Page 1

Data Sheet

Superheat controller

Type EIM 336

For stepper motor valves

The EIM 336 is a superheat controller that can

be used to control the opening degree of a

valve based on the superheat of the evaporator.

This is applicable in applications such as air

conditioning, heat pumps and refrigeration.

An alternative option is to use the controller in

manual mode via modbus communication and

use it as a valve driver by setting the valve

opening degree manually.

Benets

• The evaporator is charged optimally even

when there are large variations in load and

suction pressure.

• The superheat control can save energy by

ensuring optimum utilization of the

evaporator.

• The superheat is controlled to the lowest

stable value.

• It controls EEV in microsteps providing a

smooth superheat curve and less noise.

Features

• Minimum Stable Superheat search regulation

(MSS).

• Maximum Operating Pressure function

(MOP).

• Defrost.

• Compressor protection functions.

• Evaporator temperature (Te) control for dehumidifying.

• Valve driver via Modbus Communication.

• Loss Of Charge indication (LOC).

AI219486429676en-000301

Page 2

Pressure transducer

Temperature sensor

Programming key / display

Electric Expansion valve

DST P110, AKS 32R, NSK BExx

AKS 21, AKS 11

MYK - EIM interfacer

ETS6

Superheat controller, Type EIM 336

1 Portfolio overview

Table 1: Related products

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 2

Page 3

Superheat controller, Type EIM 336

2 Functions

2.1 Acronyms and abbreviations

LOC Loss of charge indication

SH Superheat

MOP Maximum operating pressure

MSS Minimum stable superheat

Te Saturated suction temperature

Pe (Po) Evaporator pressure

S2 Evaporator refrigerant outlet temperature

S4 Evaporator medium outlet temperature

OD Opening degree

PNU Parameter number - is equivalent to the modbus register no. (modbus adress + 1)

2.2 Functions

Minimum Stable Superheat (MSS)

The controller will search for the minimum stable superheat between an upper and lower boundary set by the user.

If the superheat has been stable for a period of 6 minutes, the superheat reference is decreased. If the superheat

becomes unstable, the reference is raised again. This process continues as long as the superheat is within the

bounds set by the user. The purpose of this is to search for the lowest possible superheat that can be obtained while

still maintaining a stable system. The superheat reference can also be xed, in which case this function is disabled.

Maximum Operating Pressure (MOP)

In order to reduce the strain on the compressor, a maximum operating pressure can be set. If the pressure comes

above this limit the controller will control the valve to provide a lower pressure instead of a low superheat. The limit

for this function is usually a xed pressure, but it is possible to oset the limit temporarily.

Evaporator temperature (Te) control for de-humidifying

A function is provided to control on the evaporator temperature instead of the superheat. This can be used to dehumidify the air owing through the evaporator. By lowering the evaporators surface temperature, the water vapor

in the air is condensed.

Superheat close

When the superheat is below a set minimum value, the valve will close faster in order to protect the compressor

from the risk of getting liquid in the suction line.

Manual control

The valve can be controlled manually by setting the desired opening degree via modbus.

Start/stop of regulation

The start or stop of the regulation can be controlled by setting the software main switch, which is accessible via

modbus. It is however also possible to use a digital input from an external Regulation control On / O switch.

Loss Of Charge indication (LOC)

A function is provided to indicate loss of refrigerant charge. This is only indicated by setting an alarm ag which can

be accessed via modbus. No special action is performed by the controller.

External sensor values

The EIM 336 has sensor inputs for the suction pressure and evaporator temperature (S2). It is however possible to

substitute these sensor inputs by sending external sensor values via modbus. These external values need to be

updated frequently.

Forced opening during startup

In some applications it is necessary to open the valve quickly when the compressor turns on, to prevent too low

suction pressure. This is ensured by setting a xed opening degree and a startup time for the controller. Note that

this will give a xed opening degree for the duration of the start time, regardless of the superheat value.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 3

Page 4

Superheat controller, Type EIM 336

Forced opening during o

In some applications the valve must remain open when the controller is o. This can be done by setting a xed

opening degree. When normal control is switched o with the main switch, the valve will keep this opening degree.

Defrost handling

The controller does not itself handle defrost of the evaporator. It is however possible to enter a special defrost

sequence, which will overrule the normal control of the valve.

Standalone function

The EIM 336 is designed to operate in conjunction with a system master controller, which will control the EIM 336

via modbus. It is however possible to use it in a standalone mode with no external control, except a digital input

from the Regulation control On / O switch. In this conguration some of the other functions will not be available.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 4

