Page 1

Data sheet

Electric Regulating Valve

Type KVS

KVS is a series of electronic suction modulating

valves for AC transport and refrigeration

applications.

Accurate temperature or pressure control is

obtained by modulating the refrigerant flow in

the evaporator with a current or voltage driver.

With an EKC 368 controller (current driver) and

an AKS sensor placed in the media to be controlled, an accuracy better than ± 0.5K can be

obtained.

The balanced design provides bi-flow operation as

well as solenoid shut-off function in both flow

directions at MOPD 33 bar (478 psig).

Features • Biflow.

• High resolution for precise control.

• Wide range for all common refrigerants R22,

R134a, R404A, R407A, R407C, R407F, R422B,

R422D, R438A, R448A, R449A, R450A, R452A,

R507, R513A, R410A, R1234ze and other

refrigerants

• Balanced port design (KVS 42).

• Solenoid tight shut-off.

• Low power consumption.

• Corrosion resistant design external as well as

internal.

• Cable and connector assemblies as accessories.

• For manual operation and service of KVS valves

an AST-g service driver is available.

For further information please contact Danfoss

(Commercial Refrigeration & Air Conditioning

Controls).

© Danfoss | DCS (sw) | 2017.10

DKRCC.PD.VC1.C7.02 | 1

Page 2

.

Data sheet | Electric regulating valve type KVS 15 – KVS 42

Technical data

Electrical data

Parameter KVS 15 KVS 42

R22, R134a, R404A, R407A, R407C,

Compatible refrigerants

Refrigerant oil All mineral and ester oils All mineral and ester oils

CE marking No Yes

MOPD 33 bar / 478.6 psig 33 bar / 478 psig

Max. working pressure 45.5 bar / 660 psig 34 bar / 493 psig

Inlet fluid temperature -40 to +65 °C / -40 to +149 °F -40 to +65 °C / -40 to +149 °F

Ambient temperature -40 to +60 °C / -40 to +140 °F -40 to +60 °C / -40 to +140 °F

Total stroke 13 mm / 0.5 inch 17.2 mm / 0.68 inch

Motor enclosure IP 67 IP 67

Material of Construction

Parameter KVS 15 and KVS 42

Stepper motor type Bi-polar - permanent magnet

Step mode 2 phase full step

Phase resistance 52 Ω ±10%

Phase inductance 85 mH

Holding current

Step angle

Nominal voltage Constant voltage drive: 12 V DC -4% – 15%, 150 steps/sec.

Phase current (Using chopper drive) 100 mA RMS -4% +15%,

Max. total power Voltage / current drive: 5.5 / 1.3 W (UL: NEC class 2)

Step rate

Total steps

Full travel time

Lifting height

Reference position Overdriving against the full close position

Electrical connection M12 connector

R407F, R422B, R422D, R438A,

R448A, R449A, R450A, R452A, R507,

R513A, R410A, R1234ze and other

refrigerants

Body and AST Encloser: Brass

Connector: Copper

Constant voltage drive: Depends on application.

Chopper drive: full current allowed (100% duty cycle)

7.5° (motor),

0.9° (lead screw),

Gearing ration 8.5:1. (38/13)2:1

Constant voltage drive: 150 steps/sec.

Chopper current drive: 0 – 300 steps/sec. 300 recommended

KVS 15: 2625 [+160 / -0] steps

KVS 42: 3810 [+160 / -0] steps

KVS 15: 17 / 8.5 sec. (voltage / current)

KVS 42: 25.4 / 12.7 sec. (voltage / current)

KVS 15: 13 mm / 0.5 inch

KVS 42: 17.2 mm / 0.68 in

R22, R134a, R404A, R407A, R407C,

R407F, R422B, R422D, R438A,

R448A, R449A, R450A, R452A, R507,

R513A, R410A, R1234ze and other

refrigerants

Body and AST Encloser: Brass

Connector: Copper

Flow curves

Compatible controller / driver EKC 368 / EKD 316 or EKD 316C

KVS 15 Capacity Curve

.

.

KVS 42 Capacity Curve

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 2

Page 3

Data sheet | Electric regulating valve type KVS 15 – KVS 42

Ordering

Accessories:

M12 Female Connector Cable

Spare parts

KVS valves in single pack

Rated capacity

Type

R22 R134a R404A/R507 ODF Code no.

kW TR kW TR kW TR mm in.

KVS 15 5.15 1.31 3.78 0.94 4.58 1.07

KVS 42 40.4 11 . 4 29.3 8.3 35.3 10.0

1

) Rated capacity is the valve capacity at evaporating temperature te = –10°C (14°F), condensing temperature tc = +25°C (77°F)

and pressure drop across valve ∆p = 0.2 bar (2.9 psig).

1)

Connections

single

pack

16 ⁄ 034G4252

22 ⁄ 034G4253

22 ⁄ 034G2858

28 1⁄ 034G2850

35 1⁄ 034G2851

- 1⁄ 034G2852

Actuator with integrated M12 connection

Items Description Quantity

[pcs]

34G179.10

Danfoss

Actuator with integrated M12 with Ceramic bearing

(incl. metal gasket) for KVS 15

Code no.

