Page 1

System Description

System

Hitch Control

www.danfoss.com

Page 2

System Description

Hitch Control

Revision history Table of revisions

Date Changed Rev

March 2020 Updated 'Angle sensor for displacement control' description. 0203

July 2017 Updated recommended suppliers summary 0202

August 2015 Converted to Danfoss layout BA

December 2008 AA

2 | © Danfoss | March 2020 11036124 | AB152886482484en-000203

Page 3

System Description

Hitch Control

Contents

Overview

System details

Control options

Hardware components

Application software

Features and benefits

About this document......................................................................................................................................................................4

Referenced product specific documents.................................................................................................................................4

Microcontroller............................................................................................................................................................................ 4

Valves...............................................................................................................................................................................................4

Software..........................................................................................................................................................................................4

System start-up procedures....................................................................................................................................................4

Latest version of technical literature....................................................................................................................................4

PLUS+1® electronic controls responsibility.............................................................................................................................4

Hitch positioning control concepts........................................................................................................................................... 4

Closed loop work control modes................................................................................................................................................6

Combination of position, force and slip control..............................................................................................................6

Adaptive force control...............................................................................................................................................................6

Fast down control.......................................................................................................................................................................6

In-cab control from HMI............................................................................................................................................................6

Remote operation.......................................................................................................................................................................7

Closed loop transport modes.......................................................................................................................................................7

Rear hitch active damping.......................................................................................................................................................7

Front hitch active damping.....................................................................................................................................................7

Overview..............................................................................................................................................................................................8

PVBZ double-acting actuator control....................................................................................................................................... 8

PVBZ-HS single-acting actuator control...................................................................................................................................8

PVBZ-HD single and double-acting actuator control..........................................................................................................9

Hitch valves...................................................................................................................................................................................... 10

Sensors...............................................................................................................................................................................................10

Draft sensors for force control............................................................................................................................................. 10

Angle sensor for displacement control............................................................................................................................ 10

Ground speed radar.................................................................................................................................................................10

Microcontrollers............................................................................................................................................................................. 10

PLUS+1® controller power supply specification............................................................................................................10

MC024-01A controller for 10 Vdc draft sensors.............................................................................................................10

HWD for PLUS+1® controllers...............................................................................................................................................11

Application block software description.................................................................................................................................12

PLUS+1® GUIDE...............................................................................................................................................................................12

PLUS+1® Service Tool....................................................................................................................................................................12

PLUS+1® Service Tool functions...........................................................................................................................................12

Keyed PLUS+1® application block software and application hardware............................................................... 12

Customer access to the Hitch application block................................................................................................................ 12

Application file contents........................................................................................................................................................12

Application file download and installation in GUIDE..................................................................................................12

Standard features...........................................................................................................................................................................13

Optional features........................................................................................................................................................................... 13

Benefits.............................................................................................................................................................................................. 13

©

Danfoss | March 2020 11036124 | AB152886482484en-000203 | 3

Page 4

System Description

Hitch Control

Overview

About this document

This document provides general information about the PLUS+1® Hitch Control System application block.

In addition, it is a reference tool for vehicle OEM design, engineering, and service personnel.

This document is one of several sources of technical information for the hitch control system. Other

sources of technical information include individual product data sheets and application block manuals,

PLUS+1® GUIDE User Manual, and PLUS+1® Service Tool User Manual.

Referenced product specific documents

Documentation for support, development, design, and implementation of the solution.

Microcontroller

•

PLUS+1® Controller Family Technical Information, 520L0719

•

PLUS+1® MC024-01A Controller Data Sheet, 11030820

Valves

•

PVG Proportional Valves Brochure, 520L0690

•

PVG 32 Proportional Valves Technical Information, 520L0344

•

Basic Module Type PVBZ Valve (hitch double-acting) Data Sheet, 520L0681

•

Basic Module Type PVBZ-HS Valve (hitch single-acting) Data Sheet, 520L0956

•

Basic Module Type PVBZ-HD Valve (hitch double-acting) Data Sheet, 11035599

Software

•

PLUS+1® GUIDE Data Sheet, 520L0708

•

PLUS+1® GUIDE User Manual, 10100824

•

PLUS+1® Service Tool User Manual, 520L0899

•

Hitch Control Application Block User Manual, 11033753

System start-up procedures

•

Recommended System Start-up Procedures Technical Information, 11010667

Latest version of technical literature

Comprehensive technical literature is online at www.danfoss.com

PLUS+1® electronic controls responsibility

The manufacturer of a machine or vehicle using PLUS+1® electronic controls is responsible for correctly

applying and programming GUIDE-programmable PLUS+1® products. Danfoss strongly recommends that

the OEM perform a system-level Failure Mode Effects Analysis (FMEA).