Page 5

Danfoss

80G39.12

AKS 11

Evaporator

EIM 336

AKS32R

ETS 6

Superheat controller, Type EIM 336

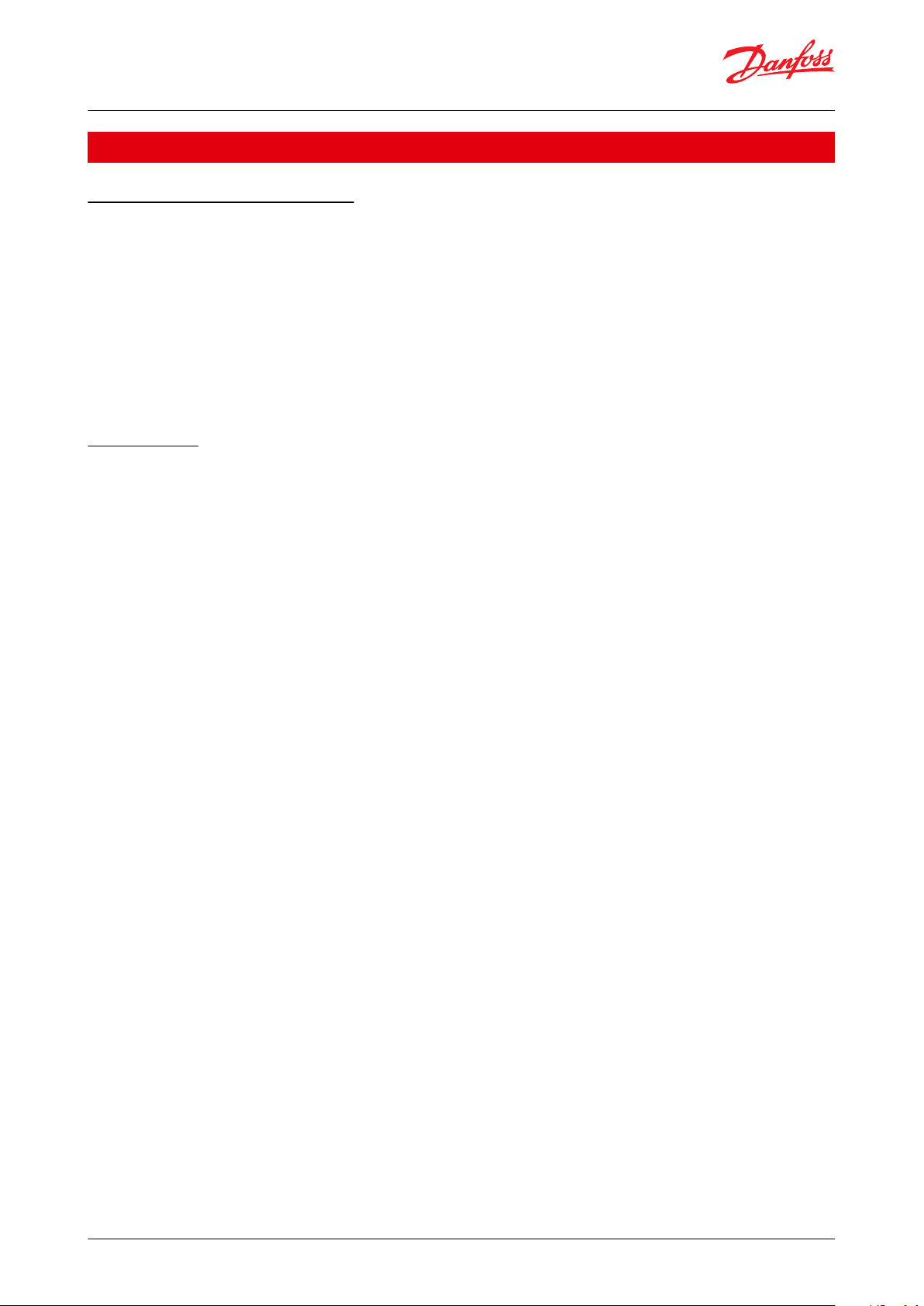

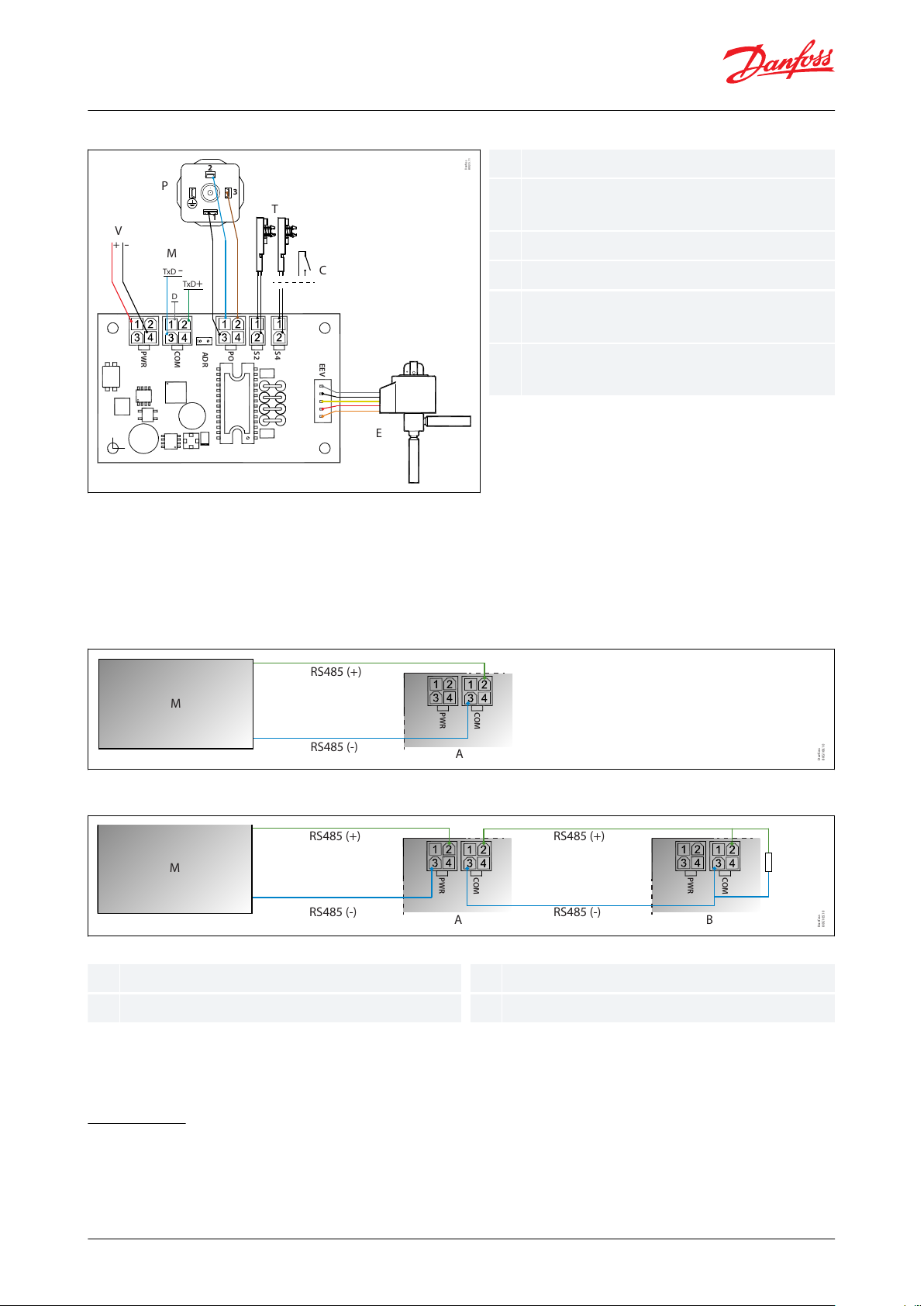

3 Applications

3.1 Regulation control

The evaporator superheat is controlled by one pressure sensor Pe (evaporator pressure) and one temperature

sensor S2 (refrigerant temperature). Alternatively the pressure and temperature signals can be received as data via

modbus. This can be useful if the pressure and temperature sensors are mounted on a separate controller.

Fitting the S4 (evaporator medium outlet temperature) is optional and has no eect on regulation, it is a readout

value only. S4 can however be setup as a Regulation control On / O switch instead to provide an external ON/OFF

function for the controller.

Figure 1: Regulation control

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 5

Page 6

Danfoss

80G164.10

PWR

PO

EEV

S4

S2

COM

ADR

1

3

2

+

-

V

P

T

C

E

VPT

C

E

Power Supply 24 V AC or DC

Pressure transmitter Ratiometric 0.5 – 4.5 V i.e.

