Page 1

Data sheet

Thermostatic actuator RAVI

- for 2-way valves RAV-/8 (PN 10), VMT-/8 (PN 10), VMA (PN 16)

Description

RAVI is self-acting thermostatic actuator

primarily for use for temperature control of

small hot water cylinders - either storage type

cylinders or instantaneous hot water heaters.

RAVI can be combined with 2-way valves:

• RAV-/8,

• VMT-/8 and

• VMA

Controller closes on rising temperature.

The temperature controller is type-tested

according to EN 14597.

Main data:

• DN 10-25

• kv 0.25 -4.0 m

3

/h

• PN 10

• Setting range: 43 … 65 °C

• Temperature:

Circ. water / glycolic water up to 30%:

2 … 120 °C with RAV-/8, VMT-/8

2 … 130 °C with VMA valves

• Return mounting

Ordering

Example:

Temperature controller, DN 15,

kv 1.6 ; PN 10; setting range

43 … 65 °C; T

with ext. thread

- 1× RAVI thermostatic actuator,

Code No: 013U 80 08

- 1× VMA DN 15 valve

Code No: 065F2034

Option:

- 1× Imm. pocket, brass

Code No: 06 5- 4 414

- 1× Weld-on tailpieces

Code No: 003H6908

130 °C; 2-way valve

max

43 … 65 °C

RAVI thermostatic actuator

Picture

1)

DIN-te sted. Type a pproval number TR 838

2)

Incl. Rp ½ senso r stuffing box

Setting range Capillary tube length Max. sensor temp.

(°C) (m) (°C)

43 … 65 2.0 70 013U8008

Code No.

1), 2)

© Danfoss | 2017.08

VD.LJ.N1.02 | 1

Page 2

Data sheet Thermostatic actuator RAVI

Ordering (continuous)

Valves

Typ e Version

RAV 10/8

DN k

(mm) (m

10 1.2

1)

v

3

/h)

PN

RAV 15/8 15 1.3 R

RAV 20/8 20 2.4 R

RAV 25/8 25 2.6 R

VMT 15/8

VMT 20/8

VMT 25/8

2)

2)

2)

2-way

15 1. 3 Rp ¾ 065F0115

20 2.4 Rp 1 065F0120

25 2.6 Rp 1 ¼ 065F0125

10

0.25

0.4 065F2031

0.63 065F2032

1.0 065F2033

16 G ¾ A

1.4 065F2034

VMA 15

15

3)

2.2 065F2035

1)

The capac ity (kv) applies with a P- band of 6 °C. For other P- bands, see Technical data.

2)

For ordering of Cu f ittings, see Accessories .

3)

For ordering ext. thread taipieces, see Accessories.

Connection

inlet outlet

R

⁄ R ⁄ 013U 0012

p

½ R ½ 013U 0017

p

¾ R ¾ 013 U002 2

p

1 R 1 013U 0027

p

Accessories for thermostat

Type designations Connection Code No.

Immersion pocket Brass, R

Immersion pocket Stainless steel, R

Housing of sensor stuffing box R

1)

Code includ es housing and gasket of sensor st uffing box

½ × M14 × 1mm, rubber EPDM Ø 12.6 × 4 × 6 mm 013U8102

½ × M14 × 1mm, Ø 12 × 170 mm 06 5-4 414

p

½ × M14 × 1mm, Ø 12 × 170 mm 065 -4415

p

Code No.

065F2030

1)

Accessories for valves

Type designations For valve Dimensions Code No.

Ø 15 × 1 013G 4125

VM T 15

Compression fittings

1), 2), 5)

VMT 20

VMT 25 Ø 28 × 1 013U 0140

Weld-on tailpieces

External thread tailpieces Con. ext. thread acc. to EN 10226-1 R ½ “ 003H 6902

Valve stuffing box

1)

Compression f itting consist of compression r ing and union

2)

For copper pipe

3)

Compression f itting consist of compression r ing and nut

4)

For steel and copp er pipe

5)

The produc ts can only be ordered in mult iple packing containing 10 pieces ea ch

5)

