Page 1

Installation Guide

VLT®AutomationDrive EZ FC 321

0.33–200 hp

vlt-drives.danfoss.com

Page 2

Page 3

e30bj018.10

R

US LISTED

76 X1 E134261 IND. CONT. EQ.

UL Voltage 525-600 V

DANGER

See manual for special condition/mains fuse

voir manual de conditions speciales/fusibles

`

15 min.

VLT

R

Automation Drive

T/C: FC-321P75KT5P20H2XGCXXXSXXXXAXBXCXXXXDX

P/N: 134G6302 S/N: 999999G999

55 kW / 75 kW; 75 kW / 90 kW (NO)

IN: 3x380-500V 50/60Hz 87/86A; 161/145A (NO)

OUT: 3x0-Vin 0-590Hz 87/83A; 105/100A (NO)

Chassis/IP20 Tamb. 50

C /122 F

o o

MADE IN USA

Danfoss A/S

6430 Nordborg Denmark

www.danfoss.com

1

2

3

4

5

6

7

8

9

10

VLT®AutomationDrive EZ FC 321

Installation Guide

Overview

1 Overview

1.1 Safety and Installation Awareness

Before starting installation, get familiarized with all safety guidelines and precautions in this guide. Additional resources - including

the VLT® Safe Torque Off Operating Guide for VLT® AutomationDrive EZ FC 321, the Programming Guide, and the Application Guide

- can be downloaded at www.danfoss.com/service-and-support.

1.2 Tools Needed

The following tools are required for installing the VLT® AutomationDrive EZ FC 321.

•

Lifting aids to place the unit into position.

•

Drill with 10 mm and 12 mm drill bits.

•

Tape measurer.

•

Torx, Phillips, and slotted screwdrivers (T15, T20, T25, T30, T50, PZ1, SL1, and SL2).

•

Wrench with extensions and 7–17 mm sockets.

•

Wire crimper.

•

Sheet metal punch and/or pliers for cable entry plate.

1.3 Items Supplied

Items supplied vary according to product configuration.

•

Make sure that the items supplied and the information on the nameplate correspond to the order confirmation.

•

Check the packaging and the drive visually for damage caused by inappropriate handling during shipment. File any claim for

damages with the carrier. Retain damaged parts for clarification.

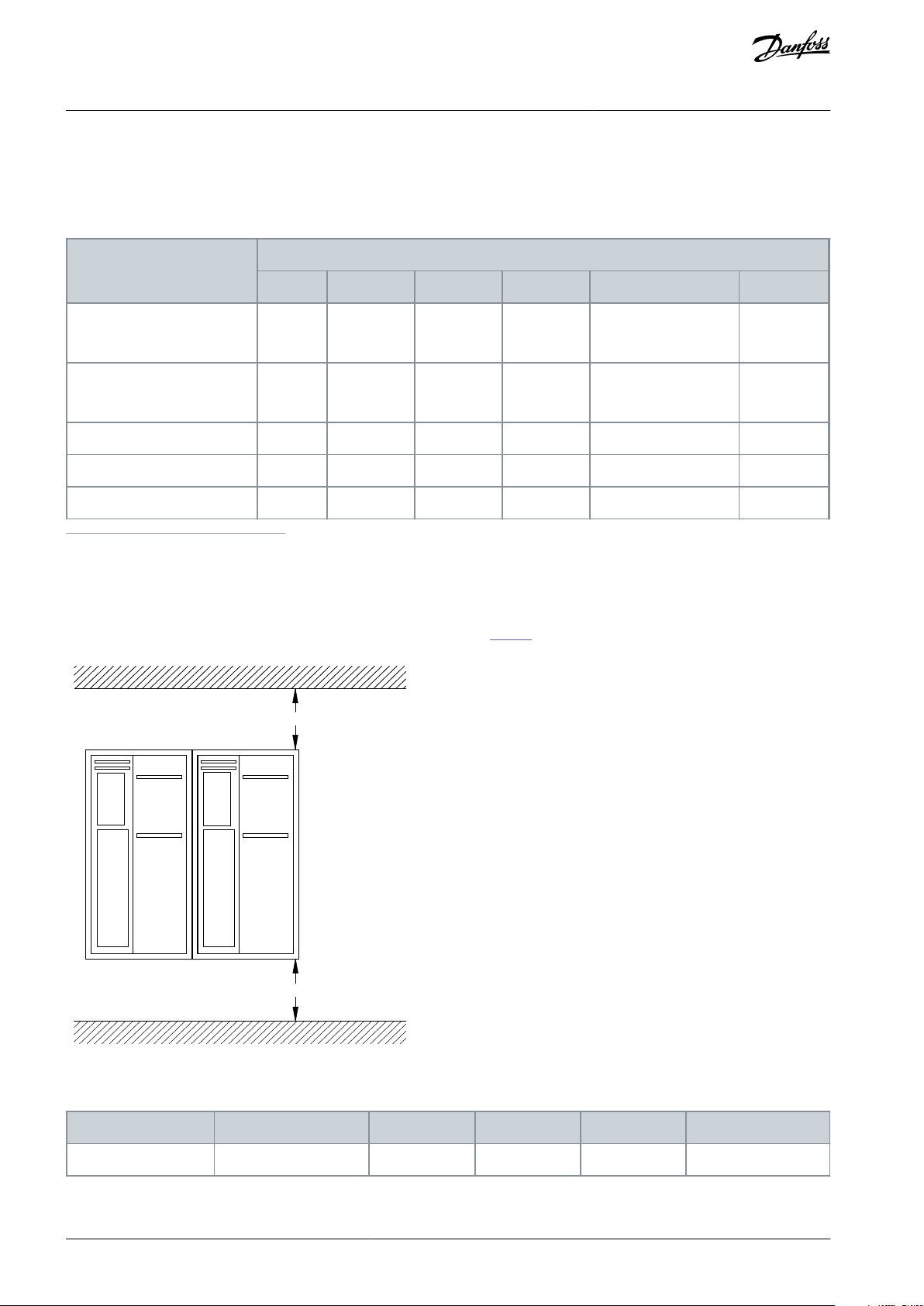

Illustration 1: Nameplate Example

AN354546796134en-000201 / 130R09542 | Danfoss A/S © 2021.05

Page 4

1

Type code

2

Code number

3

Serial number

4

Power rating

5

Input voltage, frequency, and current (at low/high

voltages)

6

Output voltage, frequency, and current (at low/high

voltages)

7

Enclosure size and IP rating

8

Maximum ambient temperature

9

Certifications

10

Discharge time (Warning)

VLT®AutomationDrive EZ FC 321

Installation Guide

N O T I C E

Do not remove the nameplate from the drive (loss of warranty).

Overview

AN354546796134en-000201 / 130R0954 | 3Danfoss A/S © 2021.05

Page 5

NOTE! Download the English and French product guides with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des guides produit contenant l'ensemble des informations

de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

VLT®AutomationDrive EZ FC 321

Installation Guide

Safety Instructions

2 Safety Instructions

2.1 Overview

This Safety chapter only relates to installing the drive. When programming or operating the drive, refer to the Application Guide or

Programming Guide for applicable safety instructions. To install this product safely:

•

Check that the content of the delivery is correct and complete.

•

Never install or start up damaged units. File a complaint immediately to the shipping company, if you receive a damaged unit.

•

Follow the instructions provided in this installation guide.

•

Make sure that all personnel working on or with the drive have read and understood this guide and any additional product

manuals. Contact Danfoss if you are unclear of the given information, or if you are missing information.

2.2 Target Group and Necessary Qualifications

Correct and reliable transport, storage, installation, operation, and maintenance are required for the trouble-free and safe operation

of the drive. Only skilled personnel are allowed to perform all related activities for these tasks. Skilled personnel are defined as

properly trained staff, who are familiar with and authorized to install, commission, and maintain equipment, systems, and circuits in

accordance with pertinent laws and regulations. Also, the skilled personnel must be familiar with the instructions and safety measures described in this manual and the other product-specific manuals. If you are not a skilled electrician, do not perform any electrical installation, and troubleshooting activities.

2.3 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

2.4 General Safety Precautions

For US and Canadian markets:

W A R N I N G

LACK OF SAFETY AWARENESS

This document gives important information on how to prevent injury and damage to the equipment or the system. Ignoring

them can lead to death, serious injury, or severe damage to the equipment.

Make sure to fully understand the dangers and safety measures incurred in the application.

-

AN354546796134en-000201 / 130R09544 | Danfoss A/S © 2021.05

Page 6

Voltage [V]

Minimum waiting time (minutes)

41520

[hp]

200–240

0.34–5.0

7.5–50

60–100

380–500

1.0–10

15–100

125–200

525–600

1.0–10

15–100

–

525–690

––125–200

VLT®AutomationDrive EZ FC 321

Installation Guide

Safety Instructions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by skilled personnel can result in death or serious injury.

Only skilled personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work can result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the time specified in the Discharge Time tables for the capacitors to discharge fully before performing any service or

-

repair work.

Measure the voltage level to verify full discharge.

-

Table 1: Discharge Time

W A R N I N G

UNINTENDED START

When the drive is connected to the AC mains, DC supply, or load sharing, the motor may start at any time, causing risk of death,

serious injury, and equipment or property damage. The motor may start by activation of an external switch, a fieldbus command,

an input reference signal from the LCP or LOP, via remote operation using MCT 10 Set-up software, or after a cleared fault condi-

tion.

Press [Off] on the LCP before programming parameters.

-

Disconnect the drive from the mains whenever personal safety considerations make it necessary to avoid unintended motor

-

start.

Check that the drive, motor, and any driven equipment are in operational readiness.

-

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

C A U T I O N

AN354546796134en-000201 / 130R0954 | 5Danfoss A/S © 2021.05

Page 7

Enclosure size

Protection rating

Dimensions (HxWxD) [in]

Weight [lb]

A2

IP20/Chassis

10.6x3.6x8.7

10.8A3IP20/Chassis

10.6x5.2x8.7

14.6

A5

IP66 - Type 4X

16.6x9.6x7.9

31.5

B1

IP66 - Type 4X

18.9x9.6x10.3

51

B2

IP66 - Type 4X

25.6x9.6x10x3

60

B3

IP20/Chassis

15.8x6.5x9.8

26.5B4IP20/Chassis

20.5x9.1x9.6

52C1IP66 - Type 4X

26.8x12.2x12.3

99C2IP66 - Type 4X

30.4x14.6x13.2

143C3IP20/Chassis

21.7x12.2x13

77C4IP20/Chassis

26x14.6x13

110

D1h

Type 12

35.5x12.8x14.9

136.7

D2h

Type 12

43.6x12.8x14.9

275.6

D3h

IP20/Chassis

35.8x19.8x14.8

136.7

D4h

IP20/Chassis

44.2x14.8x14.8

238.1

VLT®AutomationDrive EZ FC 321

Installation Guide

Safety Instructions

C A U T I O N

HOT SURFACES

The drive contains metal components that are still hot even after the drive has been powered off. Failure to observe the high

temperature symbol (yellow triangle) on the drive can result in serious burns.

