Page 1

USER’S GUIDE

WORKSHARPTOOLS.COM

T

o reduce the risk of injury, the user must read and understand this instruction

manual before using product. Save these instructions for future reference.

• CA

UTION!

Page 2

Table of Contents

Safety Information.........................................................................3

Sharpening Basics ..........................................................................8

Getting To Know Your Tool ..........................................................10

Setting Up Your Tool ....................................................................12

Know Your Knife ...........................................................................13

Sharpening Reference Chart .......................................................14

Sharpening Outdoor Knives ........................................................15

Sharpening Serrated Knives........................................................17

Sharpening Fillet Knives ..............................................................18

Sharpening Gut Hooks .................................................................18

Sharpening Kitchen Knives .........................................................19

Sharpening Scissors .....................................................................20

Grinding, Polishing, Deburring ....................................................21

Tool Grinding Attachment ...........................................................22

Blade Grinding Attachment .........................................................24

Troubleshooting ...........................................................................26

Parts Index ....................................................................................27

Thank you for purchasing this tool. Your support makes a real

impact on our small business. We are confident you will be very pleased with

your purchase. If that is not the case, please contact us. We know you work

hard for your money and we want to provide you with a high performance,

high value tool. Please keep in touch and let us know how we’re doing. Until

then, stay sharp out there…

Team Darex,

Ashland Oregon

Page 3

3

You will be creating incredibly sharp knives and tools with this sharpener .

Please handle them with care. Use caution to avoid cutting yourself.

General Power Tool Safety Warnings

• WARNING! Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result in electric shock, re

and/or serious injury .

Save all warnings and instructions for future reference. The term “power

tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

• WARNING! CHOKING HAZARD!

Small Parts - Not for children under 3-yrs.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tool in explosive atmospheres, such as in the

presence of ammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodied plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away fr om heat, oil,

sharp edges or moving parts. Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock.

Safety Information

Page 4

4

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you ar e tir ed

or under the inuence of drugs, alcohol or medication. A moment of

inattention while operating power tool may result in serious personal injury .

b) Use personal protective equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power sour ce or battery pack, picking up or

carrying the tool. Carrying power tools with your nger on the switch or

energizing power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench befor e turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury .

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts. Air vents often cover moving parts

and should also be avoided.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and pr operly used. Use of dust

collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the corr ect power tool for your

application. The correct power tool will do the job better and safer at the rate

for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing power tools. Such

preventative safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the r each of childr en and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

Page 5

5

parts, breakage of parts and any other condition that may affect the

power tool’ s operation. If damaged, have the power tool repair ed befor e

use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions, taking into account the working conditions and the work

to be performed. Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) Service

• Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

• Do not dispose of electrical products with household waste.

Waste electrical products should not be disposed of with household

waste. Please recycle where facilities exist. Check with your local

authority or retailer for recycling advice.

• To replace a damaged power supply cord (Type Y), your power

tool must be returned to the Service Center.

Specific Safety Rules

• WARNING: AL WAYS use proper safety glasses. Everyday

eyeglasses are NOT safety glasses. Also use face or dust mask

if operation is dusty . AL WAYS WEAR CERTIFIED SAFETY

EQUIPMENT.

• WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals, work in a well ventilated

area, and work with approved safety equipment, such as those dust masks that

are specially designed to lter out microscopic particles.

Darex, LLC

210 E. Hersey St.

Ashland OR 97520

USA

Tel.: 1 (800) 597-6170

Fax.: 1 (541) 552-1377

E-mail: techsupport2@darex.com

Internet: www.worksharptools.com

Page 6

6

• WARNING: Use of this tool can generate and/or disperse dust, which

may cause serious and permanent respiratory or other injury. Always

use NIOSH/ OSHA approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.

• CAUTION: Wear appr opriate hearing protection during use. Under some

conditions and duration of use, noise from this product may contribute to hearing loss.

• Hold tool by insulated gripping surfaces when performing an operation where

the abrasive belt may contact hidden wiring or its own cord. Contact with a

“live” wire will make exposed metal parts of the tool “live” and shock the operator .

• Always hold tool rmly.

• Use clamps or another practical way to secur e and support the work piece to a

stable platform. Holding the work by hand or against your body leaves it unstable

and may lead to loss of control.

• Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling, and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes,

or lie on the skin may promote absorption of harmful chemicals.

SAFETY GUIDELINES — DEFINITIONS

It is important for you to read and understand this manual. The information

it contains relates to protecting YOUR SAFETY and PREVENTING

PROBLEMS. The symbols below are used to help you recognize this

information:

• DANGER: Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury .

• WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury .

• CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury .

CAUTION: Used without the safety alert symbol (•) indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

The label on your tool may include the following symbols.

V ...................Volt A .............amperes

Hz

..................Hertz W ............ watts

min

................minutes .......... alternating current

...............direct current

n

o............ no load speed

.................Class II Construction ........... earthing terminal

• ..................safety alert symbol rpm ......... revolutions or

......................... reciprocations per minute

Page 7

7

Motor

Be sure your power supply agrees with nameplate marking. 110 Volts AC

only means your tool will operate on standard 60 Hz household power. Do not

operate AC tools on DC. A rating of 110 volts AC/DC means that your tool

will operate on standard 60 Hz AC or DC power. This information is printed on

the nameplate. Lower voltage will cause loss of power and can result in overheating.

Extension Cords

When using an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. The following table shows

the correct size to use depending on cord length and nameplate ampere rating. If

in doubt, use the next heavier gage. The smaller the gage number, the heavier the

cord.

SAVE THESE INSTRUCTIONS

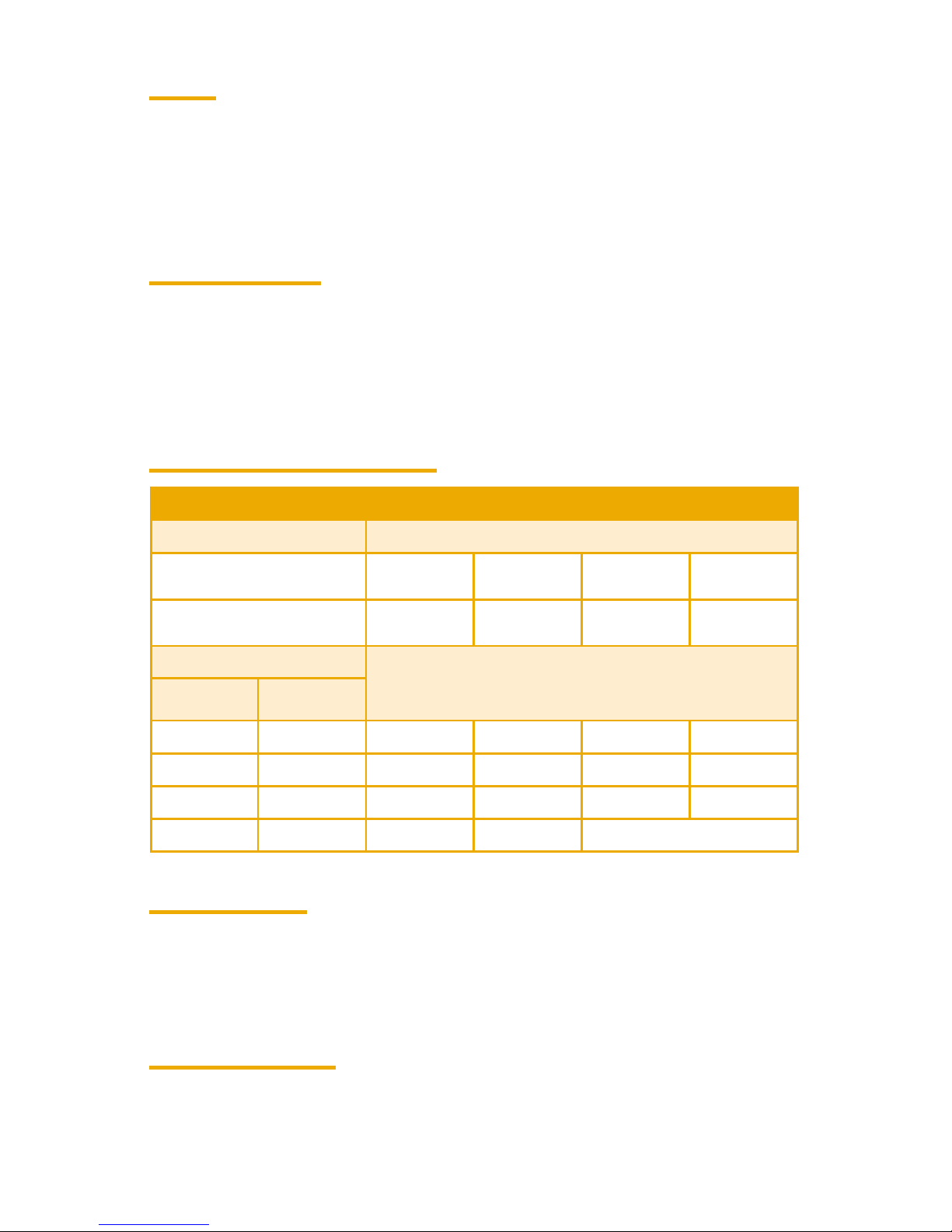

Minimum Gauge for Cord Sets

Volt Total Length of Cord in Feet

120V

0 - 25

(0-7.6 m)