VM A 15

Ø 16 × 1 013G 4126

Ø 18 × 1 013G 4128

Ø 18 × 1 013U 0134

Ø 22 × 1 013U 0135

- 003H6908

RAV/VMT/VMA 065F0006

2 | VD.LJ.N1.02

© Danfoss | 2017.08

Page 3

Data sheet Thermostatic actuator RAVI

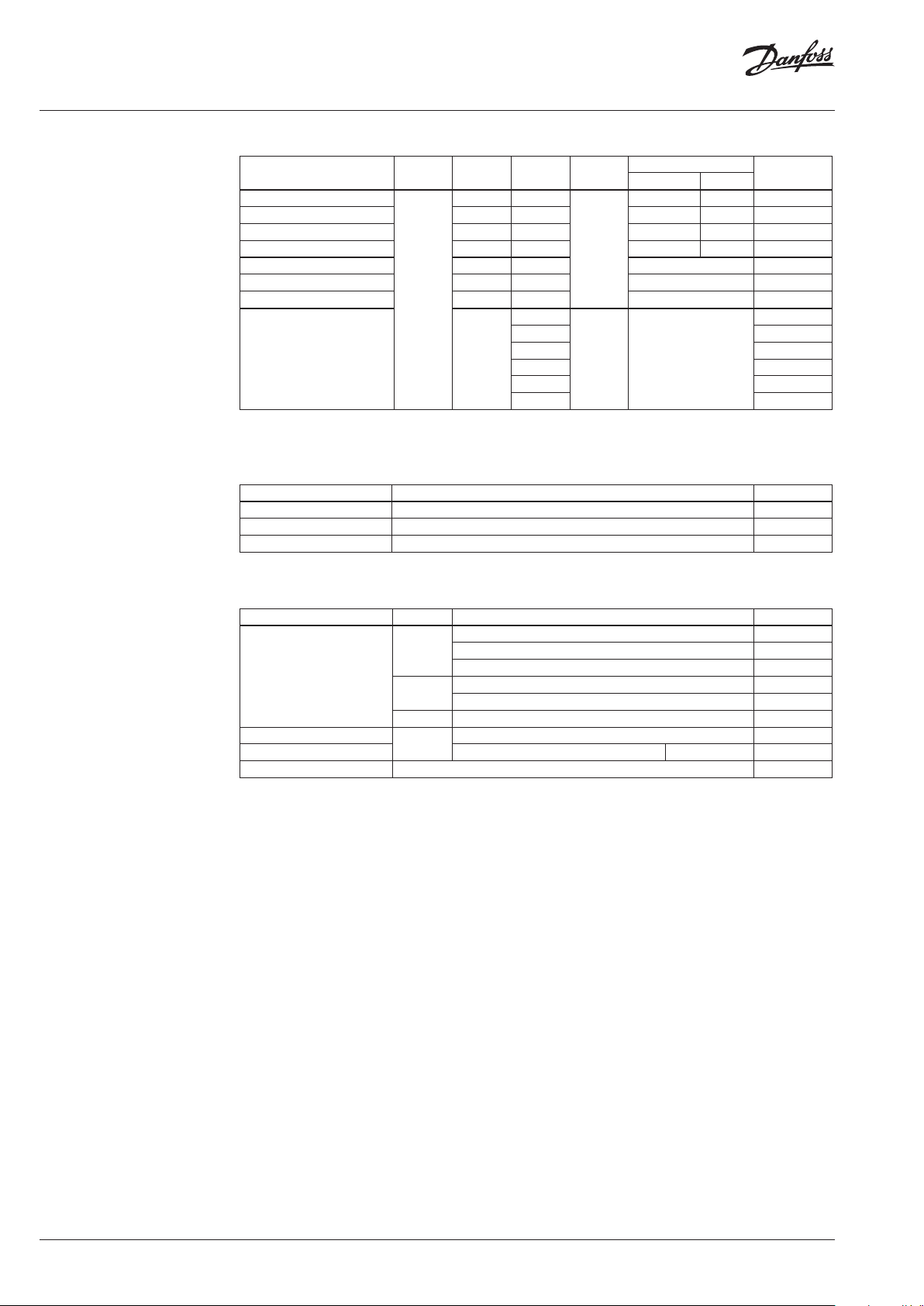

Technical data

Application principles

3

Typ e RAV I

RAV 10/8 0.70 1.00 1. 20

RAV/VMT 15/8 0.70 1.10 1.30

RAV/VMT 20/8 1.00 1.80 2.40

RAV/VMT 25/8 1.20 2.00 2.60

VMA 15 (k

VMA 15 (k

VMA 15 (k

VMA 15 (k

VMA 15 (k

VMA 15 (k

Materials RAV/ VMT VMA

Valve body Brass DZR

Valve cone NBR rubber EPDM

Spindle - DZR

Temperature sensor Cu

Immersion pocket Brass or stainless steel

Capillary tube Cu

1)

In installations w here quiet function is re quired, the different ial pressure across the valve should n ot exceed 1 bar.

