Page 1

Data Sheet

Pressure transmitter

Type MEP

For use in mobile hydraulic, industrial hydraulic and air compressor applications

MEP 2200 and MEP 2250 versions:

• For use in mobile hydraulic applications

• Dual output

Output 1: Switch output

• Hysteresis 1% FS

• Time constant 1 ms

Output 2: Analogue output

• Ratiometric or absolute voltage output

MEP 2600 and MEP 2650 versions:

• For use in mobile hydraulic, industrial

hydraulic and air compressor applications

• Single output

Output 1: Switch output

• Hysteresis 1 – 8% FS

• Time constant 8 – 512 ms

• Immunity towards VFD

The series are available in 2 versions:

• MEP 2200, MEP 2600 – without integrated

pulse-snubber

• MEP 2250, MEP 2650 – with integrated pulsesnubber

The integrated pulse-snubber oers a high

degree of protection against cavitations and

liquid hammer. The well thought out design

results in excellent vibration stability and an

exceptional robustness. The high degree of EMI

protection equips the electronic pressure

switch to meet most requirements.

AI197986426634en-000601

Page 2

P

P

Pulse-snubber

Pressure transmitter, Type MEP

Features

• Designed for use in severe OEM applications

• Excellent long term stability with zero drift

• No leakages due to fully welded design

• Wetted parts made of stainless steel

• For medium and ambient temperatures up to 125 °C

• Dual output versions with switch function and an analogue output signal:

0 – 5 V, 1 – 5 V, 1 – 6 V, 0 – 10 V, 10 – 90% ratiometric voltage as additional output

• Switch versions with customized hysteresis and time constant

• A wide range of pressure and electrical connections

• EMC protection up to 100 V/m

• Thermal overload protected

Application

Figure 1: Pulse-snubber

The pulse-snubber protects the sensor element in the event of cavitation, liquid hammer and pressure peaks, which

may occur in liquid lled systems with changes in ow velocity, e.g. fast closing of a valve or pump starts and stops.

The problem may occur on the inlet and outlet side, even at rather low operating pressures. The media viscosity has

only little eect on the response time.

Even at viscosities up to 100 cSt, the response time will not exceed 4 ms.

