Page 1

Data sheet

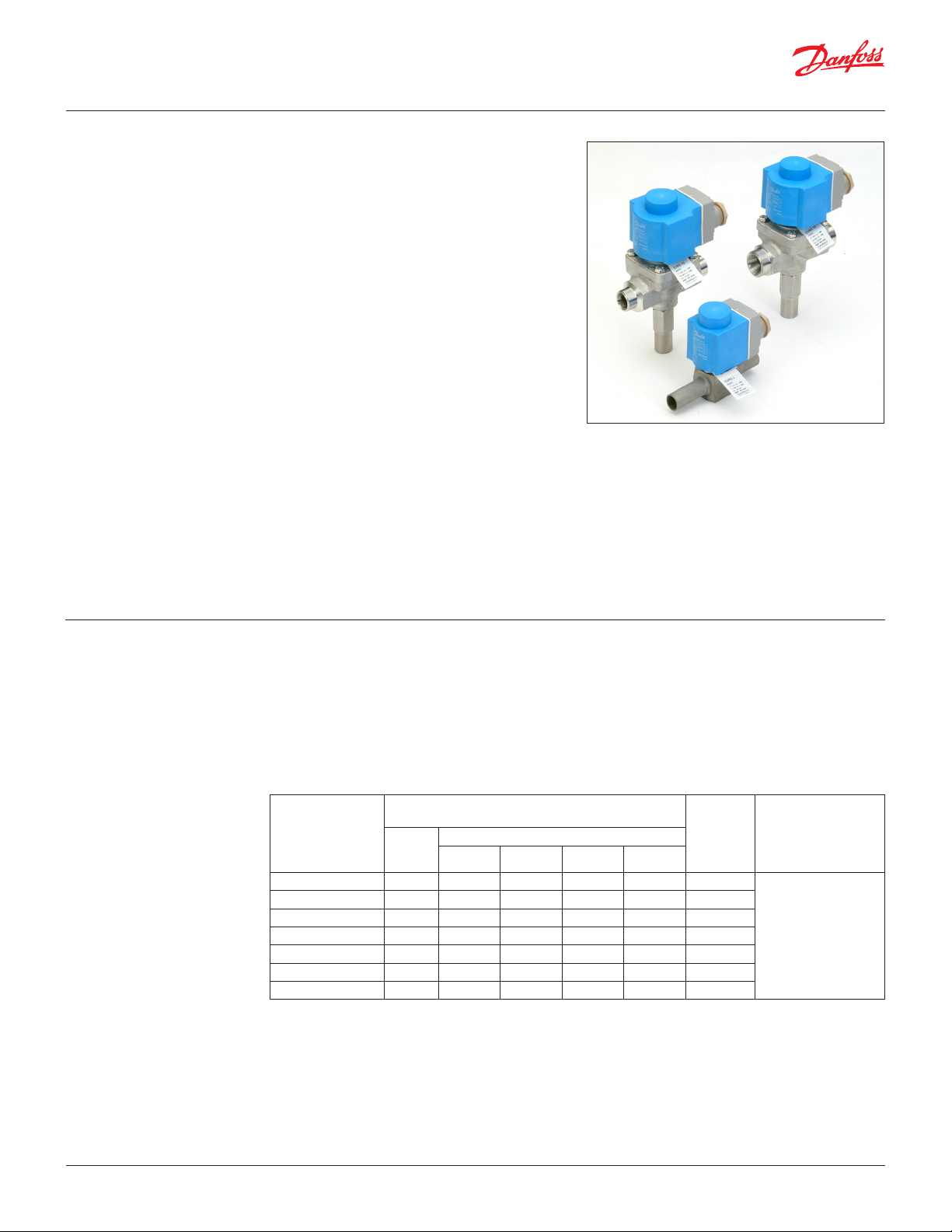

Industrial Refrigeration

Stainless Steel Valves

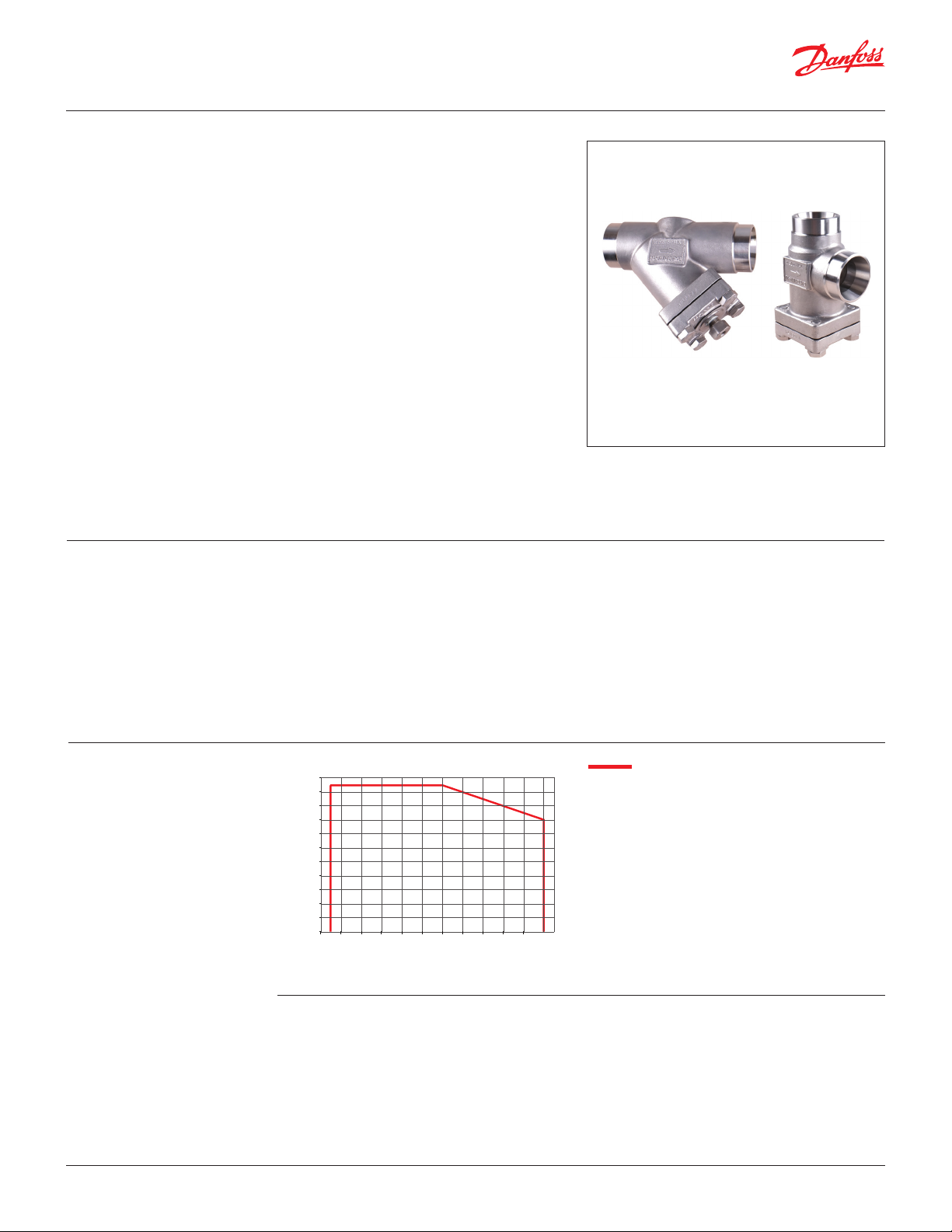

Shut-off valves SVA-S/L SS

Hand-operated regulating valves REG-SA/SB SS

Check & stop valves SCA-X SS

Check Valves CHV-X SS

Strainers FIA SS

Pressure regulating valves OFV-SS

Gauge valves SNV-SS

Solenoid valves EVRS/EVRST

Danfoss Industrial Refrigeration extends a range of

stainless steel valves for special

application requirements.

The valve range includes for valve sizes

DN 15 mm (1/2 in.) to DN 125 mm (5 in.) in angleway

and straight execution and includes:

The range has been extended to meet the

increased demand brought about by

1. the need for higher protection of external

surfaces on valves and fittings

2. the need to meet developments in the way

that plants are being designed.

In certain specific areas such as outdoor

applications and corrosive atmospheres, such as

coastal installations, there is a need for high surface

protection to prevent failure due to corrosion.

Today's food safety standards often call for daily

treatment with detergents to protect against

bacteria growth, again producing a need for high

surface protection.

Features

© Danfoss | DCS (ms) | 2020.01

• Optional accessories:

SVA-S/L SS X X

REG-SA/SB SS X

SCA-X SS X

CHV-X SS

FIA SS

OFV-SS X

Vented cap Handwheel

• Designed to give favourable flow conditions.

• Internal backseating enables replacement

of the spindle seal whilst the valve is active, i.e.

under pressure (SVA-S/L SS, REG-SA/SB SS,

SCA-X SS, OFV-SS).

• Housing is made of special cold resistant stainless

steel approved for low temperature operations.

• Easy to disassemble for inspection and service.

• SVA-S/L SS Shut-off valves can accept flow in

either direction.

• Compact and light valves for easy handling and

installation.

• Classification: DNV, CRN, BV, EAC etc.

To get an updated list of certification on the

products please contact your local Danfoss Sales

Company.

AI235186440137en-US1101 | 1

Page 2

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Contents Page

Shut-off valves SVA-S/L SS:

Features SVA-S/L SS ................................................................................................3

Pressure and temperature range....................................................................................3

Technical data .....................................................................................................3

Design.............................................................................................................4

Connections .......................................................................................................4

Material specification ..............................................................................................5

Dimensions and weights ...........................................................................................9

Ordering......................................................................................................... 12

Hand-operated regulating valves REG-SA SS and REG-SB SS:

Features REG-SA SS and REG-SB SS................................................................................ 14

Pressure and temperature range.................................................................................. 14

Technical data ...................................................................................................14

Design........................................................................................................... 15

Connections ..................................................................................................... 15

Computation and selection....................................................................................... 16

Material specification ............................................................................................ 22

Dimensions and weights ......................................................................................... 23

Ordering......................................................................................................... 24

Check & stop valves and check valves SCA-X SS and CHV-X SS:

Features SCA-X SS and CHV-X SS.................................................................................. 26

Pressure and temperature range.................................................................................. 26

Technical data ...................................................................................................26

Design........................................................................................................... 27

Connections ..................................................................................................... 27

Material specification ............................................................................................ 28

Dimensions and weights ......................................................................................... 29

Ordering......................................................................................................... 30

Strainers FIA SS:

Features FIA SS................................................................................................... 31

Pressure and ....................................................................................................31

temperature range............................................................................................... 31

Technical data ...................................................................................................31

Design........................................................................................................... 32

Connections ..................................................................................................... 32

Selection of strainer size.......................................................................................... 33

Material specification ............................................................................................ 34

Dimensions and weights ......................................................................................... 35

Ordering......................................................................................................... 36

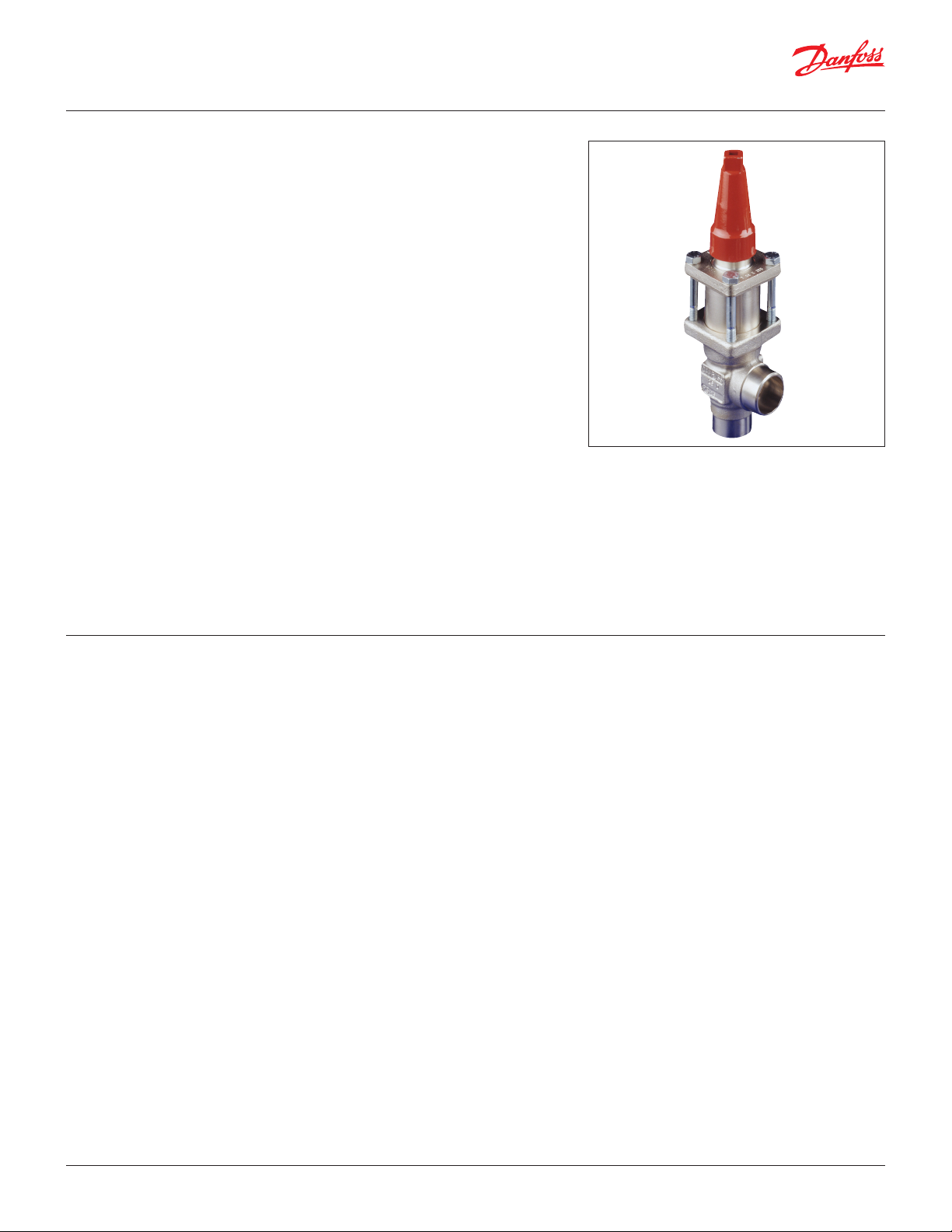

Pressure regulating valves OFV-SS:

Features OFV-SS..................................................................................................37

Technical data ...................................................................................................37

Design........................................................................................................... 38

Connections ..................................................................................................... 38

Material specification ............................................................................................ 39

Dimensions and weights ......................................................................................... 40

Ordering......................................................................................................... 41

Gauge valve SNV-SS:

Features SNV-SS..................................................................................................42

Technical data ...................................................................................................42

Design........................................................................................................... 42

Connections ..................................................................................................... 42

Material specification ............................................................................................ 43

Dimensions and weights ......................................................................................... 44

Ordering......................................................................................................... 44

Solenoid valves EVRS and EVRST:

Features EVRS and EVRST......................................................................................... 45

Technical data ...................................................................................................45

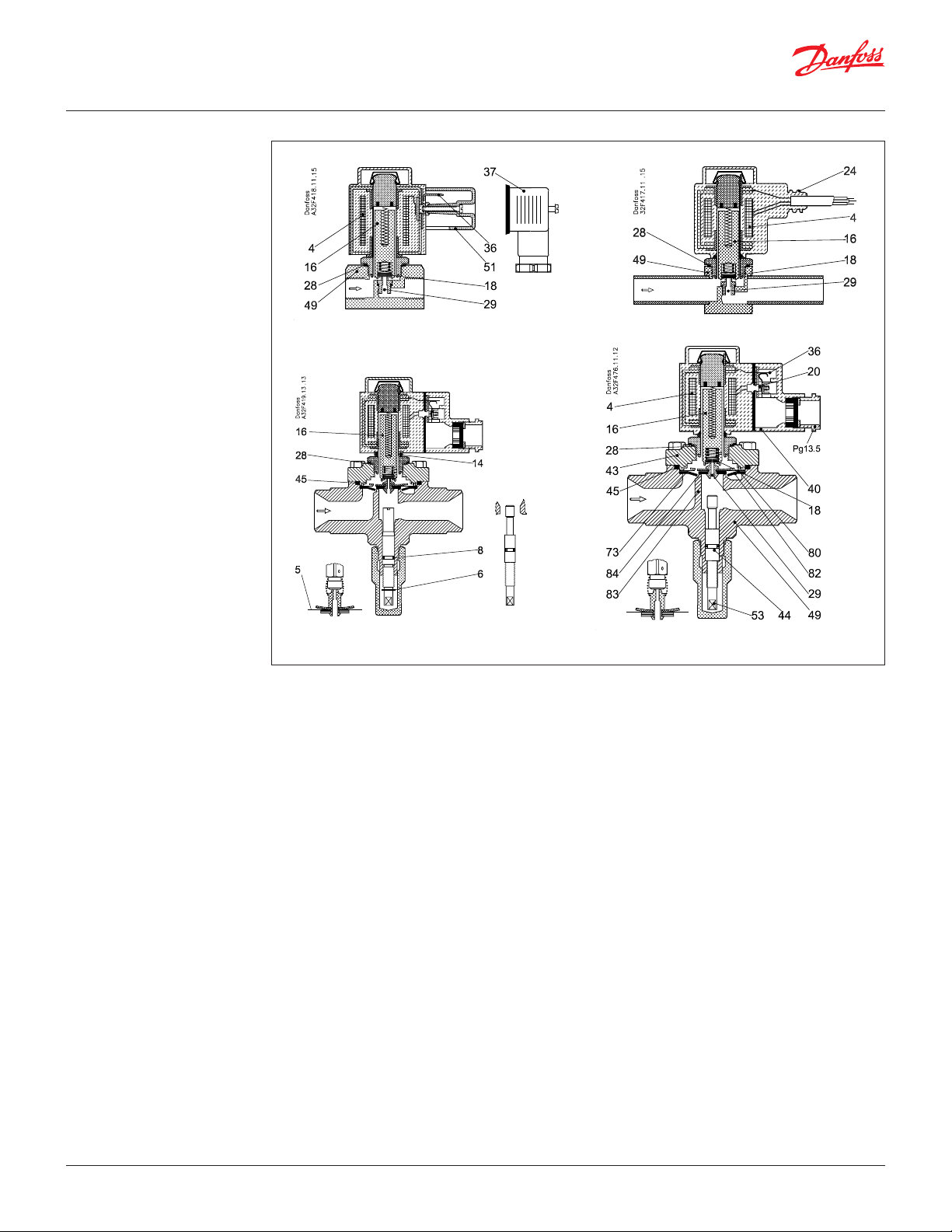

Design/Function ................................................................................................. 47

Material specification ............................................................................................ 48

Dimensions and weights ......................................................................................... 49

Ordering......................................................................................................... 50