1 034G2088

34G179.10

Danfoss

Actuator with integrated M12 with ceramic bearing

1 034G2087

(incl. metal gasket) for KVS 42

Metal Gasket 1 034G2344

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 3

Page 4

34G211.10

Pr

C

Data sheet | Electric regulating valve type KVS 15 – KVS 42

Accessories:

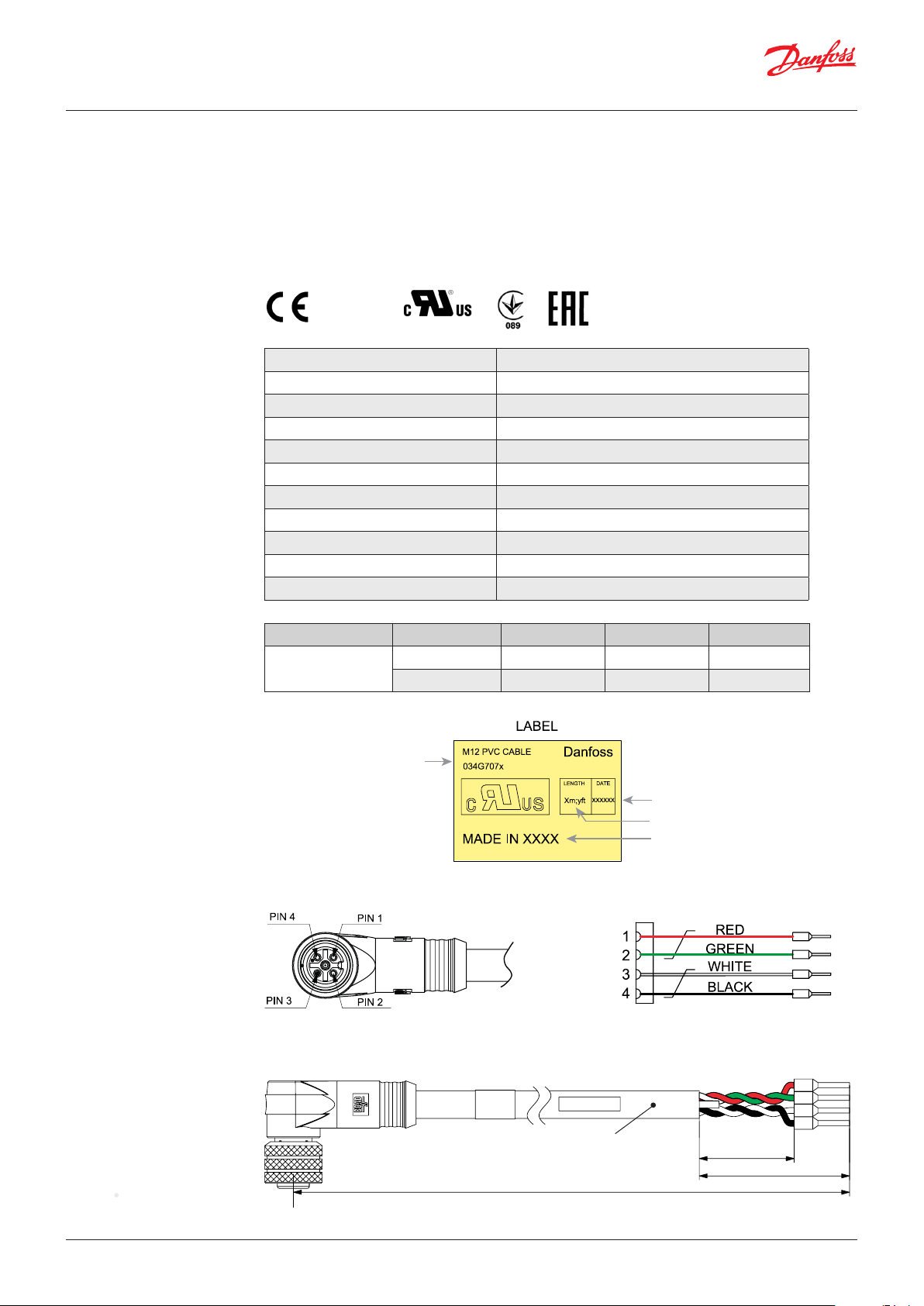

M12 angle cable

M12 angle female connector is intended for use with a standard M12 male connector,

available on stepper motor valves.

This cable is designed to offer high flexibility and small outer diameters with tensile strength.

The angle way M12 cable consist of paired, twisted wires, which decreases mutual influence between

signals transmitted along the cable and reduces influence of external sources of interference. The

cables thus provides a higher degree of protection against lost steps compared to other cables.

Approvals

Specification

Ordering

Identification

RoHS

Jacket PVC - black

Cable outer sheath Oil - resistant

Water proof rating IP 67

Operating temperature range -40 – +80 °C

Wire type Twisted pair, cross section 20 AWG / 0.5 mm2

Cable outer diameter 7.0 mm

Minimum bending radius 10 x cable diameter

Cable combustibility / test Flame retardant / VW-1 / CSA FT - 1

M12 standard EN 61076-2-101

Reference standard UL style 2464 and DIN VDE 0812

LVD directive 73/23/EEC and 93/68/EEC

Cable Cable length (L) Insulation Packing format Code no.

