Page 1

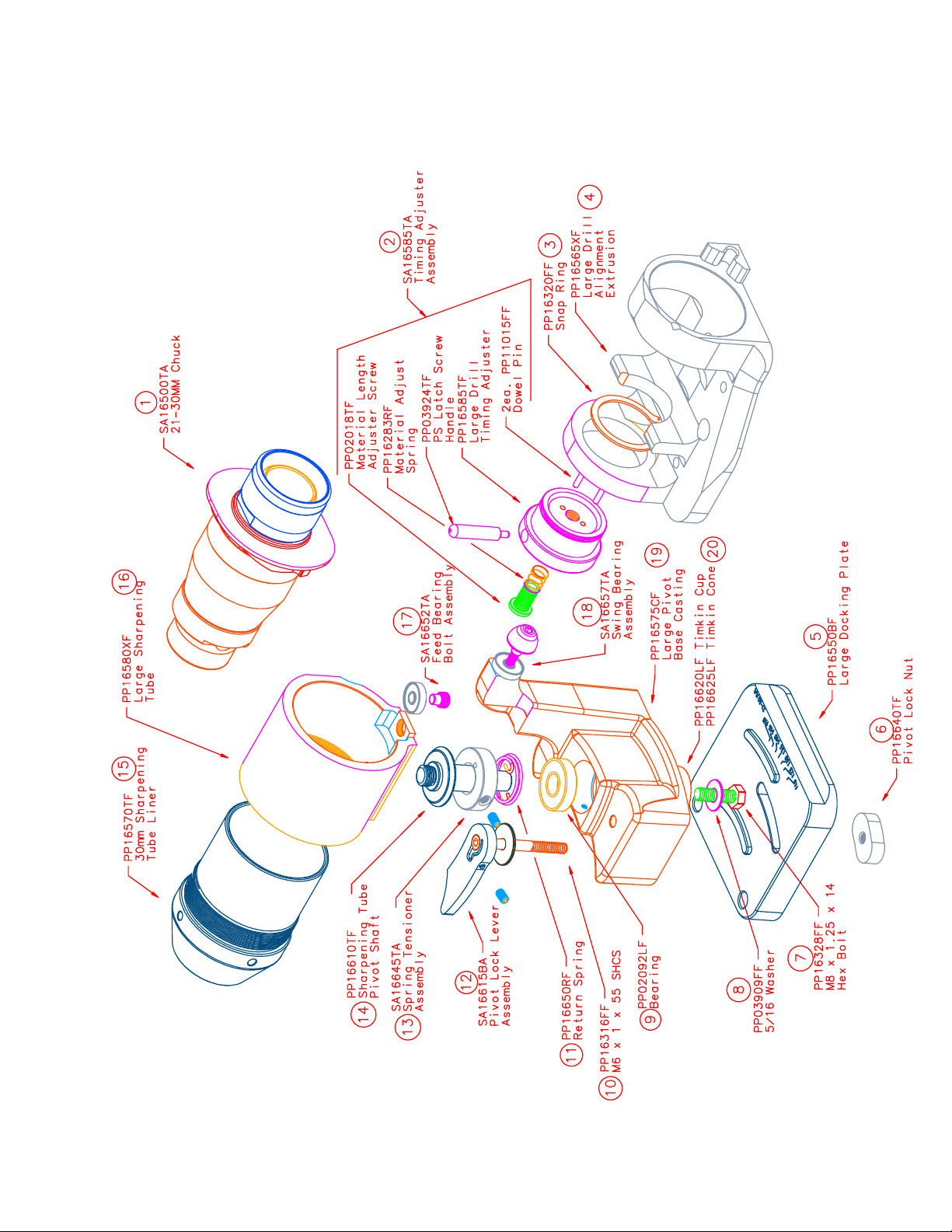

Large Drill Attachment

LEX050

Congratulations on the purchase of your Darex

XT-3000 Large Drill Attachment. (21 mm—30

mm) As part of the assembly (see picture from

left to right) you should have a SA16565XA Large

drill alignment, SA16575CA Sharpening fixture,

and SA16500TA Large Drill Chuck.

