Page 1

MAKING MODERN LIVING POSSIBLE

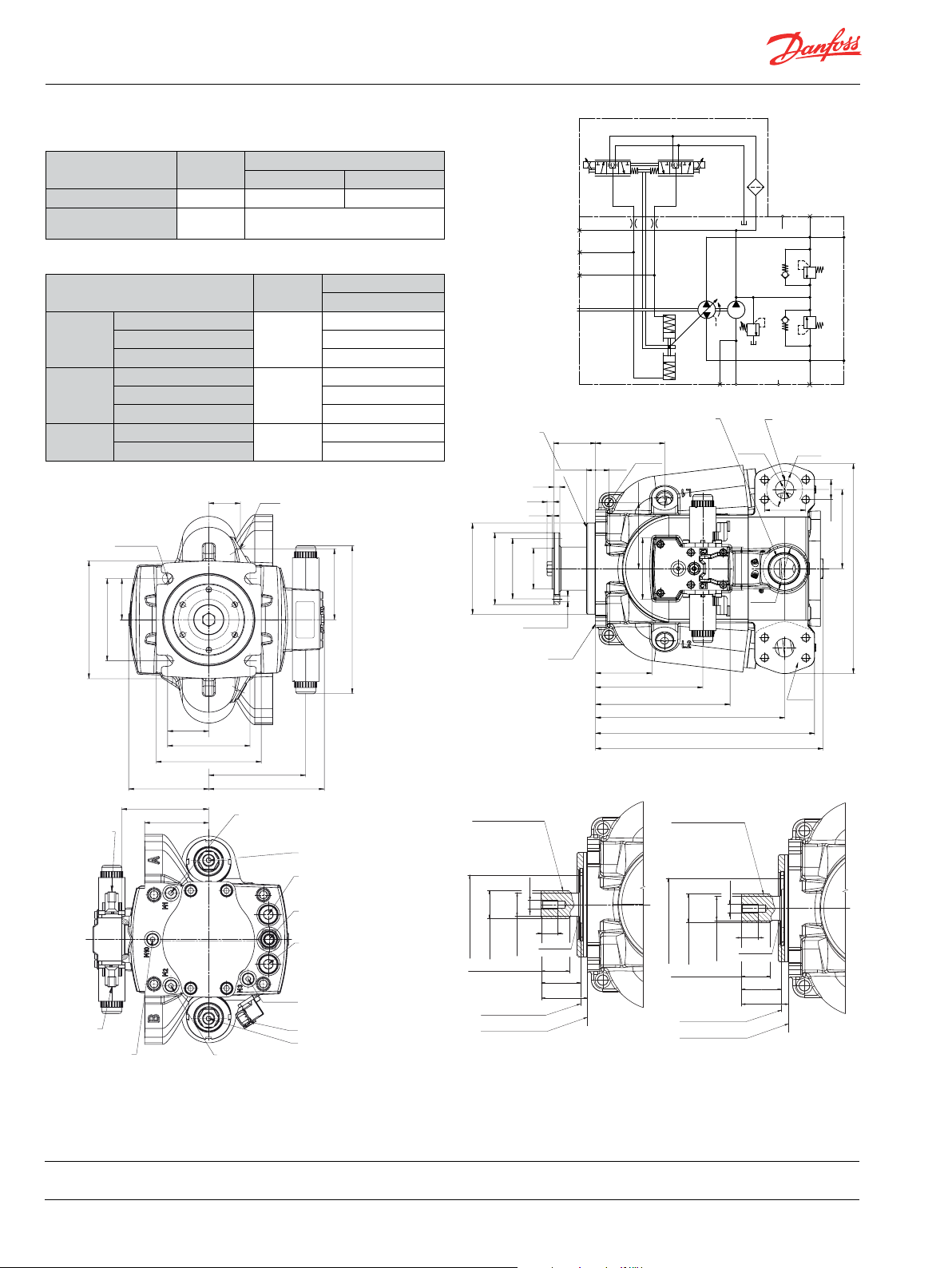

Data Sheet

Transit Mixer Pump 070/089 cm

TMP EDC

3

For more than 40 years, Danfoss has been

developing state-of-the-art components and

systems for mobile machinery used in

off-highway operations around the world.

We have become a preferred supplier by

offering the best of what really matters: The

hardware inside your vehicle application.

TMP EDC – our new generation of servocontrolled hydrostatic pumps – has been

specially designed for Transit Mixer

applications.

The TMP EDC is built around an advanced

electrical control and is available in 70 cm³

and 89 cm³ pump displacements. Offering high

quality and reliability, the new pump provides

expanded functionality, greater total efficiency,

and easy installation on the Transit Mixer.

The TMP EDC control and sensors options are

PLUS+1® Compliant. PLUS+1 allows you to

rapidly develop and customize electronic

machine control. It opens up the future by

combining machine controls and diagnostics

in an integrated operating network.

