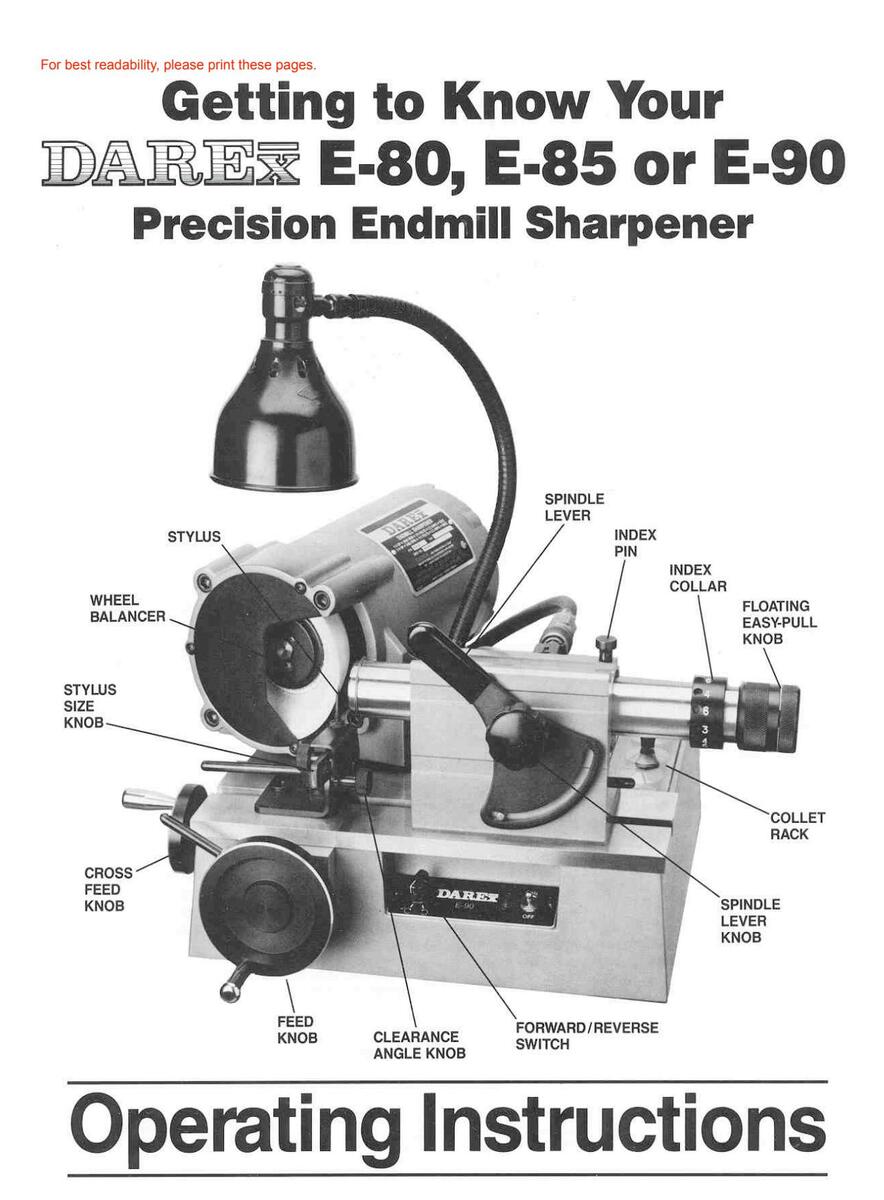

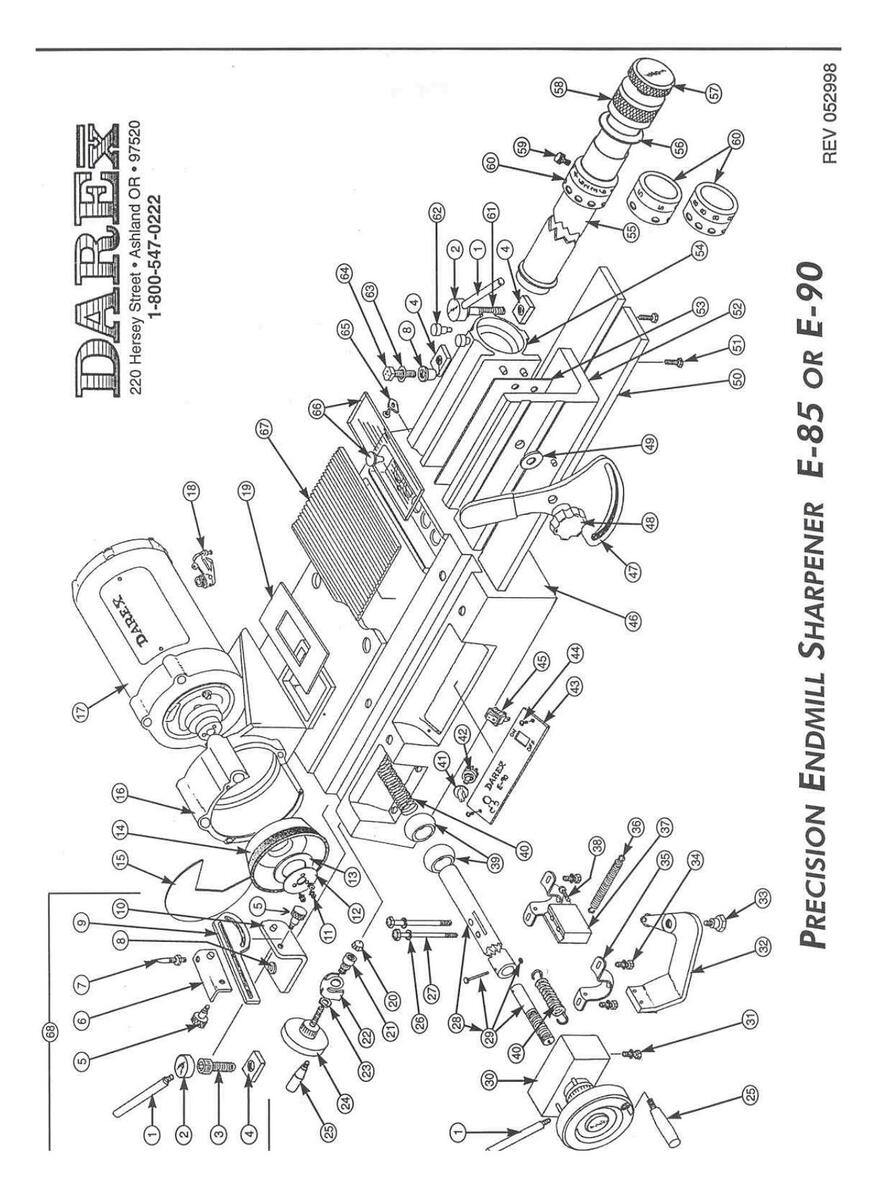

Darex Getting to Know your Darex E-80, E-85 or E-90 precision end mill sharpener Instruction Guides

Safety Instructions for DARE Grinders

CAUTION

For Your Own Safety Read Instructions Manual Before Operating Grinder.

