Page 1

Technical Information

Transit Mixer Axial Piston Motor

Size 070/084/089

powersolutions.danfoss.com

Page 2

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Revision history Table of revisions

Date Changed Rev

June 2017 Update to Engineering Tomorrow 0202

Mar 2014 Converted to Danfoss layout – DITA CMS BA

10 Aug 2012 New TMM images AD

15 Feb 2012 TMM detail view added AC

20 Jan 2012 Pictures` numbers were added, MMC change. AB

08 Dec 2011 First edition AA

2 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 3

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Contents

Revisions

Technical Specifications

Literature reference ........................................................................................................................................................................5

General description......................................................................................................................................................................... 5

TMM fixed displacement motor sectional view.................................................................................................................... 6

System schematic.............................................................................................................................................................................6

TMM technical data......................................................................................................................................................................... 7

Output Speed...............................................................................................................................................................................9

System Pressure...........................................................................................................................................................................9

Case Pressure................................................................................................................................................................................9

External Shaft Seal Pressure.................................................................................................................................................... 9

Temperature................................................................................................................................................................................. 9

Viscosity........................................................................................................................................................................................10

Filtration............................................................................................................................................................................................ 10

Case Drain.........................................................................................................................................................................................10

Reservoir............................................................................................................................................................................................10

Determination of nominal motor sizes..................................................................................................................................11

High-pressure relief valve (HPRV).............................................................................................................................................11

Anti-cavitation valve.....................................................................................................................................................................12

Loop flushing shuttle spool........................................................................................................................................................12

Loop flushing relief valve............................................................................................................................................................12

Speed sensor description............................................................................................................................................................13

Speed and temperature sensor...........................................................................................................................................13

Sensor PPU, KPP*13808..........................................................................................................................................................14

Master Model Code

TMM master model code............................................................................................................................................................ 15

Operation

Bearing life........................................................................................................................................................................................17

Bearing life with no external shaft side load...................................................................................................................17

External radial shaft loads......................................................................................................................................................17

Mounting Flange Loads...............................................................................................................................................................18

Estimating overhung load moments.................................................................................................................................18

Output shafts...................................................................................................................................................................................19

Installation drawings

Dimensions.......................................................................................................................................................................................22

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 3

Page 4

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Revisions

4 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 5

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

Literature reference

Further available literature

Title

Speed and Temperature Sensor

Hydraulic Fluids and Lubricants

Design Guideline for Hydraulic Fluid Cleanliness

TMM Axial Piston Motor

General description

This motor is designed primarily to be combined with others pumps in closed circuit system to transfer

hydraulic power, especially for Transit Mixer Application.

