Page 1

Servie guide

PAH, PAHT, PAHT G pumps

PAH 10-12.5, PAHT 10-12.5 and

PAHT G 10-12.5

Disassembling and assembling

hpp.danfoss.com

Page 2

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

Table of Contents 1. Disassembling the pump ...................................................................................................................3

2. Inspection ............................................................................................................................................7

2.1. Port plate and valve plate .................................................................................................................7

2.2. Pistons ....................................................................................................................................................7

2.3. Cylinder barrel ..................................................................................................................................... 8

2.4. Housing ..................................................................................................................................................8

2.5. Swash plate ..........................................................................................................................................8

3. Assembling ...........................................................................................................................................9

4. Spare parts list for PAH 10-12.5 / PAHT 10-12.5 ...........................................................................15

4.1. Exploded view PAH 10-12.5 / PAHT 10-12.5 ..................................................................................16

5. Spare parts list for PAHT G 10-12.5 .................................................................................................17

5.1. Exploded view PAHT G 10-12.5 .......................................................................................................18

Introduction

NOTE: If the pump is disassembled within the warranty period, the pump is no longer covered

by the warranty.

This document covers the instructions for

disassembling and assembling the axial piston

pumps PAH / PAHT / PAHT G 10-12.5.

Tools provided with tool set 180Z0235:

• Shaft bush, torpedo

• Press bush ø18 (Plastic)