USE WHEELS MARKED AT OR OVER RPM OF 3450.

REPLACE CRACKED WHEEL IMMEDIATELY. ALWAYS USE GUARDS AND EYESHIELDS. SECURELY TIGHTEN WHEEL SCREWS. USE ONLY WASHERS FURNISHED WITH THIS GRINDER.

Always disconnect grinder from the power supply while motor is being connected or reconnected.

INSTALLATION

Check grinder nameplate to make certain the rating is correct for the power supply, voltage and frequency.

Mount grinder on solid bench. It may be used without bolting down for light work. For heavy work it should be bolted down to the mounting surface. If mounted on pedestal, bolt grinder securely to pedestal and bolt pedestal to floor.

All attachment plugs and any receptacles shall be replaced with devices rated for the voltage for which the motor is reconnected.

After making connections, make sure they are secured and properly insulated.

When starting a grinder for the first time, or after installing a replacement wheel, it is most important that the operator stand aside for at least one minute.

This is the correct practice since grinding wheels can explode if they have received minor cracks from shipping.

OPERATION

Check that switch is in "OFF" position and that wheels rotate freely. Insert plug into receptacle and turn on switch. Grinder should come up to speed smoothly and without vibration.

MAINTENANCE

No maintenance, other than replacement of worn wheels, is needed. Wheels should be replaced when worn down to one-half the original width.

The ball bearings used are lubricated for life and do not require additional lubrication.

Wipe off and dispose of grinding dust to prevent accumulation.

Safety Instructions

A. GROUNDING INSTRUCTIONS

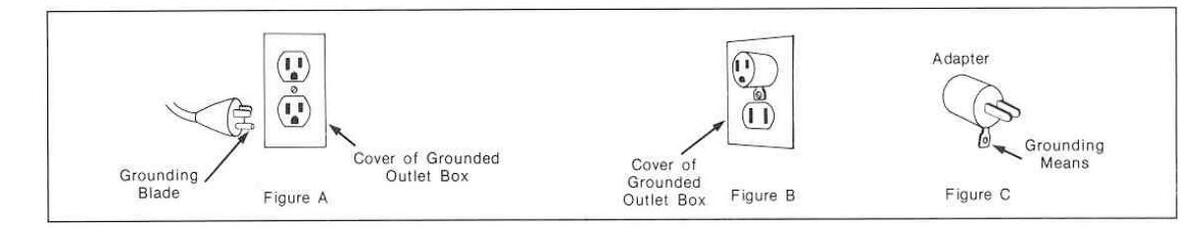

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided—if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor with insulation, having an outer surface that is green with or without yellow stripes, is the equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool's plug.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating less than 150 volts:

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Figure A. The tool has a grounding plug that looks like the plug illustrated in Figure A. A temporary adapter, which looks like the adapter illustrated in Figures B and C, may be used (except in Canada) to connect this plug to a 2-pole receptacle as shown in Figure B, if a properly grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified electrician. The greencolored rigid ear, lug, etc. extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box.

Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating between 150-250 volts, inclusive:

| Required | MATER | AL SAF | ETY DATA SHEET | ||

|---|---|---|---|---|---|

| 2 | d under USDL Safet | ty and H | ealth Regulations for Ship Rep | airing, | |

| pounding, and S | SE( | CTION I | |||

| MANUFACTURE | R'S NAME | EMERGENCY | TELEPH | IONE NO. | |

| Darex Corpor | ration | (503) | 488-2224 | ||

| ADDRESS (Numb | er, Street, City, Str | ate and 7 | (IP Code) | 6-53 | and the lands |

| 220 Hersey S | treet, Ashland, Öre | igon 975 | 20 | ||

| CHEMICAL NAM | E AND SYNONYMS | 5 | TRADE NAME | ANDSY | NONYMS |

| Alpha Alumir | na | Vitrified Bench | Grindin | g Wheels | |

| CHEMICAL FAMI | LY | E | ORMULA | ||

| AL 203 | 100000 | 96.3% | |||

| PAINTS PRESER | SECTION II | - HAZAF | IDOUS INGREDIENTS | TLV | |

| & SOLVENTS | S (Units) | ALLOY | SAND METALLIC COATINGS | . % | (Units) |

|

PIGMENTS

CATALYST |

ALLOY | METAL. | |||

| ··· METALLIC COATINGS | (e++, 1 | ||||

| ADDITIVES |

FILLER METAL

PLUS COATING O |

COATING OR CORE FLUX | |||

| DTHERS | S MIXTURSE CC 1 | OTHER | TLV | ||

| NAIF | S MINTORES OF C | UNERL | INGIDS, SOLIDS OR GASES | 1 | (Units) |

| SECTION S | ECTION | III - PHYSICAL DATA | |||

|

BUILING POINT (

VAPOR PRESSUR |

TE (mm Hg) N | aif |

SPECIFIC GRAVITY (H 20

PERCENT, VOLATILE |

= 1) | Nait |

| VAPOR DENSITY | (air = 1) N | aif |

BY VOLUME (%)

EVAPORATION RATE |

Nait | |

| SOLUBILITY IN W | ATER N | aif | |||

| APPEARANCE AN | ND ODOR N | ait | |||

| SECTION IV - FIR | EANDE | XPLOSION HAZARD DATA | |||

| FLASH POINT (Me | ithod Used) | FLAM | MABLE LIMITS Let | Uel | |

| NAIF | 1000 | ||||

| WATER | MEDIA | ||||

| SPECIAL FIRE FIG | SHTING PROCEDU | RES | |||

| UNUSUAL FIRE A | ND EXPLOSION H | AZARDS | |||

| None | - Minang Constant State | ||||

| SECTION | V - HEA | LTH HAZARD DATA | |||

| THRESHOLD LIMI | IT VALUE | ||||

| THRESHOLD LIMI |

IT VALUE

REXPOSURE |

0.000000 | |||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may |

T VALUE

REXPOSURE created elevated so |

ound lev | els which may effect hearing | ||

|

TH RESHOLD LIMI

EFFECTS OF OVE Grinding may EMERGENCY AND Obtain medic |

IT VALUE

REXPOSURE created elevated so D FIRST AID PROC al assistance |

ound lev | els which may effect hearing | ||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may EMERGENCY AND Obtain medic |

IT VALUE

REXPOSURE created elevated so D FIRST AID PROC al assistance SECTIO |

ound lev

EDURES |

ets which may effect hearing

S |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may EMERGENCY ANI Obtain medic |