Innovation with reliable technology

•

Loop flushing device integrated

•

High pressure relieve valves integrated

•

Anti-cavitation valves – optional

•

Speed and temperature sensor – optional

•

Speed sensor

•

Metric / Inch connections

•

High pressure ports for 3000 and 6000 psi on one side

•

Sizes: 70 cm3, 84 cm3 and 89 cm

•

3

Type

Technical Information

Technical Information

Technical Information

Service Manual

Literature number

11046759

520L0463

520L0467

L1211037

TMM fixed displacement motor

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 5

Page 6

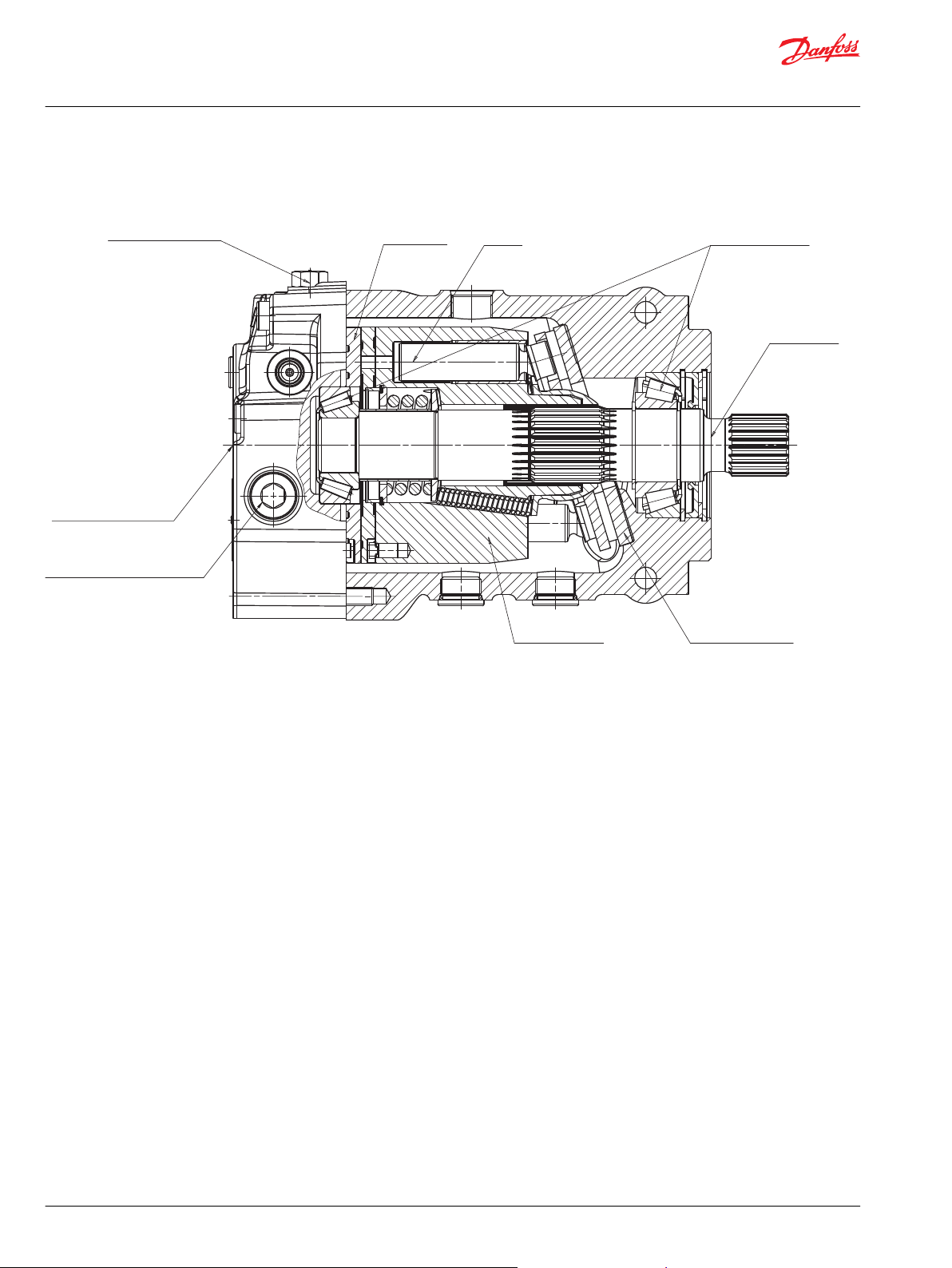

Anti-cavitation valve

High pressure relieve valve

Loop flushing valve

Valve plate

Piston

Conical bearings

Output shaft

Fixed swashplate

Cylinder block

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

TMM fixed displacement motor sectional view