AKS 32R

Temperature sensors PT 1000 i.e. AKS 11

Regulation control On/O switch (Enable

parameter HW Main Switch to 1)

Electric expansion valve ETS 6 with JST-XHP 5

connector

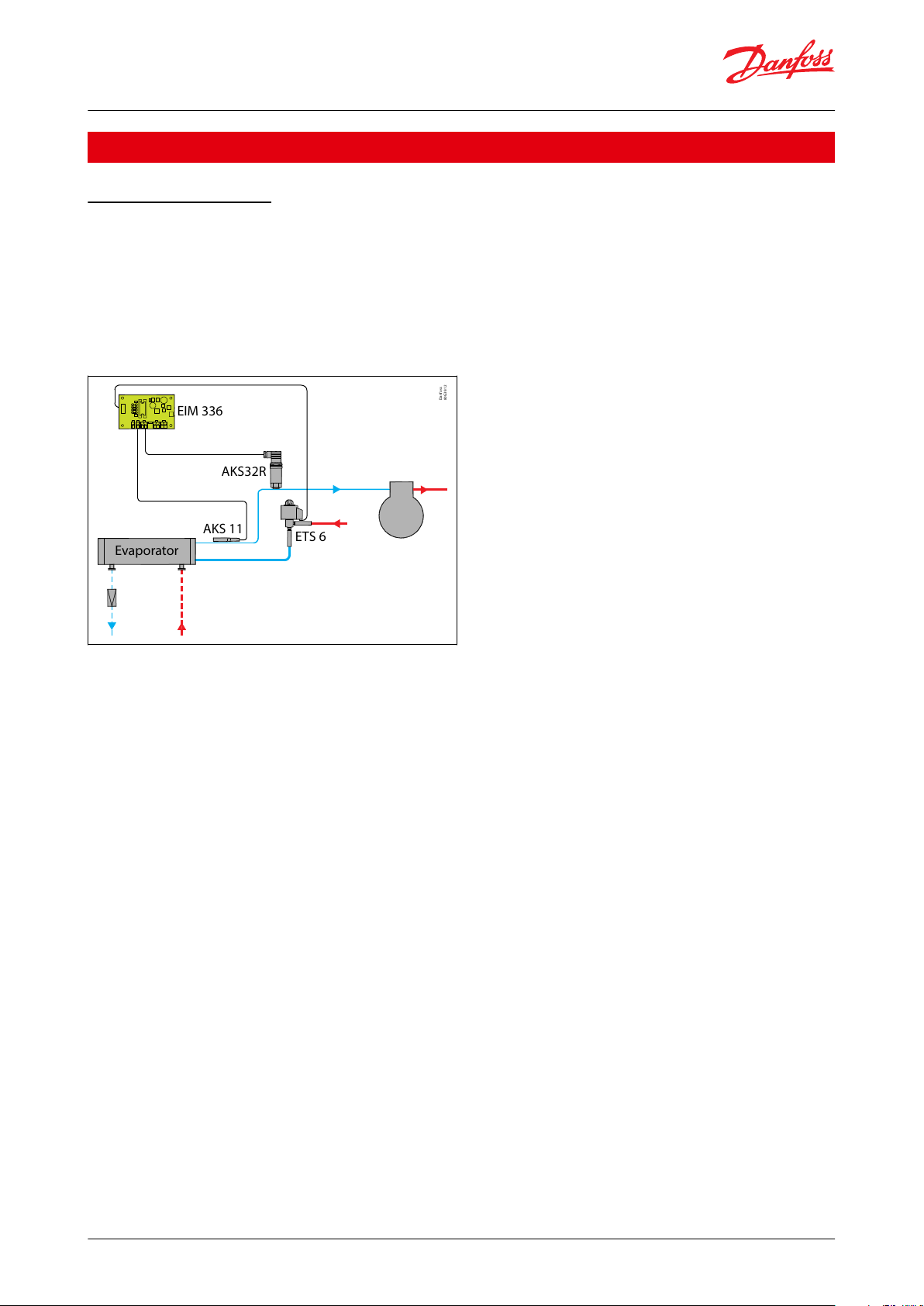

Features

Description

Supply voltage

24 V AC / DC (± 15%), 50 / 60 HZ, 15 VA / 8 Watt, Class II isolation

Power consumption

Idle

Max. 150 mA @ 24 V DC

Operating

Max. 150 mA @ 24 V DC

Input signals

For the EMC compliance, sensor cable length must be < 3m / 118 in.

For longer sensor cable, a ferrite bead should be used.

Po

AKS 32R (or similar ratiometric pressure transmitter)

S2

PT1000 (measuring range -60 – +120°C / -76 – 248 °F)

S4

PT1000 or digital input from external contact.

EEV driver

Max. current 150 mA RMS

EEV

Uni- or bipolar coil with JST XHP-5 connector

Data communication

RS485 – Modbus RTU (Not terminated internally)