2

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 3

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

1. Disassembling the

pump

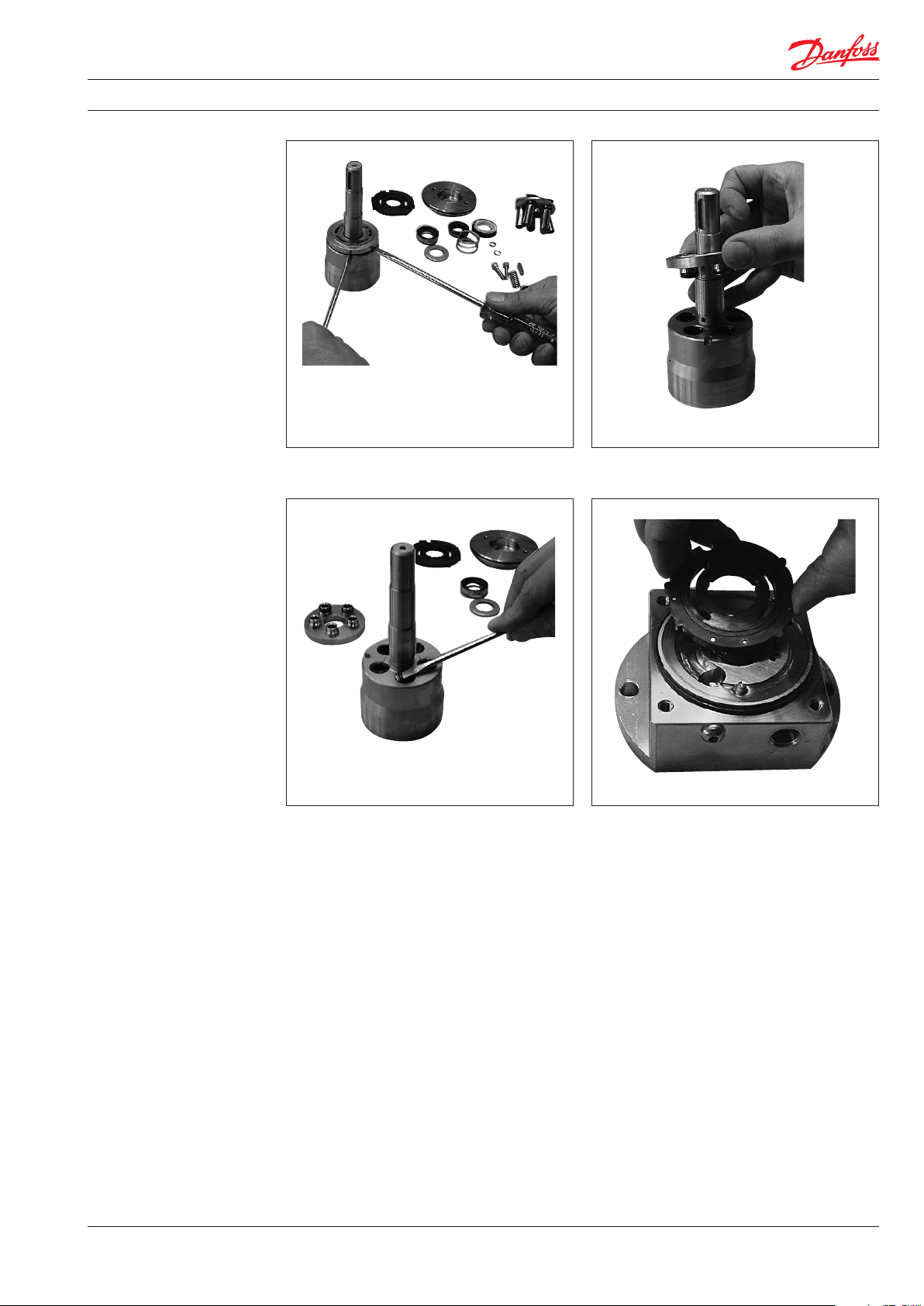

2. Remove the parallel key and unscrew the

front cover.1. Tools required for dismantling.

4. Remove the shaft seal using two

screw drivers.

Caution: Avoid scratching the sealing

3. Dismantle the front cover using a vice.

surface on the shaft.

5. Remove the two small O-rings from the

ange. Remove the seal from the front

cover using a screwdriver. 6. Unscrew the four screws for the housing.

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

3

Page 4

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

7. Remove the housing. 8. Remove the cylinder barrel.

9. Remove the pistons and the retainer plate

from the cylinder barrel.

10. Remove the retainer guide.

12. Remove the spring.11. Remove the spring guide.

4

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 5

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

13. Loosen the valve plate using two

screwdrivers. Place one of the

screwdrivers in the slot of the valve plate.

14. Remove the valve plate.

15. Remove the ve O-rings and the ve

back-up O-rings. 16. Remove the port plate from the ange.

17. Wash all parts and replace all seals

(inclusive shaft seal).

18. Inspect all parts carefully (see

and replace any worn parts.

“Inspection”

19. If the pump has failed, the reason for the

failure must be found and xed before the

repaired pump is re-installed.

)