26 - 50

(7.6-15.2 m)

51 - 100

(15.2-30.4 m)

101 - 150

(30.4-45.7 m)

230V

0 - 50

(0-15.2 m)

51-100

(15.2-30.4 m)

101-200

(30.4-60.9 m)

201-300

(60.9-91.4 m)

Ampere Rating

American Wire Gauge

More Than Not More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

Intended Uses:

• Grinding, Sharpening and Honing applications on knives and tools.

• Light duty grinding in metal.

• Only for use with consumer applications.

• Tool should only be used with sharpening cassette installed.

Unintended Uses:

• Industrial or commercial grinding or sharpening applications.

• Extended, continuous heavy duty use.

Page 8

8

What edge angle and why?

Our recommendations (found in section 4) are based on our extensive testing and

driven by three primary factors: 1) Optimizing the edge angle for the intended

purpose of the knife. 2) Optimizing edge retention for the knife’s purpose. 3) Speed of

sharpening process.

Why is a convex edge superior?

Our blade use and sharpness testing have taught us that a convex edge is a superior

edge. The smooth radius edge type does not have ‘shoulders’ like a flat grind and

creates less friction or resistance when cutting. A convex edge provides more steel

behind the edge to support it, so the edge stays sharper longer. Lastly, our convex

method thins the bevel when you sharpen the blade, while flat ground blades get

thicker and thicker as you re-sharpen.

The Sharpening Process

Angle Changes - what to expect with a decreased angle:

Duration: If you are sharpening a knife to an angle lower than the factory grind

(example: factory 25° sharpening to a 15°), you should expect this process to take

longer. This is due to the amount of material being removed to ‘thin’ the edge. Expect

this reduced angle edge to be more prone to damage and edge rolling.

Bevel height: You should also expect the look of your edge to change if you are

decreasing the edge angle. The height of the bevel will increase as the edge angle is

reduced and create more surface area. This also increases sharpening time since the

surface area of the blade being sharpened is higher.