Environment

Storage: -34 °C to 71 °C / -30 °F to 160 °F

Operating: -25 °C to 60 °C / -13 °F to 140 °F

Humidity: <95% RH, non condensing

Dimensions

25 × 50 × 80 mm / 0.98 × 1.97 × 3.15 inch

Operation

Stand alone or via Modbus data communication

Superheat controller, Type EIM 336

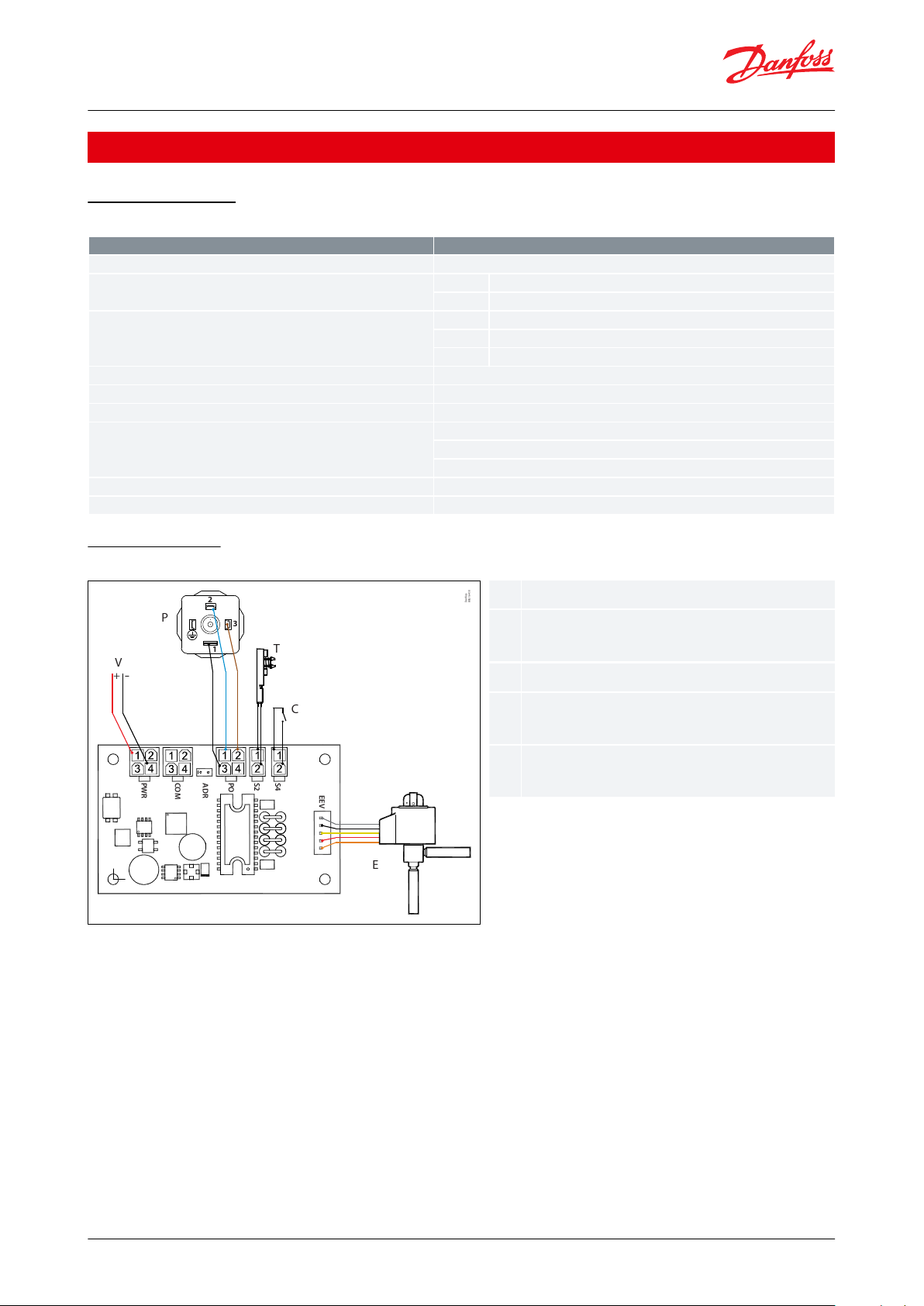

4 Product specication

4.1 Technical data

Table 2: Technical data

4.2 Connections

Figure 2: Stand alone conguration

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 6

Page 7

Danfoss

80G15.11

PWR

POS4S2

COM

ADR

+

-

TxD+

TxD

-

D

EEV

1

3

2

V

M

P

T

C

E

VPM

T

C

E

Power Supply 24 V AC or DC

Pressure transmitter Ratiometric 0.5 – 4.5 V i.e.

AKS 32R

Modbus to master controller

Temperature sensors PT 1000 i.e. AKS 11

Regulation control On/O switch (Enable

parameter HW Main Switch to 1)

Electric expansion valve ETS 6 with JST-XHP 5

connector

MAB

R

Danfoss

80G166.10

PWR

COM

M

RS485 (-)

A

RS485 (+)

M

A B

RS485 (-)

RS485 (+)

RS485 (-)

RS485 (+)

Danfoss

80G165.10

PWR

COM

PWR

COM

Master controller

EIM slave 1

EIM slave 2

120 Ohm min. 0.25 Watt

Superheat controller, Type EIM 336

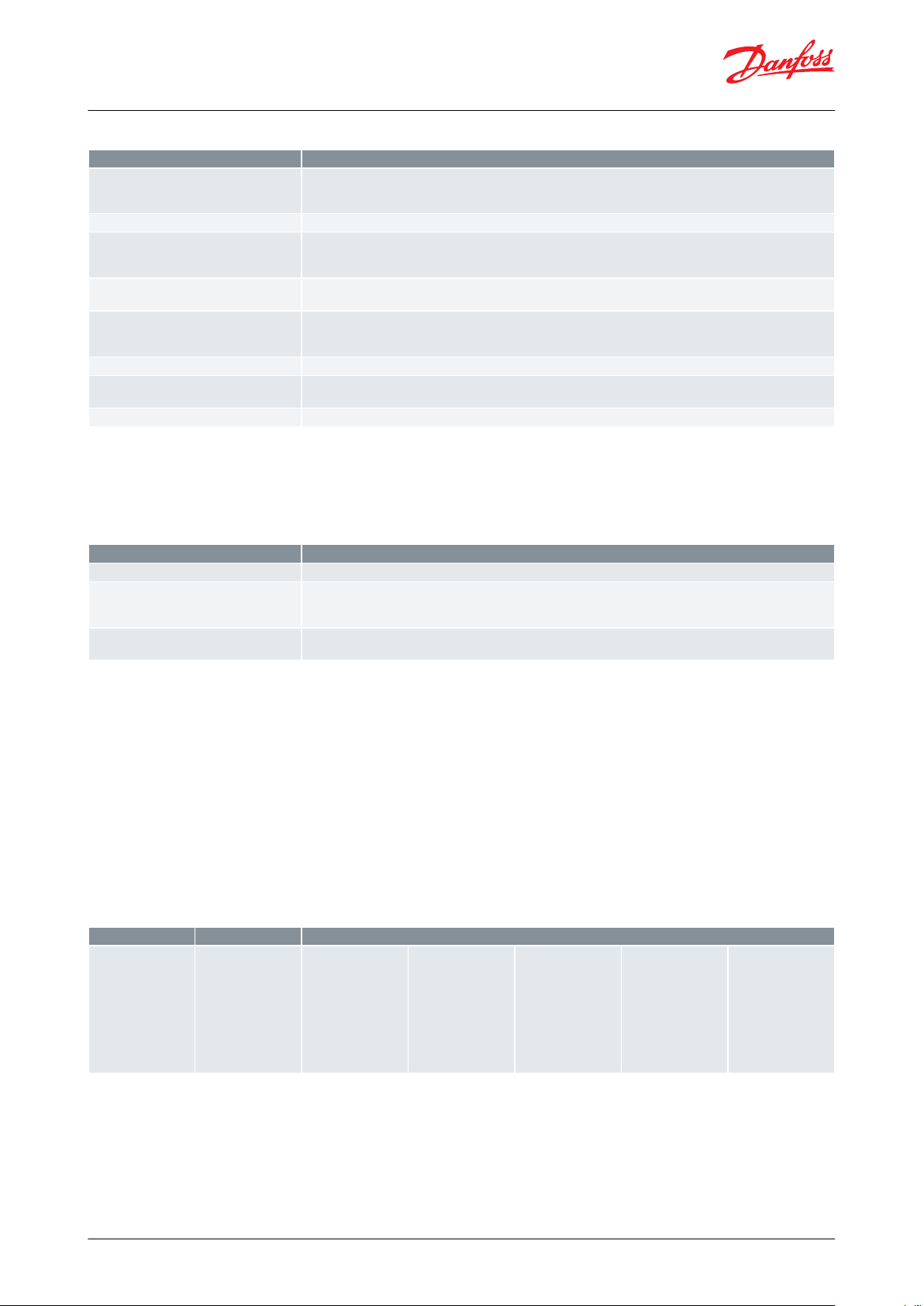

Figure 3: System conguration (default factory settings)

IMPORTANT:

• The supply voltage is not galvanically separated from the input and output signals, hence it is not recommended

to use shared power supply.

