Page 1

DAREX V390

®

Drill Sharpener

1/8” (3mm) to ¾” (19mm) size range

OPERATING

INSTRUCTIONS

PP11852KF

03/20/06

Operating

Instructions

CAUTION! To reduce the risk of injury, the user must read and understand this

instruction manual before using product. Save these instructions for future reference.

Page 2

2

Table of Contents

The Darex Story......................................................................................... Page 3

Safety Instructions..................................................................................... Page 4

Getting to Know Your V391......................................................................... Page 5

Drill Information......................................................................................... Page 6

Quick Step Instructions............................................................................... Page 7-8

Detailed Operating Instructions.................................................................... Page 9-11

Machine Adjustments.................................................................................. Page 12-13

Troubleshooting.......................................................................................... Page 14-15

Maintenance Instructions............................................................................. Page 16-17

Drawings & Parts List.................................................................................. Page 18-19

Page 3

3

The Darex Story

Darex Corporation began in 1973 in Beecher, Illinois. The D, A and R of Darex are the initials of three

generations of the Bernard family; David, Arthur and Richard Bernard. David and his father Richard

founded Darex. Grandfather Arthur Bernard, who earlier founded the Bernard Welding Company

contributed his energy and guidance to Darex until his death. Art’s inventions revolutionized the

welding industry.

In 1978, Darex relocated to Ashland, Oregon. Grandson Dave and son Dick carry on Arthur’s legacy of

inventiveness. Darex grew to become the most recognized name in the cutting tool sharpening

industry. Today, Darex is a world-leading manufacturer of precision cutting tool sharpeners.

Darex is proud to offer a complete line of quality precision cutting tool sharpeners at affordable prices.

Before our first days, we at Darex had looked at our competitor’s sharpeners and asked ourselves:

”Must cutting tool sharpeners be complicated?

prohibitive accuracy or low price inaccuracy?” Our sharpeners prove you can have it all: simplicity,

accuracy and affordability.

We have always emphasized innovative product design and tested technology. The experienced

personnel at our modern manufacturing facility use the latest production methods. The Darex

marketing team knows first-hand the machines we sell and will guide you to the best machine for

your needs. Our skilled technical service department is happy to answer your questions about our

products or cutting tools.

Why must the choice in sharpeners have either cost

The V390

This limited duty unit is the most economically priced of the Darex Industrial Sharpeners. It is

designed for the small fabrication or job-shop where a lower volume of drill sharpening is required.

Point angle range is 118 to 140 degrees. Size range is 1/8” to ¾” (3mm to 19mm). This sharpener

has point splitting capabilities. With the standard electroplated CBN (Cubic Boron Nitride) grinding

wheel the V390 will sharpen hig

electroplated diamond wheel is available to sharpen carbide drill bits. The electroplated diamond and

CBN wheel will sharpen approximately 1000-2000 drills before replacement is required. The Darex

V390 is most efficient when used to sharpen drill bits to their original point angle. The troubleshooting

section of this manual is designed to anticipate many common questions and applications. To keep

your DAREX V390 in top condition, please refer to the maintenance section of this manual. A complete

schematic breakdown, replacement wheels and parts are listed on page 18 and 19.

h-speed steel, cobalt, parabolic, TiN and other coated drill bits. An

Page 4

4

Safety Instructions

WARNING:

REMEMBER FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL

BEFORE OPERATING TOOL AND SAVE THESE INSTRUCTIONS.

Wear Eye Protection. Never touch internal parts of the sharpener

when the sharpener is on. The rotating grinding wheel can cause

injury. Use caution when replacing the grinding wheel. Follow

instructions entitled “Replacing The Grinding Wheel”, in this

Instruction Manual. Regularly empty accumulated grinding dust.

Follow instructions entitled “DAREX V391 Maintenance” in this

Instruction Ma

WARNING: WHEN USING ELECTRIC TOOLS, BASIC SAFETY

PRECAUTIONS SHOULD ALWAYS BE F

RISK OF FIRE, ELECTRIC SHOCK AND PERSONAL INJURY,

INCLUDING THE FOLLOWING:

1.KEEP GUARDS IN PLACE and in working order. Never perform

grinding operation with the wheel cover removed.

2. REMOVE WRENCHES. Form a habit of checking to see that the

wrench is removed from tool before turning it on.

3 .KEEP WORK AREA CLEAN. Cluttered areas and benches invite

accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Do not use power

tools in d

5. STORE EQUIPMENT in a safe place when not in use. Keep out

of reach of children.

6. DON’T FORCE TO

rate for which it was designed.

7. USE THE RIGHT TOOL. Don’t force tool or attachment to do a

job it was not designed for.

8. ALWAYS USE SAFETY GLASSES. Also use face or dust mask if

cutting operation is dusty. Everyday eyeglasses only have

impact resistance lenses, they are NOT safety glasses.

9. MAINTAIN TOOL WITH CARE. Keep tools

best and safest performance.

10. DISCONNECT TOOLS from the power supply before service.

11. AVOID ACCIDENTAL STARTING Make sure switch is in the “OFF”

position before plugging it in.

12. USE

manual for recommended accessories. The use of improper

accessories may cause hazards.

13. CHECK FOR DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked to

assure that it will operate properly and perform its intended

function. Check for alignment o

parts, breakage of parts, mounting and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

14. DO NOT USE DAMAGED OR UNSHAPED WHEELS. Use grinding

wheels suitable for speed of grinder.

5. NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off.

1

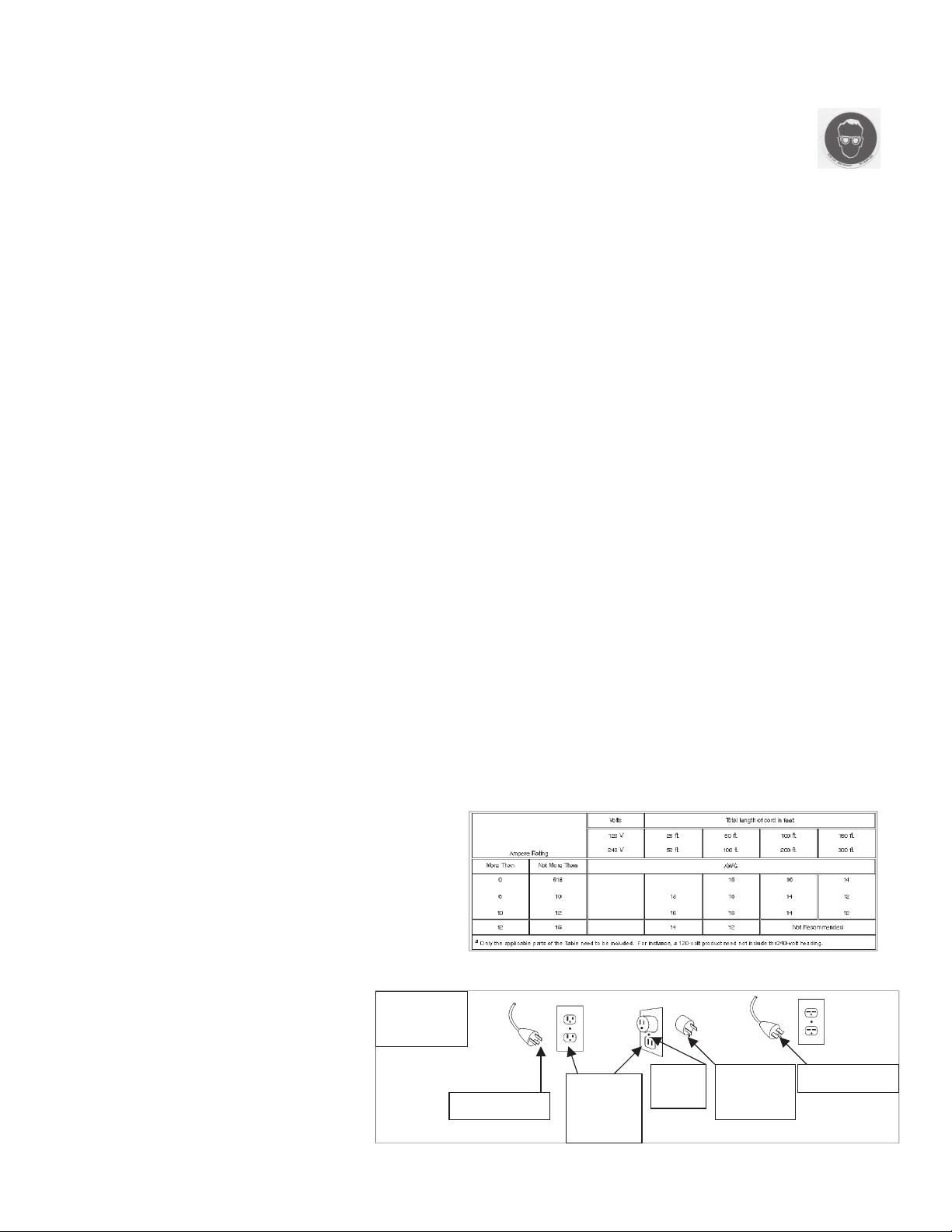

16. USE PROPER EXTENSION CORD. Make sure extension cord is in

good condition. When using an extension cord be sure to use one

heavy enough to carry the current the Drill Sharpener will draw. An

undersize cord will

power and/or overheating.

17. The continuous A-weighted equivalent sound pressure level at

the operator’s ear is not over 60 dB (A).

1

8. Risk of injury due to accidental starting. Do not use in an area

where children may be present.

19. WARNING: This product contains a chemical

known to the State of California to cause cancer.

Some dust created by power sanding and grinding

as well as contents from the machine may contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

20. The weight root mean square acceleration value

to which the arms are subjected to does not exceed

2.5 m/s .

nual.

OLLOWED TO PREVENT THE

amp or wet locations, or expose them to rain.

OL. It will do the job better and safer at the

sharp and clean for

RECOMMENDED ACCESSORIES, Consult the owner’s

f moving parts, binding of moving

cause a drop in line voltage,

resulting in a loss of

Fig .1

Grounding

methods

2

21. TO MINIMIZE THE RISK OF INJURY, ALWAYS USE

PROPER EYE AND RESPIRATORY PROTECTION: Everyday

eyeglasses only have impact resistance lenses and they are

NOT safety glasses. (See Decal at Left.) Use appropriate

respiratory face or dust mask.

GROUNDING INSTRUCTIONS

1. All grounded, cord connected tools:

In the event of a malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of

electric shock. This tool is equipped with an electric cord having an

equipment-grounding conductor and

must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided-if it will not fit the outlet, have the

proper outlet installe

Improper connection of the equipment-grounding conductor can

result in a risk of electric shock. The conductor with insulation,

having an outer surface that is green with or without yellow stripes,

is the equipment-grounding conductor

the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if in doubt as to

whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs

and 3-pole receptacles that accept the tool’s pIug.

pair or replace damaged or worn cord immediately. See table 1

Re

minimum gauge cord below.

2. Grounded, cord-connected tools intended for us

circuit having a nominal rating less than150 volts:

This tool is intended for use on a circuit that has an outlet that looks

like the one illustrated in Figure A. The tool has a grounding plug

that looks like the plug illustrated in Figure A. A temporary adapter

which looks like the adapter illustrated in Figures B and C, may be

used (except in Canada) to connect this plug to a 2-pole receptacle

as shown in Figure B, if a proper

The temporary adapter should be

grounded outlet can be installed by a qualified electrician. The green

colored rigid ear lug, etc. extending from the adapter must be

connected to a permanent ground such as a properly grounded

outlet box. See Fig. 1. Grounding methods below.

3. Grounded, cord-connected tools intended for use on a

supply circuit having a nominal rating between 150-250 volts,

inclusive. See Table 1. Minimum gauge for cord below.

Table 1. Minimum Gauge Cords

d by a qualified electrician.