You can find additional information about OEM responsibilities in the:

•

PLUS+1® Controller Family Technical Information, 520L0719

•

Recommended System Start-up Procedures Technical Information, 11010667

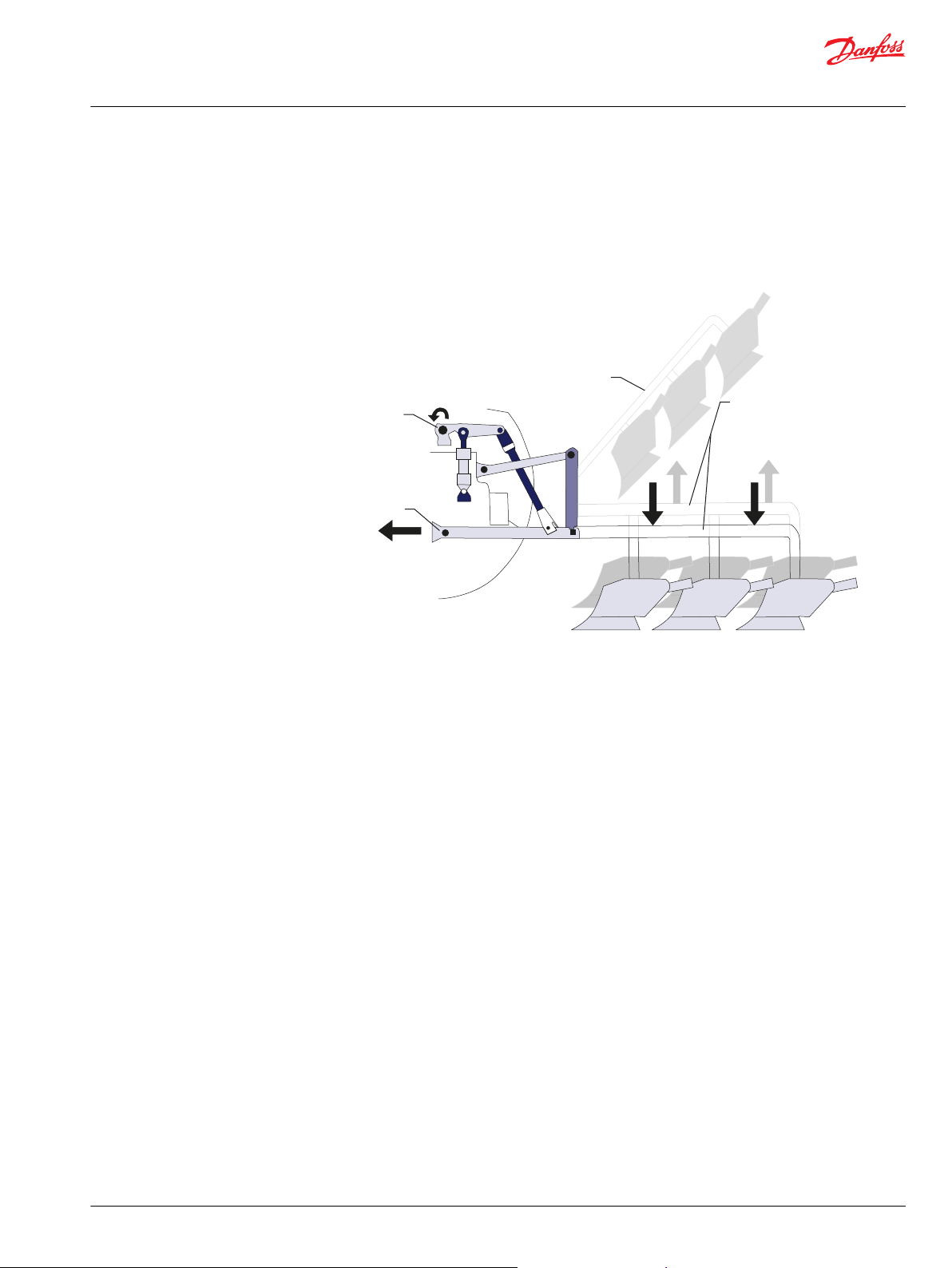

Hitch positioning control concepts

The purpose of the hitch control system is to allow the operator to position the hitch linkage either in a

work or transport position. Set points for transport and work are adjustable parameters. A closed loop

position control compares the set-point to the actual input from the position sensor. If there is a

difference, it controls the valve to lower or raise the linkage.

The goal of an automated hitch control system is to:

4 | © Danfoss | March 2020 11036124 | AB152886482484en-000203

Page 5

Lower

Lift

Force

Transport mode with

active damping

Work mode:

Lift/ lower around lower

reference setting

Angle sensor

placement

Draft sensor placement

System Description

Hitch Control

Overview

Facilitate fast and easy attachment of implements to the tractor

•

Optimize the tractor implement output during field operation as measured in acres/hour or fuel

•

consumption/acres relative to manually controlled systems

Provide a safer and more comfortable transport of the implement between field operations

•

Typical rear hitch

©

Danfoss | March 2020 11036124 | AB152886482484en-000203 | 5

Page 6

Active damping

Speed scaling

ramp deadband

Valve

Danfoss

OEM supplied

OEM supplied

Danfoss Hitch Application Block

Feedback

sensors

Set-point creation and position control

Force control

Slip control

Reference setpoint

Raising and lowering speed

Human

Machine

Interface

(HMI)

