHT (-PB)

3.005 lb.

1363 gms.

3.120 lb.

1415 gms.

12

Page 14

NOTES:

13

Page 15

NOTES:

14

Page 16

REPAIR PROCEDURE

In the event that a Product manufactured by Dart Controls Incorporated (DCI) is in need of

repair service, it should be shipped, freight paid, to: Dart Controls, Inc., 5000 W. 106th Street,

Zionsville, IN. 46077, ATTN: Repair Department. Please include Name, Shipping Address (no

P.O. Box), Phone Number and if possible, e-mail address.

Those orders received from anyone without an existing account with DCI must specify if they

will be paying COD or Credit Card (Master Card/Visa/American Express). This information is

required before work will begin. If you have an account with Dart your order will be processed

according to the terms listed on your account. Products with Serial Number date codes over

5 years old will automatically be deemed Beyond Economical Repair (BER). A new, equivalent

device will be offered at a substantial discount.

Completed repairs are returned with a Repair Report that states the problem with the control

and the possible cause. Repair orders are returned via UPS Ground unless other arrangements

are made. If you have further questions regarding repair procedures, contact Dart Controls,

Inc. at 317-873-5211.

YOUR MOTOR SPEED CONTROL SOLUTION PROVIDER

OEM Chassis SCR Drives

Dual Input voltage, adjustable HP

range, isolated signal follower and

Closed loop accuracy, 4-20mA and

Dart C ontrols, Inc. is a

designer, manufacturer, and

marketer of analog and

digital electronic variable

speed drives, controls, and

accessories for AC, DC,

and DC brushless motor

applications.

reversing options

Digital SCR Drives

serial communications, integral

programmable display

Shown abov e is j ust a

sampling of the expanded

line of Dart controls that

feature the latest in electronic

technology and engineering.

Products are manufactured

in the U.S.A. at our Zionsville

(Indianapolis, Indiana)

NEMA 4/4X SCR Drives

Dual Input voltage, adjustable HP

range, isolated signal follower and

reversing options

Brushless DC Drives

Closed loop accuracy, line and low

voltage versions through 1 HP

production and headquarters

facility - with over 2,000,000

variable speed units in the

field.

In addition to the standard

off-the-shelf products, you

can select from a wide variety

of options to customize

controls for your specific

application. For further

information and application

assistance, contact your local

Dart sales representative,

stocking distributor, or Dart

Controls, Inc.

Low Voltage/Battery

PWM Drives

Chassis and NEMA 4X versions,

speed pot and signal follower

operation

Digital Accessory &

Resale Items

Motors to 700 HP, VFD's to 200

HP, NEMA rated encoder, digital

programmable potentiometers and

tachometers

Dart Controls, Inc.

facturer of high quality

Manu

DC and AC motor speed

controls and accessories

since 1963.

Loading...

Loading...