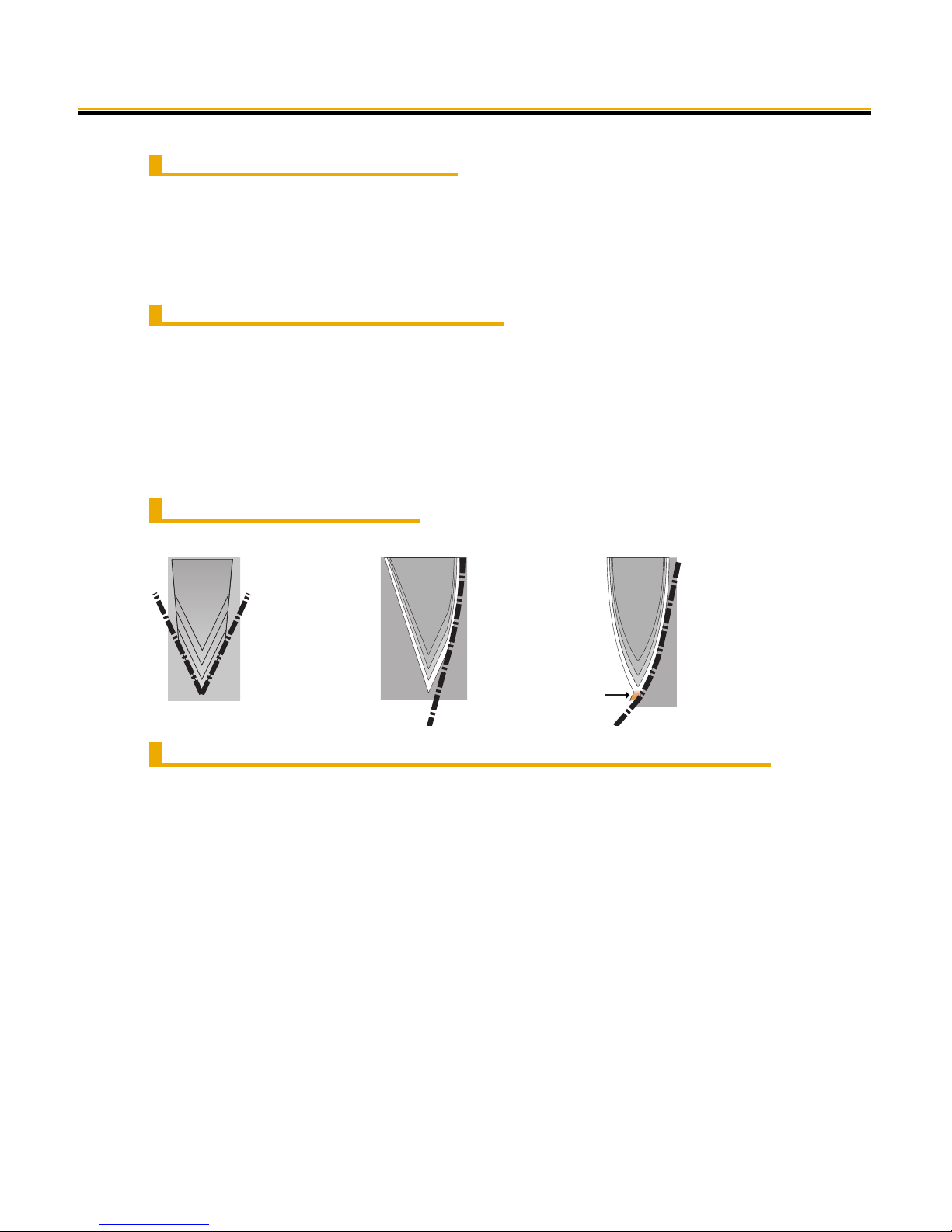

Most knives are

flat ground and

have a smaller

bevel height or

surface area.

Factory

Re-sharpening

to a lower

angle and a

convex grind

takes time.

In Process

Sharpen until

a burr is raised

before switching

to a finer grit belt.

Continue to Next Grit

Burr

Sharpening Basics:

Page 9

9

Definitions of sharp:

• Toothy Sharp: This is a sharp edge that has micro serrations at the cutting edge

and is considered a ‘toothy’ edge since it bites into material. This is the ideal knife

edge for general kitchen use and a working edge on a pocket knife for tasks like

cutting rope or boxes.

• Shaving Sharp: This is a sharp edge that has been sharpened / honed / refined

past a Toothy edge. The micro serrations or ‘teeth’ have been honed away to

reveal a smooth keen edge. This is the ideal edge for field dressing animals or

cutting raw meat in the kitchen.

• Shiny Sharp: This is a sharp edge that has been honed / stropped past a Shaving

Sharp edge. This lower angle edge has a mirror reflective bevel that has little to no

abrasive scratches in the surface finish of the blade and is the ultimate edge. No

bleeding please!

The fastest way to a sharp edge: Toothy Sharp

• Outdoor Knife: Angle = 25° | Speed = Low/Med

- X65: 6-10 strokes, then X22 (2 strokes)

• Kitchen Knife: Angle = 20° | Speed = Low

- X65: 4-8 strokes, then X22 (2 strokes)

For a more refined cutting edge: Shaving Sharp

• Outdoor Knife: Angle = 25° | Speed = Low/Med

- X65: 6-10 strokes, then X4 (10 strokes)

• Kitchen Knife: Angle = 20° | Speed = Low

- X65: 4-8 strokes, then X4 (10 strokes)

For the ultimate cutting edge: Shiny Sharp

• Outdoor Knife: Angle = 22.5° | Speed = Low/Med

- X65, then X22, then X4 (10 strokes each)

• Kitchen Knife: Angle = 17.5° | Speed = Low

- X65, X22, and X4 (10 strokes each)

Note: Stroke count is for each side of the blade.

Sharpening Basics (cont.)

Page 10

10

Sharpening Guide Slots

Belt Tensioner

Belt Change Lever

Handle

Sharpening Cassette

Power Platform

Not Pictured:

Bench Mount Fastener (1/4” x 20)

Edge Guide

Angle Adjustment Knob

Cassette

Lock Lever

Belt Tracking Lever

with variable speed dial

Power Switch

Power Switch Lock Out

Getting To Know Your Tool

1

Page 11

11

Extra Coarse

P120

Norton SG

Tool Sharpening

Knife Repair

Belt Name

Grit

Size

What it Sharpens

Uses

Coarse

X65

Norax 65µ

Knife

Shape

Medium

X22

Norax 22µ

Knife

Sharpen

Fine

X4

Norax 4µ

Knife & Scissor

Hone

Extra Fine

6000

SiC 2µ

Gut Hooks

Serrations

15° - 30° in 1° increments. Included (total) edge

angle is 2 x the angle selected. Align desired

angle with the indicator line on top of guide.