Be aware that internal components, such as busbars, may be extremely hot even after the drive has been powered off.

-

Do not touch exterior areas that are marked by the high temperature symbol (yellow triangle). These areas are hot while the

-

drive is in use and immediately after being powered off.

2.5 Lifting the Drive

N O T I C E

LIFTING HEAVY LOAD

The weight of the drive is heavy and failure to follow local safety regulations for lifting heavy weights may cause death, personal

injury, or property damage.

Ensure that the lifting equipment is in proper working condition.

-

Check the weight of the drive and verify that the lifting equipment can safely lift the weight.

-

Always lift the drive using a lifting bar inserted into the lifting eyes. Maximum diameter for the lifting bar: 20 mm (0.8 in).

-

The angle from the top of the drive to the lifting cable: 60° or greater.

-

Test lift the unit approximately 610 mm (24 in) to verify the proper center of gravity lift point. Reposition the lifting point if

-

the unit is not level.

Table 2: Drive Weights and Dimensions

AN354546796134en-000201 / 130R09546 | Danfoss A/S © 2021.05

Page 8

VLT®AutomationDrive EZ FC 321

Installation Guide

Safety Instructions

2.6 Mechanical Installation Precautions

W A R N I N G

EXPLOSIVE ATMOSPHERE

Installing the drive in a potentially explosive atmosphere can lead to death, personal injury, or property damage.

Install the unit in a cabinet outside of the potentially explosive area.

-

Use a motor with an appropriate ATEX protection class.

-

Install a PTC temperature sensor to an ATEX PTC-Thermistor device to monitor the motor temperature.

-

Install short motor cables.

-

Use sine-wave output filters when shielded motor cables are not used.

-

2.7 Electrical Installation Precautions

Before you do electrical work on the drive, lock out and tag out all power sources to the drive.

W A R N I N G

INDUCED VOLTAGE

Induced voltage from output motor cables that run together can charge equipment capacitors, even with the equipment turned

off and locked out/tagged out. Failure to run output motor cables separately or to use shielded cables could result in death or

serious injury.

Run output motor cables separately or use shielded cables.

-

Simultaneously lock out/tag out all the drives.

-

Protective earth connection and RCD requirements

A properly dimensioned protective earth (PE) setup is essential for the safety of the drive system protecting the user against electrical shock. The PE connections of the drive installation ensure that the drive system remains safe preventing that the single fault

currents will generate any hazardous voltages on accessible conductive part, for example, conductive enclosure parts.

The VLT® AutomationDrive EZ FC 321 shall be installed according to the requirement for PE connection and supplementary protective bonding as specified in IEC/EN 60364-5-54 cl. 543 and 544.

For the automatic disconnection, if there is a fault at the motor side, it shall also be ensured that the impedance of the PE connection between drive and motor is sufficiently low to ensure compliance with IEC/EN 60364-4-41 cl. 411 or 415. The impedance is

verified by initial and periodic test according to IEC 60364-4-41.

In some regions, extra local requirements apply and must be adhered to.

The suitability for connection of PE and protective bonding of accessible conductive parts according to IEN/EN 60364-5-54 to the

drive is ensured by following the design according to IEC/EN 61800-5-1.

Where the FC 321 is used as a component inside specific applications, special requirement for proper connection to the PE may

apply, for example, IEC/EN 60204 and IEC/EN 61349-1.

AN354546796134en-000201 / 130R0954 | 7Danfoss A/S © 2021.05

Page 9

VLT®AutomationDrive EZ FC 321

Installation Guide

Safety Instructions

W A R N I N G

ELECTRICAL SHOCK HAZARD - LEAKAGE CURRENT HAZARD >3.5 MA

Leakage currents exceed 3.5 mA. Failure to connect the drive properly to protective earth (PE) can result in death or serious in-

jury.

Ensure reinforced protective earthing conductor according to IEC 60364-5-54 cl. 543.7 or according to local safety regula-

-

tions for high touch current equipment. The reinforced protective earthing of the can be done with:

a PE conductor with a cross-section of at least 10 mm2 (8 AWG) Cu or 16 mm2 (6 AWG) Al

-

an extra PE conductor of the same cross-sectional area as the original PE conductor as specified by IEC 60364-5-54 with a

-

minimum cross-sectional area of 2.5 mm2 (14 AWG) (mechanical protected) or 4 mm2 (12 AWG) (not mechanical protected).

a PE conductor completely enclosed with an enclosure or otherwise protected throughout its length against mechanical

-

damage.

a PE conductor part of a multi-conductor power cable with a minimum PE conductor cross-section of 2.5 mm2 (14 AWG)

-

(permanently connected or pluggable by an industrial connector. The multi-conductor power cable shall be installed with an

appropriate strain relief).

NOTE: In IEC/EN 60364-5-54 cl. 543.7 and some application standards (for example IEC/EN 60204-1), the limit for requiring

-

reinforced protective earthing conductor is 10 mA leakage current.

W A R N I N G

ELECTRICAL SHOCK HAZARD - LEAKAGE CURRENT

Leakage currents can exceed 5%. Failure to ground the drive properly can result in death or serious injury.

When the leakage currents exceed 5%, the protective earth (PE) shall be oversized by one number according to IEC/EN

-

60364-5-54 cl. 543.

Ensure that the minimum size of the ground conductor complies with local safety regulations.

-

W A R N I N G

ELECTRICAL SHOCK AND FIRE HAZARD - RCD COMPLIANCE

The unit can cause a DC fault current in the PE conductor. Failure to use a Type B residual current-operated protective device

(RCD) may lead to the RCD not providing the intended protection and therefore may result in death, fire, or other serious hazard.

When an RCD is used for protection against electrical shock or against fire, only a Type B device is allowed on the supply side.

-

Other precautions

C A U T I O N

THERMISTOR INSULATION

Risk of personal injury or equipment damage.

To meet PELV insulation requirements, use only thermistors with reinforced or double insulation.

-

N O T I C E

EXCESSIVE HEAT AND PROPERTY DAMAGE

Overcurrent can generate excessive heat within the drive. Failure to provide overcurrent protection can result in risk of fire and

property damage.

Other protective devices such as short-circuit protection or motor thermal protection between drive and motor are required

-

for applications with multiple motors.

Input fusing is required to provide short circuit and overcurrent protection. If fuses are not factory-supplied, the installer

-

must provide them. See 4.11 Fuses and Circuit Breakers for fuse specifications.

AN354546796134en-000201 / 130R09548 | Danfoss A/S © 2021.05

Page 10

VLT®AutomationDrive EZ FC 321

Installation Guide

Safety Instructions

N O T I C E

PROPERTY DAMAGE

Protection against motor overload is not included in the default setting. The ETR function provides class 20 motor overload pro-

tection. Failure to set the ETR function means that motor overload protection is not provided and property damage can occur if

the motor overheats.

Enable the ETR function. See the application guide for more information.

-

2.8 Safe Operation

When operating the unit, refer to the Programming Guide and Application Guide for guidance and all applicable safety instructions.

•

The drive is not suitable as the only safety device in the system. Make sure that additional monitoring and protection devices on

drives, motors, and accessories are installed according to the regional safety guidelines and accident prevention regulations.

•

Keep all doors, covers, and terminal boxes closed and securely fastened during operation.

AN354546796134en-000201 / 130R0954 | 9Danfoss A/S © 2021.05

Page 11

Location

Enclosure sizes

A2–A5

B1/B3

B2/B4

C1/C3

C2/C4

D1h/D3h

Mains terminals [in-lb]

4.4–5.3

15.9

39.8

89

124 (up to 3 AWG)

212 (over 3 AWG)

168/335

(1)

Motor terminals [in-lb]

4.4–5.3

15.9

39.8

89

124 (up to 3 AWG)

212 (over 3 AWG)

168/335

(1)

Ground terminals [in-lb]

–

17.7–26.6

17.7–26.6

17.7–26.6

17.7–26.6

84/169

(2)

Brake terminals [in-lb]

4.4–5.3

15.9

39.88912484Relay terminals [in-lb]

