Page 1

Installation guide

Pressure switch

KPU

Application

KPU pressure switches are for use on commercial

refrigeration and air conditioning systems to give protection

060R9767

against excessively low suction pressure or excessively

high discharge pressure.

They are also used for starting and stopping refrigeration

Refrigerants:

R22, R134a, R404A, R407A, R407C, R407F, R410A*), R422B,

R422D, R438A, R448A, R449A, R450A, R452A, R507A, R513A

For complete list of approved refrigerants, go to

http://products.danfoss.com/all-products/

*) R410A only for KPU 6W and KPU 6B

compressors and fans on air-cooled condensers.

KPU pressure switches are fitted with the Single-Pole SingleThrow (SPST) or Single-Pole Double-Throw (SPDT) switches,

suitable for direct as well as indirect (with a contactor) control.

KPU pressure switches are available in several pressure ranges

and are compatible with refrigerants listed below. KPU 6W and

KPU 6B are fail safe switches for high pressure refrigerants.

Standard enclosure is ~NEMA 1.

Product Specification

Code number

Application Typ e

KPU 1 060-52 31 060- 5233 Auto. SPDT — 6 in. – 108 10 – 60 250 290

Low Pressure

Switch Cut O ut

on pressure

fall

Fan switch KPU 5 060 -5241 060-5242 Auto. SPST(NO) close High open Low 100 – 465 25 – 85 510 530

High Pressure

Switch

Cut Out on

pressure rise

* 610psig - MWP for products used according to 2014/68/EU PED directive.

KPU 1 060- 5236 — Auto. SPST(NO) close High open Low 6 in. – 108 10 – 60 250 290

KPU 2 060-5237 060 -5235 Auto. SPST(NO) close High open Low 6 in. – 73 6 – 30 250 290

KPU 2 060-5239 060 -5240 Auto. SPDT — 6 in. – 73 6 – 30 250 290

KPU1B 060 -5232 060-52 34 Man (Min.) SPDT — 28 in. – 100 10 fixed 250 290

KPU 6W

KPU

6B

¼ in

male flare

060 -5243 060-5245 Auto. SPDT — 100 – 600 58 – 145 675 / 610* 725

060 -5244 060-5246 Man. (Max.) SPDT — 100 – 600 60 fixed 675 / 610* 725

36 in. cap.

tube w. ¼

in flare nut

Reset

Contact system

Typ e

Switch

action

Regulating

range

[inHg] [psig]

Differential

∆p

[psi]

Max.

working

pressure

[psig]

Max.

testing

pressure

[psig]

060R9767

Ambient

temp.

[°F]

-40 – 122

(175 for

max.

2 hours)

Installation

Select an accessible location, where the switch and pressure connection line will not be subject to damage.

IMPORTANT:

Mount the pressure switch in a position that

will allow drainage of liquids away from switch

bellows. Pressure connection of the switch

must always be located on the top side of the

refrigerant line.

This reduces the possibility of oil, liquids, or

sediment collecting in the bellows, which could

cause the switch malfunction.

IMPORTANT:

Ensure the ambient temperature for the pressure

switch is higher than the refrigeration line as that

will prevent liquid migration and accumulation in

the bellows.