Cover of

Grounding Pin

grounded

outlet box

a grounding plug. The plug

. If repair or replacement of

e on a supply

ly grounded outlet is not available.

used only until a properly

Metal

Screw

Grounded

Means

Grounding Pin

Page 5

5

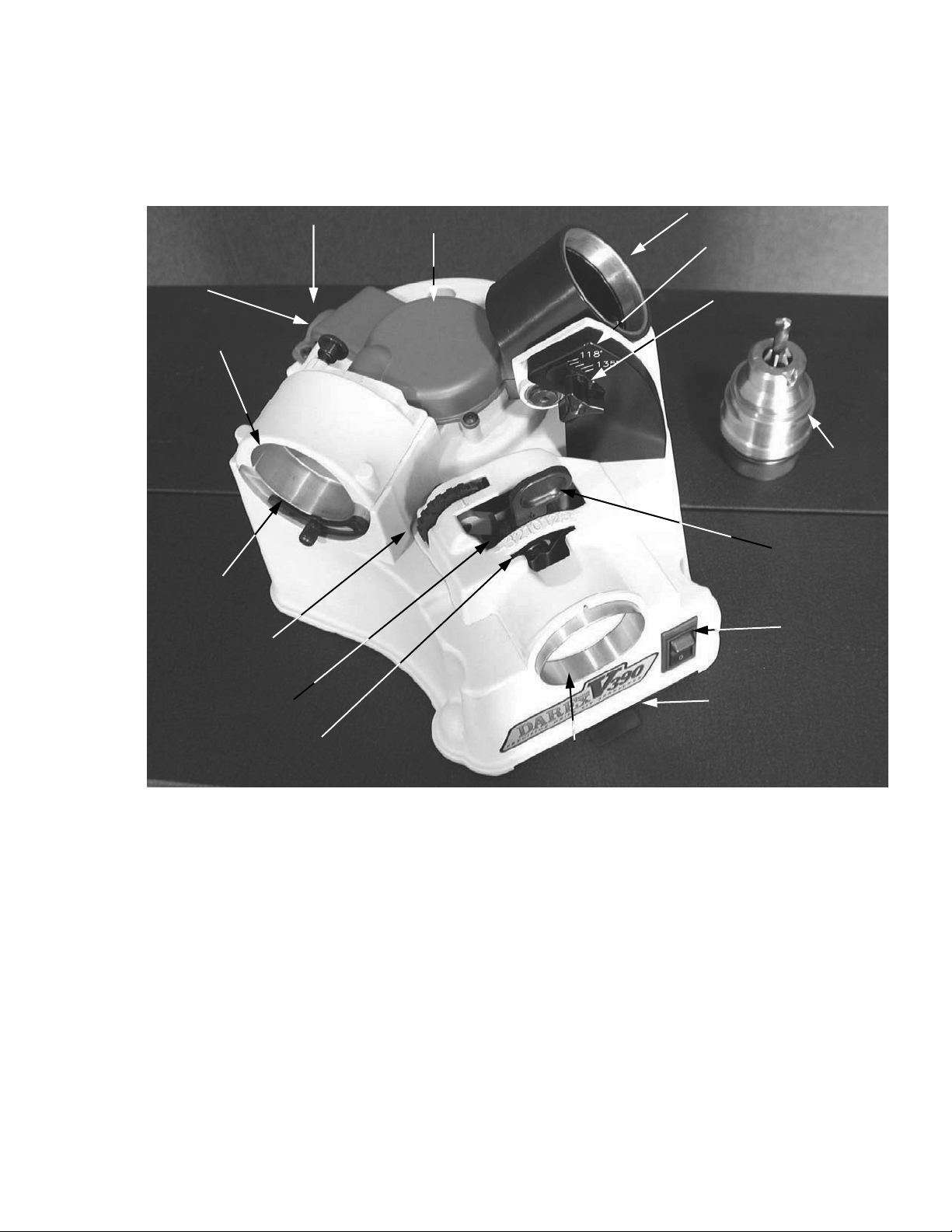

Getting to know your V390

Before you sharpen your first drill bit, please take a few minutes to familiarize yourself with your

new DAREX V390 Drill Sharpener and its basic parts and features (shown below). The time it takes

to read this page and the remainder of the manual will be made up when you sharpen your first drill

bits.

Vacuum Port

Point Split

Port Depth

Adj.

Knob

Point Split

Port

Point Split

Angle Adj.

Bracket

Material Removal

Knob

Wheel Cover

Sharpening Port

Point Angle Bracket

Point Angle Lock Knob

Chuck

Relief Paddle

On / Off

Switch

Relief Setting Numbers

Viewing Port

Alignment Port

Quick Step

Instruction

Specifications

x Recommended use: The V390 is a light duty sharpener, recommended use is 30 - 50 drills per

week.

x Sharpen: Two flute twist drill bits SAE and metric. HSS, Cobalt, TiN coated, Parabolic. Reduced

shank drill bits. Carbide drill bits require the optional diamond wheel. Unlimited maximum drill

bit length.

x Capacity: 1/8" to 3/4", 3mm to 19mm

x Accuracy: ANSI Standards.

x Wheel care: Does not require coolants. Wheels are super-abrasive and electroplated and do not

require truing or dressing.

x Cycle time: Typically a 1/8" drill bit can be sharpened within 15 seconds and a 3/4" drill bit will

take up to 60 seconds. Material removal is adjustable.

x Motor: 115 volt, 4.5 amp, 60hz, 3450 RPM

x Machine dimensions: 12" x 11" x 9"

x Packing dimensions: 17" x 15" x 11.5"

x Weight 18 lbs. (8.2 kg)

x Shipping Weight: 24 lbs. (11 kg)

x Operating ambient temperature range: 4 - 35C (40 - 95F)

