Page 1

®

Operating

Instructions

CAUTION: To reduce the risk of injury, the user must read and understand this

instruction manual before using this product. Save these instructions for future reference.

1

Page 2

Page 3

Table of Contents

The Darex Story .................................................................................... page 2

Safety Instructions ............................................................................... page 3

XT-3000 Specification Sheet................................................................. page 5

Capabilities & Performance .................................................................. page 6

XT-3000 Reference Drawing................................................................. page 7

Setting Up the XT3000.......................................................................... page 8

Drill Alignment...................................................................................... page

Drill Sharpening .................................................................................... page 12

Drill Point Splitting ............................................................................... page 14

Chuck Information................................................................................ page 16

Wheel Information................................................................................ page 18

General Maintenance ............................................................................ page 21

Trouble Shooting Section...................................................................... page 24

Drill Nomenclature................................................................................ page 25

Wiring Diagram.........................................

Electrical Diagram................................................................................. page 27

Chuck Parts List .................................................................................... page 28

Exploded View - Chuck ......................................................................... page 29

Parts List - Machine Rev B Serial Number ............................................ page 30

Exploded View - Machine Rev B Serial Number .................................... page 31

Exploded View - Sharpening Fixture 118°-150° (All Models)............... page 32

Exploded View - Alignment Schematic Rev B Serial Number................ page 33

Parts List - Machine Rev A Serial Number ............................................ page 34

Exploded View - Machine Rev A Serial Nu

Exploded View - Alignment Schematic Rev A Serial Number................ page 36

LEX050 - Large Drill Attachment .......................................................... page 39

LEX100 - XY Table Attachment ............................................................. page 43

LEX150 - Countersink Attachment........................................................ page 44

LEX200 - Brad Point Attachment .......................................................... page 48

LEX250 - Step Drill Attachment ............................................................ page 50

L

EX300 - 90º - 120º Drill Attachment........

LEX350 & 351 - Mini Attachment........................................................... page 58

XT3000 Auto Sharpener Attachment..................................................... page 61

*For Technical Service visit our web site at www.darex.com

Or call Darex 800-547-0222

Or contact your Darex Distributor

............................................ page 26

mber .................................... page 35

........................................... page 54

9

3

Page 4

The Darex Story

Darex Corporation began in 1973 in Beecher, Illinois. The D, A and R of Darex are the initials of three

generations of the Bernard family; David, Arthur and Richard Bernard. David and his father Richard

founded Darex. Grandfather Arthur Bernard, who earlier founded the Bernard Welding Company,

contributed his energy and guidance to Darex. Art’s inventions revolutionized the welding industry.

In 1978, Darex relocated to Ashland, Oregon. Grandson Dave and son Dick carry on Arthur’s legacy of

inventiveness. Darex grew to become the most recognized name in the cutting tool sharpening

industry. Today, Darex is a world-leading manufacturer of precision cutting tool sharpeners.

Darex is proud to offer a complete line of quality precision cutting tool sharpeners at affordable prices.

Before our first days, we at Darex had looked at our competitor’s sharpeners and asked ourselves:

“Must c

accuracy or low price inaccuracy?” Our sharpeners prove you can have it all: Simplicity, Accuracy,

and Affordability.

We have always emphasized innovative product design and tested technology. The experienced

personnel at our modern manufacturing facility use the latest production methods. The Darex

marketing team knows first-hand the machines we sell and will guide you to the best machine for

your needs. Our skilled technical service department is happy to answer your questions about our

products or cutting tools.

utting tool sharpeners be complica

ted? Why must the choice be limited to cost prohibitive

The XT-3000 Sharpener

The Darex XT-3000 Xpandable Drill Sharpener sharpens standard and split point drills at any angle

from 118 to 150 degrees. It sharpens drills sized from 3mm to 21mm. (.118 - .826) This sharpener

comes standard with CBN wheels for sharpening HSS and cobalt drills. Diamond wheels for

sharpening carbide drills are available as an option. The XT-3000 allows you to control each drill’s

point configuration including the relief and design of the split point. All adjustment and attachment

changes are done without tools. To keep your Darex XT-3000 in top condition, please refer to the

maintenance section of this manual.

Replacement wheels and parts are listed in the parts list on page 30. Schematic breakdowns begin

on page 31 of the manual.

*Optional accessories allow you to sharpen other cutting tools; including 90° spot drills, step drills,

brad points, larger drills, Weldon, single flute, 3 flute, 6 flute countersinks and left hand drills.

2

Page 5

Safety Instructions

Safety Instructions

FOR YOUR OWN SAFETY, READ INSTRUCTION

Caution:

Caution:

WHEN USING ELECTRIC TOOLS, BASIC SAFETY

PRECAUTIONS SHOULD ALWAYS BE FOLLOWED

TO PREVENT THE RISK OF FIRE, ELECTRIC

SHOCK AND PERSONAL INJURY, INCLUDING

THE FOLLOWING:

230v~,50Hz,6A

230v~,50Hz,8A

MANUAL BEFORE OPERATING MACHINE!

• WE DO NOT RECOMMEND OPERATING

MACHINE WITHOUT A VACUUM SYSTEM

RUNNING

• GRINDING DUST INHALED/INGESTED

CAN BE HARMFUL TO YOUR HEALTH.

• GRINDING PARTIALS WILL CAUSE

DAMAGE TO THE INTERNAL

COMPONENTS

• WHEN MAINTENANCE OR MACHINE

ADJUSTMENTS ARE PERFORMED ON

SHARPENER ALWAYS: Push the emergency

stop button, unplug unit from power supply

and use a “LOCK OUT” “TAG OUT” procedure.

• FOLLOW INSTRUCTIONS ENTITLED

“DAREX XT-3000 Maintenance" in this

Instruction Manual.

• NEVER TOUCH INTERNAL PARTS OF THE

S

HARPENER WHEN THE SHARPENER IS

ON The rotating grinding wheel can cause

injury.

• USE CAUTION WHEN REPLACING THE

GRINDING WHEEL Foll

entitled “How to change a wheel”, on page 18

of this Instruction Manual.

• KEEP GUARDS IN PLACE and in working

order. See Decal at left.

• REMOVE WRENCHES Always check to see

that any tools have been removed from

sharpener before turning it on.

• KEEP WORK AREA CLEAN Cluttered areas

and benches invite accidents.

• DON'T USE IN DANGEROUS

ENVIRONMENT Do not use power tools in

damp or wet locations, or expose them to rain.

Do not use tools in the presence of flammable

liquids or gases.

• KEEP WORK AREA WELL LIT

• STORE EQUIPMENT in a safe place when not

in use.

• DON'T FORCE TOOL It will do the job better

and safer at the rate for which it was designed.

• USE THE RIGHT TOOL Don’t force tool or

attachment to do a job it was not designed for.

• TO MINIMIZE THE RISK OF INJURY, ALWAYS

USE PROPER EYE AND REPIRATORY PROTECTION:

Everyday eyeglasses only have impact resistance lenses

and they are NOT safety glasses. (See Decal at left.)

Use appropriate respiratory face or dust mask.

• AVOID ACCIDENTAL STARTING Make sure

switch is in the “OFF" position before plugging

it in.

• USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. The use of improper accessories

may cause hazards. See Decal at left.

• CHECK FOR DAMAGED PARTS Before

further use of the tool, a guard or other part

that is damaged should be carefully checked to

assure that it will operate properly and perform

its intended function. Check for alignment of

moving parts, binding of moving parts,

breakage of

conditions that may affect its operation. A

guard or other part that is damaged should be

properly repaired or replaced.

parts, mounting and any other

ow instructions

• NEVER LEAVE TOOL RUNNING

UNATTENDED Turn power off.

• USE PROPER EXTENSION CORD Make sure

extension cord is in good condition. When using

an extension cord be sure to use one heavy

enough to carry the current the Drill Sharpener

will draw. An undersize cord will cause a drop in

line voltage, resulting in a loss of power and/or

overheating.

• DO NOT USE DAMAGED OR UNSHAPED

WHEELS Use grinding wheels suitable for speed

of grinder.

• THE CONTINUOUS A-WEIGHTED sound

pressure level at the operator’s ear is not over

60dB (A).

• RISK OF INJURY DUE TO ACC

STARTING. Do not use in an area where

children may be present.

• THE WEIGHTED ROOT MEAN SQUARE

ACCELERATION VALUE to which the arms are

subjected to does not exceed 2.5 m/s2.

• WARNING: This product contains a chemical

known to the State of California to cause cancer.

Some dust created by power sanding and grinding

as well as contents from the machine may contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

IDENTAL

3

Page 6

GROUNDING INSTRUCTIONS

• FOR ALL GROUNDED CORD CONNECTED

TOOLS:

• In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. Do not modify the plug provided if it

will not fit the outlet, have the proper outlet

installed by a qualified electrician. Improper

connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation, having an outer

surface that is green with or without yellow

stripes, is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug

is necessary, do not connect the equipmentgrounding conductor to a live terminal. Check

with a qualified electrician or serviceman if the

grounding instructions are not completely

understood, or if in doubt as to whether the tool

is properly grounded. Use only 3-wire extension

cords that have 3-prong grounding plugs and 3pole receptacles that accept the tool’s plug.

Repair or replace damaged or worn cord

immediately.

• GROUNDED, CORD-CONNECTED TOOLS

INTENDED FOR USE ON A SUPPLY CIRCUIT

HAVING A NOMINAL RATING LESS THAN

250 VOLTS: See Table 1 for minimum gauge

cords.

Table 1 Minimum Gauge Cords

Volts

120 V 25 / 7.5 50 / 15 100 / 30 150 / 45

Ampere Rating

M o re than Not more than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

240 V 50 / 15 100 / 30 200 / 60 300 / 90

Total length of cord (feet / meters)

AWG

Not Recommended

4

Page 7

XT-3000 Specification Sheet

XT-3000

5

DRILL SHARPENER

XT-3000 Features

The XT-3000 was designed incorporating Versatility, Simplicity & Expandability. Optional attachments

sharpen other cutting tools including step drills, brad points, larger drills, Weldon and single flute

countersinks. This unit is an upgrade-able sharpener that grows with your needs. Simplicity will allow

multiple users successful results with minimal training.

Specifications for 115V & 230V

· Standard Grinding Wheels: 180 Grit CBN - HSS, Cobalt & 180 Grit Diamond - Carbide

· Max Wheel Diameter: 6.45 inch ( 164 mm)

· Arbor Size: 1.25 inch (31.75 mm)

· Wheel Surface Speed: 75 ft/sec (23m/sec) for 60 Hz Model 115V

95 ft/sec (29m/sec) for 50 Hz Model 230V

· Motor Specs: ¼ hp - 2850 rpm – 60 Hz Model 115V

¼ hp - 3450 rpm – 50 Hz Model 230V

· Operating Time: Continuous Duty

· Voltage: 115 VAC +/- 10% & 230 VAC +/- 5%

· Frequency: 60 Hz +/- 5% - Model 115V

50 Hz +/- 5% - Model 230V

· Sharpener Current: 2.5A Run / 40A Start Model 115V

1.6A Run / 25A Start Model 230V

· Accessory Current: 6.0A Run Max.

· Operating Temperature: 40° to 95° F ambient (4° to

. Humidity: Non-condensing

35° C)

Page 8

Capabilities & Performance

Capabilities & Performance

• Drill Types: Two fluted HSS, Cobalt or Carbide SAE & Metric twist drills

• Drill Point Styles: Standard Conic & Split Point

• Split Point Styles: Standard X split

• Point Angles: 118° - 150°

• Drill Diameter: 3 mm - 21 mm (.118 to .826)

• Lip Height Accuracy: ANSI B94.11, NAS 907 and ISO 10899 Standards

Decal Identifications

“Wear Safety Glasses” -

Accessory receptacle capacity -

115v~,50Hz,6A

115v~,50Hz,8A

“Do not operate without

wheel guard cover” -

6

Page 9

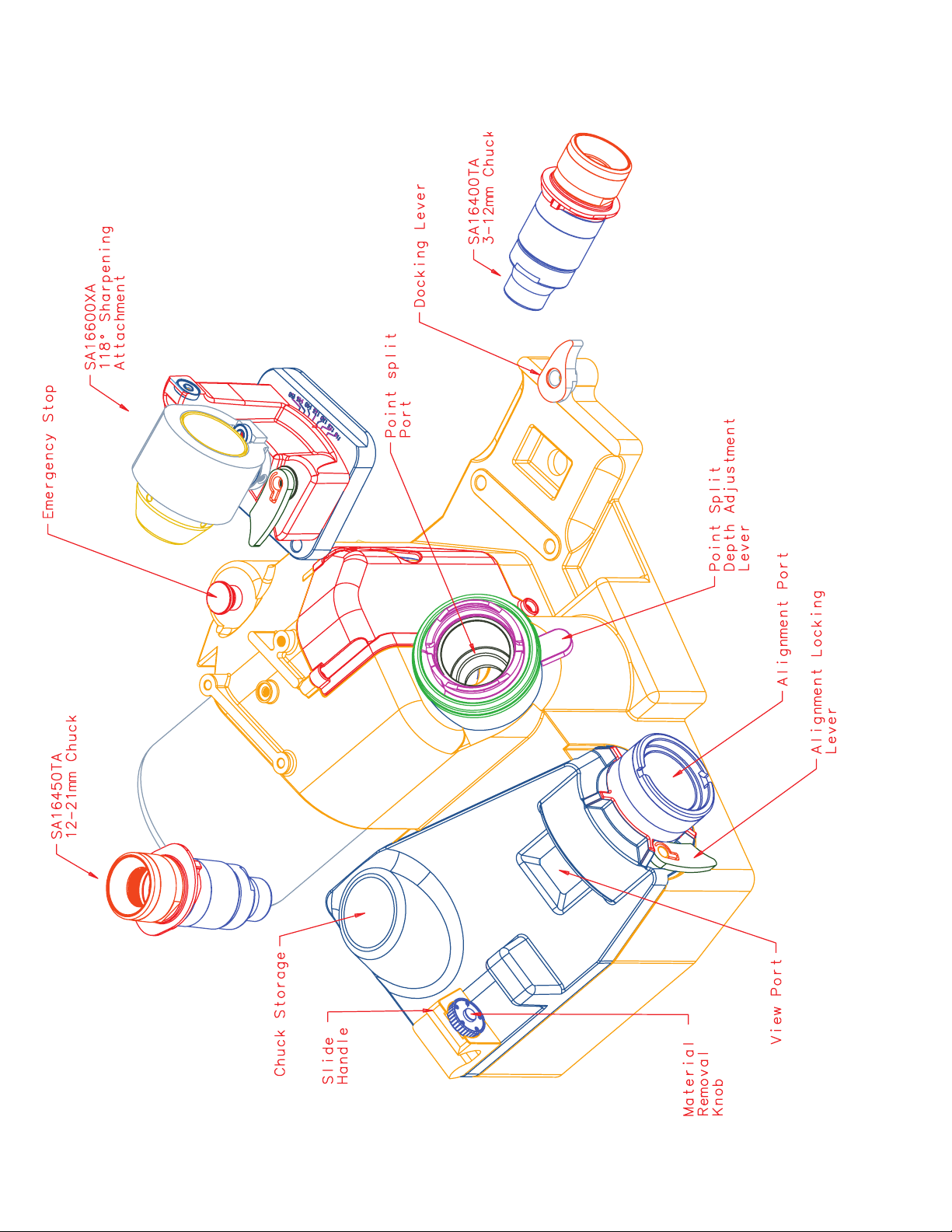

XT-3000 Reference Drawing

230V Units Only

7

Page 10

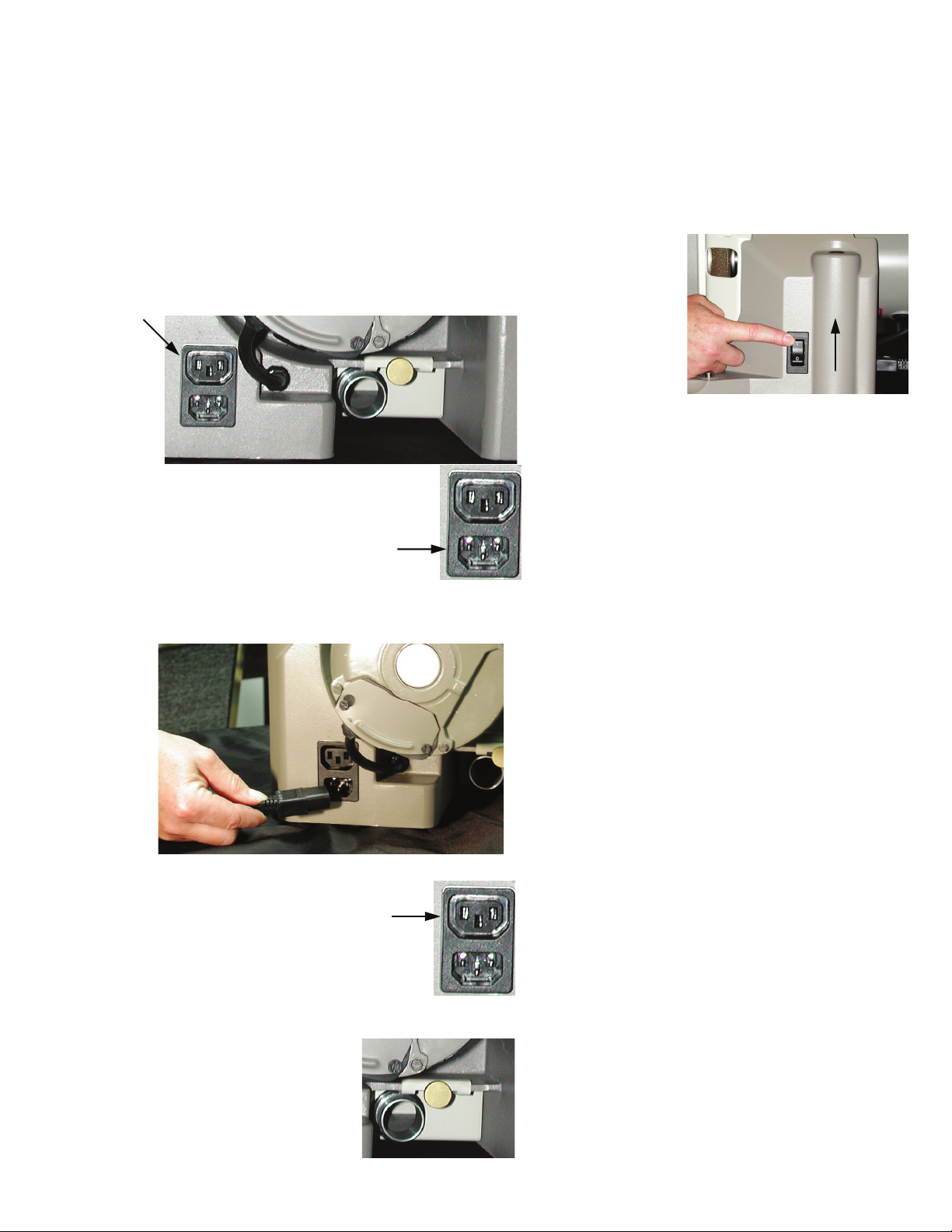

Setting up the XT3000

The XT-3000 comes equipped with grinding wheels, a

sharpening fixture and 2 chucks, 1; 3mm – 12mm & 1; 12mm

– 21mm.