–

4.4–5.3

4.4–5.3

4.4–5.3

4.4–5.3

4

a

a

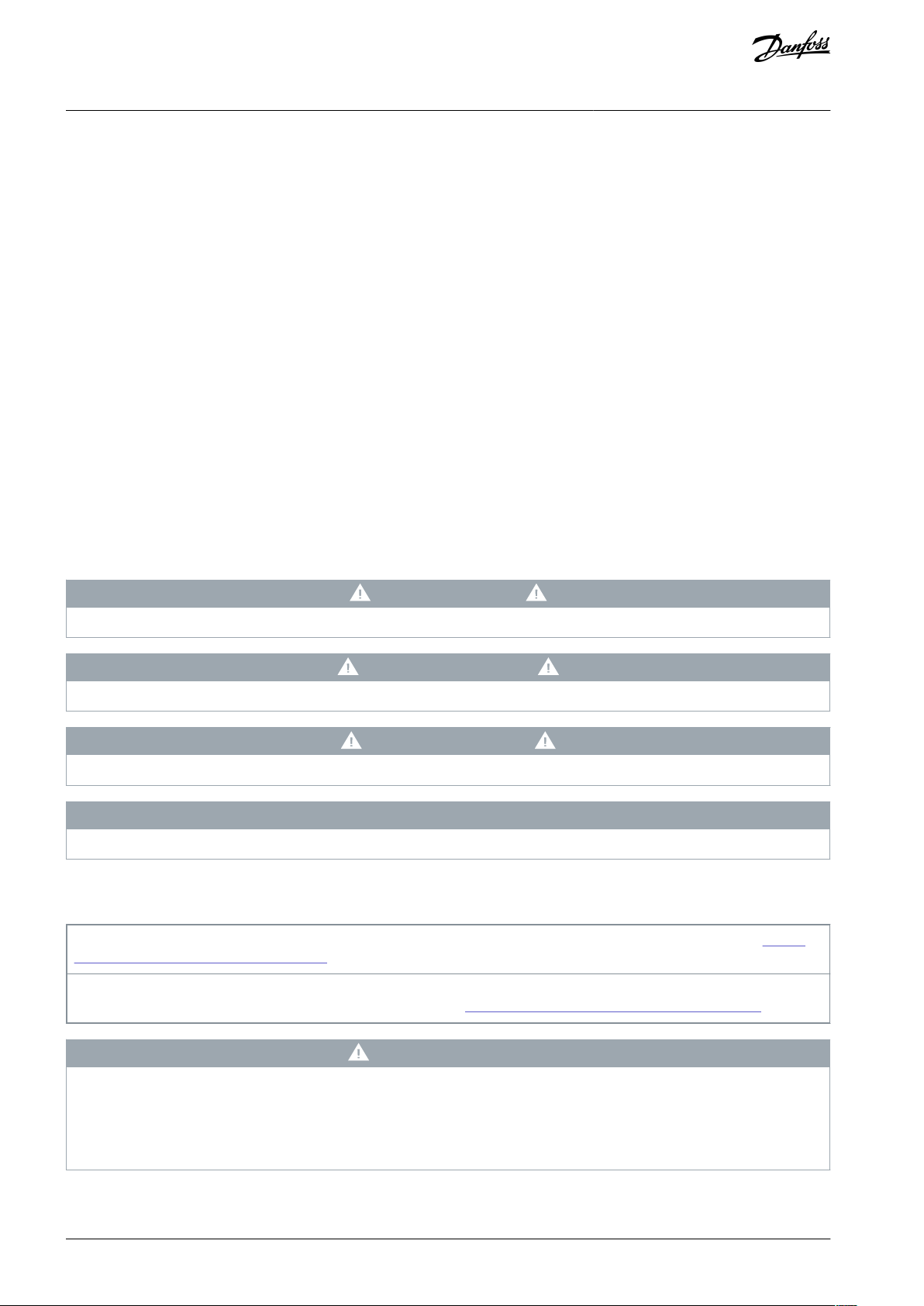

e30bd528.10

Enclosure

A2–A3, A5

B1–B4

C1, C3

C2, C4

D1h–D4h

a [in]

3.9

7.8

7.8

8.9

8.9

VLT®AutomationDrive EZ FC 321

Installation Guide

3 Mechanical Installation

3.1 Connection Tightening Torques

Table 3: Tightening Torque for Cables

Mechanical Installation

1

Bolt size M10/M12

2

Bolt size M8/M10

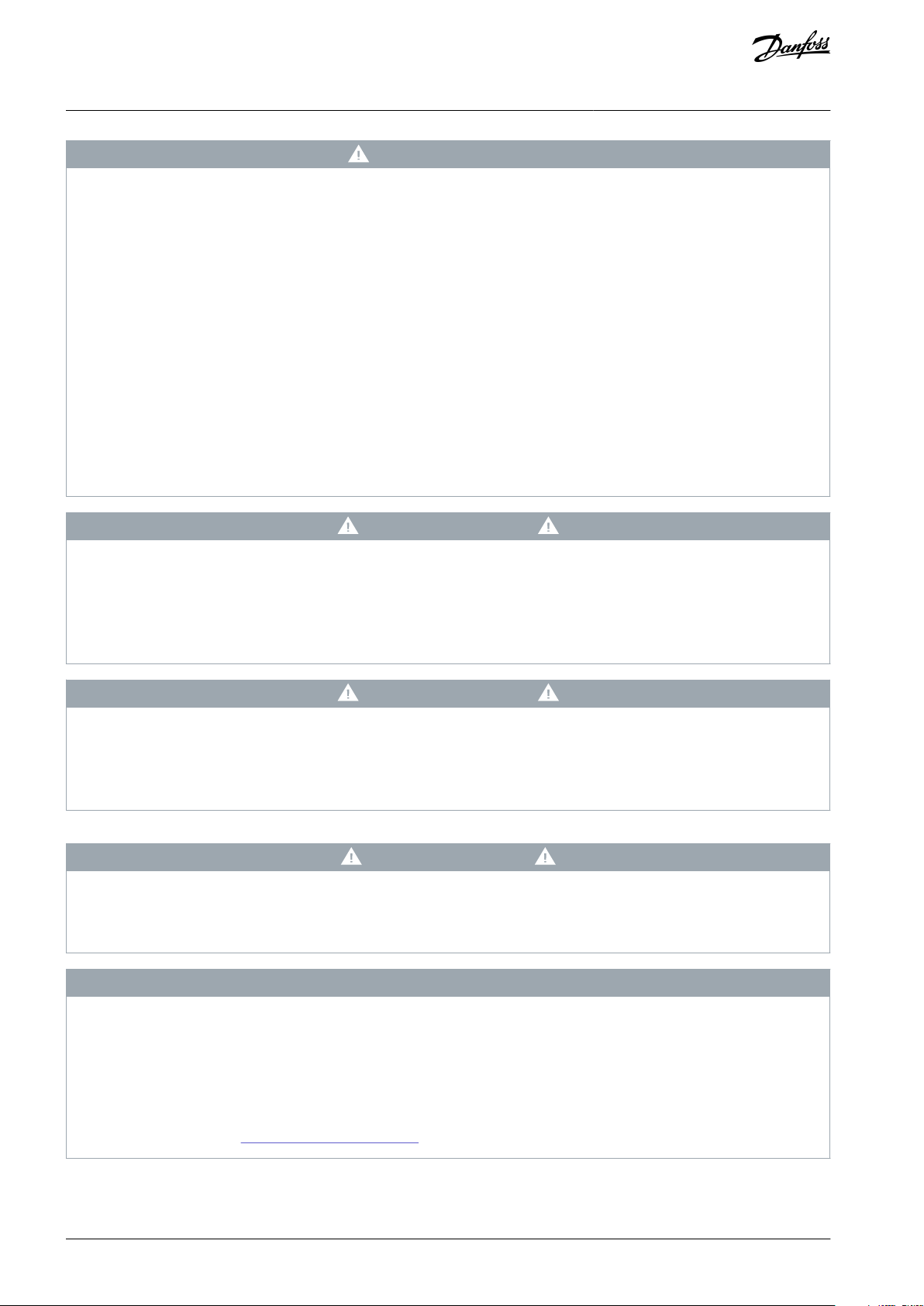

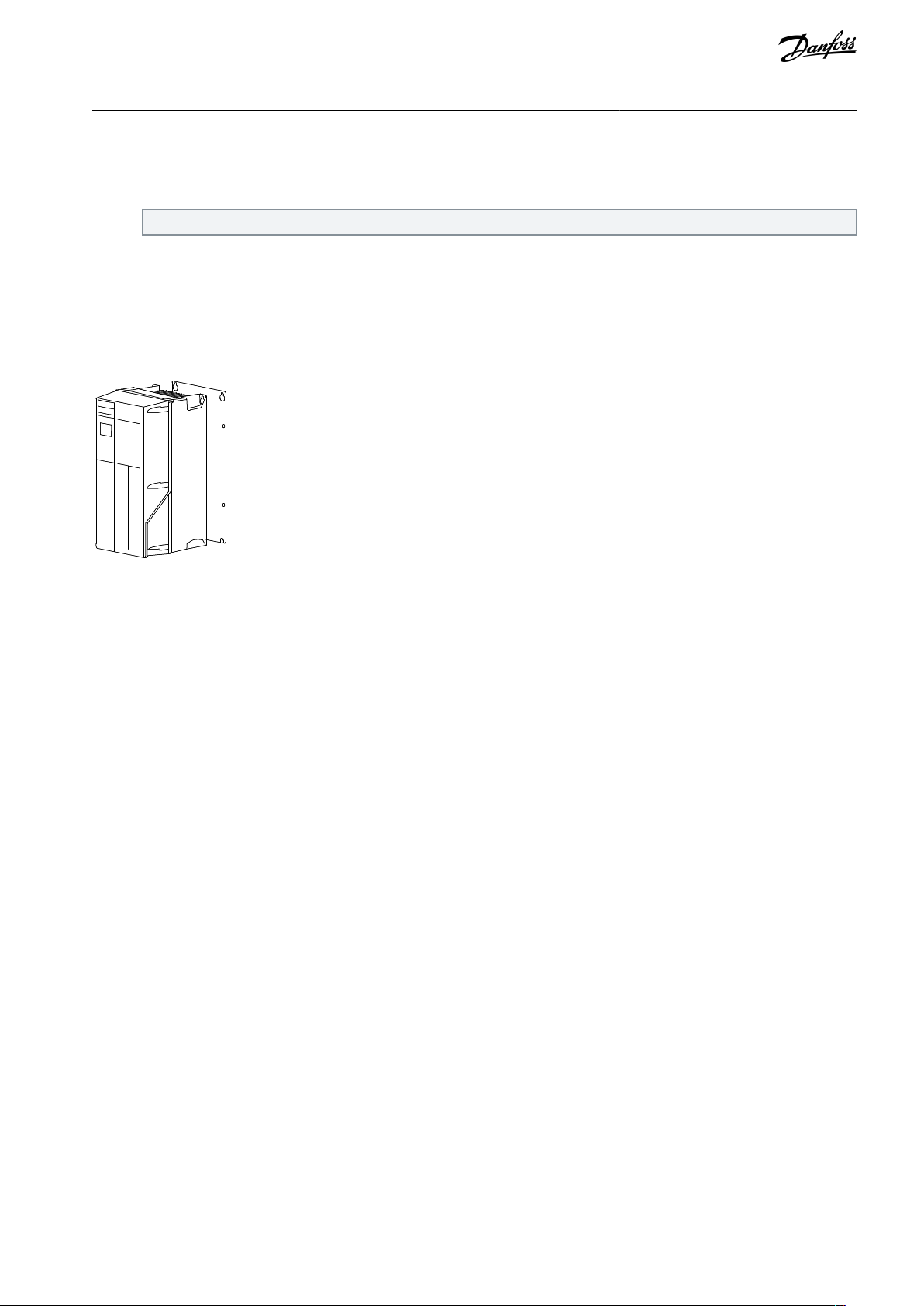

3.2 Cooling

Ensure that top and bottom clearance for air cooling is provided. See

•

Table 4 for clearance requirements.