Page 6

6

Drill Information

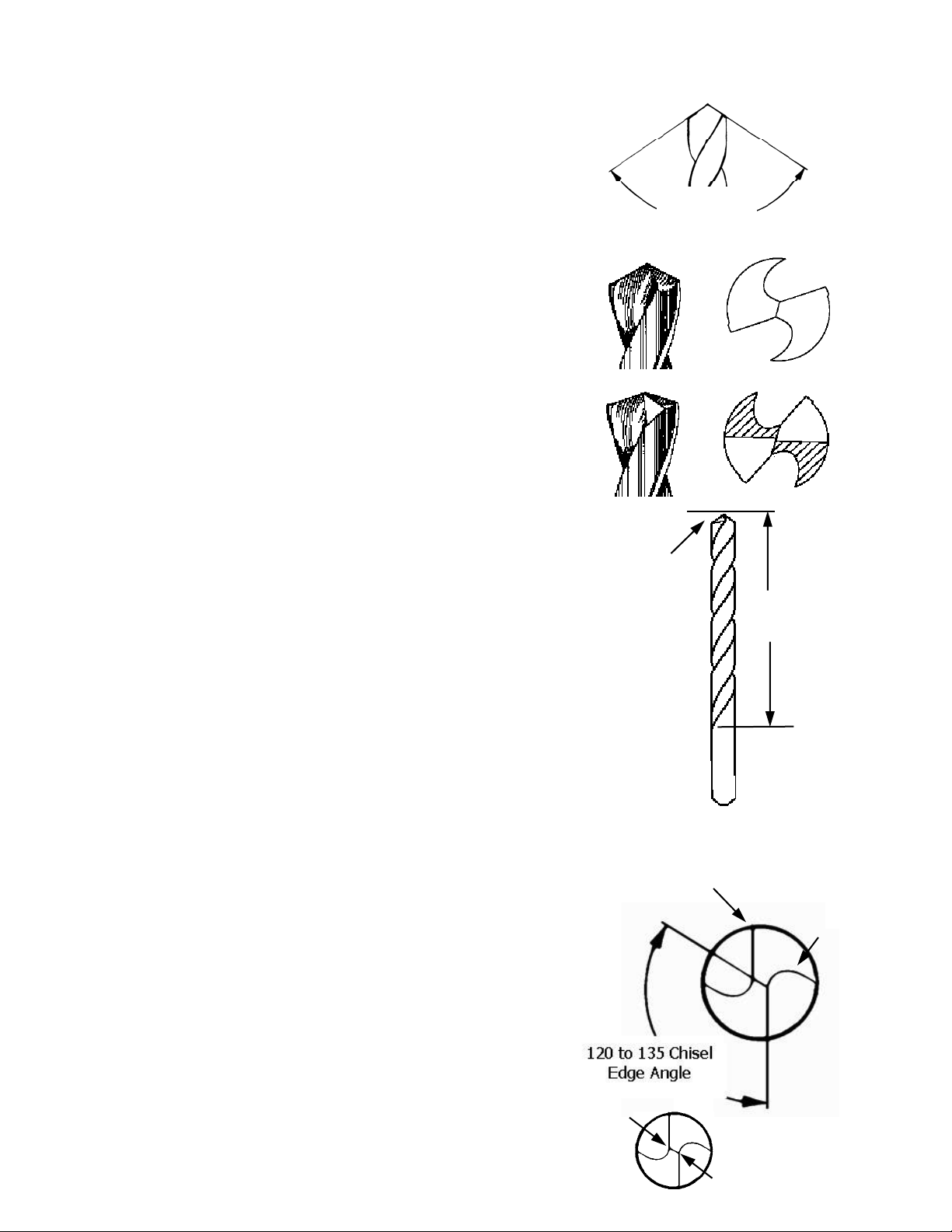

118º STANDARD POINT: This drill bit point angle is considered a

standard general-purpose geometry. It is used for drilling soft or mild

materials such as cold rolled steel, aluminum, and wood. Typically the

standard drill bit is made of High Speed Steel (HSS). The tip of the

drill bit can easily be split making it a high performance drill bit.

135º HIGH PERFORMANCE SPLIT-POINT: The flatter point angle of this

drill is designed for harder, tougher materials such as tempered steels,

hard alloys or hard cast metals. Due to the thicker web and flat point

angle this drill point works best when its split-point is maintained.

SPLIT POINTS: Split point drill bits do not walk around on the material

before they begin to cut. This feature is described as self-centering.

Center punching or center drilling is

bit chisel point has to wear an area in the middle of the hole prior to

the cutting lips removing material. Due to its additional cutting lips

along the chisel edge, a split point will begin cutting immediately. Much

less thrust is required to drill a hole with a split point as compared to a

non-split or conventional point. You can split either the 118º or the

135º degree points on this DAREX V390 precision Drill Sharpener.

often eliminated. A standard drill

Included Point

Angle

118

135

CARBIDE DRILL BITS: This point angle is typically 130º to 135º.

Carbide is harder and more brittle than high speed steel and cobalt.

This type of drill is used for drilling te

With an optional diamond wheel carbide drill

your DAREX V390 Drill Sharpener equipped with an optional diamond

wheel.

PARABOLIC AND COBALT DRILL BITS: These drills have a thicker web

than regular drill bits. Parabolic drill bits are designed to drill deep

holes. Cobalt drill bits are for drilling tougher metals. They are extra

thick in the center, (web) and have split points. Often these bits are

Titanium Nitride coated. TiN is applied to increase a drill bits cutting

efficiency. Most of these drill bits can be sharpened with your DAREX

V390 Drill Sharpener.

LIP RELIEF ANGLE: The relief on a drill bit is the downward angle

between the cutting lips (leading edge) and the heel (trailing edge) on

he drill point. If the drill bit cutting lips are no

t

then the drill bit will not cut into the material. This is often referred to

as negative relief. (see page 11

Drill Sharpener is designed to grind a standard factory relief on your

drill bits.

CHISEL EDGE ANGLE: The chisel edge is the line in the center of the

drill bit where both cutting surfaces intersect. Note that in the drawing

(seen at right) the chisel edge angle is between 120º and 135º.

Another way to look at this is to imagine the drill point as a clock face.

With the cutting lips horizontal, the chisel edge should point to the 1

and 7 o’clock positions. This is the most common drill bit chisel angle.

The degree of this angle is directly affected by the amount of lip relief

ground on the drill. Excessive relief on the drill bit will rotate the chisel

angle clockwise and vise versa.

mpered steels, alloys, glass, etc..

bits can be sharpened on

t higher than the heel,

About Relief Settings

) The DAREX V390

Lip Relief

Angle

8 to 12

Flute

Length

Cutting Lip

Heel

Web

WEB: The web is the core thickness of a drill point. A new

typically around 18% of the drill bit diameter. As a drill bit is sharpened

and becomes shorter the web thickness will increase. Splitting the point

or thinning the web on a drill bit will maintain drill bit performance.

HSS drill is

Page 7

7

QUICK STEP INSTRUCTIONS

(Detailed instructions start on page 9)

A SELECT POINT ANGLE

1. Determine angle of your drill bit (A-1)

2. Set point angle from 118 to 140 degrees (A-2).

3. Set relief paddle to +1 for 118 or -1 for 135-degree point angles. These are starting reference values, settings may need adjustment. (A-3)

4. Set material removal knob from 1 to 4. Approximate removal

per digit .005 inch. (A-4)

☞TIP:

Check the point angle

indicator and make sure

that it is set to the same

angle as the drill point.