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 2

Page 3

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Pressure

Temperature

psi

bar

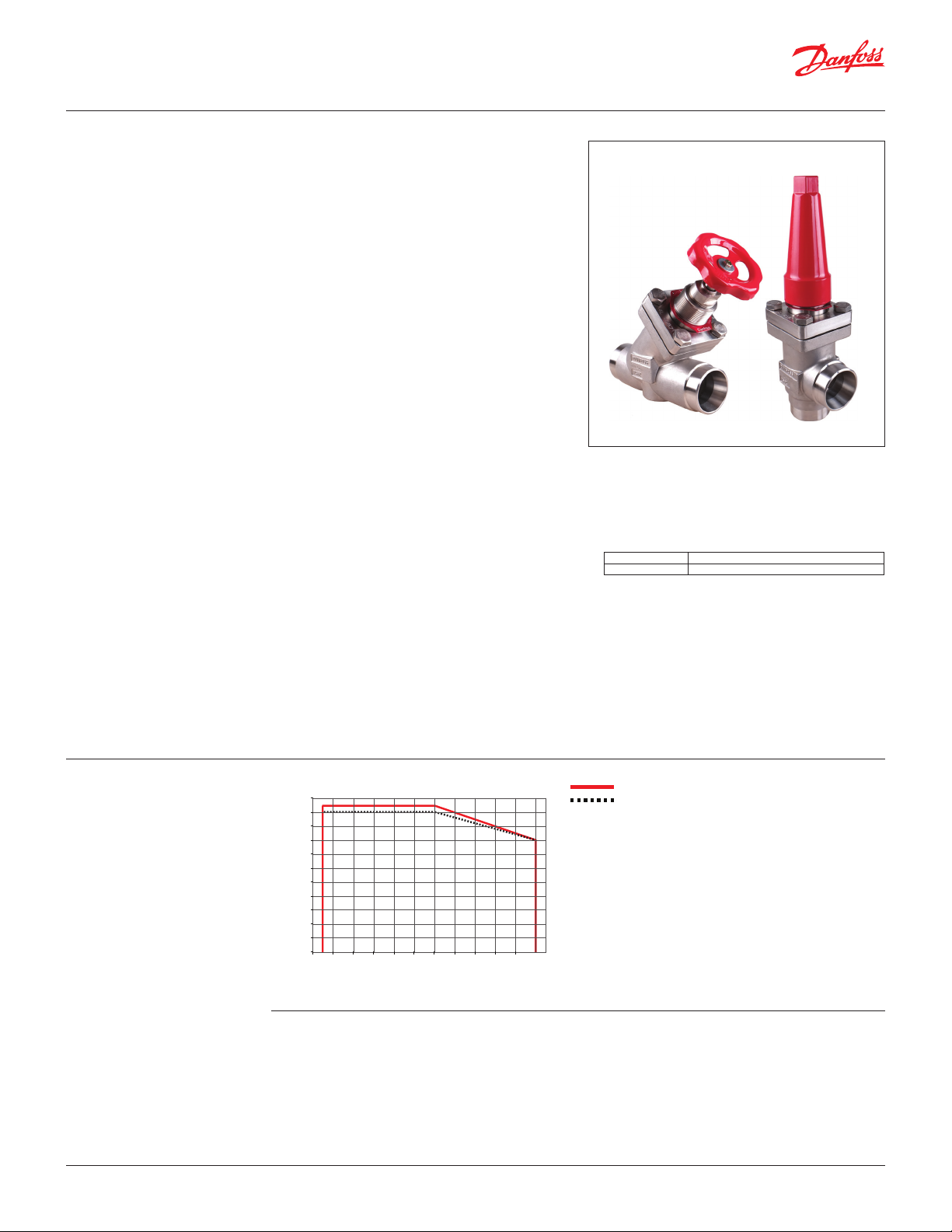

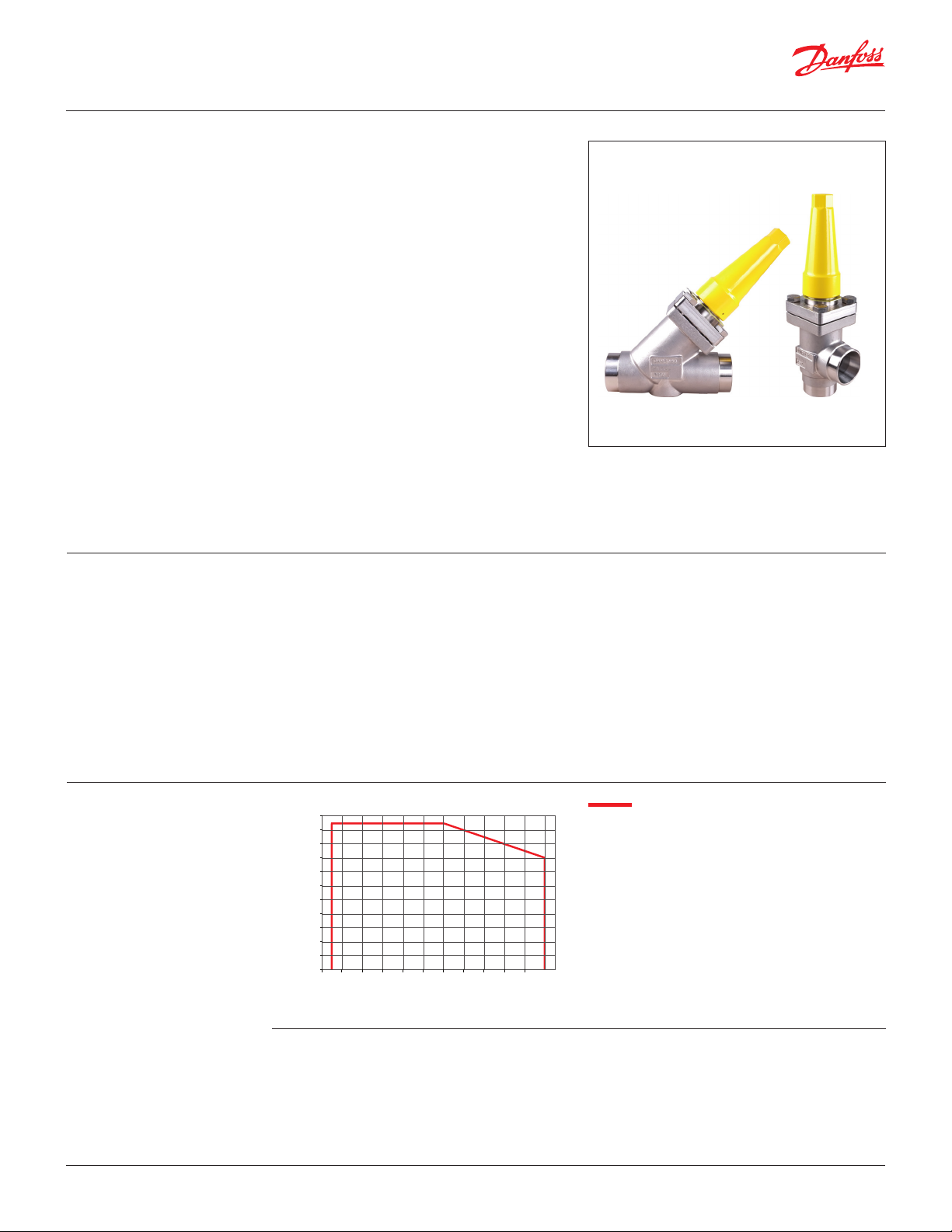

Shut-off valves

SVA-S/L SS

Features

SVA-S/L SS

In certain specific areas such as outdoor

applications and corrosive atmospheres, such

as coastal installations, there is a need for high

surface protection to prevent failure due to

corrosion.

Today's food safety standards often call for daily

treatment with detergents to protect against

bacteria growth, again producing a need for high

surface protection.

SVA-S/L SS are angleway and straightway

stainless steel shut-off valves, which are designed

to meet all industrial refrigeration application

requirements.

The valves are designed to give favourable

flow characteristics and are easy to dismantle

and repair when necessary. The valve cone is

designed to ensure perfect closing.

• Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2) and all flammable refrigerants.

• Optional accessories:

– Heavy duty industrial hand wheel for

frequent operation.

– Cap for infrequent operation.

• Available in angleway and straightway versions

with Standard neck or Long neck (DN 15 to

DN 40) for insulated systems.

• Designed to give favourable flow conditions.

• Internal backseating enables replacement

of the spindle seal whilst the valve is active, i.e.

under pressure.

• Housing is made of stainless steel approved for

low temperature operations.

• Easy to disassemble for inspection and service.

• SVA-S/L SS shut-off valves can accept flow in

either direction.

• Butt-weld DIN and ANSI connections.

• Maximum allowable working pressure and

temperature range:

DN 15-65 52 bar / 754 psi at -60 – 50 °C / -76 – 122 °F

DN 80-125 50 bar / 725 psi at -60 – 50 °C / -76 – 122 °F

For SVA-S/L SS see the relation between PS and

temperature in the below curve.

• Tem perature range:

-60 – 150 °C / -76 – 302 °F.

• Compact and light valves for easy handling and

installation.

• Classification: DNV, CRN, BV, EAC etc.

To get an updated list of certification on the

products please contact your local Danfoss Sales

Company.

Pressure and

temperature range

Technical data • Refrigerants

798

55

725

50

653

45

580

40

508

35

435

30

363

25

Pressure

290

20

218

15

145

10

73

5

0

0

-70

-50-30 -101030507090 110 130 150

-94-58 -22145086 122 158 194 230 266 302

˚C

˚F

• Pressure range

Applicable to HCFC, HFC, R717 (Ammonia),

R744 (CO2) and all flammable refrigerants.

SVA-S/L SS DN15-DN65

SVA-S SS DN80 - DN125

The valves are designed for max. working

pressure 52 bar g / 754 psi g.

For further information please contact your

local Danfoss Sales Company.

© Danfoss | DCS (ms) | 2020.01

• Temperature Range

-60 – 150 °C / -76 – 302 °F.

AI235186440137en-US1101 | 3

Page 4

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

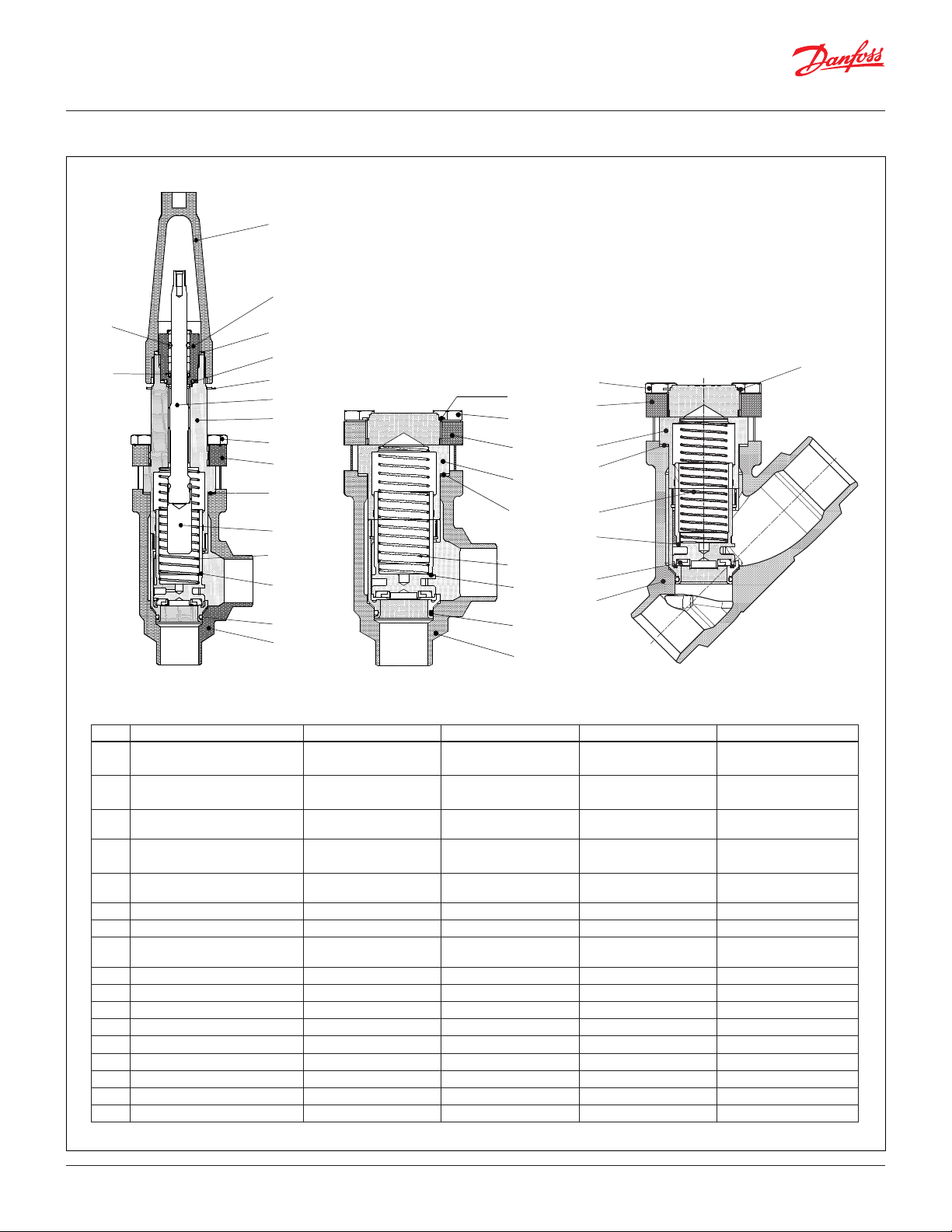

Design

Connections

Available with the following connections:

• Butt-weld DIN (EN 10220)

DN 15 – 125 (½ – 5 in.)

• Butt-weld ANSI (B 36.19M)

DN 15 – 100 (½ – 4 in.)

Housing

Made of stainless steel approved for low

temperature operations.

Valve cone

The valve cone can be turned on the spindle, thus

there will be no friction between the cone and

the seat, when the valve is opened and closed. A

teflon tightening ring provides

perfect sealing at a minimum closing

momentum.

Spindle

Made of polished stainless steel, ideal for

O-ring sealing. Furthermore, parts of the

spindle are heat treated to obtain

anti-abrasive / adhesive properties.

Packing gland

The stainless steel packing gland comprises

a spring loaded seal packing gland which

ensures a perfect tightness in the range:

-60 – 150 °C / -76 – 302 °F.

The packing glands are equipped with a scraper

ring to prevent penetration of dirt and ice into

the packing gland.

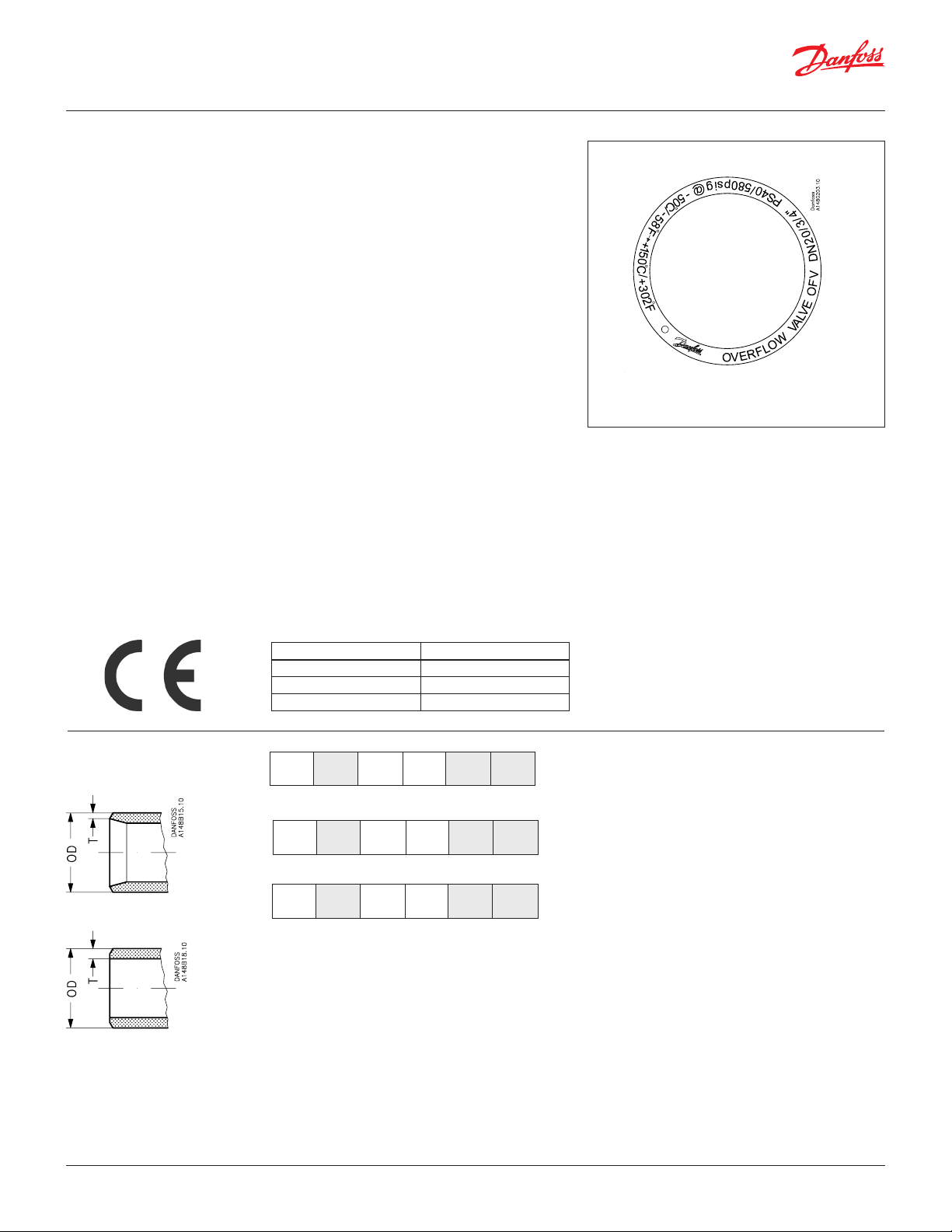

Pressure Equipment Directive (PED)

The stainless steel valves are approved and

CE marked in accordance with the Pressure

Equipment Directive - 97/23/EC.

Installation

It is recommended that the valves be installed in

the direction of flow indicated by the arrow on

the valve body. The valve can be installed in the

opposite direction but this slightly reduces the

kv-value (Cv-value).

The valve is designed to withstand high internal

pressure. However, the piping system in general

should be designed to avoid liquid traps and

reduce the risk of hydraulic pressure caused by

thermal expansion.

For further information refer to installation

instructions for SVA-S/L SS.

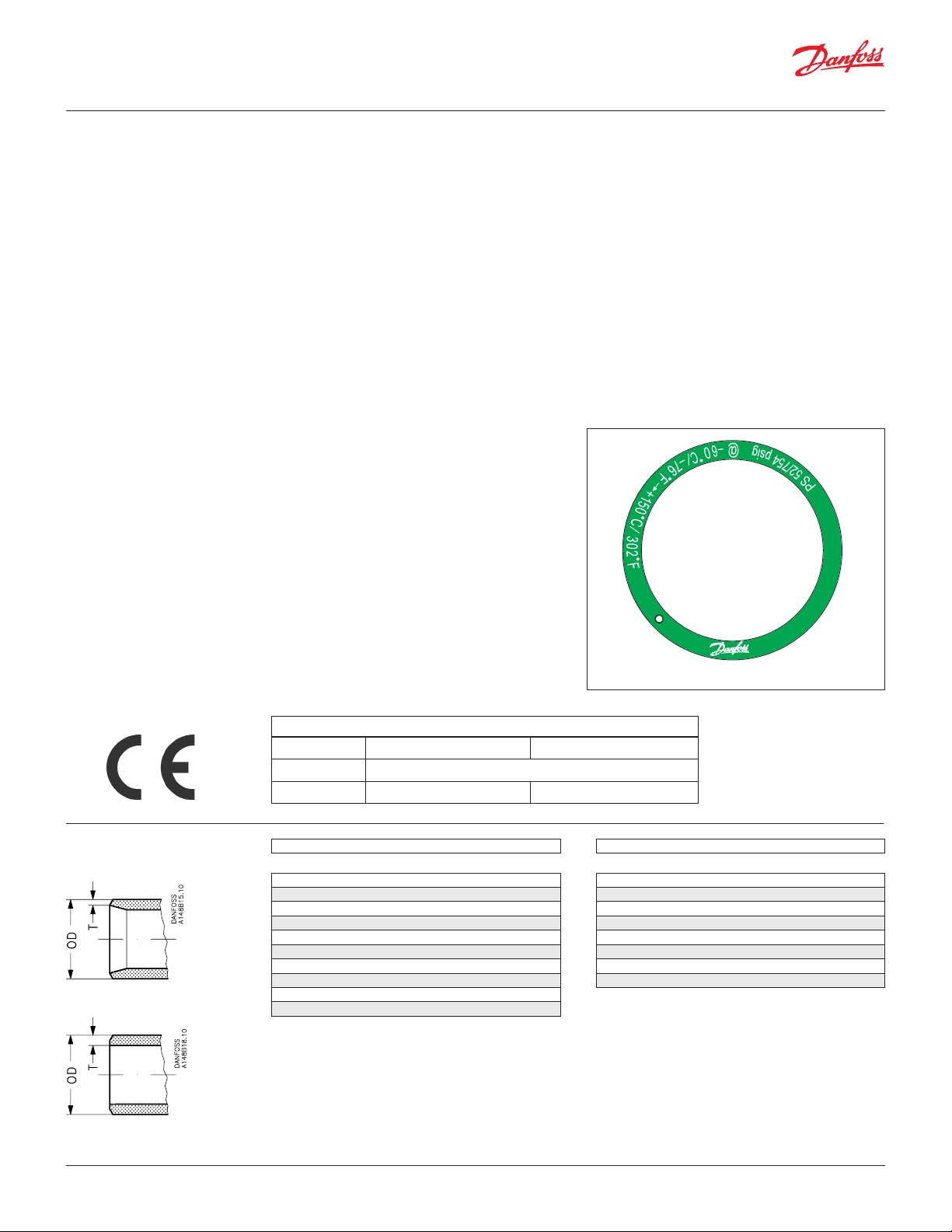

@

–

6

0

°

C

\

–

7

6

°

F

1

5

0

°

C

\

3

0

2

°

F

g

i

s

p

5

2

7

/

0

5

S

P

”