Features y Designed for quality and reliability

– Designed specifically for Transit Mixer

applications

– Robust rotating group concept

– Based on the latest technological

developments

y Installation and packaging benefits

– All connections are located on one side

– Include Manual Overides

– Length optimized pump

– Through drive pump

– Coupling flange or spline shaft availability

– High corner power

– Standard connector interface

– Metric connections

– Expanded functionality through PLUS+1®

L1109001 • Rev BA • Jan 2014

y Optimized for electrical control

– Electrohydraulic control including Electrical

Displacement Control (EDC)

y Expanded functionality

– PLUS+1 Compliant control and sensor

options

– Speed and temperature sensors

y Greater total efficiency

– Minimized control losses

– Proven rotating group from Series 20

– Low control pressure and control loses

Page 2

Data Sheet Transit Mixer Pump 070/089 cm3, TMP EDC

[11.496 ]

[12.458]

0

Split ange boss

Charge pump inlet S

43.9

M12x1.5; 12.7 [.5] full thread depth

M12x1.5; 12.7 [.5] full thread depth

M06-6S

Ø71.7 max [Dia2.823]

Ø71.7 max [Dia2.823]

to be paint free

Physical properties

Features Unit

3

Displacement cm

Weight dry

(standard)

[in3] 68 .3 [4 .17] 89.0 [5.43]

kg [lb] 61 [135]

070 089

Operating parameters

Features Unit

Input

speed

System

pressure

Case

pressure

* Applied pressures above maximum working pressure requires Danfoss application approval.

Dimensions

Deutsch DT04-2P

P0055 69

Connector CB

Deutsch DT04-2P

Charge pump inlet pressure

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

L1109001 • Rev BA • Jan 2014 www.danfoss.com © Danfoss A/S, 2014-01

Minimum

Rated 2500

Maximum 2900

Max. working pressure*

Maximum pressure 450 [6525]

Minimum pressure 10 [145]

Rated pressure

Maximum pressure 5.0 [73]

[1.728]

+0.8

Ø15

-0.3

+0.031

[Dia 0.591 ]

-0.012

57.25

[2.254]

164

114.5

[6.457]

[4.508]

57.25

[2.254]

114.5

[4.508]

146

[5.748]

111.4

[4.386]

121

[4.764]

89

Connector CB

Gauge port M10

[3.504]

Gauge port M2

System pressure Port B,

min

(rpm)

bar

[psi]

bar

[psi]

Case drain port L1

use highest port as outlet

M22x1.5 - 11 min [.433] depth

134.8

[5.306]

160.8

[6.329]

Gauge port M1

System pressure Port A, M12x1.5

12.7 [0.5] full thread depth

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Size

-1

98.8

[3.89]

Gauge port M4

Servo pressure M12x1.5

High pressure relief valve

Port A

Charge pressure relief valve

High pressure relief valve

Port B

Gauge port M3

Charge pressure M12x1.5

12.7 [0.5] full thread depth

Connector Deutsch DT

Gauge port M5

Servo pressure M12x1.5

Size

070 / 089

500

420 [6090]

3.0 [44]

206

[8.11]

M3

M5

M4

P00 5447

Auxiliary mounting pad

Flange 127 - 4

per ISO3019 (SAE J744C)

0

-0.05

-0.002

Ø127

Ø100 ±0.3

[Dia 3.937 ±0.012]

[Dia 4.999 ]

Ø84

[Dia 3.307 ]

[Dia 0.319 ]

[0.366]

[0.091]

0

[0.335]

9.3

2.3

-0.06

57

[0.488 ±0.01]

8.5

0

-0.002

[2.244 ]

+0.23

Ø8.1

+0.08

+0.009

+0.003

Paint free

58.2

[2.291]

12.4 ±0.25

[0.738]

18.8

78.4

[3.086]

[3.781]

96

Ø12.5

[Dia0.492]

92

[3.624]

86

149

[5.87]

P00557 0

ISO 3019-1 (SAE C, 23-teeth) ISO 3019-1 (SAE C, 21-teeth)

Spline data:

Number of teeth: 23

Pitch fraction: 16/32

Pressure angle: 30°

Pitch Ø: 36.513 [1.438]

Meas. over pins: 40.973/41.024

[1.6131/1.6151]

Pin Ø: 3.048 [0.12]

M10-6H

Coupling Diameter

Ø37.6 ±0.09

Full spline lenght

Coupling must not protrude

beyond this point

Mounting ange surface

Flange SAE-C per ISO 3019-1

to be paint free

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

0

-0.2

Ø32

[Dia1.48 ±0.004]

34.35

[1.352 ]

0

-0.08

[0.079 ±0.004]

[Dia1.26 ]

0

-0.5

0

-0.02

20 min

[0.787]

R2 ±0.11

47.5 ±0.2

[1.87 ±0.008]

[2.205]

56

CBCA

M42x2 - 6H

20 [0.79] full thread depth

Ø26 (2x)

[Dia1.024]

60

304.5

[11.99]

316.4

0

[1.352 ]

0

-0.2

-0.08

Ø29

[Dia1.142 ]

34.35

-0.5

0

-0.02

M10-6H

[0.079 ±0.004]

0

[2.362]

[Dia 2.362]

20 min

[0.787]

R2 ±0.11

47.5 ±0.2

[1.87 ±0.008]

Ø60

[2.205]

56

[3.386]

187

[7.366]

263

[10.353]

Spline data:

Number of teeth: 21

Pitch fraction: 16/32

Pressure angle: 30°

Pitch Ø: 33.338 [1.313]

Meas. over pins: 37.783/37.833

[1.4875/1.4895]

Pin Ø: 3.048 [0.12]

Coupling Diameter

Ø34.41 ±0.09

Full spline lenght

Coupling must not protrude

beyond this point

Mounting ange surface

Flange SAE-C per ISO 3019-1

[Dia1.355 ±0.004]

Danfoss

Power Solutions

(Shanghai) Co. Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

SchematicTechnical Specifications

M1

L1

L2S M2M10

DN25 typ I 420 bar

Series per ISO 6162

M12, 21 [0.83] full thread depth

Ø50 min

[Dia1.97]

57.2 (2x)

[2.252]

Paint free

[1.094 ]

27.8 (2x)

P005 429EP005 428E

A

B

110

[4.331]

292

Loading...

Loading...