IT VALUE

REXPOSURE created elevated so D FIRST AID PROC al assistance SECTIO istable x CONC |

ound lev

EDURES IN VI - PI |

els which may effect hearing

: EACTIVITY DATA TO AVOID |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may EMERGENCY AND Obtain modici Obtain modici STABILITY Un Sta INCOMPATABILIT |

IT VALUE REXPOSURE created elevated so D FIRST AID PROC al assistance SECTIO Istable x CONC (Y (Materials to avo |

ound levi

EDURES DN VI - PI DITIONS |

els which may effect hearing

BEACTIVITY DATA TO AVOID |

||

|

THRESHOLD LIM

EFFECTS OF OVE Grinding may EMERGENCY AN8 Obtain medic. STABILITY Un Sta NCOMPATABILIT NAIF HAZARDOUS COM |

T VALUE IREXPOSURE Created elevated si Created elevated si D FIRST AID PROC al assistance SECTIO Istable X CONE (Y (Materials to avo MPOSITION PRODI |

ound lew

EDURES IN VI - PI DITIONS iid) UCTS |

els which may effect hearing

B EACTIVITY DATA TO AVOID |

||

|

THRESHOLD LIM

EFFECTS OF OVE Grinding may EMERGENCY AN& Obtain medic Obtain medic STABILITY Un STABILITY Un STABILITY Un STABILITY Un ALE NOOM PA TABILITY NAIF HAZARDOUS COM NAIF |

T VALUE REXPOSURE created elevated si OFIRST AID PROC al assistance SECTIO stable x CONC (Y (Materials to avo MPOSITION PRODL May Occur |

ound leve

EDURES IN VI - PI DITIONS rid) UCTS |

els which may effect hearing

EACTIVITY DATA TO AVOID |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may EMERGENCY ANI Obtain modici STABILITY NAIF HAZARDOUS CON NAIF HAZARDOUS CON NAIF |

T VALUE REXPOSURE created elevated sc or FIRST AID PROC al assistance SECTIO stable x CONC vy (Materials to avo wPOSITION PRODU May Occur |

ound leve

EDURES IN VI - PI DITIONS iid) UCTS X |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may Obtain modic Obtain modic STABILITY Un STABILITY UN STABILITY UN NAIF HAZARDOUS CON NAIF HAZARDOUS CON |

TY VALUE REXPOSURE Created elivated si CONC al assistance SECTIO VI (V (Materials to avo MPOSITION PRODL N Máy Occur N Máy Occur SECTION VII- |

ound leve

EDURES IN VI - PI DITIONS vid) UCTS X - SPILL C |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID DR LEAK PROCEDURES |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Gending may MERGENCY ANI Obtain medic STABILITY Un Str NCOMPATABILIT NAIF HAZARDOUS COM NAIF HAZARDOUS COM STEPS TO BE TAK |

TY VALUE REXPOSURE Created elivated si Conc elitation Concentration Concen |

OUND IEV

EDURES ON VI - PI DITIONS OITIONS OITIONS VICTS X SPILL C ERIAL IS |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may MERGENCY ANI Obtain medic STABILITY Un Sta NCOMPATABILIT NAIF HAZARDOUS CO NAIF HAZARDOUS CO STEPS TO BE TA Normal Crean WASTE DISPOSA |

TY VALUE REXPOSURE Created elevated st D FIRST, AID PROC al assistance SECTION MAN OCCUT SECTION PRODI CASE MATIG CREN IN CASE MATIG D Procedure |

ound leve

EDURES DN VI - PI DITIONS oid) UCTS X - SPILL C ERIAL IS |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID DR LEAK PROCEDURES RELEASED OR SPILLED |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may MERGENCY ANI Obtain medic STABILITY Un Str BILTY UN STABILITY UN STABILITY HAZARDOUS CO NAIF HAZARDOUS CO NOLYMERIZATION STEPS TO BE TAR Normal Crean WASTE DISPOSA Standard Iand |

TY VALUE REXPOSURE Created elevated si Conco al assistance SECTIO May Occur SECTION PRODU May Occur SECTION VII KEN IN CASE MATIG UD Procedure L METHOD dfill methods |

ound lev

EDURES DN VI - PI DITIONS VID UCTS X - SPILL C ERIAL IS |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID DR LEAK PROCEDURES RELEASED OR SPILLED |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may MERGENCY ANI Obtain medic: STABILITY Un Strability Un STABILITY IN NOM PA TABILIT NAIF HAZARDOUS COM NAIF HAZARDOUS COM STEPS TO BE TAM Normal Crean WASTE DISPOSA Standard land |

TY VALUE REXPOSURE Created elivated si CONC al assistance SECTIO May Occur MOSITION PRODU MAY Occur MAY Occur SECTION VII KEN IN CASE MATI Grup Procedure LMETHOD dilli methods SECTION VIII - SPI |

EDURES

EDURES DITIONS DITIONS UCTS X SPILL C ERIAL IS ECIAL PI |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED ROTECTION INFORMATION |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may MERGENCY ANI Obtain medic STABILITY Un Strability Un STABILITY IN NOM PATABILIT NAIF HAZARDOUS CO NAIF HAZARDOUS CO NOT BE TAR STEPS TO BE TAR Normal Clean WASTE DISPOSA Standard Iano |

TY VALUE REXPOSURE Created elivated st OFIRST AID OFIRST AID PROC al assistance SECTION MANY COUNT N MANY COUNT SECTION VII SECTION VII AND |

EDURES

EDURES IN VI - PI DITIONS Id) UCTS X - SPILL C ERIAL IS ECIAL PI |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED ROTECTION INFORMATION |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may MERGENCY ANI Obtain medic STABILITY Un Strability Un STABILITY IN NOOM PATABILIT NAIF HAZARDOUS COM NAIF HAZARDOUS COM NAIF HAZARDOUS COM STEPS TO BE TAK Normal Crean WASTE DISPOSA Standard land RESPIRATORY PE RESPIRATORY PE RESPIRATORY PE |

TVALUE REXPOSURE created elevated st created elevated st op FIRST, AID O FIRST, AID |

bund level

EDURES DN VI - PI DITIONS Idd) UCTS X SPILL C ERIAL IS ECIAL PI fy type) d see OS |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES IRELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 |

||

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may BRERGENCY ANI Obtain medic: STABILITY Un Strability Un STABILITY IN NOOM PA TABILIT NAIF HAZARDOUS COM NAIF HAZARDOUS COM NAIF HAZARDOUS COM STEPS TO BE TAK Normal Clean WASTE DISPOSA Standard Iand RESPIRATORY PE Respiratory p VENTILATION |

TY VALUE REXPOSURE created elevated sit Created elevated sit DEFIST, IN DO FIRST, IN DO FIRST, AID OF SIT SECTION MASSING COUNT MARKED SITUATION PRODU MARKED SITUATION SECTION VIII | DUNDIEVES |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES IRELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 SP |