3

/

0

8

N

D

S

S

S

-

A

V

S

E

V

L

A

V

P

O

T

S

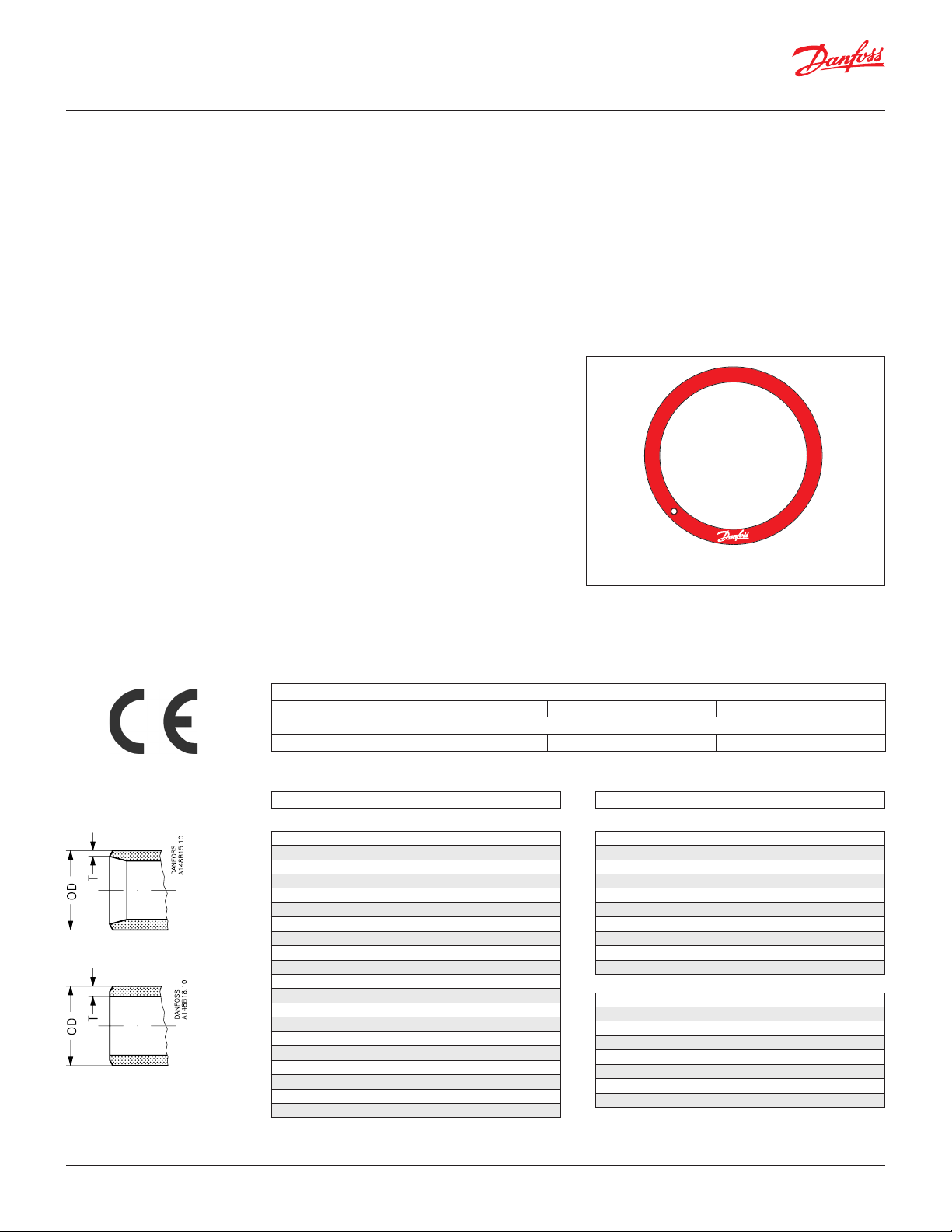

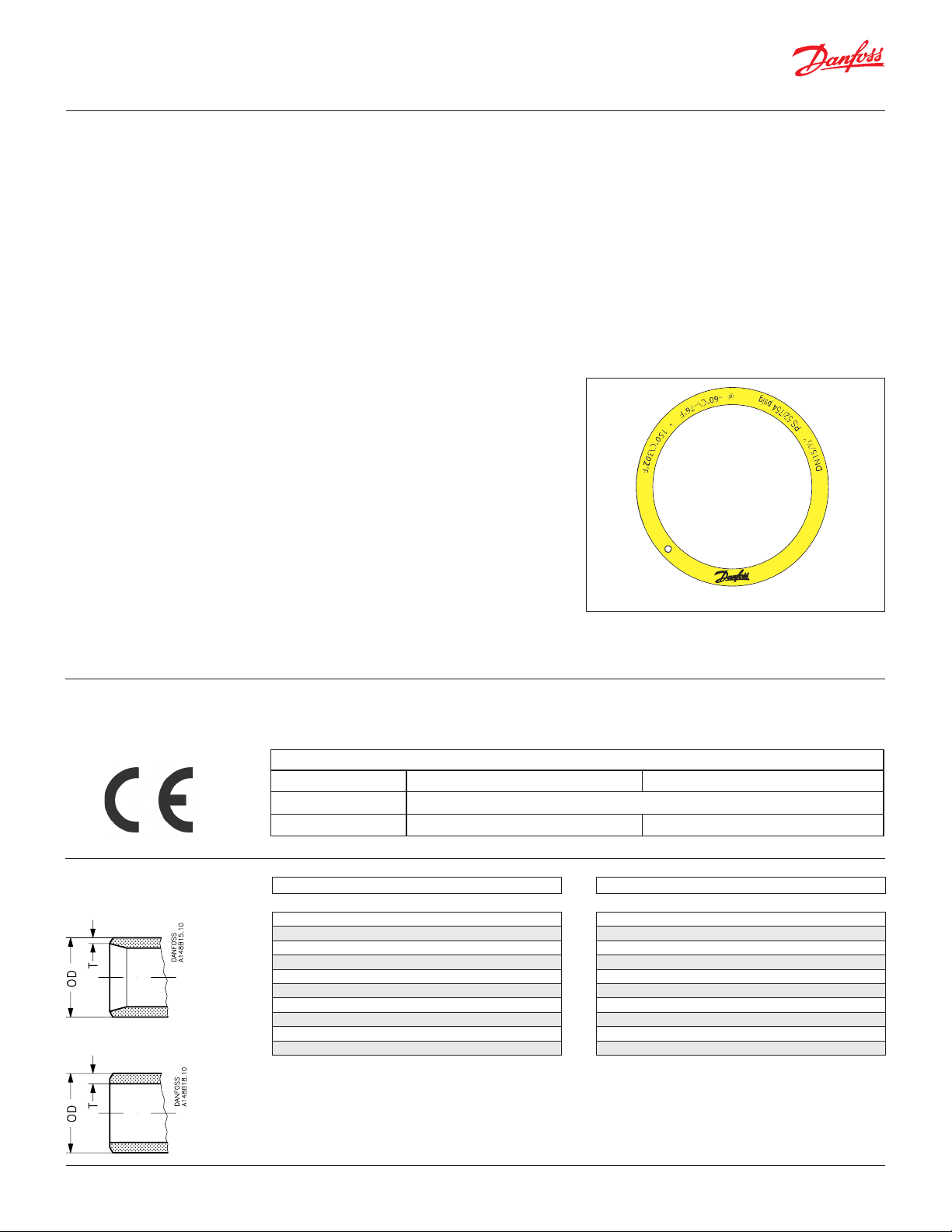

Example of Marking Ring

Connections

DIN

ANSI

SVA-S/L SS

Nominal bore DN≤ 25 mm (1 in.) DN32-80 mm (1 ¼ – 3 in.) DN100 – 125 mm (4 – 5 in.)

Classified for Fluid group I

Category Article 3, paragraph 3 II III

Size OD T

Butt-weld DIN (EN 10220)

15 mm 21.3 2.3

½ in. 0.839 0.091

20 mm 26.9 2.3

¾ in 1.059 0.091

25 mm 33.7 2.6

1 in. 1.327 0.103

32 mm 42.4 2.6

1 ¼ in. 1.669 0.102

40 mm 48.3 2.6

1 ½ in. 1.902 0.103

50 mm 60.3 2.9

2 in. 2.37 0.11

65 mm 76.1 2.9

2 ½ in. 3 0.11

80 mm 88.9 3.2

3 in. 3.50 0.13

100 mm 114.3 3.6

4 in. 4.50 0.14

125 mm 139.7 4.0

5 in. 5.50 0.16

Size OD T

Butt-weld ANSI B 36.19M, SCHEDULE 40

15 mm 21.3 2.8

½ in. 0.839 0.11

20 mm 26.9 2.9

¾ in 1.06 0.11

25 mm 33.7 3.5

1 in. 1.33 0.14

32 mm

1 ¼ in. 1.67 0.14

40 mm 48.3 3.7

1 ½ in. 1.9 0.15

42.4 3.6

Butt-weld ANSI B 36.19M, SCHEDULE 10

50 mm 60.3 2.8

2 in. 2.37 0.11

65 mm 73 3.1

2 ½ in. 2.87 0.12

80 mm 88.9 3.1

3 in. 3.5 0.12

100 mm 114.3 3.1

4 in. 4.5 0.12

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 4

Page 5

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Danfoss

M148B0035_1

M148B0038_1

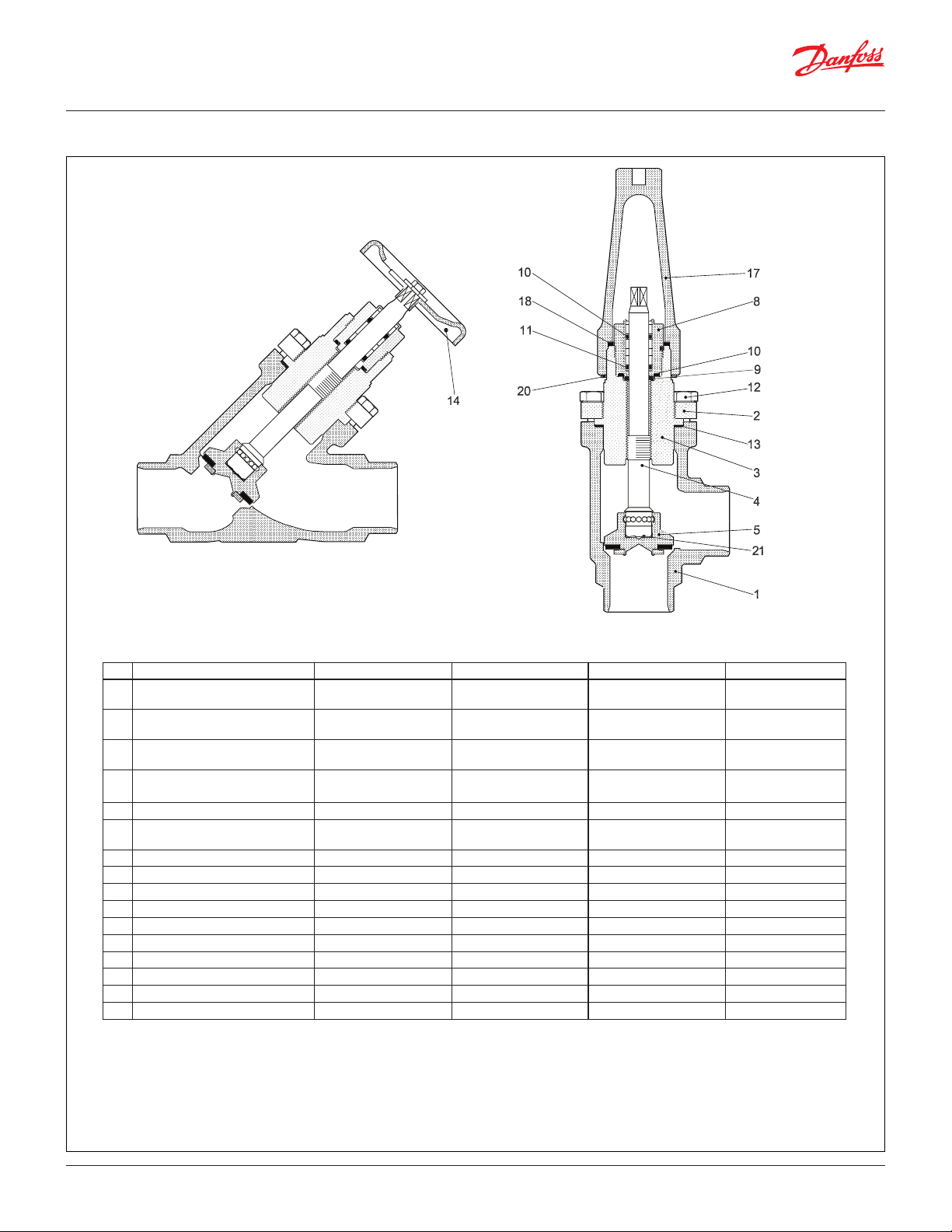

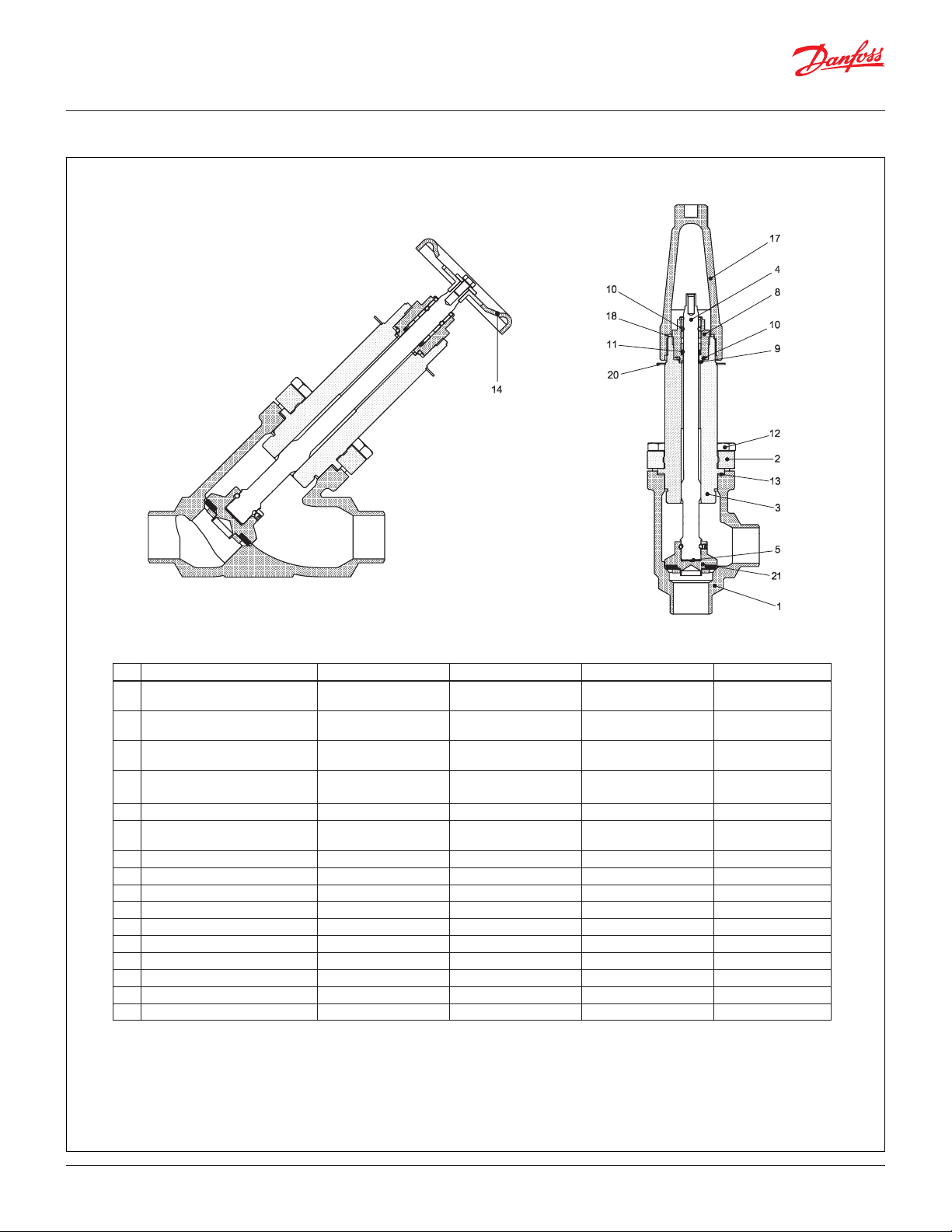

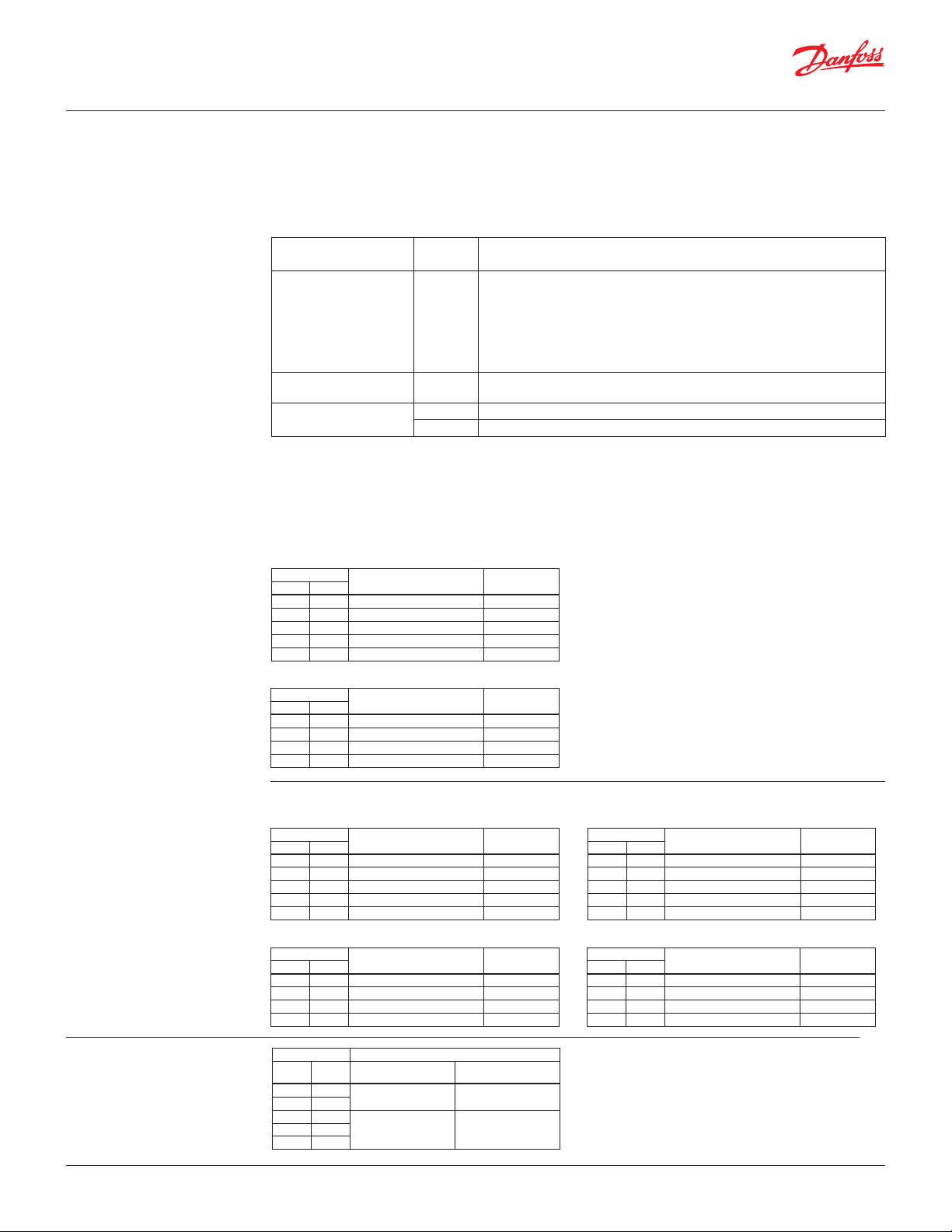

Material specification

SVA-S SS 15 – 40 (½ – 1 ½ in.)