= 0.25 ) 0.23 0.24 0.25

vs

= 0.4 ) 0. 35 0.38 0.40 5

vs

= (0.6 ) 0.53 0.63 0.63 2

vs

= 1.0 ) 0.60 0.85 1.00 2

vs

= 1.6 ) 0.64 1.20 1.40 2

vs

= 2.5 ) 1. 00 1.55 2.20 1

vs

with a P-b and in °C of

/h)

kv (m

Max. pressure

PN

(bar)

10 0.8 16 120

16

∆p

(bar)2 4 6

5

1)

Tes t

pressure

(bar)

25 130

Max. flow

temp.

(°C)

Max. ad m. temp.

at sensor

(°C)

70

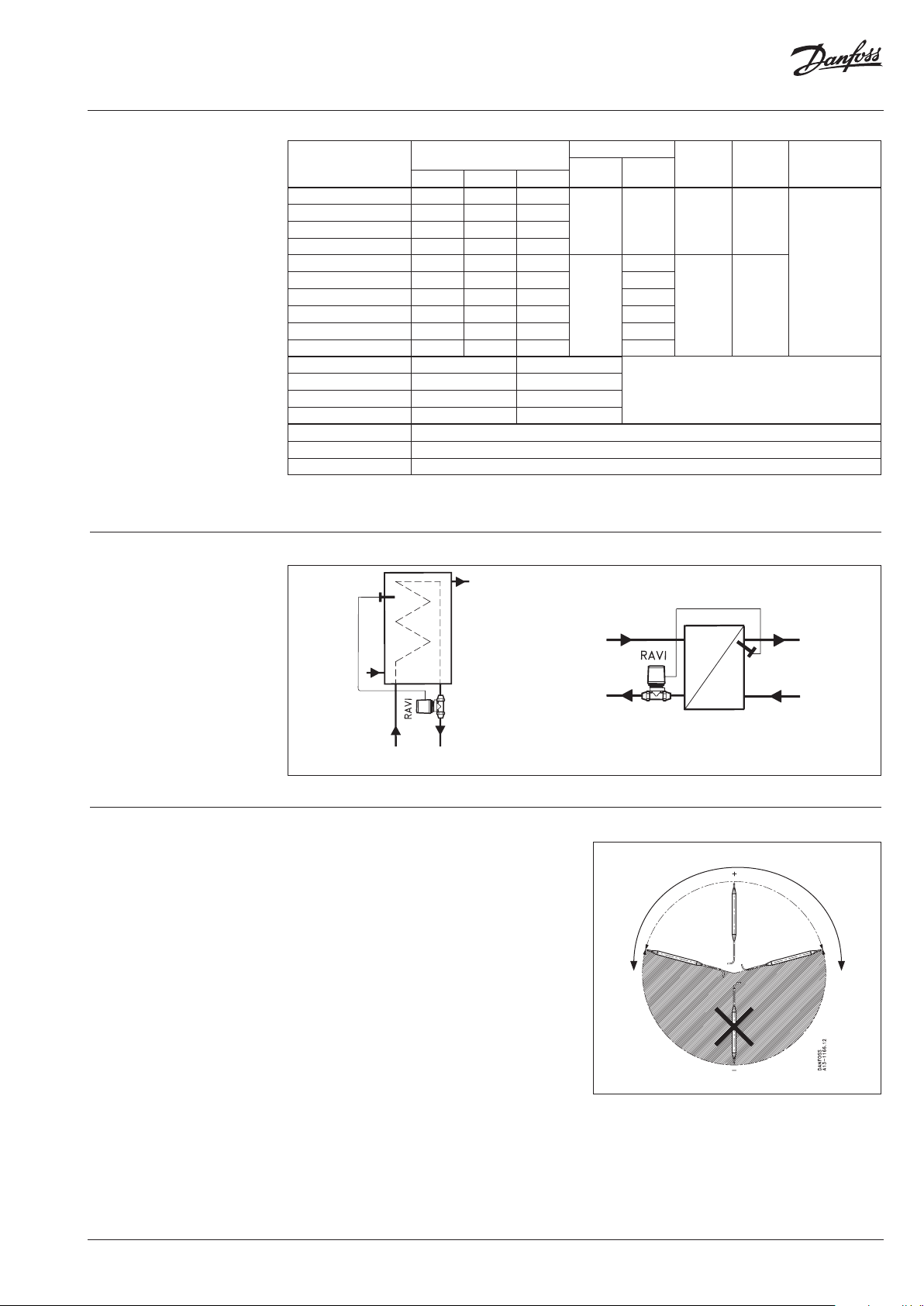

The actuator RAVI must be

installed in the return pipeline

only.