A-1

A-2

A-3

A-4

B ALIGN DRILL BIT

1. Insert drill bit into chuck and close down jaws until drill is supported but free to turn. (B-1)

2. Push the relief paddle backward to

open the pawls. (B-2)

3. Position the line on the O.D. of the

chuck (B-3) with the alignment detent

of the face of the alignment port. (B-4)

Insert chuck into alignment port.

4. Push drill bit all the way to the back

so it touches the drill stop.

5. Release the relief paddle (B-5) and

rotate the drill until the pawls grip inside the flutes. (narrowest width of

drill)

B-4

B-3

B-1

B-2

Page 8

8

Quick Step

6. Make sure the drill tip is still up against stop, tighten the chuck.

Remove from the alignment port.

C SHARPEN DRILL BIT

1. Turn power switch to on.

2. Insert the chuck into the sharpening port with a slight lifting

motion.

3. Rotate the chuck clockwise in half rotation increments, keeping

consistent, slight downward and inward pressure on the chuck. Let

the cam drive the natural in and out motion.

4. Continue rotating the chuck until the grinding is complete, then

remove the chuck from the sharpening port.

5. Inspect the drill. It may be necessary to repeat steps B and C to

complete grinding of the drill point.

Note: do not remove the drill from chuck if the point is to

be split. Proceed to step D to create a split point drill bit.

B-5

Alignment

Pin Slot

D-1

☞TIP:

Apply light, steady pressure

while sharpening the drill to

prevent excessive heat

D SPLIT DRILL BIT

1. Insert chuck into the point split port, aligning the point split tab

notch (D-1) with the point split tab on the point split angle adj.

bracket. (D-2)

2. Ease the chucked drill bit into the wheel until the chuck hits the

depth stop. Hold for a "o

3. Pull chuck out far enough to rotate 180 degrees. Push chuck

slowly back into the wheel for the “one count”, splitting the opposite side.

4. Inspect the drill bit. If you wish to increase the split depth, adjust the point split port depth adjustment knob clockwise and resplit. (D-3)

5. If you wish to decrease the split depth, the drill bit must be resharpened to remove the old split. After re-sharpening, turn the

point split port depth adjustment knob at least one full turn

counter-clockwise and re-split. Adjust split depth as needed.

ne count."

Point Split

Tab Notch

D-2

Point Split Tab

D-3

Page 9

9

Darex V390 Detailed Instructions

If possible, the first couple of drill bits you sharpen should be about 3/8” in diameter, or a large enough drill bit to

see the detail of the point. Study the machine information on page 5 and the drill information on page 6. Various

drill bit facts and drill sharpener nomenclature will be referenced in these sections.

STEP 1: Drill angle identification and

sharpener set up

A. Place the drill in a point angle gauge or mechanic’s protractor.

Note how the cutting lips fit in the gauge. A correct fit is when the

protractor edges are set flat along the entire cutting edge.

(See Picture #1)

B. The reading from the gauge will be the angle set on the sharpener point angle plate. Loosen the point angle lock knob and set

the sharpening port to the same angle as the drill point. Note: You

may change the drill point to a different angle than your drill tip if

you wish. (See Picture #2 )

C. The relief paddle is set to achieve lip relief. These settings will

vary as you sharpen drill bits with different helix angles. If your

drilling operation requires more relief for faster drilling or drilling

softer material, (usually 118 degree point) set the alignment paddle to the “plus” (+) direction at one (1) or two (2). If more accurate holes are required or harder material is being drilled, (135 degree point angle) set the alignment paddle at the minus (-) direction at one

the drill bit”. (See Picture #3)

Note: For more information on increasing or decreasing “relief” on

a drill bit, (see page 11

and applications.

(1) or two (2). The alignment tube is now set to “time

About Relief Settings

) for more discussion

Pic 1

Pic 2

Pic 3

Pic 4

D. Set the material removal knob to #1 mark. (See Picture #4) At

this minimal setting the material removal will be approximately .005” to .010”. Each number past #1 on the knob will add

another .005” removal to the setting. If the cutting lips are very

dull or chipped, more material will need to be removed.

STEP 2: Aligning the drill bit

for sharpening

A. Turn the chuck knob counter-clockwise (CCW) to open the

chuck jaws, until you can insert the drill bit into the chuck. Once

the drill bit is inserted into the chuck, turn the chuck knob clockwise (CW), this will close the chuck jaws onto the drill. Turn the

chuck knob until it stops, then loosen the chuck jaws slightly by

turning the chuck knob CCW. At this stage the drill bit should have

a “slip-fit” and will slide in or out and rotate freely within the

chuck. (See Picture #5)

NOTE: If the drill bit is held in the chuck too tightly during the

alignment process, you might not achieve proper alignment.

Pic 5

Page 10

10

Detailed Instructions Cont.

B. Carefully push the relief paddle back all the way to the rear and

hold it there. (See Picture #6)

C. In the bottom of the alignment port is a locating pin, (See Picture #7) and located on the nose of the chuck is a milled slot. (See

Picture #8) To insert the chuck into the alignment port, both the

pin and slot must be aligned.

For easier alignment, a reference line (See Picture #9) has been

milled on the O.D. of the chuck, as well

as an alignment detent located on to

the face of the alignment port. (See

Picture #10) By aligning these two reference points you have properly positioned the locating pin and slot. If both

are in alignment you will be able to,

successfully slide the chuck into the

alignment port. At this point the c

nose should be entirely hidden inside

the alignment port.

huck

Pic 10

Pic 9

Pic 6

Pic 7

Pic 8

D. Grasp the shank of the drill bit and push it into the chuck to the

drill stop. (See Picture #11)

E. Release the relief paddle, but continue pushing the drill bit in

against the stop. The two pawls will close onto the drill bit. (See

Picture# 12)

F. Look down into the viewing port in front of the relief paddle.

Note the location of the two spring steel pawls. Rotate the drill bit

until the pawls slip in and grab the flutes at the narrowest point.

(See Picture #12 and Illustration #12b) Continue to push the drill

bit against the drill stop.

G. With the drill point against the drill stop and the pawls in the

flute of the drill, use the other hand to tighten the chuck by turning

the chuck knob clockwise. Push the relief paddle back again to

release the drill bit and remove the chuck and drill from the alignment port. Snug the chuck knob clockwise using both hands to

secure the drill bit.

NOTE: Short drill bits may be aligned first without the chuck. After

aligning the short drills, slip the chuck over th

alignment port and tighten the chuck jaws, securing the drill bit.