1. Remove from shipping box and all packaging

material before powering up the machine. NOTE:

Due to the weight of the XT-3000, it is suggested that

the lip of the casting, located above the motor, can be

used as a handle for lifting.

2. Located at the back and on the right side of the

XT3000 is the power receptacle. Within that

receptacle you will find a power inlet and accessory

receptacle.

3. The power inlet is located at the bottom

of the power receptacle.

the power cord in to the power inlet and then in

Plug

to the power outlet source.

6. Un-box the chucks.

7. Make sure sharpening fixture is secured

more information on mounting the sharpening

fixture. See

page 12.

8. To power on

the machine,

push the rocker

switch to the

ON position to

start the

grinding wheel

in motion.

9. To sharpen a drill follow steps in the next three

sections; Align, Sharpen and Point Splitting.

to base. For

4. The accessory receptacle is located at the

top of the power receptacle and will allow

you to use a dust extraction system in

conjunction with the use of the XT3000.

*We highly recommend the use of a

vacuum when the machine is in use.

Darex offers a vacuum system compatible

with your XT3000. Call Darex for more information.

• SA12075EA - 115V

• SA12072EA - 230V

5. Make sure the grit tray is in

place and secure.

8

Page 11

Drill Alignment

The alignment port is located on the left side of

the XT-3000.

The first stage to sharpening a drill starts with

the alignment process. In the alignment

process, you will go through a few necessary

steps prior to sharpening. Setting the material

removal amount, adjusting the alignment tube

to produce desired relief amount. Use the

Darex easy align to set the drill to length and

time the cutting edge.

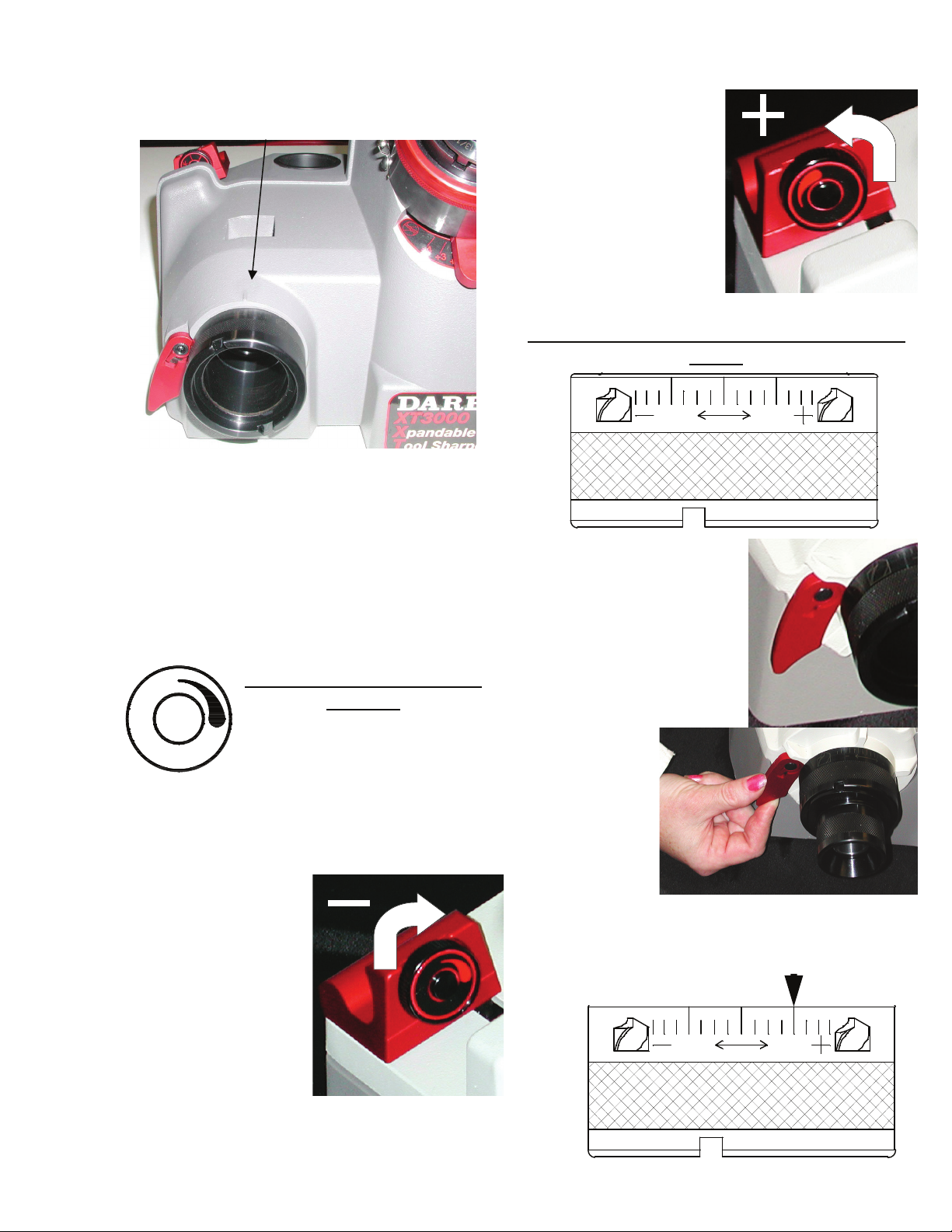

Setting Material Removal

Amount

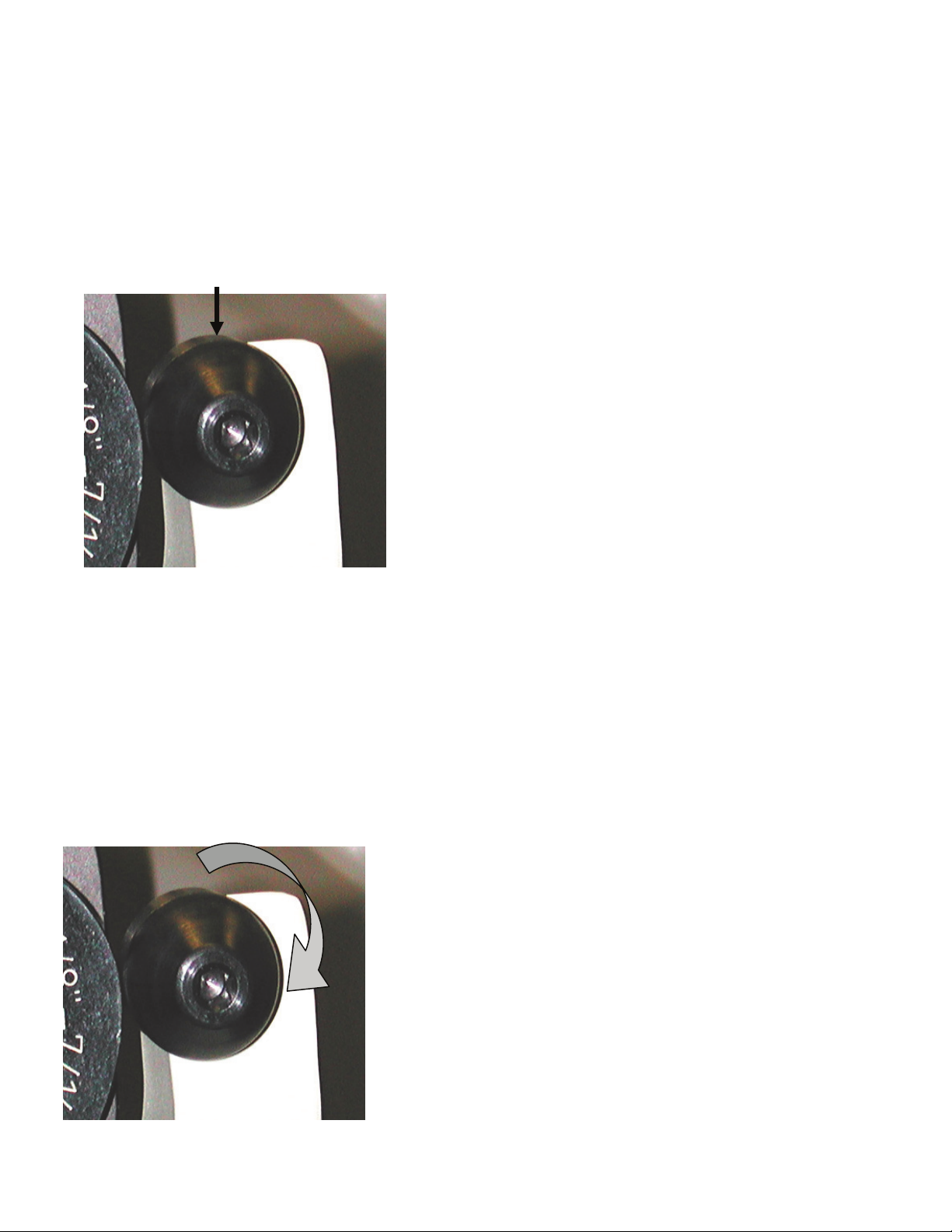

1. Rotate the material removal

knob to adjust the amount of

stock you want to remove from

the end of the drill. Stock

removal ranges from approximately .010 .030. Remove more material if the drill is

excessively worn or damaged. Remove less

material if you are

renewing the drill.

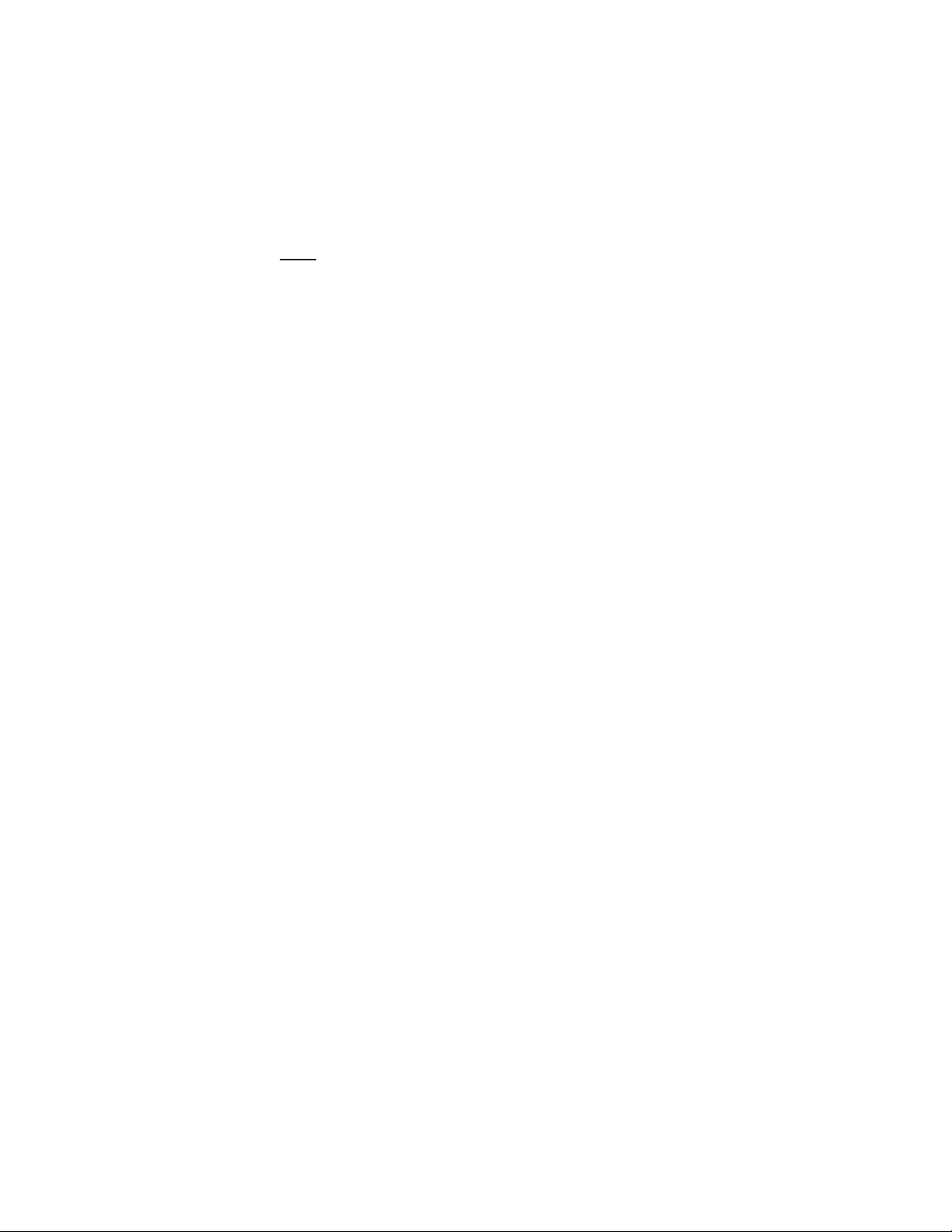

2. Rotate the

material removal

knob clockwise to

decrease the

amount of material

removal

Tip:

Sharpen drills

on Minimum MTO to

achieve longer

wheel life.

or counterclockwise to

increase material

removal.

Setting Alignment Tube for Desired Heel

Relief

To increase or

decrease the amount of

heel relief produced

during sharpening,

change the position of

the alignment tube.

1. Lift the

alignment

locking

lever.

This will

allow you

to rotate

the alignment tube in either direction.

2. To increase heel relief, rotate the

alignment tube counterclockwise.

118°135°

118°135°

9

Page 12

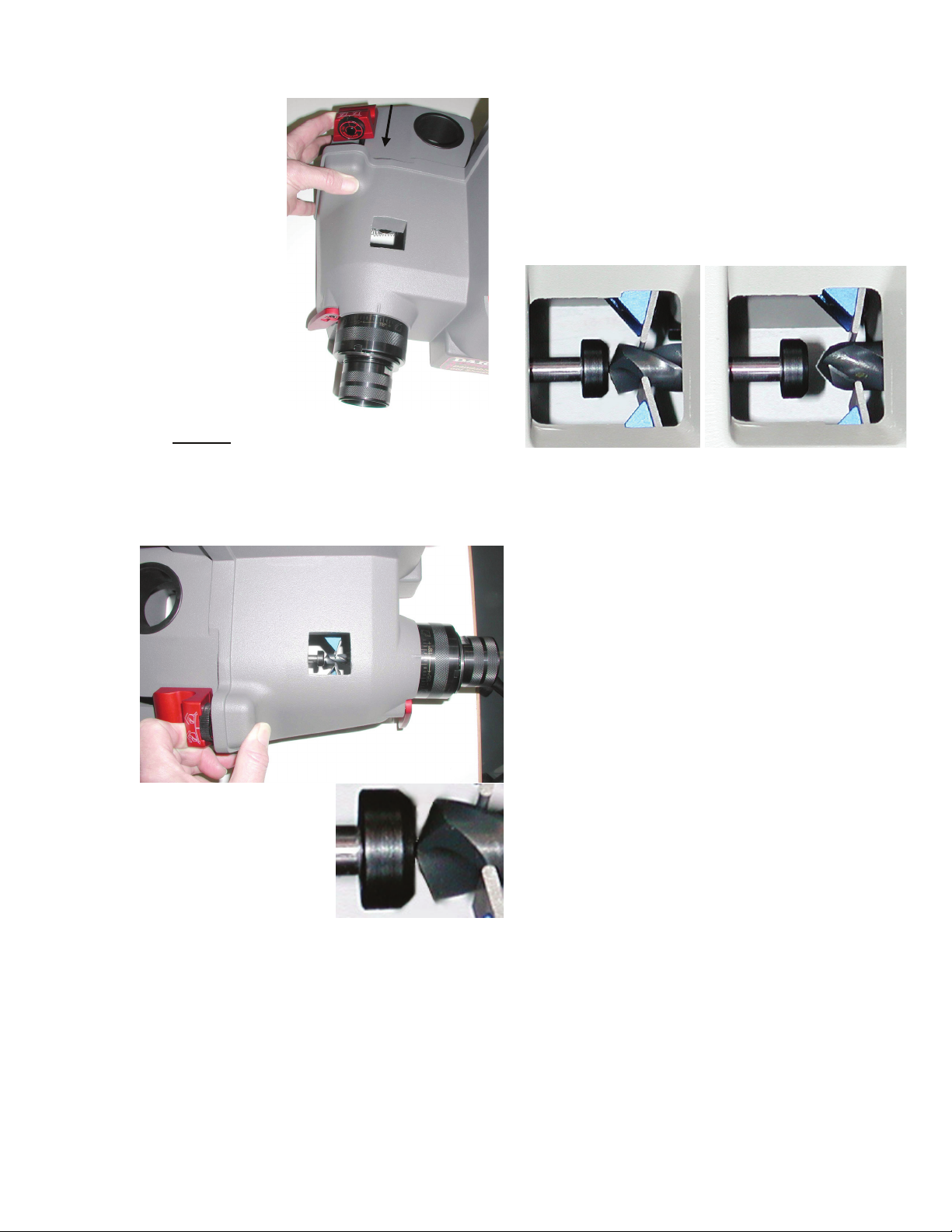

Drill Alignment

To decrease heel relief, rotate clockwise.

