Page 1

Service Manual

Transit Mixer Axial Piston Pump

Size 070/089

powersolutions.danfoss.com

Page 2

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

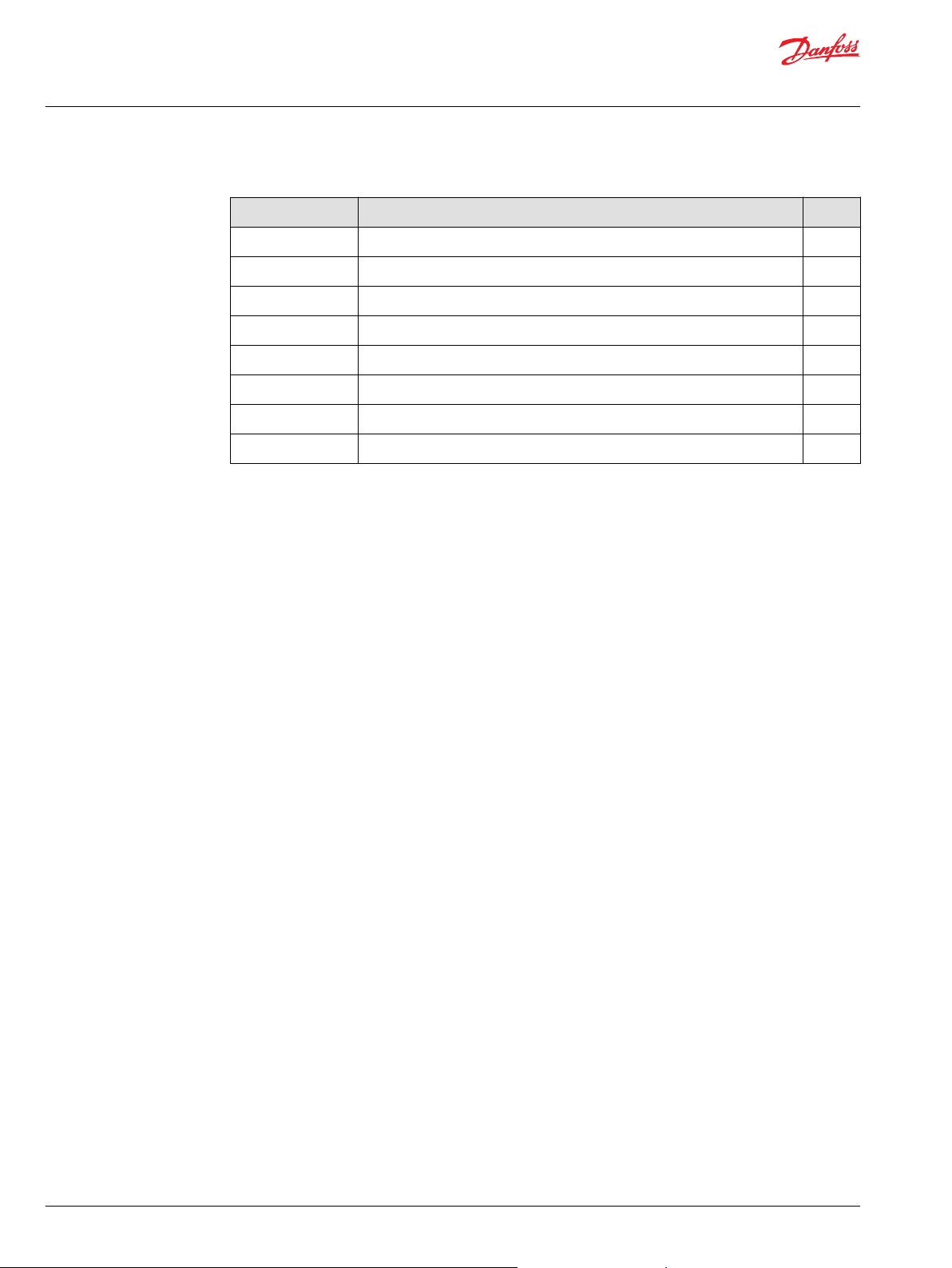

Revision history Table of revisions

Date Changed Rev

July 2017 Updated to Engineering Tomorrow 0203

Mar 2014 Converted to Danfoss layout – DITA CMS BB

19 Oct, 2012 Major update - The MDC control added BA

14 Oct, 2011 Images data change AE

Jul, 2011 Grammar spelling, new images with speed sensor AD

02 Nov, 2010 No technical change, word spelling AC

24 Aug, 2010 New Backpage AB

24 Jun, 2010 First Edition AA

2 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 3

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Contents

Literature reference

TMP literature reference ............................................................................................................................................................... 5

Introduction

Overview..............................................................................................................................................................................................6

Warranty.............................................................................................................................................................................................. 6

Symbols used in Danfoss literature............................................................................................................................................6

General instructions........................................................................................................................................................................ 6

Safety precautions............................................................................................................................................................................7

Unintended machine movement..........................................................................................................................................8

Flammable cleaning solvents.................................................................................................................................................8

Fluid under pressure..................................................................................................................................................................8

Personal safety............................................................................................................................................................................. 8

Hazardous material.................................................................................................................................................................... 8

Design...................................................................................................................................................................................................8

System circuit.....................................................................................................................................................................................9

Basic Closed Circuit.....................................................................................................................................................................9

Case drain and heat exchanger..............................................................................................................................................9

Operation

High pressure relief valve (HPRV) and charge check valve.............................................................................................11

Charge pressure relief valve (CPRV) ....................................................................................................................................... 12

Electrical Displacement Control (EDC)................................................................................................................................... 12

EDC Principle..............................................................................................................................................................................12

Manual Displacement Control (MDC).....................................................................................................................................13

MDC principle............................................................................................................................................................................ 13

MDC with control cut off (CCO)...........................................................................................................................................13

Manual Over Ride (MOR)............................................................................................................................................................. 14

Operating Parameters

Overview........................................................................................................................................................................................... 15

Input Speed......................................................................................................................................................................................15

System Pressure..............................................................................................................................................................................15

Charge Pressure..............................................................................................................................................................................15

Charge inlet pressure....................................................................................................................................................................16

Case Pressure...................................................................................................................................................................................16

Temperature and Viscosity.........................................................................................................................................................16

Temperature...............................................................................................................................................................................16

Viscosity........................................................................................................................................................................................16

General specification.................................................................................................................................................................... 16

Physical Properties.........................................................................................................................................................................17

Operating parameters..................................................................................................................................................................17

Fluid Specifications....................................................................................................................................................................... 18

Fluid and Filter Maintenance

Fluid and filter recommendations........................................................................................................................................... 19

Port Locations and Gauge Installation...................................................................................................................................19

Initial Startup Procedures

General ..............................................................................................................................................................................................21

Start-Up procedure........................................................................................................................................................................21

Troubleshooting

Overview........................................................................................................................................................................................... 22

Safety Precautions......................................................................................................................................................................... 22

Electrical Troubleshooting (TMP EDC)....................................................................................................................................22

System Operating Hot..................................................................................................................................................................22

Neutral Difficult or Impossible to Find................................................................................................................................... 23

System Will Not Operate in Either Direction........................................................................................................................23

System Noise or Vibration...........................................................................................................................................................24

Sluggish System Response.........................................................................................................................................................24

Transmission Operates Normally in One Direction Only.................................................................................................24

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 3

Page 4

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Contents

Adjustments

Pump Adjustment..........................................................................................................................................................................25

Standard Procedures.................................................................................................................................................................... 25

Charge Pressure Relief Valve Adjustments...........................................................................................................................25

EDC neutral adjustment.............................................................................................................................................................. 26

MDC Control Neutral Adjustment............................................................................................................................................27

Mechanical Neutral Adjustment...............................................................................................................................................29

Pump setup.................................................................................................................................................................................31

Servo adjustment..................................................................................................................................................................... 31

Minor Repair

Standard Procedures, Removing the Pump.........................................................................................................................32

Disassembly................................................................................................................................................................................32

Inspection....................................................................................................................................................................................32

Reassembly................................................................................................................................................................................. 32

EDC/MDC Control.......................................................................................................................................................................... 32

Removal........................................................................................................................................................................................32

Inspection....................................................................................................................................................................................32

Reassembly................................................................................................................................................................................. 32

EDC Control......................................................................................................................................................................................34

Control Solenoids...........................................................................................................................................................................35

Removal........................................................................................................................................................................................35

Inspection....................................................................................................................................................................................35

Reassembly................................................................................................................................................................................. 35

MDC with CCO Control................................................................................................................................................................ 36

Control Solenoids...........................................................................................................................................................................37

Removal........................................................................................................................................................................................37

Inspection....................................................................................................................................................................................37

Reassembly................................................................................................................................................................................. 37

Shaft Seal Replacement...............................................................................................................................................................37

Removal........................................................................................................................................................................................38

Inspection....................................................................................................................................................................................38

Reassembly................................................................................................................................................................................. 38

Charge Pump...................................................................................................................................................................................38

Charge Pump Removal (Removable Auxiliary Pad/Cover)........................................................................................38

Inspection....................................................................................................................................................................................39

Reassembly................................................................................................................................................................................. 39

High Pressure Relief Valves (HPRV)..........................................................................................................................................40

Removal........................................................................................................................................................................................40

Inspection....................................................................................................................................................................................40

Reassembly................................................................................................................................................................................. 40

Charge Pressure Relief Valve......................................................................................................................................................41

Removal........................................................................................................................................................................................41

Inspection....................................................................................................................................................................................41

Reassembly................................................................................................................................................................................. 41

Torque Chart

Fastener Size and Torques..........................................................................................................................................................43

Plug Size and Torques..................................................................................................................................................................43

EDC Fasteners and Plugs.............................................................................................................................................................43

MDC Fasteners and Plugs........................................................................................................................................................... 45