Before removing the chucked drill bit from the alignment port compare the position of the drill bit against the pawls with the “correct”

illustration. (See Illustration #12b )

e drill bit and into the

Pic 11

Pic 12

Pic 12b

Incorrect Correct

Page 11

11

STEP 3: Sharpening the drill point

A. Push the Drill Sharpener switch to the ON ( | ) position.

B. Insert the chuck into the sharpening port. While lightly pushing

in and down, rotate the chuck clockwise in half rotation increments. The chuck will move in and out and the sharpening

port will slightly swing during this process. Let the

on the chuck dictate the natural in and out sharpening motion.

NOTE: The swing motion of the sharpening port is generated as

the geometry of the swing cam (See Picture #14) contacts and

rolls over the bearing which is located inside the sharpening port.

DO NOT LIFT THE CHUCK UP AS YOU ROTATE IT. The initial

grinding occurs when the geometry of the feed cam (See Picture

#14) rides against the in-feed cam bearing also located in t

sharpening port. Once the drill bit has sparked out, (grinding noise

reduced to a minimum) the sharpening is complete. Inspect the

drill point and if it does not have adequate relief see the next paragraph. DO NOT REMOVE THE DRILL FROM THE CHUCK IF THE

POINT IS TO BE SPLIT.

cams

he

Detailed Instructions

In- feed

cam

Ill 15

Pic 14

Swing

Cam

About Relief Settings

After aligning and sharpening the drill bit, if the lip relief needs to

be increased or decreased, then follow step A or B.

A. Rotate the relief paddle from “0” to the “plus” side numbers,

#1, #2 or #3 to increase the relief setting. The further right the

relief paddle is positioned, the more lip relief the drill will have

after aligning and re-sharpening.

B. To decrease lip relief, move the relief paddle left, in the

“Minus” direction to the #1, #2 or #3 numbers. The further left

the relief paddle is positioned, the amount of lip relief will be reduced, once the drill ha

reground. NOTE: The degree of the chisel edge angle is directly

effected by the amount of lip relief ground on the drill bit. Excessive relief on a drill bit will rotate the chisel edge angle clockwise

and vise versa.

See Illustration 15

s been realigned at the new setting and

STEP 4: Splitting the drill point

You can split any drill point that the V390 is capable of

sharpening. See “Point Split Depth, Angle & Center Adjustment”

TIP:

When adjusting the Point

Split Port, make sure to

leave .002 to .005

between the split.

TIP:

Page 12

12

Machine Adjustments

diagrams (page 12 & 13) to help you understand split point drill bit

geometry.

A. Once the drill is sharpened, do not remove it from the chuck.

Align the Point Split Tab Notch, on the chuck, with Point Split Tab

on the point split angle adj.

bracket. (See Picture # 16

& 17a & 17b) Make sure

chuck is held in-line and

square with the face of the

point split port.

B. Slide the chuck into the

grinding wheel for a “one

count” pull the chuck out of

the split point port , about

1/2 inch and rotate it 180

degrees. Repeat “B”.

C. Use the point split port depth adjustment knob to feed the drill

bit into the wheel (See Picture #18) to increase the depth of split.

Pic 18

Alignment

Pin Slot

Point Split

Tab

Pic 16

Point Split

Tab Notch

Pic 17a

Point Split Depth Adjustment:

What to do if the drill point is split too much or too little:

The point s

knob is located at the rear of the point split port. (See Picture #18)

If the split point is incorrect a slight adjustment under the following

notes will need to be made.

x Drill point is split correctly: (See Diag ”A”) Use the posi-

tion of the “split line” on the right side of the drill bit as the reference line. Compare the position of the right “split line” to the

left “split line”. If the “split line” on the right is lower than the

“split line” on the left, the drill bit is under-split or split too little. (See Diagram “B”) If the “split line” on the right is higher

than the “split line” on the left, the drill bit is over-split or split

too much. (See Diagram “C”).

x Drill point is split too little: (See Diag “B”) Turn the point

split port depth adj. knob counterclockwise, (unscrew). Each

mark on the sleeve of the knob will move the drill .002”. Rotate

the adjustment knob one half of a line, at a time, in the point

split adjustment process. Re-split the point, then check the results.

plit depth is adjustable. The point split port depth adj.

Pic 17b

Diag A

Diag B

Notch

Tab

Split

lines

Correct

split

Split

too

little

x Drill point is split too much: (See Diag “C”) The drill will

need to be realigned and re-sharpened prior to adjusting.

Once the drill is re-sharpened, turn the point split adjustment

knob clockwise approximately one full turn. Insert the drill into

the point split port and split both sides of the drill. Inspect the

drill point. If the split is now not deep enough then rotate the

adjustment screw counterclockwise (unscrew), one half of a

line. Re-sharpen, then split the drill point again and check to

see if split is correct, if not, adjust accordingly.

Diag C

Split

too

much

Page 13

13

Split Angle Adjustment:

If the chisel angle of the drill has changed due to the relief ground

on the drill, then the point split rotational angle may need to be

changed. To adjust the split rotational angle, loosen the thumbscrew, (See Picture #19) located on the point split port. Move the

bracket slightly to the left of the alignment detent (See Illustration

20) This will increase the split angle that is required if the relief has

been increased. Move the bracket to the right, counterclockwise, if

the relief has been reduced. The key to this process is to intersect

or remove the chisel line when splitting the drill point. (See Illustration 21a & 21b located at bottom this page)

Center Split Adjustment:

The drill is split using the top edge of the grinding wheel. Because

the grinding wheel is seated on a hub, to correct the centering of

the split, you must raise or lower

ing the wheel hub height. After a wheel change, grind a drill and

split the drill. If the center of the split is incorrect (See Illustration

#21) the height of the wheel hub will need to be adjusted.

x UNPLUG machine and remove wheel guard cover (See Picture

#22)

x Remove the exhaust vent located on the left side of the

machine. (See Picture #23)

x A 5/32 Allen set-screw is located on the side of the wheel hub.

(See Picture #24)

x Using a 5/32 T-Handle Allen wrench, loosen the set-screw.

(counterclockwise)

x Raise or lower the hub to correct the split. Moving the wheel

hub a small amount will change the centering of the split significantly.

the edge of the wheel by adjust-

Ill 21a

Thumbscrew

Pic 19

Detent

Ill 20

Ill 21b

Pic 22

(Illustration C of 21) - Under split: When the top edge of the grinding wheel is too low, the split will NOT come to center.