• No voltage should be supplied externally, if S4 terminal is setup as a Regulation on/o switch.

• Do not reverse the polarity of the power connection cables or Modbus signal cable else it could damage the

terminals.

Figure 4: Modbus one to one connection

Figure 5: Modbus in Daisy Chain

• If two EIMs are connected remember to remove the addressing jumper on one of the EIMs.

• Modbus transmission lines usually require termination resistors, especially for longer cable lengths.

4.3 Settings

NOTE:

4.3.1 Setting controller in Superheat control mode

NOTE:

Make sure that r12 = 0 (OFF) and change the settings. The setting will depends on the system requirement.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 7

Page 8

Features

Description

Enabling Regulation control ON/O switch

(optional)

HwMainSwitch = 1 (default is 0, i.e S4 sensor)

For standalone conguration it is recommended to enable Regulation control ON/O switch in order to control start/

stop regulation when needed, otherwise the controller will start regulating when controller is powered up.

Select Refrigerant

o30 = 1 - 42 (default value is 20 i.e R407C)

Select valve setting(optional)

n37 = 384 x 10 micro step (3840 micro steps = 480 half steps).

n38 = Max. steps/sec, default value is 31 half steps

For other valve type than Danfoss check the technical spec. of the valve.

Dene pressure sensor range in bar absolute

(x10)

o20 = Min. Transducer pressure

o21 = Max. Transducer pressure

Dene min/max superheat

n10 = min. superheat reference

n09 = max. superheat reference

For xed superheat dene n09 = n10

Dene MOP (optional)

n11 = maximum operating pressure (default is 12.5 bar absolute, max. 200 = MOP o)

Set force opening of the valve ( optional)

Start OD% (n17 )

StartUp time (n15)

To start the superheat control

Set r12= ON

Features

Description

Select Application mode

o18 (PNU 2075 )= 1 i.e Manual control

Select valve setting(optional)

n37 = 384 x 10 micro step (3840 micro steps = 480 half steps).

n38 = Max steps/sec, default value is 31 half steps

for other valve type than Danfoss check the technical spec of the valve

Select Manual opening degree

o45 Manual OD % (PNU 2064)

0 = fully closed, 100 = fully open.

Symbolic name

PNU

Description

o30 Refrigerant

2551

1 = R12

2 = R22

3 = R134a

4 = R502

5 = R717

6 = R13

7 = R13b1

8 = R23

9 = R500

10 = R503

11 = R114

12 = R142b

13 = User dened

14 = R32

15 = R227

16 = R401A

17 = R507

18 = R402A

19 = R404A

20 = R407C

21 = R407A

22 = R407B

23 = R410A

24 = R170

25 = R290

26 = R600

27 = R600a

28 = R744

29 = R1270

30 = R417A

31 = R422A

32 = R413A

33 = R422D

34 = R427A

35 = R438A

36 = Opteon XP10

37 = R407F

38 = R1234ze

39 = R1234yf

40 = R448A

41 = R449A

42 = R452A

Superheat controller, Type EIM 336

Table 3: Setting controller in Superheat control mode.

4.3.2 Setting controller in valve driver mode using Modbus signal

NOTE:

Make sure that r12 = 0 (OFF) and change the settings so they t to their application.

Table 4: Setting controller in valve driver mode using Modbus signal

By changing parameter o45 Manual OD, the valve will move accordingly regardless of r12 parameter value.

4.3.3 Selecting a refrigerant

The controller needs to know which refrigerant is used in order to accurately control the superheat. This can be

selected by setting the “o30 Refrigerant” to the desired refrigerant as dened in the list below.

If no refrigerant is selected (“o30 Refrigerant” is set to 0 meaning the refrigerant is undened), the “No Rfg. Sel.”

alarm is set and the controller will not start regulating.

Refrigerant setting

Before refrigeration can be started , the refrigerant has to be dened. You can select the following refrigerant.

Table 5: Related parameters

WARNING:

Wrong selection of refrigerant may cause damage to the compressor.

4.3.4 Connecting and setting up a valve

The EIM 336 controller is designed to be used with Danfoss ETS 6 valves with a maximum of 480 pulses from fully

closed to fully open. This setting should not be changed.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 8

Page 9

Symbolic name

PNU

Description

n38 Max. Steps Sec.

3033

Steps per second

n39 Start BckLsh

3034

Backlash, is the additional amount of steps, in percent, to close at startup and when the valve opening degree is less than 1%.

n40 Backlash

3035

Start Backlash is the amount of steps to compensate for spindle play.

Symbolic name

PNU

Description

o20 MinTransPres

2034

Minimum transducer pressure (in bar absolute x 10). Example: 0 bar absolute is entered as 0

o21 MaxTransPres

2033

Maximum transducer pressure (in bar absolute x 10). Example: 13 bar absolute is entered as 130

Superheat controller, Type EIM 336

The speed of the valve can be changed by increasing or decreasing the number of pulses per second, “n38 Max

StepsSec”. A larger value will make the valve open or close faster. Note that the torque of a stepper motor decreases

as the speed increases. Too high speeds should therefore be avoided. For the ETS 6 valve, the recommended speed

setting is 31 pulses per second.

When the controller is powered, the valve will rst be closed fully so that the controller starts from a known opening

degree (0%). In order to make sure that it is fully closed, the valve will be closed 100% plus an additional

contribution known as start backlash. The start backlash takes into account that the stepper motor may loose some

steps due to too low torque or mechanical slippage in the gears etc. The start backlash is the amount of extra steps

in percent to close once the valve is closed (less than 1%). If the valve is opening and reaches its destination, it will

move additional steps in the opening direction, then move the same amount of steps in the closing direction. This is

called backlash and is the amount of steps to add to compensate for spindle play.

Table 6: Related parameters

4.3.5 Connecting and setting up a pressure sensor

The pressure sensor input is setup by default to accept an AKS32R pressure transducer. If another sensor is to be

used, it is important to note that it needs to be a 0.5 - 4.5 V d.c. ratiometric type (10% - 90% of supply voltage).