Danfoss

No. Part Material EN ISO ASTM

1 Housing Stainless steel GX5CrNi19-10

AISI 304

EN10213-4

2 Bonnet, Flange Stainless steel X5CrNi18-10

AISI 304

EN10088

3 Bonnet, Insert Stainless steel X8CrNiS18-9

AISI 303

DIN 17440

4 Spindle

Stainless steel X8CrNiS18-9

Type 17, 683/13 AISI 303

DIN 17440

5 Cone Steel

8 Packing gland Stainless steel X8CrNiS18-9

10088

Type 17

683/13

AISI 303

9 Packing washer Aluminium

10 O-ring Cloroprene (Neoprene)

11 Spring loaded Teflon ring PTFE

12 Bolts Stainless steel A2-70 A2-70 Type 308

13 Gasket Fiber, Non-asbestos

14 Handwheel Steel

17 Cap Aluminium

18 Gasket for cap Nylon

20 Identification ring Stainless steel

21 Disk spring Steel

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 5

Page 6

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

M148B0040_1

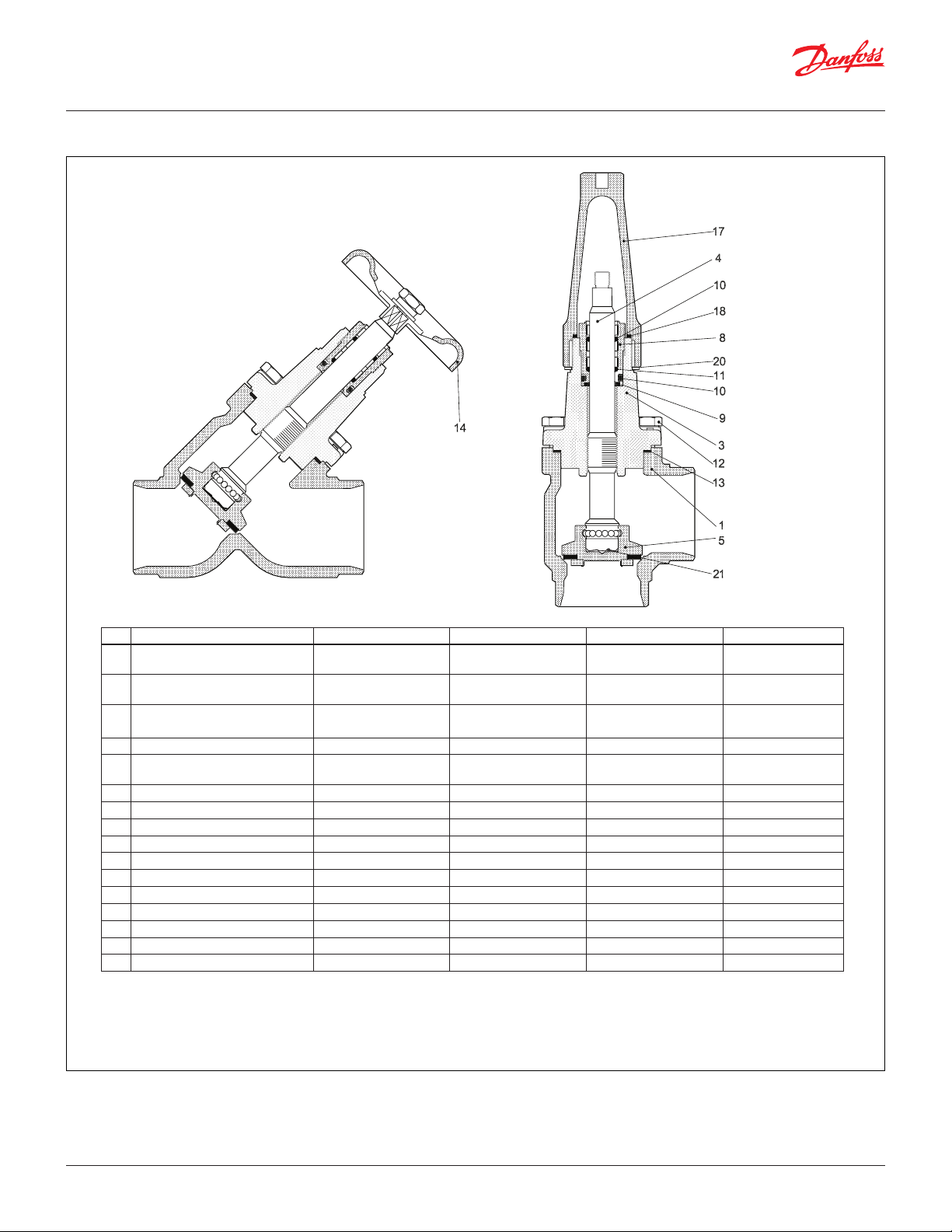

Material specification

SVA-L SS 15 – 40 (½ – 1 ½ in.)

Danfoss

s

No. Part Material EN ISO ASTM

1 Housing Stainless steel GX5CrNi19-10

AISI 304

EN10213-4

2 Bonnet, Flange Stainless steel X5CrNi18-10

AISI 304

EN10088

3 Bonnet, Insert Stainless steel X8CrNiS18-9

AISI 303

DIN 17440

4 Spindle

Stainless steel X8CrNiS18-9

Type 17, 683/13 AISI 303

DIN 17440

5 Cone Steel

8 Packing gland Stainless steel X8CrNiS18-9

10088

Type 17

683/13

AISI 303

9 Packing washer Aluminium

10 O-ring Cloroprene (Neoprene)

11 Spring loaded Teflon ring PTFE

12 Bolts Stainless steel A2-70 A2-70 Type 308

13 Gasket Fiber, Non-asbestos

14 Handwheel Steel

17 Cap Aluminium

18 Gasket for cap Nylon

20 Identification ring Stainless steel

21 Disk spring Steel

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 6

Page 7

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

M148B0039_1

M148B0036_1

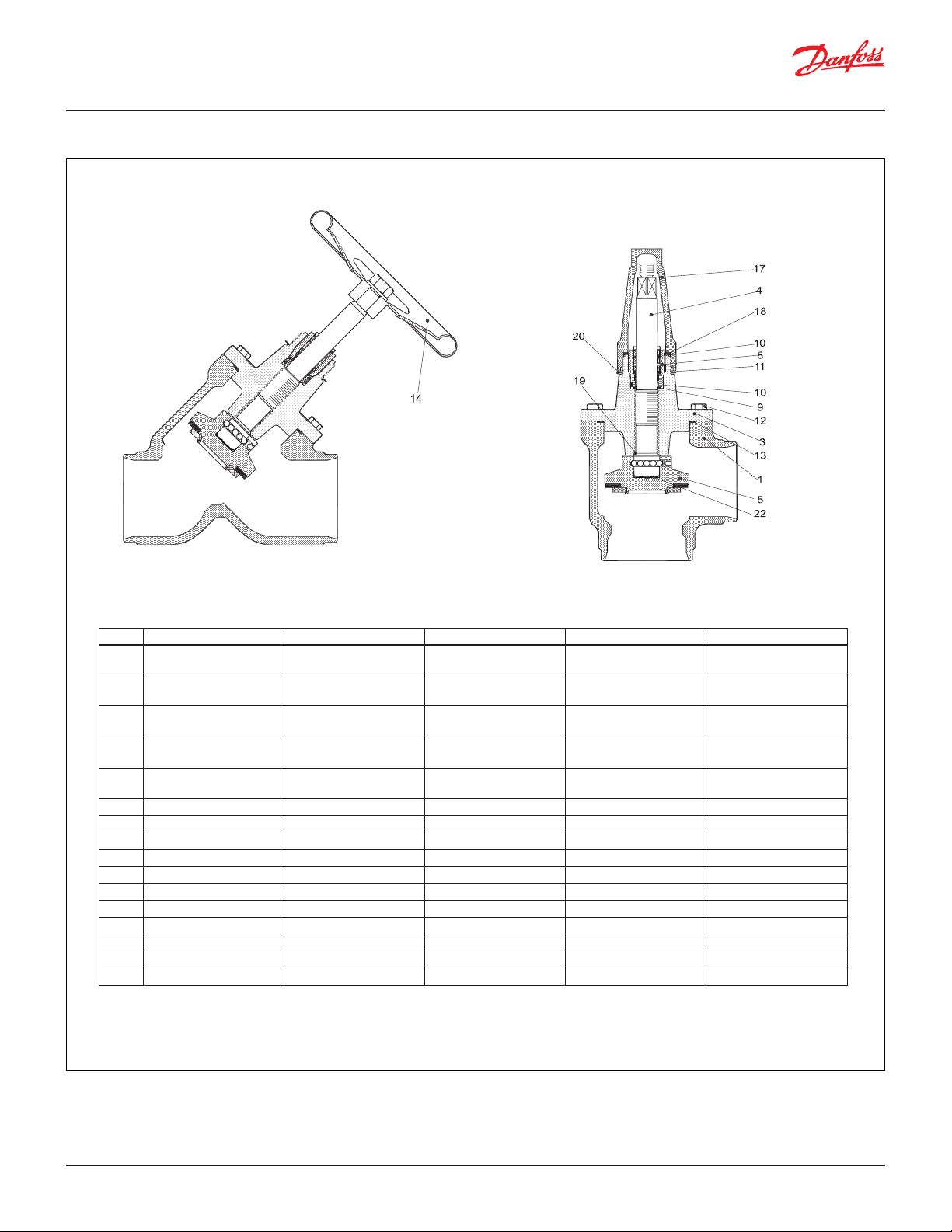

Material specification

SVA-S SS 50 – 65 (2 – 2 ½ in.)

Danfoss

Danfoss

No. Part Material EN ISO ASTM

1 Housing Stainless steel GX5CrNi19-10

AISI 304

EN10213-4

3 Valve bonnet Stainless steel GX5CrNi19-10

AISI 304

EN10213-4

4 Spindle

Stainless steel X8CrNiS18-9

Type 17, 683/13 AISI 303

DIN 17440

5 Cone Steel

8 Packing gland Stainless steel X8CrNiS18-9

10088

Type 17

683/13

AISI 303

9 Packing washer Aluminium

10 O-ring Cloroprene (Neoprene)

11 Spring loaded Teflon ring PTFE

12 Bolts Stainless steel A2-70 A2-70 Type 308

13 Gasket Fiber, Non-asbestos

14 Handwheel Steel

17 Cap Aluminium

18 Gasket for cap Nylon

19 Locking nut Steel

20 Identification ring Stainless steel

21 Disk spring Steel

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 7

Page 8

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Danfoss

M148B0096_1

M148B0006_1

Material specification

SVA-S SS 80 – 125 (3 – 5 in.)

Danfoss

No. Par t Material EN ISO ASTM

1 Housing Stainless steel GX5CrNi19-10

AISI 304

EN10213-4

3 Valve bonnet Stainless steel GX5CrNiMo19-11-2

AISI 304

EN10213-4

4 Spindle

Stainless steel X5CrNi18-10

Type 17, 683/13 AISI 303

DIN 17440

5 Cone

Cone seal

8 Packing gland Stainless steel X8CrNiS18-9

Steel

Teflon (PTFE)

10088

Type 17

R 683/13

AISI 303

9 Packing washer Aluminium

10 O-ring Cloroprene (Neoprene)

11 Spring loaded Teflon ring PTFE

12 Bolts Stainless steel A2-70 A2-70 Type 308

13 Gasket Fiber, Non-asbestos

14 Hand wheel Steel

17 Cap Aluminium

18 Gasket for cap Nylon (PA 6)

19 Soft backseat Teflon (PTFE)

20 Identification ring Stainless steel

22 Disk spring Steel

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 8

Page 9

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

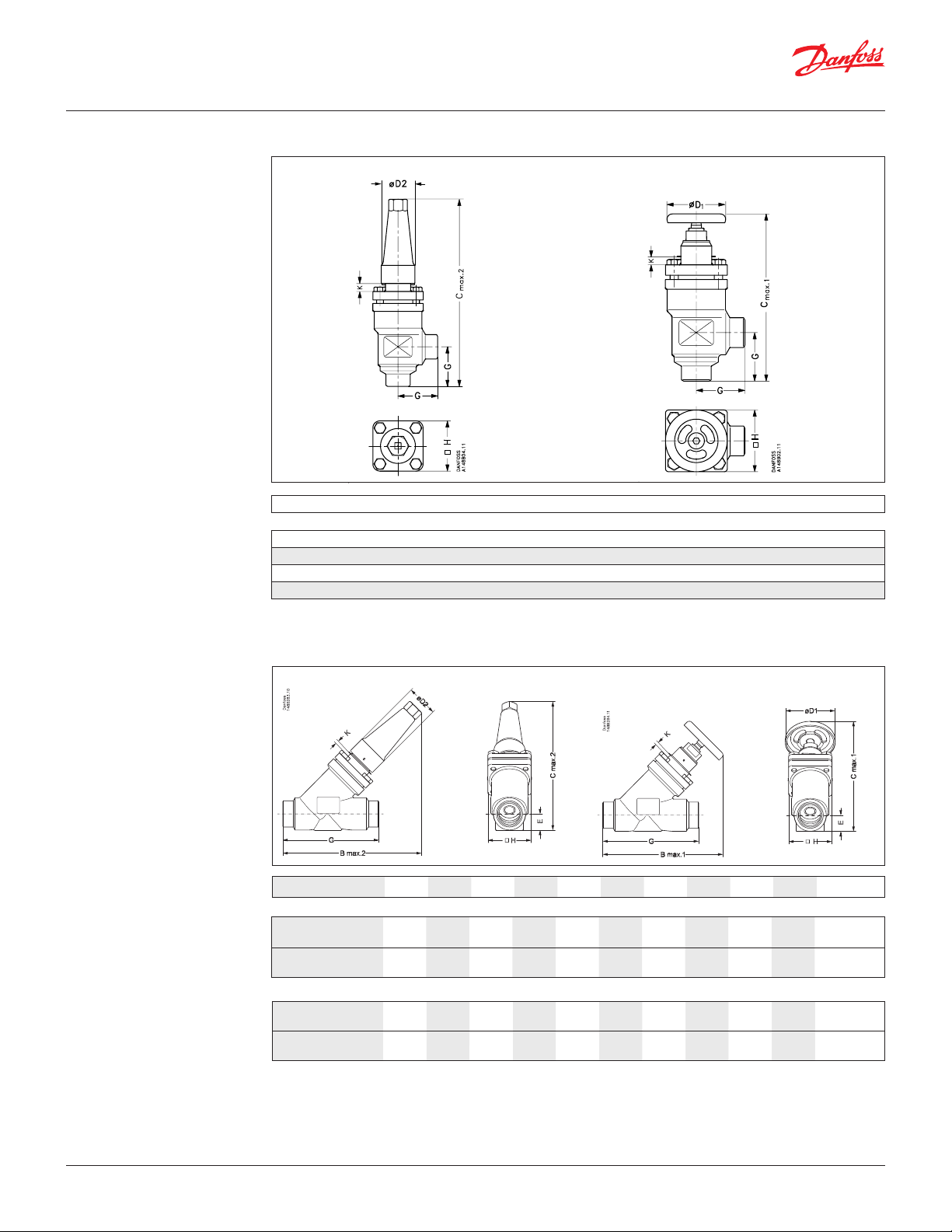

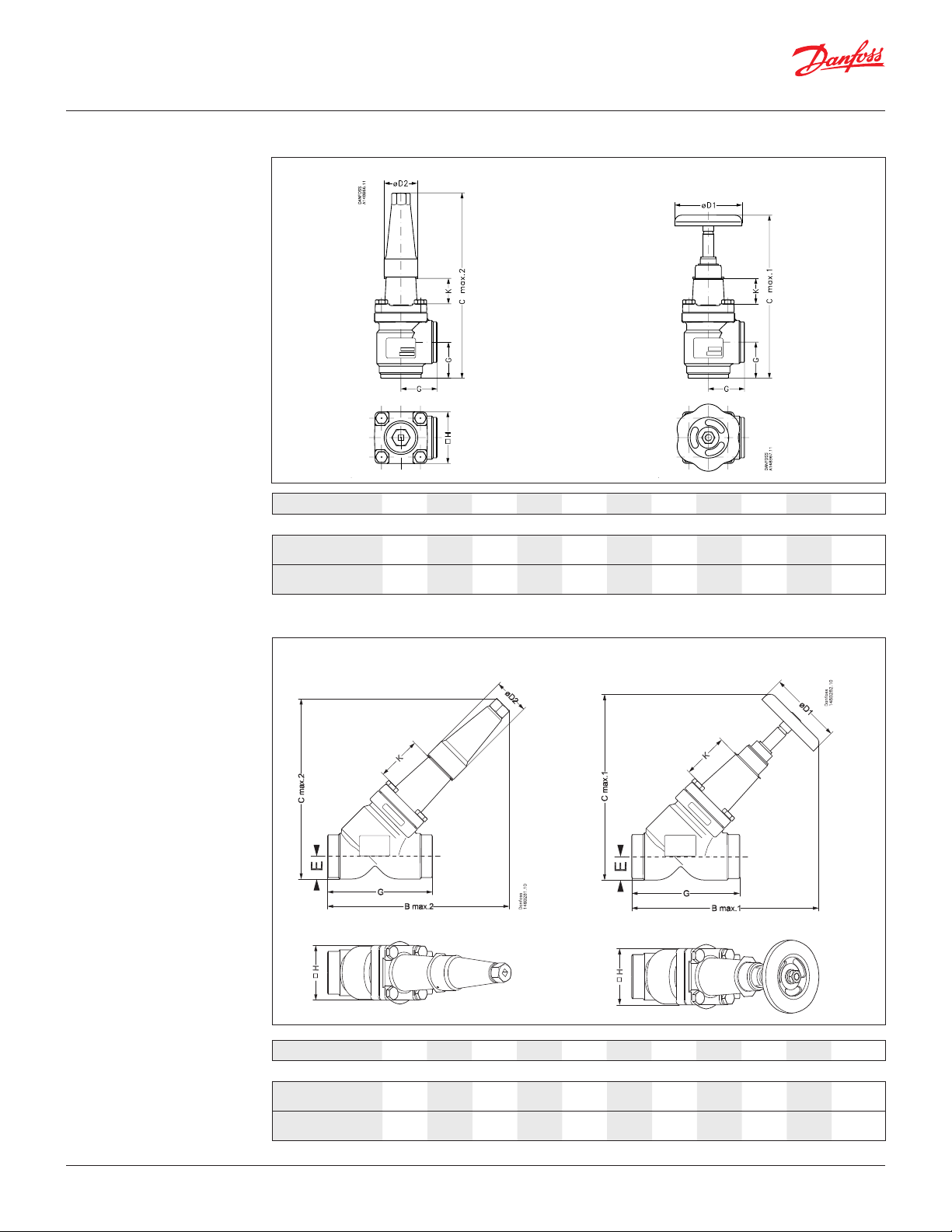

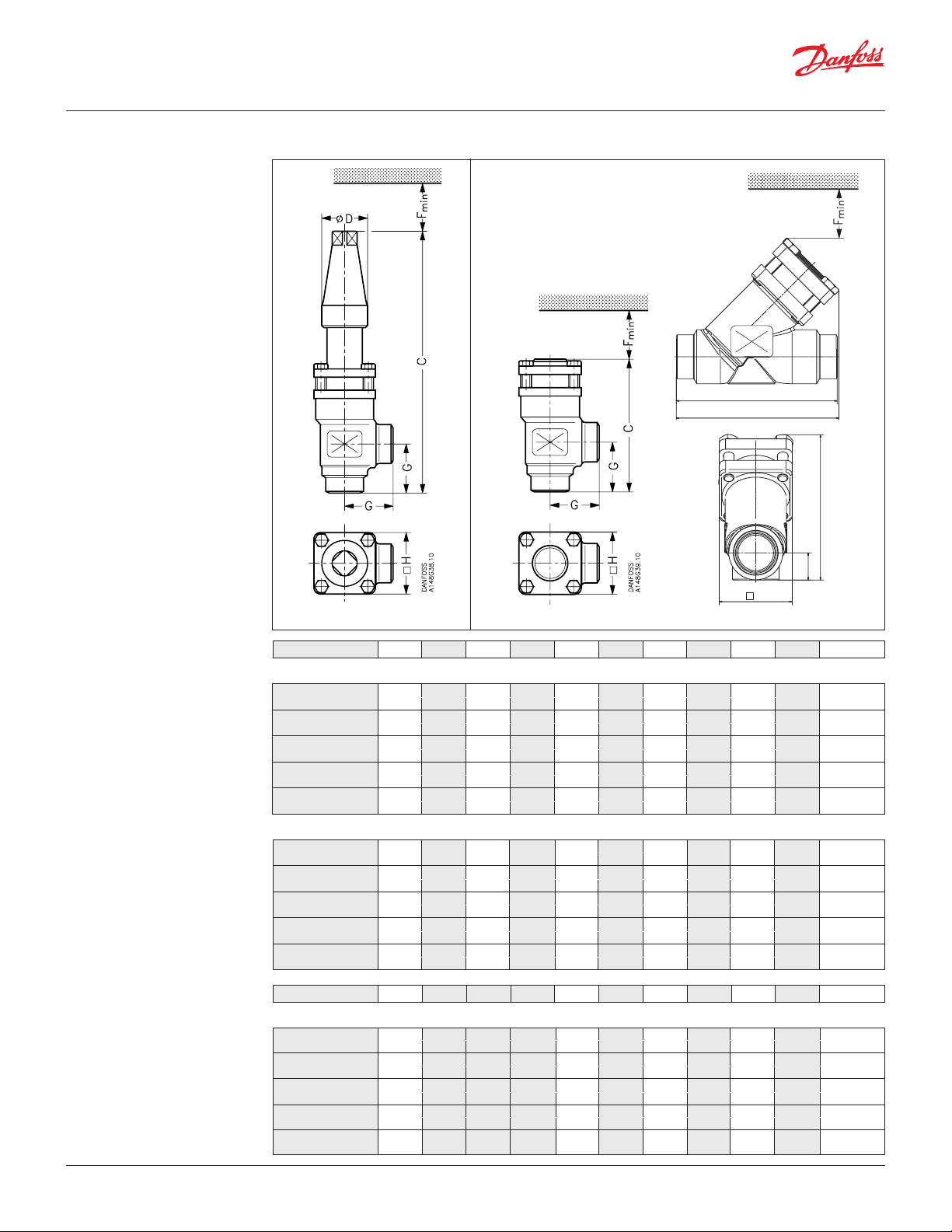

Dimensions and weights

SVA S SS 15 - 40 (½ – 1 ½ in. ) in angleway version with cap / hand wheel

SVA-xx x x ANG CAP

Valve size K C

max .1Cmax .2

G ØD1ØD

SVA-S SS

SVA-S SS 15 – 20 mm 4 178 189 45 60 38 60 1.4 kg

SVA-S SS 1/2 – 3/4" in. 0.16 7.00 7.44 1.77 2.36 1.5 2.36 3.1 lbs

SVA-S SS 25 – 40 mm 12 234 268 55 80 50 70 2.4 kg

SVA-S SS 1 – 11/2" in. 0.47 9.21 10.55 2.17 3.15 1.97 2.76 5.3 lbs

Specified weights are approximate values only.