PVC - black

2 m / 6.6 ft SR-PVC Single pack 034G7073

8 m / 26.2 ft SR-PVC Single pack 034G7074

oduct type

ode no

Connections

Dimensions

A2 black

A1 white

B1 red

B2 green

34G210.10

8 meters / 26.2 feet

Manufacturing date

Meters / Feets

Country

34G209.10

Ø 63 mm / 1/4 inch

35 mm / 1.4 inch2 meters / 6.6 feet

49 mm / 1.9 inch

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 4

Page 5

Danfoss

34G212.10

A

B

Data sheet | Electric regulating valve type KVS 15 – KVS 42

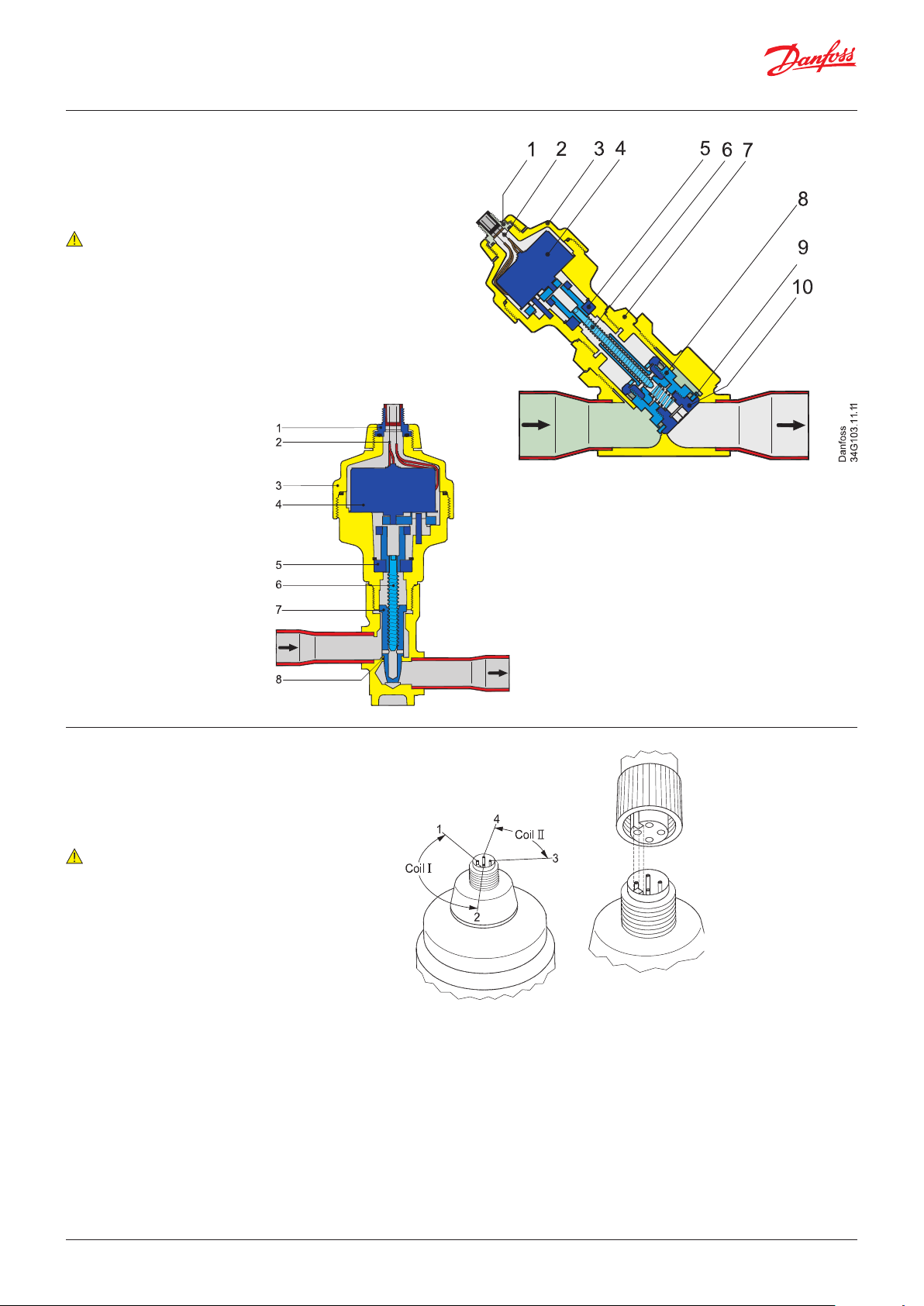

Design

Note:

Flow direction from A to B

refers the normal flow.

KVS 42

1. M12 Connector

2. Glass seal

3. AST motor housing

4. Stepper motor

5. Bearing

6. Spindle

7. Top nut

8. Valve piston

9. Valve seat

10. Valve cone

Danfoss

34G45.12.10

A

B

KVS 15

1. M12 connection

2. Glass seal

3. AST motor housing

4. Stepper motor

5. Bearing

6. Spindle

7. Cone and lead nut

8. Valve seat

Electrical wiring

Note:

Electrical check of

stepper motor and

wiring: coil I = 52 ohm

coil II = 52 ohm

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 5

Page 6

Data sheet | Electric regulating valve type KVS 15 – KVS 42

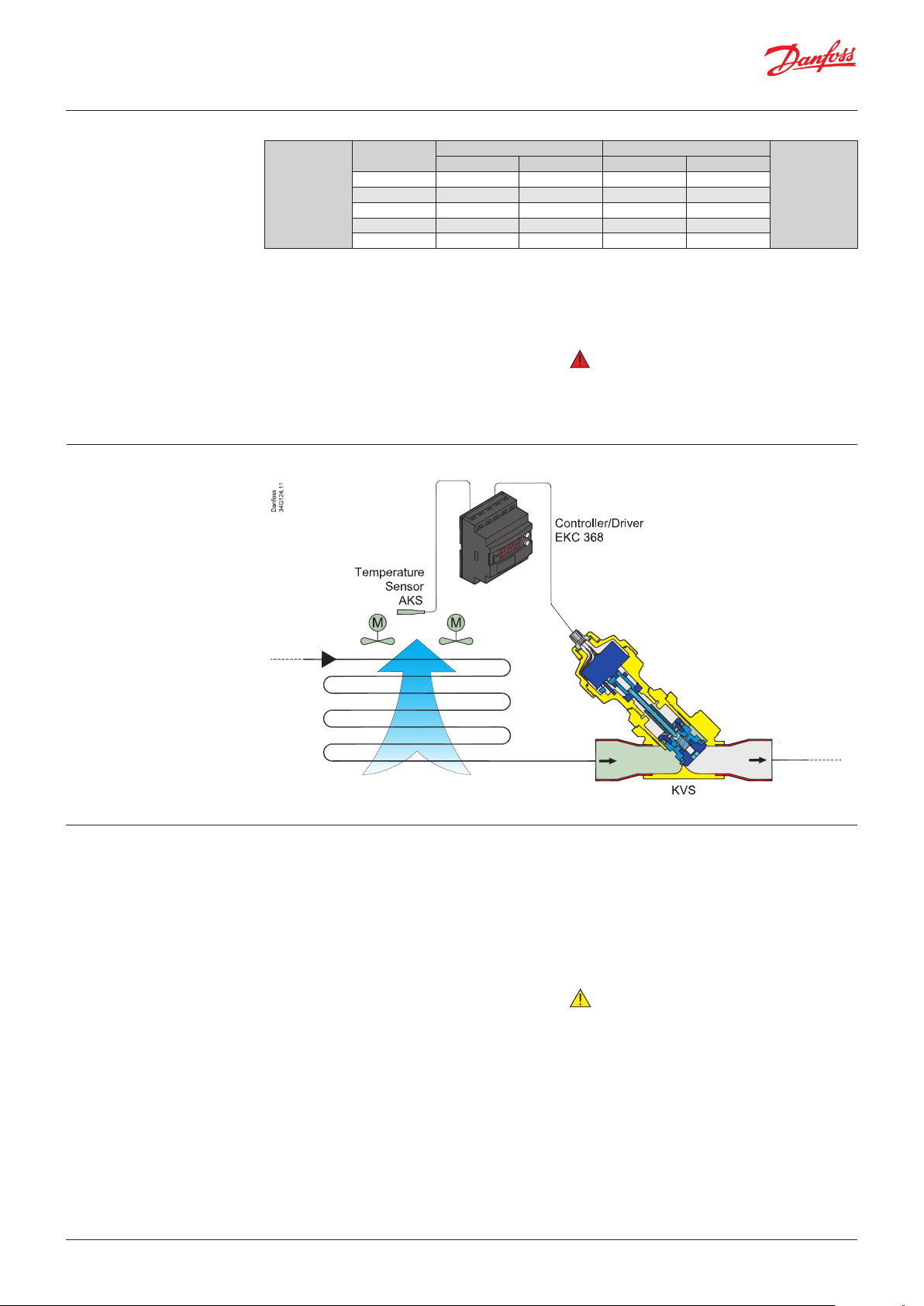

Stepper motor switch

sequence

Valve application

Coil I Coil II

Red Green White Black

↑ CLOSING ↑

STEP

1 + - + 2 + - - +

3 - + - +

4 - + + 1 + - + -

If the controller driving the KVS valve is from

another manufacturer than Danfoss or a custom

design, the following points must be considered

in order to overcome potential step loss.

a. To ensure total closing of the valve, the controller should have a function to overdrive the

valve in the closing direction. It is recommended

to overdrive ten percent of the full step range at

appropriate intervals.

↓ OPENING ↓

b. The amount of lost steps may increase as a

function of the amount of changes of the opening degree. Such designed controller should be

able to compensate the lost steps after a defined

number of changes in opening degree.

Warning:

At power failure the KVS valve will remain in the

opening position it has at the moment of power

failure, unless a safety device in the form of a battery backup is installed.

Evaporator

Valve operation The KVS valves operate modulating by electroni-

cally controlled activation of the AST stepper

motor. The motor is a type 2-phase bipolar,

which stays in position, unless power pulses from

a driver initiate the two discrete sets of motor

stator windings for rotation in either directions.

The direction of the rotation of the spindle

depends on the phase relationship of the power

pulses. This is decisive for the travel of the piston.

The motor is operating the spindle, whose rotating movements are transformed into linear

motion by the transmission in the cage assembly.

The AST motor housing has an integrated M12

connector.

The KVS 42 valves have a pressure slide port

respectively exponential cone, combining the

best performance qualities at part load conditions as well as providing a zero-resistance at

maximum capacity.

The piston design is fully power balanced, giving

identical bi-flow performance capabilities and

nearby identical maximum capacities.

Closing the valve by overdriving, ensures that the

reference number in steps is always correct.

Operating the KVS series requires a controller

with either 12 V dc voltage drive (5.5 W) or using

chopper drive (100 mA RMS).

Danfoss EKC 368 in an example of a qualified

controller.

Note:

Cable length between driver and actuator

exceeding 10 m (30 feet) can set off self-induction with reduction in the transmitted power and

irregularity in the sequences as consequence.