3. To secure the alignment position,

tighten locking

lever.

118°135°

Setting the

drill to the

proper length

1. Holding the chuck

in a horizontal

position insert the drill into the appropriate

sized chuck. (Sizes are on the cam)

2. Rotate the chuck knob clockwise, which

closes the chuck jaws onto the drill. Then

slightly loosen the chuck jaws by rotating

the chuck knob counterclockwise, about ½

turn. To determine how tightly the drill

should be held during the alignment

process, the drill should slide freely and

drop out when the chuck is held in a

vertical position.

Timing the cutting edge

3. Insert the

chuck and drill

into the

alignment tube.

Align the cam dogs with the slots.

10

The cam dogs should bottom out against

the slots.

Allow the drill to protrude approximately 2

inches as shown.

2”

Page 13

Drill Alignment

4. S-L-O-W-L-Y

squeeze

together the

red slide

handle until it

touches

casting. We

emphasize

slowly,

because

squeezing the

handles too

quickly pushes

the drill too

deeply into

the chuck.

NOTE:

If this happens, the drill will not

touch the wheel during the sharpening

process.

5. With the handles held together, look

through the viewing port and see if drill is

The pawls should be seated in the helix of

the drill. If incorrect, loosen chuck knob

and repeat step 4. The jaws are most likely

gripping the drill body too tightly and will

not allow the drill to rotate into position.

CORRECT INCORRECT

6. Once the drill has been aligned correctly

and without releasing the slide handle,

tighten the chuck knob clockwise until the

chuck jaws grip the drill securely. Release

the slide handle and remove chuck from

alignment tube.

positioned correctly.

Drill point should be

touching the end of

the pusher shaft cap.

11

Page 14

Drill Sharpening

The Sharpening fixture is located on the right

side of the machine.

Mounting the Sharpening fixture

1. Rotate the locking lever so the flat edge is at

the top, horizontal and in a straight line with

the base casting.

2. Position the sharpening

fixture so that the 2

location holes on the

base of the alignment fixture are aligned

with the 3/8 dowel pins.

3. After sharpening

fixture is in place,

rotate the locking

lever clockwise until

snug. This will secure

the fixture to the base.

Adjusting the Point Angle

You must loosen the

sharpening fixture and

slide the point angle

indicator to the desired

degree.

1. To loosen, pull

the locking

lever towards

you.

2. Place fingers on each

side of the sharpening

pivot base casting.

3. Gently slide base

casting in either

direction to align

the angle

indicator with the

desired point angle

degree.

4. Secure the selected

point angle position by

pushing the locking

lever away from you

until it stops.

5. Before sharpening, make sure the sharpening

fixture is secure and no longer slides in either

direction.

12

Page 15

Drill sharpening

WARNING: Make sure Split Port Cover

and Eye Shield are in place before

sharpening. (International Models Only)

Power up machine

To turn the machine on, push the top of the

rocker switch. The machine will power up and

the grinding wheels will begin to rotate.

Sharpen

1. To make sure

the drill clears

the wheel, push

the sharpening

tube all the way

to the left

before inserting

chuck.

2. Insert the chuck

with the thickest

part of the cam

touching the

swing bearing.

3. Release sharpening tube very slowly.

4. With slight

pressure

towards the

grinding wheel,

rotate the

chuck 360

degrees,

several times in

a clockwise

direction. To

achieve an

efficient and

balanced

sharpening on

both cutting

edges, avoid stopping when the drill is in

the grind. Do not reposition your hand in

mid-sharpening, wait until the drill rotates

off the wheel. Continue rotating the chuck

in 360 degree rotations until the grinding

noise is minimized to a near silence.

5. Before removing the chuck, push the

sharpening tube to the left, remove

chuck. Release sharpening tube slowly.

13

Page 16

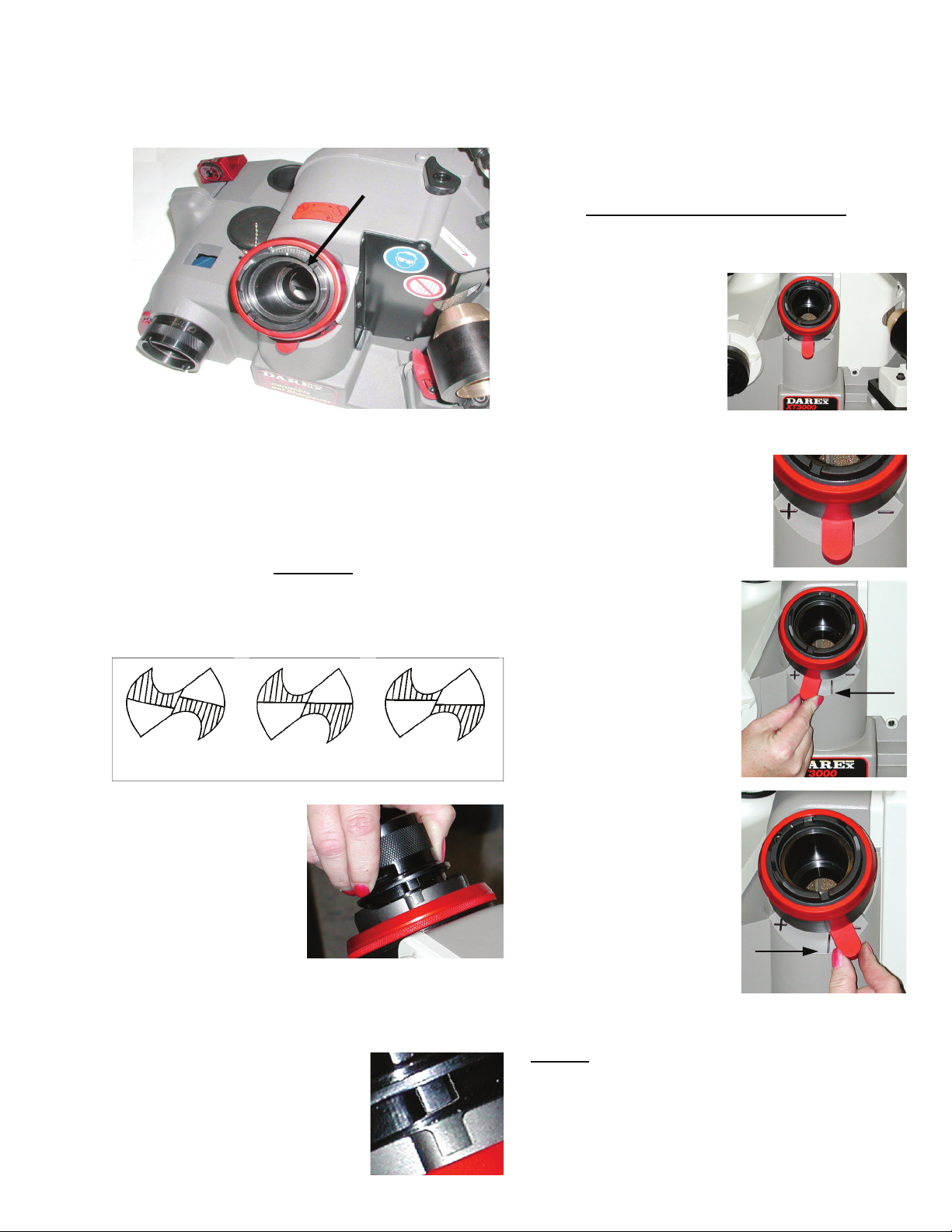

Drill Point Splitting

The Point Splitting Port is located in the center

of the machine.

Approximately 3-7° rake is created, producing a

drill with a self-centering point. Its advantages

are the ability to reduce thrust and eliminate

walking at the drill point. This is a distinct

advantage where drill bushings/fixtures are not

used.

Splitting

POINT SPLIT DIAGRAMS

DEPTH OF SPLIT DIAGRAM

Past Center To Center Below Center

Upon completion of

the sharpening

procedure, Do Not

loosen the drill in the

chuck. Insert the

chuck into the point

splitting port. Align the

cam dogs with the

slots on the point split

tube. Let the weight of the chuck ease the drill

down and onto the grinding wheel. With slight

pressure, be sure the chuck stays seated in the

point splitter.

When the grinding noise is

reduced to near silence pull the

chuck out about 1/2 way and

rotate it 180 degrees to split

the opposite side of the drill

point.

NOTE: Do not force the chuck into the grinding

wheel or damage to the drill or wheel may

occur.

Adjusting the Depth of Split

The depth of split can vary from drill

manufacturer to drill manufacturer. The point

split depth adjustment

feature designed on the

XT-3000 makes it easy to

mimic multiple split

styles. The point split

depth adjustment lever is

attached to the point

split chuck tube. As you

move the lever, it backs the chuck tube away

from the wheel or moves it

closer into it.

1. Located on the underside

of the point splitter is the

point split depth

adjustment lever.

2. To increase the

depth of split, push

lever to the left

toward the + sign.

This will allow the

drill to travel deeper

into the wheel,

increasing the depth

of split.

3. To decrease the

depth of split, push

the lever to the right

toward the – sign.

This will back the

drill away from the

wheel.

NOTE:

deeper than desired, you will have to regrind the

drill beyond the over split portion before splitting

again.

To correct a drill that has been split

14

Page 17

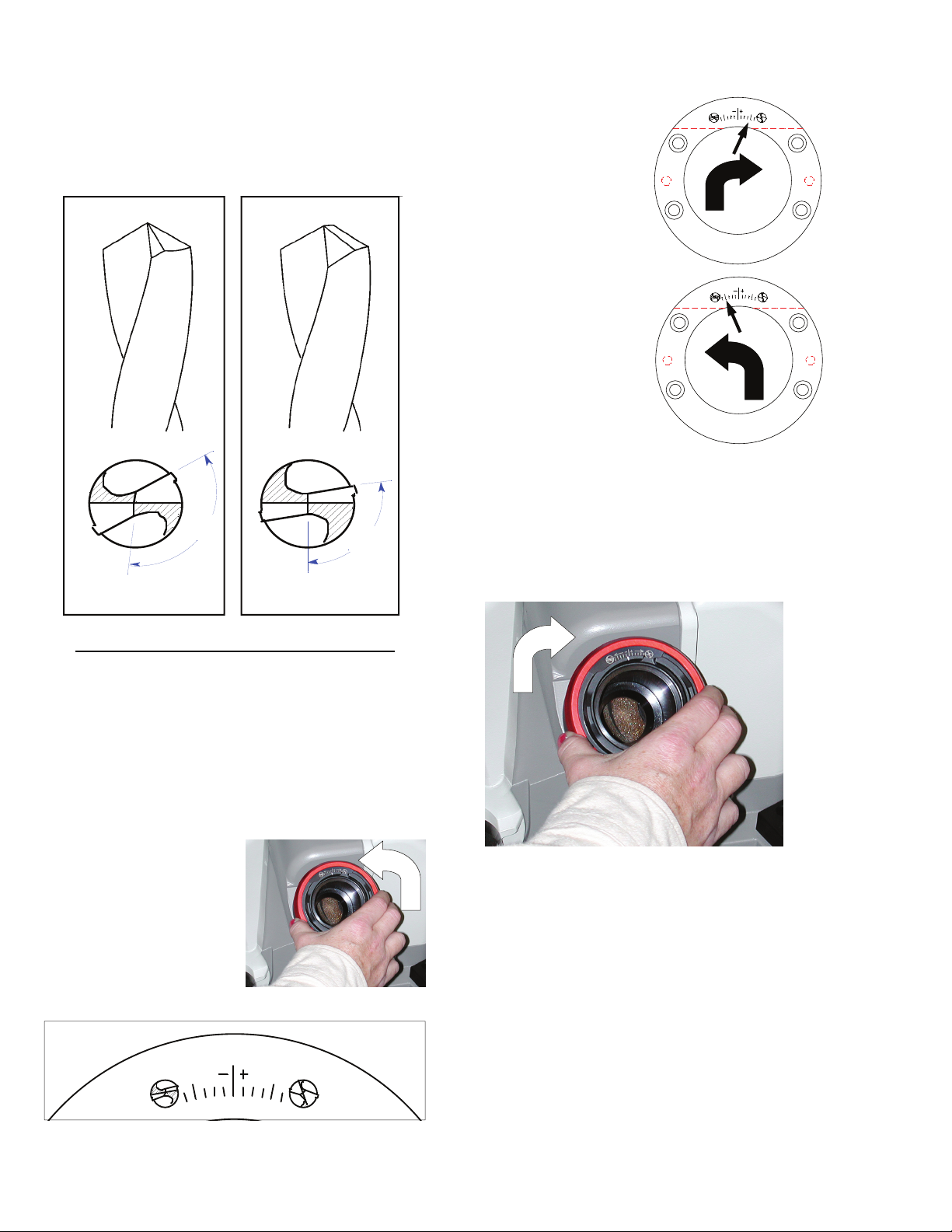

Drill Point Splitting

POINT SPLIT ANGLE

DIAGRAM

120°

130°

Pointed Flat

Adjusting the Split Angle Rotation

Typically the split angle of a drill is 120° - 130°

from the cutting edge. By increasing the rotation

of the split angle, the split portion of the drill

meets the cutting lip at a greater angle, which

will give the drill more strength and durability.

This added split angle creates a pointed profile

at the very center of the drill, producing a selfcentering effect and reduces drill point walking

at the start of a hole.

1. Loosen the point

split nut by

rotating the nut

counterclockwise.

2. Rotate the point

95°

105°

split angle adjuster

135°118°

clockwise to

increase the split

angle.

3. Rotate the adjuster

counter clockwise

135°118°

to decrease the

split angle.

4. Once split angle adjustment has been

made, rotate the point split nut clockwise

to retain the selected setting and secure

the point split angle adjuster.

15

135°118°

Page 18

We recommend the

Darex dust extraction system.

Chuck Information

A regular maintenance program should

be set up for each chuck. Keeping your

chuck clean and grit free will help

maintain drill concentricity and lengthen the life

of your chucks. For detailed cleaning

instruction, See Maintenance page 22.

XT-3000 CHUCKS

The XT-3000 jaw chuck system was designed

with accuracy and simplicity in mind. As a result,

the XT-3000 chuck allows you to cover a large

diameter range of drills without the aid of

individual collets. You can quickly change from

the largest drill diameter to the smallest in

seconds. The accuracy of the chuck will produce

drills that exceed ANSI, NAS 907 & & ISO 10899

standards. The various chucks and accessories

have drill diameter capabilities that range

from .059” – 1.1875” (1.5mm to 30mm).

Make sure large drills are secure

after tightening the chuck.

Morse Taper drills:

To secure a Morse Taper drill in the chuck, it is

necessary for the drill to have a minimum flute

length of 4.000 inches. The taper will then be

free from the grasp of the jaws, eliminating

interference with the larger tapered shank. The

other option for holding these types of drills is a

split bushing. Bush the body of the drill up to or

larger than the interfering diameter.

End Mill shank drills:

Typically, an end mill drill has a shank diameter

larger than the body of the drill.

Some End Mill shank drills can be sharpened on

the XT-3000, depending on the length of the

flute verses the length of the shank.