ECIAL

None |

|

|

THRESHOLD LIMI

EFFECTS OF OVE Grinding may BERERGENCY ANI Obtain medic: STABILITY Un Strability Un STABILITY IN NOOM PA TABILIT NAIF HAZARDOUS COM NAIF HAZARDOUS COM NAIF HAZARDOUS COM Normal Clean Normal Clean Normal Clean RESPIRATORY PF Respiratory p VENTILATION |

TVALUE REXPOSURE created elevated si CONC al assistance SECTIO VI (V (Materials to avo MPOSITION PRODU M May Occur N May Occur SECTION VII (V (Materials to avo MPOSITION PRODU SECTION VII SECTION VII (V (Materials to avo MPOSITION PRODU M (May Occur N May Occur SECTION VII (V (Materials to avo MPOSITION PRODU M (May Occur N May |

Dound leve

EDURES NN VI - PII DITIONS Idi DUCTS X - SPILL C ECIAL PI FILL C ECIAL PI ST 19 (type) ST Tinded ser S. (General S. (General |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES IRELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 SP COSHA 29 CFR 1910.94 |

ECIAL

None HER Nane |

|

|

THRESHOLD LIMI

EFFECTS OF OVE

Grinding may EMERGENCY ANI Obtain medic STABILITY Un STABILITY UN STABILITY NAIF HAZARDOUS CO STEPS TO BE TAA Normal Clean WASTE DISPOSA Standard land RESPIRATORY PF Respiratory p VENTILATION PROTECTIVE GLC |

TY VALUE REXPOSURE Created elivated st Created elivated st OFIRST AID OFINIT OFINITIAN PRODU MODITION PRODU MADY OCCUT N MAY OCUT N MAY OCU | DUND INVIPUT |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 © OSHA 29 CFR 1910.94 SP Tai) ON |

ECIAL

None HER None |

|

|

THRESHOLD LIMI

EFFECTS OF OVE

Grinding may EFFECTS OF OVE STABILITY Un STABLATABOUS COM NAIF HAZARDOUS COM NOTHAL COM STEPS TO BE TAA Normal Clean WASTE DISPOSA Standard land RESPIRATORY PF Respiratory p RESPIRATORY PF Respiratory p PROTECTIVE GLC As desired by CALE SALE S |

TY VALUE REXPOSURE Created elivated si SECTIO Massistance CONC Massistance Concorr Massistance Mas |

Sound levi

EDURES N VI - PI DITIONS V SIGNA ECIAL PI SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA SIGNA S |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 E OSHA 29 CFR 1910.94 SP CON ON UPD DESCRIPTION |

ECIAL

None None |

|

|

THRESHOLD LIMI

EFFECTS OF OVE

Gending may EFFECTS OF OVE Gending may STABILITY Un STABILITY STABLET HAZARDOUS CO HAZARDOUS |

TY VALUE REXPOSURE Created elivated si Concorrect May Occur SECTION VII Recomme MECHANIGAL Recomme MUSE EQUIPMENT VIE EQUIPMENT |

Sound levi

EDURES N V1 - PI DITIONS V - SPILL C ECIAL PI Sounded Sounded Sounded ECIAL PI Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Sounded Soun |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 E OSHA 29 CFR 1910.94 SP CON ON ON ON 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 001 0 |

ECIAL

None HER None |

|

| THRESHOLD LIM EFFECTS OF OVE Grinding may EMERGENCY ANI Obtain medic STABILITY Un STABILITY UN KAIP HAZARDOUS CON NAIF HAZARDOUS CON NAIF HAZARDOUS STO BE TAA Normal Clean WASTE DISPOSA Standard land RESPIRATORY PF Respiratory p Respiratory p GENTILATION PROTECTIVE GLC As desired by OTHER PROTECT Hearing prote | TY VALUE REXPOSURE Created elivated si Concorrect May Occur SECTION VII Recomme MECHANIGAL Recomm |

Sound levi

EOURES NV1-PI DITIONS idd) UCTS X SPILL C ERIAL IS ECIAL PI 19 type) 19 type) 19 type) 19 type) 19 type) 19 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 type) 10 t |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 E OSHA 29 CFR 1910.94 SP CALL OR COSHA 29 CFF 11910.94 ON DON DON DESCRIPTIONS |

ECIAL

None HER None |

|

| THRESHOLD LIM EFFECTS OF OVE Grinding may EMERGENCY ANI Obtain medic STABILITY Un STABILITY UN KAT NATE UN COMPATABILIT NATE NATE UN COMPATABILIT NATE NATE UN COMPATABILIT NATE NOT NOT NATE NOT NATE NOT N | TY VALUE REXPOSURE Created elivated si CONC al assistance SECTIO IN May Occur IV Materials to avo MPOSITION PRODU MAY Occur IV May Occur SECTION VII Recomme MECHANIGAL Recomme MELEXAUS RECOMMENT CIGn Sec DEHA 29 SECTION IN DE BE TAKEN IN HA |

NVI-PI

EDURES NVI-PI DITIONS X -SPILLC ERIAL IS ECIAL PI fy type) d see 05 37 anded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded ser inded se |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES RELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 © OSHA 29 CFR 1910.94 SP CON ON ded see OSHA 29 CFF 11910. 10.133 CIAL PRECAUTIONS AND STORING |

ECIAL

None HER None |

|

|

THRESHOLD LIM

EFFECTS OF OVE Grinding may EMERGENCY ANI Obtain medic STABILITY NAT NAT MAZAPDOUS CO NAT NAT NOP ATABILT NAT NAT NOP ATABILT NAT NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY NAT STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY STABILTY |

TY VALUE TREXPOSURE Created elevated ski OFIRST AID PROC al assistance SECTIO Istable X CONC Istable X CONC ISTON PROD ISTON VII- SECTION SECTION VII- SECTI |

A SPILL C

A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C A SPILL C |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES IRELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 E OSHA 29 CFR 1910.94 SP CONDITIONS INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION INFORMATION |

ECIAL

None HER None |

|

| THRESHOLD LIMI EFFECTS OF OVE Grinding may EMERGENCY ANI Obtain medic STABILITY Un SI STABILITY Un NAIF HAZARDOUS CON HATARDOUS CON HAT | T VALUE TREXPOSURE Created elevated ski Created elevated ski DEFINT AID PROC al assistance SECTION Issible X CONC (Y (Materials to avo MPOSITION PRODU N WILL NOT Occur N WILL NOT Occur SECTION VIII- SPI COCAL EXAUS Recomme MECHANICAL Recomm | AND A CONTRACT OF A CONTRACT O |

els which may effect hearing

EACTIVITY DATA TO AVOID CONDITIONS TO AVOID OR LEAK PROCEDURES IRELEASED OR SPILLED ROTECTION INFORMATION HA 29 CFR 1910.134 E OSHA 29 CFR 1910.94 SP CON ON ON ON ON ON CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIO |

ECIAL

None HER None |

|

B. FOR ALL TOOLS

- 1. KEEP GUARDS IN PLACE and in working order.

- REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

- 3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

- DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet locations, or expose them to rain. Keep work area well lighted.

- 5. KEEP CHILDREN AND VISITORS AWAY. Remove starter keys and turn off master switches.

- 6. PADLOCK EQUIPMENT or work area when not in use.

- DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

- 8. USE RIGHT TOOL. Don't force tool or attachment to do a job it was not designed for.

- 9. WEAR PROPER APPAREL. No loose clothing, neckties, rings, bracelets, or other jewelry to get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

- 10. ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses only have impact resistance lenses; they are NOT safety glasses.

- 11. SECURE WORK. Use clamps or a vise to hold work when practical. It's safer than using your hand and it frees both hands to operate tool.

- 12. DON'T OVERREACH. Keep proper footing and balance at all times.

- 13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow instructions for lubricating and changing accessories.

- 14. DISCONNECT TOOLS before servicing; when changing accessories such as blades, bits, cutters, etc.

- 15. AVOID ACCIDENTAL STARTING. Make sure switch is in "OFF" position before plugging in.

- 16. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended accessories. The use of improper accessories may cause hazards.

- 17. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

- 18. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to assure that it will operate properly and perform in its intended function—check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

- 19. NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off.

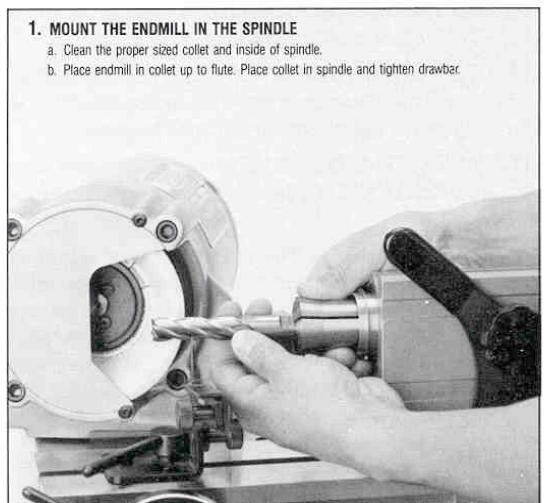

Endmill Sharpener Instructions

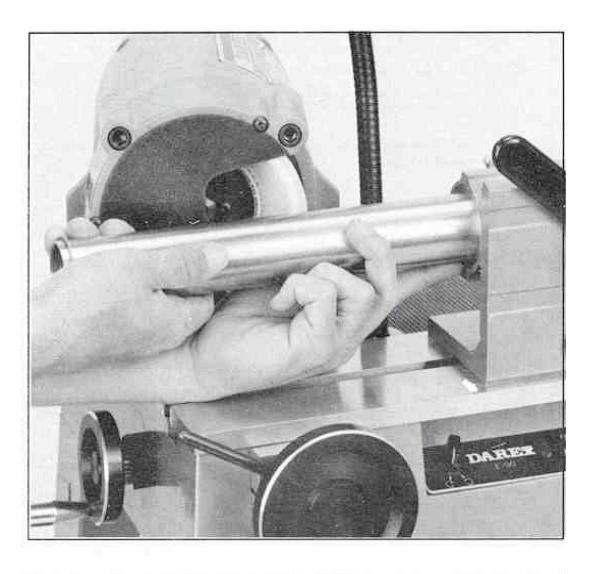

INSTALL THE SPINDLE

Attach compressed air of at least 90 psi to the sleeve housing. (It's best to have an air filter and water trap installed between the shop air and the air spindle.)

Thoroughly clean the spindle and the sleeve bore (with the air on) using a clean lint-free cloth and a cleaner that leaves no residue.

- 2. Remove the drawbar from the spindle and with the air on, carefully place the spindle into the sleeve.

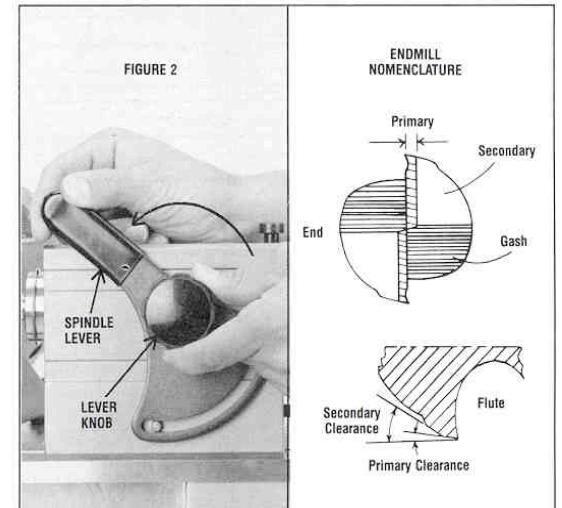

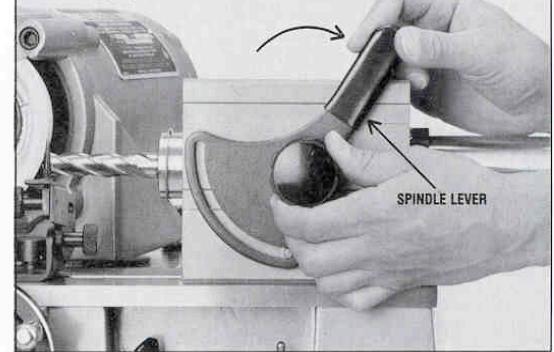

- Make sure the spindle is in its highest position by loosening the spindle lever knob and moving the spindle lever all the way to the left (Figure 2).

BEGIN WITH A STANDARD ENDMILL

With these instructions and a Darex Endmill Sharpener, you will find that getting "the feel" of good endmill sharpening is not difficult. At first, as with anything new, the steps will seem unfamiliar, even if you have had sharpening experience. But these instructions were designed to alleviate any apprehension you might have.

First of all, there are no hidden "tricks" you need to know before you can resharpen your endmills. Everything is revealed step-by-step in these instructions. If you start at the beginning and take your time, you will soon learn how to sharpen endmills with ease and precision.

The real key is patience. Since you will learn by doing and by making some mistakes, don't feel bad about them. Figure on an hour or so of practice to become comfortable with your Darex. IMPOR-TANT: Start with a two or four flute endmill of at least 3/8" in diameter. It's sometimes helpful to color the areas you will be grinding with a felt pen. This helps you see what you have ground.

