Page 1

Large Drill Attachment

(DAREX Part # 4200)

Installation and Operating Instructions

Installation

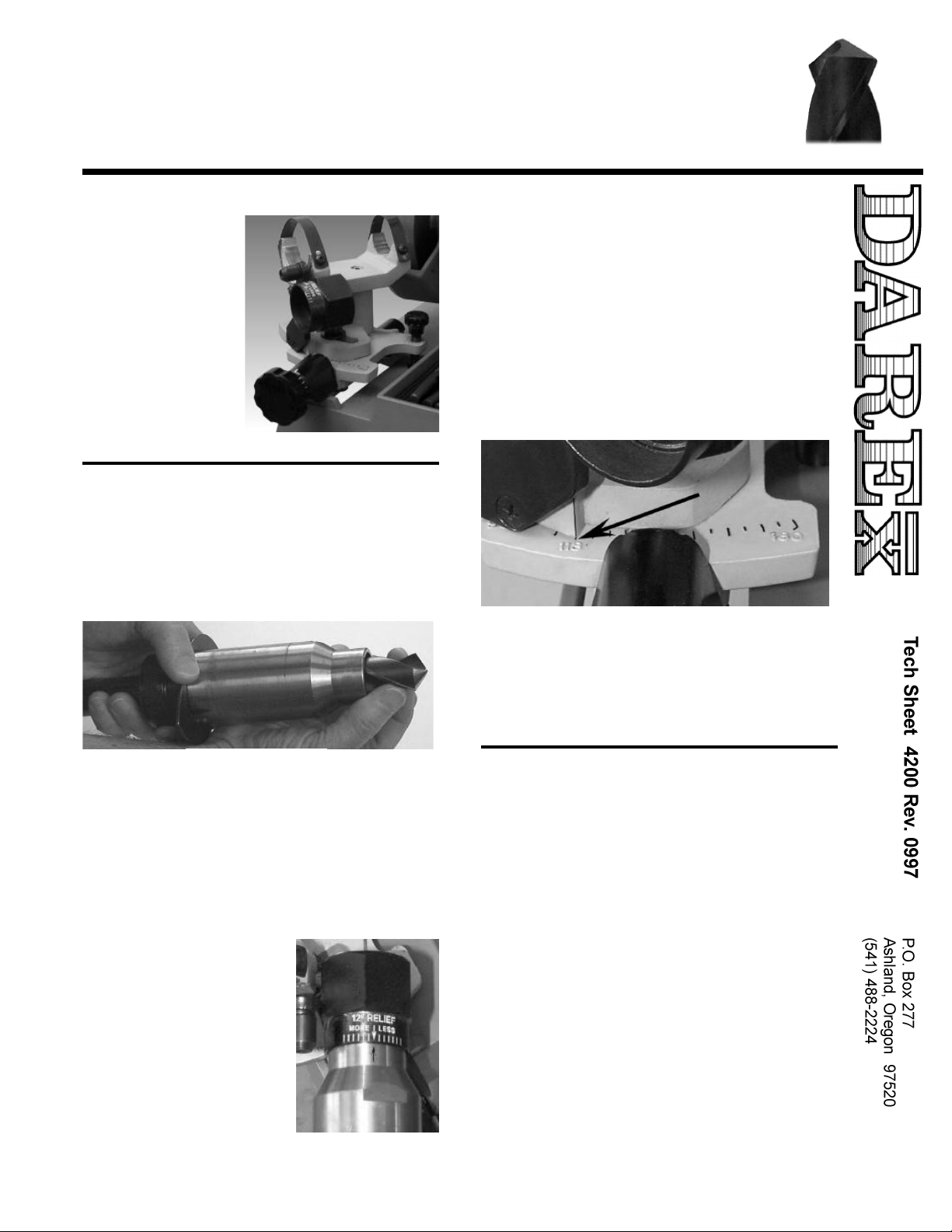

Mount sharpening

fixture as shown in

Figure 1. Unscrew

wing nut, remove

standard sharpening fixture assembly. Replace with

the # 4200 fixture

assembly and

secure with wing

nut.

Figure 1

Operating Instructions

¾” through 1-1/8” ( 19 - 28 mm)

3. Secure drill in the chuck.

Grasp the chuck body with your left hand. With

your right hand, turn drill closing knob until drill is

firm in the chuck. Make sure the chuck does not

rotate in the alignment when tightening or the setting will change. Pull the chuck out of the alignment fixture and complete the tightening process.

4. Setting the point angle

Loosen the wing nut on the sharpening fixture and

rotate the fixture to the desired point angle mark.

Use the corner angle of the fixture base as the

pointer. (See fig. 4)

1. Insert drill into chuck

A Adjust the chuck drill closing knob to hold drill

loosely. ( Drills should be loose enough to slide

back and forth easily.)

B Drill should protrude approximately one inch from

end of chuck. (See Fig. 2)

Figure 2

2. Setting drill to length and aligning for relief.

A Insert chuck into alignment fixture, making sure

the flutes of the drill go between the two stop pins

allowing the drill to go all the way in. Continue

pushing the chuck in as far as it will go.

B Grasp wing cam and rotate chuck CLOCKWISE

until alignment arrow coincides with arrow on the

lip relief scale. To set

for more relief locate

the chuck arrow a line

or so to the left of the

alignment arrow or to

the right for less relief.

(Never turn chuck

counterclockwise,

merely rotate chuck

around again to make

sure the cutting lips are

against the stop pins

inside of the alignment

tube.) (See Fig. 3)

Figure 3

Figure 4

5. Sharpening the drill

Use the same procedure for sharpening as shown

on page 3 in the operating instructions.

( M5OPS Rev: 0796)

Tips

1 To sharpen 90 degree drills in this fixture :

When aligning the drill, hold the chuck about

1/4" from being inserted all the way into the

alignment port. This procedure will allow the

drill to extend out of the chuck further and eliminate the sharpening mechanism from touching

the wheel while sharpening.

2 To grind drills upwards of 1" the wheel position-

ing knob may need to be used to position the

drill point in such a way so as to make sure it is

being covered completely by the wheel in the

grinding process.

Loading...

Loading...