Page 1

User Guide

Portable gas monitor

Type PAGM for CO and Halocarbon

www.danfoss.com

Page 2

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

Contents

1. Visual inspection .............................................................................................................................................................. 3

2. Connecting gas-sample probe and exhaust and zero air filter assembly ............................................. 3

2.1 Gas-Sample Probe ..................................................................................................................................................... 3

2.2 Purge/Zero Air Carbon Filter Assembly ............................................................................................................. 3

2.3 Battery ........................................................................................................................................................................... 4

3. Front Panel Display & Controls .................................................................................................................................. 4

4. General operation ............................................................................................................................................................ 5

4.1 Normal operation ...................................................................................................................................................... 5

4.2 System Faults Screen ................................................................................................................................................6

4.3 Related to fault codes page ................................................................................................................................... 7

5. Maintenance ..................................................................................................................................................................... 8

5.1 Replacing filters .......................................................................................................................................................... 8

5.2 Replacing Internal Hydrophobic Filters ............................................................................................................ 8

5.3 Verification ................................................................................................................................................................... 9

© Danfoss | DCS (vt) | 2021.032 | BC372016561395en-000101

Page 3

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

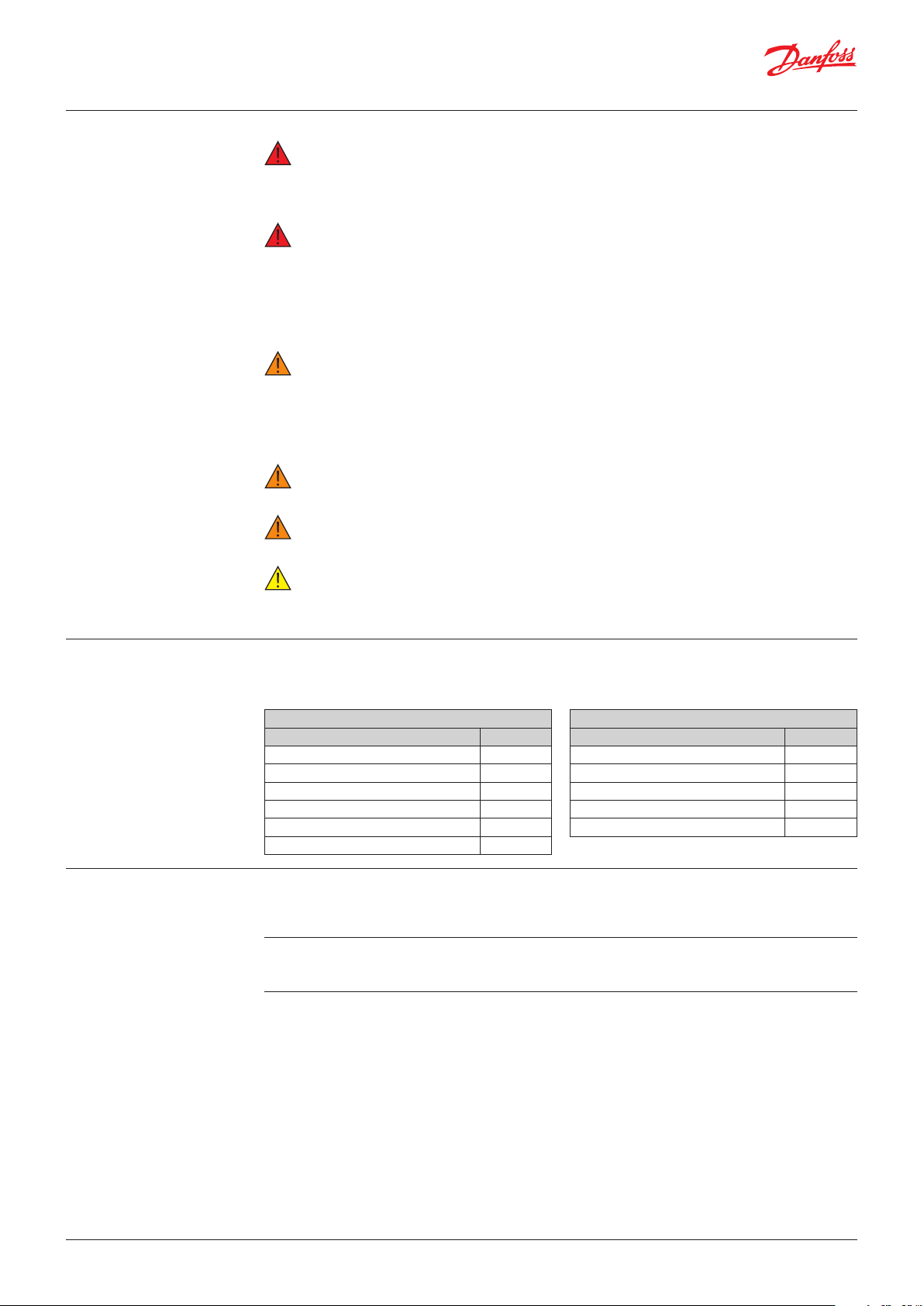

Hazardous area warning:

This instrument has not been designed to be intrinsically safe for use in areas classified as hazardous

locations. For your safety, DO NOT use it in hazardous (classified) locations.

Do not operate this equipment in the presence of flammable liquids, vapours or aerosols.