Illustration 2: Top and Bottom Cooling Clearance

Table 4: Minimum Airflow Clearance Requirements

AN354546796134en-000201 / 130R095410 | Danfoss A/S © 2021.05

Page 12

e30bd504.11

VLT®AutomationDrive EZ FC 321

Installation Guide

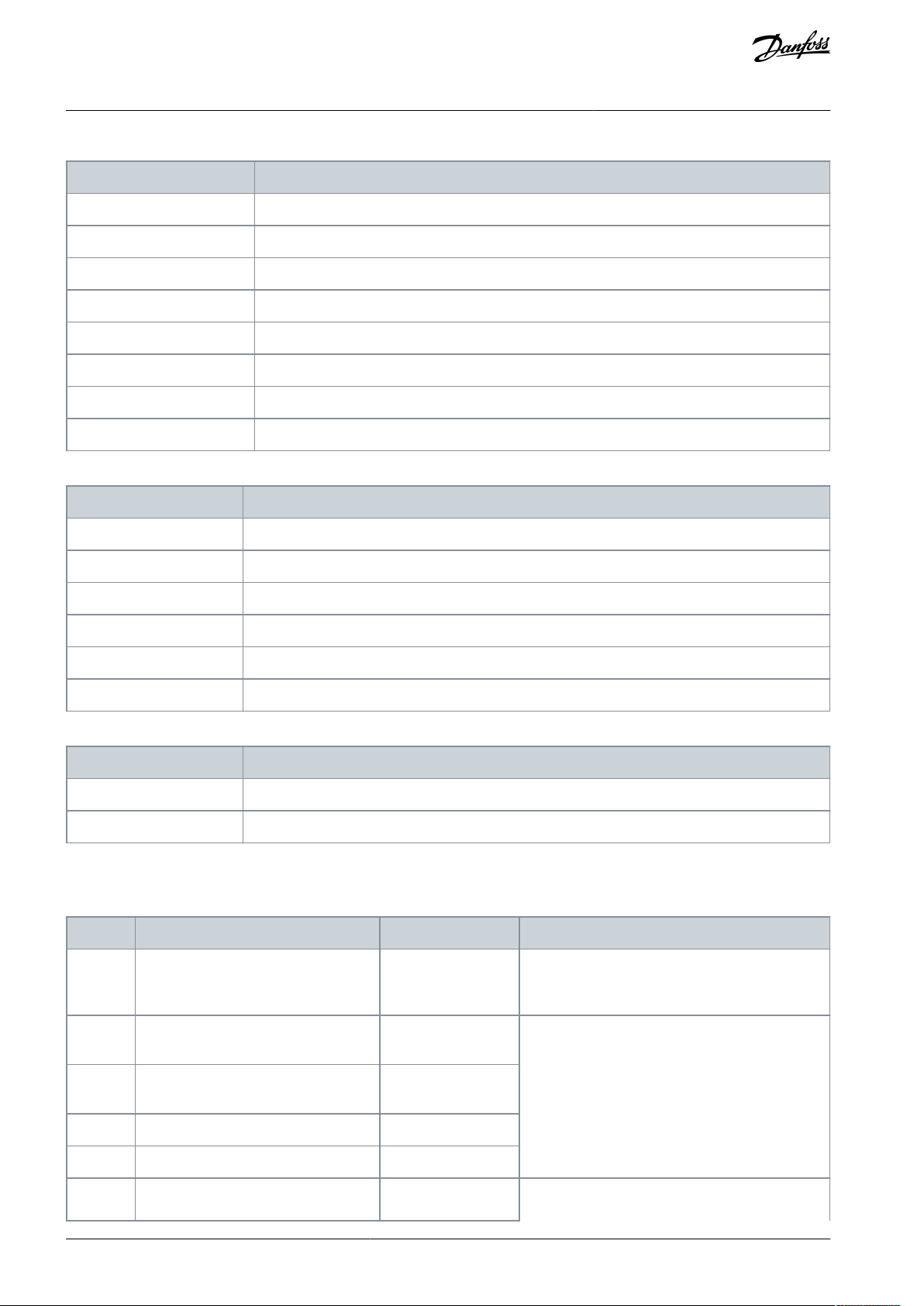

3.3 Mounting

Procedure

1.

Ensure that the strength of the mounting location supports the unit weight.

The drive allows side-by-side installation.

2.

Place the unit as near to the motor as possible. Keep the motor cables as short as possible.

3.

Mount the unit vertically to a solid flat surface or to the optional backplate to provide cooling airflow.

4.

Use the slotted mounting holes on the unit for wall mount, when provided.

3.3.1 Mounting with Mounting Plate and Railings

A mounting plate is required when mounted on railings.

Mechanical Installation

Illustration 3: Proper Mounting with Mounting Plate

3.4 Preparing Cable Entry Holes

Procedure

1.

Remove cable entry from the drive. Avoid that foreign parts fall into the drive when removing the knockouts.

2.

Support the cable entry where the knockout is to be removed.

3.

Remove the knockout with a strong mandrel and a hammer.

4.

Remove burrs from the hole.

5.

Mount the cable entry on the drive.