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 2

Page 3

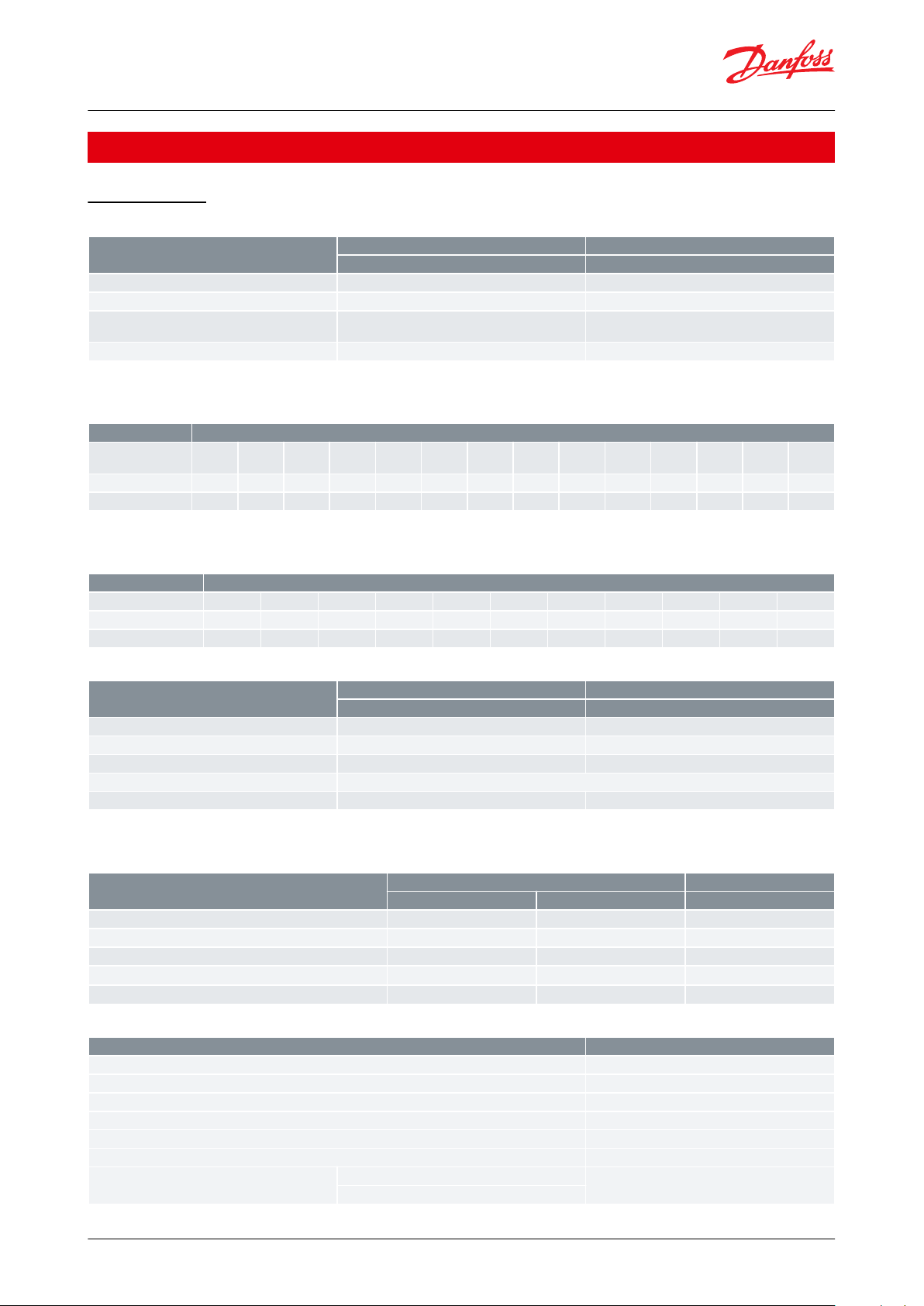

Type

MEP 2200 and MEP 2250

MEP 2600 and MEP 2650

Dual output (Switch and Analogue - output)

Switch output (Switch - output)

Switch Hysteresis

~ 1% FS

(1)

1 – 8% FS

Switch Time delay

1 ms

8 – 512 mS

Accuracy

(incl. non-linearity, hysteresis and repeatability)

2% FS

2% FS (1 – 5% Hysteresis)

3% FS (6 – 8% Hysteresis)

Thermal accuracy

< ± 0.15% FS / 10K

< ± 0.15% FS / 10K

Features

Values

Nominal pressure

[bar]

1016254060

100

160

250

400

500

600

1000

(2)

1600

(2)

2200

(2)

Overload pressure

30488080140

200

320

500

800

1400

1400

2000

2500

3000

Burst pressure

400

640

800

800

1400

2000

1600

2500

4000

> 4000

> 4000

> 4000

> 4000

> 4000

Features

Values

Nominal pressure [bar]

1016254060

100

160

250

400

500

600

Overload pressure

3048120

120

210

300

480

750

1200

2100

2100

Burst pressure

400

640

800

800

1400

2000

1600

2500

4000

> 4000

> 4000

Type

MEP 2200 and MEP 2250

MEP 2600 and MEP 2650

Dual output (Switch and Analogue - output)

Switch output (Switch - output)

Max. load

(3)

500 mA

500 mA

Electrical connector types

See Electrical connections

See Electrical connections

Max. inrush load

1.6 A

600 mA

Supply voltage

8 – 32 V

Over/reverse voltage

± 36 V

± 33 V

Nom. output signal (Short-circuit protected)