Low speed (+/-) is 1200 SFM

Mid speed (+/-) is 2000 SFM

High speed (+/-) is 2800 SFM

SFM = Surface Feet per Minute

Belt Information

•

Engineered abrasives are long lasting and should meet your sharpening needs.

•

Keep clean for best performance and life.

•

6000 Belt is narrow for improved gut hook sharpening.

•

Belt Grits are labeled on backing (µ = micron).

•

For reference, belts are equivalent to: X65 (P220) | X22 (P1000) | X4 (P3000)

Knife Sharpening Guide Adjustment

Speed Control Adjustment

Belt discoloration is not an indicator of wear. Engineered belts expose new

abrasive as they break down. Used belts may take extra strokes but will

continue to remove material. These belts will keep going longer than you think.

Keep using them as long as they cut.

Abrasive Belt Wear

Page 12

12

Slide guide onto cassette (A)

Snap into place. Pull firmly to release.

Cassette Lock Lever (B)

Push & hold to rotate cassette from

sharpening to grind mode.

Edge Guide: Pull & Rotate (C)

Clockwise to use, Counterclockwise to

raised position.

Bench Mounting (D)

Use 1/4” 20 fastener

to secure tool.

Belt Change:

Lift & hold Belt Change Lever to remove belt. Route belt

around all 3 pulleys, then release the lever. Be sure belt is

within pulley flanges. Lay tool onto its back for easier belt changes.

Belt Tracking Lever

Push lever inward, then slide up or down to track belt onto the center of the top pulley.

Trigger Lock

Pull trigger & push button in to lock “on” position. Pull trigger to release. Not

intended for use when knife sharpening, use for grinding applications only.

Sharpening Guide:

Rotate knob to select angle. Align number with mark on top.

Removing the Sharpening Cassette:

1. Remove belt from sharpening cassette.

2. Push and hold lock lever and rotate cassette to position shown.

3. Dismount cassette by pulling outward.

4. Locate this same position to re-install sharpening cassette or attachments.

SharpeningRemove

Grinding

B

B

D

C

A

Setting Up Your Tool

2

A

Side View

Page 13

13

Outdoor Knife

Tip

Heel

Bolster

Finger Guard

HandleBlade

Edge

Spine

Point

Tip

Heel

Finger Guard

Choil

Primary

Bevel

Re-Curve

Handle

Blade

Edge

Belly

Spine Ricasso

Point

Kitchen Knife

Blade Types

Re-Curve

Skinner

Drop

Point

Hawk

Bill

Sheepfoot Clip

Combo

Tanto

Spear

Point

Know Your Knife

3

Page 14

14

Kitchen Knives

Pull rate: 1”/sec • Use Edge Guide

Western

Asian

Paring

Cleaver

Bread

Angle

20°

16°

20°

30°

X

Speed

L

L

L

H

L

X65

4-8

0

4-8

4-8

0

X22

4-8

4-8

4-8

2-8

0

X4

10

10

10

0

0

6000

0

0

0

0

2

Pocket

Hunting

Fillet

Serrated

Gut Hook

Angle

25°

25°

20°

X

X

Speed

L/M

L/M

L/M

L

M

X65

6-10

6-10

6-10

0

0

X22

6-10

6-10

6-10

0

0

X4

10

10

10

0

0

6000

0

0

0

2

2

Outdoor Knives

Pull rate: 1”/sec • No Edge Guide

Best Techniques:

Position belt at the very start

of the edge with motor off.

Place blade in guide then simultaneously

power up and pull the blade.

Sharpening Reference Chart

4

• Resharpen using X4 only.

• Follow the curve of the knife when sharpening for best results.

• Use the Edge Guide on long or flexible blades when possible.

• Masking tape can protect blade from scratching during sharpening.

• Use a practice knife to learn.

Number of strokes per side.

Number of strokes per side.

Page 15

15

Reference Section 4 and the Sharpening Reference Chart

for recommended angle settings, belt selection, stroke count,

speed and choice of edge type.

1. Place the blade in the guide

With power off, insert blade into right side of sharpening guide

all the way to the start of the edge.

Place knife to bottom and outside edge of guide slot.

Do not put pressure onto / into the sharpening guide. It is intended

to provide a reference point for blade position. Only use light

pressure (weight of the blade) when using the sharpening guide to

yield best results.

2. Power on and Pull the knife

With power off and blade placed in the guide, simultaneously squeeze the power switch

and pull blade steadily through the guide (1” per second).