Combustible/flammable gas warning:

This is NOT a safety device. Some gases which this instrument can detect may be combustible/

flammable. When properly configured, this instrument is designed to alarm at concentrations that

are lower than the explosive limit of the gas. As such, it is the buyer’s responsibility to initiate an

immediate planned response to any gas leaks as soon as they are detected. This equipment should

NEVER be used to measure or sample gases at or above their respective lower explosive limits.

Operation of any electrical equipment in such an environment constitutes a safety hazard.

Warning:

A gas monitor is a delicate and complex device and it is not to be used in any application that is

beyond its intended purpose or beyond the scope of its specifications. For details on appropriate use,

refer to the general description, application, and operation discussions in this manual. Before risking

equipment damage or personal injury, contact the manufacturer if you are unsure of the validity of a

particular gas monitor application.

Warning:

A potential risk exists if the operating instructions are not followed.

Warning:

To avoid risk of injury from electric shock, do not open the enclosure when power is applied.

1. Visual inspection

2. Connecting gas-sample

probe and exhaust and

zero air filter assembly

2.1 Gas-Sample Probe

2.2 Purge/Zero Air Carbon

Filter Assembly

Caution:

Except for the maintenance detailed in this manual, this product should ONLY be opened and / or

serviced by authorized personnel. Failure to comply may void the warranty.

When you receive the instrument, please unpack from it from shipping carton and perform visual

check on the enclosure to ensure no damage to the external parts of the unit which might have

occurred during shipment. Check that all the below items have been received.

PAGM-IR Halogen gas (code no. 080Z2149)

Item Qty.

Refrigerant monitor 1

Soft carrying case with shoulder strap 1

Battery pack and charger kit 1

Probe assembly 1

Coalescing filter 1

Carbon filter 1

Item Qty.

Refrigerant monitor 1

Soft carrying case with shoulder strap 1

Battery pack and charger kit 1

Probe assembly 1

Coalescing filter 1

PAGM-IR CO (code no. 080Z2148)

Before first power up connect all necessary accessories as described on below, this will ensure correct

functionality of the unit.

To connect the gas-sample probe to the monitor, connect the probe to the gas sample port (see

picture below).

A Purge/Zero Air Carbon Filter must be installed to properly use the Portable Aspirated Refrigerant/

Gas Monitor (PAGM).

Filter installation:

1. Unfasten the Velcro on the front of the monitor soft case.

2. Slide the Purge/Zero Air Carbon Filter into the front pocket. Route the tubing through the hole in

the back of the pocket, along the side of the housing.

3. Insert the connector extending from the Purge/Zero Air Carbon Filter into the Zero Air Inlet Port on

the monitor.