NPN and PNP

NPN

0 – 5, 1 – 5, 1 – 6 V

0 – 10 V

10 – 90% ratiometric

Supply voltage [UB], polarity protected

8 – 32 V

12 – 32 V

–

Supply – current consumption

4.5 mA

4.5 mA

4.5 mA

Output inpedance

≤ 90 Ω

≤ 90 Ω

≤ 90 Ω

Load [RL] (connected to 0 V)

RL ≥ 10 kΩ

RL ≥ 10 kΩ

RL ≥ 5 kΩ

Load [RL] (connected to + V)

Not possible

Not possible

RL ≥ 5 kΩ

Features

Values

Media temperature range

- 40 – 125 °C

Ambient temperature range

-40 – 125 °C

Compensated temperature range

- 40 – 125 °C

Transport temperature range

-55 – 150 °C

EMC – Emission

EN 61326-2-3: 2013

EMC Directive

2014/30/EU

EMC – Immunity RF eld

100 V/m, 26 Mhz – 1 GHz

EN 61326-2-3 Cable < 30 m

3 V/m, 1.4 GHz – 2.7 GHz

Pressure transmitter, Type MEP

Product specication

Technical data

Table 1: Performance (EN 60770)

(1)

(1)

For detailed information please contact Danfoss.

For detailed information please contact Danfoss.

Table 2: Overload and burst pressure – without pulse-snubber

(2)

(2)

Only available wih M12 × 11.5 P high pressure port, type FC06. Please contact Danfoss.

Only available wih M12 × 11.5 P high pressure port, type FC06. Please contact Danfoss.

Table 3: Overload and burst pressure – with integrated pulse-snubber

Table 4: Electrical specications

(3)

(3)

For inductive load limits, please contact Danfoss.

For inductive load limits, please contact Danfoss.

Table 5: Secondary output reference for MEP 2200 and 2250

Table 6: Technical data

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 3

Page 4

Features

Values

Electrical performance comply with

ISO 7637 pulse 1 – 4 V (MEP 26XX)

ISO 7637-2 / ISO 16750 (MEP 22XX) (pulse 5b <45 V)

Vibration stability

20 g, 10 – 2000 Hz, sinus

EN 60068-2-6

Shock resistance

100 g

EN 60068-2-27

Enclosure (depending on electrical connection)

see page 8

Materials

Wetted parts

17 – 4 PH

Enclosure

AISI 304 or plastic

Pressure connection

17 – 4 PH

Electrical connection

See Electrical connections

Code no.

Switch state change – NC and NO

NPN and PNP connection

Code 1

Normally open (NO)

(1)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G498

NPN – dual output

NPN / Switch to ground

+ Supply

Load

- Supply

Pressure signal

(absolute and ratio

metric mode)

Danfoss

60G499

Code 2

Normally closed (NC)

(2)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G500

NPN – dual output

NPN / Switch to ground

+ Supply

Load

- Supply

Pressure signal

(absolute and ratio

metric mode)

Danfoss

60G499

Code 3

Normally open (NO)

(1)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G498

PNP – dual output

PNP / Switch to supply

+ Supply

Load

- Supply

Pressure signal

(absolute voltage)

Danfoss

60G501

Code 4

Normally closed (NC)

(2)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G500

PNP – dual output

PNP / Switch to supply

+ Supply

Load

- Supply

Pressure signal

(absolute voltage)

Danfoss

60G501

Pressure transmitter, Type MEP

Table 7: Mechanical conditions

Conguration codes

MEP 2200 and MEP 2250

Table 8: Conguration codes for MEP 2200 and MEP 2250

(1)

NO:

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 4

Page 5

Code no.