TMM cross-sectional view

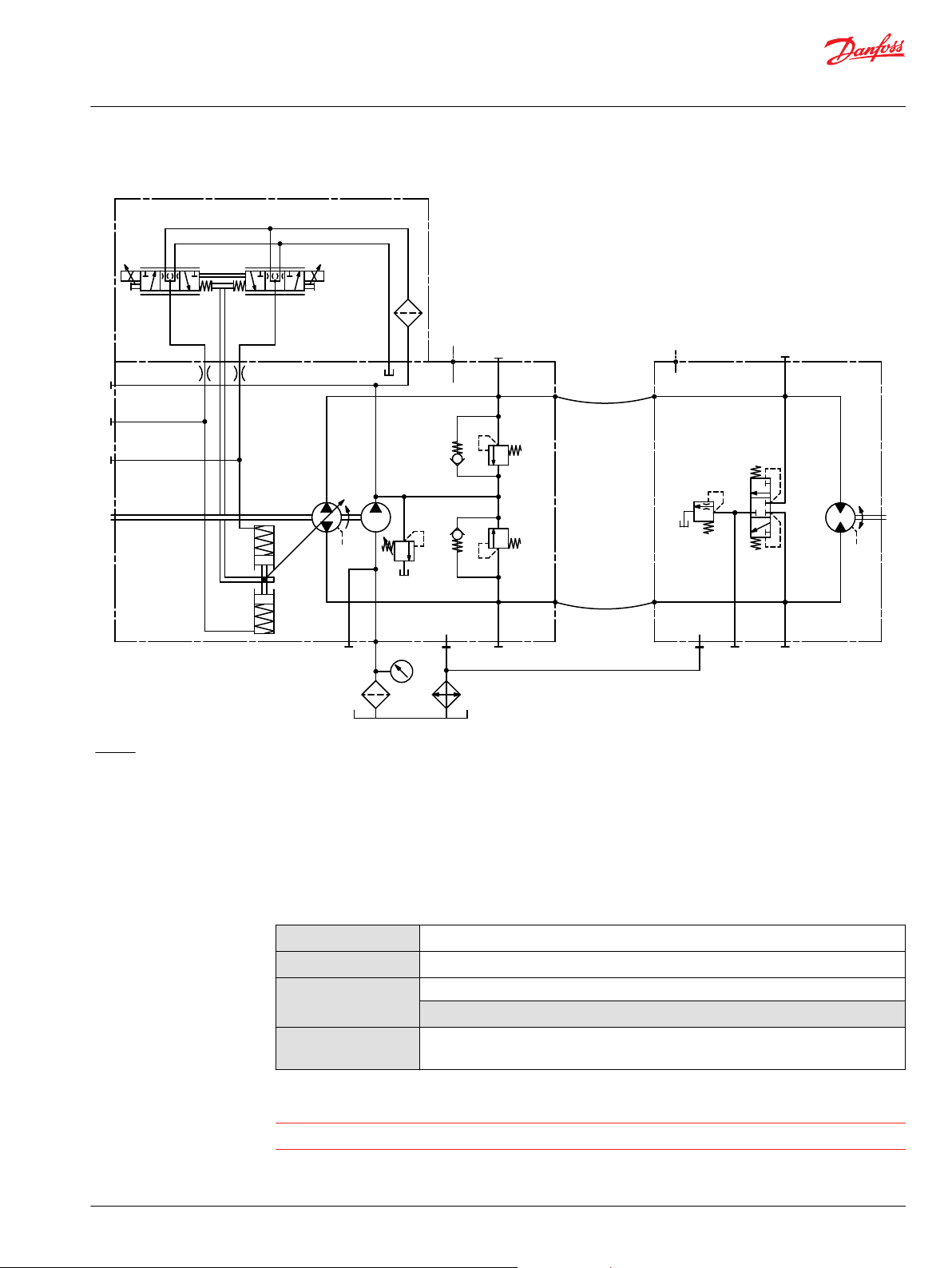

System schematic

The schematic below shows the function of a hydrostatic transmission using a TMP axial variable

displacement pump with electric proportional displacement control (EDC) and a TMM fixed displacement

motor with integrated loop flushing device.

6 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 7

AA

B B

L2 M3

M3

M5

M4

TMMTMP

M2L2

S

M2

M10

L1

C2C1

M1 L1 M1

W

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

TMM with TMP EDC

Legend:

A, B – System ports

L1, L2 – Case drain ports

M1, M2 – System A/B gage ports

M3 – Charge gage port, after filtering

M4, M5 – Servo gage ports

M10 – Charge pump inlet pressure port

S – Charge inlet port

Detailed information about ports see the section Installation drawings, pages Dimensions on page 22.