4. Refasten the Velcro.

The Leak Detector will periodically (up to 4-minute intervals) draw clean air from an inlet port on the

side of the chassis for the CO.

The external Purge/Zero Air Carbon Filter must be connected to the intake port in order to absorb any

refrigerant present in the area of operation.

© Danfoss | DCS (vt) | 2021.03 BC372016561395en-000101 | 3

Page 4

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

Note: When the Carbon Purge/Zero Air filter is saturated and can no longer absorb refrigerant,

refrigerant can pass through and offset the baseline measurements of the unit which will than result in

unit going into fault condition <0100> error will appear. Please adhere to filter maintenance intervals

as below recommended.

Coalescing Inline Filter Element

Tubing connection

Gas

sample

port

Power

switch

Zero air

inlet port

Exhaust

port

Battery pack

connector

Purge/Fresh Air

Carbon Filter

2.3 Battery

3. Front Panel Display &

Controls

The monitor is powered by a rechargeable battery pack located in a pouch on the side of the monitor’s

soft carrying case. The battery pack can be recharged at any time, regardless of the battery’s current

charge state. The lithium-ion battery will likely be partially charged. However, you should fully charge

the battery prior to operating the PAGM-IR. Refer to the battery manufacturer’s instruction sheet for

the proper charging procedure.

Before the unit can be used please connect the battery pack the unit is designed for a 16 V DC input.

Set battery voltage output to 16 V (refer to the battery manufacturer’s instruction sheet for details).

A fully charged battery pack will power the monitor for a minimum of 8 hours.

ALARM (Red LED)

SYSTEM FAULT (Yellow LED)

MONITOR ON (Green LED)

(flashed during warm-up)

SILENCE/ESC

Press this button to:

1. Temporarily silence the audible alarm

2. Return to the previous screen without

saving data

DISPLAY SCREEN

ENTER key

1. Press to zero the peak reading

2. When in the Control/Setup menu

mode, press to save a displayed

value

KEYPAD

When in the Control/Setup menu mode,

use these buttons to:

1. Move the arrow (>) on the display

screen to the desired function

2. Scroll through data

3. Change a function’s value

Enter the Control/Setup menu mode

by pressing the left and right arrow

buttons simultaneously

RS-232 connector

POWER ON/OFF (toggle switch)

Carrying handle

© Danfoss | DCS (vt) | 2021.034 | BC372016561395en-000101

Page 5

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

Absolute

CO

PAGM-IR FOR CO - ONLY

Important:

• The CO PAGM-IR (PN: 080Z2148) displays CO PPM gas readings that are relative to ambient air, NOT

absolute CO PPM readings.

• If the air in purge air bag is contaminated, use the EMPTY BAG function to clear the bag, then fill the

bag with clean air.

4. General operation

4.1 Normal operation

To turn ON the monitor, lift up the shield located in front of the handle and press the red power ON/

OFF switch.

Important:

• The CO PAGM-IR (PN: 080Z2148) during warm-up needs to be filled with ambient/clean air (outside

(prior to CO testing.

When the monitor has been powered ON immediately all front panel lights turn ON and a splash

screen appears showing the monitor’s current firmware revision level. After a brief moment the Warm

Up screen is displayed along with the front panel ON light (green) blinking allow the monitor it to

warm up for approx. 5 minutes.

PAGM-IR for halogen gas

After the Warm Up has finished the unit is ready to measure gas, please select the appropriate gas

using the display menu.

During normal operation Display screen shows when the monitor is performing the following

functions:

• MEASURE indicates that the monitor is actively measuring the refrigerant gas level at the sample

point. To reset the peak value to zero, press the ENTER button.

• PURGE is displayed when the monitor is resetting baseline ppm value using fresh Air.

• PRES CHK is displayed when the monitor is performing an atmospheric pressure check, which is

done to ensure the accuracy of the gas measurement under varying atmospheric conditions. This

pressure check is performed every 30 minutes.