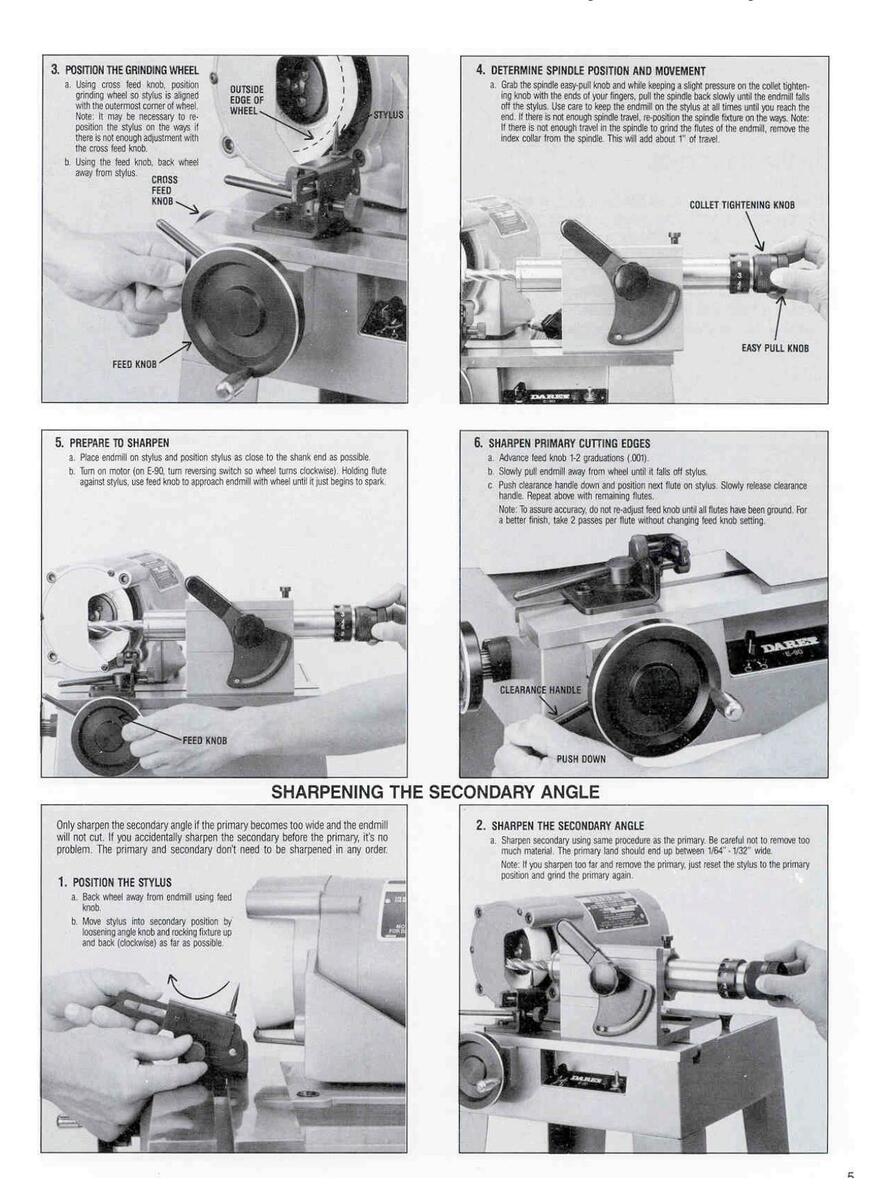

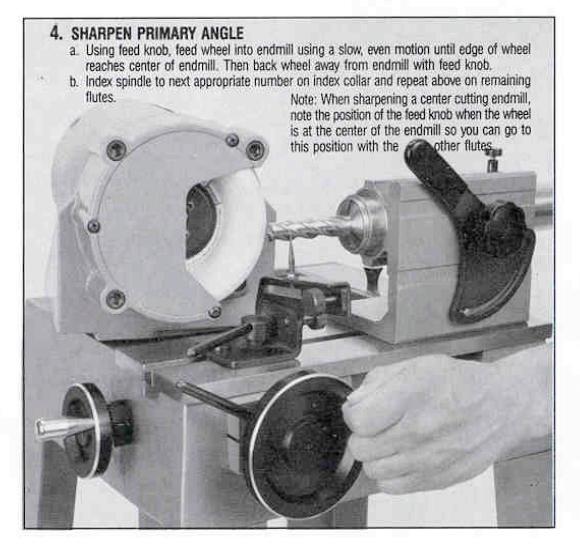

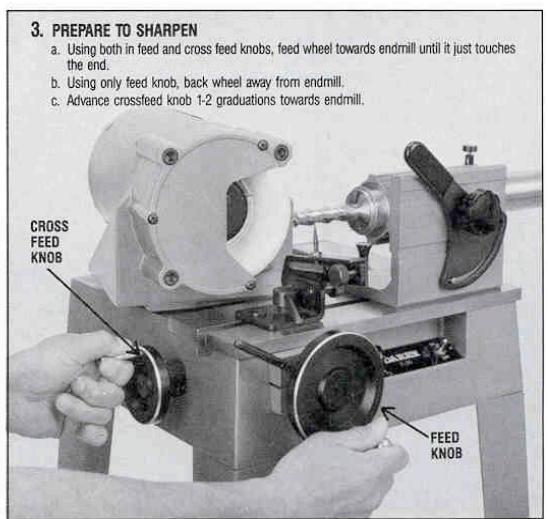

SHARPENING THE PRIMARY ANGLE ON THE FLUTES

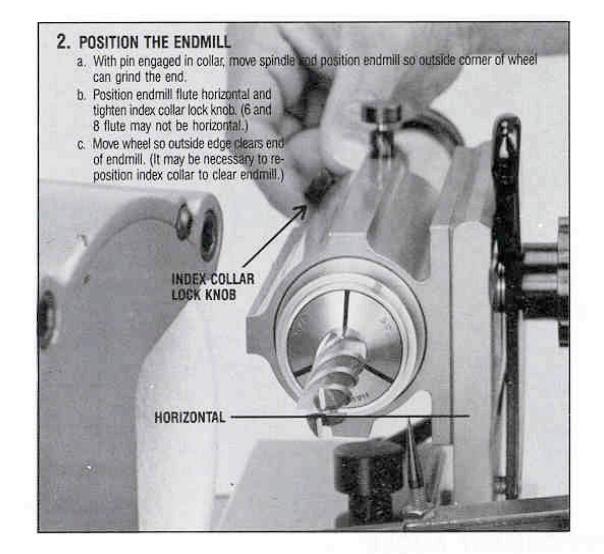

SHARPEN THE ENDS

Make sure the corner of the grinding wheel is sharp before sharpening the end. (See wheel dressing, page 7). The sharpener is set to automatically produce a 2 degree "fishtail" on the end.

Note: E-80 users should position the grinding wheel so its centerline height is approximately 1/4" above the center height of the spindle in its highest position.

5. SHARPEN SECONDARY ANGLE

- Note: Only sharpen secondary when primary becomes too wide:

- a. Loosen spindle knob and move spindle lever to the right so spindle is in its lowest position.

- b. Use same procedure as for sharpening primary. Don't remove too much material. Leave about a 1/16" - 1/8" wide primary edge.