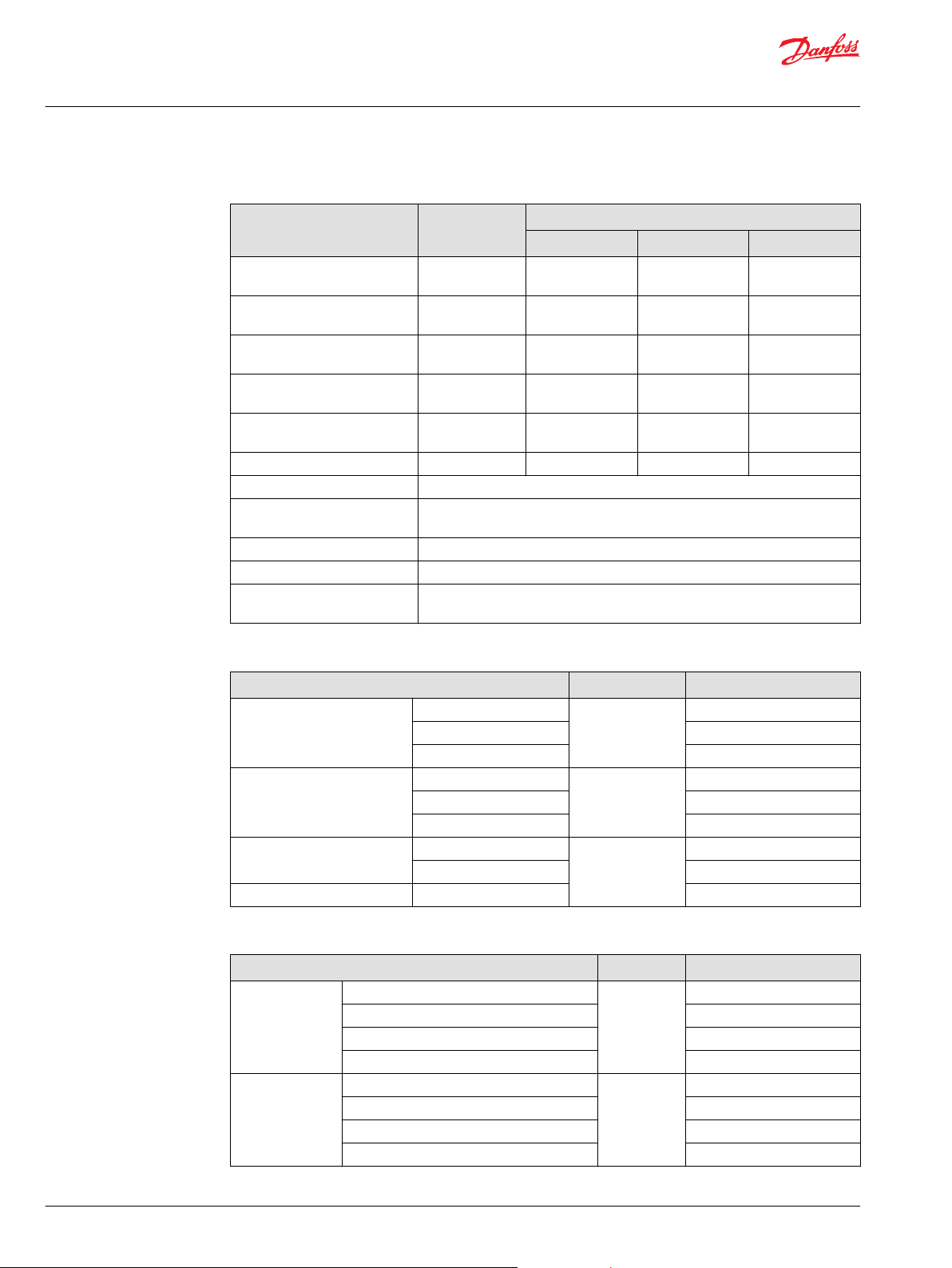

TMM technical data

General specifications

Design

Direction of rotation

Pipe connections

Recommended

installation position

Axial piston motor with fixed swashplate design with fixed displacement

Bi-directional

Main pressure ports: ISO split flange boss

Remaining ports: ISO/SAE straight thread O-ring boss

Motor installation position is discretionary

The housing must always be filled with hydraulic fluid. .

Warning

The front shaft seal must not be exposed to oil pressure from outside of the unit.

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 7

Page 8

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

Technical data

Features Unit Size

Displacement maximum cm

Flow at rated (continuous) speed l/min

Torque (theoretical) N•m/bar

Mass moment of inertia of

rotating components

Weight dry (standard) kg

Oil volume l [US gal] 2 [0.53] 2 [0.53] 2 [0.53]

Mounting flange SAE ISO 3019/1 flange 127-4 (SAE C), M12x1,75

Output shaft Spline shaft SAE, 21 teeth, pitch = 16/32

Main port configuration Twin ports SAE J518b Size 1, with metric or inch screws

Case drain ports L1, L2 M22x1,5 (O-ring boss) or 7/8–14 UNF-2B

Other ports ISO straight thread O-ring boss or SAE. See Installation drawings, page

3

[in3]

[US gal/min]

[lbf•in/1000 psi]

2

kg•m

[lbf•ft2]

[lb]

Spline shaft SAE, 23 teeth, pitch = 16/32

Dimensions on page 22.

070 084 089

68.3

[4.17]

171

[45.2]

1.09

[665]

0.0209

[0.0159]

34.8

[76.9]

83.8

[5.11]

209.5

[55.3]

1.33

[812]

0.0209

[0.0159]

34.8

[76.9]

89.0

[5.43]

222.5

[58.8]

1.42

[867]

0.0209

[0.0159]

34.8

[76.9]

Operating parameters

Features Unit 070/084/089

Output speed Minimum min-1 (rpm) 100

Rated 2500

Maximum 2900

System pressure Max. working pressure bar

Maximum pressure 450 [6525]

[psi]

420 [6090]

Minimum pressure 10 [145]

Case pressure Rated bar

Maximum 5.0 [73]

[psi]

3.0 [44]

Lip seal external pressure Maximum 0.4 [5.8]

Fluid specifications

Features Unit 070/084/089

Viscosity Intermittent

Minimum 7 [49]

Recommended range 12-80 [66-370]

Maximum 1600 [7500]

Temperature

2

range

Minimum (cold start)

Recommended range 60-85 [140-185]

Rated 104 [220]

Maximum intermittent

1

3

1

mm2/s [SUS] 5 [42]

°C [°F] -40 [-40]

115 [240]

8 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 9

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

Fluid specifications (continued)

Features Unit 070/084/089

Filtration

(recommended

minimum)

1

Intermittent = Short term t < 1 min per incident and not exceeding 2 % of duty cycle based load-life

2

At the hottest point, normally case drain port

3

Cold start = Short term t < 3 min, p ≤ 50 bar [725 psi], n ≤ 1000 min-1(rpm)

Output Speed

Minimum speed is the lowest output speed. Operating below minimum speed limits the system can be

unstable.

