Page 1

Data sheet

Data sheet

PAHT pumps

PAHT 2-308 pumps /

PAHT 2-6.3/PAHT/10-12.5/PAHT 20-25/

PAHT G 2-308 pumps /

PAHT 50-90 and PAHT 256-308

ATEX PAHT G pump

danfoss.high-pressurepumps.com

hpp.danfoss.com

Page 2

Data sheet PAHT 2-308 pumps

Table of Contents

1. Introduction ............................................................................2

2. Benets.................................................................................3

3. Application examples ...................................................................3

4. Technical data ..........................................................................4

4.1 PAHT 2-12.5 .............................................................................4

4.2 PAHT 20-32 .............................................................................5

4.3 PAHT 50-90 .............................................................................6

4.4 PAHT 256-308...........................................................................7

5. Flow ....................................................................................8

5.1 PAHT 2-6.3 typical ow curves at max pressure ..........................................8

5.2 PAHT 10-12.5 typical ow curves at max pressure ........................................9

5.3 PAHT 20-32 typical ow curves at max pressure.........................................10

5.4 PAHT 50-90 typical ow curves at max pressure.........................................11

5.5 PAHT 256-308 typical ow curves at max pressure ......................................12

6. Motor requirements....................................................................13

7. Installation.............................................................................14

7.1 Filtration ..............................................................................14

7.2 Noise ..................................................................................14

7.3 Open-system design ...................................................................15

7.4 Closed-system design .................................................................16

8. Dimensions and connections...........................................................17

8.1 PAHT 2-6.3 .............................................................................17

8.2 PAHT 10-12.5...........................................................................18

8.3 PAHT 20-32 ............................................................................19

8.4 PAHT 50-90 ............................................................................20

8.5 PAHT 256-308..........................................................................21

1. Introduction

9. Service.................................................................................22

The Danfoss range of PAHT high-pressure pumps

is specically designed for use with technical

water such as:

• Ultra-pure water that has undergone

multiple reverse osmosis processes

• De-ionized water

• Demineralized water

Danfoss PAHT pumps are positive displacement

pumps, with axial pistons that move a xed

amount of water in each cycle. Flow is proportional to the number of input shaft revolutions

(rpm). Unlike centrifugal pumps, they produce

the same ow at a given speed independently of

no matter what the discharge pressure.

2

AI106586503085en-000901 | 05.2021

Page 3

Data sheet PAHT 2-308 pumps

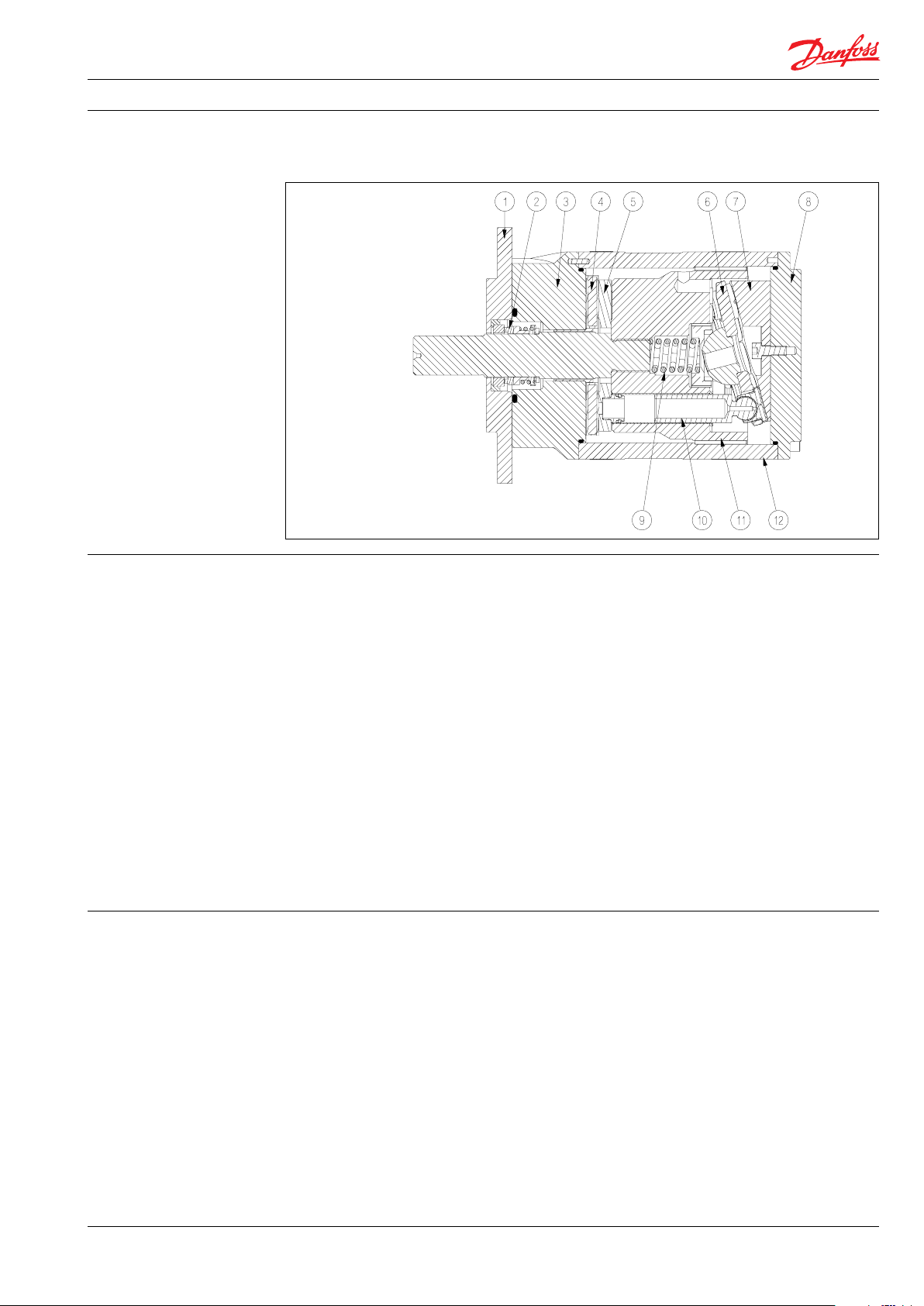

Below sectional drawing is an example of a PAHT pump.