3514

System Description

Hitch Control

System details

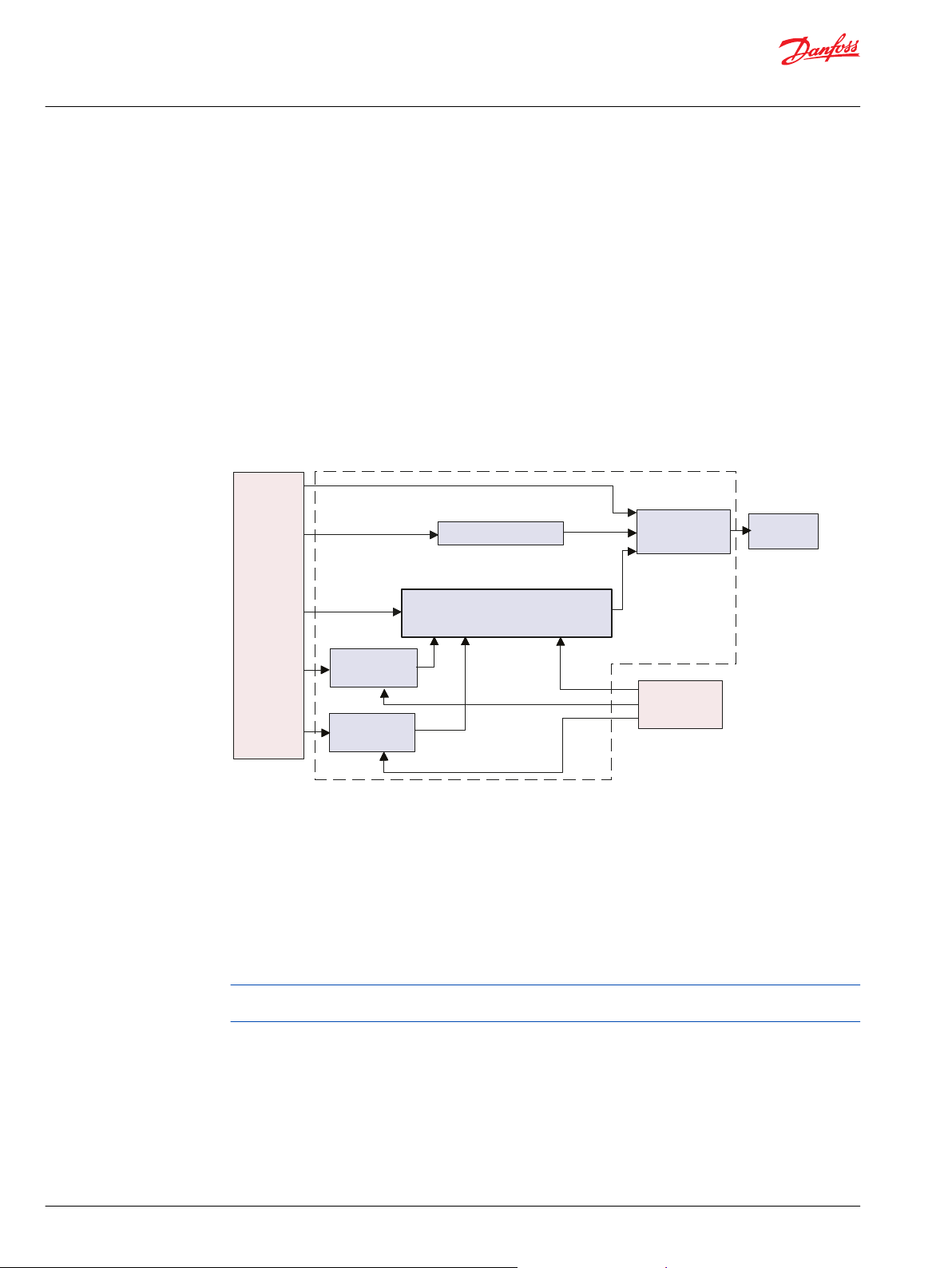

Closed loop work control modes

When the operator chooses work control mode, the position control adjusts the linkage to the depth

reference set point.

Combination of position, force and slip control

In work position it is not always possible for the tractor to do the job with the specified set point.

Therefore different sensors in the system collect information about the pull force and the wheel slip.

The system compares these inputs with an operator defined preset maximum value. If the current pull

force or wheel slip are higher than the preset maximum value, it calculates a delta and adds to the set

point for the work position.

When the set point is increased, the pull force/wheel slip decreases, and causes recalculation of the delta.

In this way, the system continually modulates the linkage position according to the sensor inputs.

Combined position, force and slip control

Adaptive force control

It is sometimes difficult for the operator to find the correct parameter settings for force control in some

work situations. Selecting adaptive force control allows the system to automatically adjust to changing

field conditions.

Fast down control

This mode gets the implement more quickly to the correct working depth.

Single acting: This mode bypasses the closed loop control and sends the valve to maximum lowering.

•

Maximum lowering is still subject to scale function according to implement weight, to avoid hazardous

lowering speeds.

Double acting: This mode maintains the closed loop control. The only difference to work mode is that

•