Rated speed is the highest input speed recommended at full power condition. Operating at or below

this speed should yield satisfactory product life.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces product

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

Cleanliness per ISO 4406 22/18/13

Efficiency (charge pressure filtration) β-ratio β15-20 = 75 (β10 ≥ 10)

Efficiency (suction and return line filtration) β35-45 = 75 (β10 ≥ 2)

Recommended inlet screen mesh size µm 100 – 125

System Pressure

Maximum working pressure is the highest recommended application pressure; and it is not intended to

be a continuous pressure. Propel systems with application pressures at, or below, this pressure should

yield satisfactory unit life given proper component sizing.

Maximum pressure is the highest allowable application pressure under any circumstance. Application

pressures above maximum working pressure will only be considered with duty cycle analysis and factory

approval.

Minimum pressure must be maintained under all operating conditions to avoid cavitation.

Case Pressure

Under normal operating conditions, the rated case pressure must not be exceeded. During cold start,

case pressure must be kept below maximum intermittent case pressure.

External Shaft Seal Pressure

In certain applications, the input shaft seal may be exposed to external pressures.

The shaft seal is designed to withstand an external pressure up to 0.4 bar [5.8 psi] above the case

pressure.

The case pressure limits must also be followed to ensure the shaft seal is not damaged.

Temperature

High temperature limits apply at the inlet port of the motor. The motor should run at or below the

maximum continuous temperature.

Cold oil generally does not affect the durability of motor components. It may affect the ability of oil to

flow and transmit power. For this reason, keep the temperature at 16°C

[60 °F] above the pour point of the hydraulic fluid.

Minimum (cold start) temperature relates to the physical properties of component materials.

Maximum continuous temperature is the allowed temperature at which normal life can be expected.

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 9

Page 10

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

Peak (intermittent) temperature: the overheating temperature that is tolerable by the machine for a

transient/limited time.

Viscosity

Minimum viscosity occurs only during brief occasions of maximum ambient temperature and severe

duty cycle operation. It's the minimum acceptable viscosity to allow normal motor life.

Maximum viscosity occurs only during cold start at very low ambient temperatures. It's the upper limit

of viscosity that allows the motor to start.

Temperature and viscosity requirements must be concurrently satisfied. Use petroleum/mineral-based

fluids.

Filtration

To prevent premature wear, ensure only clean fluid enters the hydrostatic transmission circuit. A filter

capable of controlling the fluid cleanliness to ISO 4406 class 22/18/13

(SAE J1165) or better, under normal operating conditions, is recommended.

These cleanliness levels can not be applied for hydraulic fluid residing in the component housing/case or

any other cavity after transport.

Filtration strategies for TMP include only suction filtration. The selection of a filter depends on a number

of factors including the contaminant ingression rate, the generation of contaminants in the system, the

required fluid cleanliness, and the desired maintenance interval. Filters are selected to meet the above

requirements using rating parameters of efficiency and capacity.

Filter efficiency can be measured with a Beta ratio¹ (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration, a filter with a β-ratio within the

range of β35-45 = 75 (β10 ≥ 2) or better has been found to be satisfactory. For some open circuit systems,

and closed circuits with cylinders being supplied from the same reservoir, a considerably higher filter

efficiency is recommended.

This also applies to systems with gears or clutches using a common reservoir.

For these systems, a charge pressure or return filtration system with a filter β-ratio in the range of β15-20

= 75 (β10 ≥ 10) or better is typically required.

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. Please see Design Guidelines for Hydraulic Fluid Cleanliness Technical Information,

520L0467 for more information.

1

Filter βX-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the

number of particles greater than a given diameter (“x” in microns) upstream of the filter to the number of

these particles downstream of the filter.

Case Drain

All TM pumps and motors are equipped with two case drain ports. Port selection and case drain routing

must enable the pump housing to maintain a volume of oil not less than half full and normal operating

case pressure limits of the unit are maintained. Case drain routing and design must consider unit case

pressure ratings.

A case drain line must be connected to one of the case outlets to return internal leakage to the system

reservoir.

Reservoir

The reservoir provides clean fluid, dissipates heat, removes entrained air, and allows for fluid volume

changes associated with fluid expansion during system operation. A correctly sized reservoir also

accommodates maximum volume changes during all system operating modes. It promotes de-aeration

10 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 11

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

of the fluid as it passes through, and accommodates a fluid dwell-time between 60 and 180 seconds,

allowing entrained air to escape.

Minimum reservoir capacity depends on the volume required to cool and hold the oil, allowing for

expansion due to temperature changes. A fluid volume of one to three times the motor output flow (per

minute) is satisfactory. The minimum recommended reservoir capacity is 125% of the fluid volume.