- Gashing can be done free hand or if you own a Darex Drill Sharpener with a point splitter, you can use the point splitter to sharpen the gash. (It may not be possible to grind secondary angle on small 6 or 8 flute endmills.)

CHANGING THE RELIEF ON THE FLUTES

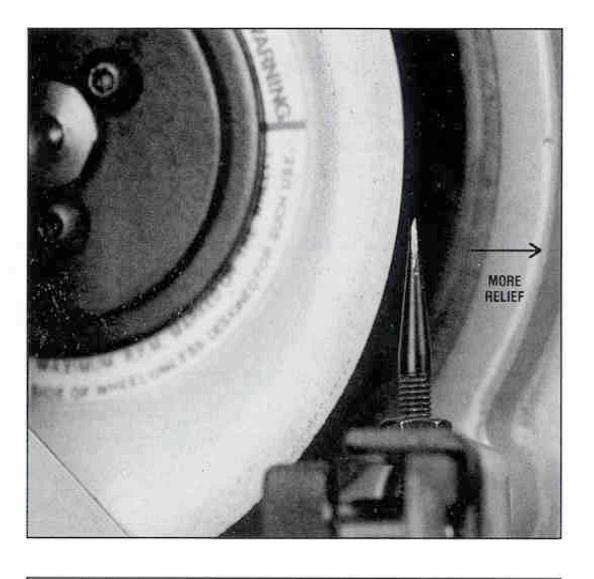

Changing the relief of the primary and secondary angle is very simple. For more relief, instead of aligning the stylus in the middle of the outside edge of the wheel, position it to the right of the high point. The further to the right you go, the more relief you will get. To get less relief, simply lower the spindle height a small amount using the spindle lever. The lower the spindle is, the less relief you will get.

DRESSING THE WHEEL

If you have a diamond dresser attachment (Darex No. 9050) first remove the stylus fixture and the spindle fixture from the ways. Mount the dresser attachment to the ways so the handle swings parallel to the grinding wheel. (It should also be parallel with the wheel guard cover.) Feed the wheel into the dresser and swing the dresser across the face of the wheel.

If you do not have a Darex diamond dresser attachment, manually dress the wheel with a dressing stick.

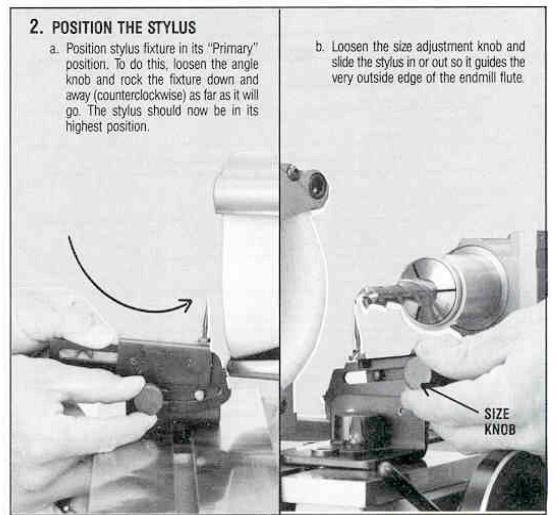

RE-SETTING THE STYLUS HEIGHT

If the stylus is accidentally ground, its height will have to be re-set to .010" below the center of the spindle. This is easily accomplished using the gauge supplied with your machine. You will find it located in the collet storage area.

To set the stylus, mount the gauge in the spindle using a 3/8" collet. Position the stylus under the gauge. (Make sure the stylus fixture is in the "primary" position.) Loosen the stylus lock nut and adjust the stylus until the tip intersects the bottom of the flat area at the tip of the gauge, as shown.

If there is not enough adjustment, the stylus will have to be replaced. Order Darex Part No. 8152

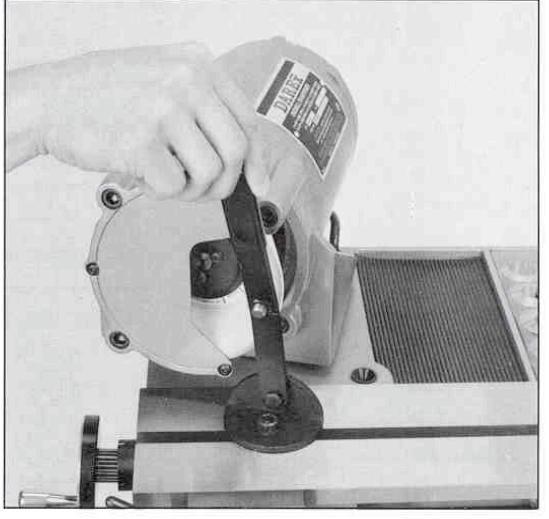

WHEEL BALANCER INSTRUCTIONS

The Darex endmill sharpeners are equipped with a device for balancing the grinding wheel. It is a washer than can be offset to counter-balance variations in the grinding wheel. Loosen the three wheel mounting screws and try positioning the washer in different positions until the machine runs smoothly. (Wheels purchased from Darex will have an arrow indicating the light side of the grinding wheel.)

Trouble Shooting Guide

| PROBLEM | CAUSE | SOLUTION | |

|---|---|---|---|

| Flutes don't cut. | 1. Stylus not in proper position. |

Use the cross feed knob

to move edge of the wheel so it aligns with the center on the stylus. |

|

|

2. Stylus not at

proper height. |

Re-set the height of the stylus. (See setting stylus height, page 7.) | ||

| 3. Primary edge too wide. | Sharpen more off the secondary angle. | ||

| 4. Improper relief. | See changing relief, page 7. | ||

| Endmill won't plunge cut. | 1. End needs to be re-gashed. | By hand, on a bench grinder. | |

| 2. End primary too wide. | Grind more off secondary. | ||

| Spindle won't float. | 1. Spindle and/or sleeve not clean. | Remove spindle and clean spindle and sleeve. | |

| 2. Spindle sleeve holes plugged. | Remove sleeve from sleeve housing and clean out holes with small wire. | ||

| 3. Not enough air pressure | Increase PSI to 90 or above. | ||

| Index pin won't drop in index collar holes. | 1. Spindle sleeve not in proper position. | Move sleeve in housing until you can drop pin into index collar. | |

| Inconsistent results (not grinding the same amount off each flute. |

|

Clean thoroughly with a clean lint-free cloth. | |

| 2. Collet is not accurate. | Try another collet that you know is accurate. | ||

| Machine vibrates excessively | 1. Wheel needs balancing. | See wheel balancing instructions above. | |