By now you are familiar with the ‘quick disconnect’

feature of your XT-3000. Start by placing the

Large Drill Alignment on the top of your XT-

3000. Rotate the ‘Docking Lever’ clockwise to

securely lock the fixture in place. In a similar

manner, remove your current sharpening fixture

and replace it with the Large Drill Sharpening

alignment is adjusted by

rotating the black lever

located at on the front of the

alignment fixture. As per the

decal, rotating the lever

towards the operator will

reduce the amount of relief

ground onto the drill and

pushing the lever away from

the operator will increase the relief. Placing the

pin at the midway point on the decal is a good

starting place for 118° drills. For 135°-150° drills

start with the alignment 2 marks towards the

operator. You can set the alignment at any setting

necessary to achieve the amount of relief desired.

Place the drill in the chuck and turn the chuck

knob clockwise until the drill slides freely through

the chuck jaws. Next slide the Chuck and drill into

the alignment rotating the chuck until one of the

Fixture.

Now would be a great

time to determine the

point angle of the drill

that is to be sharpened

and adjust both the

sharpening fixture and

alignment to that point

angle. The Sharpening

fixture is adjusted by

pulling the red lever

towards (counter

clockwise) the operator

and sliding the fixture to

the point angle desired. Lock the fixture by

returning the red lever to its original position. The

‘cam dogs’ aligns with the

mating ‘notch’ in the fixture.

You will notice the opposite

‘dog’ aligns with a reference

mark machined into the

alignment fixture.

Now push the drill through the chuck until it

contacts the stop. Rotate the drill clockwise until

Incorrect Correct

41

Page 2

the outer edge of the cutting lip is touching the

pins in the setting fixture.

Firmly tighten the chuck by turning the knob

clockwise while the chuck is still in the fixture.

Remove the chuck and drill. The drill is now

aligned and set to length to the chuck cam for the

necessary grinding.

Slide the chuck into the Sharpening fixture and

rotate the Chuck clockwise applying slight

pressure into the wheel. It is also necessary to

keep the cam up against the swing cam follower

bearing.

Try to sharpen the drill

in such a manner that

the drill is off the wheel

before you reposition

your hand on the chuck.

Grinding time will vary depending on wheel

condition and amount of material removal but it

should require a minimum of 8-10 rotations.

NOTE: The MTO drill stop setting is adjustable

using a 5/32” or 4 mm hex key if you think more

or less material removal is desired.

Please Note, you do not have the ability to split

drills from 21 mm to 30 mm on the XT-3000.