PAGM-IR for CO

Important:

• The CO PAGM-IR (PN: 080Z2148) has an internal purge air bag that needs to be filled with ambient/

clean air prior to CO testing. This air is used to purge the IR detector of sample gas and establish a

“zero” ppm baseline. Therefore, for greatest accuracy, it is important to ensure the purge air bag is

filled with clean ambient air from outside (away from breathing, car exhaust, etc.).

• The CO PAGM-IR (PN: 080Z2148) displays CO PPM gas readings that are relative to ambient air, NOT

absolute CO PPM readings.

• If the air in purge air bag is contaminated, use the EMPTY BAG function to clear the bag, then fill the

bag with clean air.

Level

2

50 ppm

0 ppm

MEASURE

50 ppm

Relative

CO2

0070 pk

CO

2

level in

refrigerant testing area

Adjusted

CO2 baseline

CO2 level in

ambient air

386 ppm

ABSOLUTE RELATIVE

436 ppm

386 ppm

Danfoss

80G8244

© Danfoss | DCS (vt) | 2021.03 BC372016561395en-000101 | 5

Page 6

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

Immediately after warm-up a message appears and an audible alarm is sounded when the monitor’s

internal Purge Air Bag is empty to fill in the Purge Air Bag press ENTER – see below message.

The purge bag needs to be filled with fresh/clean air failure to do so can result in wrong ppm readings

or Bag Fill Fault - error code <2000>.

After the bag has been filled with air it will last for approximately 40 minutes of normal operation after

that time the bag needs to be filled again, press the ENTER button to start the refill process ensure that

it is filled with clean/fresh air.

After the air bag has been filled successfully, the monitor starts or resumes normal operation by

displaying the Data Display Screen Measure.

4.2 System Faults Screen

To access the Main Menu from the Data Display screen, press both the Keypad Left and Right buttons

at the same time. Next, use the Keypad buttons to move the arrow (>) until it points to the desired

function, and then press the ENTER button to select that function.

If a system malfunction occurs the front panel FAULT light will flash and the audible alarm, if activated

will start beeping.

The FAULT light and audible alarm will automatically turn OFF after the cause of the fault has been

eliminated.

Pressing the SILENCE button while a fault condition still exists causes the internal audible alarm to

turn OFF for a period of time as set by the SILENCE. The front panel FAULT light will continue to flash.

Once the FAULT function is selected on the Data Display press the ENTER button to select that

function. FAULT menu will appear which contains records of the last 30 fault events. The most recent

event is displayed when the Fault screen is first displayed. After 30 events have been recorded, the

newest record overwrites the oldest. Each record lists an event’s numeric fault code plus the date and

time at which the event occurred. If the fault is still present when the FAULTS function is selected, then

the current cause of the fault is displayed If the cause of the fault has been cleared, then the Faults Log

screen will show <0000> along with the date and time the fault was cleared, see fault table below for

troubleshooting.

No FAULTS

Data display

FAULT 1800

The cause of the fault is identified by a numeric fault code. To convert the fault code into a text

description of the fault, first press the ENTER button and then use the Keypad buttons to scroll

through the display until the text description of the fault appears. If the fault code is a combination of

two or more faults, then continue to use the Keypad buttons until all fault text descriptions have been

displayed. For example, the fault code <1800> represents the summary of both a Sample Flow <0800>

and a Purge Flow <1000> fault as shown to the left.

© Danfoss | DCS (vt) | 2021.036 | BC372016561395en-000101

Page 7

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

Code Type Description

<0001> Box Temperature Fault Enclosure temperature is outside normal range (or IR detector has

<0002> Bench Temperature Fault Optical sensor is outside normal operating range (or IR detector has

<0004> Manifold Pressure Fault The manifold pressure is outside its normal operating range (or IR

<0040> Fill Flow Fault The purge-air bag’s pressure drop is outside expected limits. Check for

<0080> Over Range Fault Monitor exposed to a gas level that exceeded 65,000 ppm

<0100> Zero Filter Fault PAGM for halocarbons indicates contamination in the carbon filter. The

<0200> Gain Set Fault The digipot autotune has failed.