This may result in loss of steps now and again or

more permanent inadequate power supply to

the step motor.

The driver circuit as well as the cable specifications are part of this interference.

Please contact Danfoss for further information

and possible countermeasures.

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 6

Page 7

Data sheet | Electric regulating valve type KVS 15 – KVS 42

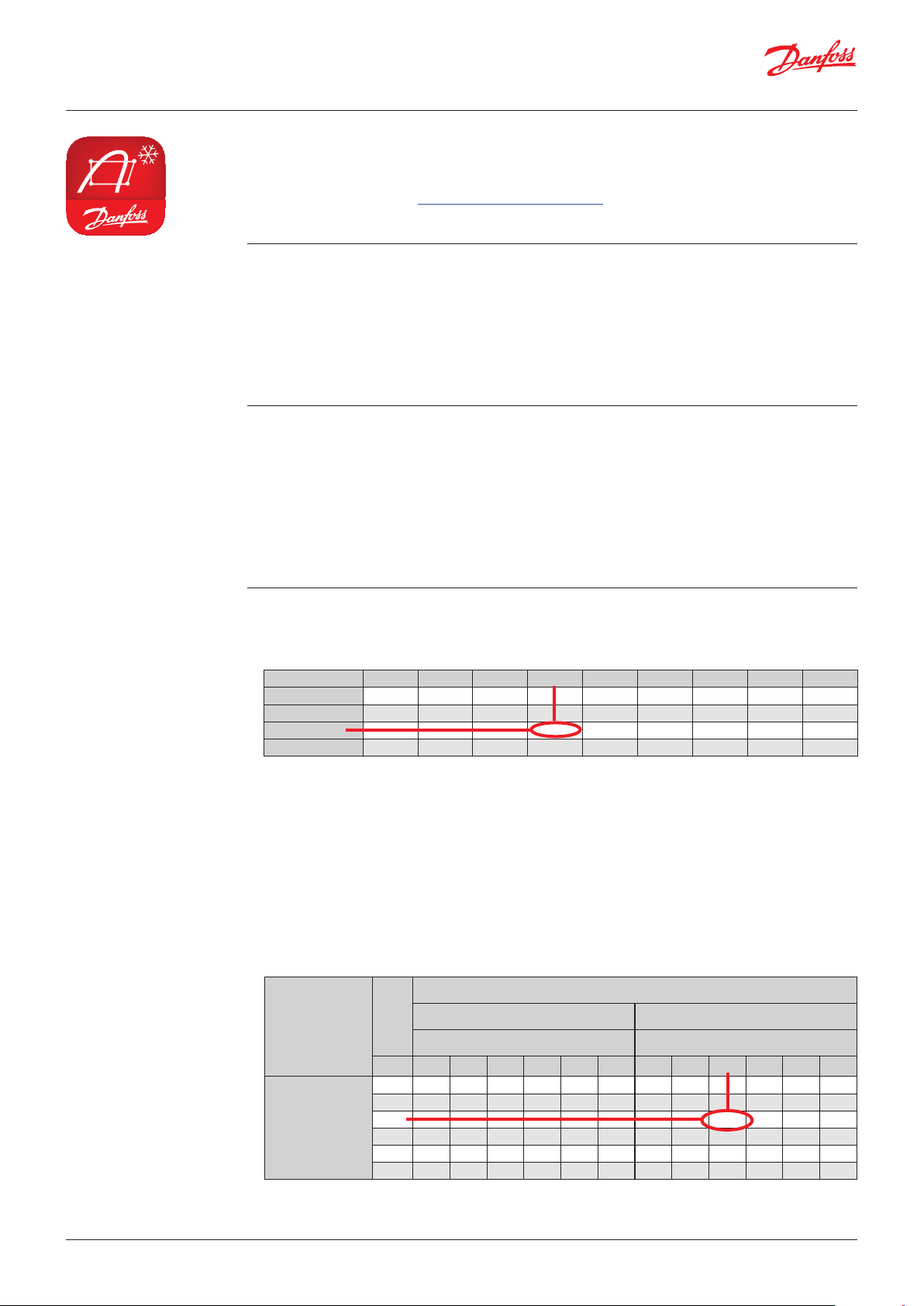

Coolselector2®

For easy and precise selection of valve, use Danfoss’ CoolSelector2® software. You can find the KVS

valves on the group, “Control and regulating valves”.

You can download it from http://coolselector.danfoss.com

Valve sizing For optimum performance, it is important to take

into consideration all system conditions and

requirements. Selection is also dependent on an

acceptable pressure drop across the valve.

The following information will be needed when

sizing a KVS valve:

Valve selection

Example

In valve selection it may be necessary to apply a

correction factor to the actual evaporator

capaity. This correction is required when system

conditions are different than table conditions.

Selection also depends on having an acceptable

pressure drop across the valve. The following

example illustrates correct sizing.