Put the return-line below the lowest expected fluid level to allow discharge into the reservoir for

maximum dwell and efficient de-aeration. A baffle (or baffles) between the return and suction lines

promotes de-aeration and reduces fluid surges.

Determination of nominal motor sizes

Use these formulae to determine the nominal motor size for a specific application:

Based on SI units Based on US units

Input flow: Q

l/min [US gal/min]

Output torque: M

N•m [lbf•in]

Output power: P

kW [hp]

Speed: n

-1

min

e

e

e

Variables: SI units [US units]

V

p

p

∆p

n

η

η

η

g

high

low

v

mh

t

=

Motor displacement per rev.

=

High pressure

=

Low pressure

=

p

– p

high

=

=

=

=

low

Speed

Motor volumetric efficiency

Mechanical (torque) efficiency

Overall efficiency (ηv • ηmh)

cm3/rev [in3/rev]

bar [psi]

bar [psi]

bar [psi]

min-1 (rpm)

High-pressure relief valve (HPRV)

The TM motors are optionally equipped with a combination of high-pressure relief and check valve. The

high-pressure relief function is a dissipative pressure control valve for the purpose of limiting excessive

system pressures. Each side of the transmission loop has a dedicated HPRV valve that is non-adjustable

with a factory set pressure.

When system pressure exceeds the factory setting of the valve, oil is passed from the high pressure

system loop into the low pressure system loop via the check valve.

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 11

Page 12

B

A

L1

M1

L2 M3 M2

High-pressure relief valve

High-pressure relief valve

Anticavitation valve

Loop Flushing Shuttle Spool

Loop Flushing Relief Valve

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

TMM with High-pressure relief Valves and Anticavitation Valve

Anti-cavitation valve

The TM motors are optional equipment with anti-cavitation valve (ACV). ACV has to garantee a minimum

oil pressure in the low pressure side in case of low engine speed and high oil temperature.

Loop flushing shuttle spool

Loop flushing relief valve

An integral loop flushing shuttle spool is used to separate system A and system B pressures, see the

schematic below.

System delta pressure will cause the shuttle spool to shift, allowing the low side system pressure to flow

to the loop flushing relief valve.

Loop flushing shuttle valve section

Schematic

The loop flushing relief valve is incorporated into all TMM motors. Use the loop flushing option in

Installations that require fluid to be removed from the low pressure side of the system circuit due to

cooling requirements and also used to facilitate the removal of contaminants from the loop.

12 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 13

0

4

8

12

16

20

24

28

0 2 4 6 8 10

432

1

12 14 16 18

Low system pressure minus case pre ssure (bar)

Case flow (l/min)

Case flow (US gal/min)

A3, 5 bar

A3, 13 bar

D2, 13 bar

4

3 2 1

P005418

5 6

Speed and temperature sensor

Connector

89.1 [3.508]

121.7 [4.79]

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

The loop flushing valve is equipped with an orificed charge pressure relief valve designed with a cracking

pressure of 5.5, 13 and 16 bar. Valves are available with several orifice sizes to meet the flushing flow

requirements of all system operating conditions.

Loop flushing flow curves

Speed sensor description

Speed and temperature sensor

Function of the speed sensor is to detect the shaft speed and the direction of rotation.Typically the

sensor will be mounted to the housing of a Danfoss pump or motor and senses the speed from a target

ring that is rotating inside the pump or pistons in cylinder block in motor. Because of the digital output

signals for speed and direction and a non speed dependent output voltage level, the sensor is ideal for

high and low speed measurements.

For diagnostics and other purposes, the sensor also has the capability to detect the case oil temperature.

The speed sensor is designed for rugged outdoor, mobile or heavy industrial speed sensing applications.

The detection of the speed is contactless. It is custom-designed for Danfoss. It is a “plug and perform”

device that does not need any calibration or adjustments.

Connector, type DEUTSCH DTM-Series 6-Pin (DTM06-6S) pins need to be gold plated;

9 pistons (impulses per revolution);

Order number: 149055.

Connector, type DEUTSCH DTM-Series 6-Pin

Speed and temperature sensor

(DTM06-6S)

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 13

Sensor pinout:

1 – Speed signal 2

2 – Direction signal

3 – Speed signal 1

4 – Supply

5 – Ground

Page 14

Packard Metri-Pack 150 Series

4-way Connector (male)

Green

Black

White

Red

Direction

Ground

Speed signal

Power +

Connector: 12162144

Terminals: 12048074

Seals: 12048086

Connector

Target ring

200mm long

speed sensor wire

Sensor PPU, KPP* 13808

(85) [3.346]

129.2 [5.087]

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Technical Specifications

6 – Temperature

Sensor PPU, KPP*13808

Function of the speed sensor is to detect the shaft speed and the direction of rotation.