42

Page 3

Large Drill Attachment

43

Page 4

Large Drill Attachment LEX050

SA16615BA Pivot Lock Lever Assembly

PP16615BF Pivot lock lever

PP16630FF 5mmX8mm SSS

SA16585TA Timing Adjuster Assembly

PP16283RF Material adjust spring

PP16285TF Material adjust screw

PP03924TF PS Latch Screw Handle

PP16585TF Large Drill Timing Adjuster

PP11015FF 1/8" Dowel Pins

SA16652TA Feed Bearing Assembly

PP16652TF Feed Bearing Bolt

PP08560LF Bearing

SA16657TA Swing Bearing Assembly

PP16655LF Swing Bearing

PP16657TF Swing Bearing Bolt

SA16645TA Spring Tensioner Assembly

PP16645TF Spring Tensioner

PP12280FF M6 x 1 x 8mm SSS

SA16500TA

21-30 MM Chuck

PP16500TF Large chuck Body 21-30mm

PP16505TF 21-30mm chuck cam

PP16510TF 21-30mm chuck knob

PP16515TF 21-30mm Closing sleeve

PP16520TF 21-30mm closing screw

PP16525NF Thrust Washer

PP16530SF Jaws

PP16535TF Jaw guide

PP16472FF Snap ring

PP16540LF Jaw race

PP12560RF Jaw springs

PP16440FF Jaw key screw

44

Page 5

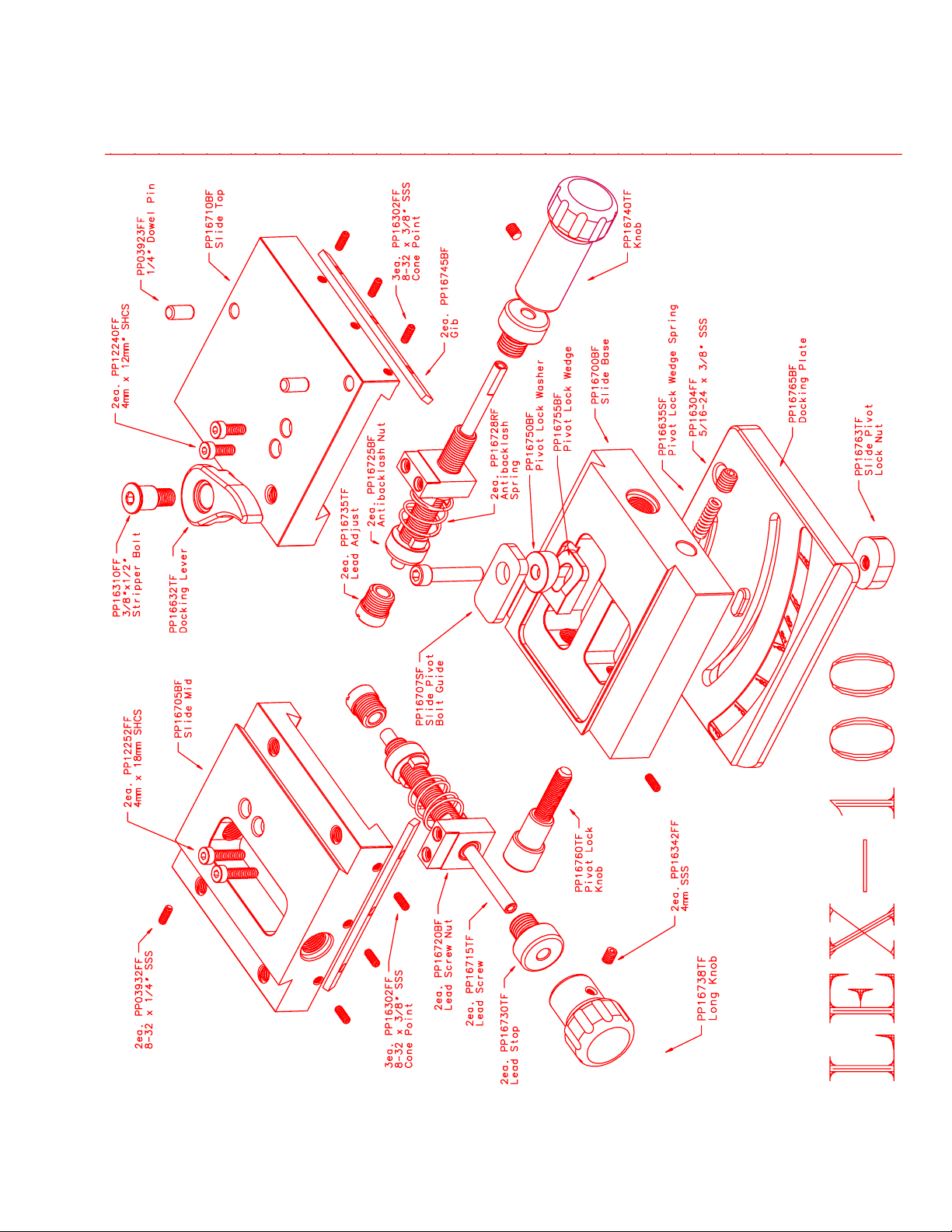

XY Table Attachment

X-Y Table No Sub Assemblies, Send in for Repair

45

Page 6

46

Page 7

Countersink Instructions

LEX150

Congratulations on the purchase of your Darex

XT-3000 Countersink Attachment. This fixture

comes with 2 V-40 double angle collets and is

used in conjunction with the Darex XT-3000 X-Y

Attachment.

X-Axis Knob

Pivot Lock Knob

Y-Axis Knob

By now you are familiar with the ‘quick disconnect’

feature of your XT-3000. Begin by removing the

current sharpening

fixture and replacing it

with the X-Y table.

Secure it in place by

rotating the ‘Docking

Lever’ clockwise. In a

similar manner, lock

the Countersink

Attachment to the top

of the machine.

It is now necessary to

determine the shank

diameter of the tool that will

be sharpened and place the

corresponding collet into the

Countersink Attachment.

