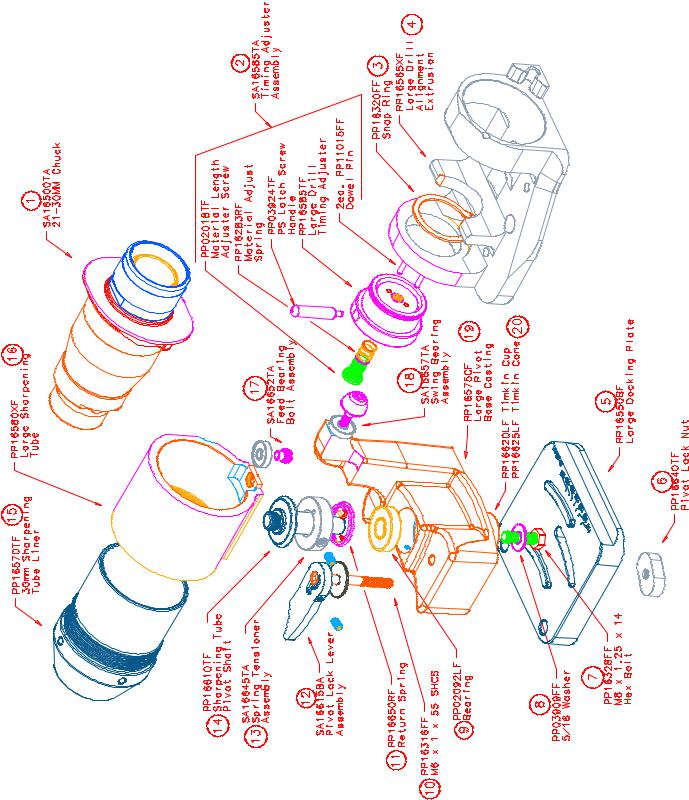

Darex XT-3000 User Manual

Large Drill Attachment

LEX050

Congratulations on the purchase of your Darex XT-3000 Large Drill Attachment. (21 mm—30 mm) As part of the assembly (see picture from left to right) you should have a SA16565XA Large drill alignment, SA16575CA Sharpening fixture,

and SA16500TA Large Drill Chuck.

By now you are familiar with the ‘quick disconnect’ feature of your XT-3000. Start by placing the Large Drill Alignment on the top of your XT3000. Rotate the ‘Docking Lever’ clockwise to securely lock the fixture in place. In a similar manner, remove your current sharpening fixture and replace it with the Large Drill Sharpening

Fixture.

Now would be a great time to determine the point angle of the drill that is to be sharpened and adjust both the sharpening fixture and alignment to that point angle. The Sharpening fixture is adjusted by pulling the red lever towards (counter clockwise) the operator and sliding the fixture to

the point angle desired. Lock the fixture by returning the red lever to its original position. The

alignment is adjusted by rotating the black lever located at on the front of the alignment fixture. As per the decal, rotating the lever towards the operator will reduce the amount of relief ground onto the drill and pushing the lever away from

the operator will increase the relief. Placing the pin at the midway point on the decal is a good starting place for 118° drills. For 135°-150° drills start with the alignment 2 marks towards the operator. You can set the alignment at any setting necessary to achieve the amount of relief desired.

Place the drill in the chuck and turn the chuck knob clockwise until the drill slides freely through the chuck jaws. Next slide the Chuck and drill into the alignment rotating the chuck until one of the

‘cam dogs’ aligns with the mating ‘notch’ in the fixture.

You will notice the opposite ‘dog’ aligns with a reference mark machined into the alignment fixture.

Now push the drill through the chuck until it contacts the stop. Rotate the drill clockwise until

Incorrect Correct

41

the outer edge of the cutting lip is touching the pins in the setting fixture.

Firmly tighten the chuck by turning the knob clockwise while the chuck is still in the fixture. Remove the chuck and drill. The drill is now aligned and set to length to the chuck cam for the necessary grinding.

Slide the chuck into the Sharpening fixture and rotate the Chuck clockwise applying slight pressure into the wheel. It is also necessary to keep the cam up against the swing cam follower bearing.

Try to sharpen the drill in such a manner that the drill is off the wheel before you reposition your hand on the chuck.

Grinding time will vary depending on wheel condition and amount of material removal but it should require a minimum of 8-10 rotations.

NOTE: The MTO drill stop setting is adjustable using a 5/32” or 4 mm hex key if you think more or less material removal is desired.

Please Note, you do not have the ability to split drills from 21 mm to 30 mm on the XT-3000.

42

Large Drill Attachment

43

Large Drill Attachment LEX050

SA16615BA |

Pivot Lock Lever Assembly |

|

|

PP16615BF |

Pivot lock lever |

|

PP16630FF |

5mmX8mm SSS |

SA16585TA |

Timing Adjuster |

Assembly |

|

PP16283RF |

Material adjust spring |

|

PP16285TF |

Material adjust screw |

|

PP03924TF |

PS Latch Screw Handle |

|

PP16585TF |

Large Drill Timing Adjuster |

|

PP11015FF |

1/8" Dowel Pins |

SA16652TA |

Feed Bearing Assembly |

|

|

PP16652TF |

Feed Bearing Bolt |

|

PP08560LF |

Bearing |

SA16657TA |

Swing Bearing |

Assembly |

|

PP16655LF |

Swing Bearing |

|

PP16657TF |

Swing Bearing Bolt |

SA16645TA |

Spring Tensioner |

Assembly |

|

PP16645TF |

Spring Tensioner |

|

PP12280FF |

M6 x 1 x 8mm SSS |

SA16500TA |

21-30 MM Chuck |

|

|

PP16500TF |

Large chuck Body 21-30mm |

|

PP16505TF |

21-30mm chuck cam |

|

PP16510TF |

21-30mm chuck knob |

|

PP16515TF |

21-30mm Closing sleeve |

|

PP16520TF |

21-30mm closing screw |

|

PP16525NF |

Thrust Washer |

|

PP16530SF |

Jaws |

|

PP16535TF |

Jaw guide |

|

PP16472FF |

Snap ring |

|

PP16540LF |

Jaw race |

|

PP12560RF |

Jaw springs |

|

PP16440FF |

Jaw key screw |

44

XY Table Attachment

X-Y Table No Sub Assemblies, Send in for Repair

45

46

Loading...

Loading...