Number of teeth on target ring: 65 (impulses per revolution)

Connector terminal

Sensor PPU, KPP*13808

14 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 15

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Master Model Code

TMM master model code

A – Product

TMM

B – Frame size / Displacement

070

084

089

C – Sense of rotation

B

Transit Mixer Motor

68.3 cm3/rev [4.17 in3/rev]

83.8 cm3/rev [5.11 in3/rev]

89.0 cm3/rev [5.43 in3/rev]

Bi-directional

G – End cap ports; High pressure setting

6MNN

3C35

6C42

Ports DN 25, Type 1, 420 bar [6000 psi], ISO 6162-2

Metric connections, without High-pressure relief valve

Ports DN 25, Type 2, 350 bar [3000 psi], ISO 6162-1

Inch connections, with High-pressure relief valve

Ports DN 25, Type 2, 420 bar [6000 psi], ISO 6162-2

Inch connections, with High-pressure relief valve

W – Special hardware features

NNN

NNC

2BN

9PN

9HN

Sensor- none, without Anticavitation valve

Sensor-none, with Anticavitation valve

Sensor PPU: KPP*13808 DIR SIGNAL “HIGH”/RIGHT, 65 impulsions/rev., without Anticavitation valve

Sensor none, Speed and temperature sensor of H1 ready (plugged), without Anticavitation valve

Speed and temperature sensor of H1, 9 impulsions/rev., without Anticavitation valve

L – Shaft

C

D

Splined shaft, 23 teeth, pitch = 16/32

Splined shaft, 21 teeth, pitch = 16/32

K – Loop flushing valve settings

A3F

A3M

D2M

Valve cone with 3x orifice ø1,5 mm and flow of 14,5 l/min by 25 bar,

Opening pressure 5,5 bar, (in conjunction with SPV, ACV)

Valve cone with 3x orifice ø1,5 mm and flow of 14,5 l/min by 25 bar,

Opening pressure 13 bar (in conjunction with SPV)

Valve cone with 2x orifice ø1,3 mm and flow of 10 l/min by 25 bar,

Opening pressure 13 bar(in conjunction with TMP)

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 15

Page 16

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Master Model Code

F – Special features

NSN

NDN

BSN

BDN

GSN

GDN

No paint, Name plate "Slovakia"

No paint, Name plate "Danfoss"

Black paint, Name plate "Slovakia"

Black paint, Name plate "Danfoss"

Gray paint, Name plate "Slovakia"

Gray paint, Name plate "Danfoss"

16 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 17

Size 070 L20 = 33 727 •

( ) • ( )

240

p

1800

n

⁄

Size 084 L20 = 17 090 •

( ) • ( )

240

p

1800

n

⁄

Size 089 L20 = 13 952 •

( ) • ( )

240

p

1800

n

⁄

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Operation

Bearing life

Bearing life with no external shaft side load

Normal bearing life with no external shaft side load in L20 hours is shown in the table below. The figures

reflect a continuous delta pressure, shaft speed, maximum displacement, and no external shaft side load.

The data is based on a standard charge pressure of 20 bar [290 psi].

Bearing life with no external shaft side load

Unit Size 070 Size 084 Size 089

Shaft speed

Delta pressure – ∆p

Bearing life – L

Conversion of bearing life for other pressure (p) and speed (n):

20

min-1 (rpm) 1800 1800 1800

bar [psi] 240 [3480] 240 [3480] 240 [3480]

hours 33 727 17 090 13 952

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 17

External radial shaft loads

TM motors are designed with bearings that can accept some external radial and axial loads.

The external radial shaft load limits are a function of the load position and orientation, and the operating

conditions of the unit. The maximum allowable radial load (Re) is based on the maximum external

moment (Me) and the distance (L) from the mounting flange to the load. In applications with external

radial shaft loads, minimize the impact by positioning the load at 0° or 180° as shown in the figure below.

The external radial and axial shaft load are limited by the bearing life L20 =10 000 [h], delta system

pressure 240 bar, speed 1800 min-1 and external radial load at 270°.

It may be determined using the following table and formula below.

Maximum external shaft load for size 089

External radial moment – M

External axial force – F

External axial force – F

in

out

e

N•m [lbf•in] 0 32.6 [288]

N [lbf] -2440 [-548] -2020 [-454]

2790 [627] 2400 [539]

Page 18

L

F out (+)

270° Re

Re

Me

180° Re

90° Re

0° Re

F in (-)

e

=

M

e

Based on SI units: Based on US units:

M = g • G • W • L M = G • W • L

Where:

M = Rated load moment N•m [lbf•in]

g = Gravity 9.81 m/s

2

G = Calculation factor for max. acceleration 30

W = Weight of pump kg [lb]

L = Distance from mounting f ange to pump center of gravity m [in]

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Operation

Radial load position

Where:

Me = shaft moment

L = flange distance

Re = external force to the shaft

Contact your Danfoss representative for an evaluation of unit bearing life.