Follow the curve of the blade as you

pull through the guide. Keep cutting

edge perpendicular to the belt for

best and most consistent results.

Use only the weight of the blade –

do not press down into / onto guide.

Hover the blade and let the tool do

the work for best results.

Guide will ‘tip over’ if too much

outer pressure is applied.

When and why to use the Edge Guide:

• Most pocket / outdoor knives are best sharpened

without using the Edge-Guide since they often

have thumb studs or belt clips that can obstruct full

blade insertion.

• It is helpful to support and guide long blades (fillet

knives and machetes) through the sharpening process.

Pull and Rotate

Sharpening Outdoor Knives

5

Best Techniques:

Page 16

16

Sharpening Outdoor Knives (continued)

3. Repeat and feel for burr

Continue sharpening on right side of guide. Check for

a burr every 2-3 strokes (see picture).

Sharpen only until a burr is created along the entire

length of the edge or you reach the recommended

stroke count found in the Sharpening Reference

Chart in section 4.

If burr is not yet raised, See

“Knife not getting sharp”

in Sharpening Basics section.

Best Techniques (Avoid Rounding the Tip):

Maintain factory blade profile / shape:

Check for a burr by brushing

fingers across/away from the

blade edge.

Repeat same number of strokes on other side of blade / sharpening guide.

Once the edge is shaped / formed, continue with finer grit belts using alternating

strokes. Alternating strokes removes the burr and refines the edge faster.

See Sharpening Reference Chart in section 4 for recommended belt use and

stroke count based on the edge you want (Toothy, Shaving, Shiny).

Abrasive Belt

STOP STOP

Abrasive Belt

Follow the curve of the blade so

the edge remains perpendicular

to the belt. Stop on belt.

Use this technique

for these

blade types:

Pull straight through the guide

and stop on the middle of the

belt. Do not lift the blade handle.

Turn power off as knife tip contacts belt.

Use this technique for these blade

types:

Page 17

17

Only use the finest grit 6000 belt (purple, narrow) for serrated sharpening.

Place flat side of blade at the bolster / handle against the fine grit abrasive belt. Set

to low speed and squeeze the power switch and pull knife steadily across the belt

from bolster to tip. An 8” blade should take 8 seconds.

Repeat until no burr remains on flat side of blade and serration ‘teeth’ are sharp.

Serrated knives can be sharpened

with or without the Knife Sharpening

Guide installed depending on height of

serrated knife.

Only place serrated blades on downhill right side of belt. Otherwise you risk cutting

the belt.

Most serrated knives have a flat side and a bevel side on the blade;

Sharpen only the flat side.

Flat Side

Blade

Belt

Beveled Side

Sharpen Serrated Knives

6

Best Techniques:

Page 18

18

Use very light pressure in the sharpening

guide so the blade does not flex.

Reference the Sharpening Reference Chart in section 4 for recommended angle

settings, belt selection and speed. Otherwise sharpening a fillet knife is the same as

other knives.

Use the Edge Guide to help support these long, flexible blades during sharpening to

ensure a consistent sharpening along the entire edge.

Sharpening Fillet Knives

7

Sharpening Gut Hooks

8

Only use finest grit 6000 belt (purple,

narrow) for sharpening gut hooks.

Place curve of gut hook over the belt on

downhill side; allow belt to conform to

blade’s curve. Squeeze power switch; hone

2 to 4 seconds. Repeat on other side.

Only place gut hook on downhill - right side of

belt. Otherwise you risk cutting the belt.

Best Techniques:

Page 19

19

With power off and blade placed in the guide, simultaneously squeeze the power

switch and pull blade steadily through the guide (1” per second).

Follow the curve of the blade as you

pull through the guide. Keep cutting

edge perpendicular to the belt for

best and most consistent results.

Use only the weight of the blade –

do not press down into / onto guide.

Hover the blade and let the tool do

the work for best results.

Guide will ‘tip over’ if too much outer

pressure is applied.

Reference the Sharpening Reference Chart in section 4 for recommended

angle settings, belt selection and speed. Otherwise sharpening a kitchen knife is

the same as other knives.

Most kitchen knives should be sharpened with the Edge-Guide.

1. Place the blade in the guide

With power off, insert blade into right side of sharpening

guide all the way to the beginning of the edge or finger guard.

Place knife to bottom and outside edge of guide slot.

Continue sharpening on right side of guide only until a burr is created along the entire

length of the edge or you have reached the recommended stroke count in section 4.

Repeat same number of strokes on other side of blade / sharpening guide.