Raise the wheel hub height.

(Illustration B of 21) - Over split: When the top edge of the grinding wheel is too high, the split will move past center.

Lower the wheel hub height.

Tighten the

5/32 set-screw, replace the exhaust vent and replace

wheel cover.

Sharpen and split drill. Repeat adjustment as needed.

Illustration B Illustration C Illustration 21

Ill 21a

Wheel too high Correct Wheel too low

Ill 21b

Pic 24

Pic 23

Hub Height

set-screw

Page 14

14

Troubleshooting

Q: I aligned the drill bit and sharpened it, but no material gets removed, why ?

A: You may have allowed the paddle to knock the drill bit back into

the chuck. Carefully realign the drill bit in the alignment port

again. Making sure the drill bit is pushed all the way against the

drill stop.

A: You may not have tightened the chuck tight enough to hold the

drill bit in place. When the drill bit hit the wheel it was pushed back

into the chuck. Realign the drill bit again using more force to

tighten the jaws on to the drill bit.

A: When changing point angles it may be required to advance the

Material Removal Knob to a higher number. Realign drill bit at new

Material Removal Setting.

Q: I'm getting negative relief! Negative relief is present when the

heel behind the cutting lip is higher than the cutting lip on the drill

bit. When negative relief occurs the drill bit will not cut.

A: To correct this problem, move the paddle toward the right, try

number 2 or 3 for an increased relief setting. Realign the drill bit

and re-sharpen.

A: Maintain consistent inward pressure on the chuck during the

sharpening process. Make sure grinding is completed and the drill

bit has been sparked out. (Grindin

A: The Material Removal Knob may be set to remove too much

material. Reduce amount of material being removed from the end

of the drill bit by setting the Material Removal Knob to a lesser

number. Realign drill bit and sharpen.

Q: Why is the drill point off center? If the tip of the drill bit appears to be sharpened off center, check the following items:

A: Make sure that there are no particles between the chuck jaws

and the drill bit, which could hold it off center.

A: Make sure the closing knob is tightened firmly enough to hold

the drill bit on center.

A: During the sharpening process be sure not to push unevenly

while rotating the chuck.

A: The drill may be bent. Roll it on a flat surface to check for

straightness.

A: Spark out the drill bit.

Q: Why don’t my drills align correctly, like the "correct" diagram?

A: There may be a burr on the drill shan

flat file).

A: The drill may be too loose or too tight in chuck.

Q: What can I do about the flat spot between the lip and t

heel?

A: The flat spots or chattering on a sharpened drill, is the result of

an incomplete or irregular rotation of the chuck in the sharpening

port. To correct, apply firm, not excessive inward pressure and

rotate the chuck smoothly while sharpening. Do not lift up on the

chuck while rotating it. Be sure to complete the grind.

g noise reduced to a minimum)

k (remove burrs with a

he

☞TIP:

If the chisel angle on the tip

is too far clockwise, realign

the drill with a reduced

relief setting.

☞TIP:

Clean CBN and diamond

wheels with an oil-less

solvent, for example,

automotive brake cleaner.

☞TIP:

Sparking out drill bits while

sharpening improves drill

point concentricity.

☞TIP:

Darex manufactures other

sharpeners capable of

creating a variety of

specialty points.

Page 15

15

Q: The chisel edge on my drill bit is too long and flat!

A: During the alignment process the pawls were not gripping "ON"

the flutes of the drill bit. Re-align the drill bit making sure that the

pawls are centered in the flutes.

A: Too much heel relief. Realign drill bit toward the minus setting

and re-sharpen.

Q: After sharpening, the grind finish on my drill is rough!

A: Grind finish is initially rough when sharpened on a new wheel.

Drill performance will not be noticeably affected. However, the finish will improve as the crystal surfaces wear evenly.

A: Rotating the chuck too fast in the sharpening process can create a rough finish.

Q: Why is my point split uneven?

Pictures on page 7, "Point Splitter Adjustments" show drill points

that are split, "Too little", "Too much", and a drill point that is

"Correctly split".

A: To correct an uneven point split, take more material off of the

under split flute. To do this, reinsert the chuck in the splitting tube

with the under split side down. Repeat procedure on page 7 - Step

B, to correct the split. A correct split point should look symmetrical. The two parallel lines formed by the split should have a sepa-

ion of .002" to .005" on the chisel angle.

rat

Q: Can I sharpen left-hand drill bits?

A: Not with this unit. However, Darex Industrial does offer other

precision drill bit sharpeners that will sharpen left-hand drill bits.

They can be reached at 1-800-547-0222 or online at

http://www.darex.com

Q: Motor stops running, won't restart!

The motor will shut off when the following occurs:

A: The wheel is jammed and the motor is stalled. Push the On/Off

switch to "OFF" and unplug the electrical cord. Remove the wheel

cover and check to see if the wheel rotates freely. Make sure that

all grindings are cleaned out and no obstructions are in the wheel

cavity area. Once this is done and the wheel turns freely, plug the

machine back in to the electrical receptacle and follow the restarting procedures.

A: The machine is tipped at

A: An extreme voltage change occurs to the motor.

A: Too heavy of use for an extended time, the motor overheats.

A: If the motor is short-circuited for any reason.

When the motor shuts off from any of the above reasons, reset the

on/off switch to “ON”. The motor should restart. If motor does

not start allow the unit to cool down for approximately 30 minutes.

Then push the “ON” switch again.

NOTICE: The V390 Drill Sharpener is equipped with multiple

safety features which turn the motor off when certain occurrences

happen to the machine. For example, turning the machine on its

side will cause the circuit breaker to trip. Machine must be placed

upright.

If the unit won't start by following the above procedures call Darex

Corporation at 1-800-547-0222 and ask for Technical Service.

an angle or is turned over.

Troubleshooting

☞TIP:

Periodically clean the

grindings from inside the

chuck to make sure it will

maintain accuracy.

☞TIP:

To sharpen very small

drills, set the material

removal at the smallest

(#1) amount of material.

☞TIP:

While aligning the drill,

make sure that the spring

steel pawls are fully inside

the flutes of the drill.