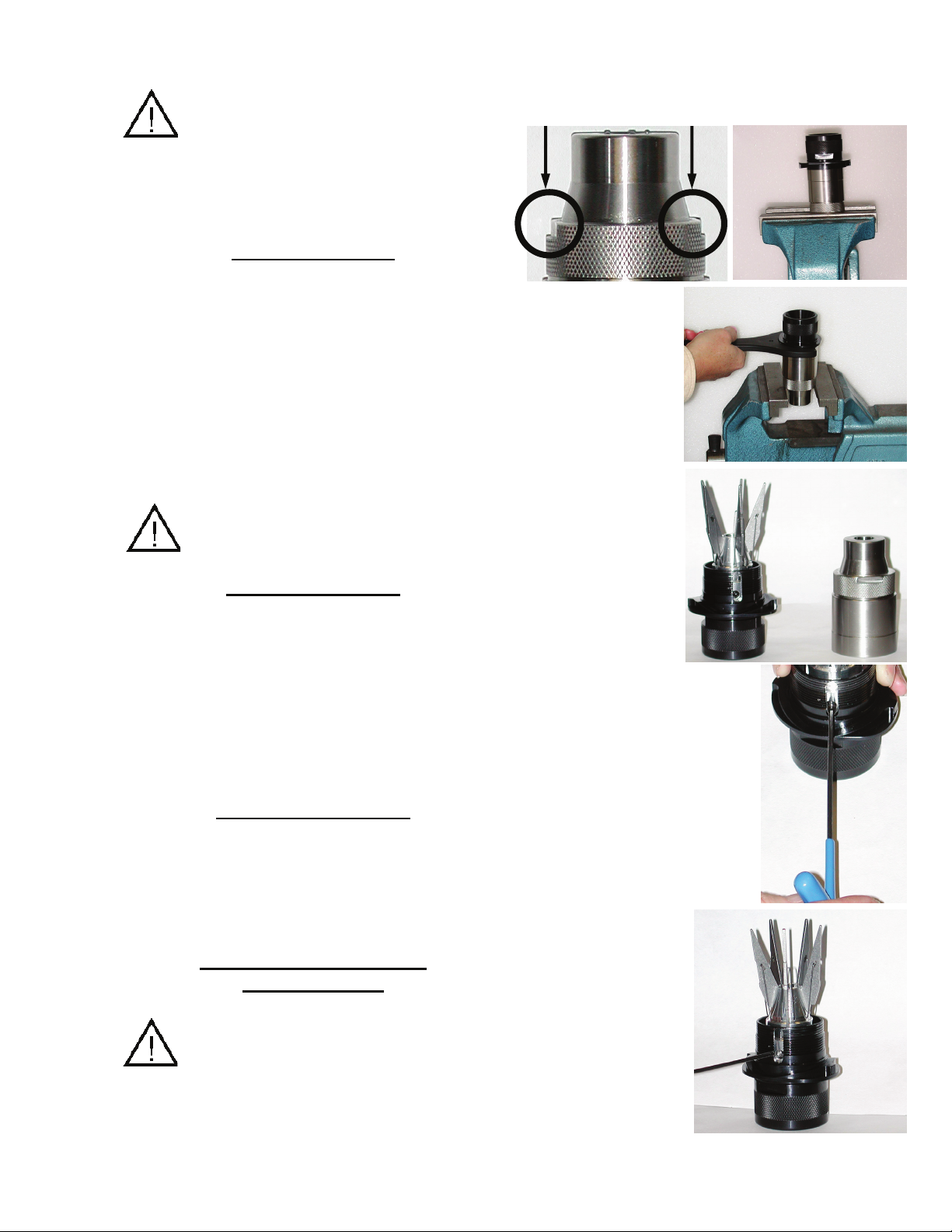

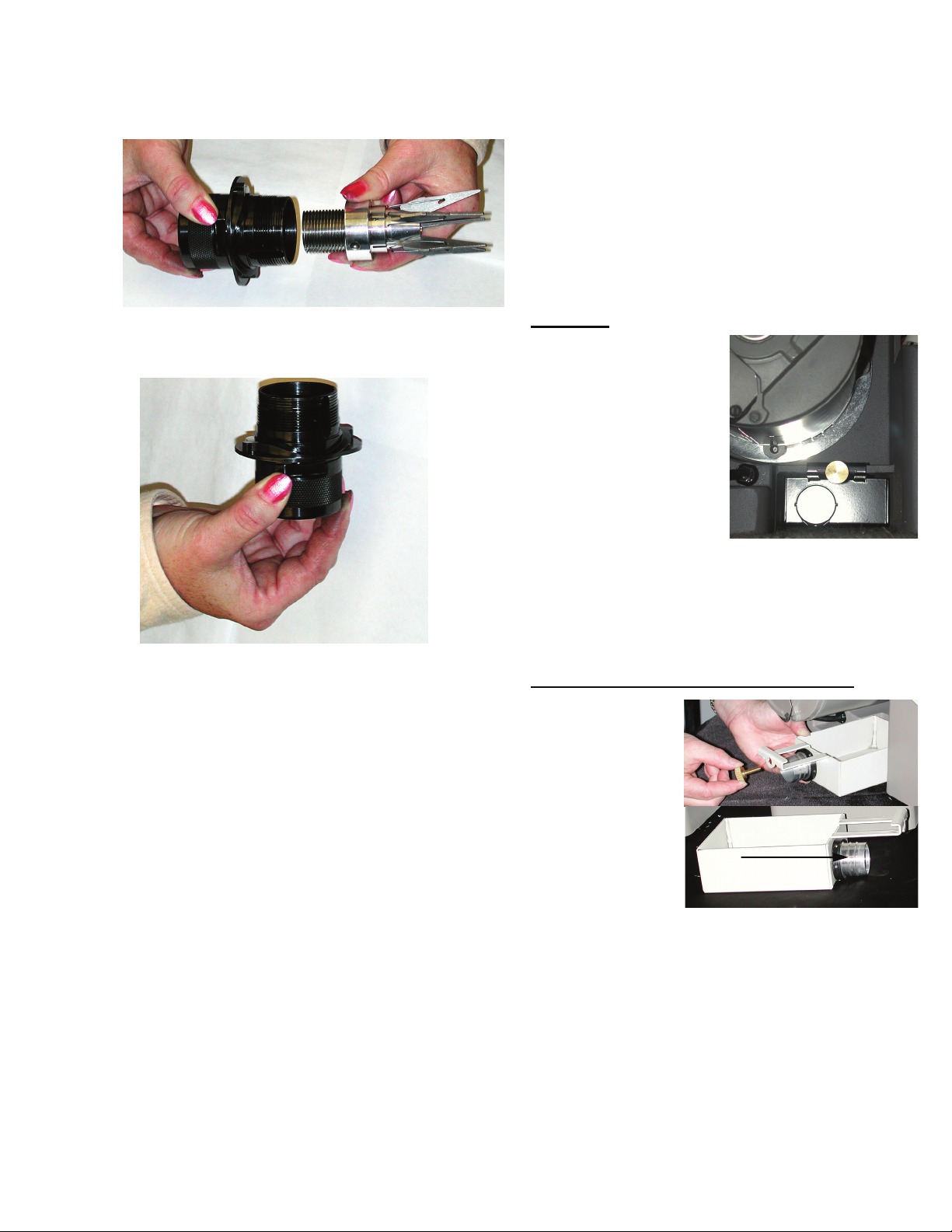

CHUCK DISASSEMBLY &

MAINTENANCE

chuck assembly should be disassembled and

cleaned periodically.

The use of a dust extraction system

during grinding will help reduce the

amount of maintenance, however, the

1. Place flats of chuck body into a vice, do not

over tighten.

2. Place chuck

wrench,

PP16480SF,

(optional) on

dogs of chuck

knob assembly.

Rotate wrench

counterclockwise to

remove chuck

knob/jaw

assembly from

chuck body.

3. Using a 2.5 mm hex

wrench remove set screw.

4. The internal

pieces must

remain keyed, in

order to remove

the closing screw

from the chuck

knob assembly.

Insert the 2.5

mm wrench into

the set screw

hole.

16

Page 19

Chuck Information

5. Rotate chuck knob

counter clockwise

until the wrench

reaches the top of

the slot.

6. Remove wrench and

reinsert into the set

screw hole above the

slot.

7. Rotate the chuck knob counterclockwise until

the closing screw exits the knob assembly.

8. The chuck knob assembly does not come

apart from this point.

TO REASSEMBLE:

Reassemble in reverse order.

CHUCK DESCRIPTIONS AND PART #’S

SA16400TA - 3-12 mm Standard Chuck

SA16450TA - 12-21mm Standard Chuck

SA16500TA - 21-30mm Large Drill Chuck

SA16975TA - 3-12mm Step Drill Chuck

SA16980TA - 12-21mm Step Drill Chuck

SA16890TA - 3-12mm 90° Chuck

SA16880TA - 12-21mm 90° Chuck

SA16916TA - 3-12mm Brad Point Chuck

SA16918TA - 12-21mm Brad Point Chuck

SA16484TA - 3-12mm Left Hand Chuck

SA16488TA - 12-21mm Left Hand Chuck

SA16401TA

SA17010TA - 3-12mm Auto Geared Chuck 3-12mm

SA17025TA - 12-21mm

- 1.5-7mm 1.5-7mm Chuck

Auto Geared Chuck 12-21mm

17

Page 20

XT-3000 WHEEL INFORMATION

The Darex XT-3000 comes equipped with

electroplated CBN (Cubic Boron Nitride). Optional

Diamond wheels are available. The wheel comes

installed on your sharpener ready to sharpen

drills.

Sharpening with an electroplated CBN (Cubic

Boron Nitride) or Diamond grinding wheel reduces

grinding cost and improves quality of the finished

product. These results are obtained because the

grinding material is super abrasive. The CBN is

second only to diamond in hardness. In fact, CBN

has twice the hardness and four times the

abrasion resistance of an aluminum oxide grinding

wheel. The CBN and Diamond wheel last longer;

the grinding process is faster and less grinding

time is lost due to wheel breakdown &

maintenance.

WHEEL MAINTENANCE

These wheels are maintenance free from truing

and dressing but will need to be cleaned

periodically.

the machine using a lock out tag out

procedure. After removing the wheel from the

sharpener, saturate the wheel with any type of

oil-less solvent, such as Automotive Brake

Cleaner.

and lightly brush the saturated wheel, loosening

the impacted grinding particles. Re-saturate the

wheel to flush out any loosened debris. Do not

use any type of dressing tool on these wheels.

Damage to surface will occur and greatly shorten

the wheel life.

NOTE:

discolor or burn, the wheel life may be exhausted

and the wheel will need to be replaced.

Disconnect the power from

It is helpful to use a soft bristle brush

If after cleaning wheel, the drills still

are available if carbide is to be sharpened

on this machine.

WHEN TO REPLACE THE

WHEEL?

Eventually, the long-life electroplated wheel in

your XT-3000 will wear out. Indicators that a

wheel change is necessary are: a drop in

performance such as drill burning or excessively

slow sharpening time. Inspect the wheel for

abrasive quality. A worn wheel will appear

smooth. If it is necessary, replace the worn

wheel(s). New wheels will initially produce a

coarser grind. However, this aggressiveness will

disappear after approximately the first one

hundred drill sharpenings. Under normal use,

you should experience 4-6 thousand drill

sharpenings from each new wheel.

*Darex does not re-plate or recommend replating the grinding wheels. For replacement

wheels, contact your Darex distributor or Darex .

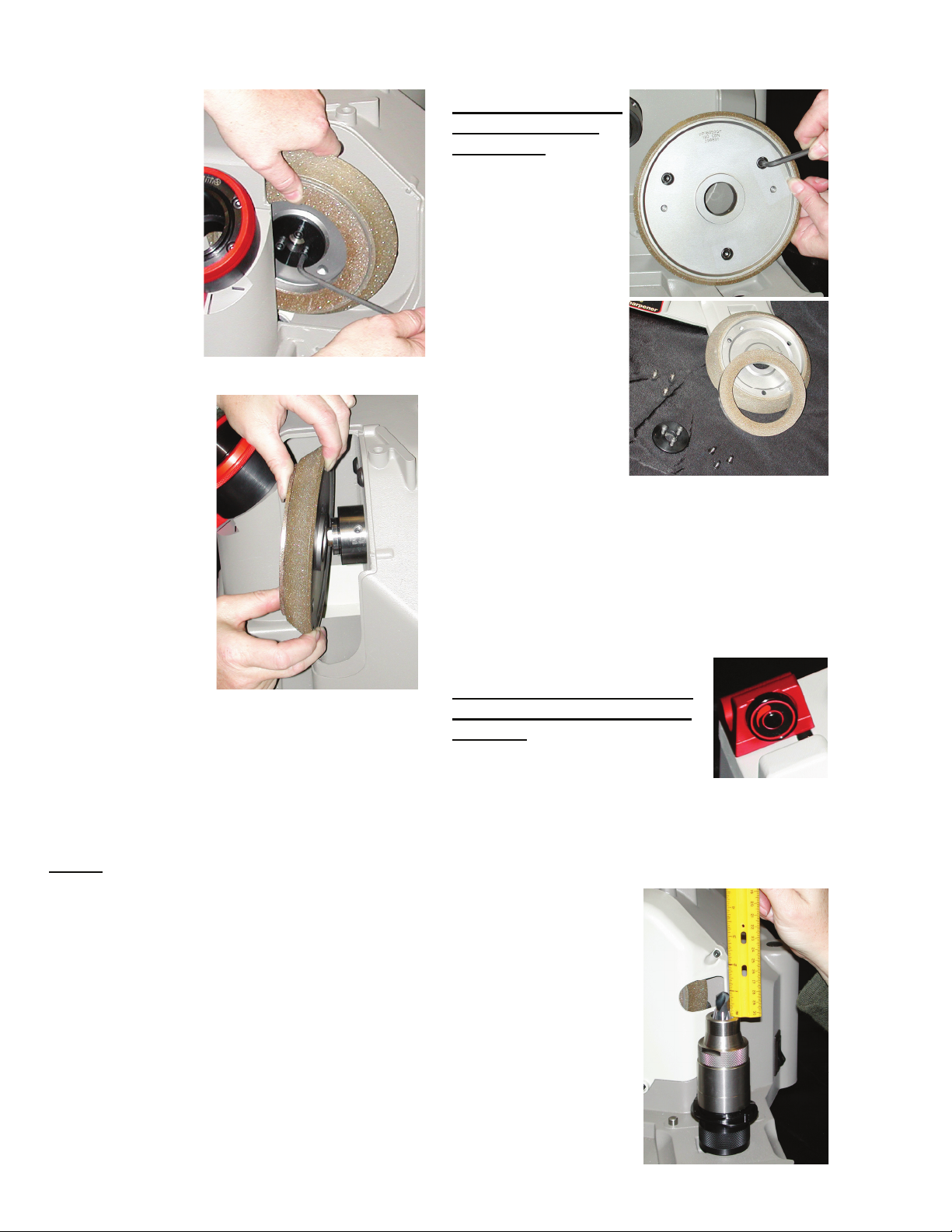

HOW TO CHANGE A WHEEL

1. Unplug unit from power supply

and use a “LOCK OUT” “TAG OUT”

procedure.

WHEEL DESCRIPTIONS AND

PART#’S

• PP16050GF – 180-grit CBN grinding wheel

• PP16060GF – 100-grit CBN Point Split

grinding wheel

• PP16052GF – 180-grit Diamond grinding

wheel

• PP16062GF – 260-grit Diamond Point Split

grinding wheel

• PP16070TF – Grind wheel retainer

Do not attempt to grind carbide drills

with CBN wheels. Diamond wheels

2. Using a

3mm hex

key, remove

3; 3mm

socket head

cap screws

(PP12240FF)

from whee

guard cover.

l

18

Page 21

Wheel Information

3. Pull wheel

guard cover

away from

wheel.

4. Using a 4 mm

hex key,

remove 3;

5mm socket

head cap

screws (PP16318FF) & split washer

(PP08650FF)

from grinding

wheel retainer.

5. Remove the

wheel retainer.

6. Pull wheel

toward you

then to the

right and out of

the machine

cavity.

7. Clean the machine cavity as well as the

mounting hub and wheel before

reinstalling.

8. Repeat steps in reverse to install new

wheel.

NOTE: Because the Darex grinding wheel

cannot be trued it is critical that the motor hub &

wheel register be cleaned. Once wheel has been

installed, rotate the wheel by hand to check that

the wheels run true. If not, loosen the screws ,

reposition the wheel and tighten the screws.

Separating grinding

wheel from point

split wheel

The grinding and point

split wheel are piggy

backed and bolted

together. To change

any one of the wheels

you must first

separate them. You

can access the bolts

from the back side of

the sharpening wheel.

1. Using a 5mm

hex key, remove

the 3; 6mm

socket head cap

screws

(PP16348FF) & split washers.(PP07013FF)

2. The two wheels can now be separated.

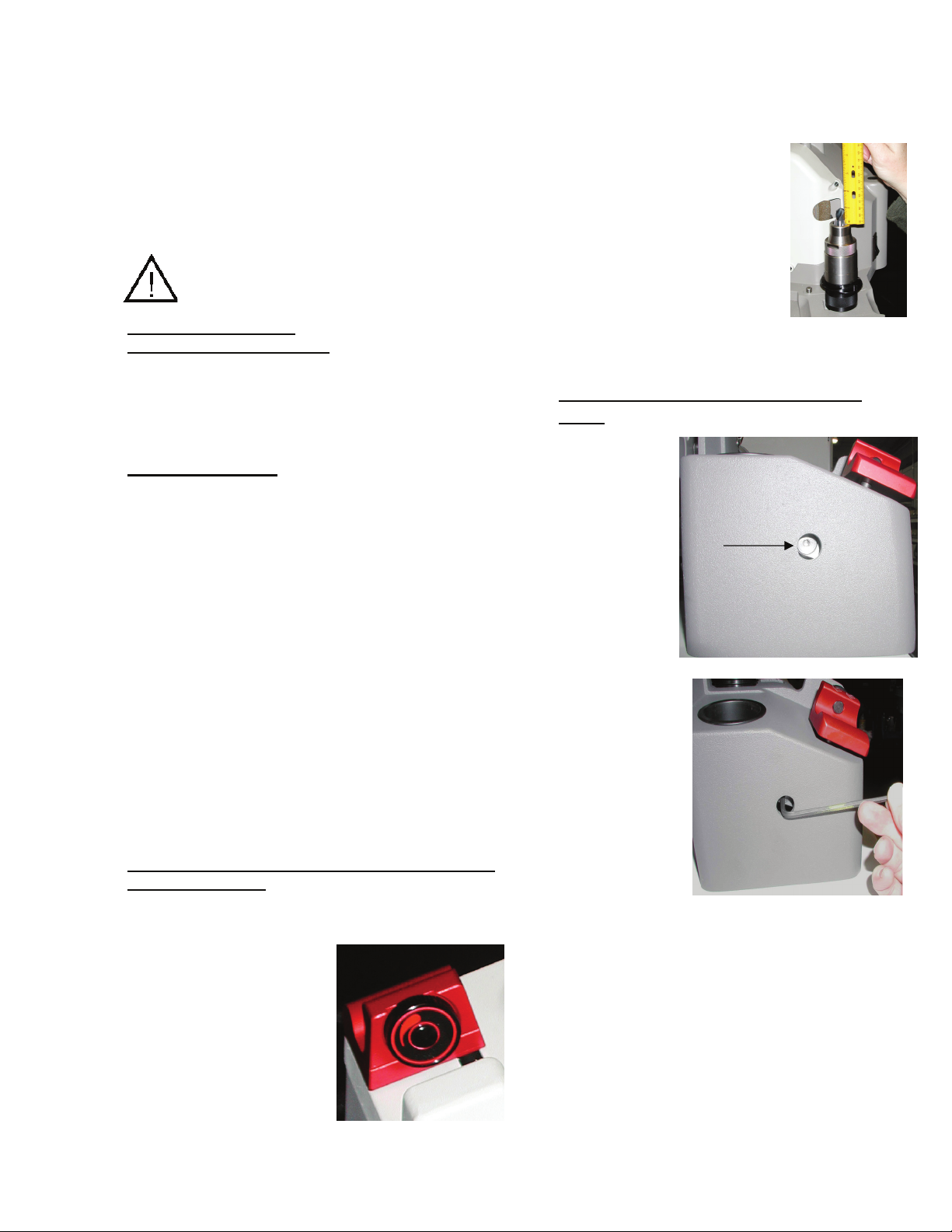

Recalibrating Material

Removal

After a wheel change, verify

and/or recalibrate material

removal.