The default range for the sensor is 0 to 16 bar absolute. This can be changed by setting the minimum transducer

pressure, “o20 MinTransPres” and the maximum transducer pressure, “o21 MaxTransPres” to the new values. The

values must be entered in bar absolute so a sensor with a range of -1 to 12 bar gauge, needs to bedened as 0 to 13

bar absolute.

Table 7: Related parameters

NOTE:

Both Danfoss AKS 32R and Danfoss Saginomiya Pressure transmitter NSK-BExxx follows the relative (gauge)

pressure, therefore same rules applies as explained above in converting and dening it in bar absolute in EIM

controller.

Mounting pressure transmitter

Installation of the pressure transmitter is less critical, but mounting of pressure transmitter should be closer to the

temperature sensor, right after the evaporator and with its head in upright position.

Power supply:

• Grounding of secondary (output) of transformer is not recommended.

• Do not reverse the polarity of the power connection cables and avoid ground loops (i.e. avoid connecting one

eld device to several controllers as this may result in short circuits and can damage your device).

• Use individual transformers for EIM 336 controller to avoid possible interference or grounding problems in the

power supply.

WARNING:

• Separate the sensor and digital input cables as much as possible (at least 3 cm) from the power cables to the loads

to avoid possible electromagnetic disturbance.

• Never lay power cables and probe cables in the same conduits (including those in the electrical panels).

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 9

Page 10

1

Danfoss

60G496.10

1

Conductive paste

Danfoss

84N365.10

OD

OD

OD

1

/2-5/8in.

12 - 16 mm

3

/4-7/8in.

12 - 16 mm

1 - 13/8in.

12 - 16 mm

OD

Danfoss

80G167.10

1 2

12Evaporator

sensor mounted close to the evaporator

Superheat controller, Type EIM 336

Mounting temperature sensor

Figure 6:

IMPORTANT:

Figure 7:

Figure 8:

• Mount sensor on a clean surface without any paints.

• Remember to put on heat conducting paste and insulate the sensor.

• Sensor mounting max. 5 cm from the outlet of the evaporator to get the precise measurements.

Figure 9: Mounting sensor

4.3.6 Using external sensor values

In some applications, the suction pressure and/or the refrigerant temperature on the evaporator outlet, is measured

by a system controller. This is often the case if the suction pressure is used to trigger low temperature/pressure

alarms by the systems main controller. In these cases the sensors can be omitted from the EIM 336, and the sensor

values can be received via modbus instead. This requires that the systems main controller continuously transmits

these values to the EIM 336. If no new sensor value is received within 5 seconds of the last transmission, the sensor

will revert to using the physical sensors.

The suction gas temperature S2 and the evaporator pressure Pe can be set by writing to the registers “ext S2 Temp”

and “ext EvapPress P0” respectively.

NOTE:

The external evaporator pressure is received in millibar so 8.4 bar absolute must be sent as 8400. It is possible to set

the S4 temperature as an external sensor value also, but since this sensor is not used in the superheat regulation,

this has little practical use.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 10

Page 11

Danfoss

80G11.10

18

16

14

12

10

8

6

4

2

0

SH

SH ref

Symbolic name

PNU

Description

ext EvapPress P0

2643

External evaporator pressure. This value can be used instead of a sensor.

This register must be written at least every 5 second, otherwise the sensor value will be used.

The entered value is in millibar

ext S2 temp

2644

External S2. This value can be used instead of a sensor.

This register must be written at least every 5 second, otherwise the sensor value will be used.

ext S4 air temp.

2646

External S4. This value can be used instead of a sensor. This register must be written at least every 5 second,

otherwise the sensor value will be used.

Symbolic name

PNU

Description

n09 Max. SH

3015

Maximum superheat reference setting.

n10 Min. SH

3021

Minimum superheat reference setting.

n20 Kp T0

3025

Pressure feedback gain.

n22 SH close

3027

Superheat close level. If the superheat goes below this value, the valve will close faster.

--- Tn SH

3103

Integration time for superheat control

--- Alpha

3111

Design time constant. A large alpha means a slow response, a small alpha mean a fast response.

--- Max. SH shdw

64301

Copy of 3015. If it is required to write n09 frequently, this should be used instead.

--- Min. SH shdw

64302

Copy of 3021. If it is required to write n10 frequently, this should be used instead.

--- Tn SH shdw

64303

Copy of 3103. If it is required to write TnSH frequently, this should be used instead.

--- Alpha shdw

64304

Copy of 3111. If it is required to write alpha frequently, this should be used instead.