© Danfoss | DCS (sb) | 2019.12

AN212086434305en-000101 | 520H11543 | 1

Page 2

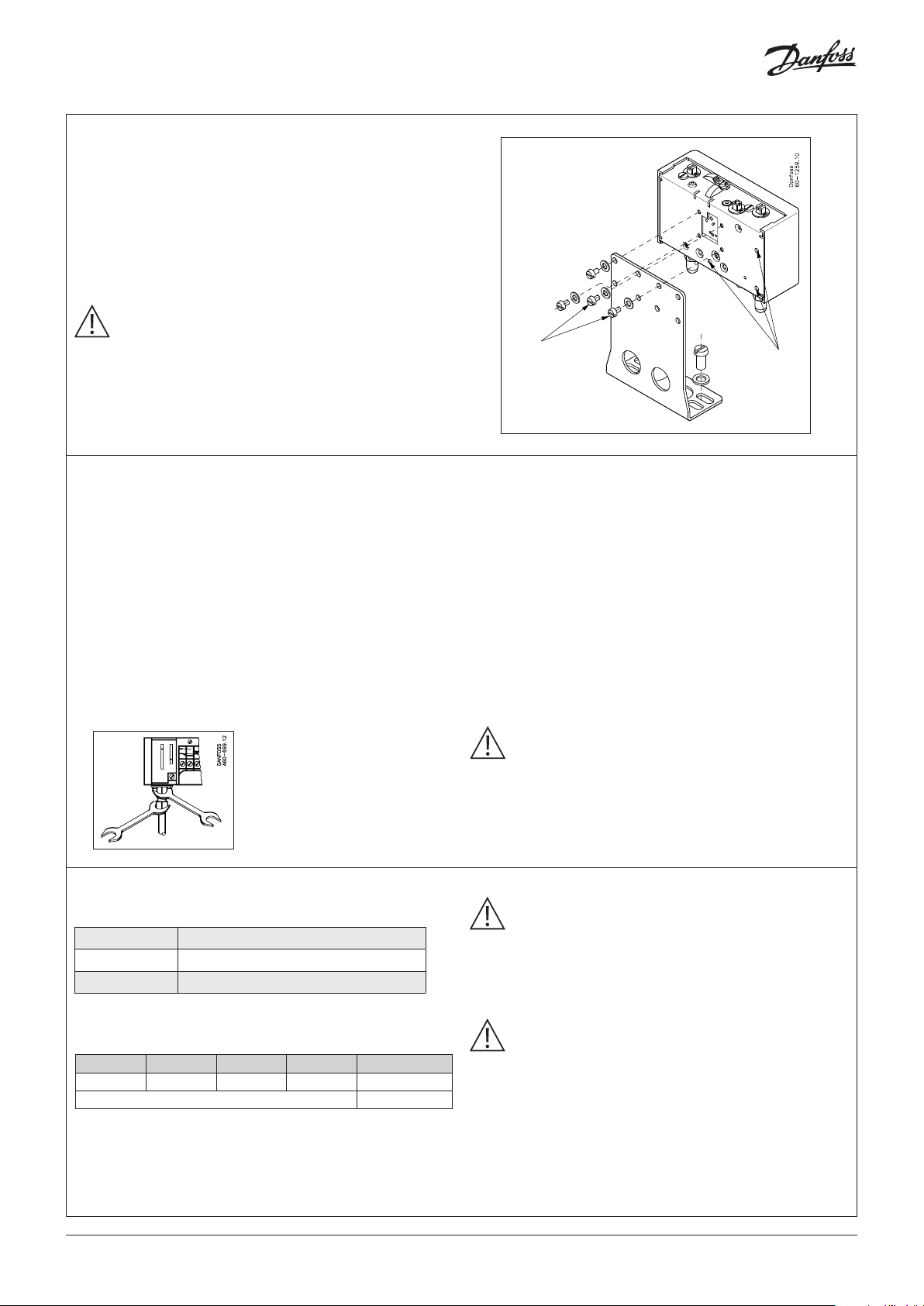

Mount the KPU pressure switch on a bracket

or on a completely flat surface.

Mounting to an uneven surface might cause improper switch

operation.

For bracket mounting use only the 10-32x3/16 screws provided

with the switch. If other screws are used function of the

pressure switch might be disturbed (they may not protrude

into the switch more than 1/8 in.).

Use only the mounting holes provided; no other holes are to

be added to the switch.

IMPORTANT:

Pressure pulsations in the refrigeration system

reduce life time of the bellows and might disturb

switch function. Pressure pulsations should always be

effectively damped e.g. by connection the pressure

switches to the refrigeration system through a capillary

tube.

Recommendations for capillary tube and flare connections:

1. Ensure self-draining of the capillary tube to minimize

clogging.

2. Coil excess capillary tube into smooth, circular coils (approx.

3 inch diameter). The coiled tube should be securely fastened

in order to prevent possible damage due to vibration.

3. Leave a little slack in the capillary tube as it helps to damp

mechanical vibrations.

4. Avoid sharp bends as well as re-bending of the capillary tube

on the same point as it weakens the material, increasing the

risk of crack.

5. Never allow for contact between the capillary tube and sharp

or abrasive objects as during vibrations the tube could be

damaged due to friction.

6. Purge the piping before connecting pressure switches.

7. Always use two wrenches

tightening the flare nut on

the pressure switch. One

wrench should support the

connector while the second

wrench is used to tighten the

nut.

8. Do not over tighten flare nuts as it may damage the threads

9. Protect the capillary tube from damage caused by vibrations

–

– when the switch is mounted remote from the compressor,

– when the switch is mounted remote from the compressor

Screws for

bracket mounting

Mounting holes

for flat surfaces

causing leaks.

from compressor:

when the switch unit is mounted directly on the compressor,

the capillary must be secured to the compressor so that

everything vibrates as a whole.

make the pressure connections away from the compressor.

and the pressure connections have to be on the compressor,

then damping coils must be used between the compressor

and the pressure switch.

NOTE:

After installing the pressure switch, evacuate the plant in

accordance with applicable EPA and other regulations,

to remove air, moisture, and other contaminants.

Wiring

Electrical ratings according to UL regulations

120 V AC 24 FLA, 144 LRA – make only

240 V AC 24 FLA, 144 LRA – make only

240 V DC 12 W pilot duty

European electrical ratings according to EN 60947

AC1 AC3 AC15 LR DC13

16 A 16 A 10 A 112 A 12 W

400 V 220 V

2 | 520H11543 | AN212086434305en-000101

CAUTION:

Disconnect power supply before wiring connections

are made or service to avoid possible electrical shock or

damage to equipment.