Use a 3/8 HSS standard twist

drill, measure the length of drill

before sharpening.

1. Rotate material removal knob to maximum

take off.

2. Align drill as

though you intend

to sharpen it.

Follow Alignment

steps on page 9.

3. Once drill is set to

length, aligned

and captured in

the chuck

securely, remove

from alignment

port.

19

Page 22

4. Measure the amount of drill protruding

from the end of the chuck to the tip of the

drill.

5. The length of the drill protruding from the

top of the chuck should measure .970-.980

(24.63 mm - 24.89 mm)

Calibrating the Material

removal knob

1. At the rear of the machine base there is a

small

access

hole.

2. Insert a

3/16 Allen

wrench into

the access

hole.

3. To advance the

pusher shaft cap,

reducing the

amount of drill

stick out, rotate

the wrench

clockwise.

4. To retract the

pusher shaft cap,

increasing the

amount of drill stick out, rotate the wrench

counterclockwise.

Each ¼ turn will adjust .010 (.25 mm) or one

full turn will adjust .04 (1.0 mm) After adjusting

the pusher shaft assembly, realign the drill and

re-measure the amount of stick out. Repeat the

steps 1-4 until the drill protrudes .970-.980 in

length. (24.63 mm - 24.89 mm)

Wheel Information

At the Minimum material removal setting, approximately .005 (.127mm) should be removed from the end of the drill.

20

Page 23

GENERAL MAINTENANCE

To extend the life of your

sharpener, we recommend a

routine maintenance program be

put in place. Every

120-machine hrs is suggested, or

more often if necessary.

WARNING: Remove the plug before

carrying out any adjustment, servicing or

maintenance.

Vacuum system:

Optional but recommended.

Using a dust extraction system can improve the

sharpening life of the machine. Unplug vacuum

from power source. Check filter or canister on a

regular basis.

Wheel cleaning:

These wheels are maintenance free from truing

and dressing but will need cleaned periodically.

After removing the wheel from the unit, saturate

the wheel with any type of oil-less solvent, such

as Automotive Brake Cleaner. It is helpful to use

a soft bristle brush and lightly brush the

saturated wheel, loosening the impacted

grinding particles. Re-saturate the wheel to flush

out any loosened debris.

Always clean a brand new wheel before

using.

If after cleaning wheel, the drills still

discolor or burn, the wheel life may be

exhausted and the wheel will need to be

replaced.

Recalibrating Material Removal

After a wheel change, verify and/or recalibrate

material removal.

Use a 3/8 HSS standard twist drill, measure the

length of drill before sharpening.

1. Rotate material

removal knob to

maximum take off.

2. Align drill as though

you intend to

sharpen it. Follow

Alignment steps on

page 9.

3. Once drill is set to

length, aligned and captured in the chuck,

securely remove from alignment port.

4. Measure the amount of drill

protruding from the end of

the chuck to the tip of the

drill, before sharpening.

5. The length of the drill

protruding from the top of

the chuck should

measure .970-.980 (24.63 mm - 24.89

mm)

Calibrating the Material removal

knob

1. Located at

the rear of

the machine

base, you

will find a

small access

hole.

2. Insert a 3/16

Allen wrench

into the access

hole.

3. To advance the pusher shaft cap, reducing

the amount of drill stick out, rotate the

wrench clockwise.

4. To retract the pusher shaft cap, increasing

the amount of drill stick out, rotate the

wrench counterclockwise.

Each ¼ turn will adjust .010 (.25 mm) or one

full turn will adjust .04 (1.0 mm). After adjusting

the pusher shaft assembly, realign the drill and

re-measure the amount of stick out. Repeat the

steps 1-4 until the drill protrudes .970-.980 in

length. (24.63 mm - 24.89 mm)

21

Page 24

General Maintenance

Chuck Maintenance

Chuck maintenance is very important. To sustain

the life of your chucks and to maintain precision

lip height concentricity, clean the chucks on a

regular basis. Some tools are necessary to

disassemble the chuck, You will need: Wrench

PP16480SF (Optional)

Disassembly:

The use of a dust extraction system while

grinding will help reduce the amount of

maintenance necessary, however, periodically

the chuck assembly should be disassembled and

cleaned.

1. Place flats of chuck body into a vice.

2. Place chuck

wrench on dogs of

chuck knob

assembly.

3. Rotate wrench

counterclockwise to

remove chuck

knob/jaw assembly

from chuck body.

4. Using a 2.5 mm hex

wrench, remove set screw.

5. The internal

pieces must remain

keyed in order to

remove the closing

screw from the

chuck knob

assembly. Insert the

2.5 mm wrench, into

the set screw hole.

6. Rotate chuck knob

counterclockwise until

the wrench reaches the

top of the slot.

7. Remove wrench and

reinsert into the set

screw hole above the

slot.

22

Page 25

General Maintenance

8. Rotate the chuck knob counterclockwise until

the closing screw exits the knob assembly.

9. The chuck knob assembly does not come apart

from this point.

Chuck Cleaning:

Once disassembled, clean all parts with a type of

oil-less solvent such as Automotive Break Cleaner.

Chuck Re-assembly:

Reassemble in reverse order.

Point Split Tube Cavity:

Routinely vacuum and using a dry cloth, wipe out

the inside of the Point Split Tube. Removing

grinding dust will help produce consistent split

point drills by retaining the ID dimensions of the

tube and reducing early wear.

Sharpening Tube Cavity:

Using a dry cloth, wipe out the inside of the brass

tube, removing grinding dust. Over time it may be

necessary to replace the sharpening tube. The

sharpening tube is threaded into the housing

using right-handed threads. To remove, rotate

tube counterclockwise using a spanner wrench.

Replace as needed.

Wheel Housing Cavity:

While grinding wheel is out of machine and before

replacing wheel, vacuum out wheel housing and

wipe around the hub area.

External Machine Castings:

Wipe down external machine castings with a

mild household cleaner.

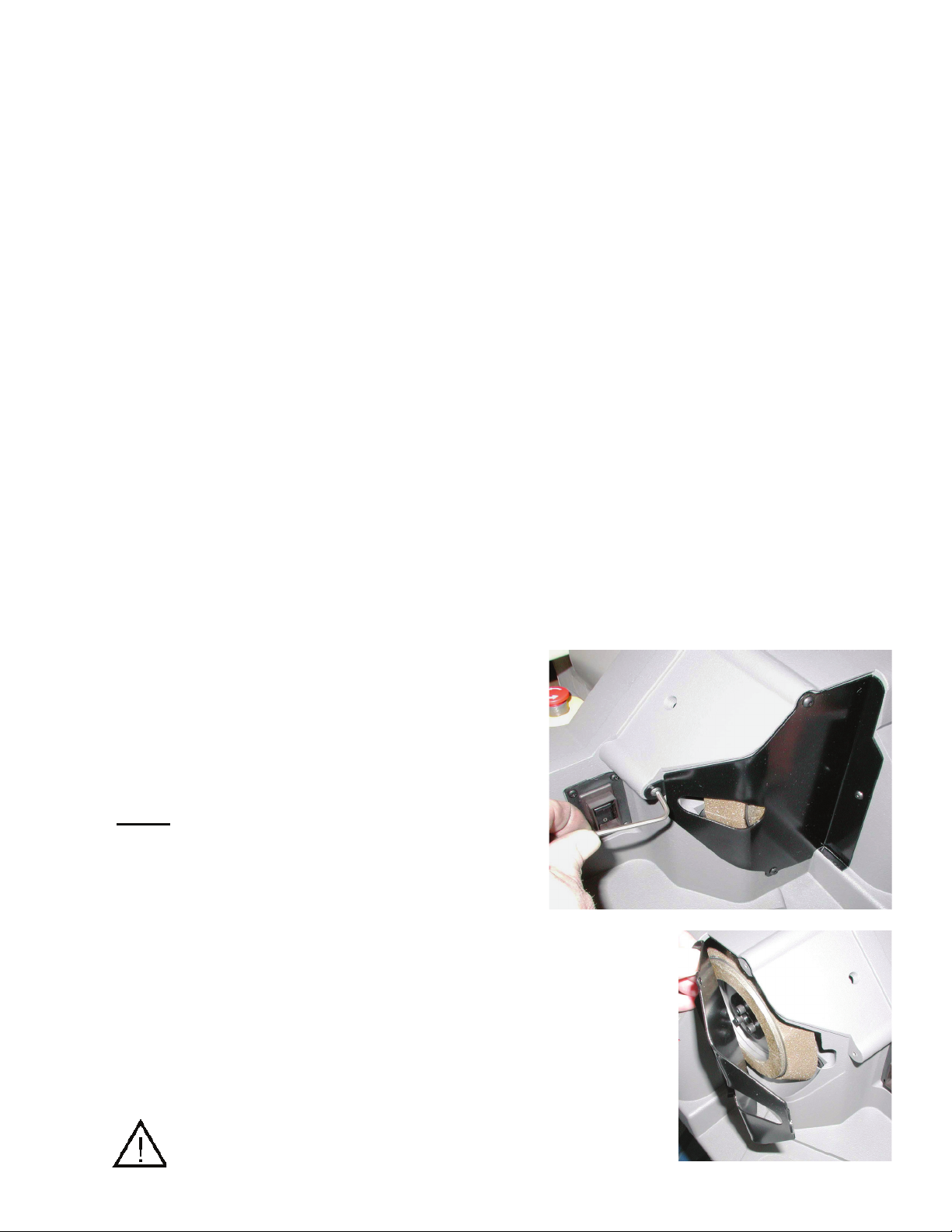

Grit Tray/Vacuum Port Connection:

Grit tray

At the back of the

machine, located

underneath the

grinding motor is the

grit tray. Drill grindings

will accumulate inside

the grit tray. The grit

tray has a magnetic

liner to attract and hold

these dust particles. Do

not let the tray become more than 1/3 full. To

remove tray, unscrew brass thumb screw.

Remove tray and dump contents. Wipe excess

dust from the tray with a rag.

Vacuum Port Connector (Optional)

The grit tray has

a knock out plug

that can be

removed by hand

and replaced with

the vacuum tube

(SA16030TA).

Use this port to

connect a vacuum

hose to the

XT3000. This method of extracting dust

particles from the machine will keep it cleaner

and is recommended.

Oil Lubrication:

Never use an oil-based lubricant on any part

of this machine! Oil-based lubricant will collect

grinding dust particles. Powdered graphite

may be applied to any sliding parts located on

the machine.

23

Page 26

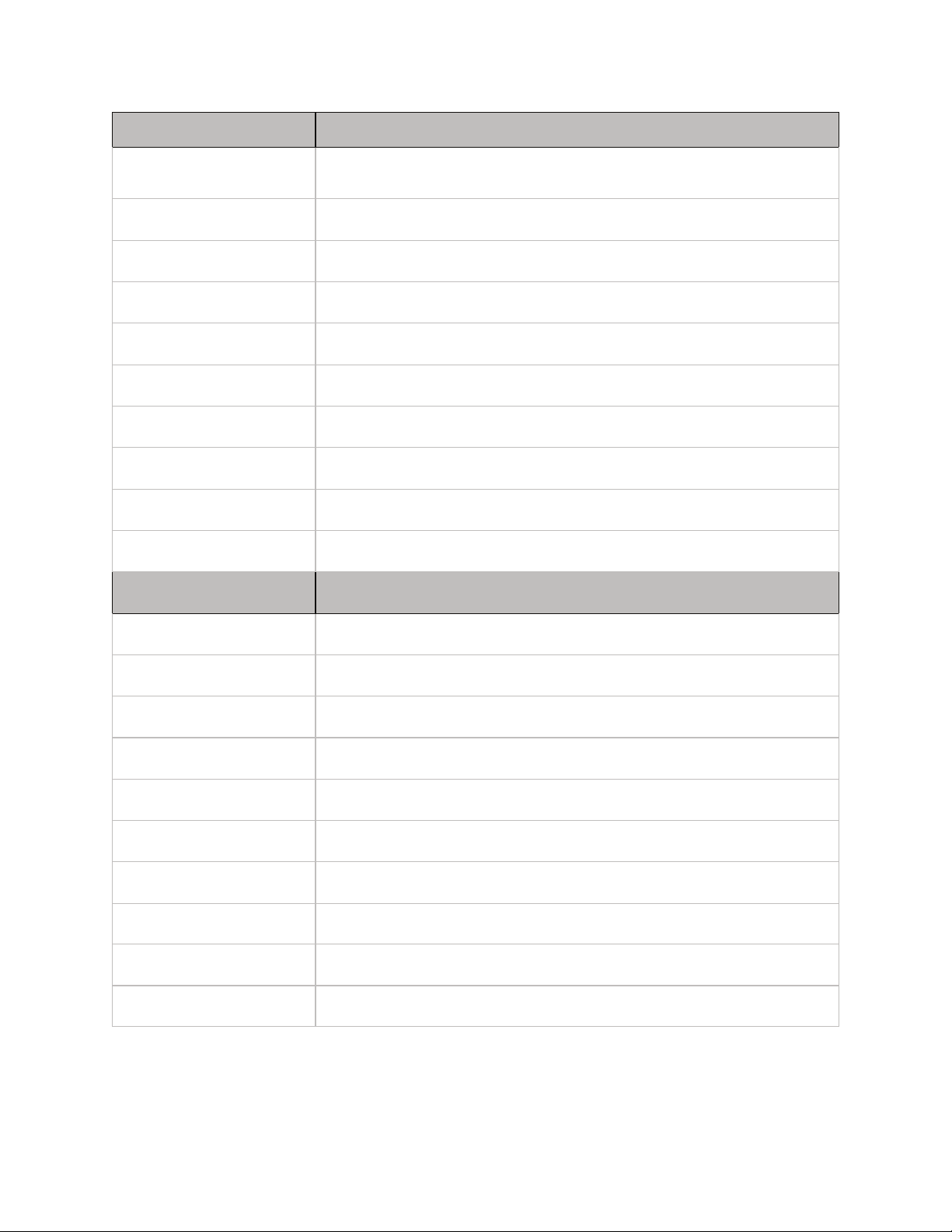

Trouble Shooting XT-3000 Drill Sharpening

Symptom

Using ON/OFF switch does not work

Machine won’t power up

Cause

• No power at outlet

• Make sure power cord is plugged in to

machine and outlet

• Release e-stop (230v machine only)

• E-stop nut is loose and stuck down in the

off position (230v machine only)