the digital output to switch between single and double acting, is set for double acting operation.

In-cab control from HMI

You can expand the Human Machine Interface (HMI) with up/down buttons or a joystick for manual

operation. In manual operation the operator gives direct input to the valve. This is very useful for

6 | © Danfoss | March 2020 11036124 | AB152886482484en-000203

attaching and detaching implements.

Page 7

System Description

Hitch Control

System details

Closed loop transport modes

Analog joystick: Control of the valve is proportional from zero to the specified maximum value.

•

Digital buttons: If the application uses on/off buttons, pressing the appropriate button sets the valve

•

to the specified maximum value.

Remote operation

It is possible to operate the hitch valve with buttons outside the cab. This operation overrides any other

mode, and leaves the system in safe state after operation. When back in the cab, the operator must

choose desired mode.

In transport mode, the position control adjusts the linkage to the upper limit set point.

Rear hitch active damping

When traveling with a heavy implement lifted, the tractor can start to oscillate around the rear axle. The

result is that the front wheels no longer have a steady contact with the road. Active damping can

modulate the linkage position to offset these oscillations. Normally, the draft sensors sense these

oscillations and provide the input signal to the control.

Front hitch active damping

Active damping can benefit a front hitch as well as the rear hitch. You can add pressure sensors to the

system to provide the necessary signals to the hitch control application block.