To do so

slowly rotate

the spindle

clockwise until

the Spindle

Lock engages

the spindle.

Spindle Lock

Now unscrew the

Draw Tube assembly.

Place the correct collet

in the end of the Draw

Tube and replace the

Draw Tube assembly

and tighten 3 or 4

revolutions. Should

you need a collet size other than the ones

provided, you may order them from Darex

Corporation. (1-800-547-0222)

Slide the cutting tool

into the spindle leaving

approximately 1” or

more of the tool

exposed. Loosen the

Alignment Thumb

Screw and rotate the

Alignment Arm

assembly around until

the dowel pin

intersects both the

cutting edge and the

heel simultaneously.

Tighten the Alignment

Thumb Screw. Rotate

the Draw tube

assembly clockwise to

tighten the tool in the

spindle. Return the

Alignment Arm to its

original position and

release the spindle lock

pin by pulling up and

turning the pin 90°.

The cutting tool is now

oriented to the spindle

cam and is ready to be

sharpened.

Alignment

Arm

Thumb Screw

47

Page 8

To sharpen the tool, determine which angle the

tool will be sharpened at. To adjust the X-Y table,

loosen the Pivot Lock Knob and swing the table to

that angle. Tighten the Pivot Lock Knob.

Pivot Lock Knob

Remove the

Countersink

Attachment from

the top of the

machine and

place it on the X-Y

Table. Again,

rotate the

Docking Lever

clockwise to secure the fixture. Turn the machine

ON.

Using both the X and Y axis feed knobs, carefully

position the cutter into the grinding wheel.

grinding wheel. Loosen the Docking Lever and

return the Countersink Assembly to the top of the

XT-3000 to remove the cutter. The sharpening is

now complete.

Y-Axis Knob X-Axis Knob

Once the

tool touches

the grind

wheel, begin

to rotate the

spindle in a

clockwise

direction

slowly

feeding the

cutter into the wheel. Once the desired amount is

ground off, continue rotating 1 or 2 more

revolutions to “spark out” the cutter. While still

rotating the spindle, use one of the feed axis

knobs to position the cutter safely away from the

48

Page 9

Countersink Attachment

49

Page 10

Counter Sink Attachment LEX150

SA16823TA Alignment Assembly

PP16823TF Alignment Thumb Screw

PP16820BF Alignment Arm

PP16312FF 1/8"x2" Dowel pin

PP08558FF Washer

SA16860BA Swing Arm Assembly

PP16860BF Swing Arm

PP06136FF Dowel Pin

PP08560LF Bearing

SA16830TA

CS Spindle lock assy.

PP16830TF Indexing Pin Bushing

PP08041TF Indexing Pin

PP08046TF Indexing Pin Knob

PP08045TF spring

PP08376FF roll pin

50

Page 11

BRAD POINT ATTACHMENT

LEX200

Congratulations on the purchase of the Darex XT3000 Brad point Attachment. (LEX200) This

attachment consists of 2 pieces, 1 Sharpening

Fixture, SA16900BA and 1 - 3mm – 12mm Chuck,

SA16916TA. (The 12mm – 21mm Chuck,

SA16918TA is available

as an optional accessory)

Both components are

laser marked with a Brad

Point icon to minimize

confusion with other XT3000 attachments.

SETTING UP:

To sharpen a

Brad Point, you

will have to

remove the

standard

sharpening fixture

and replace it

with the X-Y

Table (LEX100).

The Brad Point Attachment works in together with

the X-Y Table. By now you are familiar with the

‘quick’ disconnect feature or your XT-3000. Begin

by removing the

current sharpening

fixture and replacing it

with the X-Y Table.

Secure it in place by

rotating the Docking

Lever CW. In much

the same manner,

secure the Brad Point

Sharpening Fixture to

the X-Y Table.

ALIGNING THE DRILL:

The alignment of the drill

happens in the XT-3000

Alignment. Loosen the

Timing Tube Lock lever and

position

the Tube

@ 118°.

Push the

lever down

to lock the

tube. Align

the drill as

CORRECT INCORRECT

Pivot Lock Knob

X-Axis Knob

Y-Axis Knob

you normally would.

SETTING UP THE X-Y TABLE:

Brad point drills are ground with the X-Y Table

positioned at the 180° mark. Loosen the Pivot

Lock Knob and rotate the X-Y Table to 180°. Lock

the Table.