Page 16

16

DAREX V390 MAINTENANCE

Cleaning the DAREX V390

Unplug the Drill Bit Sharpener. Using a dry paintbrush or a cloth,

clean the inside and outside of the Alignment, Sharpening and

Splitting ports to remove any grindings that may have accumulated. (See Picture #25) The attachment of a vacuum with a standard vacuum hose works well to keep the grit area clean. (See

“Vacuum Tube” below)

Removing the wheel cover

Unplug the Drill Bit Sharpener. Using a 3mm hex wrench, remove

the three hex head screws holding the wheel cover on. (See Picture #26) Lift the wheel cover off and with a dry brush remove

any grinding dust. (See Picture #27)

Determining if a wheel change is required

1. Sharpened drill bits will burn or turn blue no matter how fast or

slow you rotate the chuck.

2. Upon inspecting the whee

abrasive. (See “Cleaning the electroplated CBN or diamond

wheel” )

3. When sharpening a drill bit, if it takes an extreme number of

rotations to sharpen the tool, then the wheel will need to be replaced. Contact the company or distributor where the sharpener

was purchased for replacement wheels.

Removing the wheel

MAKE SURE THE UNIT IS UNPLUGGED! Once wheel cover is removed, insert a Phillips head screwdriver into the wheel retainer

bolt on the top of the wheel and turn it counterclockwise to loosen.

(See Picture #28) Using a hex wrench remove the bolt and wheel

retainer. Lift the wheel off of the motor hub. (See Picture #29)

Remove dust particles from the wheel hub and grinding wheel area

with a small dry brush. Dispose of drill grinding dust in a safe and

environmentally approved manner. Prior to re-installing the wheel

make sure to clean all grindings off of hub and wheel.

Replacing the wheel

To re-install wheel, reverse steps taken to remov

l, it appears smooth as if there is no

e wheel.

Pic 25

Pic 26

Pic 27

Pic 28

Pic 29

Cleaning the chuck

Using pressurized air, blow grindings out of the chuck from the

knob end. For further cleaning, disassemble the chuck by merely

unscrewing the closing knob on the chuck and removing the chuck

body. Clean the inside of the chuck with a dry paintbrush. Do not

remove the springs and jaws from the holder! Once the inside of

the chuck has been cleaned, apply a drop or so of light lube on the

threads. Slide the chuck body onto the jaws, rotate the closing

knob clockwise to reassemble the chuck. (See Picture #30)

Pic 30

Page 17

17

Vacuum tube PP11230TF)

If a vacuum system is available it is strongly recommended to attach the air vacuum tube to the exhaust of the sharpening port. To

attach the tube: Unplug the machine. Remove the wheel cover

screws and remove the vacuum port plug. (See Picture #31) Insert the vacuum tube into the groove in the port. (See Picture

#32) Re-install the screws that hold the wheel cover down. Attach

a vacuum source to the 1-1/4" diameter tube.

Cleaning the electroplated CBN or diamond wheel

These wheels are maintenance free. No truing or dressing is required on these type of wheels. However, wheels should be

cleaned on a routine basis. After removing the wheel from the

unit, saturate with any type of oil-less solvent, such as Automotive

Brake Cleaner. If you wish to, you can use a soft bristle brush and

lightly brush the wheel after sa

remove any debris that was loosened.

NOTE: If the wheel performs as though it needs changing, it may

just need cleaning.

turation, re-saturate the wheel to

Maintenance

Pic 31

Pic 32

Pic 33

Changing the light bulb

Unplug machine

Lay machine on it side (See Picture #33)

Remove screws and the bottom cover plate (See Picture #34)

The 10 watt bulb is held in a bayonet lamp receptacle. See Picture

#35)

To remove push in and twist bulb counter-clockwise. (See Picture

#36) Remove bulb.

To replace the bulb. Align the tang on the bulb with slot on receptacle. Push to the back and turn clockwise.

(2)SA02184EA - 115-125 volt 10 Watt Bulb

(1)PP02185EF - 230-volt 10 Watt Bulb (International units)

(1)SA02186EA - Bayonet Lamp Receptacle (115v & 230v)

Pic 34

Pic 35

Pic 36

Page 18

18

Page 19

19

SA11308TA - PS Depth Screw w/spring Assy. 2SA11130TA - Grinding Wheel Retainer w/bolt Assy. 3PP11125GF - CBN Grinding Wheel (Standard)

1

PP11115GF - DIA Grin ding Wheel (Optional)

SA11335SA - PS Adjustment Brkt Assy. 5PP11200CF - Wheel Guard Casting

3

4

DRWG # JVT390 & JVT391

SA11610TA - V390 Chuck Complete

PP11605TF - V390 Chuck Body

SA11612TA - V390 Steel Chuck Knob w/internal Assy. 9PP11053EF - 115v Switch/Breaker

6

7

8

PP11056EF - 230v Switch/Breaker

SA11500CA - Alignment Mtg Bracket Assy.

PP11067EF - Electrical Cover

PP11103FF - Set Screw (Hub)

SA11022MA - 115v Motor Assy. 13SA11010MA - 230v Motor Assy.14SA11106TA - Wheel Hub Assy. 15PP11725BF - Sharpening Fixture Mounting Bracket

9

10

11

12

13

PP10144EF - 115v Cord-set

PP10148EF - 230v Cord-set

PP11040EF - 115v Motor Relay

PP11035EF - 230v Motor Relay

PP11057EF - Power Receptacle w/ground lead

PP11095PF - Motor Exhaust Vent 20SA11765TA - Swing Bearing Assy. (1) 21SA11790PA - Angle Adjustment Knob Assy. 22SA11718TA - Feed Bearing Assy. (1) 23SA11708TA - Sharpening Port Assy. Complete

16

16

17

17

18

19

SA11230TA - Vacuum Port/Plug Assy. 25SA02186EA - Bayonet Lamp Receptacle (115v & 230v)

24

SA02184EA - 115-125 volt 10 Watt Bulb (2)

PP02185EF - 230-volt 10 Watt Bulb (International units) (1)

26

26

Page 20

WORLD’S BEST SELLING INDUSTRIAL DRILL SHARPENERS

Phone:

800-547-0222

541-488-2224

Darex

P O Box 730

210 E Hersey St

Ashland, OR 97520

USA

Fax:

541-488-2229

Email:

techsupport2@darex.com

Web:

www.darex.com

PP11852KF - Rev 3

Loading...

Loading...