Switch state change – NC and NO

NPN and PNP connection

Code 5

Normally open (NO)

(1)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G498

NPN – switch output

NPN / Switch to ground

+ Supply

Load

- Supply

Danfoss

60G502

Code 6

Normally closed (NC)

(2)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G500

NPN – switch output

NPN / Switch to ground

+ Supply

Load

- Supply

Danfoss

60G502

Code 7

Normally open (NO)

(1)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G498

PNP – switch output

PNP / Switch to supply

+ Supply

Load

- Supply

Danfoss

60G503

Code 8

Normally closed (NC)

(2)

Switch state

Set point

Hysteresis 1% FS

bar

high

low

Danfoss

60G500

PNP – switch output

PNP / Switch to supply

+ Supply

Load

- Supply

Danfoss

60G503

Pressure transmitter, Type MEP

At rising pressure (P0 - P

Max

) when reaching the set point the switch will connect the applied load

(switch state change from low to high).

At falling pressure (P

Max

- P0) when reaching the set point + hysteresis the switch will disconnect the applied load

(switch state change from high to low).

(2)

NC:

At rising pressure (P0 - P

Max

) when reaching the set point the switch will disconnect the applied load

(switch state change from high to low).

At falling pressure (P

Max

- P0) when reaching the set point + hysteresis the switch will connect the applied load

(switch state change from low to high).

MEP 2600 and MEP 2650

Table 9: Conguration codes for MEP 2600 and MEP 2650

(1)

At rising pressure (P0 - P

(switch state change from low to high).

At falling pressure (P

(switch state change from high to low).

(2)

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 5

NO:

NC:

Max

) when reaching the set point the switch will connect the applied load

Max

- P0) when reaching the set point + hysteresis the switch will disconnect the applied load

Page 6

Type code

C1C3C7

M12 × 1

EN60947-5-2

Deutsch DT04-4P

Deutsch DT04-3P

NOTE:

The diameter of all housings is

19 mm.

18.3 9.7

M12X1P

38

1.9

21

25

3.4

38

Type code

BD08

PT04

AC04/AF04

AC02/AF02

GB04

Recommended

torque

18 – 20 Nm

2 – 3 turns after

fnger tightend

2 – 3 turns after

fnger tightend

2 – 3 turns after

fnger tightend

30 – 35 Nm

7⁄16 – 20 UNF-2A

1⁄4 – 19 Pt

1⁄4 – 18 NPT / NPTF

1⁄8 – 27 NPT / NPTF

G 1⁄4 A DIN 3852-E

Type code

C1C3C7

Key

Danfoss

60G505

1 4

2 3

Danfoss

60G506

A

B

C

M12x1 EN60947-5-2

Deutsch DT04-4P

Deutsch DT04-3P

Enclosure

IP67

IP67

IP67

Material

SS, PBT 30%

GFR

Gold (Au) plated

Glass lled PBT 30%

GFR

Gold (Au) plated

Glass lled PBT 30%

GFR

Tin (Sn) plated

Electrical connections, MEP 22XX

Pin 1: + supply

Pin 2: pressure output

Pin 3: ÷ supply

Pin 4: switch output

Pin 1: ÷ supply

Pin 2: + supply

Pin 3: switch output

Pin 4: pressure output

Pin A: + supply

Pin B: ÷ supply

Pin C: switch output

Electrical connections, MEP 26XX

Pin 1: + supply

Pin 2: switch output

Pin 3: ÷ supply

Pin 4: N/A buried

Pin A: + supply

Pin B: ÷ supply

Pin C: switch output

Pressure transmitter, Type MEP

At rising pressure (P0 - P

Max

) when reaching the set point the switch will disconnect the applied load

(switch state change from high to low).

At falling pressure (P

Max

- P0) when reaching the set point + hysteresis the switch will connect the applied load

(switch state change from low to high).

Dimensions / Combinations

Table 10: Dimensions / Combinations

Table 11: Dimensions / Combinations with recommended torque

NOTE:

HEX is 22 mm across ats.

Electrical connections

Table 12: Electrical connections

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 6

Page 7

Ordering standard for dual output version type MEP 2200 and MEP 2250

MEP 22..