SVA-xx x x ANG H-WHEEL

2

H

Weight

SVA-S/L SS 15 - 40 (½ – 1½ in. ) straightway version with cap / hand wheel

SVA-xx x x STR CAP

Valve size K C

max.1Cmax.2Bmax.1Bmax.2

SVA-xx x x STR H-WHEEL

E G ∅D1 ∅D

Weight

H

2

SVA-S SS

SVA-S SS 15 - 20 mm 4 146 141 160 156 20 120 60 38 60 2.0 kg

SVA-S SS (½ – ¾) in. 0.16 5.74 5.55 6.30 6.14 0.79 4.72 2.36 1.50 2.36 4.4 lb

SVA-S SS 25 – 40 mm 12 199 208 212 222 26 155 80 50 70 3.0 kg

SVA-S SS (1 – 1 ½) in. 0.47 7.83 8.19 8.35 8.74 1.02 6.10 3.15 1.97 2.76 6.6 lb

SVA-L SS

SVA-L SS 15 – 20 mm 63 188 184 202 198 20 120 60 38 60 2.0 kg

SVA-L SS (½ – ¾) in. 2.48 7.40 7.24 7.95 7.80 0.79 4.72 2.36 1.50 2.36 4.4 lb

SVA-L SS 25 – 40 mm 74 243 252 256 265 26 155 80 50 70 3.0 kg

SVA-L SS (1 – 1 ½) in. 2.91 9.57 9.92 10.08 10.43 1.02 6.10 3.15 1.97 2.76 6.6 lb

Specified weights are approximate values only.

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 9

Page 10

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Dimensions and weights

SVA-S SS 50 – 65 (2 – 2 ½ in.) in angleway version with cap / hand wheel

SVA-xx x x ANG CAP

Valve size K C

max.1Cmax.2

SVA-xx x x ANG H-WHEEL

G ∅D1 ∅D2

H

Weight

SVA-S SS

SVA-S SS 50 mm 70 284 315 60 100 50 77 3.2 kg

SVA-S SS (2) in. 2.76 11.18 12.40 2.36 3.94 1.97 3.03 7.1 lb

SVA-S SS 65 mm 70 310 335 70 100 50 90 4.8 kg

SVA-S SS (2 ½) in. 2.76 12.20 13.19 2.76 3.94 1.97 3.54 10.6 lb

Specified weights are approximate values only.

SVA-S SS 50 – 65 (2 – 2 ½ in.) in straightway version with cap / hand wheel

SVA-xx x x STR CAP

SVA-xx x x STR H-WHEEL

© Danfoss | DCS (ms) | 2020.01

Valve size K B

max.1Bmax.2Cmax.1Cmax.2

E G ∅D1 ∅D

Weight

H

2

SVA-S SS

SVA-S SS 50 mm 70 259 259 257 257 32 148 100 50 77 4.2 kg

SVA-S SS (2) in. 2.76 10.20 10.20 10.12 10.12 1.26 5.83 3.94 1.97 3.03 9.3 lb

SVA-S SS 65 mm 70 284 280 284 280 40 176 100 50 90 6.3 kg

SVA-S SS (2 ½) in. 2.76 11.18 11.02 11.18 11.02 1.57 6.93 3.94 1.97 3.54 13.9 lb

Specified weights are approximate values only.

AI235186440137en-US1101 | 10

Page 11

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

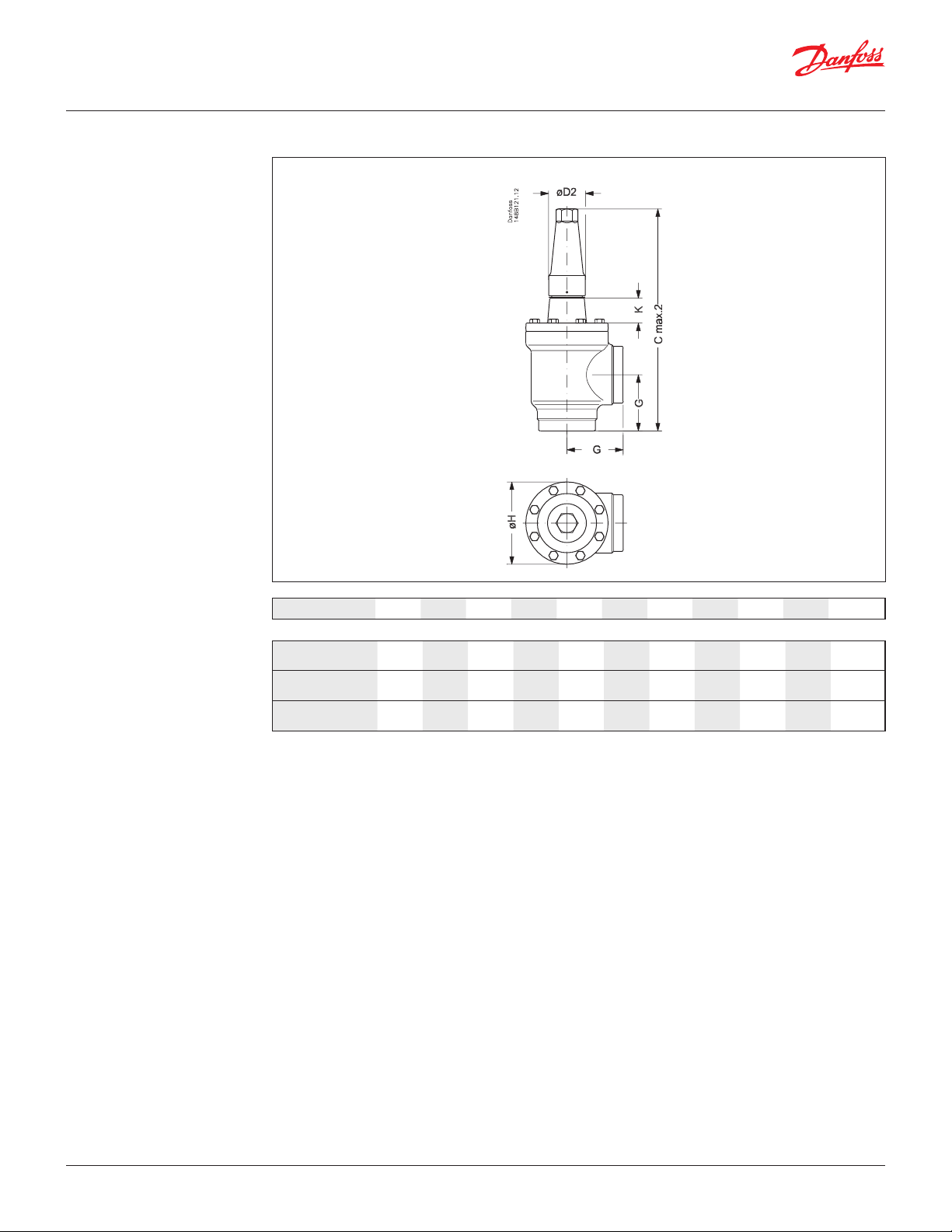

Dimensions and weights SVA-S SS 80 – 125 (3 – 5 in.) angleway version with cap / hand wheel

SVA-xx x x ANG CAP

Valve size K C

SVA-S SS

SVA-S SS 80

SVA-S SS (3)mmin.

SVA-S SS 100

SVA-S SS (4)mmin.

SVA-S SS 125

SVA-S SS (5)mmin.

Specified weights are approximate values only.

76

3.00

90

3.54

90

3.54

max.2

388

15.28

437

17.20

533

20.98

G ∅D1∅D2 ∅H Weight

90

3.54

106

4.17

128

5.04

200

7.87582.28

250

9.84582.28

315

12.40742.91

129

5.08

156

6.14

193

7.60

9.7 kg

21.4 lb

15.3 kg

33.7 lb

28.1 kg

61.9 lb

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 11

Page 12

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Ordering

Please note that the type codes only serve to

identify the valves, some of which may not form

part of the standard product range. For further

information please contact your local Danfoss Sales

Company.

Type codes

Valve type SVA-S/L SS Shut-off valve

Nominal size in mm Available connections

(valve size measured

on the connection

diameter)

Connections D

Valve housing ANG

Other equipment H-WHEEL

15 DN 15 (½) x x

20 DN 20 (¾) x x

25 DN 25 (1) x x

32 DN 32 (1 ¼) x x

40 DN 40 (1 ½) x x

50 DN 50 (2) x x

65 DN 65 (2 ½) x x

80 DN 80 (3) x x

100 DN 100 (4) x x

125 DN 125 (5) x

A

STR

CAP

Butt-weld connection

Butt-weld connection

Angle flow

Straight flow

Hand wheel

Cap

D A

: DIN EN 10220

: ANSI B 36.19M

Important!

Where products need to be certified according

to specific certification societies or where higher

pressures are required, the relevant information

should be included at the time of order.

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 12

Page 13

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Ordering

Ordering SVA-S/L SS

Example:

SVA-S SS 20 DIN angleway with

hand wheel = 148B5377

Important!

Where products need to be certified

according to specific certification

societies or where higher pressures are

required, the relevant information should

be included at the time of order.

Size

mm in. bar psi

Type

MWP

Code

number

Butt-weld DIN (EN 10220)

15 ½ SVA-S SS 15 D ANG H-WHEEL 52 754 148B5289

15 ½ SVA-S SS 15 D ANG CAP 52 754 148B5290

20 ¾ SVA-S SS 20 D ANG H-WHEEL 52 754 148B5377

20 ¾ SVA-S SS 20 D ANG CAP 52 754 148B5378

25 1 SVA-S SS 25 D ANG H-WHEEL 52 754 148B5486

25 1 SVA-S SS 25 D ANG CAP 52 754 148B5487

32 1 ¼ SVA-S SS 32 D ANG H-WHEEL 52 754 148B5566

32 1 ¼ SVA-S SS 32 D ANG CAP 52 754 148B5567

40 1 ½ SVA-S SS 40 D ANG H-WHEEL 52 754 148B5646

40 1 ½ SVA-S SS 40 D ANG CAP 52 754 148B5647

50 2 SVA-S SS 50 D ANG H-WHEEL 52 754 148B5753

50 2 SVA-S SS 50 D ANG CAP 52 754 148B5754

65 2 ½ SVA-S SS 65 D ANG H-WHEEL 52 754 148B5847

65 2 ½ SVA-S SS 65 D ANG CAP 52 754 148B5848

80 3 SVA-S SS 80 D ANG CAP 50 725 148B5928

100 4 SVA-S SS 100 D ANG CAP 50 725 148B6032

125 5 SVA-S SS 125 D ANG CAP 50 725 148B6126

Size

mm in. bar psi

Type

MWP

Code

number

Butt-weld ANSI (B 36.19M SCHEDULE 40)

15 ½ SVA-S SS 15 A40 ANG CAP 52 754 148B5396

20 ¾ SVA-S SS 20 A40 ANG CAP 52 754 148B5395

25 1 SVA-S SS 25 A40 ANG CAP 52 754 148B6477

32 1 ¼ SVA-S SS 32 A40 ANG CAP 52 754 148B5595

40 1 ½ SVA-S SS 40 A40 ANG CAP 52 754 148B5683

Size

mm in. bar psi

Type

MWP

Code

number

Butt-weld ANSI (B 36.19M SCHEDULE 10)

50 2 SVA-S SS 50 D/A10 ANG CAP 52 754 148B5754

65 2 ½ SVA-S SS 65 A10 ANG CAP 52 754 148B6448

80 3 SVA-S SS 80 D/A10 ANG CAP 52 754 148B5928

100 4 SVA-S SS 100 A10 ANG CAP 52 754 148B6035

SVA-S SS StraightwaySVA-S SS Angleway

Size

mm in. bar psi

Type

Butt-weld DIN (EN 10220)

15 ½ SVA-S SS 15 D STR H-WHEEL 52 754 148B5291

15 ½ SVA-S SS 15 D STR CAP 52 754 148B5292

20 ¾ SVA-S SS 20 D STR H-WHEEL 52 754 148B5379

20 ¾ SVA-S SS 20 D STR CAP 52 754 148B5380

25 1 SVA-S SS 25 D STR H-WHEEL 52 754 148B5488

25 1 SVA-S SS 25 D STR CAP 52 754 148B5489

32 1 ¼ SVA-S SS 32 D STR H-WHEEL 52 754 148B5568

32 1 ¼ SVA-S SS 32 D STR CAP 52 754 148B5569

40 1 ½ SVA-S SS 40 D STR H-WHEEL 52 754 148B5648

40 1 ½ SVA-S SS 40 D STR CAP 52 754 148B5649

50 2 SVA-S SS 50 D STR H-WHEEL 52 754 148B5755

50 2 SVA-S SS 50 D STR CAP 52 754 148B5756

65 2 ½ SVA-S SS 65 D STR H-WHEEL 52 754 148B5849

65 2 ½ SVA-S SS 65 D STR CAP 52 754 148B5850

Size

mm in. bar psi

Type

Butt-weld ANSI (B 36.19M SCHEDULE 40)

15 ½ SVA-S SS 15 A40 STR CAP 52 754 148B5397

20 ¾ SVA-S SS 20 A40 STR CAP 52 754 148B5398

25 1 SVA-S SS 25 A40 STR CAP 52 754 148B5399

32 1 ¼ SVA-S SS 32 A40 STR CAP 52 754 148B5596

40 1 ½ SVA-S SS 40 A40 STR CAP 52 754 148B5684

Size

mm in. bar psi

Type

Butt-weld ANSI (B 36.19M SCHEDULE 10)

50 2 SVA-S SS 50 D/A10 STR CAP 52 754 148B5756

65 2 ½ SVA-S SS 65 A10 STR CAP 52 754 148B6449

MWP

MWP

MWP

number

number

number

Code

Code

Code

ANG = Angleway

STR = Straightway

CAP = Cap

H-WHEEL = Hand wheel

Size

mm in. bar psi

Type

MWP

number

Butt-weld DIN (EN 10220)

15 ½ SVA-L SS 15 D ANG H-WHEEL 52 754 148B6546

15 ½ SVA-L SS 15 D ANG CAP 52 754 148B6547

20 ¾ SVA-L SS 20 D ANG H-WHEEL 52 754 148B6550

20 ¾ SVA-L SS 20 D ANG CAP 52 754 148B6551

25 1 SVA-L SS 25 D ANG H-WHEEL 52 754 148B6554

25 1 SVA-L SS 25 D ANG CAP 52 754 148B6555

32 1 ¼ SVA-L SS 32 D ANG H-WHEEL 52 754 148B6558

32 1 ¼ SVA-L SS 32 D ANG CAP 52 754 148B6559

40 1 ½ SVA-L SS 40 D ANG H-WHEEL 52 754 148B6562

40 1 ½ SVA-L SS 40 D ANG CAP 52 754 148B6563

Code

SVA-L SS StraightwaySVA-L SS Angleway

Size

mm in. bar psi

Type

Butt-weld DIN (EN 10220)

15 ½ SVA-L SS 15 D STR H-WHEEL 52 754 148B6548

15 ½ SVA-L SS 15 D STR CAP 52 754 148B6549

20 ¾ SVA-L SS 20 D STR H-WHEEL 52 754 148B6552

20 ¾ SVA-L SS 20 D STR CAP 52 754 148B6553

25 1 SVA-L SS 25 D STR H-WHEEL 52 754 148B6556

25 1 SVA-L SS 25 D STR CAP 52 754 148B6557

32 1 ¼ SVA-L SS 32 D STR H-WHEEL 52 754 148B6560

32 1 ¼ SVA-L SS 32 D STR CAP 52 754 148B6561

40 1 ½ SVA-L SS 40 D STR H-WHEEL 52 754 148B6564

40 1 ½ SVA-L SS 40 D STR CAP 52 754 148B6565

MWP

number

Code

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 13

Page 14

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Pressure

Temperature

psi

bar

Hand-operated

regulating valves

REG-SA SS and REG-SB SS

Features

REG-SA SS and REG-SB SS

In certain specific areas such as outdoor

applications and corrosive atmospheres, such as

coastal installations, there is a need for high surface

protection to prevent failure due to corrosion.

Today's food safety standards often call for daily

treatment with detergents to protect against

bacteria growth, again producing a need for high

surface protection.

REG-SA SS and REG-SB SS are angle-way and

straight-way hand-operated regulating valves,

which act as normal stop valves in closed position.

The valves are designed to meet the strict

quality requirements on refrigerating

installations specified by the international

classification societies and are carefully

designed to present favourable flow

conditions and accurate linear characteristics.

The valves are equipped with vented cap and have

internal backseating enabling the spindle

seal to be replaced with the valve still under

pressure.

• Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2), Propane, Butane, Iso-Butane and Ethane.

R717 Heat Pump and Propylene applications

with replaced O-ring.

• Designed to give favourable flow conditions.

• Internal backseating enables replacement

of the spindle seal whilst the valve is active, i.e.

under pressure

• Housing is made of special cold resistant

stainless steel approved for low temperature

operations.

• Easy to disassemble for inspection and service.

• Butt-weld DIN and ANSI connections.

• Max. operating pressure:

52 bar g / 754 psig

• Tem perature range:

-60 – 150 °C / -76 – 302 °F.

• Compact and light valves for easy handling and

installation.

• Classification: DNV, CRN, BV, EAC etc.

To get an updated list of certification on the

products please contact your local Danfoss Sales

Company.

Pressure and

temperature range

Technical data • Refrigerants

798

55

725

50

653

45

580

40

508

35

435

30

363

25

Pressure

290

20

218

15

145

10

73

5

0

0

-70

-50-30 -101030507090 110 130 150

-94-58 -22145086 122 158 194 230 266 302

Temperature

˚C

˚F

• Temperature range

Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2), Propane, Butane, Iso-Butane and Ethane.

R717 Heat Pump and Propylene applications

with replaced O-ring.

For further information please contact your local

• Max working pressure

• Flow coefficients

Danfoss Sales Company.

© Danfoss | DCS (ms) | 2020.01

REG-SA SS/REG-SB SS DN15-DN40

-60 – 150 °C / -76 – 302 °F

52 bar g / 754 psi g

Flow coefficients for fully opened valves from

kv = 0.15 to 80 m3/h (Cv = 0.17 to 92.5 USgal/min).

AI235186440137en-US1101 | 14

Page 15

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

R

E

G

U

L

A

T

I

N

G

V

A

L

V

E

R

E

G

-

S

A

S

S

Design

Housing

Made of stainless steel approved for low

temperature operations.

Connections

Available with the following connections:

• Butt-weld DIN (EN 10220)

DN 15 - 40 (½ - 1½ in.)

• Butt-weld ANSI (B 36.19M)

DN 15 - 40 (½ - 1½ in.)

The cone

The valves are available in two different

versions – REG-SA SS with an A cone and REGSB SS with a B cone. The A cone is designed for

expansion lines, while the B cone is designed for

regulating purposes e.g. liquid lines.

The valve cone is designed to ensure perfect

regulation and provide an extensive regulating

area. Irrespective of the refrigerant used, it is easy

to obtain the correct capacity. A cone seal ring

provides perfect sealing at a minimum closing

momentum.