1: Mounting ange

2: Shaft seal

3: Connecting ange

4: Port plate

5: Valve plate

6: Retainer plate

7: Swash plate

8: End cap

9: Spring

10: Pis ton

11: Cylinder barrel

12: Housing with bearing

2. Benets • Zero risk of lubricant contamination:

- Oil lubricants are replaced with the

pumped medium, water, so there is no

contamination risk from the pump.

• Low maintenance costs:

- Ecient design and all-stainless steel

construction ensure exceptionally long

lifetime. When Danfoss specications

are met, service intervals of up to 8,000

hours can be expected. Service is easy,

and can be carried out on site due to

the simple design and few parts.

• Low energy costs:

- The highly ecient axial piston design

provides the lowest energy consumption of any comparable pump on the

market.

• Easy installation:

- The lightest and most compact design

available.

3. Application examples • High-pressure cleaning with ultra-pure

water, as used in the manufacturing of

at-panel displays and many other

electronic products.

• High-pressure cleaning with ultra-pure

water, as used in the manufacturing of

parts for the automobile industry.

• Adiabatic cooling systems to replace or

supplement standard A/C systems in server

rooms and factories.

- Pump can be installed horizontally or

vertically.

- No pulsation dampeners necessary due

to extremely low-pressure pulsation.

- Powered by electric motors or combustion engines.

- Suitable for both boosted inlet

pressure and water supply from a tank.

- No need for cooling circuits due to very

high mechanical eciency.

• Certied quality:

- Fullls the stringent hygiene requirements, VDI 6022, HACCP.

- Certicates:

ISO 9001, ISO 14001

API available on request

• Humidication in oce buildings, elec-

tronic component manufacturing, dairies,

greenhouses, etc.

• Dust suppression and odor control

systems, for example in paper, textile and

wood production.

• Reduction of NOx emissions in diesel

engines and gas turbines.

• Gas turbine by inlet fogging and fuel wash

systems.