Mounting Flange Loads

Estimating overhung load moments

TMM load moment M

18 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 19

W

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Operation

Rated and maximum torque ratings

W L Max. load moment M

35 kg [77 lb] 0,1338 mm [5.268 in] 1378 N•m [12 170 lbf•in]

Output shafts

Rated and maximum torque ratings for each available shaft is shown in the following table:

Specifications

Spline Min active spline length Rated torque* Maximum torque**

mm [in] N•m [lbf•in] N•m [lbf•in]

21 teeth, 16/32 pitch 30.7 [1.21] 660 [5840] 1200 [10 620]

23 teeth, 16/32 pitch 30.7 [1.21] 790 [6990] 1600 [14 160]

1

The specified torque rating of the shaft documented above is based on the cross-sectional diameter of

the shaft, through the keyway, and assumes the proper clamp and fit between shaft and coupling.

Danfoss guarantees the design and manufactured quality of the splined shaft. The customer is

responsible for the design and manufactured quality of the mating female coupling and key and applied

torque on the nut.

Danfoss has made provisions for the key in accordance to the ISO specification with the understanding

that the key is solely to assist in the installation of the mating coupling.

Warning

Torque or loading inadvertently transmitted by the customer supplied key may lead to premature shaft

failure.

1

* Rated torque - measure of teeth wear. ** Maximum torque - ratings are based on torsional fatigue strength

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 19

Page 20

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Operation

ISO 3019-1 (SAE C, 23-teeth)

20 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 21

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Operation

ISO 3019-1 (SAE C, 21-teeth)

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 21

Page 22

Gauge Port M2

System Pressure Port B

M12x1.5

Optional: 9/16-18 UNF-2B

Gauge Port M3

Flushing Pressure

M12x1.5

Optional: 9/16-18 UNF-2B

Loop Flushing Valve

Gauge Port M1

System Pressure Port A

M12x1.5

Optional: 9/16-18 UNF-2B

High Pressure

Relief Valve

Port ‘A’

High Pressure

Relief Valve

Port ‘B’

Charge Pressure Relief Valve

Anticavitation Valve

190.6

[7.504]

146 ±2.8

[5.748 ±0.11]

164 ±2

[6.457 ±0.079]

190 ±1.6

[7.47 ±0.063]

205

[8.071]

Ø15

[DIA 0.591 ]

0.8

-0.3

0.031

-0.012

57.25 (2x)

[2.254 ]

0.3

-0.5

0.012

-0.020

57.25 (2x)

[2.254 ]

0.3

-0.5

0.012

-0.020

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Installation drawings

Dimensions

TMM ports

22 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 23

Case drain M22x1.5

Optional: 7/8-14UNF-2B

Optional: Port for sensor PPU

7/8-14UNF-2B

Optional: M22x1.5

Case drain port

M22x1.5

Optional: 7/8-14UNF-2B

Primer Free

(Entire surface)

Primer Free

(Entire surface)

2x Split flange boss per

ISO 6162-1 FPS1x25 or FPS2x25

except as noted

(centerline distances)

2x Split flange boss per

ISO 6162-1 FPS1x25 or FPS2x25

except as noted

(centerline distances)

Plugged - ready for speed

and temperature sensor

Optional: Speed and

temperature sensor

73

[2.874]

100

[3.937]

95

[3.74]

95.6

[3.764]

73

[2.874]

125

[4.921]

119

[4.685]

250

[9.843]

252

[9.921]

Ø50

[DIA 1.97]

Ø24 (2x)

[DIA 0.945]

41.6 (2x)

[1.638]

219

[8.622]

13

[0.512 ]

1.2

-0.5

0.047

-0.020

85

[3.346]

85

[3.346]

L2

P005416E

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Installation drawings

TMM dimensions

Ports description

Port Description TMM without HPRV TMM with HPRV

A, B

L1, L2

M1, M2

M3

System ports ISO DN25 SAE Ø 25.4 mm

Case drain ports M22x1.5 7/8-14

System A/B gauge ports M12x1.5 9/16-18

Flushing pressure port M12x1.5

Please contact Danfoss for specific installation drawings.

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 23

Page 24

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

24 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 25

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202 | 25

Page 26

Technical Information

TMM Transit Mixer Axial Piston Motor, Size 070/084/089

26 | © Danfoss | June 2017 L1108123 | BC00000193en-US0202

Page 27

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | June 2017 L1108123 | BC00000193en-US0202

Loading...

Loading...