<0400> A/D Fault A fault has occurred in the analog-to-digital circuitry. Turn on/off unit if

<0800> Sample Flow Fault Check for a restriction in the gas-sample inlet or exhaust. Check the

<1000> Purge Flow Fault Check for a restriction in the gas-sample exhaust. Check the external

<2000> Bag Fill Fault A punctured bag or disconnected tubing. Refill the bag, FILLBAG

<4000> Zero Range Fault The IR detector’s output voltage is out of tolerance. Enter the DIAG

<8000> Clipping Fault The detector voltage may be out of tolerance. Use the DIAG function to

failed). Monitor has been subjected to extreme temperatures potential

damage to the unit.

Contact service department for further instructions.

failed). Monitor has been subjected to extreme temperatures potential

damage to the equipment.

Contact service department for further instructions.

detector has failed). Enter the DIAG function and record ALL data.

Contact service department for further instructions.

a punctured bag or disconnected tubing. Refill the bag using FILLBAG

function - see manual for instruction.

If the issue persist contact service department.

filter need to be replaced, replace the filter.

PAGM for CO2 the purge-air bag is contaminated with gas. Take

monitor to a clean-air area and use the EMPTYBAG and FILLBAG

functions to decontaminate the purge-air bag,

If the issue persist contact service department.

Contact service department for further instructions.

the issue persist. Contact service department for further instructions.

external Coalescing Inline Filter and/or internal Hydrophobic Filters

replace if necessary. Once the air stream has been restored, the

monitor will return to normal operation after it completes a purge

cycle. If the issue persist contact service department.

Carbon Filter and/or internal Hydrophobic Filter replace if necessary.

Once the purge air stream has been restored, the monitor will return to

normal operation after it completes a purge cycle.

function - see manual for instruction. If the issue persist contact service

department.

function and record all data.

Contact service department for further instructions.

check the IR detector voltage.

Contact service department for further instructions.

4.3 Related to fault codes

page

The DIAG function displays sensor data and status information useful to users for troubleshooting

various fault conditions. Explanations of the data shown in these screens are given below.

First diagnostic screen

Screen item Description

Sensor voltage This is the current peak-to-peak output of the IR detector. In the absence of gas this

Noise The noise value is a 16 point running average of the noise portion of the IR detector’s

Detector Temperature This is the current detector temperature in °C

Box Temperature This is the current internal enclosure temperature in °C

Fault Code Current fault code. A value of <0000> indicates that no faults are being detected.

Pressure Reading This is the pressure as measured every purge cycle with the sample pump off and the

Purge Valve Asterisk (*) The purge valve can be opened and closed by pressing the Keypad Left button. An

value can range from 3.90000 – 4.50000 V

output. This reading is valuable mainly when gas is NOT present.

gas-sample inlet open. Its value is weather and altitude dependent and can range

from 10.0 – 15.5 PSIA.

asterisk appears on the display when the purge valve is open causing the monitor to

draw air from its purge-air port.

© Danfoss | DCS (vt) | 2021.03 BC372016561395en-000101 | 7

Page 8

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

Second diagnostic screen

Screen item Description

PPM Level Parts Per Million level is the current detected gas level, and is the volume concentration

Average Absorption

Unit

µMoles/Liter This is the absolute concentration in micro-moles per liter of gas.

Detector Voltage This is a running average of the IR detector’s sensor voltage.

Purge Valve Asterisk (*) The purge valve can be opened and closed by pressing the Keypad Left button. An

referenced to standard temperature and pressure.

This is the optical absorbency. In the abscene of the gas the absorbency is 0.00000 au.

When sampling gas, its value varies proportionally with the gas concentration

asterisk appears on the display when the purge valve is open causing the monitor to

draw air from its purge-air port.

5. Maintenance

5.1 Replacing filters

The Refrigerant Monitor requires periodic maintenance to ensure peak performance and accuracy

including replacement of internal and external filters and calibration accuracy check refer to the

manual for reference.