The valve cone can be turned on the spindle, thus

there will be no friction between the cone and the

seat when the valve is opened and closed.

Spindle

Made of polished stainless steel, ideal for

O-ring sealing. Furthermore, parts of the

spindle are heat treated to obtain

anti-abrasive/adhesive properties.

Packing gland - REG-SA SS and REG-SB SS

The stainless steel packing gland comprises

a spring loaded seal packing gland which

ensures a perfect tightness in the range:

-60 – 150 °C / -76 – 302 °F.

The packing glands are equipped with a scraper

ring to prevent penetration of dirt and ice into the

packing gland.

Installation

Install the valve with the spindle up or in horizontal

position. The flow must be directed towards the

cone.

The valve is designed to withstand high internal

pressure. However, the piping system in general

should be designed to avoid liquid traps and

reduce the risk of hydraulic pressure caused by

thermal expansion.

For further information refer to product instruction

for REG-SA SS and REG-SB SS.

Example of marking ring, REG-SA SS

Connections

DIN

ANSI

© Danfoss | DCS (ms) | 2020.01

Pressure Equipment Directive (PED)

REG-SA/SB SS valves are approved according to the European standard specified in the Pressure

Equipment Directive and are CE marked.

REG-SA SS and REG-SB SS valves

Nominal bore

Classified for Fluid group I

Category Article 3, paragraph 3 II

Size OD T

Butt-weld DIN (EN 10220)

15 mm 21.3 2.3

½ in. 0.839 0.091

20 mm 26.9 2.3

¾ in 1.059 0.091

25 mm 33.7 2.6

1 in. 1.327 0.103

32 mm 42.4 2.6

1¼ in. 1.669 0.102

40 mm 48.3 2.6

1½ in. 1.902 0.103

DN = < 25 mm (1 in.) DN32-40 mm (1¼ - 1½ in.)

Size OD T

Butt-weld ANSI B 36.19M, SCHEDULE 40

15 mm 21.3 2.8

½ in. 0.839 0.11

20 mm 26.9 2.9

¾ in 1.06 0.11

25 mm 33.7 3.5

1 in. 1.33 0.14

32 mm 42.4 3.6

1¼ in. 1.67 0.14

40 mm 48.3 3.7

1½ in. 1.9 0.15

AI235186440137en-US1101 | 15

Page 16

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

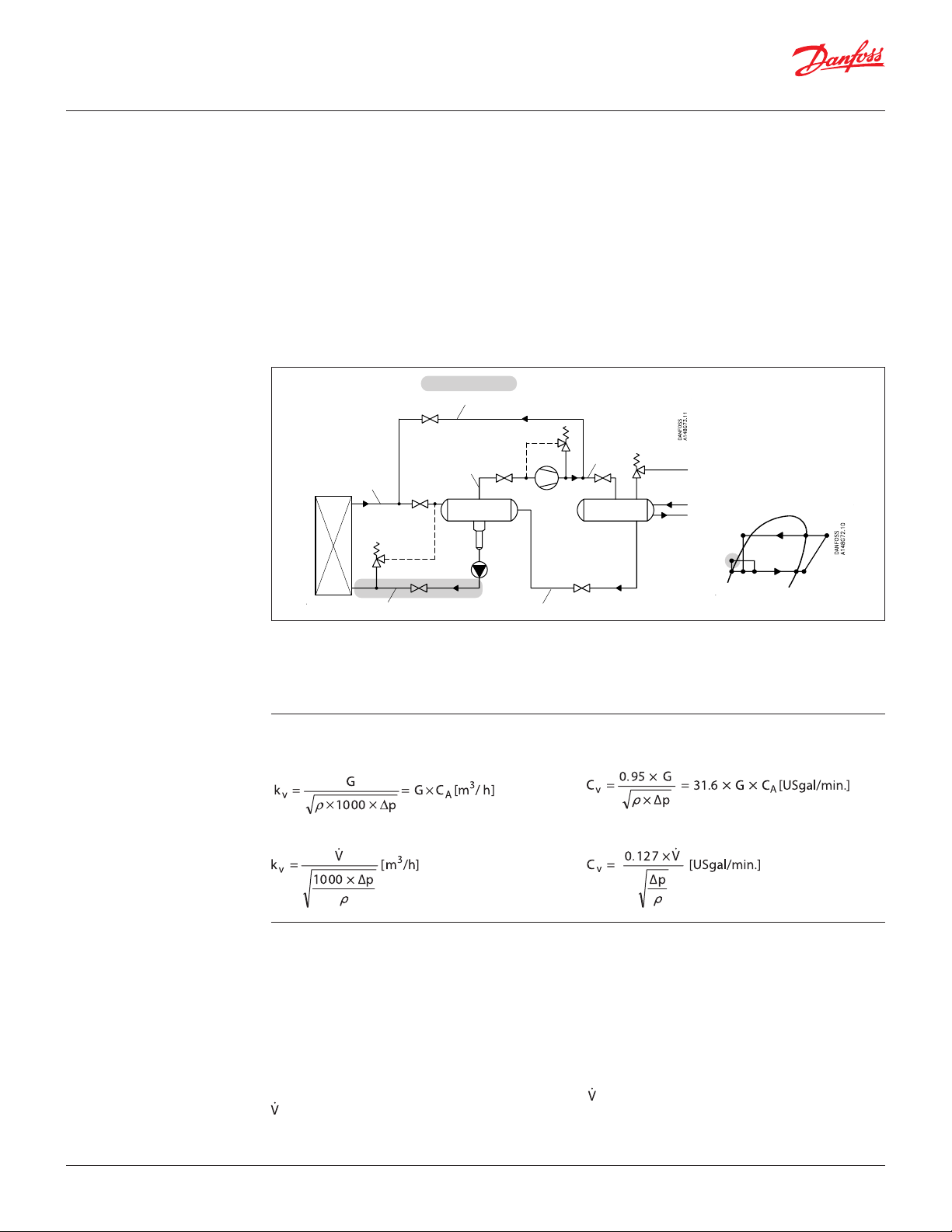

Computation and selection

Introduction

In refrigeration plants, regulating valves

are primarily used in liquid lines in order to

regulate the flow of refrigerant. The valves can,

however, also be used as expansion valves. From

a calculation point of view the two fields of

application are very different.

Normal flow is the term used to describe the

general case where the flow through the valve is

proportional to the square root of the pressure

drop across it and inversely proportional to the

density of the refrigerant (Bernouillis equation).

Location of valve in system (marked with grey)

Hot gas by-pass & defrost line

Dry suction line

Wet suction line

REG-SA/SB SS

This relationship between mass flow, pressure

drop and density satisfies the majority of all valve

applications with refrigerants and brines.

Normal flow is characterised by turbulent flow

through the valve without any phase change. The

following capacity curves are based on the above

mentioned assumption.

Application of the regulating valves outside

the normal flow area will reduce the capacity

of the valve considerably. In such cases it is

recommended to use "DIRcalc™" (Danfoss

Industrial Refrigeration calculation programme).

Discharge

line

Liquid line without phase change Liquid line with or without phase change

Sizing regulating valve for liquid flow

Liquid refrigerants: Use the liquid tables, fig. 6 - 10.

For other refrigerants and brines, "Normal flow"

(Turbulent flow); see below and use the flow

coefficient tables (fig. 1 - 2).

SI-units

Mass flow:

Volume flow:

kv [m3/h] Quantity [m3/h] of water flowing

Imperial units

Mass flow:

Volume flow:

Cv [US gal/min] Quantity [US gal/min] of water

through a valve at a pressure loss of

1 bar (according to VDE/VDI Norm

2173).

P1 [psi] Pressure before the valve

P1 [bar] Pressure before the valve

(upstream).

P2 [psi] Pressure after the valve

P2 [bar] Pressure after the valve

(downstream).

∆p [psi] Actual pressure loss across the

∆p [bar] Actual pressure loss across the valve

(P1–P2).

G [kg/h] Mass flow through the valve.

[m3/h] Volume flow through the valve.

G [lb/min] Mass flow through the valve.

[US gal/min] Volume flow through the valve.

ρ [lb/ft3] Density of the refrigerant before

ρ [kg/m3] Density of the refrigerant before the

valve.

CA Calculation factor (fig. 5).

CA Calculation factor (fig. 5).

flowing through a valve at a

pressure loss of 1 psi.

(upstream).

(downstream).

valve (P1–P2).

the valve

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 16

Page 17

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

B

A

0% 25% 50%75% 100%

Turn of spindle

Opening

K

v

(Cv)

0

2

4

6

8

10

12

14

16

18

20

012345678910 11 12

(23.20)

(20.88)

(18.56)

(16.24)

(13.92)

(11.60)

(9.28)

(6.96)

(4.64)

(2.32)

B

A

0

0

0% 25% 50%75% 100%

Turn of spindle

Opening

K

v

(Cv)

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

123456789

(5.80)

(5.22)

(4.64)

(4.06)

(3.48)

(2.90)

(2.32)

(1.74)

(1.16)

(0.58)

Computation and selection

Flow coefficient

REG-SA SS 15 – 20 and REG-SB SS 15 – 20

Fig. 1

Flow coefficient

Fig. 2

© Danfoss | DCS (ms) | 2020.01

REG-SA SS 25 – 40 and REG-SB SS 25 – 40

AI235186440137en-US1101 | 17

Page 18

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

kg/h

kg/h

Computation and selection

(Continued)

Liquid R 717, density: 670 kg/m3 [42 lb/ft3]

(lb/min)

REG-SA SS 15 – 20 and REG-SB SS 15 – 20

8000

(294)

4000

(147)

0

1

2

3

4

5

6

7

8

9

Turn of spindle

A

Turn of spindle

B

∆P = 2 bar (29 psi)

∆P = 1.5 bar (22 psi)

∆P = 1 bar (14 psi)

∆P = 0.5 bar (7 psi)

0%

25%

50%

75%

100%

Opening

Fig. 3

(lb/min)

30000

(1103)

20000

(735)

10000

(368)

0

1

2

3

4

5

6

7

8

9

10

11

12

Turn of spindle

REG-SA SS 25 – 40 and REG-SB SS 25 – 40

A

∆P = 2 bar (29 psi)

∆P = 1.5 bar (22 psi)

∆P = 1 bar (14 psi)

∆P = 0.5 bar (7 psi)

0%

25%

50%

75%

100%

B

Opening

Fig. 4

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 18

Page 19

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Computation and selection

(Continued)

For choice of valve size and

connection see "Connections".

Calculation factor CA

Fig. 5

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 19

Page 20

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

kg/h

Computation and selection

Example 1.

Refrigerant: R 717

Refrigerant flow: 2200 kg/h

Pressure drop:∆p = 0.5 bar

The above mentioned example is illustrated on

the following flow rate diagram and shows that

REG-SB SS 15 and 20 with cone B can be used. The

main rule is that nominal regulation range should

be below 85% opening degree. If the arrowline is

crossing 2 cone curves, the smaller cone should be

selected if opening degree

< 85%.

Flow rate diagram

(lb/min)

REG-SA SS 15 – 20 and REG-SB SS 15 – 20

8000

(294)

4000

(147)

2200

(81)

0

The example is only correct if the density of the

refrigerant is approx. 670 (kg/m3), and there must

be no build-up of flash gas in the valve.

∆P = 2 bar (29 psi)

∆P = 1.5 bar (22 psi)

∆P = 1 bar (14 psi)

∆P = 0.5 bar (7 psi)

1

2

3

4

5

6

7

8

9

Turn of spindle

0%

25%

50%

75%

Turn of spindle

A

B

100%

Opening

Fig. 6

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 20

Page 21

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

0% 25% 50% 75% 100%

e

Opening

K

(Cv)

Computation and selection

Example 2.

Brine, density ρ: 1150 [kg/m3]

Brine flow G: 2,700 [kg/h]

Pressure drop ∆p: 0.5 [bar]

In this example it is not possible to use the

selection diagrams (fig. 3 and 4) as the refrigerant

in question is not included.

Calculation example:

Required kv-value

CA = 0.00132 (from fig. 18)

kv = CA × G

kv = 0.00132 × 2,700 [kg/h]

= 3.56 [m3/h]

Calculation factor C

Use the curves of the kv-values instead (fig. 1 - 2)

and calculate the required kv by means of the

formulas in the "Introduction" passage at the

beginning of this chapter. Alternatively calculate

the kv-values by means of the calculation factor CA

(fig. 7) and the flow rate diagram (in this example:

fig. 8) as per the following calculation example.

A

Density kg/m3

[lb/ft]

Fig. 7

Flow rate diagram

v

5

(5.80)

4.5

(5.22)

4

3.56 m3/h

(from

calculation

above)

REG-SB SS 15 and REG-SB SS 20

(4.64)

3.5

(4.06)

3

(3.48)

2.5

(2.90)

2

(2.32)

1.5

(1.74)

1

(1.16)

0.5

(0.58)

0

123456789

0

with cone B can be used.

B

A

Turn of spindl

Fig. 8

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 21

Page 22

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Danfoss

M148B0010_1

17

11

18

8

10

9

7

12

2

13

3A

4

1

21

5

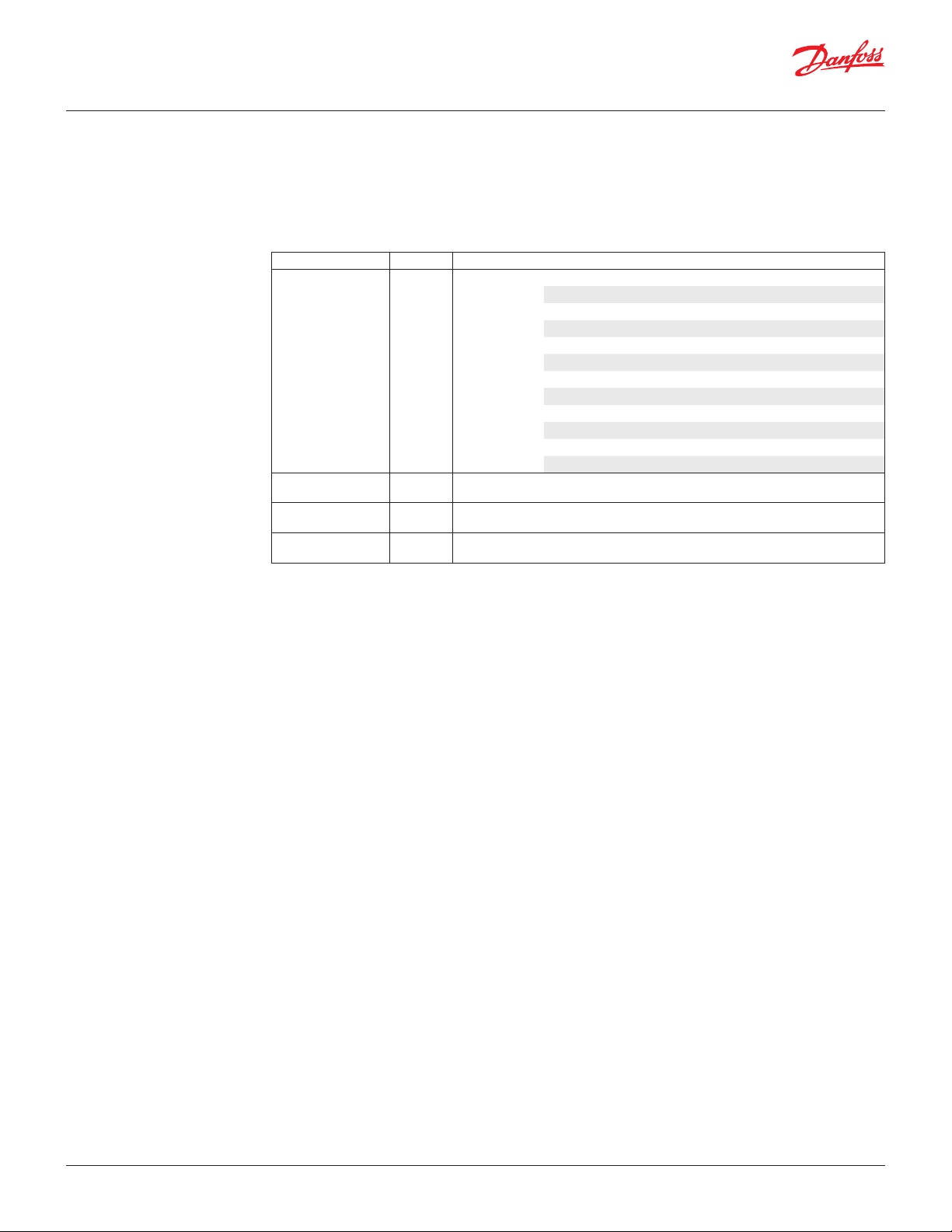

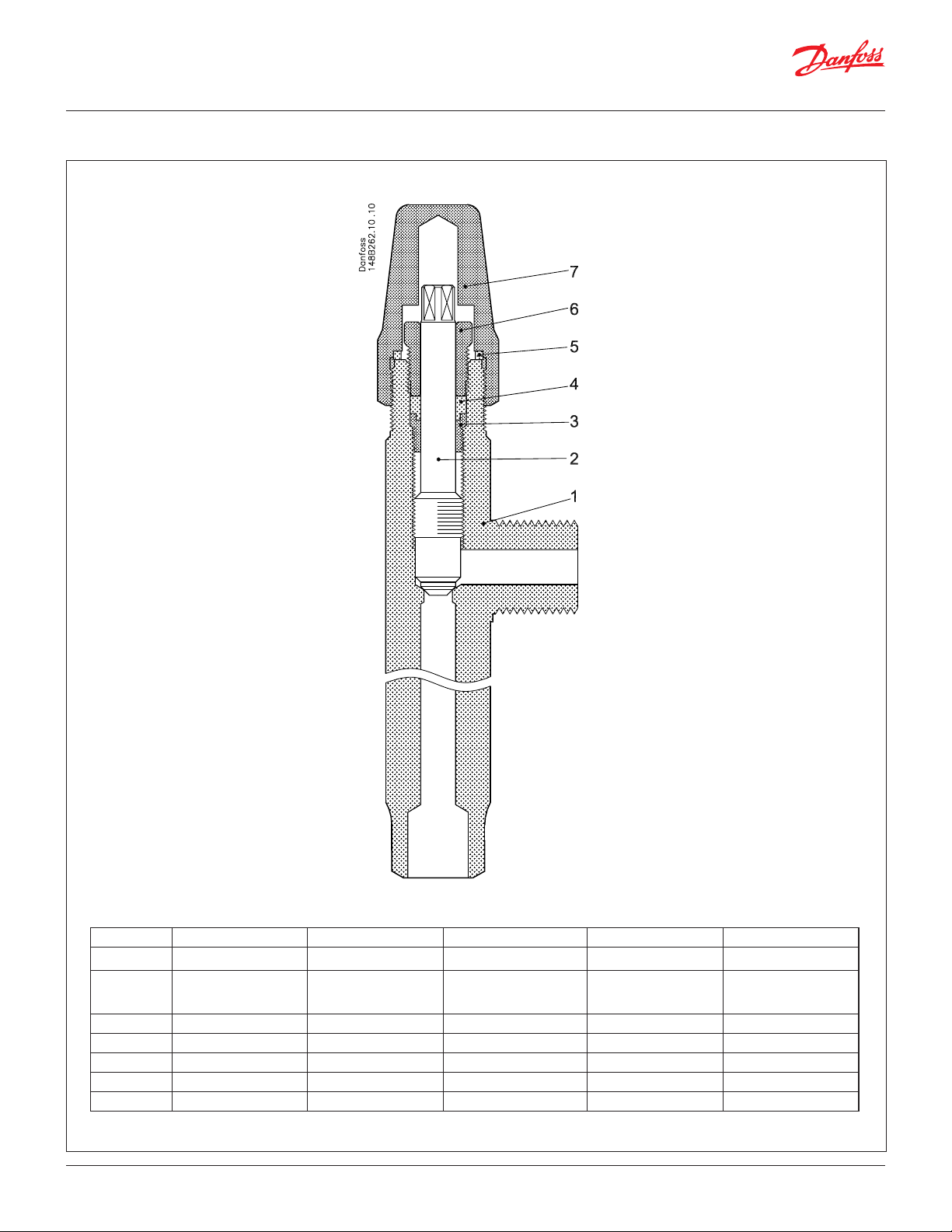

Material specification

REG-SA SS and REG-SB SS 15 – 40

No. Part Material EN ISO ASTM

1 Housing

2

Bonnet, Flange Stainless steel X5CrNi18-10

3A

Bonnet, Insert Stainless steel

4 Spindle Stainless steel X8CrNiS 18-9, DIN 17440 Type 17, 683/13 AISI 303

5 Cone Steel

7 Packing washer Aluminium

8 Packing gland Stainless Steel X8CrNiS 18-9, 10088 Type 17, 683/13 AISI 303

9 O-ring Cloroprene (Neoprene)

10 Spring loaded Teflon ring PTFE

11 O-ring Cloroprene (Neoprene)

12 Bolts Stainless steel A2-70 A2-70 Type 308

13 Gasket Fiber, non asbestos

14 Bottom insert Steel

17 Seal cap Aluminium

18 Gasket f. seal cap Nylon

19 Locking nut Steel

20 Screw Steel

21 Disk spring Steel

Stainless steel GX5CrNi19-10

EN10213-4

EN10088

X8CrNiS18-9

DIN 17440

AISI 304

AISI 304

AISI 303

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 22

Page 23

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Dimensions and weights REG-SA SS and REG-SB SS 15 – 40 in angleway version

REG-SA SS and REG-SB SS 15 – 40

Valve size C G ∅D

REG-SA SS/SB SS 15 – 20

REG-SA SS/SB SS (½ – 3/4) mmin.