• On/off switch needs to be replaced

• Wiring lead disconnected

• Grinding wheel obstructed and can’t rotate

• Grinding motor bad

Symptom

Tip of drills burn or discolor

Cause

• Wheel needs to be cleaned

• Material take off too aggressive

• Wheel needs to be replaced

Symptom

Unable to secure drill in or release drill

from chuck

Cause

• Tapered shank drill

• The drill may have a slight taper to the

body

• Shank of drill larger than body

• Drill has multiple diameters that are

interferi

• Incorrect drill diameter for that particular

ch

• Drill flutes are damaged or have burrs

• Chuck needs to be cleaned

Symptom

Drill incorrectly split

Cause

• Check settings on the split point fixture

• Did not align correctly

• Point Split Tube calibration is off

Symptom

Material take off varies

Cause

• Wheel not secure to motor hub

• Wheel calibration is off after new wheel

change

• Cam dog not properly seated in alignment

slot during alignment set up

• Drill is pushing back in the chuck during

grinding

• Operator is not sparking drill out

ng with jaws

uck

Symptom

No material take off during grinding

Cause

• Drill loose in chuck

• Drill tip not touching the pusher shaft cap

during alignment process

Symptom

Length of time drill is in the grind becomes

excessive

Cause

• Material take off too excessive

• Grinding wheel needs to be cleaned

• Grinding wheel needs to be replaced

Symptom

Lip h

eight concentricity is out of tolerance

Cause

• Material take off too excessive

• Chuck needs to be cleaned

• Sharpening tube needs to be cleaned

• Chuck is worn out and needs to be

replaced

• Sharpening tube is worn and needs to be

replaced

• Wheel is not running true

24

Page 27

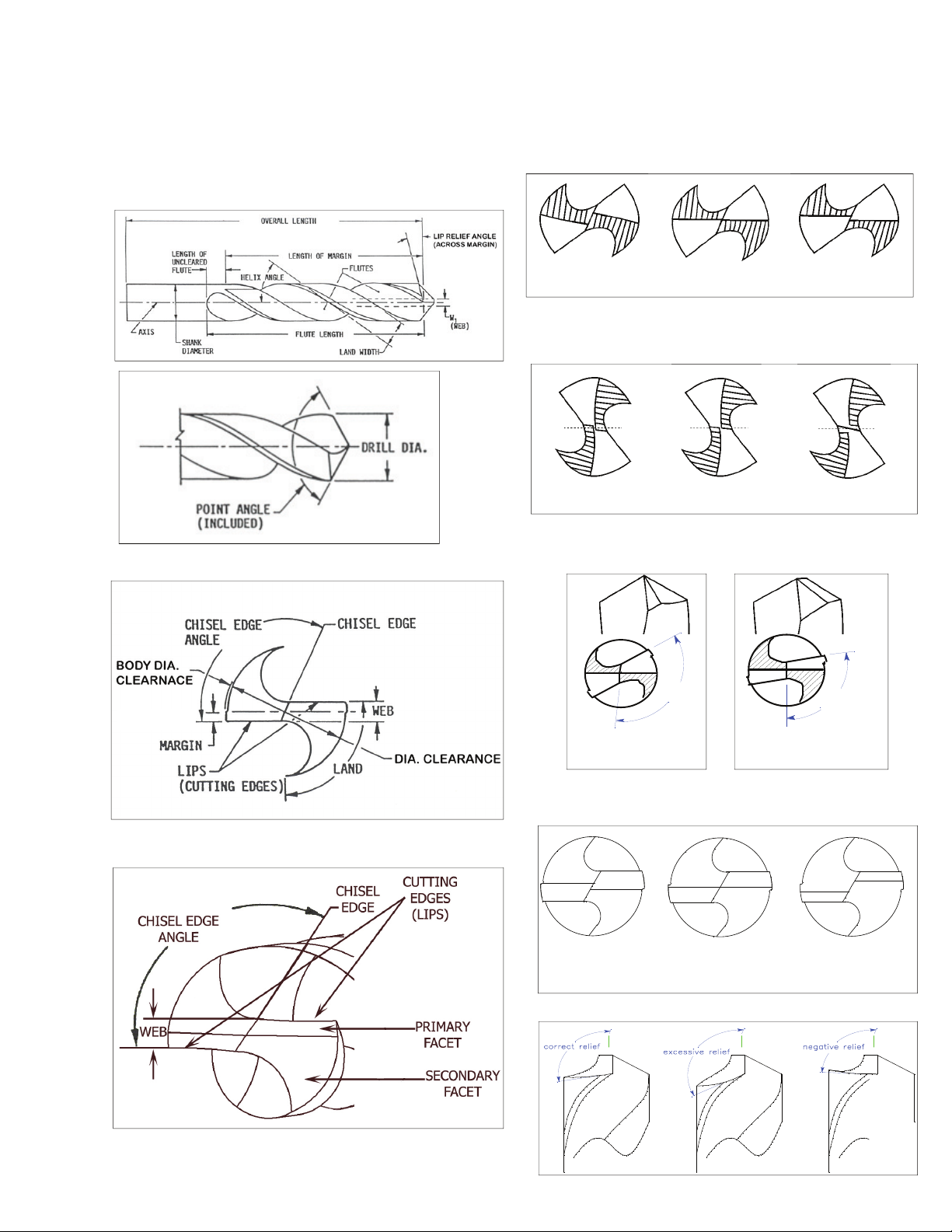

DRILL NOMENCLATURE

Drill Nomenclature

FACET & CONIC DRILL STYLE

PICTURE AND

NOMENCLATURE

CONIC DRILL

CLEARANCE

FACET DRILL

POINT SPLIT

DEPTH OF SPLIT DIAGRAM

Past Center To Center Below Center

CENTER OF SPLIT DIAGRAM

Past Center To Center Below Center

POINT SPLIT ANGLE DIAGRAM

120°

130°

Pointed Flat

Facet Diagram (

re-sharpen on the XPS16)

95°

105°

Past Center

(over facet) (under facet)

To Center Below Center

RELIEF

25

Page 28

Wiring Diagram

26

Page 29

Electrical Diagram

27

Page 30

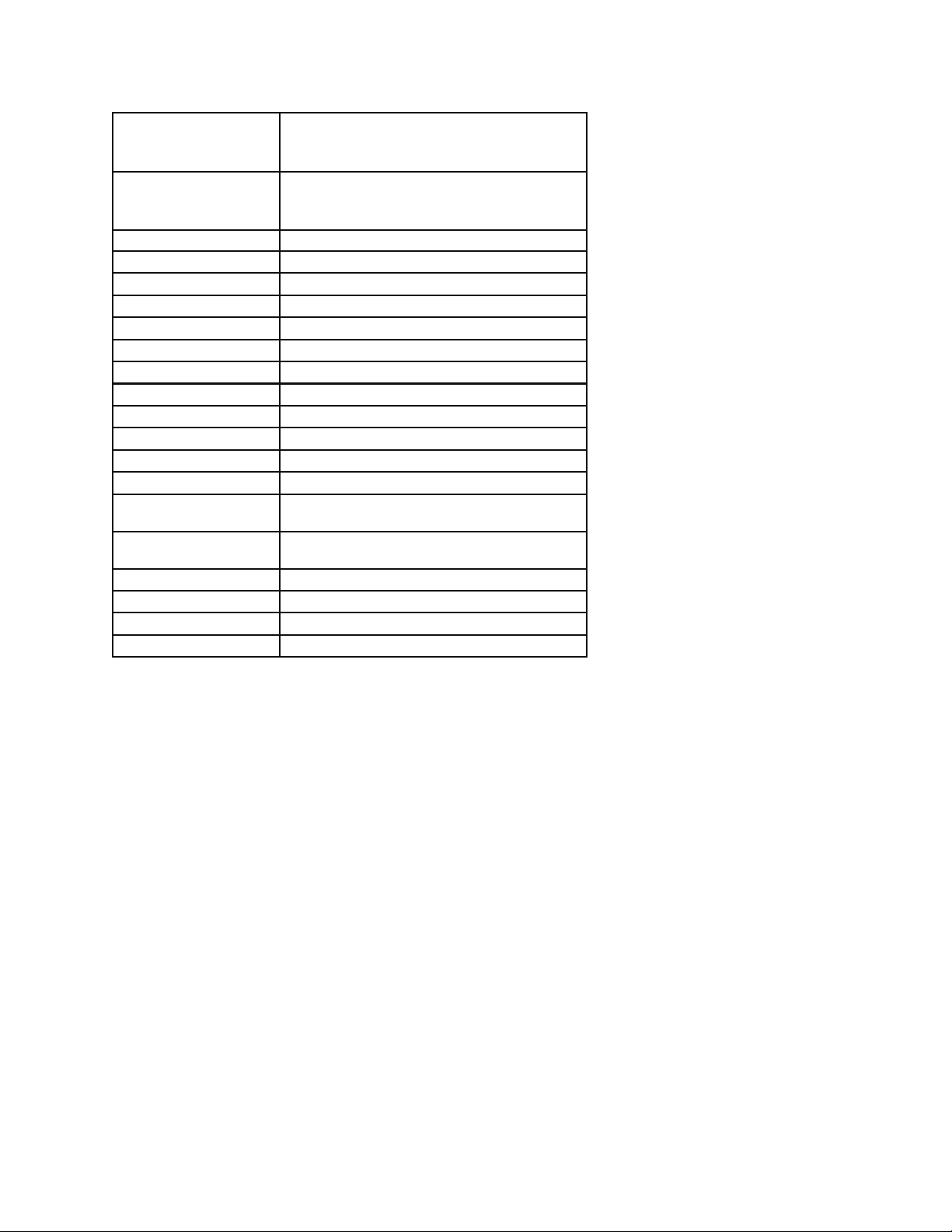

Chuck Parts List

ITEM ITEM_DESC ITEM ITEM_DESC

SA16425SA JAW SET (5 PIECES) SA16425SA JAW SET (5 PIECES)

1-3 FL53461PP ECAR WAJ MM21-3 FL53461PP

ITEM ITEM_DESC ITEM ITEM_DESC

SA16427SA JAW SET (7 PIECES) SA16427SA JAW SET (7 PIECES)

J MM12-21 FL07461PP ECAR WAJ MM12-21 FL07461PP

1PP

ITEM ITEM_DESC ITEM ITEM_DESC

M03-12 FT53561PP

28

)DRADNATS( KCUHC LLIRD PETS MM21-3 AT57961AS KCUHC MM21-3 AT00461AS

)N S PB B( YDOB KCUHC MM21-3 FT00461PP )N S PB B( YDOB KCUHC MM21-3 FT00461PP

)SECEIP 5( SGNIRPS WAJ KCUHC AR56521AS )SECEIP 5( SGNIRPS WAJ KCUHC AR56521AS

SSS MM01 X MM8. X MM5 FF04461PP SSS MM01 X MM8. X MM5 FF04461PP

)N S PB B( EDIUG WAJ MM21-3 FT03461PP )N S PB B( EDIUG WAJ MM21-3 FT03461PP

ECAR WAJ MM2

)N S PB B( WERCS GNISOLC MM21-3 FT02461PP )N S PB B( WERCS GNISOLC MM21-3 FT02461PP

)N S PB B( EVEELS GNISOLC MM12-3 FT51461PP )N S PB B( EVEELS GNISOLC MM12-3 FT51461PP

GNIR PANS MM12-3 FF24461PP GNIR PANS MM12-3 FF24461PP

REHSAW TSURHT 1 & 8/5 4/1 FS40420PP REHSAW TSURHT 1 & 8/5 4/1 FS40420PP

MAC LLIRD PETS MM21-3 FT57961PP )B( MAC MM21-3 FT50461PP

B B( BONK KCUHC MM12-3 FT01461PP )N S PB B( BONK KCUHC MM12-3 FT01461PP

SSS MM01 X MM8. X MM5 FF04461PP SSS MM01 X MM8. X MM5 FF04461PP

ECAR WA

GNIR PANS MM12-3 FF24461PP GNIR PANS MM12-3 FF24461PP

)SECEIP 5( TES WAJ AS52461AS )SECEIP 9 ( SWAJ KCUHC MM03-12 AS03561AS

SSS MM01 X MM8. X MM5 FF04461PP SSS MM01 X MM8. X MM5 FF04461PP

ECAR WAJ MM21-3 FL53461PP ECAR WAJ FL04561PP

GNIR PANS MM12-3 FF24461PP GNIR PANS MM03-12 FF27461PP

)N S P

)LANOITPO( KCUHC LLIRD PETS MM12-21 AT08961AS KCUHC MM12-21 AT05461AS

)N S PB B( YDOB KCUHC MM12-21 FT05461PP )N S PB B( YDOB KCUHC MM12-21 FT05461PP

)SECEIP 7( SGNIRPS WAJ KCUHC AR76521AS )SECEIP 7( SGNIRPS WAJ KCUHC AR76521AS

)N S PB B( EDIUG WAJ MM12-21 FT56461PP )N S PB B( EDIUG WAJ MM12-21 FT56461PP

)N S PB B( WERCS GNISOLC MM12-21 FT81461PP )N S PB B( WERCS GNISOLC MM12-21 FT81461PP

)N S PB B( EVEELS GNISOLC MM12-3 FT51461PP )N S PB B( EVEELS GNISOLC MM12-3 FT51461PP

REHSAW TSURHT 1 & 8/5 4/1 FS40420PP REHSAW TSURHT 1 & 8/5 4/1 FS40420PP

MAC LLIRD PETS MM12-21 FT08961PP )B( MAC MM12-21 FT2246

)N S PB B( BONK KCUHC MM12-3 FT01461PP )N S PB B( BONK KCUHC MM12-3 FT01461PP

)DRADNATS( KCUHC MM21-3 EERGED 09 AT09861AS KCUHC MM03-12 AT00561AS

)N S PB B( YDOB KCUHC MM21-3 FT00461PP YDOB KCUHC MM03-12 FT00561PP

)SECEIP 5( SGNIRPS WAJ KCUHC AR56521AS )SECEIP 9( SGNIRPS WAJ KCUHC AR96521AS

)N S PB B( EDIUG WAJ MM21-3 FT03461PP EDIUG WAJ M

)N S PB B( WERCS GNISOLC MM21-3 FT02461PP WERCS GNISOLC MM03-12 FT02561PP

)N S PB B( EVEELS GNISOLC MM12-3 FT51461PP EVEELS GNISOLC MM03-12 FT51561PP

REHSAW TSURHT 1 & 8/5 4/1 FS40420PP REHSAW TSURHT MM03 FN52561PP

MAC KCUHC MM21-3 EERGED 09 FT09861PP MAC KCUHC MM03-12 FT50561PP

S PB B( BONK KCUHC MM12-3 FT01461PP BONK KCUHC MM03-12 FT01561PP

)N

Page 31

Exploded View - Chuck

ITEM ITEM_DESC ITEM ITEM_DESC

SA16916TA 3-12MM BRAD POINT CHUCK (STANDARD) SA16880TA 90 DEGREE 12-21MM CHUCK (OPTIONAL)

)N S PB B( YDOB KCUHC MM12-21 FT05461PP )N S PB B( YDOB KCUHC MM21-3 FT00461PP

SA16425SA JAW SET (5 PIECES) SA16427SA JAW SET (7 PIECES)

)SECEIP 7( SGNIRPS WAJ KCUHC AR76521AS )SECEIP 5( SGNIRPS WAJ KCUHC AR56521AS

SSS MM01 X MM8. X MM5 FF04461PP SSS MM01 X MM8. X MM5 FF04461PP

)N S PB B( EDIUG WAJ MM12-21 FT56461PP )N S PB B( EDIUG WAJ MM21-3 FT03461PP

R WAJ MM21-3 FL53461PP

PP16420TF 3-12MM CLOSING SCREW (B BP S N) PP16418TF 12-21MM CLOSING SCREW (B BP S N)

ITEM ITEM_DESC ITEM ITEM_DESC

SA16918TA 12-21MM BRAD POINT CHUCK (OPTIONAL) SA16484TA LEFT HAND 3-12MM CHUCK (OPTIONAL)

SA16427SA JAW SET (7 PIECES) SA16425SA JAW SET (5 PIECES)

L07461PP

PP16418TF 12-21MM CLOSING SCREW (B BP S N) PP16420TF 3-12MM CLOSING SCREW (B BP S N)

P

ECAR WAJ MM12-21 F

ITEM ITEM_DESC

SA16488TA LEFT HAND 12-21MM CHUCK (OPTIONAL)

PP16450TF 12-21MM CHUCK BODY (B BP S N)

SA16427SA JAW SET (7 PIECES)

SA12567RA CHUCK JAW SPRINGS (7 PIECES)

PP16440FF 5MM X .8MM X 10MM SSS

PP16465TF 12-21MM JAW GUIDE (B BP S N)

PP16470LF 12-21MM JAW RACE

PP16418TF 12-21MM CLOSING SCREW (B BP S N)

PP16415TF 3-21MM CLOSING SLEEVE (B BP S N)

PP16442FF 3-21MM SNAP RING

PP02404SF 1/4 5/8 & 1 THRUST WASHER

PP16488TF LEFT HAND 12-21MM CAM (B)

ECAR WAJ MM12-21 FL07461PP ECA

)N S PB B( EVEELS GNISOLC MM12-3 FT51461PP EVEELS GNISOLC MM03-12 FT51561PP

GNIR PANS MM12-3 FF24461PP GNIR PANS MM12-3 FF24461PP

REHSAW TSURHT 1 & 8/5 4/1 FS40420PP REHSAW TSURHT 1 & 8/5 4/1 FS40420PP

MAC 12-21 EERGED 09 FT08861PP MAC KCUHC TP DARB MM21-3 FT61961PP

)N S PB B( BONK KCUHC MM12-3 FT01461PP )N S PB B( BONK KCUHC MM12-3 FT01461PP

)N S PB B( YDOB KCUHC MM21-3 FT00461PP )N S PB B( YDOB KCUHC MM12-21 FT05461PP

)SECEIP 5( SGNIRPS WAJ KCUHC AR56521AS )SECEIP 7( SGNIRPS WAJ KCUHC AR76521AS

SSS MM01 X MM8. X MM5 FF04461PP SSS MM01 X MM8. X MM5 FF04461PP

)N S PB B( EDIUG WAJ MM21-3 FT03461PP )N S PB B( EDIUG WAJ MM12-21 FT56461PP

ECAR WAJ MM21-3 FL53461PP

)N S PB B( EVEELS GNISOLC MM12-3 FT51461PP EVEELS GNISOLC MM03-12 FT51561PP

GNIR PANS MM12-3 FF24461PP GNIR PANS MM12-3 FF24461PP

REHSAW TSURHT 1 & 8/5 4/1 FS40420PP REHSAW TSURHT 1 & 8/5 4/1 FS40420PP

)B( MAC MM21-3 DNAH TFEL FT48461PP MAC KCUHC TP DARB MM12-21 FT81961PP

)N S PB B( BONK KCUHC MM12-3 FT01461PP )N S PB B( BONK KCUHC MM12-3 FT01461P

PP16410TF 3-21MM CHUCK KNOB (B BP S N)