AI106586503085en-000901| 05.2021

3

Page 4

Data sheet PAHT 2-308 pumps

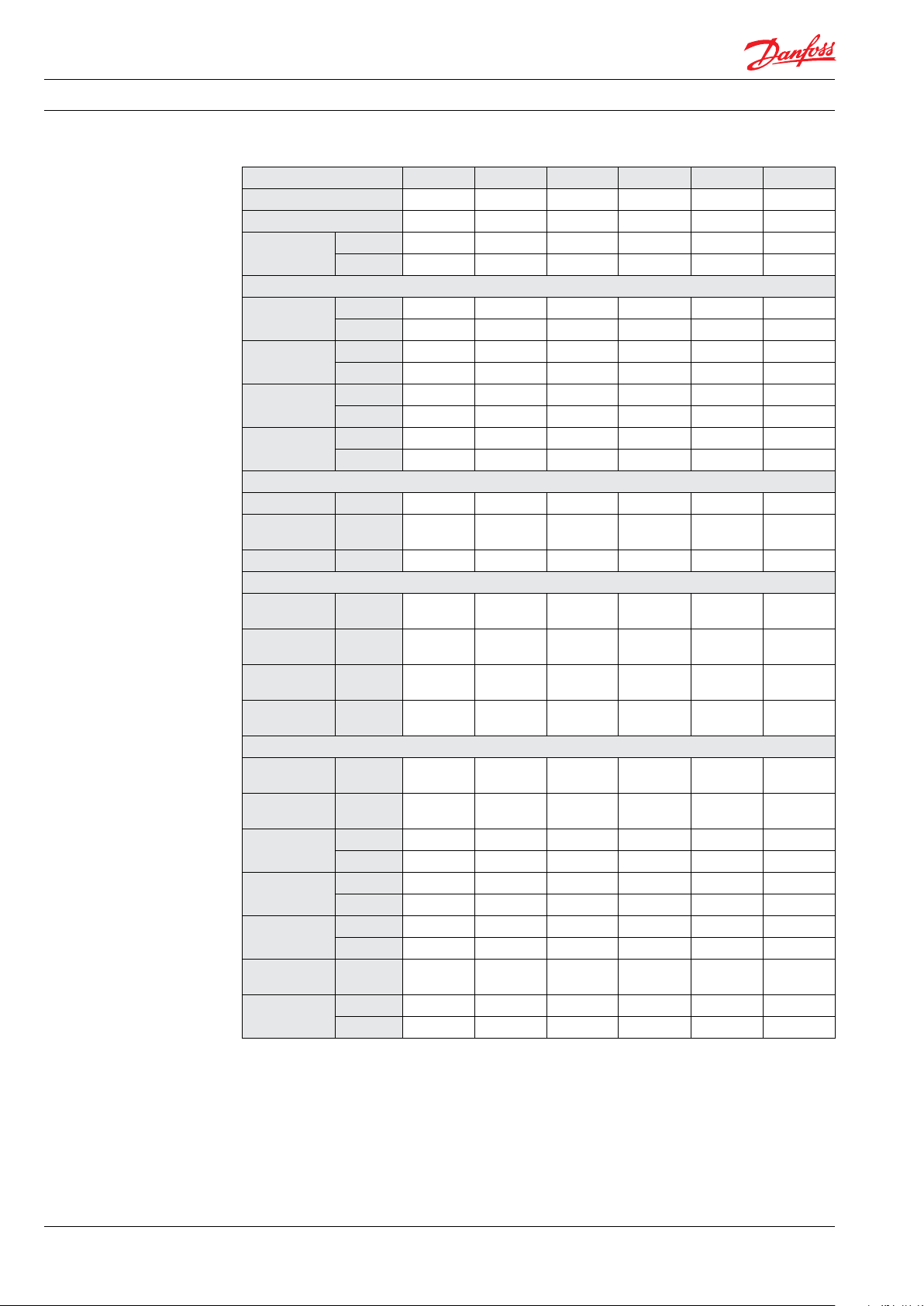

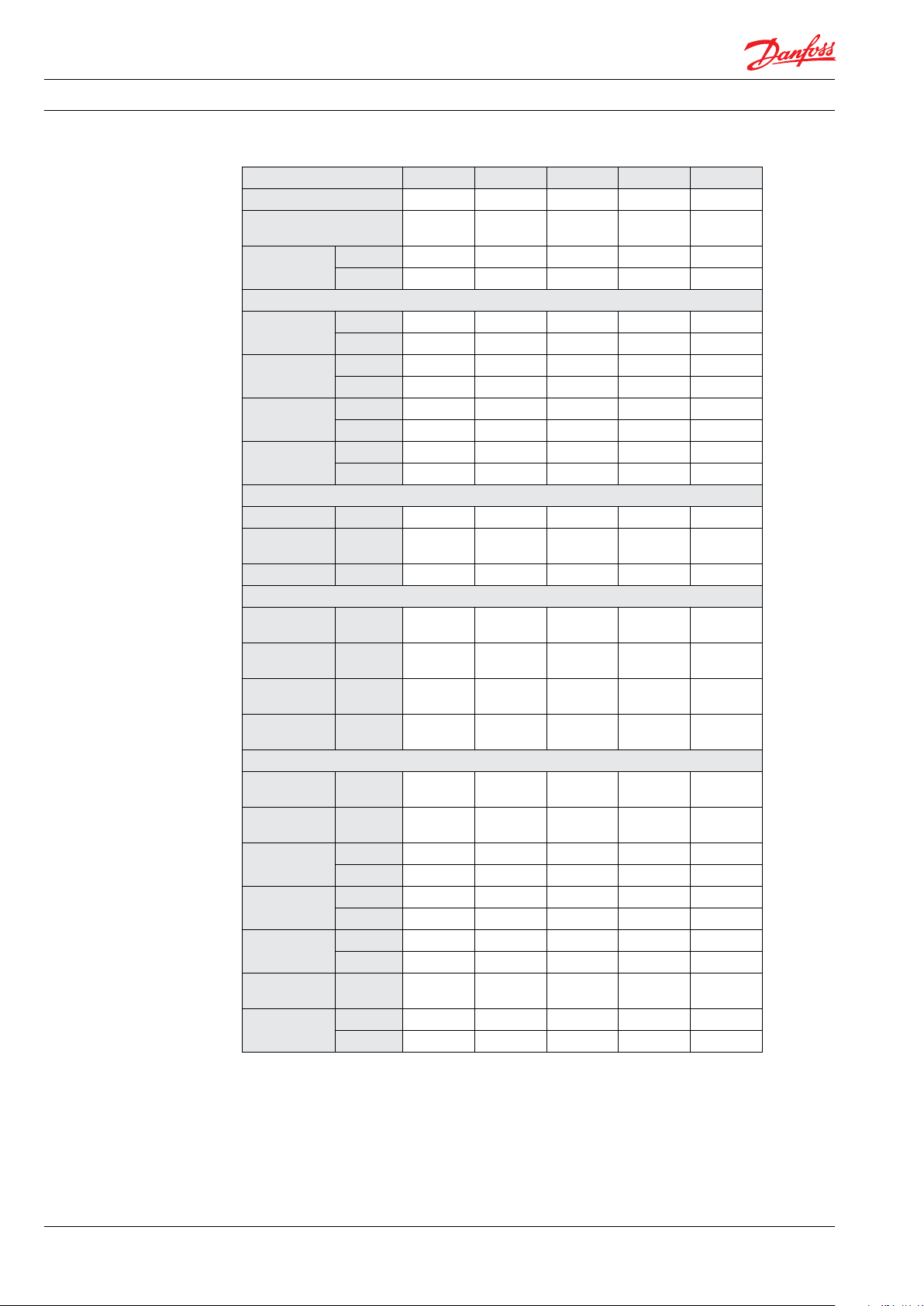

4. Technical data 4.1 PAHT 2-12.5

Pump size 2 3.2 4 6.3 10 12 .5

Code number PAHT 180B0 031 180B0077 180B0030 180B0029 180B0032 180B0033

Housing material AISI 304 AISI 304 AISI 304 AISI 304 AISI 304 AISI 304

Geometric

displacement

Pressure

Min. outlet

pressure

Max. outlet

pressure

Inlet pressure,

continuous

Max. inlet

pressure, peak

Speed

Min. speed rpm 1000 1000 1000 1000 1000 1000

Min. speed,

continuous

Max. speed rpm 3000 3000 3000 3000 2400 2400

Typical ow - Flow curves available in section 5

1000 rpm at

max. pressure

1500 rpm at

max. pressure

1200 rpm at

max. pressure

1800 rpm at

max. pressure

Typical motor size

1500 rpm at

max. pressurekW50 Hz

1800 rpm at

max. pressurehp60 Hz

Torque at max.

outlet pressure

Media

temperature

Ambient

temperature

Sound

pressure level

Weight kg 4.4 4.4 4.4 4.4 7.7 7.7

cm³/rev 2 3.2 4 6.3 10 12. 5

in³/rev 0.12 0.20 0.24 0.38 0.61 0.76

barg 30 30 30 30 30 30

psig 435 435 435 435 435 435

barg 100 100 100 100 14 0 140

psig 1450 1450 1450 1450 2031 2031

barg 0-4 0-4 0-4 0-4 0-4 0-4

psig 0-58 0-58 0-58 0-58 0-58 0-58

1)

barg 4 4 4 4 4 4

psig 58 58 58 58 58 58

rpm 1000 1000 1000 1000 1000 1000

l/min 0.7 2.0 3.0 5.5 7. 6 10.2

l/min 1.7 3.6 5.0 8.6 12.6 16.5

gpm 0.3 0.7 1.0 1.8 2.5 3.3

gpm 0.6 1.2 1.6 2.7 4.0 5.3

Nm 4.4 6.7 8.1 12. 4 25.6 31.7

lbf-ft 3.2 4.9 6.0 9. 2 18.9 23.4

°C 2-50 2-50 2-50 2-50 2-50 2-50

°F 37-122 37-12 2 37-122 37-122 37-122 37-12 2

°C 0-50 0-50 0-50 0-50 0-50 0-50

°F 32-122 32-12 2 32-122 32-12 2 32-122 32-122

dB(A) 76 76 76 76 75 75

2)

lbs 9.7 9.7 9.7 9.7 17.0 17. 0

0.75 1.1 1.5 2.2 4.0 5.5

1.0 1.5 2.0 3.0 7.5 7. 5

1)

1% per minute peak, 10% per minute during start up.

2)

Measurements according to EN ISO 3744: 2010 / dB(A) [L

Measured at max pressure and rpm for a motor pump unit.

4

AI106586503085en-000901 | 05.2021

] values are calculated.