Step 1

Determine the correction factor for liquid temperature t

Correction factors for liquid temperature t

tl °C 10 15 20 25 30 35 40 45 50

R134 a 0.88 0.92 0.96 1.0 1.05 1.10 1.16 1.23 1.31

R22 0.90 0.93 0.96 1.0 1.05 1.10 1.13 1.18 1.24

R404A / R507 0.84 0.89 0.94 1.0 1.07 1.16 1.26 1.40 1.57

R407C 0.88 0.91 0.95 1.0 1.05 1.11 1.18 1.26 1.35

ahead of expansion valve.

l

l

• Refrigerant

• Evaporator capacity Qe in kW or TR

• Evaporating temperature te in °C or °F

• Liquid temperature ahead of expansion valve

tl in °C or °F

• Max. acceptable pressure drop in the KVS valve

in bar or psig

• Connection size

• Refrigerant: R 404A

• Evaporator capacity: Qe = 20 kW / 5.7 TR

• Evaporating temperature:

te = –10°C ~ 3.4 bar / 14°F ~ 49.3 psig

• Liquid temperature ahead of expansion valve:

t

= 25°C / 77°F

l

• Max. pressure drop in the valve:

∆p = 0.2 bar / 2.9 psig

• Connection type: Solder

• Connection size: 11/8 in.

From the correction factors table (see below) a

liquid temperature of 25°C / 100°F, R404A

corresponds to a factor of 1.0.

Step 2 Corrected evaporator capacity is

Qe = 20 × 1.0 = 20 kW / 5.7 × 1.0 = 5.7 TR

Step 3 Now select the appropriate capacity table,

R404A, and choose the column for an

evaporating temperature of te = –10°C / 14°F.

Using the corrected evaporator capacity, select a

valve that provides an equivalent or greater

capacity at an acceptable pressure drop across

the valve of 0.2 bar / 2.9 psig.

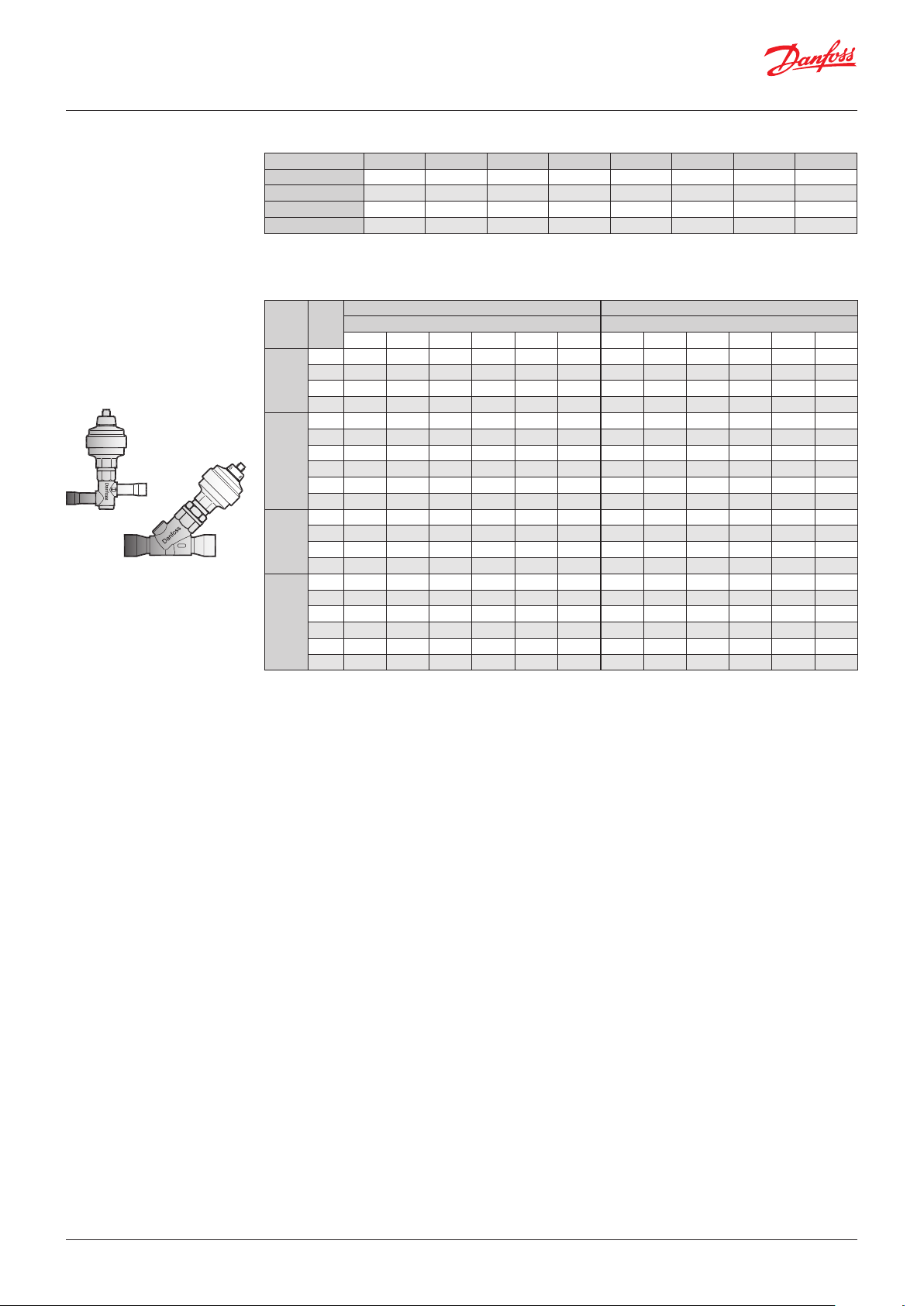

Rated Capacity (kW) SI units

t

e

Pressure drop ∆p [bar] Pressure drop ∆p [bar]