Continue sharpening with finer grit belts using alternating strokes. Alternating

strokes removes the burr and refine the edge faster.

No finger guard Finger guard

2. Power on and Pull the knife

Sharpening Kitchen Knives

9

Page 20

20

Sharpen only the beveled side of your scissors. Marking the beveled side with a

black marker will make it easier to see when the cutting edge has been sharpened.

Beveled Side

Once scissor blade is properly placed in

Sharpening Guide, squeeze power switch and

simultaneously pull the scissor blade steadily

through the guide.

Repeat 1-2 more times or until marker is

removed from cutting edge.

Repeat on other scissor blade.

Test scissors for sharpness. Continue sharpening

as needed.

Use the X22 belt at medium

speed to sharpen scissors.

Sharpening Scissors

10

Page 21

21

NOTE:

Tools such as these

do not require sharpening to

a precise angle; just let the belt

conform to the edge of the tool. It will

take longer to restore an edge to

severely damaged tools.

Best Techniques:

• Always clamp or fixture work piece before grinding for optimum safety.

• Let the tool do the work. Do not overload the tool during grinding. Abrasive

selection and belt speed are already optimized.

• Only sharpen tools on the right hand / downhill side of the belt.

• Tool Grinding Attachment available for heavier grinding tasks (see Section 12).

Remove Sharpening Guide. Pull up firmly.

Ensure the Edge Guide is in the raised position and

that the Knife Sharpening Guide has been removed

before grinding.

Push Cassette Lock Release Lever to rotate cassette

to grind mode.

Use the P120 belt and high speed for light

sharpening and grinding tasks.

Grinding, Polishing, Deburring

11

Page 22

22

Tracking Lever

Slack Grind

Platen Grind

Ball Detent

Hub Fastener

(Left-Handed Thread)

Quick Lock

Tensioner

Push lock release lever and rotate knife

sharpening cassette to position shown,

pull outward to remove cassette.

1. Install pulley drive hub onto tool using provided Left-Hand Thread Hub Fastener –

turn LEFT to tighten and RIGHT to loosen, do not over-tighten fastener

.

Be sure the drive pulley is properly aligned onto the keyed motor shaft.

2. Install metal Tool Grinding Attachment by pressing inward and rotating forward.

3. Push in and turn tensioner to install / uninstall belt. Use tracking lever to center belt

on pulley.

Tool Grinding Attachment

12

Page 23

23

Sharpen

Mower Blade

Belt Selection and Education:

P60 grit Zirconia Alumina belt from Norton

is designed and intended for grinding

tasks in metal.

• Remember – Lefty Tighty / Righty Loosey on Hub Fastener.

• Keep tool and attachment clean for optimum life and performance.

• Avoid overheating tool.

- Allow tool to cool to room temperature between rated operating periods.

• Speed Setting: Use at full speed for optimum performance.

• Always secure work piece and wear eye protection when grinding.

Deburr Pipe

P60

Norton ZA

Grinding

Belt Information:

Best Techniques:

Page 24

24

Installation

Push lock release lever & rotate knife sharpening cassette to remove cassette.

Install Blade Grinding Attachment by aligning the chassis to the keyed ‘on / off’

position then rotate into ‘sharpening position’.

Install Left-Hand Belt Flange Fastener onto drive shaft.

Optional:

Use a clamp to secure to work bench

Push in and turn tensioner clockwise to install / uninstall belt.

Use tracking knob to center belt on pulley.

X65

Norax 65µ

Shape

Grit

Size

Use

X22

Norax 22µ

Sharpen

Belt Information:

X4

Norax 4µ

Hone

12000MM

SiC 1µ

Strop

Blade Grinding Attachment

13

Bench

Mount Tabs

Tensioner Assembly

Clamp Lever

Angle Selection

Clamp Knob

Short Center Distance

Long Center Distance

Angle Adjustment

Lever

Tensioner

Assembly

Tracking

Knob

Hub Fastener

(Left-Handed Thread)

Reference

Plate

Angle

Indicator

90°

Grind

Plate

For reference, belts are equivalent to: X65 (P220) | X22 (P1000) | X4 (P3000)

Page 25

25

1) Choose either short or long center location for pulley depending on preference

2) Select desired sharpening angle by moving the Angle Adjustment lever

3) Tighten Angle Selection Clamp Knob to secure selected angle

4) Mount the belt of your choice based on task at hand (see chart left)

5) Turn on power to medium speed and press switch lock out button

6) Ensure belt is properly tracking so it is centered on the pulleys

7) Place blade flat onto reference plate

(see fig. 1)

8) While keeping blade flat, move up onto belt surface and place the heel of the

blade edge onto the abrasive. Use very light pressure on belt (3/16” deflection)

9) Move blade flat across abrasive (1” per second) and stop the tip on the middle of

the belt. Then pull blade away from the belt

10) Continue until a burr is raised along entire edge (count strokes)

11) Repeat same number of strokes on other side of blade

12) Continue up the grit scale until desired sharpness is achieved

13) Ensure tracking and tension is properly set when you change belts

Be mindful that accommodations will need to be made for every blade such as

thumb studs, pocket clips, blade profile or handle design. Test run the blade through

the process on both bevels without power first to ensure accommodations can be

made before sharpening.