29

Page 32

Machine Parts List-Beginning Serial # 5015 Rev B

XT-3000 Exploded View Rev B-page 37

Exploded View / Alignment Rev B-page 39

Not Shown PP09090PF - MACHINE COVER 41) - PP02022TF - PUSHER SHAFT CAP***

Not Shown SA12072EA - 230V VACUUM ASSEMBLY COMPLETE 40) - PP16220XF - PUSHER WEDGE***

Not Shown SA12075EA - 115V VACUUM ASSEMBLY COMPLETE 39) - PP02028RF - WEDGE RETURN SPRING***

Not Shown SA16400TA- 3MM - 12MM STANDARD CHUCK COMPLETE 38) - PP16230TF - PUSHER GUIDE TUBE***

Not Shown SA16450TA- 12MM - 21MM STANDARD CHUCK COMPLETE 37) - PP16227BF - PUSHER GUIDE TUBE SUPPORT***

ot Shown PP16480SF - CHUCK WRENCH )63 - PP16235TF - PUSHER SHAFT***

N

Not Shown SA16936TA - PROTECTIVE EYE SHIELDS (220V MACHINES ONLY) 35) - PP16237RF - PUSHER BAR RETURN SPRING***

Not Shown SA16937TA - POINT SPLIT PLUG/LEASH ASSEMBLY (220V MACHINES ONLY) 34) - PP16240BF - MATERIAL ADJUST BRACKET***

95) - PP16934PF - 3/8 DOME PLUG (115V MACHINES ONLY) 33) - PP02030TF - PUSHER RETURN REAR SPRING GUIDE***

95) - SA16936TA - EYESHIELD ASSEMBLY (220V MAC

93) - PP16632SF - DOCKING LEVER 31) - SA16227BA - PUSHER SHAFT ASSEMBLY COMPLETE***

92) - PP16634TF - DOCKING LEVER BOLT 30) - SA16215XA - PAWL ARM ASSEMBLY COMPLETE**

91) - PP03923FF - LOCATING PIN 1/4x1/2

90) - SA16075TA - 115v MOTOR/HUB ASSEMBLY )82 - PP16285TF - MATERIAL LENGTH ADJUST SCREW*

90) - SA16077TA - 220v MOTOR/HUB ASSEMBLY 27) - PP16385FF - 5MM X .8X 45MM SHCS (4 REQUIRED)*

89) - PP02674PF - DOME PLUG (115V MACHINES ONLY) 26) - PP16212BF - PUSHER BAR*

89) - PP12040EF - 220v EMERGENCY STOP (220V MACHINES ONLY) 25) - SA08560LA - BEARING W/ 1/4 - 20 BHCS (SET OF 3)*

88) - SA16001CA - 115v BASE CASTING ASSEMBLY (REV B) 24) - PP16280TF - BRAKE STOP SET SCREW*

88) - SA16003CA - 220V BASE CASTING ASSEMBLY (REV B) 23) - PP16205SF - BRAKE BRACKET*

87) - PP16035EF - 115v SWITCH BREAKER 22) - SA16615SA

87) - PP16037EF - 220v SWITCH BREAKER 21) - PP16245TF - ALIGNMENT TUBE*

86) - PP12065EF - ELECTRICAL RECEPTACLE 21) - PP16242TF - OSG ALIGNMENT TUBE*

85) - PP16009SF - RECEPTACLE PLATE 20) - PP16275TF - ALIGNMENT TUBE LOCK BOLT*

84) - PP16042EF - ELECTRICAL BOTTOM COVER 19) - PP16250TF - ALIGNMENT TUBE NUT*

83) - -SA16030TA - VACUUM TUBE/NUT ASSEMBLY 17) - SA16271XA - SLIDE HANDLE ASSEMB

82) - SA16020SA - GRIT TRAY ASSEMBLY*

81) )HCAE 4( SCHB MM61 X MM6 & TEEF REBBUR - AP46680AS -

80) REVOC DRAUG LEEHW - FS34061PP -

79) - SA16070TA - GRIND WHEEL RETAINER W/ LOCK WASHER & SHCS (3 EACH)

78) - PP16060GF - CBN POINT SPLIT GRINDING WHEEL 100 GRIT nwohS toN SA16500TA - LARGE DRILL CHUCK 21MM - 30MM*

78) - PP16062GF - DIAMOND POINT SPLIT GRINDING WHEEL 260 GRIT (OPTIONAL) Not Shown SA16565XA - LARGE DRILL ALIGNMENT FIXTURE - 30MM*

77) - PP16050GF- CBN GRINDING WHEEL 180 GRIT Not Shown SA16580XA - LARGE DRILL SHARPENING FIXTURE - 30MM*

77) - PP16052GF - DIAMOND GRINDING WHEEL 180 GRIT (OPTIONAL) Not Shown LEX 100

76) - SA16945BA - POINT SPLIT DEPTH ASSEMBLY* Not Shown LEX150 - COUNTERSINK ATTACHMENT COMPLETE

75) - PP16935TF - POINT SPLIT CHUCK TUBE* Not Shown LEX 150INTL- COUNTERSINK ATTACHMENT (w/ metric collets)

73) - PP16925TF - POINT SPLIT TUBE* Not Shown PP16862TF - PP16862TF - 3 FLUTE COUNTERSINK CAM (OPTIONAL)

73) - PP16922TF - OSG POINT SPLIT TUBE Not Show n PP16864TF - P

72) - PP16930TF - POINT SPLIT FAN ADJUSTER* Not Shown LEX 200 - BRAD POINT ATTACHMENT COMPLETE

72) - PP16932TF - OSG POINT SPLIT FAN ADJUSTER Not Shown SA16916TA - BRAD POINT CHUCK 3MM - 12MM*

71) - PP16940TF - POINT SPLIT NUT* Not Shown SA16918TA - BRAD POINT CHUCK 12MM - 21MM (OPTIONAL)

70) - SA16925TA - POINT SPLIT ASSEMBLY COMPLETE* (#76 - #71) Not Shown SA16950BA - LEX 250 -

29) - PP16283RF - MATERIAL LENGTH ADJUST SPRING*

Exploded View / Sharpening Fixture All Models-page38

Not Shown SA16980TA - STEP DRILL CHUCK 12MM - 21MM (OPTIONAL)

60) - SA16615SA - PIVOT LEVER ASSEMBLY* Not Shown SA16970XA - STEP DRILL ALIGNMENT FIXTURE*

61) - PP16610TF - SHARPNEING TUBE PIVOT SHAFT* Not Shown SA16950BA - STEP DRILL SHARPENING FIXTURE*

59) - PP16640TF - PIVOT LOCK NUT* Not Shown LEX 300 - 90° -120° POINT ATTACHMENT COMPLETE*

PP16630BF - DOCKING PLATE Not Shown SA16995XA - 90° - 120° SHARPENING FIXTURE

58) -

57) - PP16650RF - RETURN SPRING* Not Shown SA16890TA - 90° POINT CHUCK 3MM - 12MM*

56) - SA16645TA - SPRING TENSIONER ASSEMBLY* Not Shown SA16880TA - 90° POINT CHUCK 12MM - 21MM (OPTIONAL)

55) - SA16652TA - FEED BEARING ASSEMBLY* Not Shown SA16484TA - LEFT HAND CHUCK 3MM - 12MM* (OPTIONAL)

54) - SA16657TA - SWING BEARING ASSEMBLY* Not Shown SA16

53) - PP16100CF - PIVOT BASE CASTING*

52) - PP16600XF - SHARPENING TUBE*

51) - PP16605TF - SHARPENING TUBE LINER*

50) - SA16600XA - 118° - 150° SHARPENING FIXTURE COMPLETE* (#60 -

HINES ONLY) 32) - PP16338FF - 3/32 X 3/8 DOWEL PIN***

- PIVOT LOCK LEVER ASSEMBLY*

16) - PP16202TF - ALIGNMENT STORAGE LINER*

Optional Accessories

- XY TABLE ATTACHMENT COMPLETE

P16864TF - 6 FLUTE COUNTERSINK CAM (OPTIONAL)

STEP DRILL ATTACHMENT COMPLETE*

Not Shown SA16975TA - STEP DRILL CHUCK 3MM - 12MM*

488TA - LEFT HAND CHUCK 12MM - 21MM (OPTIONAL)

Not Shown LEX350 - MINIATURE DRILL CHUCK ATTACHMENT (OPTIONAL)

Not Shown LEX400 - AUTO SHARPENING ATTACHMENT 3 - 12MM (OPTIONAL)

Not Shown LEX450 - AUTO SHARPENING ATTACHMENT 12-21MM (OPTIONAL)

#51)

Not Shown LEX500 - AUTO SHARPENING ATTACHMENT 3 - 21MM (OPTIONAL)

LY*

30

Page 33

Exploded View Beginning Serial # 5015 Rev B

31

Page 34

EXPLODED VIEW SHARPENING FIXTURE 118-150 (All Models)

32

Page 35

EXPLODED VIEW ALIGNMENT (Rev B)

33

Page 36

Machine Parts List-Serial # 0 - 5014 Rev A

XT-3000 PARTS LIST

41) - PP02022TF - PUSHER SHAFT CAP***

Exploded View / Machine Rev A-page 41

93) - PP16632SF - DOCKING LEVER 39) - PP02028RF - WEDGE RETURN SPRING***

92) - PP16634TF - DOCKING LEVER BOLT 38) - PP16230TF - PUSHER GUIDE TUBE***

91) - PP16005TF - LOCATING PIN 37) - PP16225BF - PUSHER GUIDE TUBE SUPPORT***

90) - SA16077TA - 230v MOTOR/HUB ASSEMBLY 36) - PP16235TF - PUSHER SHAFT***

89) - PP12040EF - 230v EMERGENCY STOP (INTERNATIONAL

MACHINES ONLY)

88) - PP12065EF - ELECTRICAL RECEPTACLE 34) - PP16240BF - MATERIAL ADJUST BRACKET***

87) - PP16035EF - 115v SWITCH BREAKER 33) - PP02030TF - PUSHER RETURN REAR SPRING GUIDE***

87) - PP16037EF - 230v SWITCH BREAKER 32) - PP16338FF - 3/32 X 3/8 DOWEL PIN***

86) - SA08664PA - RUBBER FEET & 6MM X 16MM BHCS (4 EACH) 31) - SA16225BA - PUSHER SHAFT ASSEMBLY COMPLETE*** (#41 - #32)

85) - SA16040EA - ELECTRICAL BOTTOM COVER W/ (4) 6-32 TYPE F

86) - SA08664PA - RUBBER FEET & 6MM X 16MM BHCS (4 EACH) 30) - SA16215XA - PAWL ARM ASSEMBLY COMPLETE**

85) - SA16040EA - ELECTRICAL BOTTOM COVER W/ (4) 6-32 TYPE F 30) - PP02079TF - PAWL ARM BOLTS (2 REQUIRED)**

30) - PP02082RF- PAWL ARM RETURN SPRING**

84) - PP12076TF- VACUUM TUBE ATTACHMENT NUT* 30) - PP04219FF - 6-32 X 1/4 BHCS (2 REQUIRED)**

83) - PP16030TF - VACUUM TUBE* 30) - PP02078NF - CARBIDE PAWLS ( 2 REQUIRED)**

-SA16030TA - VACUUM TUBE/NUT ASSEMBLY 30) - PP16215XF - PAWL ARMS (2 REQUIRED)**

82) - SA16020SA - GRIT TRAY ASSEMBLY* 29) - PP16283RF - MATERIAL LENGTH ADJUST SPRING*

81) - PP12240FF - WHEEL GRD CSTING 4 MM X 18MM SHCS (3

REQUIRED)

80) - PP16045CF - WHEEL GUARD CASTING 27) - PP16334FF - 5MM X 22MM SHCS (4 REQUIRED)*

79) - SA16070TA - GRIND WHEEL RETAINER W/ 3 BOLTS 26) - PP16210BF - PUSHER BAR*

25) - SA08560LA - BEARING W/ 1/4 - 20 BHCS (SET OF 3)*

78) - PP16062GF - DIAMOND POINT SPLIT GRINDING WHEEL 260

GRIT

78) - PP16060GF - CBN POINT SPLIT GRINDING WHEEL 100 GRIT 23) - PP16205SF - BRAKE BRACKET*

77) - PP16052GF - DIAMOND GRINDING WHEEL 180 GRIT 22) - SA16615SA - PIVOT LOCK LEVER ASSEMBLY*

77) - PP16050GF- CBN GRINDING WHEEL 180 GRIT 21) - PP16245TF - ALIGNMENT TUBE*

Not Shown PP16480SF - CHUCK WRENCH 20) - PP16275TF - ALIGNMENT TUBE LOCK BOLT*

76) - SA16945BA - POINT SPLIT ADJUSTING LEVER* 19) - PP16250TF - ALIGNMENT TUBE NUT*

75) - PP16935TF - POINT SPLIT CHUCK TUBE* 18) - PP16200CF - ALIGNMENT CASTING*

74) - PP16340FF - 5 MM X 50 MM SHCS (4 REQUIRED)* 17) - SA16270XA - SLIDE HANDLE ASSEMBLY*

73) - PP16925TF - POINT SPLIT TUBE* 16) - PP16202TF - ALIGNMENT STORAGE LINER*

72) - PP16930TF - POINT SPLIT FAN ADJUSTER* 15) - SA16200CA - ALIGNMENT ASSEMBLY COMPLETE* (#31 - #16) & (#41 - #32)

71) - PP16940TF - POINT SPLIT NUT*

70) - SA16925TA - POINT SPLIT ASSEMBLY COMPLETE* (#76 - #71)

75) - PP16935TF - POINT SPLIT CHUCK TUBE*

74) - PP16340FF - 5 MM X 50 MM SHCS (4 REQUIRED)*

73) - PP16925TF - POINT SPLIT TUBE*

72) - PP16930TF - POINT SPLIT FAN ADJUSTER*

71) - PP16940TF - POINT SPLIT NUT*

70) - SA16925TA - POINT SPLIT ASSEMBLY COMPLETE* (#76 - #71)

Exploded View / Alignment Assembly Rev A-page 36

40) - PP16220XF - PUSHER WEDGE***

35) - PP16237RF - PUSHER BAR RETURN SPRING***

28) - PP16285TF - MATERIAL LENGTH ADJUST SCREW*

24) - PP16280TF - BRAKE STOP SET SCREW*

34

Page 37

EXPLODED VIEW-Serial # 0 - 5014 Rev A

35

Page 38

EXPLODED VIEW ALIGNMENT ASSEMBLY Serial # 0 - 5014 Rev A

36

Page 39

XT-3000

Attachments

LEX050 - Large Drill Attachment .......................................................... page 39

LEX100 - XY Table Attachment ............................................................. page 43

LEX150 - Countersink Attachment........................................................ page 44

LEX200 - Brad Point Attachment .......................................................... page 48

LEX250 - Step Drill Attachment ............................................................ page 50

L

EX300 - 90º - 120º Drill Attachment................................................... page 54

LEX350 - Mini Attachment..................................................................... page 58

XT-3000 Auto Attachment.................................................................... page 61

37

Page 40

This page intentionally left blank.

38

44

Page 41

Large Drill Attachment

LEX050

Congratulations on the purchase of your Darex

XT-3000 Large Drill Attachment. (21 mm—30

mm) As part of the assembly (see picture from

left to right) you should have a SA16565XA Large

drill alignment, SA16575CA Sharpening fixture,

and SA16500TA Large Drill Chuck.

By now you are familiar with the ‘quick disconnect’

feature of your XT-3000. Start by placing the

Large Drill Alignment on the top of your XT-

3000. Rotate the ‘Docking Lever’ clockwise to

securely lock the fixture in place. In a similar

manner, remove your current sharpening fixture

and replace it with the Large Drill Sharpening

The alignment is adjusted by

rotating the black lever

located on the front of the

alignment fixture. As per the

decal, rotating the lever

towards the operator will

reduce the amount of relief

ground onto the drill and

pushing the lever away from

the operator will increase the relief. Placing the

pin at the midway point on the decal is a good

starting place for 118° drills. For 135°-150° drills

start with the alignment 2 marks towards the

operator. You can set the alignment at any setting

necessary to achieve the amount of relief desired.

Place the drill in the chuck and turn the chuck

knob clockwise until the drill slides freely through

the chuck jaws. Next slide the Chuck and drill into

the alignment rotating the chuck until one of the

Fixture.

Determine the point

angle of the drill to be

sharpened and adjust

both the sharpening

fixture and alignment to

that point angle. The

Sharpening fixture is

adjusted by pulling the

red lever towards

(counterclockwise) the

operator and sliding the

fixture to the point angle

desired. Lock the fixture

by returning the red lever to its original pos

‘cam dogs’ aligns with the

mating ‘notch’ in the fixture.

You will notice the opposite

‘dog’ aligns with a reference

mark machined into the

alignment fixture.

Now push the drill through the chuck until it

contacts the stop. Rotate the drill clockwise until

ition.

Incorrect Correct

39

Page 42

the outer edge of the cutting lip is touching the

pins in the setting fixture.

Firmly tighten the chuck by turning the knob

clockwise while the chuck is still in the fixture.

Remove the chuck and drill. The drill is now

aligned and set to length to the chuck cam for the

necessary grinding.

Slide the chuck into the Sharpening fixture and

rotate the Chuck clockwise applying slight

pressure into the wheel. It is also necessary to

keep the cam up against the swing cam follower

bearing.

Try to sharpen the drill

in such a manner that

the drill is off the wheel

before you reposition

your hand on the chuck.

Grinding time will vary depending on wheel

condition and amount of material removal but it

should require a minimum of 8-10 rotations.

NOTE: The MTO drill stop setting is adjustable

using a 5/32” or 4 mm hex key if you think more

or less material removal is desired.

Please Note, you do not have the ability to split

drills from 21 mm to 30 mm on the XT-3000.

