Page 1

Service Kit Instructions

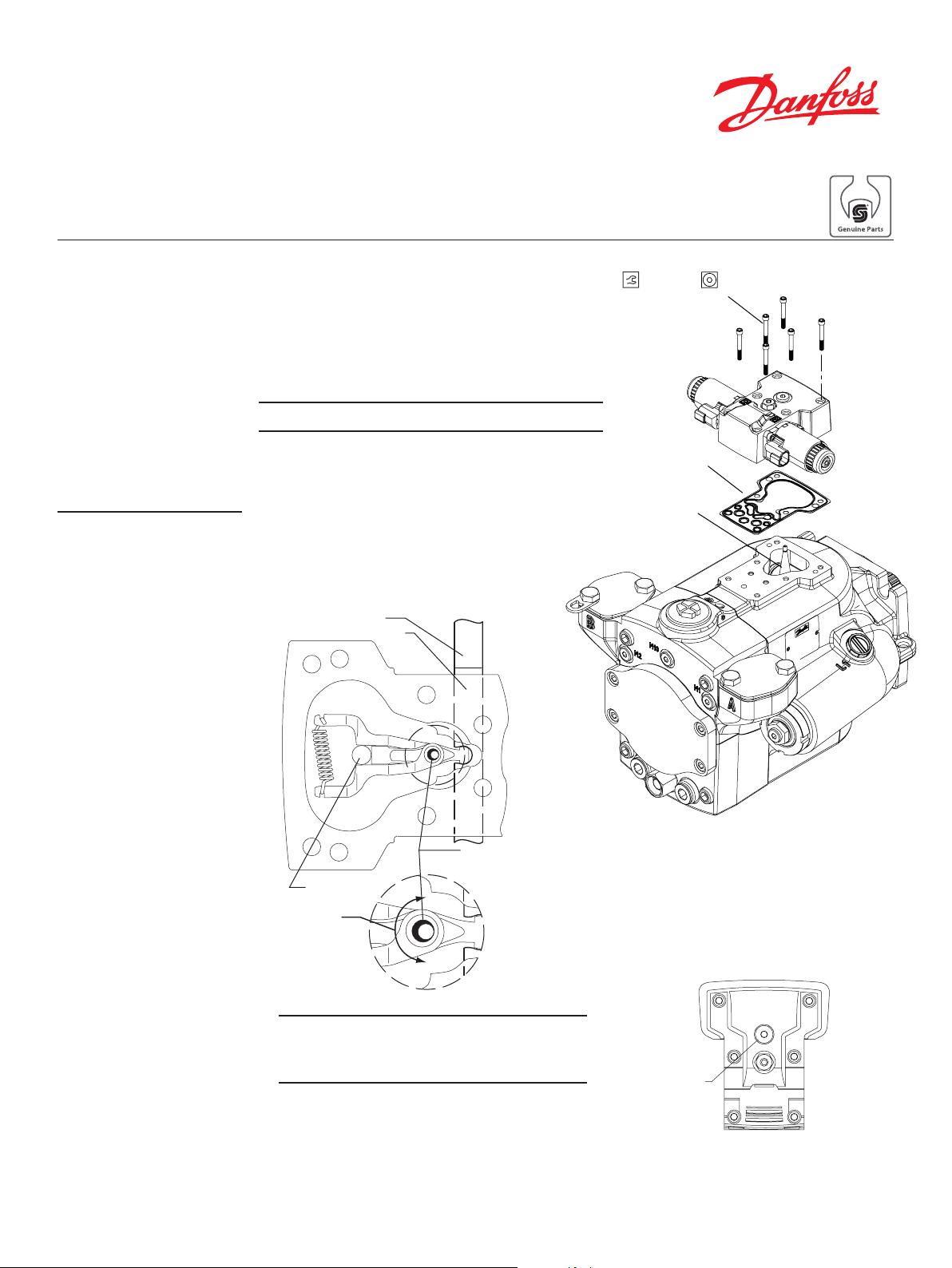

Torque sequence

D065

TMP pump

Electrical displacement control (EDC) replacement procedure

Removal of EDC

Installation of EDC

1. Clean pump externally with clean solvent to

remove debris.

2. Remove control screws (D250) using a 5 mm

internal hex wrench.

3. Remove the control from the pump.

Dowel pins (M140) must remain in pump housing.

4. Remove and discard the control gasket.

1. Install new control gasket (D150).

2. Position control on pump housing. Ensure

that feedback pin on swashplate is positioned

properly in control arm.

Solenoid shaft

Control spool

13.5 N•m

[10 lbf•ft]

D150

Feedback link

D250

5 mm

Adjusting

screw

Feedback pin

Maximum

adjustment

180°

P106 046E

(cam)

4

5

Remove plug (D065) and verify the swashplate

feedback pin is properly positioned between

control feedback arms.

3. Using a 5 mm internal hex wrench, fasten

control to pump with screws (D250). Torque

2

6

1

3

screws to 13.5 N•m [10 lbf•ft] following

torque sequence shown to the right.