Do not over tension belt or it may negatively affect belt tracking.

fig. 1 fig. 2

Best Techniques:

Page 26

26

Troubleshooting

14

Knife not getting sharp?

• More strokes - Grind all the way to the edge. Continue until a burr is raised. Then

progress to a finer belt.

• Higher Speed - Slow belt speeds may not be removing enough material.

• Coarser Belt - Coarser grit belts will remove material more aggressively.

a) Problem: The tips of my knives are becoming rounded. See Section 5.

Solution 1: Stop the tip on the belt while powering down the tool.

Solution 2: Keep the blade edge perpendicular to the belt. To reduce tip rounding,

follow the curve of the blade.

b) Problem: The belt is cutting into the sharpening guide or edge guide.

Solution 1: Use the belt tracking lever to re-adjust the belt position to center

of the pulley.

c) Problem: How do I feel for a burr at the cutting edge to know when to proceed to a

finer belt?

Solution 1: Slide your finger perpendicular and away from the cutting edge. The burr

will feel like a small ‘ridge’ or ‘wire’ at the edge.

d) Problem: My knives are cutting through my edge guide.

Solution 1: Use much lighter pressure on the Edge Guide. Using only the weight of

the blade provides best results.

Best Techniques:

Only use P120 on blades with edge damage, thick / wide edges or very hard blade

steels (D2 S30V, 154CM, etc.). This belt will remove material and raise a burr very

quickly. Use sparingly and check for a burr after every stroke.

Page 27

27

Accessory List:

Replacement Belts:

WSKTS-KO Belt Kit (¾” x 12” belts):

WSSAKO81113

Individual Extra Coarse P120 Grit Belt (¾” x 12” belt):

PP0002934

Individual Coarse X65 Grit Belt (¾” x 12” belt):

PP0002936

Individual Medium X22 Grit Belt (¾” x 12” belt):

PP0002937

Individual Fine X4 Grit Belt (¾” x 12” belt):

PP0002938

Individual Extra Fine 6000 Grit Belt (½” x 12” belt):

PP0002409

Tool Grinding Attachment:

WSKTS-KO Tool Grinding Attachment:

WSSAKO81111

WSKTS-KO Tool Grinding Belt Kit (¾” x 12” belts):

WSSAKO81114

Individual Extra Coarse P60 ZA (¾” x 12” belt):

PP0003110

Blade Grinding Attachment

WSKTS-KO Blade Grinding Attachment:

WSSAKO81112

WSKTS-KO Blade Grinding Belt Kit (1” x 18” belts):

WSSAKO81115

Individual Extra Coarse P120 Grit Belt (1” x 18” belts):

PP0002770

Individual Coarse X65 Grit Belt (1” x 18” belts):

PP0002940

Individual Medium X22 Grit Belt (1” x 18” belts):

PP0002942

Individual Fine X4 Grit Belt (1” x 18” belts):

PP0002943

Individual Extra Fine 12,000 Grit Belt (1” x 18” belts):

PP0002952

Leather Belt Kit (1” x 18” belts with .5µ compound):

WSSA0002782

Warranty

1-year warranty on all WORK SHARP® components; excludes abrasives.

Warranty for consumer not industrial use.

Or register online at www.worksharptools.com

...or complete and mail back the Warranty Registration in the WORK SHARP® box:

Darex, LLC

P.O. 730

210 E. Hersey St.

Ashland, OR 97520 USA

Parts Index

15

Visit worksharptools.com for a full list of replacement parts.

Page 28

PP0003075 Rev 1 8/13

WORK SHARP® is a trademark of Darex, LLC.

Darex, LLC

210 E. Hersey St.

Ashland OR 97520

USA

Tel.: 1 (800) 597-6170

Fax.: 1 (541) 552-1377

E-mail: techsupport2@darex.com

Internet: www.worksharptools.com

KNIFE & TOOL SHARPENER

Loading...

Loading...