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

5

Page 6

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

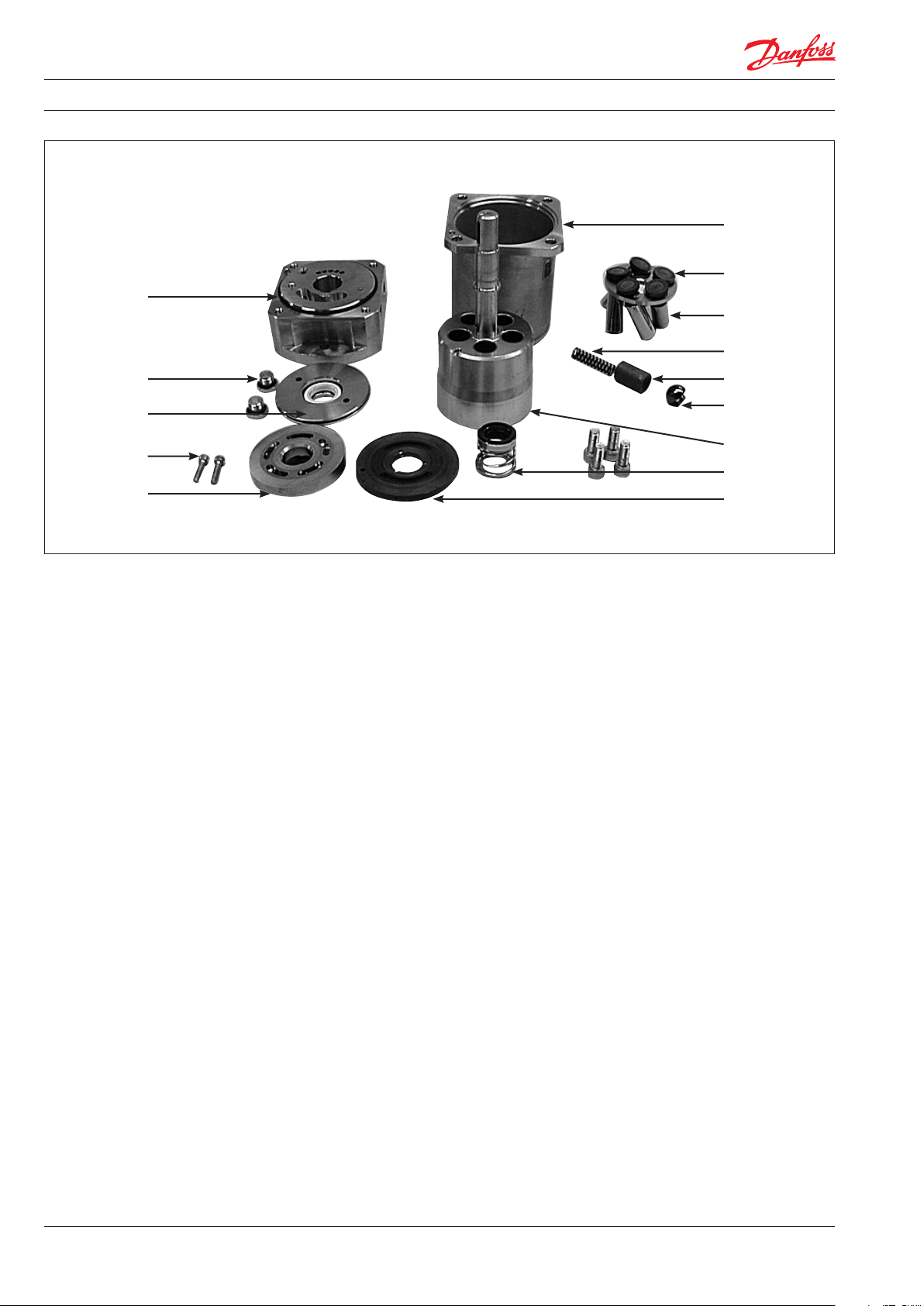

Flange

Housing with

swash plate

and bearing

Retainer plate

Pistons

Spring

Plugs

Front cover

Front

cover crews

Valve plate with

sealing

Spring guide

Retainer guide

Cylinder barrel

Shaft seal

Port plate

6

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 7

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

2. Inspection 2.1. Port plate and valve plate

2. Hold a ruler against the surface of the

1. Neither port plate nor valve plate must

show any sign of wear.

plates and check the tightness against a

light source.

3. Check that both O-rings and back-up rings

are not broken and do not show severe

wear.

2.2. Pistons

1. The play in the ball and socket joint must

not exceed 0.1 mm.

2. The thickness of the piston shoes must be

at least 4.1 mm.

3. Hold a ruler against the surfaces of the

piston shoes to check that the surfaces

are even and smooth and without any

scratches.

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

7

Page 8

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

2.3. Cylinder barrel

2. Check that the bushings are free from

seizure and large scratches.

3. Ensure that the pistons can move freely in

the bushings.

1. Check the outer bearing surface for large

wear grooves (not critical).

2.4. Housing

2. Check the bearing (the black part) for

large wear grooves (not critical).

1

2

1. Check that the swash plate surface is

smooth and without any big scratches

(depth more than 0.1 mm).

2.5. Swash plate

2. Unscrew center bolt from the swash plate.1. Mounted swash plate:

8

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 9

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

Guide pin1. Remove swash plate and guide pin.

3. Assembling

WARNING:

Do not use silicone when assembling the

pump. Do not reuse disassembled O-rings;

they might be damaged. Always use new

O-rings.

1. Lubrication:

• To prevent seizing-up, lubricate all

threads with PTFE lubrication type.

• O-rings inside pump may be lubricated

only with clean ltered water.

• O-rings for port ange, mounting ange

and ushing valve must be lubricated.

• It is important to lubricate ALL parts to

be assembled with clean ltered water

(Especially all PEEK parts).

Important:

It is essential that the pump is serviced in

conditions of absolute cleanliness. All parts

must be absolute clean before mounting.

2. Parts and tools required for assembly.

Check that all parts are OK. Replace all

seals.

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

9

Page 10

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

Guide pin

4. Mount the port plate in its right position

using the pin as guide.3. Mount the O-ring on the ange.

5. Mount the valve plate with seals on the

cylinder barrel.

7. Check that the gap between the cylinder

barrel and the valve plate is 1.5-2.5 mm.

6. Press the valve plate into the cylinder

barrel using a piece of plastic.

8. Mount the cylinder barrel in the ange.

10

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 11

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

10. Mount the spring guide.9. Mount the spring in the centre hole.

11. Mount the retainer guide on the spring

guide.

12. Mount the retainer plate on the retainer

guide. Ensure that the bended surface

points downwards.

14. All pistons inserted.13. Insert the pistons.

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

11

Page 12

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

15. Place pin and place swash plate ttet on

guide pin and center hole.

Alignment

hole

Guide pin

18. Mount the pump housing using the pin as

guide.

17. Tighten to a torque of 10 ±1 Nm.16. Place the screw in the center hole.

19. Press the housing down by hand and

insert the screws.

12

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 13

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

21. Mount the two O-rings in the ange and

the O -ring on the front cover.20. Tighten the screws to a torque of 22 Nm.

22. Wet the shaft seal with water and mount it

in the front cover. Ensure that it is pressed

to the bottom.

23. Mount the washer with the edge pointing

upwards.

25. Fit the hollow bush onto the shaft.24. Mount the spring.

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

13

Page 14

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

26. Wet the shaft seal and slide it over the

bush.