4 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 5

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Literature reference

TMP literature reference

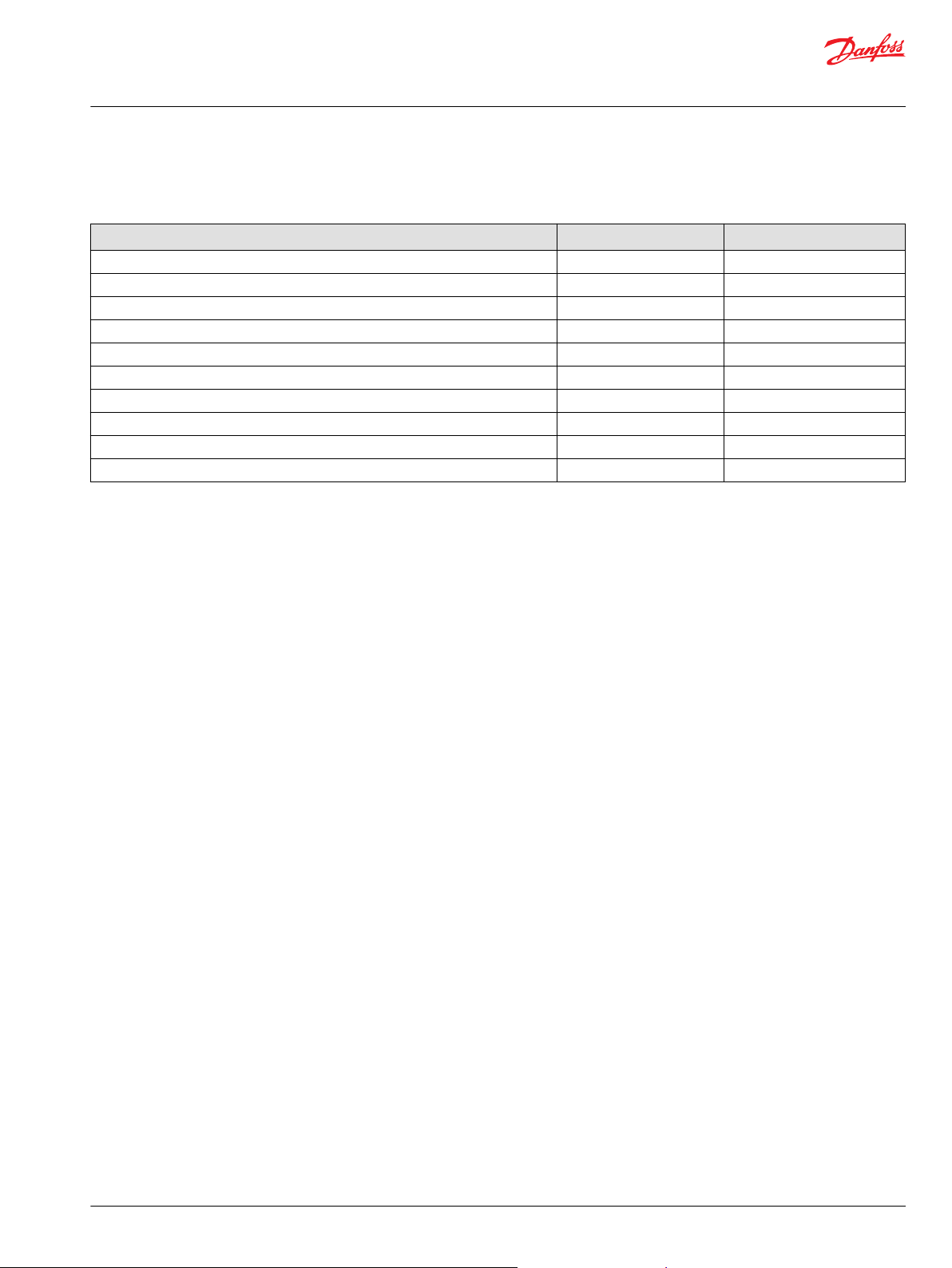

Further available literature

Description

TMP Transit Mixer Axial Piston Pump, Size 070/089

TMP Transit Mixer Axial Piston Pump, Size 070/089

TMP Transit Mixer Axial Piston Pump, EDC/MDC, Size 070/089

TMP Transit Mixer Axial Piston Pump, NFPE, Size 070/089

TMP EDC Axial Piston Pump, Size 070/089

TMP MDC Axial Piston Pump, Size 070/089

H1 Electrical Displacement Control (EDC)

Speed and Temperature Sensor

Hydraulic Fluids and Lubricants

Design Guideline for Hydraulic Fluid Cleanliness

Type

Technical Information

Service Manual

Repair Instruction

Repair Instruction

Datasheet

Datasheet

Technical Information

Technical Information

Technical Information

Technical Information

Literature number

L1006391

L1010109

L1031073

11029271

L1109001

L1214176

11022744

11046759

520L0463

520L0467

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 5

Page 6

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Introduction

Overview

This manual includes information on the installation, maintenance, and minor repair of TMP pumps. It

includes a description of the unit and its individual components, troubleshooting information, and minor

repair procedures.

Performing minor repairs requires the unit to be removed from the vehicle/machine. Thoroughly clean

the unit before beginning maintenance or repair activities. Since dirt and contamination are the greatest

enemies of any type of hydraulic equipment, follow cleanliness requirements strictly. This is especially

important when changing the system filter and when removing hoses or plumbing.

A worldwide network of Danfoss Authorized Service Centers is available for major repairs. Danfoss trains

and certifies Authorized Service Centers on a regular basis. You can locate your nearest Authorized

Service Center using the distributor locator at www.sauer-danfoss.com.

Warranty

Performing adjustments and minor repairs according to the procedures in this manual will not affect your

warranty. Major repairs requiring the removal of a unit's center section, servo sleeves, or front flange

voids the warranty unless a Danfoss Authorized Service Center performs them.

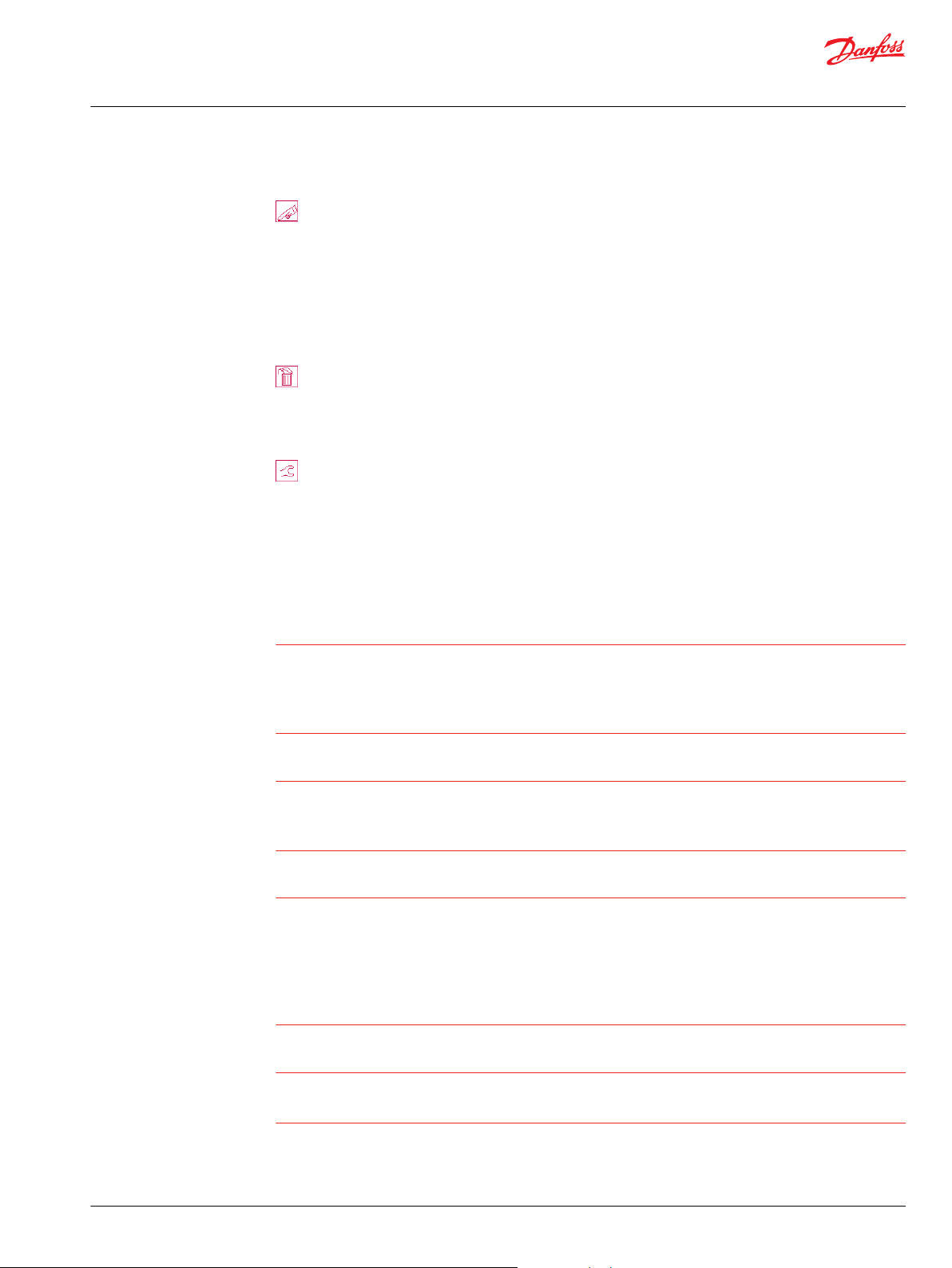

Symbols used in Danfoss literature

Service symbols used in Danfoss literature

Symbol description

The symbols above appear in the illustrations and text of this manual. They are intended to communicate

helpful information at the point where it is the most useful to the reader. In most instances, the

appearance of the symbol itself denotes its meaning. The legend above defines each symbol and

explains its purpose.

WARNING may result in injury

CAUTION may result in damage to product or property

Non-reusable part, use a new part

External hex head

Internal hex head

Lubricate with hydraulic fluid

Pressure measurement/gauge location or specification

Clean area or part

Be careful not to scratch or damage

Note correct orientation

Torque specification

Pull out with tool – press fit

Cover splines with installation sleeve

Inspect for wear or damage

General instructions

Follow the general procedures below when repairing TMM constant displacement closed circuit motors:

Remove the unit

Prior to performing major repairs, remove the unit from the vehicle/machine. Chock the wheels on

the vehicle or lock the mechanism to inhibit movement. Be aware that hydraulic fluid may be under high

pressure and/or hot. Inspect the outside of the pump and fittings for damage. Cap hoses and plug ports

after removal to prevent contamination.

6 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 7

W

W

W

W

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Introduction

Keep it clean

Cleanliness is a primary means of assuring satisfactory motor life on both new and repaired units.

Clean the outside of the motor thoroughly before disassembly. Take care to avoid contamination of the

system ports. Cleaning parts by using a clean solvent wash and air drying is usually adequate. As with any

precision equipment, you must keep all parts free of foreign material and chemicals. Protect all exposed

sealing surfaces and open cavities from damage and foreign material. If left unattended, cover the pump

with a protective layer of plastic.

Replace all O-rings and gaskets

We recommend you replace all O-rings and seals during service. Lightly lubricate O-rings with clean

petroleum jelly prior to assembly.

Secure the unit

For repair, place the unit in a stable position with the shaft pointing downward. It will be necessary to

secure the motor while removing and torquing fasteners and components.

Safety precautions

Always consider safety precautions before beginning a service procedure. Take the following general

precautions whenever servicing a hydraulic system:

Warning

Unintended machine movement

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Warning

Flammable cleaning solvents

Some cleaning solvents are flammable. To avoid possible fire, do not use cleaning solvents in an area

where a source of ignition may be present.

Warning

Fluid under pressure

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious

injury and/or infection. This fluid may also be hot enough to cause burns. Use caution when dealing with

hydraulic fluid under pressure. Relieve pressure in the system before removing hoses, fittings, gauges, or

components. Never use your hand or any other body part to check for leaks in a pressurized line. Seek

medical attention immediately if you are cut by hydraulic fluid.

Warning

Personal safety

Protect yourself from injury. Use proper safety equipment including safety glasses at all times.