Superheat controller, Type EIM 336

Table 8: Related parameters

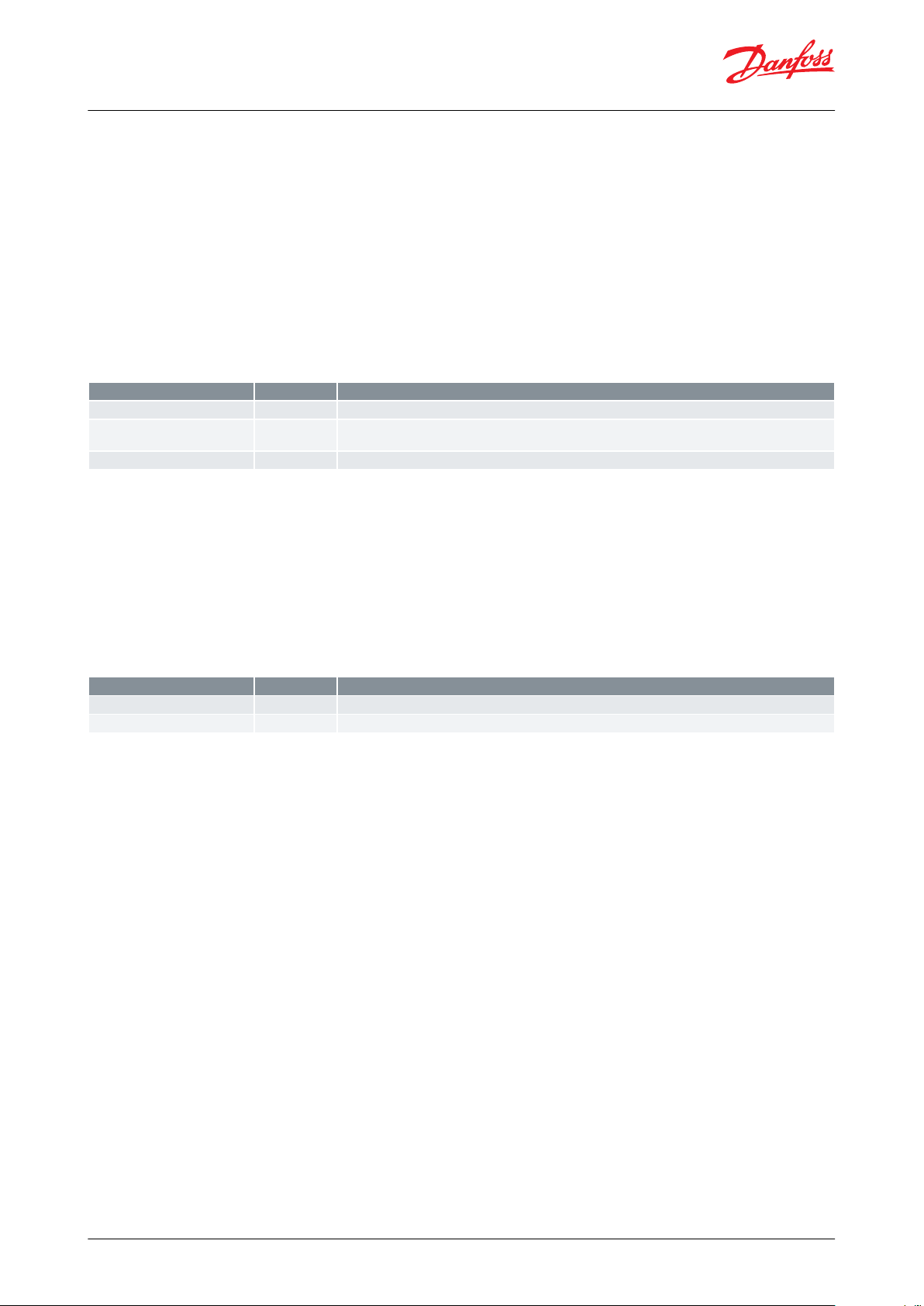

4.3.7 Conguring the superheat control

The superheat control algorithm will attempt to regulate the superheat down to the lowest stable value between

the minimum superheat setting, “n10 Min SH” and the maximum superheat setting, “n09 Max SH”. If a xed

superheat reference is desired instead, the “n10 Min SH” and “n09 Max SH” can both be set to the desired reference

value. This will disable the minimum stable superheat search algorithm and the controller will instead regulate the

superheat according to this reference.

The time constant for the superheat control can be changed by setting “Tn SH”.

The alpha value is the design time constant and should be in reasonable proximity to the time constant of the

evaporator. A large alpha value means a slow reaction, a small alpha value means a fast reaction.

If the superheat drops below “n22 SH close”, the controller will close the valve faster to avoid the risk of liquid in the

compressors suction line.

Figure 10:

Table 9: Related parameters

NOTE:

Main Switch r12 should be ON to start the regulation. This can also be accomplished with the external Regulation

control ON/O switch. See Interactions for details.

4.3.8 System conguration

The EIM 336 controller has a default conguration to be operated via modbus and to rely on a constant connection

to the master controller of the system it is located within. In this conguration the master controller reads the

readout registers from the EIM 336 and uses the parameters to change the control behaviour of the EIM 336 (see

Parameter list).

The following control modes are available:

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 11

Page 12

ETS 6

Evaporator

S4

S2 P

EIM 336

Modbus

Danfoss

80G41.11

Symbolic name

PNU

Description

o18 Manual ctrl.

2075

0 = Superheat control,

1 = Manual control

o45 Manual OD%

2064

Manual opening degree in percent.

0 = fully closed,

100 = fully open.

Used when the o18 Manual Control is set to 1.

Superheat controller, Type EIM 336

• Minimum Stable Superheat search (MSS) is the default control mode

• Manual control

• Defrost

• Maximum Operating Pressure control (MOP)

• Te control (De-humidifying).

Controlling manually via modbus

When setting the manual control register “o18 Manual ctrl.” to 1, the controller will be in manual control. During this

mode the opening degree is controlled by setting the “Manual OD%”. The manual control mode does not depend

on the “r12 Main Switch”, and will set the opening degree regardless of its setting. Setting “o18 Manual ctrl.” to 0

again, the controller will assume normal control, and will open or close from the current opening degree.

Figure 11: Controlling manually via modbus

NOTE:

On using system conguration , it is necessary to read the "Ctrl Stats" register 3100 continuosly, failure to do so will

start the MSS regulation automatically irrespective to the dierent status of the regulation On / O switch. Refer

Appendix 1 for detail.

Table 10: Related parameters

Standalone conguration (no Modbus communication)

The EIM 336 can be set in a standalone conguration by setting the modbus register i.e “HWMainSwitch” to 1. This

will setup the S4 input to be used as a Regulation On / O switch. Note that only external control of the EIM 336 in

this conguration is through the Regulation On / O switch.

The following control modes are available:

• Minimum Stable Superheat search (MSS) is the default control mode

• Maximum Operating Pressure control (MOP), but the Di MOP option is not available

The following control modes are not available:

• Manual control

• Defrost

• Te control (De-humidifying)

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 12

Page 13

EIM 336

S4 = 1

Danfoss

80G40.11

ETS 6

Evaporator

S2 P

Symbolic name

PNU

Description

--- HWMainSwitch

64100

0 = no external main switch

1 = regulation control On / O switch

Superheat controller, Type EIM 336

Figure 12: Standalone conguration (no modbus communication)

NOTE:

That the only external control of the EIM 336 in this conguration is through the Regulation control On / O switch.

It is not possible to manually control the opening degree or change settings, and the defrost and Te control modes

are not available.

Table 11: Related parameters

4.3.9 MODBUS Communication

Setting up modbus parameters

The modbus baud rate, “Modbus Baud”, can be set to three dierent baud rates. The modbus parity “ModbusParity”

can be set to either no parity, odd parity or even parity. The modbus stop bit can be set to either 1 or 2 stop bits. The

default settings are 19200 baud, even parity and 1 stop bit.

A jumper KM7 has been added to the EIM 336, for selecting between two predened addresses. This is useful for

applications such as reversible air conditioning/heat pump systems with both an indoor and an outdoor unit. In this

way the address can be changed without the need to recongure the controllers settings. The primary unit address

“o03 Unit addr.” is used when the jumper is mounted. The secondary unit address “Unit Addr. 2” is used when the

jumper is not mounted. The default primary address is 165, the default secondary address is 164.

NOTE:

Changes to these parameters will become active immediately. This means that a modbus tool or controller that

changes these settings will loose connection to the EIM 336 and will need to reestablish connection using the new

settings.

The EIM 336 “read holding registers” function (0x03) is limited to a maximum of 20 consecutive registers per read

request. If a modbus tool or a controller is used to read parameters over modbus, it needs to take this into account.