27. Use the shaft seal tool when pressing the

shaft seal downwards.

28. Press the shaft seal in position. 29. Remove the bush.

30. Mount the front cover and align it to the

screw holes. 31. Tighten the screws to a torque of 7 Nm.

14

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 15

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

4. Spare parts list for

PAH 10-12.5 / PAHT 10-12.5

Pos. Qty. Designation Material

- 1 Shaft bush, torpedo - X

- 1 Press bush - X

1 1 Housing AISI 304 / PEEK

2 1 Pin AISI 316 X

5 4 Screw AISI 304 X

31 1 Swash plate AISI 431 X X

32 1 Screw AISI 304 X X

33 1 Washer AISI 304 X X

34 1 Pin AISI 316 X X

61 1 Cylinder barrel AISI 431 / PEEK X X

62 1 Spring AISI 316Ti X X

63 1 Spring guide PEEK X X

64 1 Retainer ball PEEK X X

65 1 Retainer plate AISI 304 X X

66 5 Piston AISI 431/ PEEK X X

67 1 Key AISI 316Ti X

91 1 Port plate AISI 304 / PEEK X

92 1 Valve plate AISI 431 X

93 5 Back up ring PTFE X X

94 5 O-ring NBR X X

121 1 Port ange AISI 304 / PEEK

122 1 O-ring NBR X

123 1 O-ring NBR X

124 1 Shaft seal AISI 304 / NBR X

125 1 End cover AISI 304

126 1 Pin AISI 316

127 2 Screw AISI 304 X

130 2 O-ring NBR X

135 1 Pin AISI 316 X

136 2 O-ring NBR X

- 1 Service instruction (180R9095) - X X X X X X X X

180B4105 - Seal set

(PA HT 10 -12. 5)

180B4107 - Cylinder barrel set

(PA HT 10 -12. 5)

180B4113 - Cylinder barrel set

(PA H 10-12.5)

180B4108 - Valve plate set

(PA HT 10 -12. 5)

180B4106 - Piston set

(PA HT 10 -12. 5)

180B4114 - Piston set

(PA H 10-12.5)

180B4305 - Swash plate set

(PAH T 10)

180B4306 - Swash plate set

(PA HT 12 . 5)

180Z0235 - Tool set

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

15

Page 16

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

4.1. Exploded view

PAH 10-12.5 / PAHT 10-12.5

16

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 17

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

5. Spare parts list for

PAHT G 10-12.5

Pos. Qty. Designation Material

- 1 Shaft bush, torpedo - X

- 1 Press bush - X

1 1 Housing AISI 304 / PEEK

2 1 Pin AISI 316 X

5 4 Screw AISI 304 X

31 1 Swash plate AISI 431 X X

32 1 Screw AISI 304 X X

33 1 Washer AISI 304 X X

34 1 Pin AISI 316 X X

61 1 Cylinder barrel AISI 431 / PEEK X

62 1 Spring AISI 316Ti X

63 1 Spring guide PEEK X

64 1 Retainer ball PEEK X

65 1 Retainer plate AISI 304 X

66 5 Piston AISI 431/ PEEK X

67 1 Key AISI 316Ti X

91 1 Port plate AISI 304 / PEEK X

92 1 Valve plate AISI 431 X

93 5 Back up ring PTFE X X

94 5 O-ring NBR X X

121 1 Port ange AISI 304 / PEEK

122 1 O-ring NBR X

123 1 O-ring NBR X

124 1 Shaft seal AISI 304 / NBR X

125 1 End cover AISI 304

126 1 Pin AISI 316

127 2 Screw AISI 304 X

130 2 O-ring NBR X

135 1 Pin AISI 316 X

136 2 O-ring NBR X

- 1 Service instruction (180R9095) - X X X X X X

180B4312 - Seal set

(PAHT G 10-12.5)

180B4315 - Cylinder barrel set

(PAHT G 10-12.5)

180B4313 - Valve plate set

(PAHT G 10-12.5)

180B4314 - Piston set

(PAHT G 10-12.5)

180B4321 - Swash plate set

(PAHT G 10)

180B4322 - Swash plate set

(PAHT G 12.5)

180Z0235 - Tool set

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

17

Page 18

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

5.1. Exploded view

PAHT G 10-12.5

18

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

Page 19

Service guide | Disassembling and assembling PAH 10-12.5, PAHT 10-12.5 and PAHT G 10-12.5

180R9095 | 521B0986 0 | DKCFN.PI.010.NA4.02| 06. 2017

19

Page 20

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2017.06

180R9095 | 521B0986 | DKCFN.PI.010.NA4.02 | 20

Loading...

Loading...