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 7

Page 8

W

W

W

W

W

W

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Introduction

Warning

Hazardous material

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state and federal environmental regulations.

Unintended machine movement

Warning

Unintended machine movement

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Flammable cleaning solvents

Warning

Flammable cleaning solvents

Some cleaning solvents are flammable. To avoid possible fire, do not use cleaning solvents in an area

where a source of ignition may be present.

Fluid under pressure

Warning

Fluid under pressure

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious

injury and/or infection. This fluid may also be hot enough to cause burns. Use caution when dealing with

hydraulic fluid under pressure. Relieve pressure in the system before removing hoses, fittings, gauges, or

components. Never use your hand or any other body part to check for leaks in a pressurized line. Seek

medical attention immediately if you are cut by hydraulic fluid.

Personal safety

Warning

Personal safety

Protect yourself from injury. Use proper safety equipment including safety glasses at all times.

Hazardous material

Warning

Hazardous material

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state and federal environmental regulations.

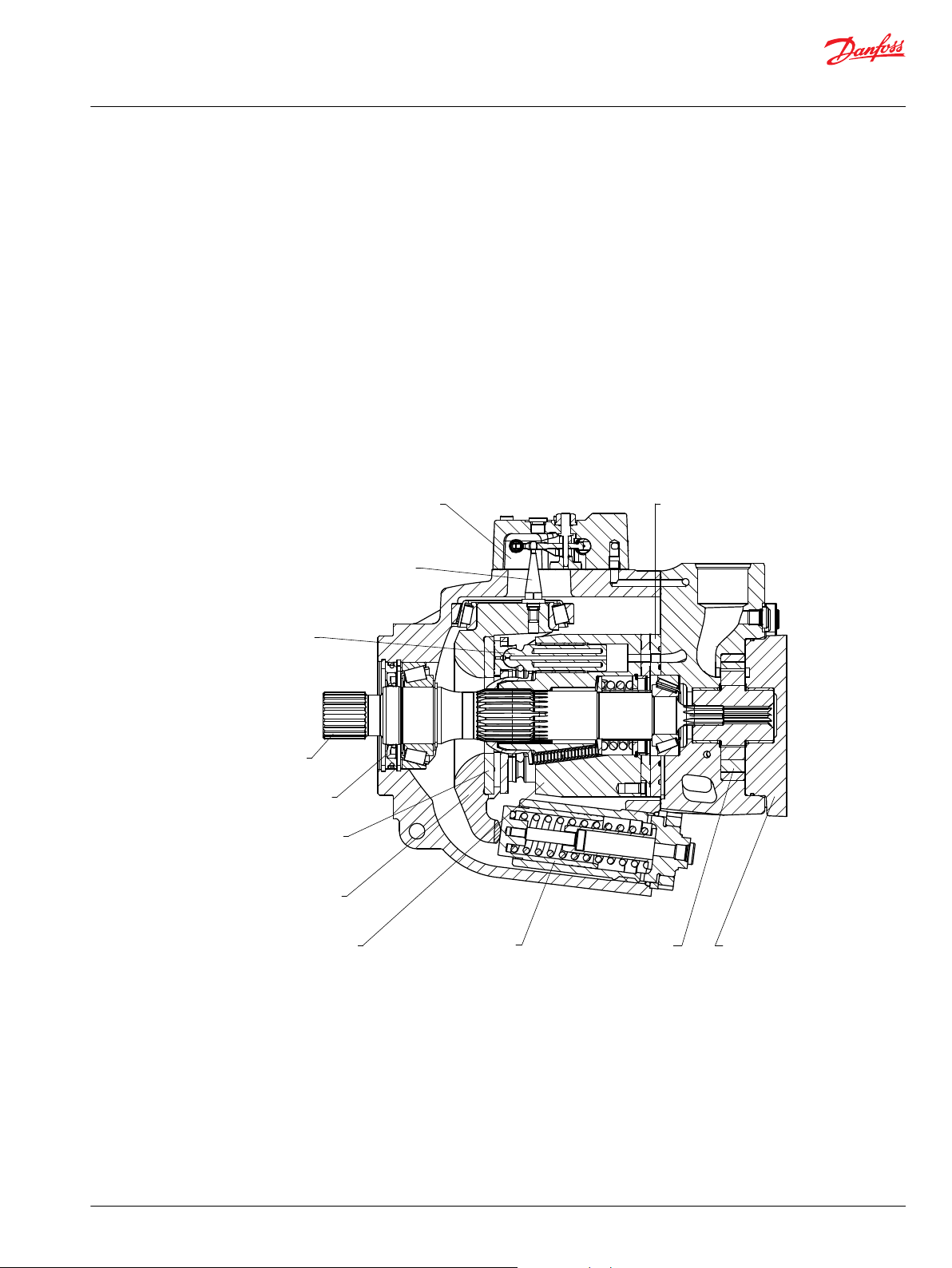

Design

Danfoss TMP closed circuit piston pumps convert input torque into hydraulic power. The input shaft

transmits rotational force to the cylinder block. Bearings at the front and rear of the pump support the

8 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 9

Electric displacement control

Valve plate

Piston

Shaft

Shaft seal

Plate thrust

Swashplate

Swashplate feedback pin

Cylinder block Servo piston Charge pump

Cover charge pump

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Introduction

shaft. Splines connect the shaft to the cylinder block. A lip-seal at the front end of the pump prevents

leakage where the shaft exits the pump housing. The spinning cylinder block contains nine reciprocating

pistons. Each piston has a brass slipper connected at one end by a ball joint. The block springs, ball guide,

and slipper retainer hold the slippers to the swashplate. The reciprocating movement of the pistons

occurs as the slippers slide against the inclined swashplate during rotation. Via the valve plate, one half of

the cylinder block is connected to low pressure and the other half to high pressure. As each piston cycles

in and out of its bore, fluid is replenished by charge flow and displaced to the outlet thereby imparting

hydraulic power into the system. A small amount of fluid is allowed to flow from the cylinder block/valve

plate and slipper/swashplate interfaces for lubrication and cooling. Case drain ports return this fluid to

the reservoir.

The angle of the swashplate controls the volume and direction of fluid displaced into the system. The

servo piston controls the angle of the swashplate. The pump control, by varying the pressure at the servo

piston, controls the piston's position. An electric signal to the control coils or mechanical signal to the

control transmits the command from the operator to the pump. Mechanical feedback of the swashplate

position to the control through the feedback pins allows for very precise displacement control and

increases overall system stability.

Cross section view of TMP

System circuit

Basic Closed Circuit

Hydraulic lines connect the main ports of the pump to the main ports of the motor. Fluid flows in either

direction from the pump to the motor and back. Either of the hydraulic lines can be under high pressure.

In pumping mode the position of the pump swashplate determines which line is high pressure as well as

the direction of fluid flow.

Case drain and heat exchanger

The pump and motor require case drain lines to remove hot fluid from the system. The pump and motor

drain from the topmost port to ensure the cases remain full of fluid. The motor case drain can connect to

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 9

Page 10

AA

B B

L2 M3

M3

M5

M4

TMMTMP

M2L2SM2

M10

L1

C2C1

M1 L1 M1

AA

B B

L2 M3

M3

M5

M4

TMMTMP

M2

L2

M2

M10

L1 M1 L1 M1

N

‘-’ ‘+’

CW

S

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Introduction

the lower drain port on the pump housing or it can tee into the case drain line upstream of the heat

exchanger. A heat exchanger with bypass valve cools the case drain fluid before it returns to the

reservoir.