© Danfoss, 2016 AN00000347en-US | 11184963• Rev 0100 • October 2016 1

Page 2

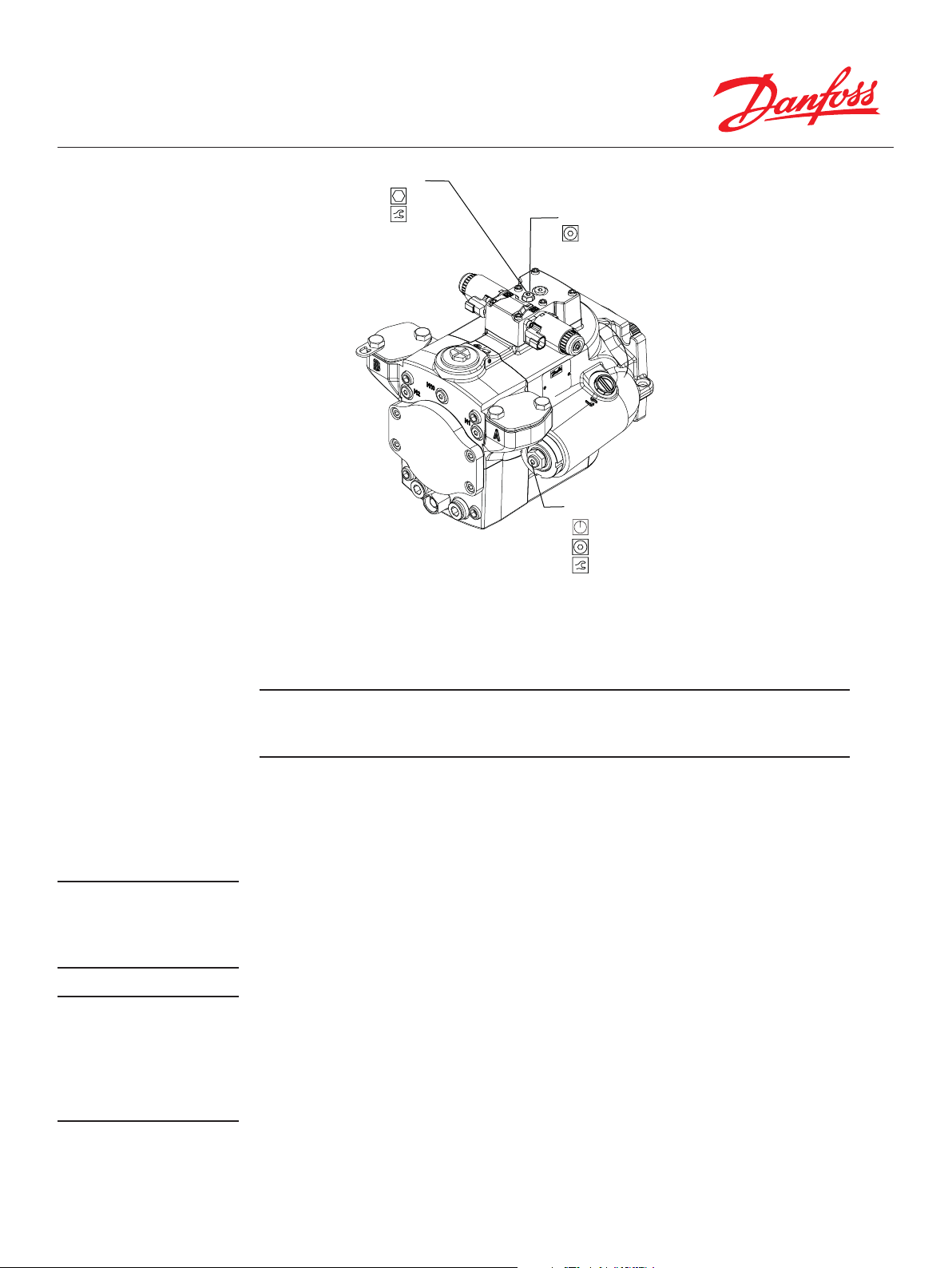

EDC adjustment

M4, M5

21 N•m [15.5 lbf•ft]

D060

13 mm

12 N•m

[8.9 lbf•ft]

D015

4 mm

Servo pressure gauge port

0 - 50 bar [0 - 1000 psi]

M12x1.5

The neutral adjustment is the only adjustment that can be made on electrical displacement controls. All other functions are preset at the factory. The neutral adjustment

must be made with the pump running on a test stand or on the vehicle/machine with

the prime mover operating.

Caution

Adjustment of the EDC is

very sensitive. Be sure to

hold the hex wrench steady

while loosening the lock nut.

A small pressure dierential

is acceptable. Final

adjustment must be within

2 bar dierential. Achieving

zero dierential is not

possible.

Warning

Unintended movement of the machine or mechanism may cause injury to the

technician or bystanders. To protect against unintended movement, secure the

machine or disable/disconnect the mechanism while servicing.

1. Install a 50 bar [1000 psi] pressure gauge in each of the two servo gauge ports (M4 and M5).

Disconnect the external control input (electrical connection) from the control. Start the

prime mover and operate at normal speed.

2. Use a 4 mm internal hex wrench to hold the neutral adjusting screw (D015) stationary while

loosening the lock nut (D060) with a 13 mm wrench.

3. If necessary, turn adjusting screw to reduce any existing pressure dierential.

4. Rotate the neutral adjusting screw (D015) clockwise until the pressure increases in one

of the pressure gauges. Note the angular position of the wrench. Then rotate the neutral

adjusting screw counterclockwise until the pressure increases by an equal amount on the

other gauge. Again note the angular position of the wrench.

5. Rotate the neutral adjusting screw clockwise half the distance between the wrench position

noted above. The gauges should read the same pressure, indicating that the control is in its

neutral position.

6. Hold the neutral adjusting screw stationary. Tighten the lock nut (D060). Torque lock nut to

12 N•m [8.9 lbf•ft]. Do not overtorque the nut.

7. When the neutral position is set, stop the prime mover, remove the gauges, and install the

gauge port plugs. Reconnect the external control input.

© Danfoss, 2016 AN00000347en-US | 11184963• Rev 0100 • October 2016 2

Loading...

Loading...