Pivot Lock Knob

SHARPENING:

With the XT-3000

sharpening mechanism making sure the drill

DOES NOT

use the X-Y axis knobs to position the drill

the wheel.

Y-Axis Knob X-Axis Knob

ON

Turn

3000. Using the same

Axis Knobs, start to

move the drill into

the grinding wheel

while rotating the

Chuck. This fixture is

meant to re-sharpen

existing drills. During the sharpening process,

should you remove an

material, due to damage, it will be necessary to

re-align the drill and sharpen again. Refer to the

diagram

below for

examples of

proper drill

geometry.

contact the grinding wheel. If it does,

your XT-

OFF

, place the Chuck in the

excessive amount of

OFF

51

Page 12

Brad Point Attachment

Brad Point Attachment LEX200

SA11790PA

PP11745FF 1/4-20 x 1 SSS

PP11790PF Point angle lock knob

SA16652TA

PP16652TF Feed Bearing Bolt

PP08560LF Feed Bearing

52

Page 13

STEP DRILL ATTACHMENT

LEX 250

Congratulations on the purchase of your Darex

XT- 3000 Step Drill Attachment. (LEX250). This

attachment consists of 3 pieces, 1 Sharpening

Fixture, SA16950BA, 1 Alignment Fixture,

SA116970XA and a 3mm – 12 mm Chuck,

SA16975TA. (The 12mm – 21mm Chuck,

SA16980TA is available as an optional accessory)

All 3 components are laser marked with a Step

Drill icon to minimize confusion with other XT3000 attachments.

the XT-3000. Rotate the Docking Lever CW to

secure the X-Y Table to the XT-3000.

X-Axis Knob

Pivot Lock Knob

Y-Axis Knob

In a similar manner, lock the Step Drill Sharpening

Fixture on to the top of the X-Y Table. Secure the

Step Drill Alignment Fixture to the top of the XT-

3000.

SHARPENING THE PILOT

Should the pilot of the step drill need resharpened, do so, just as you sharpen a standard

twist drill. Having the exploded view drawing

handy will be beneficial at this point.

SHARPENING THE STEP

SETTING UP:

To sharpen the ‘step’ on your step drill, you will

have to remove the standard sharpening fixture

and replace it with the X-Y Table (LEX100). The

Step Drill Attachment works together with the X-Y

Table.

Rotate the

Docking Lever

CCW to free the

standard

sharpening

fixture, then

remove. Place

the X-Y Table on

ALIGNING THE DRILL:

Place the drill in the chuck and tighten chuck by

rotating the chuck knob CW. Stop just before the

chuck jaws make contact with the drill. Make sure

the drill still slides easily through the chuck. Place

the Chuck in

the Alignment

fixture until

the shoulder

of the chuck

stops against

the

alignment.

53

Page 14

Rotate the Chuck

until 1 of the

alignment dogs rests

firmly against the

Alignment.

Rotate the Pawl

Locating Cam until

the arrow lines up to

the major diameter

of the drill. As

indicated by the logo

on the Timing Arm,

rotating it will have

an impact on the

amount of relief

ground on the drill. Unless the drill is intended for

a unique material, it is

our recommendation

that it stay in its normal

location. Push the drill

through the chuck until

the pilot starts to pass

through the Alignment.

Slide the Length Setting Pawl until it almost

touches the pilot. Continue to slide the drill

through the chuck until the major diameter stops

against the Length Setting Pawl.

With the XT-3000

OFF,

Slide the chuck into the

Sharpening Fixture making sure the drill is clear of

the grinding wheel. Using both the X and Y axis

knobs, position the drill close to, but not touching

the wheel.

Y-Axis Knob X-Axis Knob

Now, turn your

machine

ON

.

Continue to

position the

drill into the

wheel while

rotating the

chuck.

It will be

necessary to

slightly undercut the pilot of the step drill to

produce a sharp corner at the end of the pilot

and beginning of the step.

Refer to the diagram below.

Rotate the drill CW until the cutting edges align

with the pawls. The drill is now set to length and

oriented to the chuck cam. Tighten the chuck and

remove it from the Alignment.