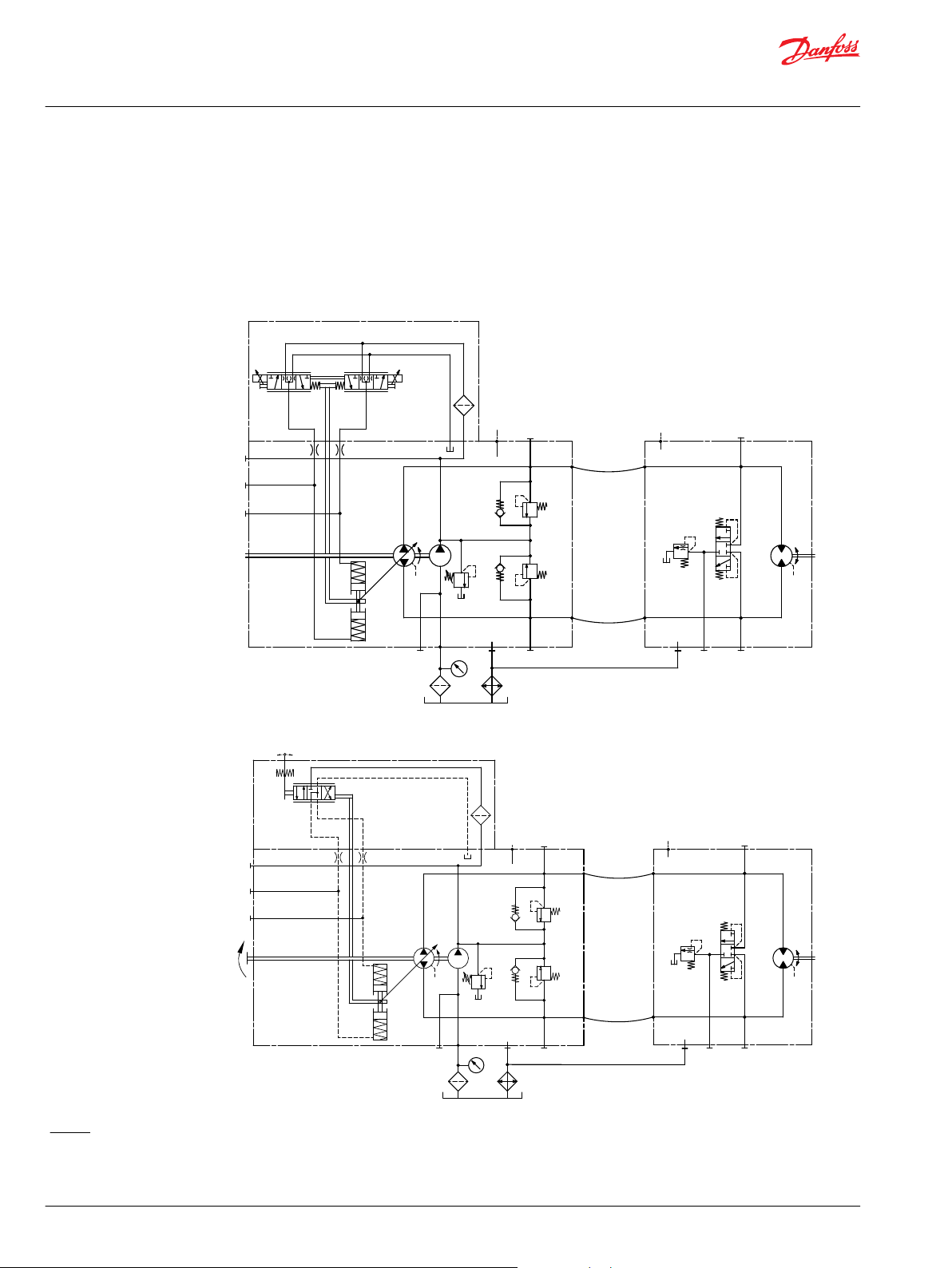

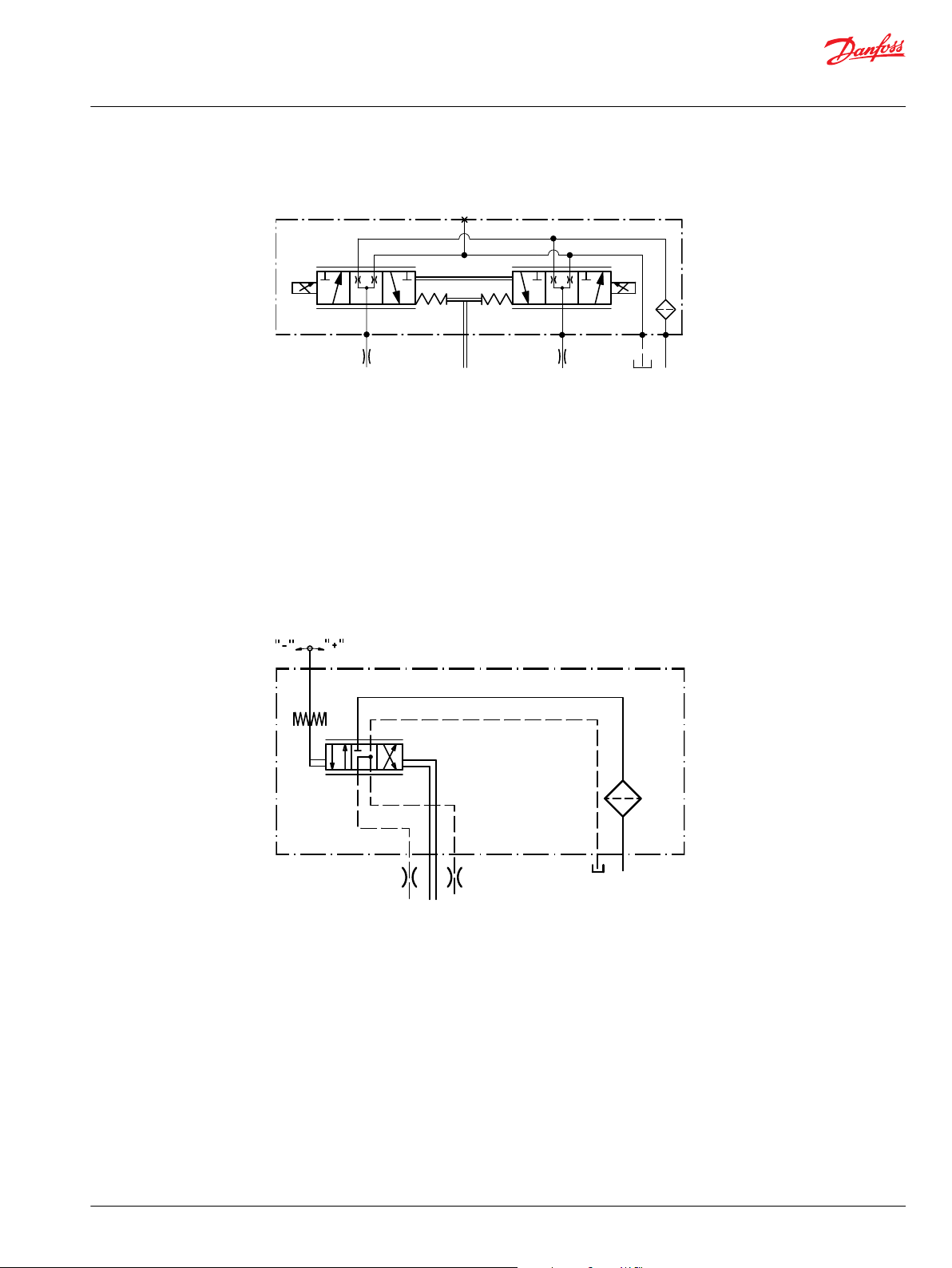

The schematics below show the function of a hydrostatic transmission using an TMP axial variable

displacement pump with electric/manual proportional displacement control (EDC/MDC) and an TMM

fixed displacement motor with integrated loop flushing device.

System circuit diagram of TMP EDC with TMM

System circuit diagram of TMP MDC with TMM

Legend:

A, B – System ports: Ø 25.4 mm

L1, L2 – Case drain ports: M22x1.5

M1, M2 – System A/B gauge ports: M12x1.5

10 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

M3 – Charge gauge port, after filtering: M12x1.5

M4, M5 – Servo gauge ports: M12x1.5

M10 – Charge pump inlet pressure port: M12x1.5

S – Charge inlet port: M42x2

Page 11

C1 C2

High pressure relief valve

Charge pressure relief valve

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operation

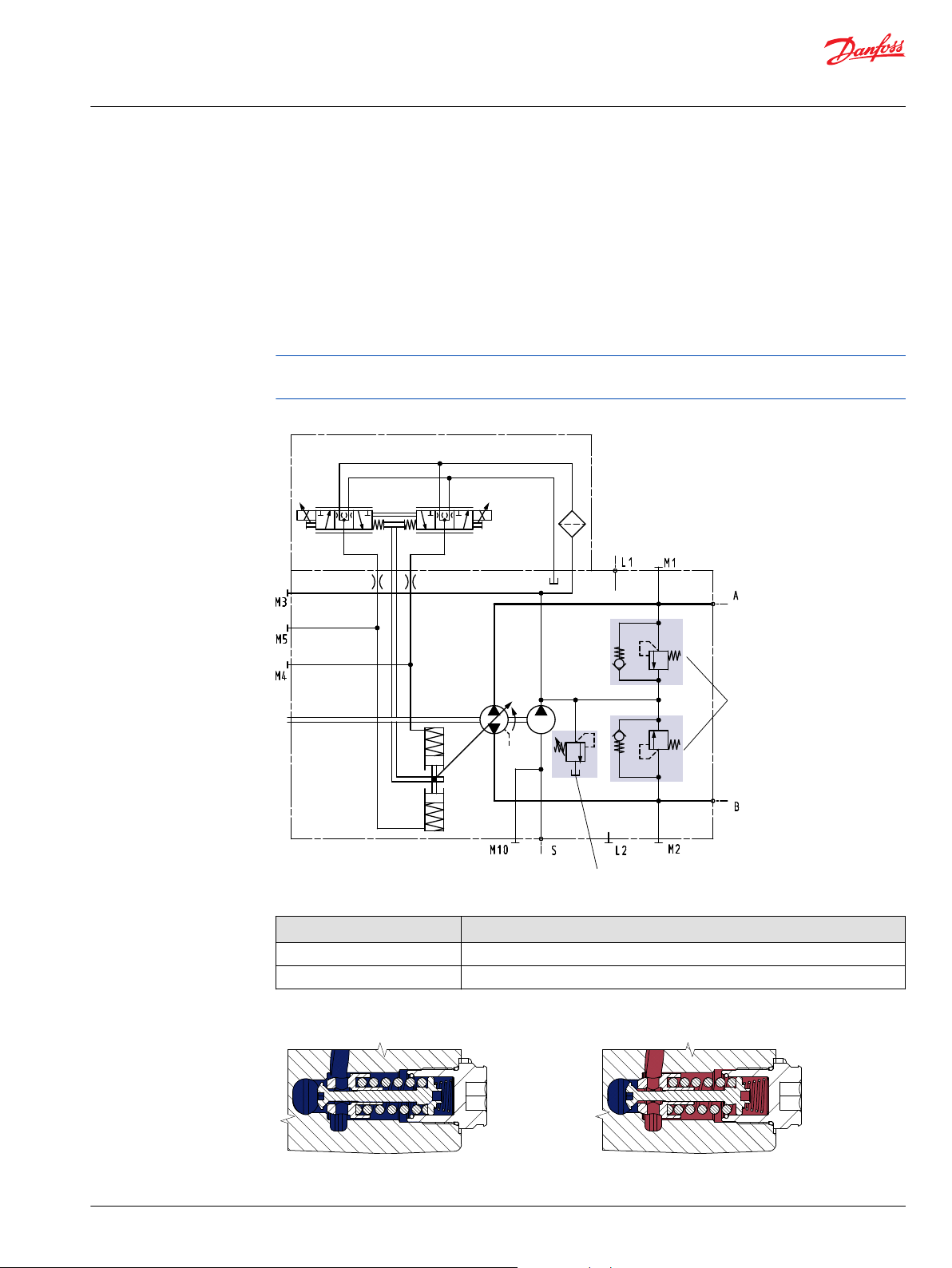

High pressure relief valve (HPRV) and charge check valve

The TMP pumps are equipped with a combination high pressure relief and charge check valve. The highpressure relief function is a dissipative pressure control valve for the purpose of limiting excessive system

pressures. The charge check function acts to replenish the low-pressure side of the working loop with

charge oil. Each side of the transmission loop has a dedicated HPRV valve that is non-adjustable with a

factory set pressure. When system pressure exceeds the factory setting of the valve, oil is passed from the

high pressure system loop, into the charge gallery, and into the low pressure system loop via the charge

check.

The pump order code allows for different pressure settings to be used at each system port.

HPRVs are set at low flow condition. Any application or operating condition which leads to elevated HPRV

flow will cause a pressure rise with flow above the valve setting. Consult factory for application.