Do never touch live parts with your fingers or with

any tool.

NOTE:

All wiring should conform to the National Electrical Code

and local regulations.

Use copper wire only.

Use terminal screws furnished in the contact block.

Do not exceed tightening torque 20 lb. in (2.3 Nm).

Do not exceed electrical ratings for the switch.

The terminal block as well as grounding screw

are accessible after dismounting of the front cover.

© Danfoss | DCS (sb) | 2019.12

Page 3

Wiring Option A:

– Low Pressure Switch Cut Out on pressure fall

– Condenser Fan Cycling

Wiring Option B:

– High Pressure Switch Cut Out on pressure rise

Load ~Line

Wire dimensions: 10 AWG max.

Cable entry: 7/8 in. cable entry for ½ in. male pipe thread

connection (conduit boss) or similar (Pg13.5 or Pg16) screwed

cable entry.

Contact function test (Manual trip)

When the electrical leads are connected the contact function

can be manually tested regardless of pressure condition in

the system. The manual trip lever is located in the left side

of the KPU. It must be operated with fingers only. Do not use

screwdriver as it will damage the switch.

B

A

C

D

Load ~Line

Adjustment

Before adjustment, loosen the locking plate.

For setting use the Universal Refrigeration Wrench.

A

B

C

D

A: Manual trip. Press the lever up. USE FINGERS ONLY!

B: Manual reset button

(available only for contols with manual reset function)

C: Terminal block

D: Grounding screw

NOTE:

While operating the manual trip on KPU

switches with manual reset it is necessary

to push the reset knob.

© Danfoss | DCS (sb) | 2019.12

A: Differential adjusting screw

B: Locking plate

C: Range adjusting screw

D: Cover screw

NOTE:

Adjust the pressure switch with settings specified by the

manufacturer of the controlled quipment.

Do not exceed the pressure ratings of the controlled

equipment or any of its components when checking

pressure switch operation or operating the controlled

equipment.

Do not adjust pointers beyond the highest or lowest

indicator marks on the scale plate, as this may cause

inaccurate switch operation.

AN212086434305en-000101 | 520H11543 | 3

Page 4

IMPORTANT:

The scale plate is only for reference and for more

precise setting a pressure gauge should be used.

IMPORTANT:

After installing and adjusting pressure switch run the

controlled equipment several times (at least three

cycles) at normal operating conditions.

Adjustment:

Low Pressure Switch

Cut out on pressure fall

with automatic reset.

Scale plate directly indicates

the Cut In and the Differential

set points.

Adjustment:

Low Pressure Switch

Cut out on pressure fall

with manual reset.

Scale plate directly indicates the Cut

Out set point. There is no pointer for

the Differential.

The Differential pressure value is

fixed and printed on the scale plate.

Adjustment:

Condenser Fan Cycling

Scale plate directly indicates

the Cut In and the Differential

set points.

1 2

1

1

1. Set Cut In by adjusting range screw.

Turn the screw clockwise to lower the set point.

2. Then set Differential by adjusting differential screw. Turn the

screw clockwise to increase the Differential.

3. The Cut Out setting equals the Cut In

less the Differential: CUT OUT = CUT IN - DIFFERENTIAL

NOTE:

Cut Out set point must be above absolute vacuum!

If the Differential is set too high then the switch

will not stop the compressor.

1. Set Cut Out by adjusting range screw.

Turn the screw clockwise to lower the set point.

2. The Cut In setting equals the Cut Out plus

the Differential: CUT IN = CUT OUT + 10 psi

2

1. Set Cut In by adjusting range screw.

Turn the screw clockwise to lower the set point.

2. Then set Differential by adjusting differential screw. Turn the

screw clockwise to increase the Differential.

3.The Cut Out setting equals the Cut In less

the Differential: CUT OUT = CUT IN - DIFFERENTIAL

Adjustment:

High Pressure Switch

Cut Out on pressure

rise with automatic reset.

Scale plate directly indicates

the Cut Out and the Differential

set points.

Adjustment:

High Pressure Switch

Cut Out on pressure

rise with manual reset.

Scale plate directly indicates

the Cut Out set point.

There is no pointer for the

Differential.

The Differential pressure value is

fixed and printed on the scale plate.

4 | 520H11543 | AN212086434305en-000101

1 2

1

1. Set Cut Out by adjusting range screw.

Turn the screw clockwise to lower the set point.

2. Then set Differential by adjusting differential screw. Turn the

screw clockwise to decrease the Differential.

3. The Cut In setting equals the Cut Out

less the Differential: CUT IN = CUT OUT - DIFFERENTIAL

1. Set Cut Out by adjusting range screw.

Turn the screw clockwise to lower the set point.

2. The Cut In setting equals the Cut Out

less the Differential: CUT IN = CUT OUT - 60 psi

© Danfoss | DCS (sb) | 2019.12

Loading...

Loading...