9 of 11

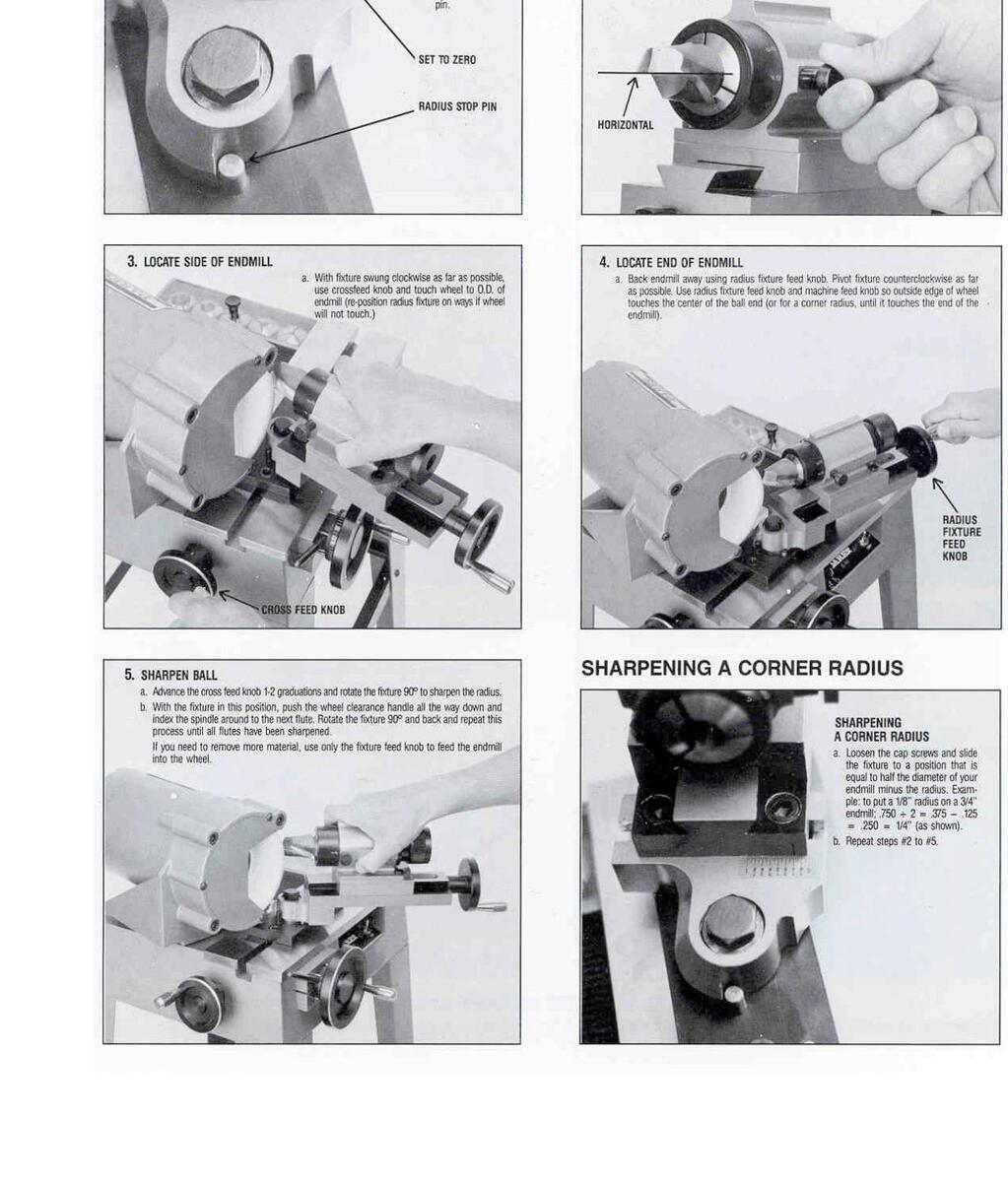

Only remove enough material to "touch-up" the endmill. A secondary angle is not necessary for ball endmills. Remove the air spindle fixtur and stylus and mount the balladger endmill adapter endmill attachment. The stylus is not required when sharpening a ball endmill. When using the E-3 SHARPENING A BALL ENDMILL on equipment other than a Darex Endmill Sharpener, position the wheel so its centerine is 1/2" above the centerine of the E42 spindle

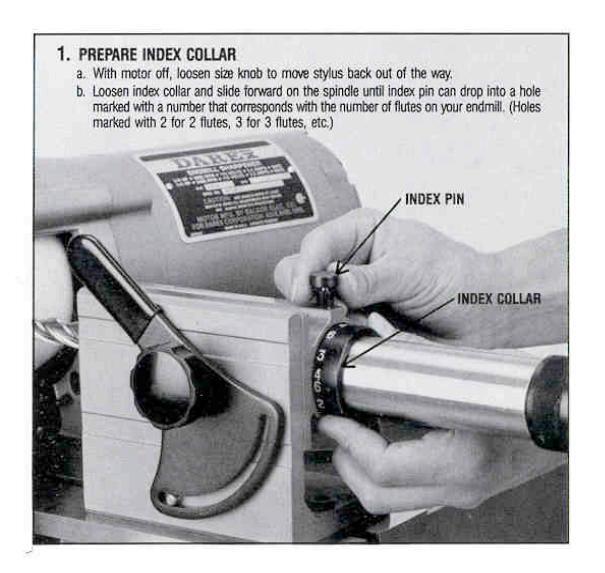

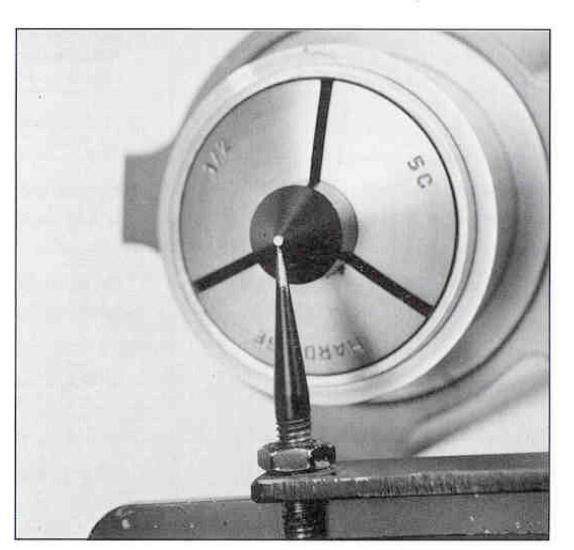

2. PREPARE INDEXING COLLAR

Rotate spindle until you can push the pin into a hole marked with a number that corresponds to the number of flutes you will be sharpening (2 for 2 flutes, 3 for 3 flutes, etc.). Clean collet and spindle, place endmill into collet and collet into spindle. Rotate flute to horizontal position and tighten collet with collet lock knob.

1. SET RADIUS FIXTURE TO "O"

a. If the radius fixture is not set to zero, loosen the 2 cap screws and slide the fixture to the zero position as

shown. Then retighten the cap screws.

4/6/10 11:24 PM

SHARPENING A TAPERED ENDMILL

SHARPENING SECONDARY ANGLE Sharpen the secondary the same way after re-positioning the stylus for a secondary angle the same way you would for a standard endmill.

10

Loading...

Loading...