AN354546796134en-000201 / 130R0954 | 11Danfoss A/S © 2021.05

Page 13

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

4 Electrical Installation

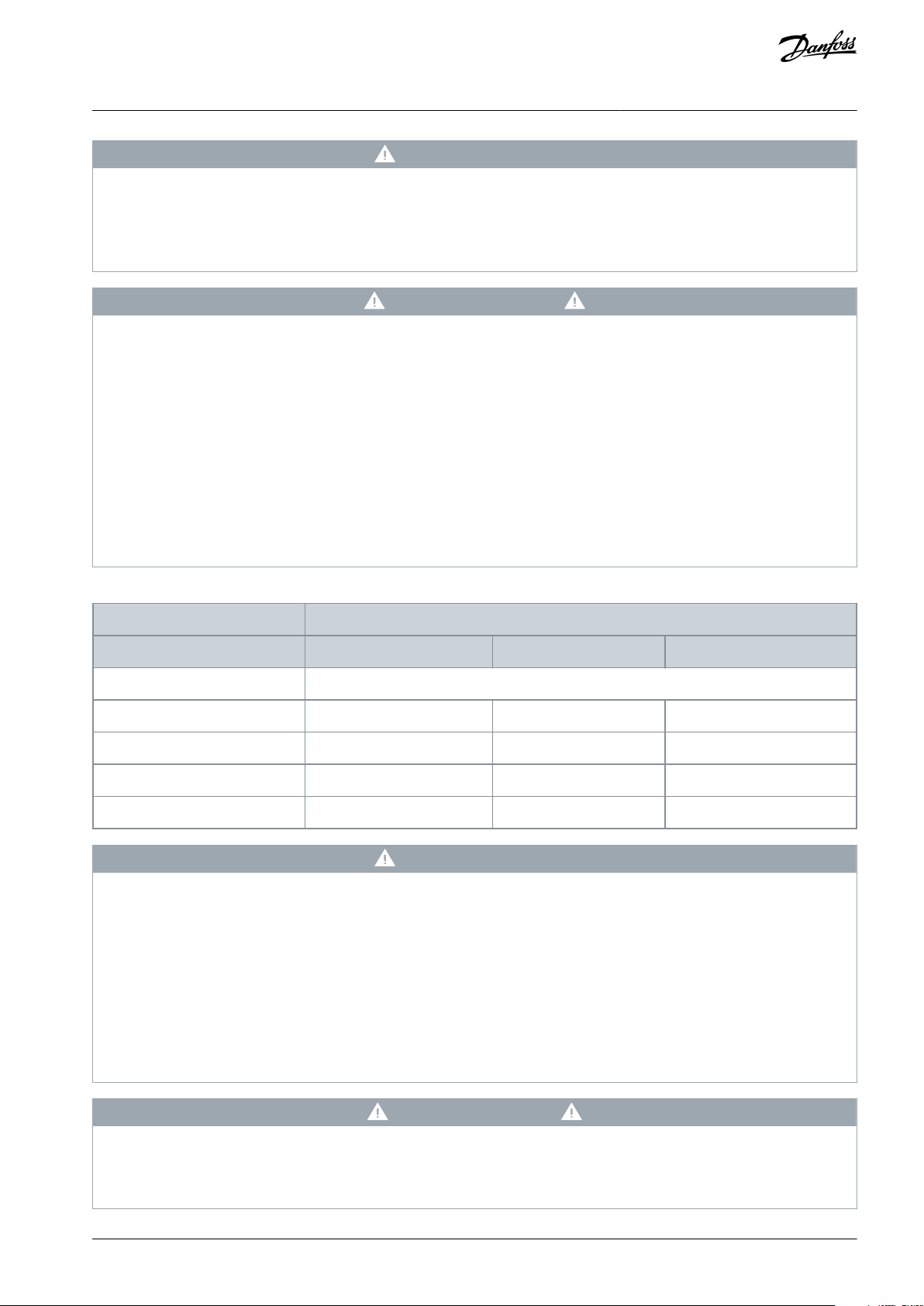

4.1 EMC-compliant Installation

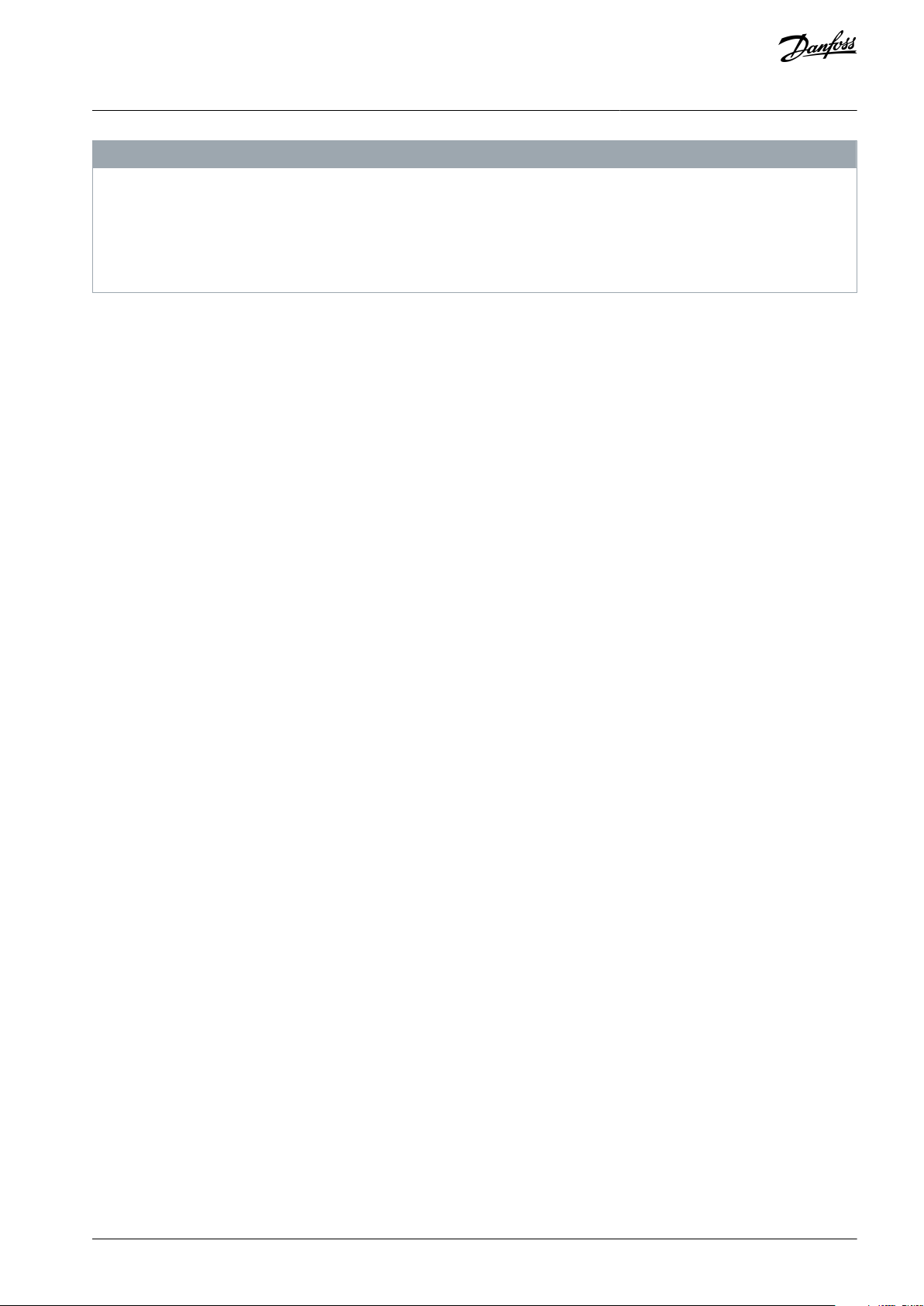

To obtain an EMC-compliant installation, refer to the wiring schematic (see Illustration 5) and follow the electrical installation instructions.

Also, remember to practice the following:

•

When using relays, control cables, a signal interface, fieldbus, or brake, connect the shield to the enclosure at both ends. If the

ground path has high impedance, is noisy, or is carrying current, break the shield connection on 1 end to avoid ground current

loops.

•

Convey the currents back to the unit using a metal mounting plate. Ensure good electrical contact from the mounting plate

through the mounting screws to the drive chassis.

•

Use shielded cables for motor output cables. An alternative is unshielded motor cables within metal conduit.

•

Ensure that motor and brake cables are as short as possible to reduce the interference level from the entire system.

•

Provide a minimum 200 mm (7.9 in) separation between mains input, motor cables, and control cables.

•

For communication and command/control lines, follow the particular communication protocol standards. For example, USB

must use shielded cables, but RS485/ethernet can use shielded UTP or unshielded UTP cables.

•

Ensure that all control terminal connections are PELV.

N O T I C E

TWISTED SHIELD ENDS (PIGTAILS)

Twisted shield ends increase the shield impedance at higher frequencies, which reduces the shield effect and increases the leak-

age current.

Use integrated shield clamps instead of twisted shield ends.

-

N O T I C E

SHIELDED CABLES

If shielded cables or metal conduits are not used, the unit and the installation do not meet regulatory limits on radio frequency

(RF) emission levels.

N O T I C E

EMC INTERFERENCE

Failure to isolate power, motor, and control cables can result in unintended behavior or reduced performance.

Use shielded cables for motor and control wiring.

-

Provide a minimum 200 mm (7.9 in) separation between mains input, motor cables, and control cables.

-

N O T I C E

INSTALLATION AT HIGH ALTITUDE

There is a risk for overvoltage. Isolation between components and critical parts could be insufficient and may not comply with

PELV requirements.

Use external protective devices or galvanic isolation. For installations above 2000 m (6500 ft) altitude, contact Danfoss re-

-

garding protective extra low voltage (PELV) compliance.

N O T I C E

PROTECTIVE EXTRA LOW VOLTAGE (PELV) COMPLIANCE

Prevent electric shock by using PELV electrical supply and complying with local and national PELV regulations.

AN354546796134en-000201 / 130R095412 | Danfoss A/S © 2021.05

Page 14

L1

L2L3PEL1L2L3PEPEu

v

w

2

1

3

5

IEC 60309

16

17

18

14

12

8

7

10

9

4

11

13

446

15

90

+DC

BR-

B

M

AINS

L1 L2 L3

91 92 93

RELA

Y 1 RELA

Y 2

99

- L

C -

UV

W

MO

T

OR

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

Illustration 4: Example of Proper EMC Installation

AN354546796134en-000201 / 130R0954 | 13Danfoss A/S © 2021.05

Page 15

1

Programmable logic controller (PLC)

2

Minimum 16 mm2 (6 AWG) equalizing cable

3

Control cables

4

Minimum 200 mm (7.9 in) between control cables,

motor cables, and mains cables

5

Mains supply options, see IEC/EN 61800-5-1

6

Bare (unpainted) surface

7

Star washers

8

Brake cable (shielded) – not shown, but same

gounding principle applies as for motor cable

9

Motor cable (shielded)

10

Mains cable (unshielded)

11

Output contactor, and so on.

12

Cable insulation stripped

13

Common ground busbar. Follow local and national

requirements for cabinet grounding.

14

Brake resistor

15

Terminal box

16

Connection to motor

17

Motor

18

EMC cable gland

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

N O T I C E

EMC INTERFERENCE

Use shielded cables for motor and control wiring, and separate cables for input power, motor wiring, and control wiring. Failure

to isolate power, motor, and control cables can result in unintended behavior or reduced performance. Minimum 200 mm (7.9 in)

clearance is required between power, motor, and control cables.

AN354546796134en-000201 / 130R095414 | Danfoss A/S © 2021.05

Page 16

e30bj012.10

––

Motor

Analog Output

ON=Terminated

OFF=Open

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

53 (A IN)

54 (A IN)

37 (D IN)

1)

18 (D IN)

10

V DC

15 mA 130/200 mA

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(P RS485) 68

(N RS485) 69

0 V

5V

S801

0/4–20 mA

RS-485

03

240 V AC, 2 A

24 V DC

02

01

05

04

06

24

V (NPN)

0 V (PNP)

0 V (PNP)

24

V (NPN)

19 (D IN)

24

V (NPN)

0 V (PNP)

24

V

0

V

24 V (PNP)

24 V (NPN)

(D IN/OUT

)

1)

0 V

24

V

29

24

V (NPN)

0 V (PNP)

0

V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

S201

ON

21

S202

ON=0/4–20 mA

95

P 5-00

21

ON

S801

(R+) 82

(R-) 81

: Chassis

240 V AC, 2 A

400 V AC, 2 A

: PE

3-phase

power

input

+10 V DC

DC bus

0/-10 V DC to

+10 V DC

0/4–20 mA

0/-10 V DC to

+10 V DC

0/4–20 mA

50 (+10 V OUT)

55 (COM A IN)

12 (+24 V OUT)

13 (+24 V OUT)

20 (COM D IN)

27 (D IN/OUT)

Switch mode

power supply

Brake

resistor

Relay 1

Relay 2

(COM A OUT) 39

(A OUT) 42

: Ground

: Ground 1

: Ground 2

(COM RS485) 61

2)

RS485

interface

OFF=0/-10 V DC

to +10 V DC

Type of cable

Maximum cross-section [AWG]

Minimum cross-section [AWG]

Flexible wire without cable end sleeves

1624Rigid wire without cable end sleeves

1624Flexible wire with cable end sleeves

1824Flexible wire with cable end sleeves with collar

20

24

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

Illustration 5: Wiring Schematic

4.2 Cable Specifications

WIRE TYPE AND RATINGS

All wiring must comply with local and national regulations regarding cross-section and ambient temperature requirements. For

power connections, minimum 167 °F rated copper wire is recommended.

Table 5: Control Cable Specifications

N O T I C E

AN354546796134en-000201 / 130R0954 | 15Danfoss A/S © 2021.05

Page 17

Enclosure size

Maximum cable size [AWG], mains, motor, brake

A2–A5

12

B1/B3

7

B2/B4

2C11/0C31/0

C2/C4

4/0

D1h/D3h

3/0

D2h/D4h

2x3/0

Enclosure size

Maximum cable size [AWG], mains, motor, and brake

A3/A5

12

B1/B3

7

B2/B4

2C11/0C31/0

C2/C4

4/0

Enclosure size

Maximum cable size [AWG], mains, motor, and brake

D1h/D3h

3/0

D2h/D4h

2x400

Terminal

Parameter

Default setting

Description

12, 13

–

+24 V DC

+24 V DC supply voltage for digital inputs and external transducers. Maximum output current

200 mA for all 24 V loads.

18

Parameter 5-10 Terminal 18 Digital Inputs

[8] Start

Digital inputs

19

Parameter 5-11 Terminal 19 Digital Inputs

[0] No operation

32

Parameter 5-14 Terminal 32 Digital Input

[0] No operation

33

Parameter 5-15 Terminal 33 Digital Input

[0] No operation

27

Parameter 5-12 Terminal 27 Digital Input

[2] Coast inverse

For digital input or output. Default setting is input.

VLT®AutomationDrive EZ FC 321

Installation Guide

Table 6: Power Cable Sizes for 104 °F Ambient Temperature, 200–240 V and 380–500 V

Table 7: Power Cable Sizes for 104 °F Ambient Temperature, 525–600 V

Electrical Installation

Table 8: Power Cable Sizes for 104 °F Ambient Temperature, 525–690 V

4.3 Terminal Descriptions

Table 9: Digital Inputs/Outputs

AN354546796134en-000201 / 130R095416 | Danfoss A/S © 2021.05

Page 18

Terminal

Parameter

Default setting

Description

29

Parameter Terminal 29 Digital Input

[14] Jog

20––

Common for digital inputs and 0 V potential for

24 V supply.

37–Safe Torque Off (STO)

Safe input. Used for STO.

Terminal

Parameter

Default setting

Description

39––

Common for analog output.

42

Parameter 6-50 Terminal 42

Output

Speed 0–high limit

Programmable analog output. 0–20 mA or 4–20 mA at a maximum of 500 Ω.

50–+10 V DC

10 V DC analog supply voltage potentiometer or thermistor.

15 mA maximum.

53

Parameter group 6-1* Analog

Input 1

Reference

Analog input. For voltage or current. Switches A53 and A54 select mA or V.

54

Parameter group 6-1* Analog

Input 2

Feedback

55––

Common for analog input.

Terminal

Parameter

Default

setting

Description

61––

Integrated RC-filter for cable shield. ONLY for connecting the shield if

EMC problems occur.

68 (+)

Parameter group 8-3* FC Port

Settings

–

RS485 interface. A control card switch is provided for termination resistance.