System schematic, single pump

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 11

Pressures marked on HPRV valve

Mark Pressure bar [psi]

28 280 [4061]

42 420 [6092]

HPRV and check valve in charging mode HPRV and check valve in relief mode

Page 12

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operation

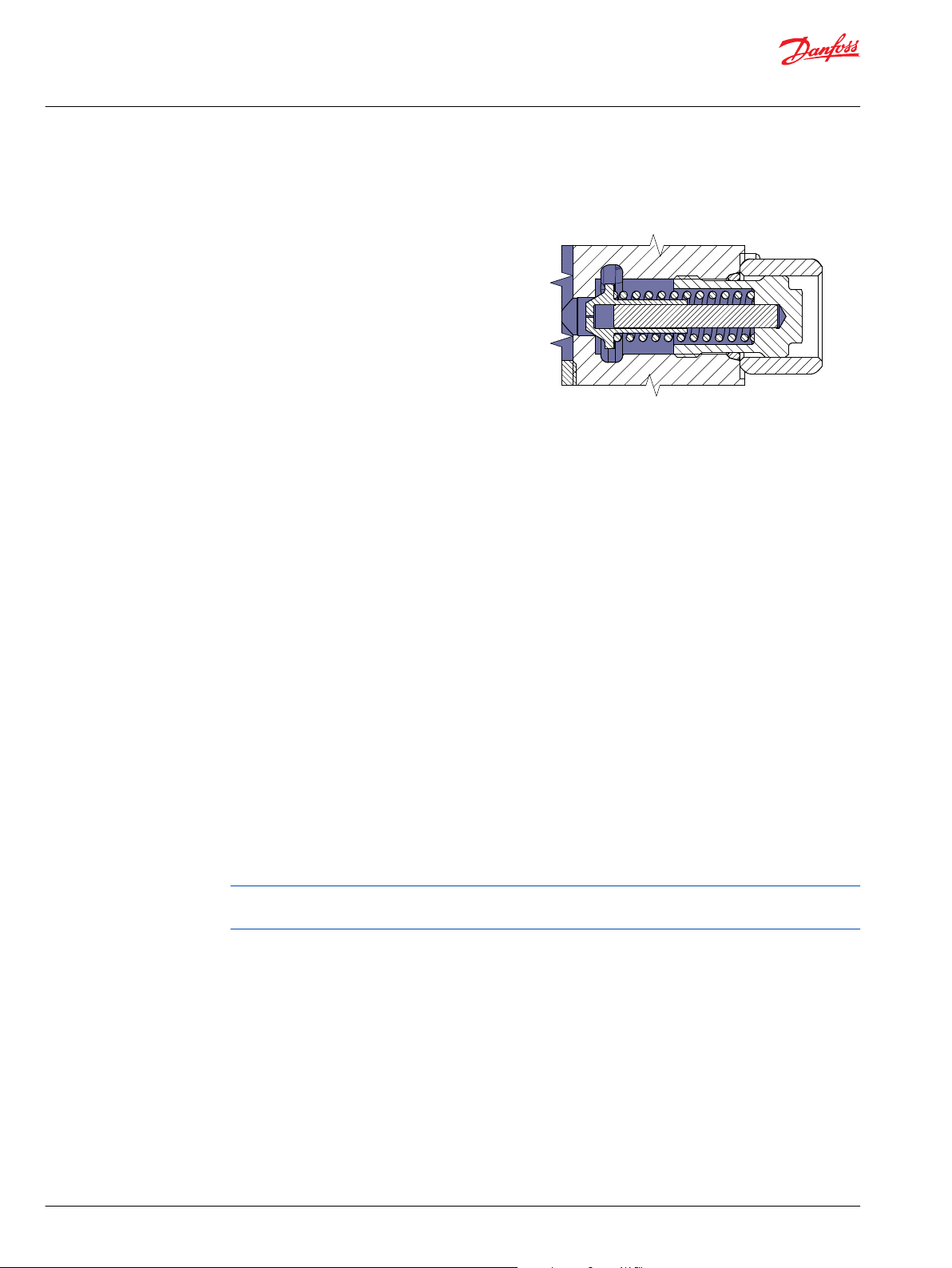

Charge pressure relief valve (CPRV)

The charge pressure relief valve maintains charge

pressure at a designated level above case pressure.

The charge pressure relief valve is a direct acting poppet

valve which opens and discharges fluid to the pump case

when pressure exceeds a designated level. Standard level

setting is ∆p = 21 ± 1.1 bar [304 ± 16 psi] with the pump

running at 1500 min-1 (rpm) and flow = 23.8 - 29.5 l/min

[ 6.3 - 7.8 US gal/min].

Typical charge pressure increase is 2 bar per 10 l/min [29

psi per 2.64 US gal/min].

Electrical Displacement Control (EDC)

EDC Principle

The Electrical Displacement Control (EDC) consists of proportional solenoids on each side of a threeposition, four-way porting spool. The proportional solenoid applies a force to the spool, which ports

hydraulic fluid to either side of the servo piston. Differential pressure across the servo piston rotates the

swashplate, changing the pump's displacement from full displacement in one direction to full

displacement in the opposite direction.

EDC operation

EDC's are current driven controls requiring a Pulse Width Modulated (PWM) signal. Pulse width

modulation allows more precise control of current to the solenoids. The PWM signal causes the solenoid

pin to push against the porting spool, which pressurizes one end of the servo piston, while draining the

other. Pressure differential across the servo piston moves the swashplate. A swashplate feedback link,

opposing control links, and a linear spring provide swashplate position force feedback to the solenoid.

The control system reaches equilibrium when the position of the swashplate spring feedback force

exactly balances the input command solenoid force from the operator. As hydraulic pressures in the

operating loop change with load, the control assembly and servo/swashplate system work constantly to

maintain the commanded position of the swashplate.

The EDC incorporates a positive neutral dead-band as a result of the control spool porting, spring preload

from the servo piston assembly, and the linear control spring. Once the neutral threshold current is

reached, the swashplate position becomes directly proportional to the control current. To minimize the

effect of the control neutral deadband, we recommended the transmission controller or operator input

device incorporate a jump up current.

Charge pressure relief valve (CPRV)

The neutral position of the control spool does provide a positive preload pressure to each end of the

servo piston assembly.

When the control input signal is either lost or removed, or if there is a loss of charge pressure, the springloaded servo piston automatically returns the pump to neutral position.

The EDC is a displacement (flow) control. Pump swashplate position is proportional to the input

command and therefore vehicle or load speed (excluding influence of efficiency), is dependent only on

the prime mover speed or motor displacement.

12 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 13

Feedback from swash-plate

PT

M14

C1 C2

Feedback from swasch plate

T P

N

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operation

EDC schematic diagram

Manual Displacement Control (MDC)

MDC principle

The Manual Displacement Control (MDC) consists of a lever with eccentric shaft centre of a threeposition, four-way porting spool. The eccentric shaft applies a force input to the spool, which ports

hydraulic pressure to either side of a double acting servo piston.

Differential pressure across the servo piston rotates the swash plate, changing the pump`s displacement

from full displacement in one direction to full displacement in the opposite direction.

MDC Schematic (P005571E)

MDC with control cut off (CCO)

If solenoid is loaded by voltage directly from truck battery 24 to 32 V pump work in normal mode if the

electric circuit will by switch off pump will go immediately to 0 position.

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 13

Page 14

P003 204

W

Feedback from swash-plate

PT

M14

C2

C1

Feedback from swasch plate

T P

N

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operation

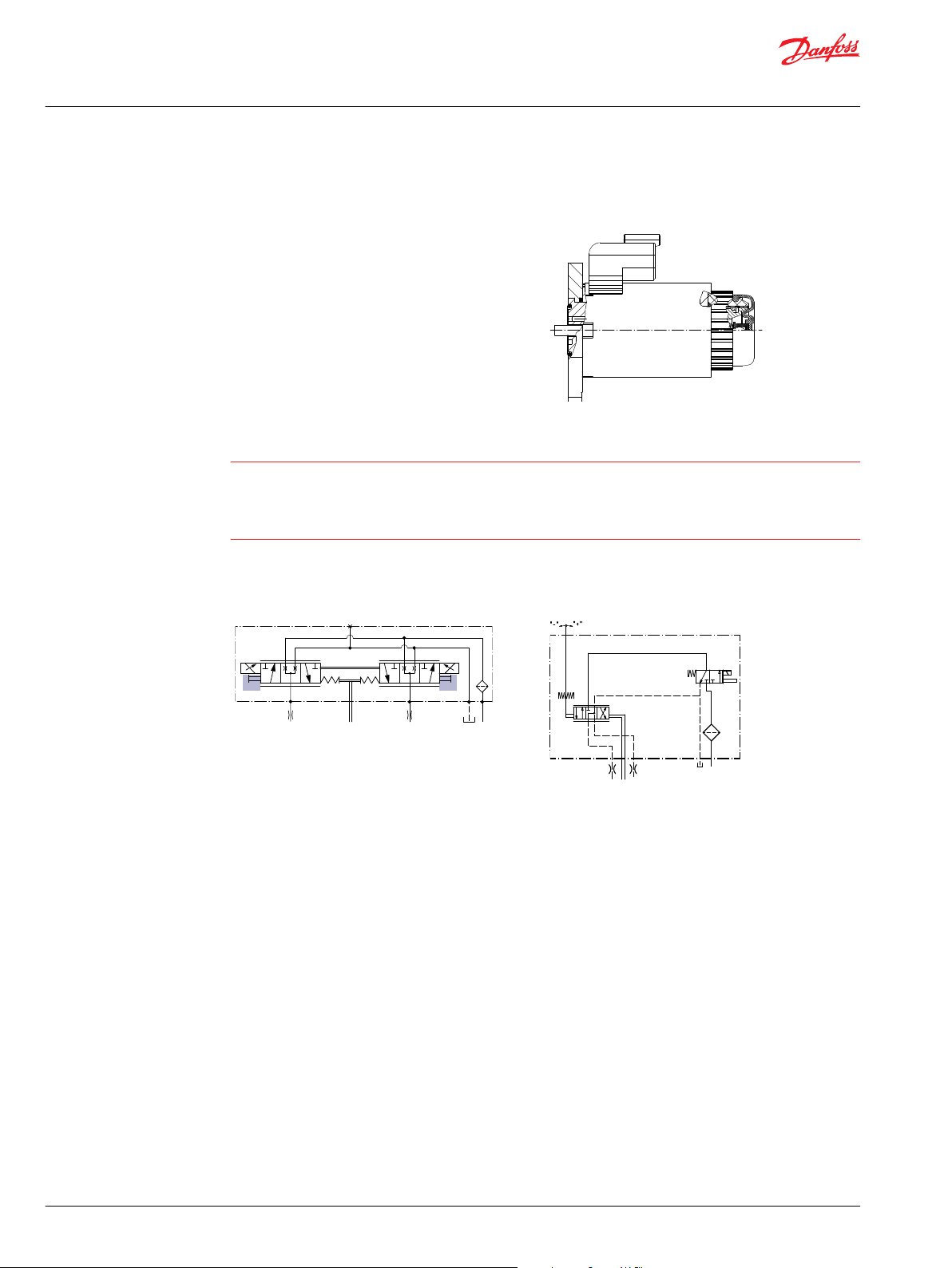

Manual Over Ride (MOR)

All controls are available with a Manual Over Ride (MOR)

either standard or as an option for temporary actuation of

MOR

the control to aid in diagnostics.

The vehicle or device must always be in a ‘safe’ condition

(i.e. vehicle lifted off the ground) when using the MOR

function.

The MOR plunger has a 4 mm diameter and must be

manually depressed to be engaged.

Depressing the plunger mechanically moves the control

spool which allows the pump to go on stroke.

The MOR should be engaged anticipating a full stroke

response from the pump.

Warning

An O-Ring seal is used to seal the MOR plunger where initial actuation of the function will require a force

of 45 N to engage the plunger. Additional actuations typically require a threshold force of 12 N to move

the MOR plunger. Force required to keep the pump at full stroke is typically 51 N. Proportional control of

the pump using the MOR should not be expected.

Refer to control flow table for the relationship of solenoid to direction of flow.

MOR schematic diagram (EDC shown)

MOR schematic diagram (MDC shown)

14 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 15

W

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operating Parameters

Overview

This section defines the operating parameters and limitations for TMP pumps with regard to input speeds

and pressures. For actual parameters, refer to the operating parameters for each displacement.

Input Speed

Minimum speed is the lowest input speed recommended during engine idle condition. Operating below

minimum speed limits the pump's ability to maintain adequate flow for lubrication and power

transmission.