PA, 1m

Page 5

Data sheet PAHT 2-308 pumps

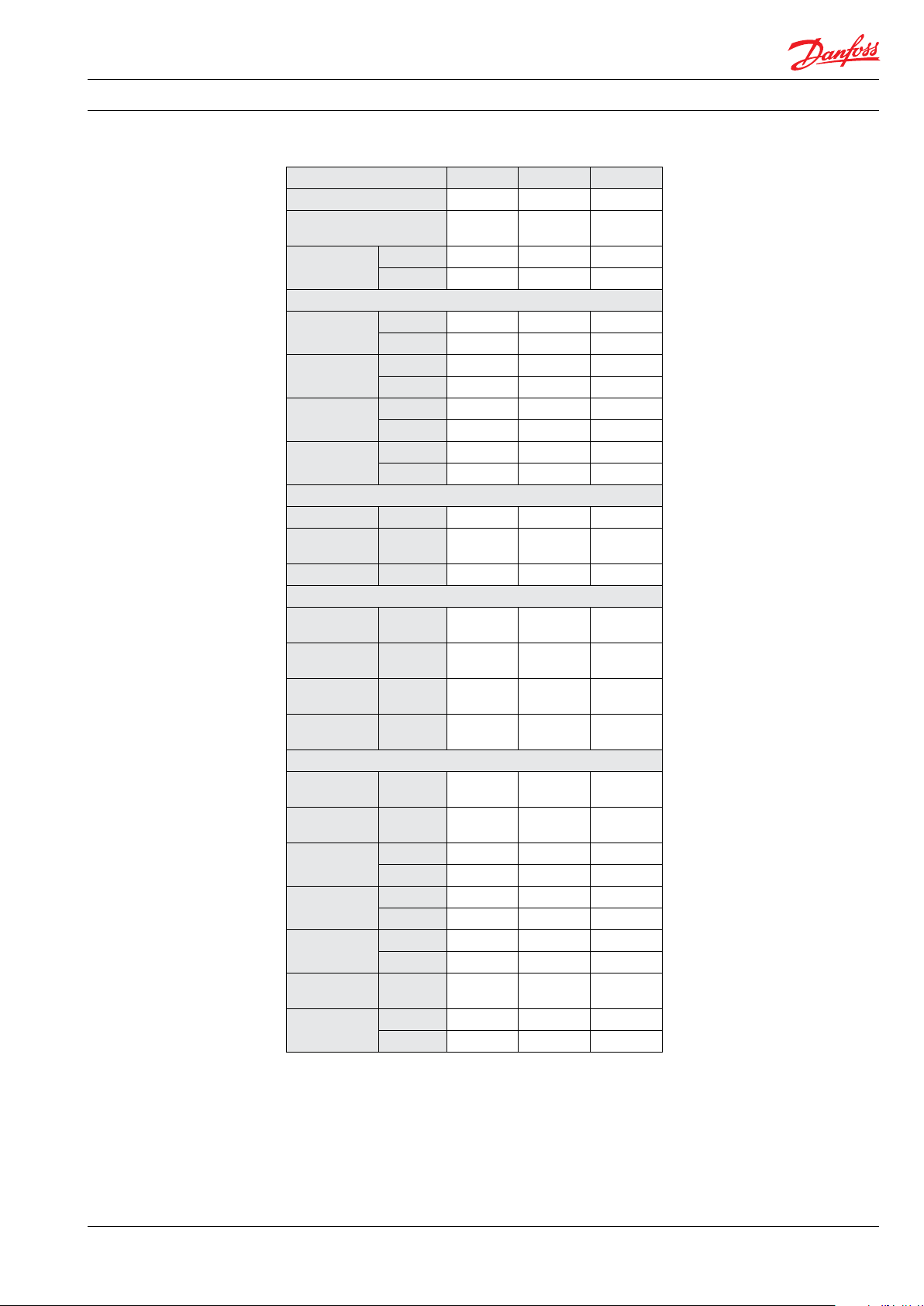

4.2 PAHT 20-32

Pump size 20 25 32

Code number PAHT 180 B0019 180 B0020 180B0021

Housing material AISI 316

Geometric

displacement

Pressure

Min. outlet

pressure

Max. outlet

pressure

Inlet pressure,

continuous

Max. inlet

pressure, peak

Speed

Min. speed rpm 700 700 700

Min. speed,

continuous

Max. speed rpm 2400 2400 2400

Typical ow - Flow curves available in section 5

1000 rpm at

max pressure

1500 rpm at

max pressure

1200 rpm at

max. pressure

1800 rpm at

max. pressure

Typical motor size

1500 rpm at

max. pressurekW50Hz

1800 rpm at

max. pressurehp60Hz

Torque at max.

outlet pressure

Media

temperature

Ambient

temperature

Sound

pressure level

Weight kg 19 19 19

cm³/rev 20 25 32

in³/rev 1.22 1.53 1.95

barg 30 30 30

psig 435 435 435

barg 100 160 160

psig 1450 2321 2321

barg 0-6 0-6 0-6

1)

psig 0-87 0-87 0-87

barg 20 20 20

2)

psig 290 290 290

rpm 1000 1000 1000

l/min 16.9 20.6 28.0

l/min 27. 0 33.2 44.2

gpm 5.4 6.7 9.0

gpm 8.6 10.6 14.0

Nm 21.0 69.2 89.0

lbf-ft 15.5 51.1 65.7

°C 2-50 2-50 2-50

°F 37-122 37-12 2 37-122

°C 0-50 0-50 0-50

°F 32-122 32-122 32-12 2

dB(A)

3)

lbs 42 42 42

or higher

or higher

5.5 11.0 15.0

7.5 20.0 20.0

79 79 79

AISI 316

AISI 316

or higher

1)

Above 1800 rpm inlet pressure 2-6 barg

2)

1% per minute peak, 10% per minute during start up.

3)

Measurements according to EN ISO 3744: 2010 / dB(A) [L

Measured at max pressure and rpm for a motor pump unit.

AI106586503085en-000901| 05.2021

] values are calculated.