69 (-)

Parameter group 8-3* FC Port

Settings

–

Terminal

Parameter

Default setting

Description

01, 02, 03

Parameter 5-40 Function Relay [0]

[9] Alarm

Form C relay output. For AC or DC voltage and resistive or inductive loads.

04, 05, 06

Parameter 5-40 Function Relay [1]

[5] Running

VLT®AutomationDrive EZ FC 321

Installation Guide

Table 10: Analog Inputs/Outputs

Electrical Installation

Table 11: Serial Communication

Table 12: Relays

4.4 Connecting the Control Cables to the Control Terminals

The control terminal connectors can be unplugged from the drive for convenience when wiring. Either solid or flexible wire can be

connected to the control terminals.

ELECTRICAL INTERFERENCE

Minimize interference by keeping control wires as short as possible and separate from high-power cables.

1.

Strip 10 mm (0.4 in) of the outer plastic layer from the end of the wire.

N O T I C E

AN354546796134en-000201 / 130R0954 | 17Danfoss A/S © 2021.05

Page 19

e30bd546.12

10 mm

(0.4 in)

12 13 18 19 27

29 32 33

12 13 18 37

e30ba155.12

322719 29 33 20

P 5-12 [0]

P 5-10 [8]

Start/Stop

+24V

Speed

Safe Stop

Start/Stop

[18]

VLT®AutomationDrive EZ FC 321

Installation Guide

2.3.Insert the control wire into the appropriate terminals.

Pull gently on the wire to ensure that the contact is firmly established.

Loose control cable can cause equipment faults or reduced performance.

4.5 Start/Stop

Terminal 18 = Parameter 5-10 Terminal 18 Digital Input [8] Start.

Terminal 27 = Parameter 5-12 Terminal 27 Digital Input [0] No operation (Default [2] Coast inverse).

Terminal 37 = Safe Torque Off.

Electrical Installation

Illustration 6: Start/Stop

4.6 Pulse Start/Stop

Terminal 18 = Parameter 5-10 Terminal 18 Digital Input [9] Latched start.

Terminal 27 = Parameter 5-12 Terminal 27 Digital Input [6] Stop inverse.

Terminal 37 = Safe Torque Off.

AN354546796134en-000201 / 130R095418 | Danfoss A/S © 2021.05

Page 20

12

13

18 37

e30ba156.12

32

2719

29 33 20

P 5 - 12 [6]

P 5 - 10[9]

+24V

Speed

Start

Stop inverse Safe Stop

Start (18)

Start (27)

12

18

27

29

32

37

+24V

Par. 5-10

Par. 5-12

Par. 5-13

Par. 5-14

e30ba021.13

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

Illustration 7: Pulse Start/Stop

4.7 Speed Up/Speed Down

Terminal 18 = Parameter 5-10 Terminal 18 Digital Input [8] Start.

Terminal 27 = Parameter 5-12 Terminal 27 Digital Input [19] Freeze reference.

Terminal 37 = Safe Torque Off.

Terminal 29 = Parameter 5-13 Terminal 29 Digital Input [21] Speed up.

Terminal 32 = Parameter 5-14 Terminal 32 Digital Input [22] Speed down.

Illustration 8: Speed Up/Speed Down

AN354546796134en-000201 / 130R0954 | 19Danfoss A/S © 2021.05

Page 21

e30ba154.11

55 50

39 42 53 54

Speed RP M

P 6-15

1 k

+10V/30mA

R

ef . v oltage

P 6-11 10V

VLT®AutomationDrive EZ FC 321

Installation Guide

4.8 Potentiometer Reference

Voltage reference via a potentiometer

Reference source 1 = [1] Analog input 53 (default).

Terminal 53, low voltage = 0 V.

Terminal 53, high voltage = 10 V.

Terminal 53, low reference/feedback = 0 RPM.

Terminal 53, high reference/feedback = 1500 RPM.

Switch S201 = OFF (U)

Electrical Installation

Illustration 9: Potentiometer Reference

4.9 Connecting the Motor

W A R N I N G

INDUCED VOLTAGE

Induced voltage from output motor cables that run together can charge equipment capacitors, even with the equipment turned

off and locked out/tagged out. Failure to run output motor cables separately or to use shielded cables could result in death or

serious injury.

Run output motor cables separately or use shielded cables.

-

Simultaneously lock out/tag out all the drives.

-

•

Run output motor cables separately or

•

Use shielded cables.

•

Comply with local and national electrical codes for cable sizes. For maximum wire sizes, see 4.2 Cable Specifications.

•

Follow motor manufacturer wiring requirements.

•

Motor wiring knockouts or access panels are provided at the base of IP55 (NEMA 12) units.

•

Do not wire a starting or pole-changing device (for example a Dahlander motor or slip ring asynchronous motor) between the

drive and the motor.

4.9.1 Grounding the Cable Shield

Procedure

1.

Strip a section of the outer cable insulation.

2.

Position the stripped wire under the cable clamp to establish mechanical fixation and electrical contact between the cable

shield and ground.

AN354546796134en-000201 / 130R095420 | Danfoss A/S © 2021.05

Page 22

e30bd531.11

U

V

W

96

97

98

VLT®AutomationDrive EZ FC 321

Installation Guide

3.

Connect the ground wire to the nearest grounding terminal.

Electrical Installation

4.

Connect the 3-phase motor wiring to terminals 96 (U), 97 (V), and 98 (W).

5.

Torque-tighten the terminals, see Table 3.

Example

Mains input, motor, and grounding for basic drives. Actual configurations vary with unit types and optional equipment.

AN354546796134en-000201 / 130R0954 | 21Danfoss A/S © 2021.05

Page 23

+DC

BR-

B

M A I N S

L1 L2 L3

91 92 93

RELAY 1 RELAY 2

99

U V W

MOTOR

99

130BF048.11

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

Illustration 10: Example of Motor, Mains, and Ground Wiring

4.10 Connecting AC Mains

•

Size the wiring based on the input current of the drive. For maximum wire sizes, see 4.2 Cable Specifications.

•

Comply with local and national electrical codes for cable sizes.

4.10.1 Connecting the Drive to Mains

Procedure

1.

Connect the 3-phase AC input power wiring to terminals L1, L2, and L3.

2.

Depending on the configuration of the equipment, connect the input power to the mains input terminals or the input disconnect.

3.

Ground the cable.

4.

When supplied from an isolated mains source (IT mains or floating delta) or TT/TN-S mains with a grounded leg (grounded

delta), ensure that parameter 14-50 RFI Filter is set to [0] Off. This setting prevents damage to the DC link and reduces

ground capacity currents in accordance with IEC 61800-3.

AN354546796134en-000201 / 130R095422 | Danfoss A/S © 2021.05

Page 24

L 1

L 2

L 3

91

92

93

e130bt336.11

Enclosure

Power [hp]

Recommended fuse

size

Recommended maximum fuse

Recommended circuit breaker

Eaton/Moeller

Maximum trip level [A]A20.34–2.0

gG-10

gG-25

PKZM0-25

25

3.0

gG-16

A3

4.0

gG-16

gG-32

PKZM0-25

25

5.0

gG-20

A5

0.34–2.0

gG-10

gG-32

PKZM0-25

25

3.0–4.0

gG-16

5.0

gG-20

B1

7.5

gG-25

gG-80

PKZM4-63

63

VLT®AutomationDrive EZ FC 321

Installation Guide

Illustration 11: Connecting to AC Mains

4.11 Fuses and Circuit Breakers

Electrical Installation

4.11.1 Fuse Recommendations

Fuses ensure that possible damage to the drive is limited to damages inside the unit. Danfoss recommends fuses and/or circuit

breakers on the supply side as protection. For further information, see the application guide Fuses and Circuit Breakers.

N O T I C E

Use of fuses on the supply side is mandatory for IEC 60364 (CE) and NEC 2009 (UL) compliant installations.

Recommendations

•

gG type fuses.

•

Eaton/Moeller type circuit breakers. For other circuit breaker types, ensure that the energy into the drive is equal to or lower

than the energy provided by Eaton/Moeller types.

For further information, see the application guide Fuses and Circuit Breakers.

The recommended CE and UL compliant fuses are suitable for use on a circuit capable of 100000 A

the drive voltage rating. With the proper fusing, the drive short circuit current rating (SCCR) is 100000 A

4.11.2 CE Compliance

Table 13: 200–240 V, Enclosure Sizes A, B, C, and D

(symmetrical), depending on

rms

.

rms

AN354546796134en-000201 / 130R0954 | 23Danfoss A/S © 2021.05

Page 25

Enclosure

Power [hp]

Recommended fuse

size

Recommended maximum fuse

Recommended circuit breaker

Eaton/Moeller

Maximum trip level [A]

10.0

gG-32

B2

15.0

gG-50

gG-100

NZMB1-A100

100B37.5

gG-25

gG-63

PKZM4-50

50B410

gG-32

gG-125

NZMB1-A100

100

15

gG-50

20

gG-63

C1

20

gG-63

gG-160

NZMB2-A200

160

25

gG-80

30

gG-100

aR-160

C2

40

aR-160

aR-200

NZMB2-A250

250

50

aR-200

aR-250

C3

25

gG-80

gG-150

NZMB2-A200

150

30

aR-125

aR-160

C4

40

aR-160

aR-200

NZMB2-A250

250

50

aR-200

aR-250

D1h/D3h

60

aR-350

aR-350

––75

aR-400

aR-400

––D2h/D4h

100

aR-550

aR-550

–

–

Enclosure

Power [hp]

Recommended fuse

size

Recommended maximum fuse

Recommended circuit breaker

Eaton/Moeller

Maximum trip

level [A]

A2

0.5–4.0

gG-10

gG-25

PKZM0-25

25

5.0

gG-16

A3

7.5–10

gG-16

gG-32

PKZM0-25

25A50.5–4.0

gG-10

gG-32

PKZM0-25

25

5.0–10

gG-16

B1

15–20

gG-40

gG-80

PKZM4-63

63B225

gG-50

gG-100

NZMB1-A100

100

30

gG-63

B3

15–20

gG-40

gG-63

PKZM4-50

50B425

gG-50

gG-125

NZMB1-A100

100

30

gG-63

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

Table 14: 380–500 V, Enclosure Sizes A, B, C, and D

AN354546796134en-000201 / 130R095424 | Danfoss A/S © 2021.05

Page 26

Enclosure

Power [hp]

Recommended fuse

size

Recommended maximum fuse

Recommended circuit breaker

Eaton/Moeller

Maximum trip

level [A]