[°C] 0.05 0.1 0.2 0.3 0.5 0.7 0.05 0.1 0.2 0.3 0.5 0.7

10 3.30 4.65 6.52 7.93 10.1 11 .7 25.5 36.0 50.5 61.4 78.1 91.0

0 2.71 3.81 5.34 6.47 8 .18 9.46 21.0 29.6 41.4 50 .1 63.7 73.3

-10 2.20 3.09 4.30 5.19 6.49 7.4 3 17.0 23.9 33.3 40.2 50.3 57. 5

-20 1.75 2.45 3.39 4.06 5.00 5. 61 13. 6 19.0 26.3 31. 5 38.7 43.5

-30 1.37 1.91 2.60 3.08 3.67 3.97 10.6 14.8 20.2 23.9 28.5 30.8

-40 1.04 1.44 1.92 2.22 2.49 2.50 8.08 11.1 14.9 17. 2 19.3 19. 4

Step 4

R404A

KVS 42, 11/8 in.:

Single pack code no. 034G2850

KVS 42 delivers 33.32 kW / 9.5 TR at a 0.2 bar /

2.9 psig) pressure drop across the valve.

Based on the required connection size of 11/8 in,

the KVS 42 is the proper selection for this

example.

Rated capacity [kW]

KVS 15 KVS 42

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 7

Page 8

Data sheet | Electric regulating valve type KVS 15 – KVS 42

Correction factor table

tl °C 10 15 20 25 30 35 40 45 50

R134 a 0.88 0.92 0.96 1. 0 1.05 1.10 1.16 1. 23 1. 31

R22 0.90 0.93 0.96 1.0 1.05 1.10 1.13 1.18 1. 24

R404A / R507 0.84 0.89 0.94 1.0 1.07 1.16 1.26 1.40 1.57

R407C 0.88 0.91 0.95 1.0 1.0 5 1.11 1.18 1.26 1.35

SI units

Capacities

Rated Capacity (kW)

t

e

[°C]

0.05 0.1 0.2 0.3 0.5 0.7 0.05 0.1 0.2 0.3 0.5 0.7

10 2.94 4.12 5.73 6.91 8.62 9.84 22.75 31.92 44.43 53.54 66.82 76.28

R134a

R404A

R407C

R22

* The valves in the capacity table refer to the evaporator capacity and based on liquid temperature

* The conditions printed are the most common for the different refrigerants.

* The pressure drop across the valve is assumed to be the difference between evaporation pressure and suction pressure.

1

) The capacity of vapour flow will not increase for pressure drops above the critical pressure drop.

0 2.38 3.33 4.60 5.50 6.75 7.56 18.46 25.81 35.67 42.65 52.32 58.56

-10 1.90 2.64 3.61 4.26 5.07 5.46 14.72 20.47 27.96 33.00 39.27 42.29

-20 1.48 2.05 2.74 3.15 3.52 3.551) 11.50 15.85 21.20 24.42 27.30 27.47

10 3.30 4.65 6.52 7.93 10.08 11.74 25.54 35.99 50.53 61.43 78.11 91.00

0 2.71 3.81 5.34 6.47 8.18 9.46 21.01 29.56 41.37 50.14 63.35 73.30

-10 2.20 3.09 4.30 5.19 6.49 7.43 17.03 23.91 33.32 40.20 50.28 57.54

-20 1.75 2.45 3.39 4.06 5.00 5.61 13.58 19.00 26.29 31.47 38.72 43.47

-30 1.37 1.91 2.60 3.08 3.67 3.97 10.61 14.76 20.18 23.85 28.47 30.78

-40 1.04 1.44 1.92 2.22 2.49 2.501)

10 3.58 5.04 7.06 8.56 10.84 12.57 27.73 39.04 54.69 66.34 83.98 97.37

0 2.94 4.14 5.77 6.97 8.74 10.03 22.81 32.05 44.71 54.01 67.74 77.75

-10 2.39 3.34 4.63 5.55 6.86 7.74 18.48 25.88 35.87 43.03 53.14 59.94

-20 1.90 2.64 3.62 4.29 5.16 5.62 14.70 20.48 28.07 33.26 39.96 43.56

10 3.74 5.26 7.38 8.96 11.36 13.19 28.95 40.76 57.16 69.40 88.01 102.22

0 3.14 4.41 6.16 7.45 9.38 10.80 24.30 34.16 47.73 57.74 72.66 83.70

-10 2.60 3.64 5.06 6.09 7.57 8.60 20.12 28.21 39.21 47.17 58.63 66.60

-20 2.12 2.96 4.07 4.85 5.90 6.54 16.40 22.90 31.55 37.59 45.75 50.67

-30 1.69 2.35 3.18 3.73 4.36 4.57 13.10 18.18 24.68 28.92 33.79 35.44

-40 1.32 1.81 2.39 2.71 2.891) x1) 10.23 14.02 18.52 20.99 22.371) x1)

tl=30°C, superheat= sub cooling = 0 K.