Rated speed is the highest input speed recommended at full power condition. Operating at or below

this speed generally yields satisfactory product life.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces product

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

When determining speed limits for a particular application see Danfoss publication Pressure and speed

limits.

Warning

System Pressure

Charge Pressure

Unintended vehicle or machine movement hazard. Exceeding maximum speed may cause a loss of

hydrostatic drive line power and braking capacity. You must provide a braking system, redundant to the

hydrostatic transmission, sufficient to stop and hold the vehicle or machine in the event of hydrostatic

drive power loss.

System pressure is the differential pressure between system ports A & B. It is the dominant operating

variable affecting hydraulic unit life. High system pressure, which results from high load, reduces

expected life. Hydraulic unit life depends on speed and normal operating—or weighted average—

pressure that you can only determine from a duty cycle analysis.

Applied pressure is the chosen application pressure in the order code for the pump. This is the pressure

at which the drive line generates maximum pull or torque in the application.

Rated pressure is the design pressure for the pump. Applications with applied pressures at or below this

pressure should yield satisfactory unit life given proper component selection.

Maximum pressure (peak) is the highest intermittent pressure allowed under any circumstances.

Applications with applied pressures between rated and maximum require factory approval with

complete application, duty cycle, and life expectancy analysis.

All pressure limits are differential pressures referenced to low loop (charge) pressure. Subtract low loop

pressure from gauge readings to compute the differential.

An internal charge relief valve regulates charge pressure. The internal charge pump supplies the control

with pressure to operate the swashplate and to maintain a minimum pressure in the low side of the

transmission loop.

Minimum charge pressure is the lowest pressure safe working conditions allow in the system loop.

Minimum control pressure requirements are a function of speed, pressure, and swashplate angle, and

may be higher than the minimum charge pressure shown in the technical specifications.

Maximum charge pressure is the highest charge pressure the charge relief adjustment allows, and

which provides normal component life. You can use elevated charge pressure as a secondary means to

reduce the swashplate response time.

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 15

Page 16

W

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operating Parameters

The charge pressure setting listed in the order code is the set pressure of the charge relief valve with the

pump in neutral, operating at 1500 min-1 (rpm), and with a fluid viscosity of 32 mm2/sec [150 SUS]. The

charge pressure setting is referenced to case pressure (the differential pressure above case pressure).

Charge inlet pressure

At normal operating temperature charge inlet pressure must not fall below rated charge inlet pressure.

Minimum charge inlet pressure is only allowed at cold start conditions. In some applications, you may

need to warm up the fluid (start the prime mover without using the vehicle/machine functions) before

moving the vehicle or operating the machine.

Case Pressure

Do not exceed rated case pressure under normal operating conditions. During cold start, keep case

pressure below maximum intermittent case pressure. Size drain plumbing accordingly.

Warning

Possible component damage or leakage. Operation with case pressure in excess of stated limits may

damage seals, gaskets, and/or housings, causing external leakage. This condition may also affect

performance since charge and system pressure are referenced to case pressure.

Temperature and Viscosity

General specification

Temperature

High temperature limits apply at the hottest point in the transmission loop, which is normally the motor

case drain. Ensure the system generally runs at or below the rated temperature.

The maximum intermittent temperature is based on material properties. Never exceed it!

Cold oil will generally not affect the durability of the transmission components, but it may affect the

ability of oil to flow and transmit power: therefore ensure temperatures remain 16 °C [30 °F] above the

pour point of the hydraulic fluid. Minimum temperature relates to the physical properties of component

materials. Size heat exchangers to keep the fluid within these limits. Danfoss recommends testing to

verify that these temperature limits are not exceeded.

Viscosity

For maximum efficiency and bearing life, ensure the fluid viscosity remains in the recommended range.

Minimum viscosity should be encountered only during brief occasions of maximum ambient

temperature and severe duty cycle operation.

Maximum viscosity should be encountered only at cold start.

General specifications

Design

Direction of rotation

Axial piston pump cradle swashplate design with variable displacement

Clockwise, counterclockwise

16 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 17

C

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operating Parameters

General specifications (continued)

Pipe connections

Recommended

installation position

Caution

The front shaft seal must not be exposed to oil pressure from outside of the unit.

Boundary position of the MDC lever must be fixed by hard stop on the customer actuation mechanism in

order to prevent any damages of MDC.

Physical Properties

Technical data

Features Unit Size

Displacement maximum cm

Oil volume l [US gal] 2 [0.53] 2 [0.53]

Mounting flange SAE ISO 3019/1 flange 127-4 (SAE C), M12x1,75

Input shaft Spline shaft SAE, 21 teeth, pitch = 16/32

Auxiliary mounting flange with metric fasteners,

shaft splines

Suction port ISO 6149-1 – M42x2 (O-ring boss)

Main port configuration Twin ports SAE J518b Size 1, with metric screws M12

Case drain ports L1, L2 ISO 6149-1 – M22x1,5 (O-ring boss)

Other ports ISO 6149-1 straight thread O-ring boss.

Main pressure ports: ISO split flange boss

Remaining ports: ISO straight thread O-ring boss

Pump installation position is discretionary; however the recommended control position is on

the top. The housing must always be filled with hydraulic fluid.

Pump shaft connection is discretionary, however it is strongly recommended to use rubber

coupling if pump is driven via “cardan” shaft.

Correct installation has a significant influence on a life time of the pump.

070 089

3

[in3]

Spline shaft SAE, 23 teeth, pitch = 16/32

Coupling for Cardan, 23 teeth (only with spline shaft SAE, 23 teeth, pitch = 16/32)

SAE A, 11 teeth, pitch = 16/32

SAE B, 13 teeth, pitch = 16/32

SAE B-B, 15 teeth, pitch = 16/32

See Port Locations and Gauge Installation on page 19.

68.3

[4.17]

89.0

[5.43]

Operating parameters

Operating parameters, size 070 / 089

Features Unit Sizes 070 / 089

Input speed Minimum

Rated

Maximum

System pressure Max. working pressure

Maximum pressure

Minimum pressure

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 17

min-1 (rpm)

bar [psi]

500

2500

2900

420 [6090]

450 [6525]

10 [145]

Page 18

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Operating Parameters

Operating parameters, size 070 / 089 (continued)

Features Unit Sizes 070 / 089

Charge pressure Minimum

Maximum

Control pressure Minimum (at corner

power for EDC)

Maximum

Charge pump inlet

pressure

Case pressure Rated

Lip seal external pressure

Rated

Minimum (cold start)

Maximum

Maximum

Maximum

bar [psi]

bar [psi]

bar (absolute)

[in Hg vacuum]

bar [psi]

bar [psi]

17 [247]

30 [436]

21 [305]

30 [435]

0.7 [9]

0.2 [24]

4 [58]

3 [44]

5 [73]

0.4 [5.8]

Fluid Specifications

Fluid specifications

Features Unit Sizes 070 / 089

Viscosity Intermittent

1

mm2/s [SUS] 5 [42]

Minimum 7 [49]

Recommended range 12-80 [66-370]

Maximum 1600 [7500]

Temperature

2

range

Minimum (cold start)

Recommended range 60-85 [140-185]

3

°C [°F] -40 [-40]

Rated 104 [220]

1

115 [240]

Filtration (recommended

minimum)

Maximum intermittent

Cleanliness per ISO 4406 22/18/13

Efficiency (charge pressure filtration) β-ratio β15-20 = 75 (β10 ≥ 10)

Efficiency (suction and return line filtration) β35-45 = 75 (β10 ≥ 2)

Recommended inlet screen mesh size µm 100 – 125

1

Intermittent = Short term t < 1 min per incident and not exceeding 2 % of duty cycle based load-life

2

At the hottest point, normally case drain port

3

Cold start = Short term t < 3 min, p ≤ 50 bar [725 psi], n ≤ 1000 min-1(rpm)

Ratings and data are based on operation with premium petroleum-based hydraulic fluids containing

oxidation, rust, and foam inhibitors.

18 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 19

W

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Fluid and Filter Maintenance

Fluid and filter recommendations

To ensure optimum life, perform regular maintenance of the fluid and filter. Contaminated fluid is the

main cause of unit failure. Take care to maintain fluid cleanliness when servicing.

Check the reservoir daily for proper fluid level, the presence of water, and rancid fluid odor. Fluid

contaminated by water may appear cloudy or milky or free water may settle in the bottom of the

reservoir. Rancid odor indicates the fluid has been exposed to excessive heat. Change the fluid and

correct the problem immediately if these conditions occur.

Inspect vehicle for leaks daily. Change the fluid and filter per the vehicle/machine manufacturer's

recommendations or at intervals shown in the table. We recommend first fluid change at 500 hours.

Fluid and Filter Change Interval

Reservoir type Max oil change interval

Sealed 2000 hours

Breather 500 hours

High temperatures and pressures will result in accelerated fluid aging. More frequent fluid changes may

be required.

Change the fluid more frequently if it becomes contaminated with foreign matter (dirt, water, grease,

etc.) or if the fluid is subjected to temperature levels greater than the recommended maximum. Dispose

of used hydraulic fluid properly. Never reuse hydraulic fluid.

Change filters with the fluid or when the filter indicator shows it’s necessary. Replace all fluid lost during

filter change.

For detailed filtration information, see Danfoss publication 520L0463 Fluids and Filtration. For

information on biodegradable fluids see Danfoss publication 520L0465 Biodegradable Hydraulic Fluids.

Warning

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state and federal environmental regulations.