©

Danfoss | March 2020 11036124 | AB152886482484en-000203 | 7

Page 8

Sensors:

Pressure sensors

Angle sensor

Wheel speed

Ground speed radar

Hitch valve section PVBZ

Human Machine Interface (HMI)

(analog/CAN)

PLUS+1®

Controller

Sensors:

Draft sensors

Angle sensor

Wheel speed

Ground speed radar

Hitch valve section PVBZ-HS

Human Machine Interface (HMI)

(analog/CAN)

PLUS+1®

Controller

System Description

Hitch Control

Control options

Overview

Control for single and double acting hitch control systems are combined in one software application

block. This allows users to select the appropriate valve for the system. Options include single acting,

double acting, and switchable (between single and double acting).

PVBZ double-acting actuator control

The PVBZ meets basic market requirements for front hitches and auxiliary valves, that raise and lower

implements hydraulically. This includes the float feature.

Typical double-acting system used for front hitch

PVBZ-HS single-acting actuator control

The PVBZ-HS meets market requirements for single-acting rear hitches, that raise implements

hydraulically and lower them by gravity.

Typical single-acting system used for rear hitch

8 | © Danfoss | March 2020 11036124 | AB152886482484en-000203

Page 9

Sensors:

Draft sensors

Angle sensor

Wheel speed

Ground speed radar

Hitch valve section PVBZ-HD

Human Machine Interface (HMI)

(analog/CAN)

PLUS+1®

Controller

System Description

Hitch Control

Control options

PVBZ-HD single and double-acting actuator control

The PVBZ-HD is a more advanced alternative to the PVBZ or PVBZ-HS. This valve can operate either as

double-acting or single-acting.

The PVBZ-HD has the ability to raise, lower, press down, or float. In double-acting mode, the PVBZ-HD

increases comfort and safety when attaching and detaching heavy implements because of its ability to

raise and lower at the same speed. For field operation you may select either single or double-acting

mode.

Advanced switching between double or single-acting

©

Danfoss | March 2020 11036124 | AB152886482484en-000203 | 9

Page 10

System Description

Hitch Control

Hardware components

Hitch valves

Sensors

The valve options for the Danfoss hitch control system include PVBZ double-acting, PVBZ-HS singleacting, and the PVBZ-HD single and double-acting valves. These proven PVG 32 valves feature pressure

compensation, low leakage ports (P/O-check), and optional PVLP shock/anticavitation valves. These

features are contained in PLUS+1® Compliant valve sections that incorporate ISO bus compatible PVED

electrical actuation, making them easy to integrate into the vehicle hydraulic system.

Following is a summary of typical sensors and recommended suppliers:

Draft sensors for force control

Vendor: Vishay

Sensor excitation voltage requirements must be compatible with the selected PLUS+1® microcontroller

power supply rating.

Angle sensor for displacement control

Vendor: Danfoss

Danfoss DST X510 and DST X520 series uses contactless Hall technology with measurement ranges up to

360°.

All sensors are designed for off-highway applications and resistant to shock and vibrations and with high

electromagnetic compatibility, and come with both Ratiometric, CANopen and SAE J1939 output.

Single and redundant sensor types are available and are produced according to PL d (EN ISO

13849-1:2015), making the complete portfolio suitable for safety-critical applications

Microcontrollers

Ground speed radar

Vendor: Dickey-john

The Dickey-john RVSIII series Radar Velocity Sensors utilize Doppler radar technology to output a signal

that is proportional to ground speed.

A wide range of keyed PLUS+1® microcontrollers are available, including 24 pin, 50 pin, and 88 pin

models.

PLUS+1® controller power supply specification

Normal sensor power supply output specification for Danfoss microcontrollers is 5 Vdc. Output current

rating ranges from 200 mA to 500 mA depending on the microcontroller model you select for your

application. Please refer to individual microcontroller data sheets for additional details.

MC024-01A controller for 10 Vdc draft sensors

The MC024-01A is an element of the PLUS+1® family of mobile machine management products. It is a

keyed general-purpose controller equally suited for use in a distributed machine control system, or as a

stand-alone controller.