REG-SA SS/SB SS 25 – 40

REG-SA SS/SB SS (1 – 1 ½) mmin.

Specified weights are approximate values only.

182

7.17

237

9.33

45

1.77

55

2.17

REG-SA SS and REG-SB SS 10 – 65 in straightway version

REG-SA SS and REG-SB SS 15 – 40

38

1.50

50

1.97

H

60

2.36

70

2.76

Weight

1.4 kg

3.1 lb

2.4 kg

5.3 lb

© Danfoss | DCS (ms) | 2020.01

Valve size C B E G ∅D

REG-SA SS/SB SS 15 – 20

REG-SA SS/SB SS (½ – 3/4) mmin.

REG-SA SS/SB SS 25 – 40

REG-SA SS/SB SS (1 – 1 ½) mmin.

Specified weights are approximate values only.

145

5.71

200

7.87

155

6.10200.79

215

8.46261.02

120

4.72

155

6.10

H

38

1.50

50

1.97

60

2.36

70

2.76

AI235186440137en-US1101 | 23

Weight

2.0 kg

4.4 lb

3.0 kg

6.6 lb

Page 24

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Ordering How to order

The table below is used to indentify the valve

required.

Please note that the type codes only serve to

identify the valves, some of which may not form

part of the standard product range. For further

information please contact your local Danfoss Sales

Company.

Type codes

Valve type REG SA SS

Nominal size in mm

(Valve size measured on

the connection diameter)

Connections D

Valve housing ANG Angle flow

Cone A Size:

Cone B Size:

REG-SB SS

DN 15

DN 20

DN 25

DN 32

DN 40

DN 15

DN 20

DN 25

DN 32

DN 40

Regulating Valves

Available connection types

15 DN 15 x x

20 DN 20 x x

25 DN 25 x x

32 DN 32 x x

40 DN 40 x x

Butt-weld connection

A

Butt-weld connection

STR Straight flow

Flow area [mm2]

36.5

36.5

178

178

178

Flow area [mm2]

115

115

531

531

531

D A

: DIN EN 10220

: ANSI B 36.19M

Example:

REG-SA SS (Cone B) 15 DIN

angleway = 148B5387

Important!

Where products need to be

certified according to specific

certification societies or where

higher pressures are required, the

relevant information should be

included at the time of order.

D = Butt-weld DIN

A = Butt-weld ANSI

ANG = Angleway

STR = Straightway

Complete REG-SA SS (Cone type A)

Butt-weld DIN (EN 10220)

Size Type Code no.

mm in.

Angleway - REG-SA SS with cone type A

15 ½ REG-SA SS 15 D ANG 148B5297

20 ¾ REG-SA SS 20 D ANG 148B5385

25 1 REG-SA SS 25 D ANG 148B5494

32 1 ¼ REG-SA SS 32 D ANG 148B5589

40 1 ½ REG-SA SS 40 D ANG 148B5674

Butt-weld ANSI (B 36.19M SCHEDULE 40)

Size Type Code no.

mm in.

Angleway - REG-SA SS with cone type A

15 ½ REG-SA SS 15 A40 ANG 148B6482

25 1 REG-SA SS 25 A40 ANG 148B6483

32 1 ¼ REG-SA SS 32 A40 ANG 148B6484

Butt-weld DIN (EN 10220)

Size Type Code no.

mm in.

Straightway - REG-SA SS with cone type A

15 ½ REG-SA SS 15 D STR 148B5298

20 ¾ REG-SA SS 20 D STR 148B5386

25 1 REG-SA SS 25 D STR 148B5495

32 1 ¼ REG-SA SS 32 D STR 148B5590

40 1 ½ REG-SA SS 40 D STR 148B5675

Butt-weld ANSI (B 36.19M SCHEDULE 40)

Size Type Code no.

mm in.

Straightway - REG-SA SS with cone type A

15 ½ REG-SA SS 15 A40 STR 148B5299

25 1 REG-SA SS 25 A40 STR 148B6485

32 1 ¼ REG-SA SS 32 A40 STR 148B6486

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 24

Page 25

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Ordering

D = Butt-weld DIN

A = Butt-weld ANSI

ANG = Angleway

STR = Straightway

Replacement kit (O-ring

replacement) for

R717 Ammonia Heat

Pump* and Propylene

applications (including

ID tag)

Complete REG-SB SS (Cone type B)

Butt-weld DIN (EN 10220)

Size Type Code no.

mm in.

Angleway - REG-SB SS with cone type B

15 ½ REG-SB SS 15 D ANG 148B5387

20 ¾ REG-SB SS 20 D ANG 148B5389

25 1 REG-SB SS 25 D ANG 148B5496

32 1 ¼ REG-SB SS 32 D ANG 148B5591

40 1 ½ REG-SB SS 40 D ANG 148B5676

Butt-weld ANSI (B 36.19M SCHEDULE 40)

Size Type Code no.

mm in.

Angleway - REG-SB SS with cone type B

20 ¾ REG-SB SS 20 A40 ANG 148B6487

40 1 ½ REG-SB SS 40 A40 ANG 148B5686

Size O-ring kit for

mm in.

10 /₈ 148B6084 148B6085

15 ½

20 ¾

25 1

40 1½

* Replacement kits for R717 Ammonia Heat Pump is

applicable for continuous operating temperature between

+100°C to 150°C (212°F to 302°F)

R717

Heat pump

148B6070 148B6077

148B6071 148B607832 1¼

R1270

Propylene

Butt-weld DIN (EN 10220)

Size Type Code no.

mm in.

Straightway - REG-SB SS with cone type B

15 ½ REG-SB SS 15 D STR 148B5388

20 ¾ REG-SB SS 20 D STR 148B5390

25 1 REG-SB SS 25 D STR 148B5497

32 1 ¼ REG-SB SS 32 D STR 148B5592

40 1 ½ REG-SB SS 40 D STR 148B5677

Butt-weld ANSI (B 36.19M SCHEDULE 40)

Size Type Code no.

mm in.

Straightway - REG-SB SS with cone type B

20 ¾ REG-SB SS 20 A40 STR 148B6488

25 1 REG-SB SS 25 A40 STR 148B6479

40 1 ½ REG-SB SS 40 A40 STR 148B5685

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 25

Page 26

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Pressure

Temperature

˚C

psi

bar

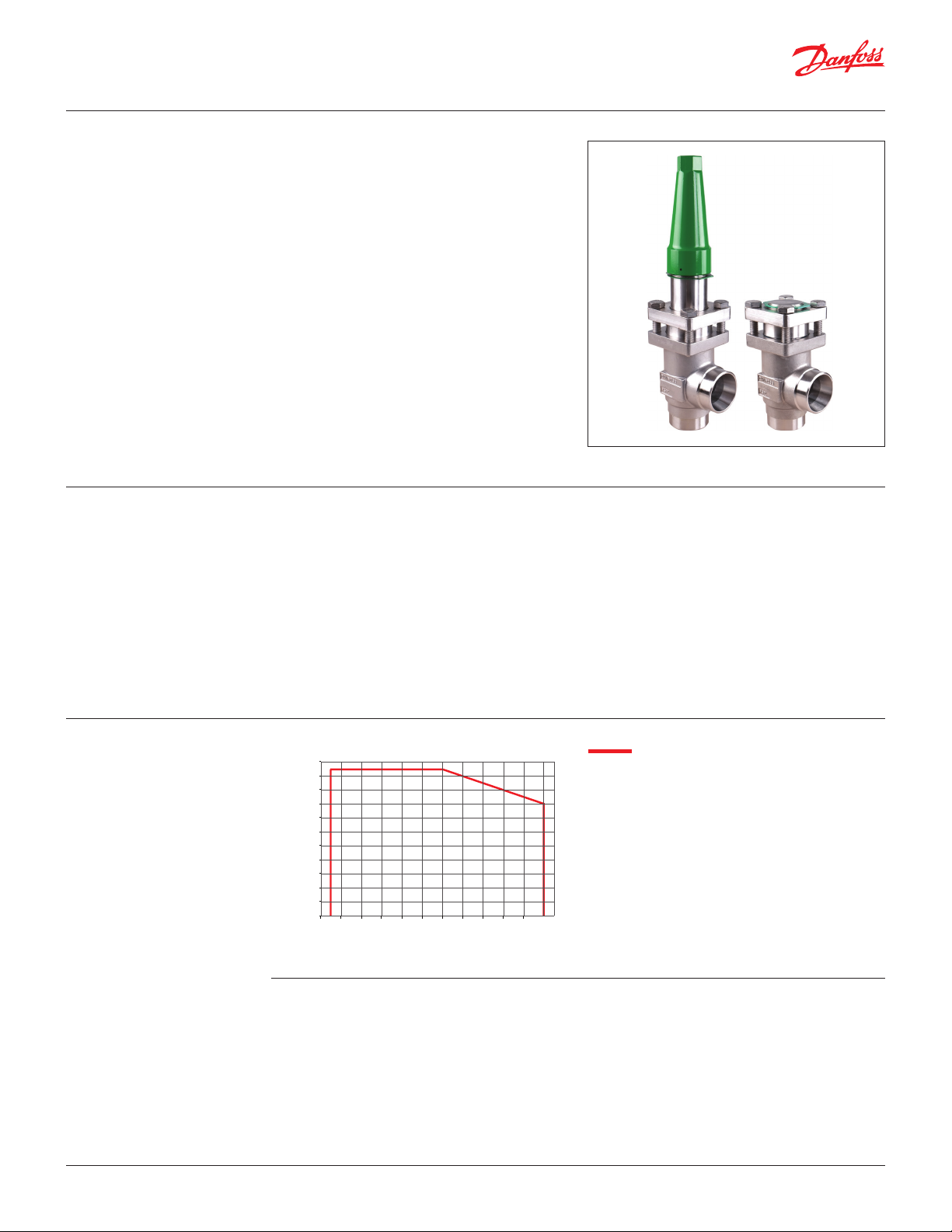

Check & stop valves and

check valves

SCA-X SS and CHV-X SS

Features

SCA-X SS and CHV-X SS

In certain specific areas such as outdoor

applications and corrosive atmospheres, such as

coastal installations, there is a need for high surface

protection to prevent failure due to corrosion.

Today's food safety standards often call for daily

treatment with detergents to protect against

bacteria growth, again producing a need for high

surface protection.

SCA-X SS are check valves with a built-in stop valve

function. CHV-X SS are check valves only.

The valves are designed to open at very low

differential pressures, allow favourable flow

conditions and are easy to disassemble for

inspection and service.

The valve cone has a built-in flexibility to ensure a

precise and tight closing towards the valve seat.

A well balanced dampening effect between the

piston and the cylinder gives an optimal protection

during low loads and against pulsations.

• Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2), Propane, Butane, Iso-Butane and Ethane.

R717 Heat Pump and Propylene applications

with replaced O-ring.

• Designed to give favourable flow conditions.

• Internal backseating enables replacement

of the spindle seal whilst the valve is active, i.e.

under pressure (SCA-SS)

• Housing is made of special cold resistant

stainless steel approved for low temperature

operations.

• Easy to disassemble for inspection and service.

• Butt-weld DIN and ANSI connections.

• Max. operating pressure:

52 bar g / 754 psig

• Tem perature range:

-60 – 150 °C / -76 – 302 °F.

• Compact and light valves for easy handling and

installation.

• Classification: DNV, CRN, BV, EAC etc.

To get an updated list of certification on the

products please contact your local Danfoss Sales

Company.

Pressure and

temperature range

Technical data • Refrigerants

798

55

725

50

653

45

580

40

508

35

435

30

363

25

Pressure

290

20

218

15

145

10

73

5

0

0

-70

-50-30 -101030507090 110 130 150

-94-58 -22145086 122 158 194 230 266 302

Temperature

Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2), Propane, Butane, Iso-Butane and Ethane.

R717 Heat Pump and Propylene applications

˚F

• Temperature range

• Max. working pressure

with replaced O-ring.

SCA-X SS/CHV-X SS DN15-DN40

-60 – 150 °C / -76 – 302 °F.

52 bar g / 754 psig.

For further information refer to the product

instruction for SCA-X SS/CHV-X SS.

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 26

Page 27

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

S

S

Design Connections

Available with the following connections:

• Butt-weld DIN (EN 10220)

DN 15 – 40 (½ – 1 ½ in.)

• Butt-weld ANSI (B 36.19M)

DN 20 – 40 (¾ – 1 ½ in.)

Housing

Made of stainless steel approved for low

temperature operations.

Valve cone

Valve cone with built in metallic stop - prevents

damage to teflon ring in case of overtightening.

Damping chamber

The chamber is filled with refrigerants (gas or

liquid), which provides a damping effect when the

valve opens and closes.

Spindle (SCA-X SS)

Made of polished stainless steel, which is ideal for

O-ring sealing.

Packing Gland (SCA-X SS)

The “full temperature range” packing gland is the

standard for the entire SVL platform.

This ensures perfect tightness throughout the

whole temperature range:

-60 – 150 °C / -76 – 302 °F.

Pressure Equipment Directive (PED)

The SCA-X SS/CHV-X SS valves are approved

according to the European standard specified

in the Pressure Equipment Directive and are CE

marked.

For further details / restrictions - see the product

instruction.

Installation

The valve must be mounted vertically with the

cone downwards.

The valve is designed to resist very high internal

pressure. However, the piping system in general

should be designed to avoid liquid traps and

reduce the risk of hydraulic pressure caused by

thermal expansion.

For further information refer to installation

instructions for SCA-X SS/CHV-X SS.

If cold refrigeration oil having low viscosity enters

and settles in the damping chamber, problems

with the check valve may arise. Consequently, it

may be necessary to modify the valve for more

viscous liquids by enlarging the hole to the

damping chamber.

”

½

/

5

1

N

D

X

-

V

H

C

E

V

L

A

V

K

C

E

H

C

Example of marking ring, CHV-X SS

Connections

DIN

ANSI

SCA-X SS/CHV-X SS valves

Nominal bore

Classified for Fluid group I

Category Article 3, paragraph 3 II

Size OD T

Butt-weld DIN (EN 10220)

15 mm 21.3 2.3

½ in. 0.839 0.091

20 mm 26.9 2.3

¾ in 1.059 0.091

25 mm 33.7 2.6

1 in. 1.327 0.103

32 mm 42.4 2.6

1 ¼ in. 1.669 0.102

40 mm 48.3 2.6

1 ½ in. 1.902 0.103

DN = < 25 mm (1 in.) DN32-40 mm (1 ¼ – 1 ½ in.)

Size OD T

Butt-weld ANSI B 36.19M, SCHEDULE 40

20 mm 26.9 2.9

¾ in 1.06 0.11

25 mm 33.7 3.5

1 in. 1.33 0.14

32 mm 42.4 3.6

1 ¼ in. 1.67 0.14

40 mm 48.3 3.7

1 ½ in. 1.9 0.15

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 27

Page 28

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Danfoss

M148G0009_1

1

2

3

5

14

13

12

6

15

17

8

9

4

3

12

13

7

14

5

1

16

15

2

6

11

10

Danfoss

M148G0008_1

Material specification

12

2

3

13

14

5

6

1

SCA-X SS 15 - 40

No. Part Material DIN/EN ISO ASTM

1 Housing

2 Bonnet, Flange

3 Bonnet, Insert Stainless steel

4 Spindle

5 Cone Steel

6

O-ring Cloroprene (Neoprene)

7 Spindle extension Steel

8 Packing gland

O-rings

9 Packing washer Aluminium

10 Spring loaded seal Teflon (PTFE)

11 O-ring Cloroprene (Neoprene)

12 Bolts Stainless steel A2-70 A2-70 Type 308

13 Gasket Fiber, non-asbestos

14 Spring Steel

15 Identification ring Stainless steel

16 Seal cap gasket Nylon

17 Spindle seal cap Aluminium

Stainless steel GX5CrNi19-10

Stainless steel X5CrNi18-10

Stainless steel X8CrNiS18-9

Teflon (PTFE)

Stainless steel

Cloroprene (Neoprene)

CHV-X SS 15 - 40

CHV-X SS 15 - 40

AISI 304

EN10213-4

AISI 304

EN10088

X8CrNiS18-9

DIN 17440

Type 17, 17440 AISI 303

DIN 17440

15

Danfoss

148G237_02-2017

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 28

Page 29

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

DA

148G238_02-201

Dimensions and weights

SCA-X SS/CHV-X SS 15 – 40 (½ – 1 ½ in.)

SCA-X SS 15 - 40

CHV-X SS 15 - 40

G

B

C

E

H

7

NFOSS

Specified weights are approximate

values only.

Valve size C G ∅D F

SCA-X SS 15 – 40

SCA-X SS 15 (½ in.)

SCA-X SS 20 (¾ in.)

SCA-X SS 25 (1 in.)

SCA-X SS 32 (1 ¼ in.)

SCA-X SS 40 (1 ½ in.)

mm 212 45 38 60 60

in. 8.35 1.77 1.50 2.36 2.36

mm 212 45 38 60 60

in. 8.35 1.77 1.50 2.36 2.36

mm 295 55 50 85 70

in. 11.61 2.17 1.97 3.35 2.76

mm 295 55 50 85 70

in. 11.61 2.17 1.97 3.35 2.76

mm 295 55 50 85 70

in. 11.61 2.17 1.97 3.35 2.76

CHV-X SS 15 – 40 Angleway

CHV-X SS 15 (½ in.)

CHV-X SS 20 (¾ in.)

CHV-X SS 25 (1 in.)

CHV-X SS 32 (1 ¼ in.)

CHV-X SS 40 (1 ½ in.)

Valve size C B E G F

mm 103

in.

mm 103 45 60 60

in. 4.06 1.77 2.36 2.36

mm 143 55 85 70

in. 5.63 2.17 3.35 2.76

mm 143 55 85 70

in. 5.63 2.17 3.35 2.76

mm 143 55 85 70

in. 5.63 2.17 3.35 2.76

4.06

45

1.77

CHV-X SS 15 – 40 Straightway

CHV-X SS 15 (½ in.)

CHV-X SS 20 (¾ in.)

CHV-X SS 25 (1 in.)

CHV-X SS 32 (1 ¼ in.)

CHV-X SS 40 (1 ½ in.)

mm 99 114 19 120 60 60 1.3kg

in. 3.90 4.49 0.75 4.72 2.36 2.36 2.87lb

mm 99 114 19 120 60 60 1.3kg

in. 3.90 4.49 0.75 4.72 2.36 2.36 2.87lb

mm 141 157 26 155 85 70 2.6kg

in. 5.55 6.18 1.02 6.10 3.35 2.76 5.73lb

mm 141 157 26 155 85 70 2.6kg

in. 5.55 6.18 1.02 6.10 3.35 2.76 5.73lb

mm 141 157 26 155 85 70 2.6kg

in. 5.55 6.18 1.02 6.10 3.35 2.76 5.73lb

60

2.36

min

2.36

min

H

60

H

Weight

1.6 kg

3.53 lb

1.6 kg

3.53 lb

3.2 kg

7.05 lb

3.2 kg

7.05 lb

3.2 kg

7.05 lb

1.2 kg

2.65 lb

1.2 kg

2.65 lb

2.3 kg

5.07 lb

2.3 kg

5.07 lb

2.3 kg

5.07 lb

Weight

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 29

Page 30

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Ordering

How to order

The table below is used to identify the valve

required.

Please note that the type codes only serve to identify the valves, some of wich may not form part of

the standard product range.

Valve type SCA-X SS

CHV-X SS

(valve size measured on the

connection diameter)

Connections D

Valve housing ANG Angle flow

Stop Check Valve

Check Valve

15 DN 15 x

20 DN 20 x x

25 DN 25 x x

32 DN 32 x x

40 DN 40 x x

Butt-weld connection

A

Butt-weld connection

STR Straight flow

Important!

Where products need to be certified according

to specific certification societies the relevant

information should be included at the time of

order.

SCA-X SS Angleway

Butt-weld DIN (EN 10220)

Size

mm in.