40

gG-80

C1

40

gG-80

gG-160

NZMB2-A200

160

50

gG-100

60

gG-160

C2

75

aR-200

aR-250

NZMB2-A250

250

100

aR-250

C3

50

gG-100

gG-150

NZMB2-A200

150

60

gG-160

gG-160

C4

75

aR-200

aR-250

NZMB2-A250

250

100

aR-250

D1h/D3h

125

aR-315

aR-315

––150

aR-350

aR-350

––200

aR-400

aR-400

–

–

Enclosure

Power [hp]

Recommended fuse

size

Recommended maximum fuse

Recommended circuit breaker

Eaton/Moeller

Maximum trip level [A]A21.0-5.0

gG-10

gG-25

PKZM0-25

25A37.5

gG-10

gG-32

PKZM0-25

25

10

gG-16

A5

7.5

gG-10

gG-32

PKZM0-25

25

10

gG-16

B1

15

gG-25

gG-80

PKZM4-63

63

20

gG-32

25

gG-40

B2

30

gG-50

gG-100

NZMB1-A100

100

40

gG-63

B3

15

gG-25

gG-63

PKZM4-50

50

20

gG-32

B4

25

gG-40

gG-125

NZMB1-A100

100

30

gG-50

40

gG-63

C1

50

gG-63

gG-160

NZMB2-A200

160

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

Table 15: 525–600 V, Enclosure Sizes A, B, C, and D

AN354546796134en-000201 / 130R0954 | 25Danfoss A/S © 2021.05

Page 27

Enclosure

Power [hp]

Recommended fuse

size

Recommended maximum fuse

Recommended circuit breaker

Eaton/Moeller

Maximum trip level [A]60gG-100

60

aR-160

aR-250

C2

100

aR-200

aR-250

NZMB2-A250

250C350

gG-63

gG-150

NZMB2-A200

150

60

gG-100

gG-150

NZMB2-A200

C4

75

aR-160

aR-250

NZMB2-A250

250

100

aR-200

Enclosure

Power [hp]

Recommended fuse size

Recommended maximum fuse

D1h/D3h

125

aR-315

aR-315

150

aR-315

aR-315

200

aR-315

aR-315

UL class

Fuse overload characteristics

Interrupting rating

[A]

AC voltage rating

[V]

Available ampere rating

RK1

Ultra fast-acting, current limiting/time delay

200.000

250

600

1–600

T

Fast-acting

200.000

300

600

1–1.200

J

Fast-acting

200.000

600

1–600

CC

Fast-acting

200.000

600

5–30

VLT®AutomationDrive EZ FC 321

Installation Guide

Table 16: 525–690 V, Enclosure Size D

Electrical Installation

4.11.3 UL Compliance

Fuse classification for UL Compliance

N O T I C E

UL COMPLIANCE

To comply with NEC 2017, it is mandatory to use fuses or circuit breakers. Danfoss recommends using a selection of the fuses

listed in the following tables. These fuses are suitable for use on a circuit capable of delivering 100000 A

500 V, or 600 V depending on the drive voltage rating. With the proper fusing, the drive short-circuit current rating (SCCR) is

100000 A

For semiconductor fuse types, the drive controller and the overcurrent protection device must be integrated within the same overall assembly.

Table 17: UL Fuse Classification Chart

rms

.

(symmetrical), 240 V,

rms

AN354546796134en-000201 / 130R095426 | Danfoss A/S © 2021.05

Page 28

Class fuses

Semiconductor fuses

Power [hp]

RK1/J/T [A]

CC [A]

SIBA

Littelfuse

Ferraz Shawmut (Mersen)

Bussmann (Eaton)

0.34–0.5

555017906-005

––FWX-5

0.75–1.5

10105017906-010

––FWX-10

2.01515

5017906-016

––FWX-15

3.02020

5017906-020

––FWX-20

4.02525

5017906-025

––FWX-25

5.03030

5012406-032

––FWX-30

7.550–

5014006-050

––FWX-50

1060–

5014006-063

––FWX-60

1580–

5014006-080

––FWX-80

20–25

125–2028220-125

––FWX-125

30

150–2028220-150

L25S-150

A25X-150

FWX-150

40

200–2028220-200

L25S-200

A25X-200

FWX-200

50

250–2028220-250

L25S-250

A25X-250

FWX-250

Class fuses

Semiconductor fuses

Power [hp]

RK1/J/T [A]

CC [A]

SIBA

Littelfuse

Ferraz Shawmut (Mersen)

Bussmann (Eaton)

0.5–1.5

665017906-006

––FWH-6

2.0–3.0

10105017906-010

––FWH-10

4.01515

5017906-016

––FWH-15

5.02020

5017906-020

––FWH-20

7.52525

5017906-025

––FWH-25

103030

5012406-032

––FWH-30

1540–

5014006-040

––FWH-40

2050–

5014006-050

––FWH-50

2560–

5014006-063

––FWH-60

3080–

2028220-100

––FWH-80

40

100–2028220-125

––FWH-100

50

125–2028220-125

––FWH-125

60

150–2028220-160

––FWH-150

75

200–2028220-200

L50-S-225

A50-P-225

FWH-200

100

250–2028220-250

L50-S-250

A50-P-250

FWH-250

VLT®AutomationDrive EZ FC 321

Installation Guide

Table 18: Recommended Maximum UL Fuse Class, Voltage Range 3x200–240 V, Enclosure Sizes A, B, and C

Electrical Installation

Table 19: Recommended Maximum UL Fuse Class, Voltage Range 380–500 V, Enclosure Sizes A, B, and C

AN354546796134en-000201 / 130R0954 | 27Danfoss A/S © 2021.05

Page 29

Class fuses

Semiconductor fuses

Power [hp]

RK1/J/T [A]

CC [A]

SIBA

1.5

5

(1)

5

5017906-005

2.0–3.0

10105017906-010

4.01515

5017906-016

5.02020

5017906-020

7.52525

5017906-025

103030

5017906-030

1535–

5014006-040

2045–

5014006-050

2550–

5014006-050

3060–

5014006-063

4080–

5014006-080

50

100–5014006-100

60

125–2028220-125

75

150–2028220-150

100

175–2028220-200

Enclosure

size

Enclosure

(1)

Voltage [V]

Power [hp]

HO

Maximum interrupting

rating for listed circuit

breakers

Maximum

ampere

rating

[A]

Further information

A4/A5

Type 4X

380–500

(T5)

0.5, 0.75,

1.0, 1.5, 2.0,

3.0, 4.0, 5.0,

7.5, 10

100 kA (at

480 V)

25

Any UL 489 listed circuit breaker, maximum

25 A.

A5

Type 4X

200–240 V

(T2)

4.0, 5.0

Specific type

25

ABB MS165-25 480V/277Y 65 kA.

A5

Type 4X

380–500 V

(T5)

7.5, 10

Specific type

25

ABB MS165-25 480V/277Y 65 kA.

A5

Type 4X

525–600 V

(T6)

5.0, 7.5, 10

Specific type

25

ABB MS165-25 600V/347Y 30 kA.

VLT®AutomationDrive EZ FC 321

Installation Guide

Table 20: Recommended Maximum UL Fuse Class, Voltage Range 525–690 V, Enclosure Sizes A, B, and C

Electrical Installation

1

Bussmann Class T allowed up to 6 A.

UL Compliance only for 525–600 V.

Table 21: UL Approved Branch Circuit Protection

N O T I C E

AN354546796134en-000201 / 130R095428 | Danfoss A/S © 2021.05

Page 30

Enclosure

size

Enclosure

(1)

Voltage [V]

Power [hp]

HO

Maximum interrupting

rating for listed circuit

breakers

Maximum

ampere

rating

[A]

Further information

B1

Type 4X

200–240 V

(T2)

7.5, 10

Specific type

40–54

ABB MS165-54 480V/277Y 65 kA.

B1

Type 4X

380–500 V

(T5)

15, 20

Specific type

40–54

ABB MS165-54 480V/277Y 65 kA.

B1

Type 4X

380–500 V

(T5)

15, 20

100 kA

60

Any UL 489 circuit breaker type with maximum

interrupt rating and maximum ampere rating

in list.

B1

Type 4X

525–600 V

(T6)

15, 20

50 kA

40

Any UL 489 circuit breaker type with maximum

interrupt rating and maximum ampere rating

in list.

B2

Type 4X

380–500 V

(T5)

25, 30

100 kA

100

Any UL 489 circuit breaker type with maximum

interrupt rating and maximum ampere rating

in list

B2

Type 4X

525–600 V

(T6)

25, 30

35 kA

60

any UL 489 circuit breaker type with maximum

interrupt rating and maximum ampere rating

in list.

C1

Type 4X

380–500 V

(T5)

40, 50, 60

100 kA

200

Any UL 489 circuit breaker type with maximum

interrupt rating and maximum ampere rating

in list.

C2

Type 4X

380–500 V

(T5)

75, 100

100 kA

250

Any UL 489 circuit breaker type with maximum

interrupt rating and maximum ampere rating

in list.

VLT®AutomationDrive EZ FC 321

Installation Guide

Electrical Installation

1

Only Type 4X enclosures can be used. Not valid for Open type (IP20) units.

AN354546796134en-000201 / 130R0954 | 29Danfoss A/S © 2021.05

Page 31

Enclosure

IP20/Chassis, IP54/NEMA 12, IP66/Type 4X

Vibration test

1.0 g

Maximum THDv

10%

Maximum relative humidity

5–93 (IEC 721-3-3); Class 3K3 (non-condensing) during operation

Aggressive environment (IEC 60068-2-43) H2S test

Class Kd

Ambient temperature

Maximum 122 °F (24-hour average maximum 113 °F)

Minimum ambient temperature during full-scale operation

32 °F

Minimum ambient temperature at reduced speed performance

14 °F

Temperature during storage/transport

-13 to +149/158 °F

Maximum altitude above sea level without derating

3280 ft

EMC standards, Emission

EN 61800-3

EMC standards, Immunity

EN 61800-3

Energy efficiency class

(1)

IE2

Supply terminals (6-pulse)

L1, L2, L3

Supply voltage

(1)(2)

200–240 V ±10%

Supply voltage

(1)(2)

380–500 V ±10%

Supply voltage

(1)(2)

525–600 V ±10%

Supply voltage

(1)(2)

575–690 V ±10%

Supply frequency

47.5–63 Hz

Maximum imbalance temporary between mains phases

3.0% of rated supply voltage

True power factor (λ)

≥0.9 nominal at rated load

Displacement power factor (cos φ)

Near unity (>0.98)

Switching on the input supply L1, L2, L3 (power-ups) ≤10 hp

Maximum twice per minute

Switching on input supply L1, L2, L3 (power-ups) 15–100 hp

Maximum once per minute

Switching on input supply L1, L2, L3 (power-ups) ≥125 hp

Maximum once per 2 minutes

Environment according to EN60664-1

Overvoltage category III/pollution degree 2

Programmable digital inputs

4 (6)

(1)

VLT®AutomationDrive EZ FC 321

Installation Guide

5 Specifications

5.1 Ambient Conditions

5.1.1 Environment

Specifications

1

Determined according to IEC 61800-9-2 and EN 50598-2 at:

Rated load.