This controller has a 10 Vdc, 0.5 A sensor supply output for use with existing hitch sensors on the market

requiring a 10 Vdc power supply.

10 | © Danfoss | March 2020 11036124 | AB152886482484en-000203

Page 11

System Description

Hitch Control

Hardware components

HWD for PLUS+1® controllers

Danfoss provides hardware description files (*.HWD file) for PLUS+1® microcontrollers. Each .HWD file

includes the operating system software for a particular microcontroller. Select a microcontroller with

input/output and power supply specifications that is suitable for your application.

©

Danfoss | March 2020 11036124 | AB152886482484en-000203 | 11

Page 12

System Description

Hitch Control

Application software

Application block software description

The hitch control application block is a graphical representation of software algorithms that provide the

foundation for automated hitch control. Specific tailoring of the block is accomplished using Danfoss

PLUS+1® GUIDE tool set. GUIDE allows developers to build application software for use with Danfoss PLUS

+1® controllers. The PLUS+1® Service Tool is used to download the compiled application to the target

microcontroller.

PLUS+1® GUIDE

Customers use the hitch control application block as the starting point for a complete hitch system

application that includes input mapping, calibration, fault handling, output mapping, and connection for

HMI devices and microcontroller outputs.

The application block is released as a .SCS file, which means it can be dragged onto the GUIDE

programming workspace to be included as the application block for a complete, user-developed hitch

system application.

PLUS+1® Service Tool

The PLUS+1® Service Tool is included with the PLUS+1® GUIDE user license.

PLUS+1® Service Tool functions

Downloads software to keyed PLUS+1® hardware

•

Transfers data from the microcontroller to a PC

•

Provides interface for developing service screens for machine diagnostics, setup, and tuning

•

Keyed PLUS+1® application block software and application hardware

If the application hardware key matches the application software key 10106603 the service tool permits

the download to the target application hardware.

Customer access to the Hitch application block

The Hitch Control Application File, 70024823.ZIP

Application file contents

Software and documents enclosed in the application file include:

Hitch Control Application Block, 10108138 (*.SCS)

•

Hitch Control Application Block User Manual, 11033753 (*. PDF)

•

Hitch Control System Description, 11036124 (*.PDF)

•

Application file download and installation in GUIDE

After downloading the application file to your hard drive, you can install the application block code in the

My Blocks tab of the GUIDE component selector menu, for easy access during application development.

Software user manual and other technical information documents from the application file may be stored

in any convenient folder on your hard drive.

12 | © Danfoss | March 2020 11036124 | AB152886482484en-000203

Page 13

System Description

Hitch Control

Features and benefits

Standard features

Optional features

Single-acting and double-acting proportional valves as well as advanced multi-function valve that

•

can switch between single and double-acting

Available PLUS+1® microcontroller with a 10 Vdc sensor supply voltage suitable for general market

•

draft sensors

Wide range of standard PLUS+1® microcontrollers with 5 Vdc sensor power supply

•

Available I/O extension modules for the microcontroller to accommodate a larger number of analog

•

signals from the HMI, if needed

A generic, user-programmable application block software for controlling the hitch position

•

Other hitch control components, such as HMI controls and sensors, are typically OEM-specific, and are not

part of the Danfoss standard hitch control portfolio at this time. However, Danfoss can work with

customers to develop custom OEM-specific interface solutions.

In addition, Danfoss can assist with development of complete software solutions, tailored to specific

requirements of the OEM interface and HMI specifications, based on the application block that is

described in this document.

Benefits

Application block software is GUIDE programmable by end user: A complete software solution can be

•

created by extending the application block provided by Danfoss

Faster and easier prototyping, set-up and tuning

•

Simple logics—better user understanding

•

Single or double acting system in one software application

•

Double acting operation features enables higher safety and comfort

•

Precise control and repeatability

•

Simplified control of displacement force and slip factors

•

Safer attachment and removal of implements

•

Stable, closed-loop control in all operating modes

•

©

Danfoss | March 2020 11036124 | AB152886482484en-000203 | 13

Page 14

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | March 2020 11036124 | AB152886482484en-000203

Loading...

Loading...