PA, 1m

5

Page 6

Data sheet PAHT 2-308 pumps

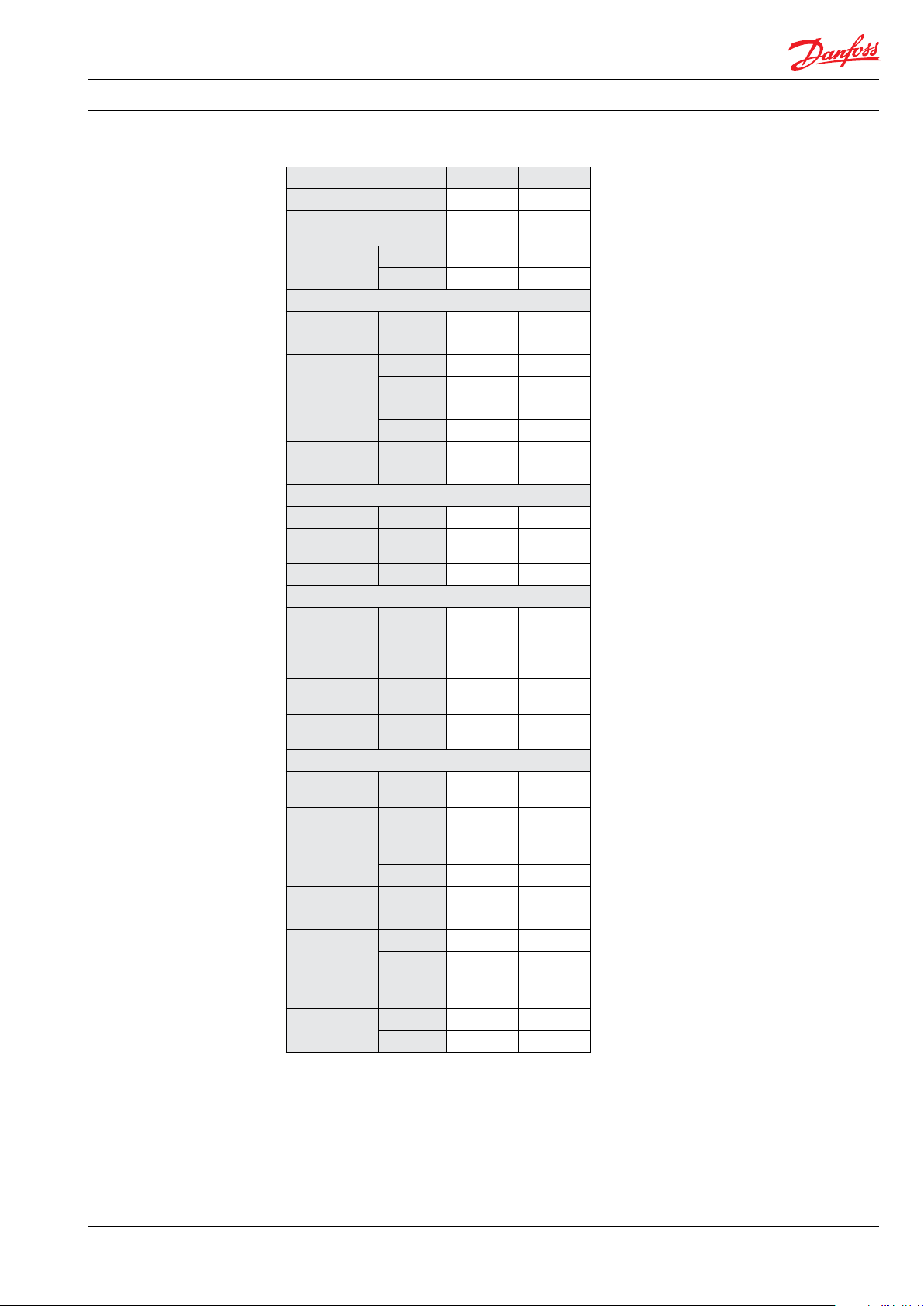

4.3 PAHT 50-90

Pump size 50 63 70 80 90

Code number PAHT 180B0085 180B0086 180B0087 180B0088 180B0089

Housing material AISI 316

Geometric

displacement

Pressure

Min. outlet

pressure

Max. outlet

pressure

Inlet pressure,

continuous

Max. inlet

pressure, peak

Speed

Min. speed rpm 700 700 700 700 700

Min. speed,

continuous

Max. speed rpm 1800 1800 180 0 1800 1800

Typical ow - Flow curves available in section 5

1000 rpm at

max. pressure

1500 rpm at

max. pressure

1200 rpm at

max. pressure

1800 rpm at

max. pressure

Typical motor size

1500 rpm at

max. pressurekW50 Hz

1800 rpm at

max. pressurehp60 Hz

Torque at max.

outlet pressure

Media

temperature

Ambient

temperature

Sound

pressure level

Weight kg 34 34 34 34 34

cm³/rev 50 63 70 80 90

in³/rev 3.05 3.84 4.27 4.88 5.49

barg 30 30 30 30 30

psig 435 435 435 435 435

barg 80 160 160 160 160

psig 1160 2321 2321 2321 2321

barg 0-6 0-6 0-6 0-6 0-6

psig 0-87 0-87 0-87 0-87 0-87

1)

barg 20 20 20 20 20

psig 290 290 290 290 290

rpm

l/min 43.7 50.5 5 7.7 68.3 77. 6

l/min 68.7 82.1 92.9 108.5 122.6

gpm 14.0 16. 4 18.7 21.9 24.9

gpm 21.8 26.3 29.6 34.5 38.9

Nm 68.5 172.6 191.8 219.8 246.6

lbf-ft 50.6 127. 4 141.5 162.2 182.0

°C 2-50 2-50 2-50 2-50 2-50

°F 37-122 37-12 2 37-122 37-122 37-122

°C 0-50 0-50 0-50 0-50 0-50

°F 32-122 32-122 32-12 2 32-122 32-122

dB(A) 80 80 80 80 81

2)

lbs 75 75 75 75 75

or higher

AISI 316

or higher

AISI 316

or higher

AISI 316

or higher

1000 1000 1000 1000 1000

11 30 30 37 45

20 50 50 60 75

AISI 316

or higher

1)

1% per minute peak, 10% per minute during start up.

2)

Measurements according to EN ISO 3744: 2010 / dB(A) [L

Measured at max pressure and rpm for a motor pump unit.

] values are calculated.