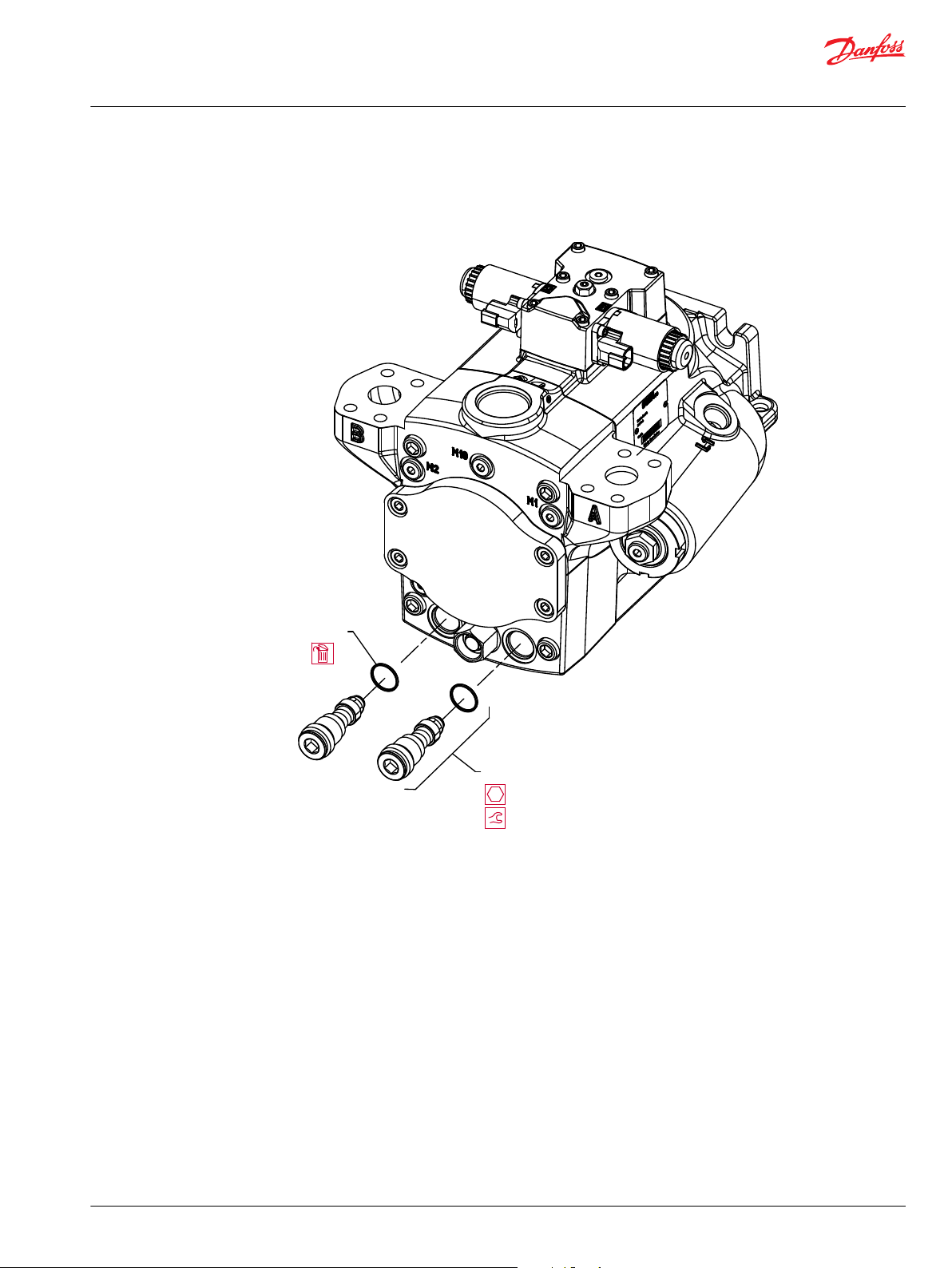

Port Locations and Gauge Installation

The following table and drawings show the port locations and gauge sizes needed. When testing system

pressures, calibrate pressure gauges frequently to ensure accuracy. Use snubbers to protect gauges.

Port Information

Identifier Port Description Size Wrench size Gauge size,

bar [psi]

L1, L2 Case drain ports M22x1.5 10 mm internal hex 10 [100]

M1, M2, M4, M5 System A/B, charge and servo gage M12x1.5 6 mm internal hex 50 [1000]

M10 Charge pump inlet pressure M12x1.5 6 mm internal hex 50 [1000]

S Charge inlet port M42x2.0 10 [100]

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 19

Page 20

Gauge port M2

System pressure port B

M12 x 1.5

Gauge port M1

System pressure port A

M12 x 1.5

Gauge port M4

Servo pressure

M12 x 1.5

Gauge port M5

Servo pressure

M12 x 1.5

Gauge port M10

Charge pump inlet pressure

M12 x 1.5

Gauge port M3

Charge pressure

M12 x 1.5

O-ring plug

7/16-20 UNF

use for air bleed when filling pump

(only by EDC)

Case drain Port L2

M22 x 1.5

O-ring boss

System port B

Charge pump inlet S

M42 x 2

System port A

Case drain Port L1

M22 x 1.5

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Fluid and Filter Maintenance

Port locations

P005443E

20 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 21

W

C

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Initial Startup Procedures

General

Follow this procedure when starting-up a new pump installation or when restarting an installation in

which the pump has been removed and re-installed on a machine. Ensure pump has been thoroughly

tested on a test stand before installing on a machine. Prior to installing the pump, inspect for damage

that may have occurred during shipping.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Start-Up procedure

1. Ensure that the machine hydraulic oil and system components (reservoir, hoses, valves, fittings, and

heat exchanger) are clean and free of any foreign material.

2. Install new system filter element(s) if necessary. Check that inlet line fittings are properly tightened

and there are no air leaks.

3. Install the pump. Install a 50 bar [1000 psi] gauge in the charge pressure gauge port M

4. Fill the housing by adding filtered oil in the upper case drain port. If the control is installed on top,

open the construction plug in the top of the control to assist in air bleed.

5. Fill the reservoir with hydraulic fluid of the recommended type and viscosity. Use a 10-micron filler

filter. Fill inlet line from reservoir to pump.

6. Disconnect the pump from all control input signals.

7. Close construction plug removed in Step 4.

Caution

After start-up the fluid level in the reservoir may drop due to system components filling. Damage to

hydraulic components may occur if the fluid supply runs out. Ensure reservoir remains full of fluid

during start-up.

Air entrapment in oil under high pressure may damage hydraulic components. Check carefully for

inlet line leaks.

Do not run at maximum pressure until system is free of air and fluid has been thoroughly filtered.

8. Use a common method to disable the engine to prevent it from starting. Crank the starter for several

seconds. Do not to exceed the engine manufacturer's recommendation. Wait 30 seconds and then

crank the engine a second time as stated above. This operation helps remove air from the system

lines. Refill the reservoir to recommended full oil level.

9. When the gauge begins to register charge pressure, enable and start engine. Let the engine run for a

minimum of 30 seconds at low idle to allow the air to work itself out of the system. Check for leaks at

all line connections and listen for cavitation. Check for proper fluid level in reservoir.

10. When adequate charge pressure is established (as shown in model code), increase engine speed to

normal operating rpm to further purge residual air from the system.

11. Shut off engine. Connect pump control signal. Start engine, checking to be certain pump remains in

neutral. Run engine at normal operating speed and carefully check for forward and reverse control

operation.

12. Continue to cycle between forward and reverse for at least five minutes to bleed all air and flush

system contaminants out of loop.

Normal charge pressure fluctuation may occur during forward and reverse operation.

13. Check that the reservoir is full. Remove charge pressure gauge.

The pump is now ready for operation.

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 21

Page 22

C

W

W

C

W

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Troubleshooting

Overview

This section provides general steps to follow if you observe undesirable system conditions. Follow the

steps listed until you solve the problem. Some of the items are system specific. We reference the section

in this manual if more information is available. Always observe the safety precautions listed in Safety

Precautions and precautions related to your specific equipment.

Safety Precautions

Caution

High inlet vacuum causes cavitation which can damage internal pump components.

Warning

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious

injury and/or infection. Relieve pressure in the system before removing hoses, fittings, gauges, or

components.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Caution

Contamination can damage internal components and void the manufacturer's warranty. Take

precautions to ensure system cleanliness when removing and reinstalling system lines

Warning

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state, and federal environmental regulations.

Electrical Troubleshooting (TMP EDC)

Item Description Action

Control operates pump in one

direction only.

No pump function No power to controller Restore power to controller.

Erratic pump function Electrical connection to pump is bad. Disconnect connection, check wires, reconnect wires.

Control coil failure Measure resistance at coil pins. Resistance should be 14.20 ohms (24V) or

3.66 ohms (12V) at 20°C [70°F]. Replace coil

If available, use manual override to check proper pump operation and verify electrical problem.

System Operating Hot

Item Description Action

Oil level in reservoir. Insufficient hydraulic fluid will not meet cooling demands

of system.

Heat exchanger. Heat exchanger is not sufficiently cooling the system. Check air flow and input air temperature for heat

22 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Fill reservoir to proper level.

exchanger. Clean, repair or replace heat exchanger.

Page 23

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Troubleshooting

Item Description Action

Charge pressure. Low charge pressure will overwork system. Measure charge pressure. Inspect and adjust or replace

charge relief valve. Inspect charge pump. Repair or replace

charge pump.

Charge pump inlet vacuum. High inlet vacuum will overwork system. A dirty filter will

increase the inlet vacuum. Inadequate line size will restrict

flow.

System relief pressure

settings

System pressure. Frequent or long term operation over system relief setting

If the system relief valves are worn, contaminated, or valve

settings are too low, the relief valves will be overworked.

will create heat in system.

Neutral Difficult or Impossible to Find

Item Description Action

Input to pump control Input to control module is operating

improperly.

Neutral Neutral set improperly Shunt servo gauge ports (M4 and M5) together with

Check charge inlet vacuum. If high, inspect inlet filter and

replace as necessary. Check for adequate line size, length or

other restrictions.

Verify settings of high pressure relief valves and replace

valves as necessary.

Measure system pressure. If pressure is too high, reduce

loads.

Disconnect input and check to see if pump comes back to

neutral. If Yes, input fault, replace/repair external controller.

If No, go to next step.

external hose and see if pump comes back to neutral. If Yes:

Control neutral improperly set (see page 31-34) If neutral

still impossible to set, balance swashplate (see Mechanical

neutral adjustment, page 35-37). If you still cannot set

neutral, replace control.

System Will Not Operate in Either Direction

Item Description Action

Oil level in reservoir. Insufficient hydraulic fluid to supply system loop. Fill reservoir to proper level.

Pump control orifices Control orifices are blocked. Clean control orifices.

Pump control screens Control screens are blocked. Replace control screens. Only a Danfoss Authorized Service

Center may remove the unit's endcap without voiding the

warranty.

Low charge pressure with

pump in neutral

Low charge pressure with

pump in stroke

Pump charge relief valve A pump charge relief valve that is leaky, contaminated, or

Charge pump inlet filter A clogged filter will under supply system loop. Inspect filter and replace if necessary.

Charge pump A malfunctioning charge pump will provide insufficient

System pressure Low system pressure does not provide enough power to

High pressure relief valve Defective high pressure relief valve cause system pressure

Input to control Input operating improperly Repair/replace control.

Low charge pressure insufficient to recharge system loop. Measure charge pressure with the pump in neutral. If

pressure is low, go to Pump charge relief valve.

Low charge pressure resulting from elevated loop leakage.

Insufficient control pressure to hold pump in stroke.

set too low will depressurize the system.

charge flow.

move load.

to be low.

Deadhead the pump to isolate it from the motor.With

pump in partial stroke and engaged for only a few seconds,

check pump charge pressure. Low charge pressure

indicates a malfunctioning pump. Continue to next step.

Good charge pressure indicates a malfunctioning motor or

other system component. Check motor charge relief

operation (if present).

Adjust or replace pump charge relief valve as necessary.

Repair or replace the charge pump.

Measure system pressure. Continue to next step.

Repair or replace high pressure relief valve.

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 23

Page 24

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Troubleshooting

System Noise or Vibration

Item Description Action

Reservoir oil level Low oil level leads to cavitation. Fill reservoir.

Aeration of the oil/pump

inlet vacuum

Cold oil If oil is cold, it may be too viscous for proper function

Pump inlet vacuum High inlet vacuum causes noise/cavitation. Check that inlet line is not restricted and is of proper size.

Shaft couplings A loose shaft coupling will cause excessive noise. Replace loose shaft coupling..

Shaft alignment Misaligned shafts create noise. Align shafts.

Charge/system relief valves Unusual noise may indicate sticking valves and possible

Sluggish System Response

Item Description Action

Oil level in reservoir Low oil level causes sluggish response. Fill reservoir.