SETTING UP THE X-Y TABLE:

Utilizing the X-Y Table, the angle ground into the

step portion of the drill can be 90°-180°. Loosen

the Pivot Lock Knob and slide table to the desired

angle. Tighten the knob.

Pivot Lock Knob

54

Once you are satisfied with the results, turn the

cross feed knob with your right hand CCW to

remove the drill from the grinding wheel. Carefully

remove the chuck from Sharpening Fixture. The

sharpening is now complete. During the

sharpening process, should you remove an

excessive amount of material, due to damage, it

will be necessary to re-align the drill and sharpen

again.

Page 15

Step Drill Attachment

55

Page 16

Step Drill Attachment SA16950BA

SA16652TA Feed Bearing Assembly

PP16652TF Feed Bearing Bolt

PP08560LF Bearing

SA03413BA Pawl Assembly

PP03440FF 10-24 Nylon hex nut

PP03435FF #10 nylon washer

PP03420TF Pawl Retaining Pin

PP03415TF Pawl Guide Pin

PP03412BF Pawl

SA16975TA

Step Drill 3mm-12mm Chuck

Step Drill 3-12mm Chuck

PP16400TF 3-12mm Body

PP16975TF Step Drill 3-12mm Cam

PP16410TF 3-12mm knob

PP16415TF 3-12mm closing sleeve

PP16420TF 3-12mm closing screw

PP02404SF Thrust Washer

PP16425SF 3-12mm - 12-21mm jaws

PP16442FF snap ring

PP16430TF Jaw guide

PP16435LF 3-12mm Jaw race

PP12560RF 3-12mm jaw springs

PP16440FF Jaw key screw

56

Page 17

90º - 120º Drill Attachment

LEX300

Congratulations on the purchase of your Darex

XT-3000 90°-120° Sharpening Attachment. As

part of the assembly you should have a

Sharpening fixture (SA16995XA) and Drill Chuck

(SA16890TA) range 3mm to 12mm. (SA016880TA

12mm to 21mm chuck available as optional

accessory.)

By now you are familiar with the ‘quick disconnect’

feature of your

XT-3000. Start

by replacing the

current fixture

with the 90°120°

attachment.

Set your desired

point angle by

pulling the red

Pivot Lock Lever

(counter

clockwise)

towards the

operator

and

sliding the fixture across the base plate to the

desired point angle.

Lock the fixture by returning the red Pivot Lock

Lever to its original posit ion.

Use the XT-3000

alignment to align the drill

in the same manner that

you are accustomed to.

The Alignment tube should

be positioned at the

mark.

With the red Slide Handle

touching the Alignment

casting, tighten the Chuck

by rotating the Chuck Knob

clockwise.

CORRECT INCORRECT

Remove the Chuck.

Gently slide the Chuck into the Sharpening fixture.

While keeping the Swing Cam in contact with the

Swing Cam Bearing, apply slight pressure into the

Grind wheel and rotate the chuck clockwise. Try

to sharpen the drill in such a manner that the drill

is off the wheel before you reposition you hand on

the Chuck Knob. Grinding time will vary depending

on wheel condition and amount of material

removal but it should require a minimum of 8-10

rotations.

118°

57

Page 18

90º - 120º Sharpening Attachment

58

Page 19

90°- 120º Attachment

SA16652TA Feed Bearing Assembly

PP16652TF Feed Bearing Bolt

PP08560LF Bearing

SA16615BA Pivot Lock Lever Assembly

PP16615BF Pivot lock lever

PP16630FF 5mmX8mm SSS

SA16657TA Swing Bearing Assembly

PP16655LF Swing Bearing

PP16657TF Swing Bearing Bolt

SA16645TA Spring Tensioner Assembly

PP16645TF Spring Tensioner

PP12280FF M6 x 1 x 8 mm SSS

SA16890TA

3-12mm 90° Chuck

PP16400TF 3-12mm body

PP16890TF 90° 3-12 mm Cam

PP16410TF Knob

PP16415TF Closing sleeve

PP16420TF Closing screw

PP02404SF Thrust Washer

PP16425SF Jaws

PP16430TF 3-12mm jaw guide

PP16435LF 3-12mm jaw race

PP12560RF Jaw springs

PP16440FF Jaw key screw

59

Loading...

Loading...