40

Page 43

Large Drill Attachment

+2 +4 +6 +8-8 -6 - 4 -2

0

PP 16569DF OS G Align ment Deca l

PP 16568DF A lignm ent De cal

41

Page 44

Large Drill Attachment LEX050

SA16615BA Pivot Lock Lever Assembly

PP16615BF Pivot lock lever

PP16630FF 5mmX8mm SSS

SA16585TA Timing Adjuster Assembly

PP16283RF Material adjust spring

PP16285TF Material adjust screw

PP03924TF PS Latch Screw Handle

PP16585TF Large Drill Timing Adjuster

PP11015FF 1/8" Dowel Pins

SA16652TA Feed Bearing Assembly

PP16652TF Feed Bearing Bolt

PP08560LF Bearing

SA16657TA Swing Bearing Assembly

PP16655LF Swing Bearing

PP16657TF Swing Bearing Bolt

SA16645TA Spring Tensioner Assembly

PP16645TF Spring Tensioner

PP12280FF M6 x 1 x 8mm SSS

SA16500TA

21-30 MM Chuck

PP16500TF Large chuck Body 21-30mm

PP16505TF 21-30mm chuck cam

PP16510TF 21-30mm chuck knob

PP16515TF 21-30mm Closing sleeve

PP16520TF 21-30mm closing screw

PP16525NF Thrust Washer

PP16530SF Jaws

PP16535TF Jaw guide

PP16472FF Snap ring

PP16540LF Jaw race

PP12560RF Jaw springs

PP16440FF Jaw key screw

42

Page 45

XY Table Attachment

X-Y Table No Sub Assemblies, Send in for Repair

43

Page 46

Countersink Instructions

LEX150

Congratulations on the purchase of your Darex

XT-3000 Countersink Attachment. This fixture

comes with 2 V-40 double angle collets and is

used in conjunction with the Darex XT-3000 X-Y

Attachment.

X-Axis Knob

Pivot Lock Knob

Y-Axis Knob

By now you are familiar with the ‘quick disconnect’

feature of your XT-3000. Begin by removing the

current sharpening

fixture and replacing it

with the X-Y table.

Secure it in place by

rotating the ‘Docking

Lever’ clockwise. In a

similar manner, lock

the Countersink

Attachment to the top

of the machine.

It is now necessary to

determine the shank

diameter of the tool that will

be sharpened and place the

corresponding collet into the

Countersink Attachment.

To do so

slowly rotate

the spindle

clockwise until

the Spindle

Lock engages

the spindle.

Now unscrew the

Draw Tube assembly.

Place the correct collet

in the end of the Draw

Tube and replace the

Draw Tube assembly

and tighten 3 or 4

revolutions. Should

you need a collet size other than the ones

provided, you may order them from Darex .

(1-800-547-0222)

Slide the cutting tool

into the spindle leaving

approximately 1” or

more of the tool

exposed. Loosen the

Alignment Thumb

Screw and rotate the

Alignment Arm

assembly around until

the dowel pin

intersects both the

cutting edge and the

heel simultaneously.

Tighten the Alignment

Thumb Screw. Rotate

the Draw tube

assembly clockwise to

tighten the tool in the

spindle. Return the

Alignment Arm to its

original position and

release the spindle lock

pin by pulling up and

turning the pin 90°.

The cutting tool is now

oriented to the spindle

cam and is ready to be

sharpened.

Alignment

Arm

Thumb Screw

Spindle Lock

44

Page 47

To sharpen the tool, determine which angle the

tool will be sharpened at. To adjust the X-Y table,

loosen the Pivot Lock Knob and swing the table to

that angle. Tighten the Pivot Lock Knob.

Pivot Lock Knob

Remove the

Countersink

Attachment from

the top of the

machine and

place it on the X-Y

Table. Again,

rotate the

Docking Lever

clockwise to secure the fixture. Turn the machine

ON.

Using both the X and Y axis feed knobs, carefully

position the cutter into the grinding wheel.

grinding wheel. Loosen the Docking Lever and

return the Countersink Assembly to the top of the

XT-3000 to remove the cutter. The sharpening is

now complete.

Y-Axis Knob X-Axis Knob

Once the

tool touches

the grind

wheel, begin

to rotate the

spindle in a

clockwise

direction

slowly

feeding the

cutter into the wheel. Once the desired amount is

ground off, continue rotating 1 or 2 more

revolutions to “spark out” the cutter. While still

rotating the spindle, use one of the feed axis

knobs to position the cutter safely away fr

om the

45

Page 48

Countersink Attachment

46

Page 49

Counter Sink Attachment LEX150

SA16823TA Alignment Assembly

PP16823TF Alignment Thumb Screw

PP16820BF Alignment Arm

PP16312FF 1/8"x2" Dowel pin

PP08558FF Washer

SA16860BA Swing Arm Assembly

PP16860BF Swing Arm

PP06136FF Dowel Pin

PP08560LF Bearing

SA16830TA

CS Spindle lock assy.

PP16830TF Indexing Pin Bushing

PP08041TF Indexing Pin

PP08046TF Indexing Pin Knob

PP08045TF spring

PP08376FF roll pin

47

Page 50

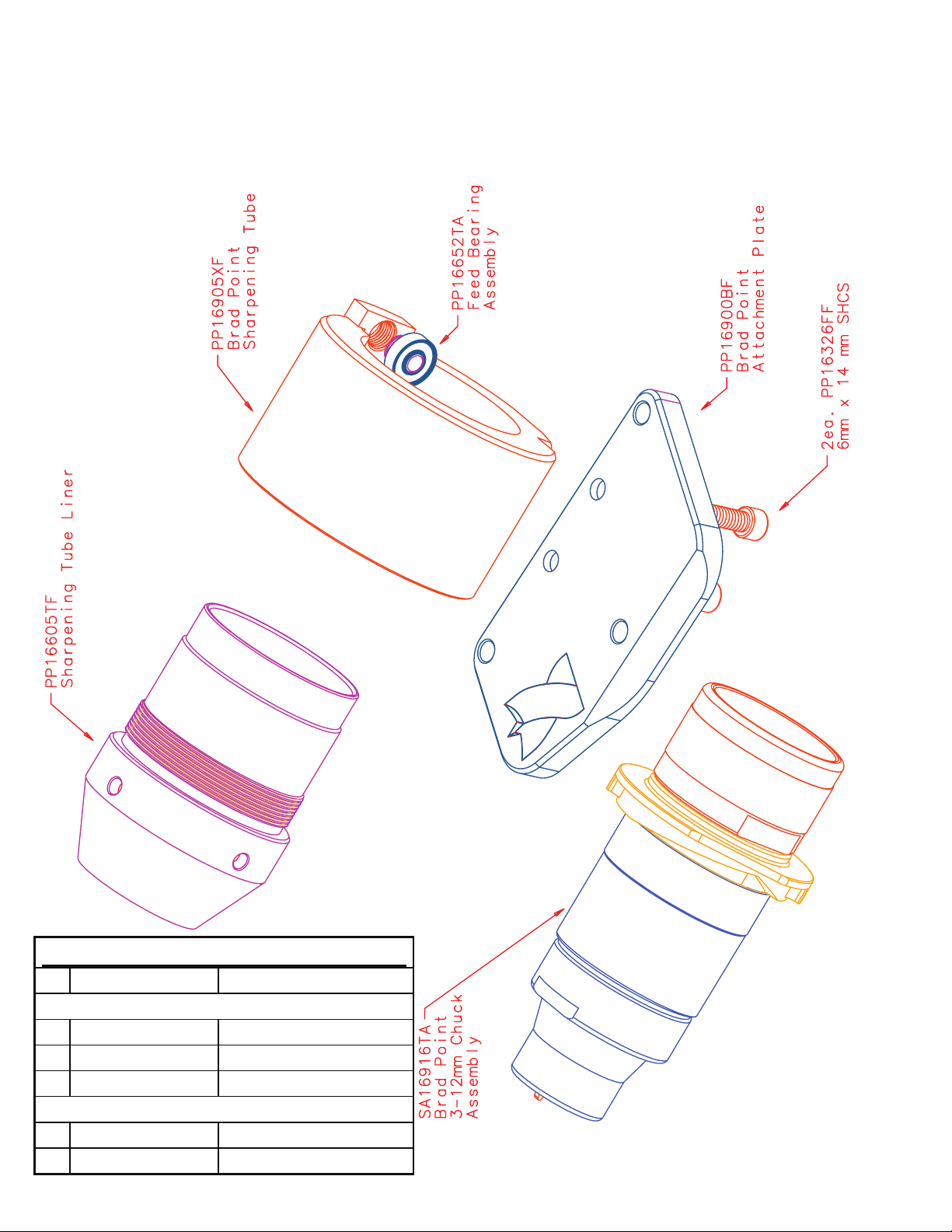

BRAD POINT ATTACHMENT

LEX200

Congratulations on the purchase of the Darex XT3000 Brad point Attachment. (LEX200) This

attachment consists of 2 pieces, 1 Sharpening

Fixture, SA16900BA and 1 - 3mm – 12mm Chuck,

SA16916TA. (The 12mm – 21mm Chuck,

SA16918TA is available

as an optional accessory)

Both components are

laser marked with a Brad

Point icon to minimize

confusion with other XT3000 attachments.

SETTING UP:

To sharpen a

Brad Point, you

will have to

remove the

standard

sharpening fixture

and replace it

with the X-Y

Table (LEX100).

The Brad Point Attachment works in conjunction

with the X-Y Table. By now you are familiar with

the ‘quick’ disconnect feature or your XT-3000.

Begin by removing the

current sharpening

fixture and replacing it

with the X-Y Table.

Secure it in place by

rotating the Docking

Lever CW. In much

the same manner,

secure the Brad Point

Sharpening Fixture to

the X-Y Table.

ALIGNING THE DRILL:

The alignment of the drill

happens in the XT-300

Alignment Tube. Loosen the

Timing Tube Lock lever

position

the Tube

@ 118°.

Push the

lever down

to lock the

tube. Align

the drill as

CORRECT INCORRECT

Pivot Lock Knob

0

X-Axis Knob

Y-Axis Knob

and

you normally would.

SETTING UP THE X-Y TABLE:

Brad point drills are ground with the X-Y Table

positioned at approx. the 160° mark. Loosen the

Pivot Lock Knob and rotate the X-Y Table to 160°.

Lock the Table.

Pivot Lock Knob

SHARPENING:

With the XT-3000

sharpening mechanism making sure the drill

DOES NOT

use the X-Y axis knobs to position the drill

the wheel.

Y-Axis Knob X-Axis Knob

ON

Turn

3000. Using the same

Axis Knobs, start to

move the drill into

the grinding wheel

while rotating the

Chuck. This fixture is

meant to re-sharpen

existing drills. During the sharpening process,

should you remove an

material, due to damage, it will be necessary to

re-align the drill and sharpen again. Refer to the

diagram

below for

examples of

proper drill

geometry.

contact the grinding wheel. If it does,

your XT-

OFF

, place the Chuck in the

excessive amount of

OFF

48

Page 51

Brad Point Attachment

Brad Point Attachment LEX200

SA11790PA

PP11745FF 1/4-20 x 1 SSS

PP11790PF Point angle lock knob

SA16652TA

PP16652TF Feed Bearing Bolt

PP08560LF Feed Bearing

49

Page 52

STEP DRILL ATTACHMENT

LEX 250

Congratulations on the purchase of your Darex

XT- 3000 Step Drill Attachment. (LEX250). This

attachment consists of 3 pieces, 1 Sharpening

Fixture, SA16950BA, 1 Alignment Fixture,

SA16970XA and a 3mm – 12 mm Chuck,

SA16975TA. (The 12mm – 21mm Chuck,

SA16980TA is available as an optional accessory)

All 3 components are laser marked with a Step

Drill icon to minimize confusion with other XT3000 attachments.

the XT-3000. Rotate the Docking Lever CW to

secure the X-Y Table to the XT-3000.

X-Axis Knob

Pivot Lock Knob

Y-Axis Knob

In a similar manner, lock the Step Drill Sharpening

Fixture on to the top of the X-Y Table. Secure the

Step Drill Alignment Fixture to the top of the XT-

3000.

SHARPENING THE PILOT

Should the pilot of the step drill need resharpened, do so, just as you sharpen a standard

twist drill. Having the exploded view drawing

handy will be beneficial at this point.

SHARPENING THE STEP

SETTING UP:

To sharpen the ‘step’ on your step drill, you will

have to remove the standard sharpening fixture

and replace it with the X-Y Table (LEX100). The

Step Drill Attachment works together with the X-Y

Table.

Rotate the

Docking Lever

CCW to free the

standard

sharpening

fixture, then

remove. Place

the X-Y Table on

ALIGNING THE DRILL:

Place the drill in the chuck and tighten chuck by

rotating the chuck knob CW. Stop just before the

chuck jaws make contact with the drill. Make sure

the drill still slides easily through the chuck. Place

the Chuck in

the Alignment

fixture until

the shoulder

of the chuck

stops against

the

alignment.

50

Page 53

Rotate the Chuck

until one of the

alignment dogs rests

firmly against the

Alignment.

Rotate the Pawl

Locating Cam until

the arrow lines up to

the major diameter

of the drill. As

indicated by the logo

on the Timing Arm,

rotating it will have

an impact on the

amount of relief

ground on the drill. Unless the drill is intended for

a unique material, it is

our recommendation

that it stay in its normal

location. Push the drill

through the chuck until

the pilot starts to pass

through the Alignment.

Slide the Length Setting Pawl until it almost

touches the pilot. Continue to slide the drill

through the chuck until the major diameter stops

against the Length Setting Pawl.

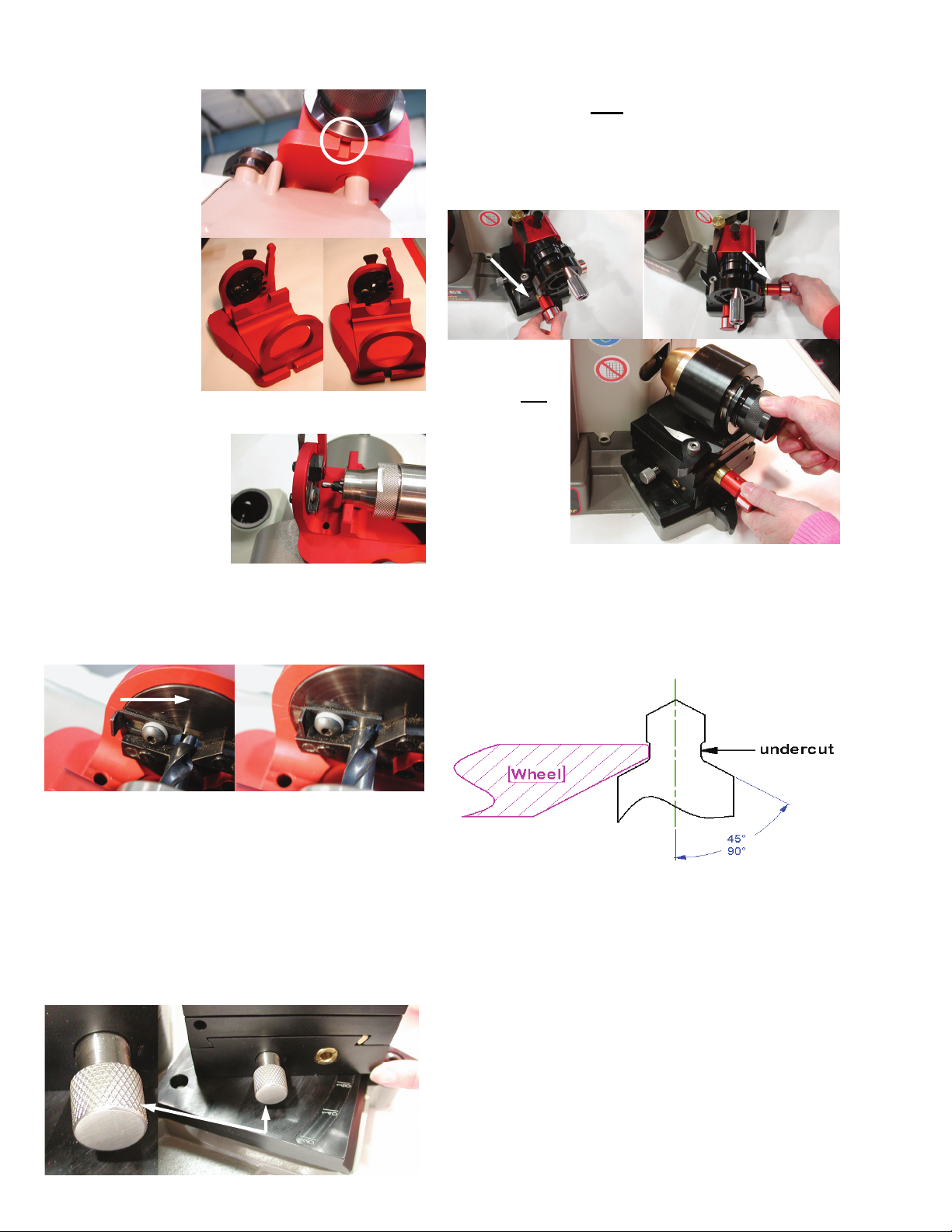

With the XT-3000

Sharpening Fixture making sure the drill is clear of

the grinding wheel. Using both the X and Y axis

knobs, position the drill close to, but not touching

the wheel.

Y-Axis Knob X-Axis Knob

Now, turn your

machine

Continue to

position the

drill into the

wheel while

rotating the

chuck.

It will be

necessary to

slightly undercut the pilot of the step drill to

produce a sharp corner at the end of the pilot

and beginning of the step.

Refer to the diagram below.

ON

OFF,