-

Gasket

Defined type

of pressure connection

Pressure connection (Hex 22)

Standard 0 0 BD08 7/16 – 20 UNF-2A

1)

With pulse-snubber 5 0 AC04/AF04 1/4 – 18 NPT/NPTF

AC02/AF02 1/8 – 27 NPT/NPTF

Measuring range GB04 G 1/4 A DIN 3852-E

1)

0 – 10 bar 2 0 PT04 1/4 – 19 PT

0 – 16 bar 2 2

0 – 25 bar 2 4 Electrical connection

0 – 40 bar 2 6 C 1 M12 x 1 EN60947-5-2

0 – 60 bar 2 8 C 3 Deutsch plug DT04-4P

0 – 100 bar 3 0

0 – 160 bar 3 2

C 7 Deutsch DT04-3P

0 – 250 bar 3 4

0 – 400 bar 3 6 Time constant

0 – 600 bar 3 8 0 1 ms

Hysteresis

Configuration code 1 1% FS

See page 4 1

See page 4 2 Secondary output signal

See page 4 3 2 0 – 5 V

See page 4 4 3 1 – 5 V

4 1 – 6 V

5 0 – 10 V

6 Ratiometric, 10 – 90% (NPN only)

0 No secondary output required

Switch point

To be entered in [bar]

x x x

1)

Incl. Viton gasket. Min. medium temperature is -25 °C

-

Pressure transmitter, Type MEP

Ordering

Dual output version, type MEP 2200 and MEP 2250

Figure 2: MEP 2200 and MEP 2250

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 7

Page 8

Ordering standard for switch version type MEP 2600 and MEP 2650

MEP 26..

-

Gasket

Defined type

- of pressure connection

Standard 0 0 Pressure connection (Hex 22)

With pulse-snubber 5 0 BD08 7/16 – 20 UNF-2A

1)

AC04/AF04 1/4 – 18 NPT/NPTF

Measuring range AC02/AF02 1/8 – 27 NPT/NPTF

0 – 10 bar 2 0 GB04 G 1/4 A DIN 3852-E

1)

0 – 16 bar 2 2 PT04 1/4 – 19 PT

0 – 25 bar 2 4

0 – 40 bar 2 6 Electrical connection

0 – 60 bar 2 8 C 1 M12 x 1 EN60947-5-2

0 – 100 bar 3 0 C 7 Deutsch DT04-3P

0 – 160 bar 3 2

0 – 250 bar 3 4 Time constant

0 – 400 bar 3 6 1 8 mS

0 – 600 bar 3 8 2 16 mS

3 32 mS

4 64 mS

Configuration code 5 128 mS

See page 5 5 6 256 mS

See page 5 6 7 512 mS

See page 5 7

See page 5 8 Hysteresis

1 1% FS

Switch point 2 2% FS

To be entered in [bar]

x x x

3 3% FS

4 4% FS

Secondary output signal 5 5% FS

Not available 0 6 6% FS

7 7% FS

8 8% FS

1)

Incl. Viton gasket. Min. medium temperature is -25 °C

Pressure transmitter, Type MEP

Switch version type MEP 2600 and MEP 2650

Figure 3: MEP 2600 and MEP 2650

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 8

Page 9

File name

Document type

Document topic

Approval authority

063R1015

EU Declaration

EMCD/ROHS

Danfoss

063R1012

Manufacturers Declaration

China RoHS

Danfoss

File name

Document type

Document topic

Approval authority

063R1015

EU Declaration

EMCD/ROHS

Danfoss

063R1012

Manufacturers Declaration

China RoHS

Danfoss

File name

Document type

Document topic

Approval authority

063R1015

EU Declaration

EMCD/ROHS

Danfoss

063R1012

Manufacturers Declaration

China RoHS

Danfoss

File name

Document type

Document topic

Approval authority

063R1015

EU Declaration

EMCD/ROHS

Danfoss

063R1012

Manufacturers Declaration

China RoHS

Danfoss

Pressure transmitter, Type MEP

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 13: MEP 2200

Table 14: MEP 2250

Table 15: MEP 2600

Table 16: MEP 2650

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 9

Page 10

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI197986426634en-000601 | 10

Loading...

Loading...