15 ½ SCA-X SS 15 D ANG 148B5293

20 ¾ SCA-X SS 20 D ANG 148B5381

25 1 SCA-X SS 25 D ANG 148B5490

32 1 ¼ SCA-X SS 32 D ANG 148B5585

40 1 ½ SCA-X SS 40 D ANG 148B5664

Butt-weld ANSI (B 36.19M SCHEDULE 40)

Size

mm in.

20 ¾ SCA-X SS 20 A40 ANG 148B6489

25 1 SCA-X SS 25 A40 ANG 148B6480

32 1 ¼ SCA-X SS 32 A40 ANG 148B6490

40 1 ½ SCA-X SS 40 A40 ANG 148B5687

Type Code No.

Type Code No.

For further information please contact your local

Danfoss Sales Company.

D A

: DIN EN 10220

: ANSI B 36.19M

ANG = Angleway

STR = Straightway

Replacement kit (O-ring

replacement) for

R717 Ammonia Heat

Pump* and Propylene

applications (including

ID tag)

© Danfoss | DCS (ms) | 2020.01

CHV-X SS Angleway

Butt-weld DIN (EN 10220)

Size

mm in.

15 ½ CHV-X SS 15 D ANG 148B5294

20 ¾ CHV-X SS 20 D ANG 148B5382

25 1 CHV-X SS 25 D ANG 148B5491

32 1 ¼ CHV-X SS 32 D ANG 148B5586

40 1 ½ CHV-X SS 40 D ANG 148B5665

Butt-weld ANSI (B 36.19M SCHEDULE 40)

Size

mm in.

20 ¾ CHV-X SS 20 A40 ANG 148B6491

25 1 CHV-X SS 25 A40 ANG 148B6481

32 1 ¼ CHV-X SS 32 A40 ANG 148B6492

40 1 ½ CHV-X SS 40 A40 ANG 148B5688

Size O-r ing kit for

mm in.

15 ½

20 ¾

25 1

40 1½

Type Code No.

Type Code No.

R717

Heat pump

148B6070 148B6077

148B6071 148B607832 1¼

R1270

Propylene

CHV-X SS Straightway

Butt-weld DIN (EN 10220)

Size

mm in.

15 ½ CHV-X SS 15 D STR 148B5678

20 ¾ CHV-X SS 20 D STR 148B5679

25 1 CHV-X SS 25 D STR 148B5680

32 1 ¼ CHV-X SS 32 D STR 148B6544

40 1 ½ CHV-X SS 40 D STR 148B6566

Type Code No.

Butt-weld ANSI (B 36.19M SCHEDULE 40)

Size

mm in.

20 ¾ CHV-X SS 20 A40 STR 148B6608

25 1 CHV-X SS 25 A40 STR 148B6609

32 1 ¼ CHV-X SS 32 A40 STR 148B6610

40 1 ½ CHV-X SS 40 A40 STR 148B6611

Type Code No.

* Replacement kits for R717 Ammonia Heat Pump is

applicable for continuous operating temperature between

+100°C to 150°C (212°F to 302°F)

AI235186440137en-US1101 | 30

Page 31

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Pressure

Temperature

˚C

psi

bar

Strainers

FIA SS

Features

FIA SS

In certain specific areas such as outdoor

applications and corrosive atmospheres, such as

coastal installations, there is a need for high surface

protection to prevent failure due to corrosion.

Today's food safety standards often call for daily

treatment with detergents to protect against

bacteria growth, again producing a need for high

surface protection.

FIA SS strainers are a range of angle-way and

straight-way strainers which are carefully

designed to give favourable flow conditions.

The design makes the strainer easy to install, and

ensures quick strainer inspection and cleaning.

FIA SS strainers are used ahead of automatic

controls, pumps, compressors etc., for

initial plant start-up and where permanent

filtration of the refrigerant is required. The

strainer reduces the risk of undesirable system

breakdowns and reduces wear and tear on

plant components.

• Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2) and all flammable refrigerants.

• Designed to give favourable flow conditions.

• Housing is made of special cold resistant

stainless steel approved for low temperature

operations.

• Easy to disassemble for inspection and service.

• Butt-weld DIN and ANSI connections.

• Max. operating pressure:

52 bar g / 754 psig

• Tem perature range:

-60 – 150 °C / -76 – 302 °F.

• Compact and light valves for easy handling and

installation.

• Classification: DNV, CRN, BV, EAC etc.

To get an updated list of certification on the

products please contact your local Danfoss Sales

Company.

Pressure and

temperature range

Technical data • Refrigerants

798

55

725

50

653

45

580

40

508

35

435

30

363

25

Pressure

290

20

218

15

145

10

73

5

0

0

-70

-50-30 -101030507090 110 130 150

-94-58 -22145086 122 158 194 230 266 302

˚F

• Temperature range

Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2) and all flammable refrigerants.

For further information please see installation

• Max. working pressure:

guide for FIA SS.

© Danfoss | DCS (ms) | 2020.01

FIA SS DN15-DN65

-60 – 150 °C / -76 – 302 °F.

52 bar g / 754 psi g.

AI235186440137en-US1101 | 31

Page 32

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

S

S

D

Design

Connections

Available with the following connections:

• Butt-weld DIN (EN 10220)

DN 15 – 65 (½ – 2 ½ in.)

• Butt-weld ANSI (B 36.19M)

DN 15 – 65 (½ – 2 ½ in.)

Strainer Insert

A filter grid and filter net of stainless steel ensure

long element life. The filter net offers a very high

degree of cleanability.

Housing

Made of stainless steel approved for low

temperature operations.

Pressure Equipment Directive (PED)

FIA SS strainers are approved in accordance with

the European standard specified in the Pressure

Equipment Directive and are CE marked.

For further details / restrictions - see Installation

Instruction.

Installation / Maintenance

The strainer is designed to resist high internal

pressures. However, the piping system in general

should be designed to avoid liquid traps and

reduce the risk of hydraulic pressure caused by

thermal expansion.

Danfoss recommends replacement/cleaning of

the strainer when the differential pressure loss

>0.5 bar / 7.3 psi in the liquid line and >0.05 bar /

0.7 psi in the suction line. The max. permissible

differential pressure is 1 bar / 15 psi.

For further information refer to installation

instruction for FIA SS.

Identification:

”

½

/

5

1

N

A

I

F

R

E

T

L

I

F

Example of marking ring, FIA SS

Connections

DIN

ANSI

Install the strainer with the cover in downward

position.

FIA SS

Nominal bore DN ≤25 (1 in.) DN 32 – 65 mm (11/4 – 2 ½ in.)

Classified for Fluid group I

Category Article 3, paragraph 3 II

Size OD T

Butt-weld DIN (EN 10220)

15 mm 21.3 2.3

½ in. 0.839 0.091

20 mm 26.9 2.3

¾ in 1.059 0.091

25 mm 33.7 2.6

1 in. 1.327 0.103

32 mm 42.4 2.6

1 ¼ in. 1.669 0.102

40 mm 48.3 2.6

1 ½ in. 1.902 0.103

50 mm 60.3 2.9

2 in. 2.37 0.11

65 mm 76.1 2.9

2 ½ in. 3 0.11

Size OD T

Butt-weld ANSI (B 36.19M)

15 mm 21.3 2.8

½ in. 0.839 0.11

20 mm 26.9 2.9

¾ in 1.06 0.11

25 mm 33.7 3.5

1 in. 1.33 0.14

32 mm 42.4 3.6

1 ¼ in. 1.67 0.14

40 mm 48.3 3.7

1 ½ in. 1.9 0.15

50 mm 60.3 2.8

2 in. 2.37 0.11

65 mm 73 3.1

2 ½ in. 2.87 0.12

© Danfoss | DCS (ms) | 2020.01

AI235186440137en-US1101 | 32

Page 33

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Selection of strainer size

Definition

Mesh is the number of threads per inch.

µ (microns) is the distance between two

threads (1µ = 1 /1000 mm).

The mesh aperture size of the strainer must

satisfy the requirements stated by the sup pliers

The following recommendations of aperture size

apply in general to refrigeration installations:

of the equipment to be protected.

All lines

First start up:.............................................................................................................. 50µ

(Use filter element with removable insert for FIA SS DN15-40 or

separate filter bag for FIA SS DN 50-65. 50µ insert should normally

be removed after the first 24 hours of operation)

Liquid Lines

Ahead of pumps: ..................................................................................................... 500µ [38 mesh]

After pumps: ............................................................................................................. 150µ [100 mesh] / 250µ [72 mesh]

In front of AKVA valves .......................................................................................... 100µ [150 mesh]

Protection of automatic regulation equipment

Generally ................................................................................................................... 150µ [100 mesh] / 250µ [72 mesh]

Sensitive equipment, e.g.

suction regulators with low temperature ...................................................... 250µ [72 mesh]

Suction Lines

Ahead of screw compressor ............................................................................... 250µ [72 mesh]

Ahead of piston compressor .............................................................................. 150µ [100 mesh]

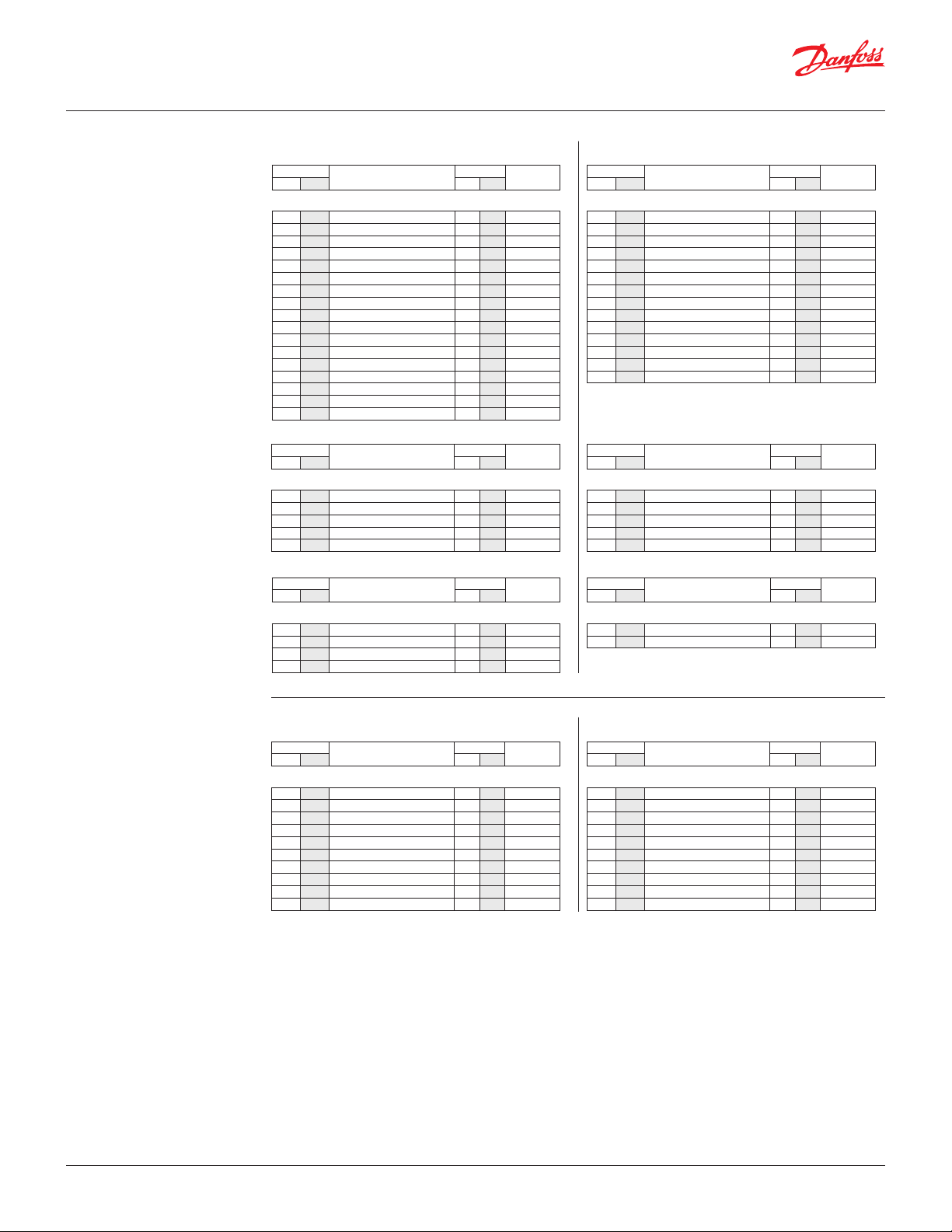

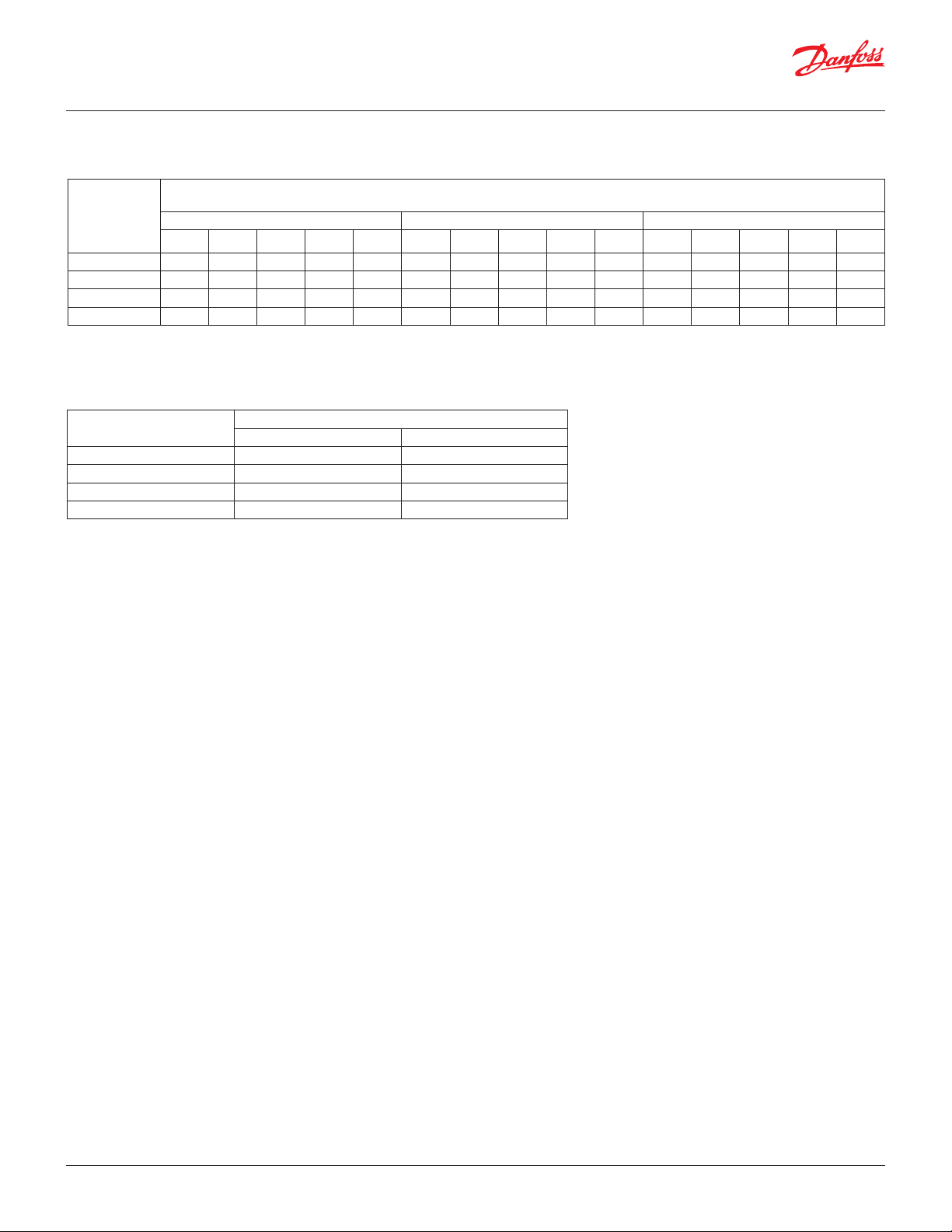

Flow coefficient (DIN / ANSI)

Connection size (DN)

FIA SS

15 - 20

(1/2” – 3/4”)

25 - 40

(1” – 1 1/2”)

50 (2”)

65 (2 1/2”)

µ

mesh wire

mm

100 0.068 0.003 35 25 3.9 45 7.0

150 100 0.10 0.004 36 25 3.9 45 7.0

250 72 0.10 0.004 51 25 3.9 45 7.0

500 38 0.16 0.006 57.6 25 3.9 45 7.0

100 0.068 0.003 35 71 11 160 25.0

150 100 0.10 0.004 36 71 11 160 25.0

250 72 0.10 0.004 51 71 11 160 25.0

500 38 0.16 0.006 57.6 71 11 160 25.0

100 0.068 0.003 35 71 11 200 31.2

150 100 0.10 0.004 36 87 13.5 200 31.2

250 72 0.10 0.004 51 87 13.5 200 31.2

500 38 0.16 0.006 57.6 87 13.5 200 31.2

150 100 0.10 0.004 36 127 19.7 305 47.6

250 72 0.10 0.004 51 127 19.7 305 47.6

500 38 0.16 0.006 57.6 127 19.7 305 47.6

wire

in.

free

space

%

Plain elements Pleated elements

2

cm

screen area

2

in

cm

2

2

in

© Danfoss | DCS (ms) | 2020.01

Kv values

DN FIA SS angle - plain filter net FIA SS angle - pleated filter net

µ100 µ150 µ250 µ500 µ150 µ250 µ500

15 3.3 3.4 3.5 3.7 4.2

20 6.9 7.1 7.3 7.7 8.8

25 13.8 14.0 14.5 15.2 17.2 17.9

32 23.0 23.8 24.7 25.5 29.2 30.5

40 25.1 25.5 26.4 28.1 31.4 32.6

50 45.1 45.9 47.6 50.2 56.7 58.8 62.0

65 56.1 57.8 60.4 69.3 71.4 74.6

DN FIA SS straight - plain filter net FIA SS straight - pleated filter net

µ100 µ150 µ250 µ500 µ150 µ250 µ500

15 2.5 2.6 2.7 2.8 3.3

20 5.3 5.4 5.6 5.9 6.9

25 10.5 10.7 11.1 11.6 13.8 14.5

32 17.6 18.2 18.9 19.5 23.9 24.7

40 19.2 19.5 20.2 21.5 25.5 26.4

50 34.5 35.1 36.4 38.4 45.9 47.6 50.2

65 42.9 44.2 46.2 56.1 57.8 60.4

AI235186440137en-US1101 | 33

Page 34

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

Material specification

FIA SS 15 - 40 (½ in. - 1½ in.)

1

1

2

6

2

3

4

FIA SS 15 - 40 (½ in. - 1½ in.)

No. Part Material DIN ISO ASTM

1 Housing Stainless steel (FIA SS only) GX5CrNi19-10

2 Gasket Fibre, Non-asbestos

3 Cover Stainless steel (FIA SS only) GX5CrNi19-10

4 Bolts Stainless steel A2-70 A2-70 Type 308

5 Marking label Aluminium

6 Filter element Stainless steel

7 Pressure relief (screw) NPT ¼” Stainless steel

FIA SS 50 - 65 (2 in. - 2½ in.)

5

7

EN10213-4

EN10213-4

3

5

7

4 6

AISI 304

AISI 304

1

2

3

1

2

3

4

FIA SS 50 - 65 (2 in. - 2½ in.)

No. Part Material DIN ISO ASTM

1 Housing Stainless steel (FIA SS only) GX5CrNi19-10

2 Gasket Fibre, Non-asbestos

3 Cover Stainless steel (FIA SS only) GX5CrNi19-10

4 Bolts Stainless steel A2-70 A2-70 Type 308

5 Marking label Aluminium

6 Filter element Stainless steel

7 Pressure relief (screw) G ½” Stainless steel

8 Packing washer Aluminium

© Danfoss | DCS (ms) | 2020.01

6

8

5

7

EN10213-4

EN10213-4

4

7

8

5

6

AISI 304

AISI 304

AI235186440137en-US1101 | 34

Page 35

Data sheet | Stainless Steel Valves 15 (½ in.) - 125 ( 5 in.)

FIA SS 15 – 65 Dimensions and weights

StraightwayAngleway

© Danfoss | DCS (ms) | 2020.01

Angleway

Strainer size A C H F

FIA SS 15 – 20 mm 45 105 60 68 1.1 kg

(1/2" – 3/4") in. 1.77 4.13 2.36 2.68 2.4 lbs

FIA SS 25-40 mm 55 132 70 95 1.7 kg

(1" – 1 1/2") in. 2.17 5.20 2.76 3.74 3.7 lbs

FIA SS 50 mm 60 132 77 92 2.8 kg

(2") in. 2.36 5.20 3.03 3.62 6.2 lbs

FIA SS 65 mm 70 152 90 107 3.8 kg