Other conditions can be calculated with Danfoss calculation software CoolSelector®

KVS15 KVS 42

Pressure drop ∆p [bar] Pressure drop ∆p [bar]

8.08 11.14 14.91 17.20 19.26 19.391)

1)

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 8

Page 9

Data sheet | Electric regulating valve type KVS 15 – KVS 42

Correction factor table

tl °F 50 60 70 80 90 100 110 120

R134 a 0.79 0.82 0.86 0.90 0.95 1. 0 1.06 1.13

R22 0.82 0.85 0.88 0.92 0.96 1.0 1.05 1.10

R404A / R507 0.71 0.75 0.80 0.85 0.92 1. 0 1.10 1.24

R407C 0.78 0.81 0.85 0.89 0.94 1.0 1. 07 1.15

US units

Capacities

Rated Capacity (TR)

(TR) = ton of refrigerants

t

e

[°F]

0.7 1.5 3 5 7 10 0.7 1.5 3 5 7 10

50 0.86 1.25 1.73 2.19 2.53 2.91 6.65 9.66 13.44 16.96 19.60 22.58

R134a

R404A

R407C

* The valves in the capacity table refer to the evaporator capacity and based on liquid temperature

* The conditions printed are the most common for the different refrigerants.

* The pressure drop across the valve is assumed to be the difference between evaporation pressure and suction pressure.

1

) The capacity of vapour flow will not increase for pressure drops above the critical pressure drop.

30 0.68 0.98 1.36 1.69 1.93 2.17 5.28 7.63 10.53 13.12 14.96 16.83

10 0.53 0.76 1.03 1.26 1.40 1.49 4.10 5.88 7.99 9.74 10.82 11.58

-5 0.43 0.61 0.82 0.96 1.03 1.031) 3.34 4.74 6.32 7.46 7.95 8.011)

50 0.98 1.43 2.00 2.56 3.00 3.53 7.59 11.06 15.53 19.84 23.23 27.33

30 0.79 1.15 1.61 2.04 2.38 2.78 6.12 8.90 12.45 15.83 18.45 21.52

10 0.63 0.91 1.26 1.59 1.84 2.12 4.85 7.03 9.78 12.34 14.26 16.41

-5 0.52 0.75 1.04 1.29 1.48 1.67 4.01 5.81 8.02 10.03 11.47 12.97

-20 0.42 0.61 0.83 1.03 1.15 1.26 3.28 4.72 6.46 7.95 8.94 9.80

-40 0.32 0.45 0.60 0.71 0.76 0.771) 2.44 3.47 4.64 5.50 5.89 5.951)

50 1.05 1.53 2.14 2.72 3.18 3.72 8.12 11.82 16.55 21.09 24.62 28.81

30 0.84 1.23 1.71 2.16 2.50 2.90 6.54 9.50 13.24 16.75 19.40 22.44

10 0.67 0.96 1.33 1.67 1.91 2.16 5.17 7.47 10.33 12.91 14.77 16.71

-5 0.55 0.79 1.08 1.33 1.50 1.64 4.26 6.14 8.40 10.34 11.62 12.73

50 1.08 1.58 2.21 2.82 3.30 3.87 8.40 12.24 17.16 21.88 25.58 29.99

30 0.89 1.30 1.81 2.30 2.67 3.10 6.92 10.06 14.04 17.80 20.68 24.01

10 0.72 1.05 1.45 1.82 2.10 2.39 5.60 8.11 11.25 14.13 16.24 18.54

R22

-5 0.61 0.88 1.21 1.50 1.70 1.90 4.72 6.81 9.36 11.62 13.18 14.69

-20 0.51 0.73 0.99 1.20 1.33 1.42 3.92 5.62 7.64 9.30 10.31 10.99

-40 0.39 0.54 0.72 0.83 0.861) x1) 2.98 4.22 5.56 6.43 6.641) x1)

tl=86°F, superheat= sub cooling = 0 K.

Other conditions can be calculated with Danfoss calculation software CoolSelector®

KVS15 KVS 42

Pressure drop ∆p [psi] Pressure drop ∆p [psi]

© Danfoss | DCS (sw) | 1017.10

DKRCC.PD.VC1.C7.02 | 9

Page 10

Dimensions and weights

KVS 15

Type

KVS 15

KVS 42

Type

KVS 42

Connections H

ODF x ODF (A x B)

[in] [mm]

5

/8 × 5/816 × 16

7

/8 × 7/822 × 22

Connections H

ODF x ODF (A x B)

[in] [mm]

7

/8 × 7/822 × 22 4.8 12 0 7. 4 188 .5 5.6 143 3.7 93 3.8 95.5 2.4 60 0.95 24 1.9 4.2

1

[in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [kg] [lb.]

1.2 30 0.5 13 2.5 64 5.9 159 2.4 60 2.4 60 2.4 60 0.7 1.5

1

[in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [kg] [lb.]

H

2

L

1

H

3

L

2

Danfoss

34G102.13

H

4

L

3

L

1

B

L

4

øD

L

2

øD

1

Weight

A

1

B

1

Weight

11/8 × 11/828 × 28 4.8 12 0 6.7 168.5 5.6 143.0 3.3 83.0 3.4 85.5 2.4 60 0.95 24 1.9 4.2

13/8 × 13/835 × 35 4.8 120 7. 0 178 .5 5.6 143.0 3.5 88.0 3.6 90.5 2.4 60 0.95 24 1.9 4.2

15/8 × 15/

- 4.8 120 7.4 188 .5 5.6 143.0 3.7 93.0 3.8 95.5 2.4 60 0.95 24 1.9 4.2

8

Related products

EKD 316 driver EKC 368 controller AKS 11 / AKS 12 temperature sensor

AKS pressure transmitter

© Danfoss | DCS (sw) | 2017.10

Code no. 034G0013

AST-G service driver

DKRCC.PD.VC1.C7.02 | 10

Loading...

Loading...