High pressure relief valves settings Incorrect pressure settings affects system reaction time. Adjust or replace high pressure relief valves.

Low prime mover speed Low engine speed reduces system performance. Adjust engine speed.

Charge pressure Incorrect pressure affects system performance. Measure and adjust charge pressure relief or

Air in system Air in system produces sluggish system response. Fill tank to proper level. Cycle system slowly for

Contaminated control orifices Control orifices are plugged. Clean control orifices.

Contaminated control screens Supply screen is plugged. Replace control screens.

Pump inlet vacuum Inlet vacuum is too high resulting in reduced system

Air in system decreases efficiency of units and controls.

Excessive noise, foaming oil, and hot oil all indicate air in

system.

causing pump cavitation.

contamination.

pressure.

Find location where air is entering into the system and

repair. Check that inlet line is not restricted and is proper

size.

Allow the oil to warm up to its normal operating

temperature with engine at idle speed.

Check filter and bypass switch.

Clean/replace valves and test pump.

replace charge pump.

several minutes to remove air from system.

Measure charge inlet vacuum. Inspect line for

proper sizing. Replace filter. Confirm proper bypass

operation.

Transmission Operates Normally in One Direction Only

Item Description Action

Input to pump control. Input to control module is operating improperly. Check control input and repair or replace as necessary.

Control orifices Control orifice(s) are blocked. Clean control orifices.

Control screens Control screen(s) are blocked. Replace control screens.

Exchange high pressure

relief valves

Servo pressure low or

decaying

Exchanging the high pressure relief valves will show if

the problem is related to the valve function.

Damaged servo seals may prevent servo piston from

stroking the pump.

If the problem changes direction, replace the valve that does not

operate correctly.

Check for torn/missing servo seals. Replace and retest. Only a

Danfoss Authorized Service Center may remove the servo piston

without voiding the warranty.

24 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 25

C

Case drain port L2

Servo pressure gauge port M4, M5

Adjustment screw

13 mm

Locknut

27 mm

65 N•m [48 lbf•ft]

Optional construction port

0 - 10 bar [0 - 100 psi]

M22x1.5

40 N•m [29.5 lbf•ft]

0 - 10 bar [0 - 100 psi]

3/16 in

12 N•m [9 lbf•ft]

0 - 50 bar [0 - 1000 psi]

M12x1.5

21 N•m [15.5 lbf•ft]

Charge pressure gauge port M3

0 - 50 bar [0 - 1000 psi]

M12x1.5

21 N•m [15.5 lbf•ft]

Locknut

M40x1.5

80 N•m [59 lbf•ft]

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Adjustments

Pump Adjustment

This section offers instruction on inspection and adjustment of pump components. Read through the

entire topic before beginning a service activity. Refer to Port Locations and Gauge Installation on page 19,

for location of gauge ports and suggested gauge size.

Standard Procedures

Caution

Contamination can damage internal components and void your warranty. Take precautions to ensure

system cleanliness when removing and reinstalling system lines.

1. With the prime mover off, thoroughly clean the outside of the pump.

2. If removing the pump, tag each hydraulic line. When you disconnect hydraulic lines, cap them and

plug each open port to prevent contamination.

3. Ensure the surrounding area is clean and free of contaminants like dirt and grime.

4. Inspect the system for contamination.

5. Check the hydraulic fluid for signs of contamination: oil discoloration, foam in the oil, sludge, or metal

particles.

6. If there are signs of contamination in the hydraulic fluid, replace all filters and drain the hydraulic

system. Flush the lines and refill the reservoir with the correct filtered hydraulic fluid.

7. Before re-installing the pump, test for leaks.

Charge Pressure Relief Valve Adjustments

This procedure explains how to check and adjust the charge pressure relief valve.

Charge Pressure Adjustment (P005619E)

Listed pressures assume a pump speed of 1500 min¯¹ (rpm). At higher pump speeds (with higher charge

flows) the charge pressure will rise over the rated setting.

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 25

Page 26

W

Servo pressure gauge port M4, M5

Adjustment screw

4 mm

Locknut

13 mm

12 N•m [9 lbf•ft]

0 - 50 bar [0 - 1000 psi]

M12x1.5

21 N•m [15.5 lbf•ft]

D060 D015

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Adjustments

1. Install a 50 bar [1000 psi] pressure gauge in charge pressure gauge port M3. Install a 10 bar [100 psi]

gauge at case drain port L1 or L2. Operate the system with the pump in neutral (zero displacement)

when measuring charge pressure.

2. Nominal charge relief valve settings 20.3 - 25 bar [294 - 326 psi] (refer to model code located on serial

number plate). This pressure assumes 1500 min-1 (rpm) pump speed and a reservoir temperature of

50°C [120°F], and is referenced to case pressure.

3. Loosen the locknut and turn the adjusting screw clockwise to increase the setting; counterclockwise

to decrease it. Approximate adjustment per turn is 2.4 bar.

4. While holding the adjusting screw, torque locknut to 65 N•m [48 lbf•ft].

EDC neutral adjustment

All functions of the Electric Displacement Control (EDC), are preset at the factory. If necessary, adjust the

pump to neutral with the pump running on a test stand or on the vehicle/machine with the prime mover

operating. If adjustment fails to give satisfactory results, you may need to replace the control or coils. See

Removal on page 35 for details.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Adjustment of the EDC is very sensitive. Be sure to hold the hex wrench steady while loosening the

locknut. Total adjustment is less than 120 degrees.

EDC Control Adjustment (P005437E)

26 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

Page 27

Solenoid shaft

Feedback pin

Adjusting

screw

(cam)

P106 046E

Maximum

adjustment

less than 120°

Control spool

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Adjustments

1. Install a 50 bar [1000 psi] gauge in each of the two servo gauge ports (M4 and M5). Disconnect the

external control input (electrical connections) from the control. Start the prime mover and operate at

normal speed.

2. Use a 4 mm internal hex wrench to hold the neutral adjusting screw (D015) stationary while

loosening the locknut (D060) with a 13 mm wrench.

3. Observe pressure gauges. If necessary, turn adjusting screw (D015) to reduce pressure differential.

4. Rotate the neutral adjusting screw (D015) clockwise until the pressure increases on the gauge. Note

the angular position of the wrench. Then rotate the neutral adjusting screw counterclockwise until

the pressure increases by an equal amount on the other gauge. Again note the angular position of

the wrench.

5. Rotate the neutral adjusting screw clockwise half the distance between the wrench positions noted

above. The gauges should read the same pressure, indicating that the control is in its neutral position.

6. Hold the neutral adjusting screw stationary and tighten the locknut (D060). Torque to 10 N•m [7.5

lbf•ft]. Do not over torque the nut.

7. When the neutral position is set, stop the prime mover, remove the gauges, and install the gauge

port plugs. Reconnect the external control input.

Neutral adjustment (EDC, bottom view)

Illustration shows how cam on adjusting pin rotates to

adjust for neutral position after pump is re-installed.

A small pressure differential of 1.5 bar [22 psi] or less is

acceptable. Zero differential is usually not possible.

MDC Control Neutral Adjustment

All functions of the Mechanical Displacement Control (MDC), are preset at the factory. If necessary, adjust

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 27

the pump to neutral with the pump running on a test stand or on the vehicle/machine with the prime

mover operating. If adjustment fails to give satisfactory results, you may need to replace the control. See

Removal on page 37 for details.

Page 28

W

Servo pressure gauge port M4, M5

Adjustment screw

4 mm

Locknut

13 mm

10 N•m [7.5 lbf•ft]

0 - 50 bar [0 - 1000 psi]

M12x1.5

21 N•m [15.5 lbf•ft]

D060 D698

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Adjustments

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Adjustment of the MDC is very sensitive. Be sure to hold the hex wrench steady while loosening the

locknut. Total adjustment is ±3 screw thread.

MDC Control Adjustment (P005612E)

1. Install a 50 bar [1000 psi] gauge in each of the two servo gauge ports (M4 and M5). Disconnect the

external control input (mechanical connections) from the control. Start the prime mover and operate

at normal speed.

28 | © Danfoss | July 2017 L1010109 | AX00000131en-US0203

2. Use a 4mm internal hex wrench to hold the neutral adjusting screw (D698) stationary while loosening

the locknut (D060) with a 13 mm wrench.

3. Observe pressure gauges. If necessary, turn adjusting screw (D698) to reduce pressure differential.

4. Rotate the neutral adjusting screw (D015) clockwise until the pressure increases on the gauge. Note

the angular position of the wrench. Then rotate the neutral adjusting screw counterclockwise until

the pressure increases by an equal amount on the other gauge. Again note the angular position of

the wrench.

5. Rotate the neutral adjusting screw clockwise half the distance between the wrench positions noted

above. The gauges should read the same pressure, indicating that the control is in its neutral position.

6. Hold the neutral adjusting screw stationary and tighten the locknut (D060). Torque to 10 N•m [7.5

lbf•ft]. Do not over torque the nut.

Page 29

Eccentric shaft

Feedback pin

Maximum

adjustment ± 3 mm

Control spool

Control lever

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Adjustments

7. When the neutral position is set, stop the prime mover, remove the gauges, and install the gauge

port plugs. Reconnect the external control input.

Neutral Adjustment (MDC, bottom view)(P005613E)

Mechanical Neutral Adjustment

Mechanical neutral is set with the pump running at 1500 min¯¹ (rpm). To set neutral, you must stroke the

pump in each direction. You can do this with a small movement of the eccentric screw on EDC or MDC

controls. To stroke a pump with EDC, you must provide a 100 Hz PWM signal to the control solenoids. If

you perform this adjustment with the pump installed in a vehicle or machine, safely elevate the wheels or

disconnect the mechanism to allow safe operation during adjustment.

This procedure details setting neutral for the pump. Alternate M4/M5 and M1/M2 to zero out forward and

reverse directions of the unit Refer to the drawing below to identify all ports.

While performing this adjustment, you will monitor the following pressures.

•

•

•

•

Illustration shows how cam on adjusting pin rotates to adjust for neutral position after pump is reinstalled.

A small pressure differential of 0.15 bar [2.2 psi] or less is acceptable. Zero differential is usually not

possible.

Servo pressure at M4 and M5

System pressure at M1 and M2

Pressure differential between M4 and M5 (optional)

Pressure differential between A and B (optional)

©

Danfoss | July 2017 L1010109 | AX00000131en-US0203 | 29

Page 30

Port M1

System pressure

Port M2

System pressure

Port M4

Servo pressure

Servo locking nut

Servo locking nut

Port M5

Servo pressure

System port B

Solenoid C1

Solenoid C1

System port A

Port M1

System pressure

Port M2

System pressure

Port M4

Servo pressure

Servo locking nut

Servo locking nut

Port M5

Servo pressure

System port B

Control lever

System port A

Service Manual

TMP Transit Mixer Axial Piston Pump, Size 070/089

Adjustments

TMP EDC system pressure gage ports for adjusting the servo neutral position

TMP MDC system pressure gage ports for adjusting the servo neutral position