PA, 1m

6

AI106586503085en-000901 | 05.2021

Page 7

Data sheet PAHT 2-308 pumps

4.4 PAHT 256-308

Pump size 256 308

Code number PAHT 180B1001 180B10 02

Housing material AISI 316

Geometric

displacement

Pressure

Min. outlet

pressure

Max. outlet

pressure

Inlet pressure,

continuous

Max inlet

pressure, peak

Speed

Min. speed rpm 450 450

Min. speed,

continuous

Max. speed rpm 1250 1250

Typical ow - Flow curves available in section 5

450 rpm at

max. pressure

1250 rpm at

max. pressure

450 rpm at

max. pressure

1250 rpm at

max. pressure

Typical motor size

1000 rpm at

max. pressurekW50 Hz

1200 rpm at

max. pressurehp60 Hz

Torque at max.

outlet pressure

Media

temperature

Ambient

temperature

Sound

pressure level

Weight kg 105 105

cm³/rev 256 308

in³/rev 15.6 18. 8

barg 30 30

psig 435 435

barg 120 120

psig 174 0 1740

barg 2-6 2-6

psig 29-87 29-87

barg 10 10

1)

psig 145 145

rpm 700 700

l/min 89.6 107. 8

l/min 294.4 354.2

gpm 23.3 28.0

gpm 76. 5 92.1

Nm 549.6 6 61.3

lbf-ft 405.6 448.0

°C 2-50 2-50

°F 37-122 37-12 2

°C 0-50 0-50

°F 32-122 32-122

dB(A) 82 87

2)

lbs 231 231

or higher

55 75

100 125

AISI 316

or higher

1)

1% per minute peak, 10% per minute during start up.

2)

Measurements according to EN ISO 3744: 2010 / dB(A) [L

Measured at max pressure and rpm for a motor pump unit.

AI106586503085en-000901| 05.2021

] values are calculated.

PA, 1m

7

Page 8

Data sheet PAHT 2-308 pumps

20

18

16

14

12

10

8

6

4

2

0 rpm

PAHT 2.0

PAHT 3.2

PAHT 4.0

PAHT 6.3

l/min

1000

1250

1500

1750

2000

2500

2250

2750

3000

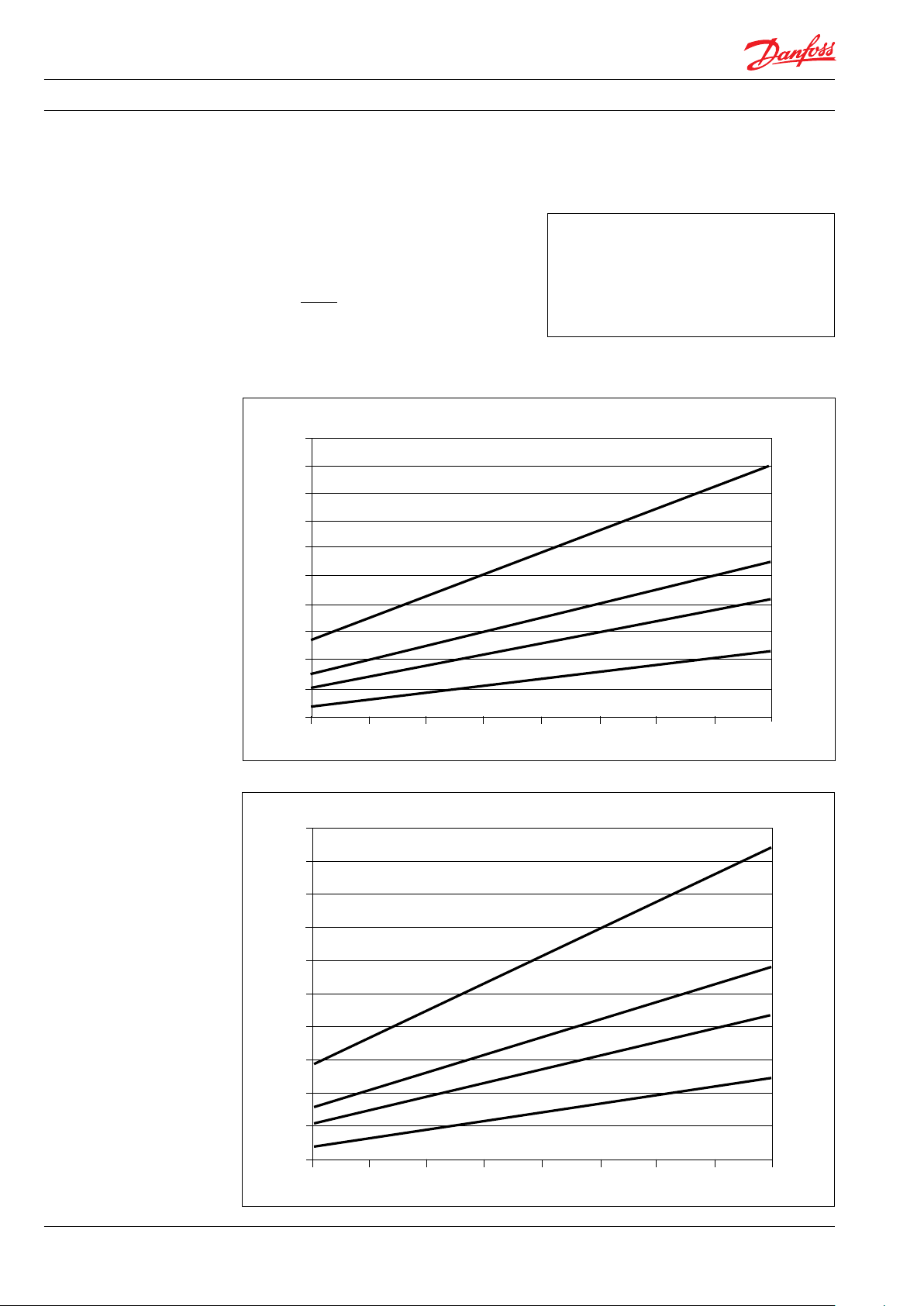

5. Flow The ow (Q

calculated with the following equation:

Q

= Q

e

) at various pressure (p

e

– [(Q

(th)

– Q (p

(th)

)) x (p / p

max

) can be

max

)]

max

The theoretical ow can be calculated with the

following equation:

V x n

Q

=

(th)

1000

5.1 PAHT 2-6.3 typical ow curves at max pressure

l/min

20

18

16

14

12

10

8

6

4

2

0 rpm

1000

1250

1500

1750

At zero pressure the true ow equals the

theoretical ow Q

: Theoretical ow (l/min / gpm)

Q

(th)

Q (p

): Flows at max. pressure (l/min and

max

p

p: Pressure (barg / psig)

gpm), see 4.1-4.4

: Max pressure (barg / psig)

max

V: Displacement (cm

.