Storage cylinder Instantaneous hot water heat exchanger

Installation positions Temperature controller

The valve body must be installed in the return

pipeline with flow in the direction indicated by

the cast-in arrow.

Temperature sensor

The sensor must always be placed warmer than

the bellows.

For best performance it is recommended to

install the sensor facing up.

f

r

o

e

r

m

p

t

s

e

B

a

n

c

e

© Danfoss | 2017.08

VD.LJ.N1.02 | 3

Page 4

Data sheet Thermostatic actuator RAVI

Sizing

Example:

Temperature control of service hot water

Given data:

Tank output: 10 kW (8600 kcal/h)

Cooling (flow – return): 20 °C

Flow:

6.8

20

3

=

hm43.0

Differential pressure

∆p across valve: 0.12 bar

Method:

Use the water quantity (0.43 m

3

/h) and

differential pressure (0.12 bar) to read off the

necessary k

-value = 1.25

v

In this case, sizing is for a P-band of 6 °C.

In the table of k

the valve body having the necessary k

this case the valve body most suitable is the

RAV 15/8 or VMT 15/8 with a k

-values, look under 6 °C and find

v

-value of 1.3 .

v

-value. In

v

4 | VD.LJ.N1.02

Required:

Correct valve size

© Danfoss | 2017.08

Page 5

Data sheet Thermostatic actuator RAVI

Design

1. Handle for temperature

setting

2. Setting spring

3. Bellows

4. Valve stuffing box

5. Bottom screw

6. Valve body

7. Valve cone

8. Temperature sensor

9. Sensor stuffing box

10.

Housing of sensor stuffing

box

11. Gasket of sensor stuffing box

12. Sealing bolt of sensor

stuffing box

11

10

12

9

Settings

Temperature setting

Relation between scale numbers 1 - 5 and

closing temperature.

The values given are approximate.

© Danfoss | 2017.08

VD.LJ.N1.02 | 5

Page 6

Data sheet Thermostatic actuator RAVI

Dimensions

Ø61

157

Ø9.5

S

1

Ø61

90

157

1

90

H

S

2

Ø9.5

120

G¾A

R½

R½

65

L

1

d

L

D

2

131

139

R½

RAVI -VMA

RAVI-RAV-/8

L

L2H1Width across flats

Typ e D d

RAVI-RAV 10/8 R

RAVI-RAV 15/8 R

RAVI-RAV 20/8 R

RAVI-RAV 25/8 R

⁄ R ⁄ 59 85 103 22 27

p

½ R ½ 66 95 103 27 30

p

¾ R ¾ 74 10 6 103 32 37

p

1 R 1 90 125 116 41 46

p

Ø61

157

Ø9.5

1

90

H

S S

1

(mm) S

(mm) S2 (mm)

1

DN

Ø12

R½

L

1

L

2

a

b

RAVI-VMT-/8

L

L2H1S

Typ e a b

RAVI-VMT 15/8 Ø 15/ Ø 16/ Ø 18 R ¾ 66 90 103 30

RAVI-VMT 20/8 Ø 18/ Ø 22 R 1 74 101 103 37

RAVI-VMT 25/8 Ø 28 R 1 ¼ 90 120 116 45

DN

Ød

L

Weld-on tailpieces

G Ød L

(mm)

15 15 35 0.18

Weight

(kg)

1

DN

External thread

G R

(“)

¾ ½ 25.5 0.17

SW22

Immersion

pockets

(mm)

L

tailpieces

L Weight

(mm) (kg)

R⁄

R

6 | VD.LJ.N1.02

© Danfoss | 2017.08

Page 7

Data sheet Thermostatic actuator RAVI

© Danfoss | 2017.08

VD.LJ.N1.02 | 7

Page 8

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Thermostatic actuator RAVI

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

8 | VD.LJ.N1.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2017.08

Loading...

Loading...