•

90% rated frequency.

•

Switching frequency factory setting.

•

Switching pattern factory setting.

•

5.2 Mains Supply

1

Mains voltage low/mains dropout: During low mains voltage or a mains dropout, the drive continues until the DC-link voltage drops below the

minimum stop level, which typically corresponds to 15% below the drive's lowest rated supply voltage. Power-up and full torque cannot be expected at mains voltage lower than 10% below the drive's lowest rated supply voltage.

2

The unit is suitable for use on a circuit capable of delivering not more than 100000 RMS symmetrical Amperes, 240/500/600 V maximum.

5.3 Control Input/Output and Control Data

5.3.1 Digital Inputs

AN354546796134en-000201 / 130R095430 | Danfoss A/S © 2021.05

Page 32

Terminal number

18, 19, 27

(1)

, 29

(1)

, 32, 33

Logic

PNP or NPN

Voltage level

0–24 V DC

Voltage level, logic 0 PNP

<5 V DC

Voltage level, logic 1, PNP

>10 V DC

Voltage level, logic 0 NPN

(2)

>19 V DC

Voltage level, logic 1 NPN

(2)

<14 V DC

Maximum voltage on input

28 V DC

Pulse frequency range

0–110 kHz

(Duty cycle) minimum pulse width

4.5 ms

Input resistance, R

i

Approximately 4 kΩ

Voltage level

0–24 V DC

Voltage level, logic 0 PNP

<4 V DC

Voltage level, logic 1 PNP

>20 V DC

Maximum voltage on input

28 V DC

Typical input current at 24 V

50 mA rms

Typical input current at 20 V

60 mA rms

Input capacitance

400 nF

Number of analog inputs

2

Terminal number

53, 54

Modes

Voltage or current

Mode select

Switch S201 and switch S202

Voltage mode

Switch S201/switch S202 = OFF (U)

Voltage level

-10 V to +10 V (scaleable)

Input resistance, R

i

Approximately 10 kΩ

Maximum voltage

±20 V

Current mode

Switch S201/S202 = ON (I)

Current level

0/4 to 20 mA (scaleable)

Input resistance, R

i

Approximately 200 Ω

Maximum current

30 mA

Resolution for analog inputs

10 bit (+ sign)

Accuracy of analog inputs

Maximum error 0.5% of full scale

Bandwidth

100 Hz

VLT®AutomationDrive EZ FC 321

Installation Guide

1

Terminals 27 and 29 can also be programmed as output.

2

Except STO input terminal 37.

5.3.2 STO Terminal 37 (Terminal 37 is Fixed PNP Logic)

Specifications

All digital inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

When using a contactor with a DC coil inside in combination with STO, it is important to make a return way for the current from the

coil when turning it off. This can be done by using a freewheel diode (or, alternatively, a 30 V or 50 V MOV for quicker response time)

across the coil. Typical contactors can be bought with this diode.

5.3.3 Analog Inputs

The analog inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

AN354546796134en-000201 / 130R0954 | 31Danfoss A/S © 2021.05

Page 33

Mains

Functional

isolation

PELV isolation

Motor

DC-bus

High

voltage

Control

+24 V

RS485

18

37

e30ba117.11

Programmable pulse/encoder inputs

2/1

Terminal number pulse/encoder

29, 33

(1)

/32

(2)

, 33

(2)

Maximum frequency at terminals 29, 32, 33

110 kHz (Push-pull driven)

Maximum frequency at terminals 29, 32, 33

5 kHz (Open collector)

Maximum frequency at terminals 29, 32, 33

4 Hz

Voltage level

See 5.3.1 Digital Inputs.

Maximum voltage on input

28 V DC

Input resistance, R

i

Approximately 4 kΩ

Pulse input accuracy (0.1–1 kHz)

Maximum error: 0.1% of full scale

Encoder input accuracy (1–11 kHz)

Maximum error: 0.05% of full scale

Programmable digital/pulse outputs

2

Terminal number

27, 29

(1)

Voltage level at digital/frequency output

0–24 V

Maximum output current (sink or source)

40 mA

Maximum load at frequency output

1 kΩ

Maximum capacitive load at frequency output

10 nF

Minimum output frequency at frequency output

0 Hz

Maximum output frequency at frequency output

32 kHz

Accuracy of frequency output

Maximum error: 0.1% of full scale

Resolution of frequency outputs

12 bit

Number of programmable outputs

1

Terminal number

42

Current range at analog output

0/4 to 20 mA

Maximum load GND - analog output less than

500 Ω

Accuracy on analog output

Maximum error: 0.5% of full scale

VLT®AutomationDrive EZ FC 321

Installation Guide

Illustration 12: PELV Isolation

5.3.4 Pulse/Encoder Inputs

Specifications

1

Pulse inputs are 29 and 33.

2

Encoder inputs: 32=A, 33=B.

The pulse and encoder inputs (terminals 29, 32, 33) are galvanically isolated from the supply voltage (PELV) and other high-voltage

terminals.

5.3.5 Digital Outputs

1

Terminals 27 and 29 can also be programmed as input.

The digital output is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

5.3.6 Analog Output

AN354546796134en-000201 / 130R095432 | Danfoss A/S © 2021.05

Page 34

Resolution of analog output

12 bit

Terminal number

12, 13

Output voltage

24 V +1, -3 V

Maximum load

200 mA

Terminal number

50

Output voltage

10.5 V ±0.5 V

Maximum load

15 mA

Terminal number

68 (P,TX+, RX+), 69 (N,TX-, RX-)

Terminal number 61

Common for terminals 68 and 69

USB standard

1.1 (full speed)

USB plug

USB type B plug

Programmable relay outputs

2

Relay 01 terminal number

1–3 (break), 1–2 (make)

Maximum terminal load (AC-1)

(1)

on 1–3 (NC), 1–2 (NO) (resistive

load)

240 V AC, 2 A

Maximum terminal load (AC-15)

(1)

(inductive load @ cosφ 0.4)

240 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 1–2 (NO), 1–3 (NC) (resistive

load)

60 V DC, 1 A

Maximum terminal load (DC-13)

(1)

(inductive load)

24 V DC, 0.1 A

Relay 02 terminal number

4–6 (break), 4–5 (make)

Maximum terminal load (AC-1)

(1)

on 4–5 (NO) (resistive load)

()()

400 V AC, 2 A

Maximum terminal load (AC-15)

(1)

on 4–5 (NO) (inductive load @

cosφ 0.4)

240 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 4–5 (NO) (resistive load)

80 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 4–5 (NO) (inductive load)

24 V DC, 0.1 A

Maximum terminal load (AC-1)

(1)

on 4–6 (NC) (resistive load)

240 V AC, 2 A

Maximum terminal load (AC-15)

(1)

on 4–6 (NC) (inductive load @

cosφ 0.4)

240 V AC, 0.2 A

VLT®AutomationDrive EZ FC 321

Installation Guide

Specifications

The analog output is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

5.3.7 Control Card, 24 V DC Output

The 24 V DC supply is galvanically isolated from the supply voltage (PELV), but has the same potential as the analog and digital

inputs and outputs.

5.3.8 Control Card, +10 V DC Output

The 10 V DC supply is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

5.3.9 Control Card, RS485 Serial Communication

The RS485 serial communication circuit is galvanically isolated from the supply voltage (PELV).

5.3.10 Control Card, USB Serial Communication

Connection to the PC is carried out via a standard host/device USB cable.

The USB connection is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

The USB ground connection is not galvanically isolated from protective earth. Use only an isolated laptop as PC connection to the

USB connector on the drive.

5.3.11 Relay Outputs

AN354546796134en-000201 / 130R0954 | 33Danfoss A/S © 2021.05

Page 35

Maximum terminal load (DC-1)

(1)

on 4–6 (NC) (resistive load)

50 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 4–6 (NC) (inductive load)

24 V DC, 0.1 A

Minimum terminal load on 1–3 (NC), 1–2 (NO), 4–6 (NC), 4–5 (NO)

24 V DC 10 mA, 24 V AC 20 mA

Environment according to EN 60664-1

Overvoltage category III/pollution degree 2

Scan interval

1 ms

Resolution of output frequency at 0–590 Hz

±0.003 Hz

Repeat accuracy of precise start/stop (terminals 18, 19)

≤±0.1 ms

System response time (terminals 18, 19, 27, 29, 32, 33)

≤2 ms

Speed control range (open loop)

1:100 of synchronous speed

Speed control range (closed loop)

1:1000 of synchronous speed

Speed accuracy (open loop)

30–4000 RPM: Error ±8 RPM

Speed accuracy (closed loop), depending on resolution of feedback device

0–6000 RPM: Error ±0.15 RPM

Torque control accuracy (speed feedback)

Maximum error ±5% of rated torque

VLT®AutomationDrive EZ FC 321

Installation Guide

1

IEC 60947 parts 4 and 5. The relay contacts are galvanically isolated from the rest of the circuit by reinforced isolation (PELV).

5.3.12 Control Card Performance

5.3.13 Control Characteristics

Specifications

All control characteristics are based on a 4-pole asynchronous motor.

AN354546796134en-000201 / 130R095434 | Danfoss A/S © 2021.05

Page 36

Term

Definition

AC

Alternating current

AWG

American wire gauge

DC

Direct current

EMC

Electromagnetic compatibility

ETR

Electronic thermal relay

IEC

International Electrotechnical Commission

IP

Ingress protection

LCP

Local control panel

LOP

Local operation pad

mA

Milliamp

NC

Normally closed

NEMA

National Electrical Manufacturers Association

NO

Normally open

PELV

Protective extra low voltage

PTC

Positive temperature coefficient

RMS

Root means square (cyclically alternating electric current)

RPM

Revolutions per minute

STO

Safe Torque Off

UPS

Uninterruptible power supply

UTP

Unshielded twisted pair

V

Volt

VLT®AutomationDrive EZ FC 321

Installation Guide

6 Appendix

6.1 Abbreviations

Table 22: Abbreviations

Appendix

AN354546796134en-000201 / 130R0954 | 35Danfoss A/S © 2021.05

Page 37

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogs, brochures, and other printed material. Danfoss reserves the right to alter its products without notice. This

also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All

trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

*130R0954*

Danfoss A/S © 2021.05

AN354546796134en-000201 / 130R0954

*M0026701*

Loading...

Loading...