(th)

3

/ rev.)

n: Motor speed (rpm)

2000

2250

2500

2750

PAHT 6.3

PAHT 4.0

PAHT 3.2

PAHT 2.0

3000

gpm

5.0

PAHT 6.3

4.5

4.0

3.5

3.0

PAHT 4.0

2.5

2.0

PAHT 3.2

1.5

PAHT 2.0

1.0

0.5

0

1000

8

AI106586503085en-000901 | 05.2021

1250

1500

1750

2000

2250

2500

2750

rpm

3000

Page 9

Data sheet PAHT 2-308 pumps

30

25

20

15

10

5 rpm

PAHT 10.0

PAHT 12.5

l/min

1000

1200

1400

1650

1800

2200

2000

2400

5.2 PAHT 10-12.5 typical ow curves at max pressure

l/min

30

25

20

15

10

5 rpm

PAHT 12.5

PAHT 10.0

1200

1200

1400

1400

gpm

1000

8

7

6

5

4

3

2

1

0

1000

1650

1650

1800

1800

2000

2000

2200

2200

2400

PAHT 12.5

PAHT 10.0

rpm

2400

AI106586503085en-000901| 05.2021

9

Page 10

Data sheet PAHT 2-308 pumps

80

70

60

50

40

30

20

10

0

rpm

PAHT 20

PAHT 25

PAHT 32

l/min

700

950

1200

1450

1950

1700

2200

2400

5.3 PAHT 20-32 typical ow curves at max pressure

l/min

80

70

PAHT 32

gpm

60

50

40

30

20

10

25

20

15

10

PAHT 25

PAHT 20

0

700

950

1200

1450

1700

1950

2200

rpm

2400

PAHT 32

PAHT 25

PAHT 20

5

0

700

950

1200

10

AI106586503085en-000901 | 05.2021

1450

1700

1950

2200

rpm

2400

Page 11

Data sheet PAHT 2-308 pumps

160

140

120

100

80

60

40

20

0

l/min

1200

950

1450

1700

1800

700

rpm

PAHT 80

PAHT 50

PAHT 63

PAHT 70

PAHT 90

5.4 PAHT 50-90 typical ow curves at max pressure

l/min

160

140

120

100

PAHT 90

PAHT 80

PAHT 70

PAHT 63

80

60

40

20

gpm

45

40

35

30

25

20

15

PAHT 50

0

700

950

1200

1450

1700

rpm

1800

PAHT 90

PAHT 80

PAHT 70

PAHT 63

PAHT 50

10

5

0

700

950

AI106586503085en-000901| 05.2021

1200

1450

1700

rpm

1800

11

Page 12

Data sheet PAHT 2-308 pumps

400

350

300

250

200

150

100

50

0

l/min

550

650

750

850

1050

1150

1250

950

450

rpm

PAHT 256

PAHT 308

5.5 PAHT 256-308 typical ow curves at max pressure

l/min

400

350

300

250

200

150

100

50

gpm

100

90

80

70

60

PAHT 308

PAHT 256

0

450

550

650

750

850

950

1050

1150

rpm

1250

PAHT 308

PAHT 256

50

850

950

1050

1150

rpm

1250

40

30

20

10

0

450

550

650

750

12

AI106586503085en-000901 | 05.2021

Page 13

Data sheet PAHT 2-308 pumps

6. Motor requirements

The required motor power can be calculated by

using the following equation:

n x V x p

P =

600.000 x η

P: Power (kW)

M: Torque (Nm)

η: Mechanical eciency

p: Pressure (barg)

n: Motor speed (rpm)

V: Displacement (cm

3

/rev.)

From the ow curves in item 5, you can determine the rpm of the pump at the desired ow.

The required torque is calculated as follows:

V x p

M =

62.8 x η

To determine the correct motor size, both the

power and torque requirement must be veried.

The mechanical eciency of the pump, at max

pressure, is as follows:

PAHT 2, 3.2, 4, 6.3 0.8

PAHT 10, 12.5 0.9

PAHT 20, 25, 32, 50, 63, 70, 80, 90 0.95

PAHT 256, 308 0.95

AI106586503085en-000901| 05.2021

13

Page 14

Data sheet PAHT 2-308 pumps

7. Installation See the gure below for instructions on how to

mount the pump and connect it to an electric

motor or combustion engine.

A CB

A: Pump

B: Bell housing

C: Coupling

D: Motor

D

If alternative mounting is required, please

contact your Danfoss sales representative for

further information.

Note: Do not add any axial or radial loads to the

pump shaft.

7.1 Filtration

Proper ltration is crucial for the performance,

maintenance and warranty of your pump.

Protect your pump, and the application in which

it is installed, by always ensuring that ltration

specications are met, and by always changing

lter cartridges according to schedule.

Since water has very low viscosity, Danfoss PAHT

pumps have been designed with very narrow

clearances in order to control internal leakage

rates and improve component performance. To

minimize wear on the pump, it is therefore

essential to lter inlet water properly.

The main lter must have a ltration eciency

of 99.98% at 10 μm. We strongly recommend

that you always use precision depth lter

cartridges rated 10 μm abs. β

Please note that we do not recommend bag

lters or string-wound lter cartridges, which

typically have only 50% ltration eciency. This

means that out of 100,000 particles that enter

such lters, 50,000 particles pass right through

them; compare this to precision depth lters that

are 99.98% ecient, and only allow 20 of the

same 100,000 particles to pass through.

≥ 5,000.

10

For more information on the importance of

proper ltration, including explanation of

ltration principles, denitions, and guidance on

how to select the right lter for your pump,

please consult our Filtration information and

specications (Danfoss document number

521B1009).

7.2 Noise

Since the pump unit is mounted on a frame, the

overall noise level can only be determined for a

complete system. To minimize vibrations and

noise throughout the system, it is therefore very

important to mount the pump unit correctly on a

frame with dampers and to use exible hoses

rather than metal pipes where possible.

The noise level is inuenced by:

• Pump speed:

High rpm makes more uid/structureborne pulsations/vibrations than low rpm.

• Discharge pressure:

High pressures make more noise than low

pressures.

• Pump mounting:

Rigid mounting makes more noise than

exible mounting because of the structureborne vibrations. Be sure to use dampers

when mounting.

• Connections to pump:

Pipes connected directly to the pump make

more noise than exible hoses because of

structure-borne vibrations.

• Variable frequency drives (VFDs):

Motors regulated by VFDs can produce

more noise if the VFD does not have the

right settings.