External Coalescing Inline Filter and Internal Hydrophobic Filters replacement filter replacement

should be carried out at least once every 6 months but is dependent on the environment and usage.

If used in harsh environment where a large amount of dust and moisture particles are present in

atmospheres the maintenance intervals need to be shortened.

The intervals for the Purge/Fresh Air Carbon filter might very and is related to time the equipment is

used and ppm it was exposed to see table below.

Carbon filter maintenance intervals

Approximate ambient refrigerant

Level Filter replacement interval

0 ppm 6 months

5 ppm 250 hrs

10 ppm 200 hrs

20 ppm 150 hrs

100 ppm 100 hrs

Replace the following components using Danfoss Maintenance Kit – LP-DHGM-MM

a. Coalescing inline Filter Element (Qty. 1)

b. Purge/Fresh Air Carbon Filter (Qty. 1)

c. Hydrophobic Filters (Qty. 2)

5.2 Replacing Internal

Hydrophobic Filters

a. b. c.

Note: Individual components not sold separately

After periodic maintenance the unit can experience faults <0200>, <2000>, <8000> please contact

Danfoss technical support department for further assistance how to adjust the unit settings.

When servicing the parts inside the Refrigerant Monitor, disassemble the monitor’s metal chassis as

follows:

Items Required:

Medium Phillips head screwdriver

Disassemble procedure:

1. Remove monitor and its battery pack from the soft carrying case.

2. Unplug battery pack from monitor.

3. Remove a total of 10 screws from the locations shown in the illustrations below.

4. Carefully separate the metal chassis.

5. Locate filters shown in the illustrations below – red circle

6. Pull off tubing from both ends of filter and remove filter from instrument.

7. Attach tubing to new filter. Ensure correct orientation of the filter – the flow direction is

highlighted with an arrow or/and green label.

8. Reassemble monitor.

© Danfoss | DCS (vt) | 2021.038 | BC372016561395en-000101

Page 9

User Guide | Portable gas monitor, type PAGM for CO2 and Halocarbon

Note: When fitting the Hydrophobic Filters please observe the correct orientation as fail to do so will

result in monitor fault condition – “NO FLOW” code <0800>.

Remove

screws (3)

Front

Remove screws (2)

Left side Rear

Remove

screws (3)

Remove screws (2)

Right side

5.3 Verification

Accuracy check should be performed once every 12 months to ensure peak performance of the unit

see below guidelines.

Important: The accuracy check can only be performed when the unit is in Normal Operation – see

above. Do NOT use pure refrigerant to perform this test as doing so will damage the unit.

PAGM-IR for CO

• Using a regulator, inflate a plastic bag (at least 20 L) with CO mixture of known concentration

(recommended 5000 ppm)

• Insert the wand and seal the plastic bag opening while minimizing any leakage. Let the PAGM

stabilize over a few minutes

• The PAGM-IR should read within +/- 5% of the calibrated gas minus the ambient CO level (typically

~390 ppm).

Example: unit exposed to 5000 ppm should read 4610 ppm +/- 5%, which is from 4380 – 4840 ppm

PAGM-IR for halogen gas

• Set-up the unit to measure R134A gas,

• Using a regulator, inflate a plastic bag (at least 20 L) with R134A gas mixture of known concertation

(recommended 500 ppm)

• Insert the wand and seal the plastic bag opening while minimizing any leakage. Let the PAGM

stabilize over a few minutes

• The PAGM-IR should read within +/- 5% of the calibrated gas ppm value

Example: Unit exposed to 500ppm should read between 475 and 525ppm.

If the unit is outside the parameters please contact Danfoss technical support department for further

assistance.

© Danfoss | DCS (vt) | 2021.03 BC372016561395en-000101 | 9

Page 10

© Danfoss | DCS (vt) | 2021.03 BC372016561395en-000101 | 10

ADAP-KOOL®

Loading...

Loading...