14

AI106586503085en-000901 | 05.2021

Page 15

Data sheet PAHT 2-308 pumps

7.3 Open-system design

A Inlet line:

Dimension the inlet line to obtain minimum pressure loss (large ow, minimum

pipe length, minimum number of bends/

connections, ttings with small pressure

losses and restrictions).

B Inlet lter:

Install the inlet lter (1) in front of the PAHT

pump (2). Please consult the Danfoss lter

data sheet for guidance on how to select

the right lter.

C Monitoring pressure switch:

Install the monitoring pressure switch (3)

between the lter and the pump inlet. Set

the minimum inlet pressure according to

specications described in item 4, technical

data. The monitoring pressure switch stops

the pump if inlet pressure is lower than the

set minimum pressure.

D Monitoring temperature switch:

Install the monitoring temperature switch

(4) between the lter and the pump, on

either side of the monitoring pressure

switch. Set the temperature value according to technical data, item 4. The monitoring temperature switch stops the pump if

inlet temperature is higher than the set

value.

E Hoses:

Always use exible hoses (5) to minimize

vibrations and noise.

F Inlet pressure:

In order to eliminate the risk of cavitation

and other pump damage, pump inlet

pressure must be maintained according to

specications described in item 4, technical

data.

G Non-return valve (6):

Should be installed after the outlet to

prevent pump backspin, which may ruin

the pump.

H Pressure relief valve:

As the Danfoss PAHT pump begins to

create pressure and ow immediately after

start-up regardless of any counter pressure,

a pressure relief valve (7) should be

installed to prevent system damage.

Note: If a non-return valve is mounted in the

inlet line, a low-pressure relief valve is also

recommended between the non-return valve

(8) and the pump to protect against high-pressure peaks.

1 4 5 5 6

PI

8

M

2

PI

SYSTEM

73

AI106586503085en-000901| 05.2021

15

Page 16

Data sheet PAHT 2-308 pumps

PI

System

PI

M

1

2

3

4

5 5

7

6

7.4 Closed-system design (not applicable

for PAHT 256-308)

A Inlet line:

Dimension the inlet line to obtain minimum pressure loss (large ow, minimum

pipe length, minimum number of bends/

connections, ttings with small pressure

losses and restrictions).

B Inlet lter:

Install the lter (1) in front of the tank (2).

Please consult the Danfoss lter data sheet

for guidance on how to select the right

lter.

C Monitoring pressure switch:

Install the monitoring pressure switch (3) in

front of the lter (1). Set the maximum inlet

pressure to 2 barg (29.0 psig). The monitoring pressure switch will stop the pump (5) if

inlet pressure is higher than 2 barg (29.0

psig), indicating that the lter element

must be changed.

D Monitoring temperature switch:

Install the monitoring temperature switch

(4) in the tank. Set the temperature value

according to technical data, item 4. The

monitoring temperature stops the pump if

inlet temperature is higher than the set

value.

E Hoses:

Always use exible hoses (6) to minimize

vibrations and noise.

F Inlet pressure:

In order to eliminate the risk of cavitation

and other pump damage, pump inlet

pressure must be maintained according to

specications described in item 4, technical

data.

G Non-return valve (7):

Should be installed after the outlet to

prevent pump backspin, which may ruin

the pump.

H Pressure relief valve:

As the Danfoss PAHT pump begins to

create pressure and ow immediately after

start-up regardless of any counter pressure,

a pressure relief valve (8) should be

installed to prevent system damage.

I System water lling:

To ensure proper ltration of new water

(10) supplied to the system, always use the

lling valve (9).

J Minimum level switch:

Install the minimum level switch (11) above

the outlet of the reservoir. The level switch

must stop the pump if the water in the

reservoir is below the switch, which

indicates that the reservoir is empty.

2

11

Reservoir

4

M

6 6 7

PI

5

PI

System

9

1

3

10

8

16

AI106586503085en-000901 | 05.2021

Page 17

Data sheet PAHT 2-308 pumps

8. Dimensions and

connections

8.1 PAHT 2-6.3

AI106586503085en-000901| 05.2021

17

Page 18

Data sheet PAHT 2-308 pumps

8.2 PAHT 10-12.5

18

AI106586503085en-000901 | 05.2021

Page 19

Data sheet PAHT 2-308 pumps

8.3 PAHT 20-32

AI106586503085en-000901| 05.2021

19

Page 20

Data sheet PAHT 2-308 pumps

8.4 PAHT 50-90

20

AI106586503085en-000901 | 05.2021

Page 21

Data sheet PAHT 2-308 pumps

8.5 PAHT 256-308

AI106586503085en-000901| 05.2021

21

Page 22

Data sheet PAHT 2-308 pumps

9. Service Danfoss PAHT pumps are designed for long

periods of service-free operation to ensure low

maintenance and life cycle costs. Provided that

the pump is installed and operated according to

Danfoss specications, Danfoss PAHT pumps

typically run 8,000 hours between service.

However, the service schedule for your Danfoss

PAHT pump may vary according to the application and other factors.

The life of a pump may be greatly shortened if

Danfoss recommendations concerning system

design and operation are not followed.

In our experience, poor ltration is the number

one cause of pump damage.

Other factors that aect pump performance and

lifetime include:

• running the pump at speeds outside

specications

• supplying the pump with water at temperatures higher than recommended

• running the pump at inlet pressures

outside specications

• running the pump at outlet pressures

outside the specications.

We recommend that you inspect your pump

after 8,000 hours of operation even if it is

running without any noticeable problems.

Replace any worn parts if necessary, including

pistons and shaft seals, to keep your pump

running eciently and to prevent breakdown. If

worn parts are not replaced, then our guidelines

recommend more frequent inspection.

22

AI106586503085en-000901 | 05.2021

Page 23

Data sheet PAHT 2-308 pumps

AI106586503085en-000901| 05.2021

23

Page 24

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg

Denmark

Danfoss ca n accept no respons ibility for pos sible errors in ca talogues, bro chures and other pr inted material. Da nfoss reserves t he right to alter its p roducts with out notice.

This also a pplies to produc ts already on ord er provided that su ch alterations ca n be made without su bsequential cha nges being nece ssary in speci cations alread y agreed.

All trade marks in this mate rial are proper ty of the respec tive companies . Danfoss and the Dan foss logotyp e are trademark s of Danfoss A/S. Al l rights reserv ed.

© Danfoss | DCS (IM) | 2021.05

AI106586503085en-000901 | 24

Loading...

Loading...