During the communication the transmitted Modbus requests are checked for CRC errrors. If the CRC is not correct,

the request is discarded and the EIM 336 waits for a new request. In this case no exception response is issued.

Loss of communication

The EIM will expect that a master controller reads the status register ( PNU 3100) at least every 30 seconds or more

often. If this does not happen the controller will switch to stand-alone control mode. Without communication it will

assume it is ON, and it will disregard the current status of the SW main switch (PNU 117). Under normal conditions it

will control the superheat by adjusting the opening degree based on the sensor inputs.

NOTE:

The 30 second timer is reset every time the status register is read by the master controller. if communication is loss

when the controller was in manual control, then it will remain in manual control, and keep its current opening

degree regardless of superheat.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 13

Page 14

Danfoss

84N404.10

RS485 +

RS485 –

N

G

NGNot in use

Gnd

Symbolic name

PNU

Description

o03 Unit addr.

2008

Primary unit address is used when jumper KM7 is mounted

--- Unit Addr. 2

2009

Secondary unit address is used when the jumper KM7 is not mounted

--- Modbus Baud

50060

Communication setting baud rate, 0 =9600 , 1 = 19200, 2 = 38400

--- ModbusParity

50061

Communication setting parity, 0 = no parity, 1 = odd parity, 2 = even

--- ModbusStopB

50062

Communication setting stop bit, 1 = 1 stop bit, 2 = 2 stop bit

Superheat controller, Type EIM 336

Table 12: Related parameters

For detailed explanation and examples, please refer to manual ‘ EKD EIM Data communication Modbus RS485 RTU’

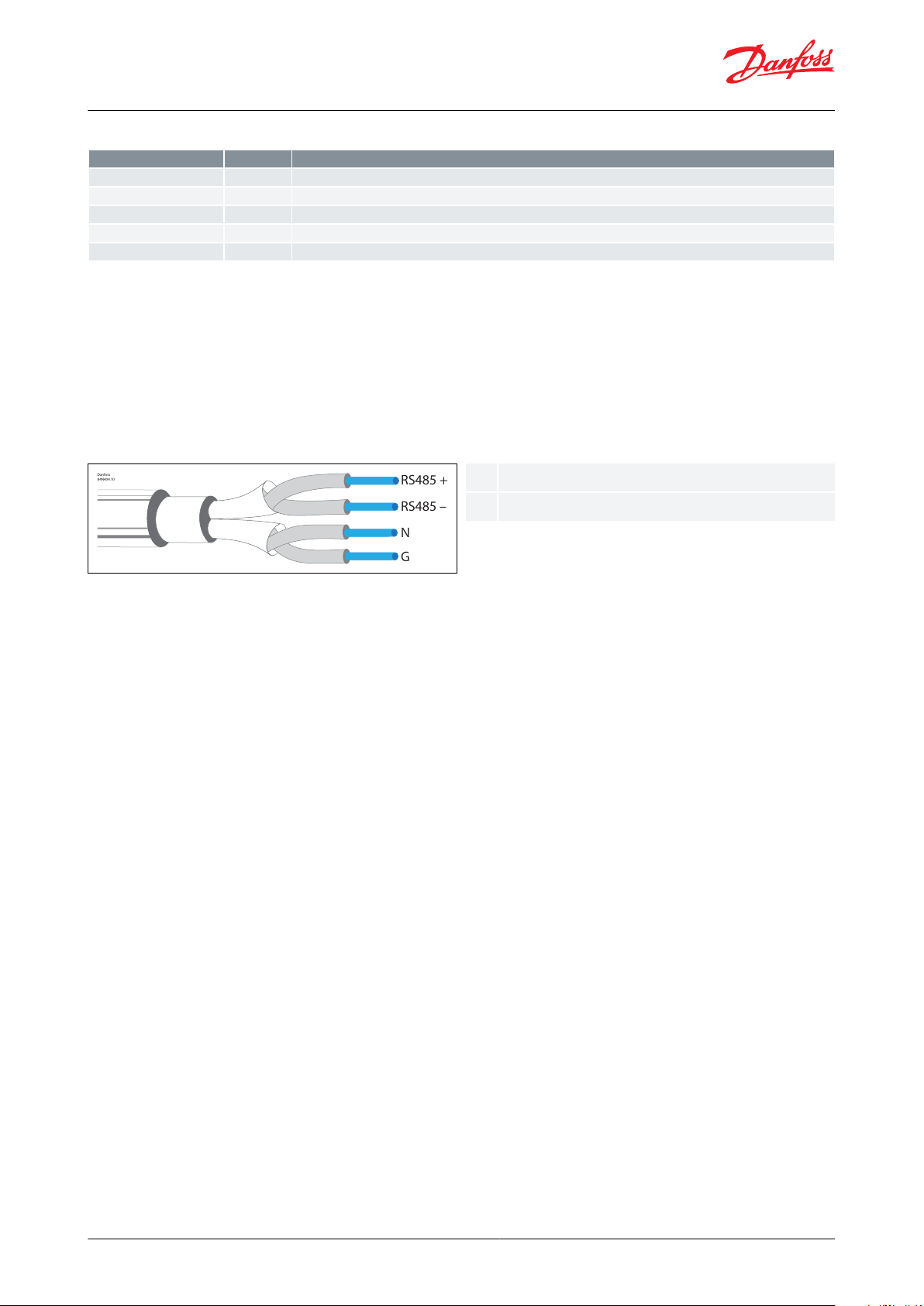

Connecting Modbus

• For the modbus cable, it is best to use 24AWG shielded twisted-pair cable with a shunt capacitance of 16 pF/ft and

100Ω impedance.

• The max. permissible number of devices simultaneously connected to RS485 output is 32. The RS485 cable is of

impedance 120 Ω with maximum length of 1000 m.

• Terminal resistors 120 Ω for terminal devices are recommended for length > 1 m.

Figure 13: Connecting Modbus

Detail explanation on Modbus installation and software parameter setting can be found in User guide: DATA

COMMUNICATION MODBUS RS 485 RTU

WARNING:

• Accidental damage, poor installation, or site conditions, can give rise to malfunctions of the control system, and

ultimately lead to a plant breakdown.

• Every possible safeguard is incorporated into our products to prevent this. However, a wrong installation, for

example, could still present problems. Electronic controls are no substitute for normal, good engineering practice.

• Danfoss will not be responsible for any goods, or plant components, damaged as a result of the above defects. It is

the installer’s responsibility to check the installation thoroughly, and to t the necessary safety devices.

• Particular attention is drawn to the need for a “force closing” signal to controllers in the event of compressor

stoppage, and to the requirement for suction line accumulators.

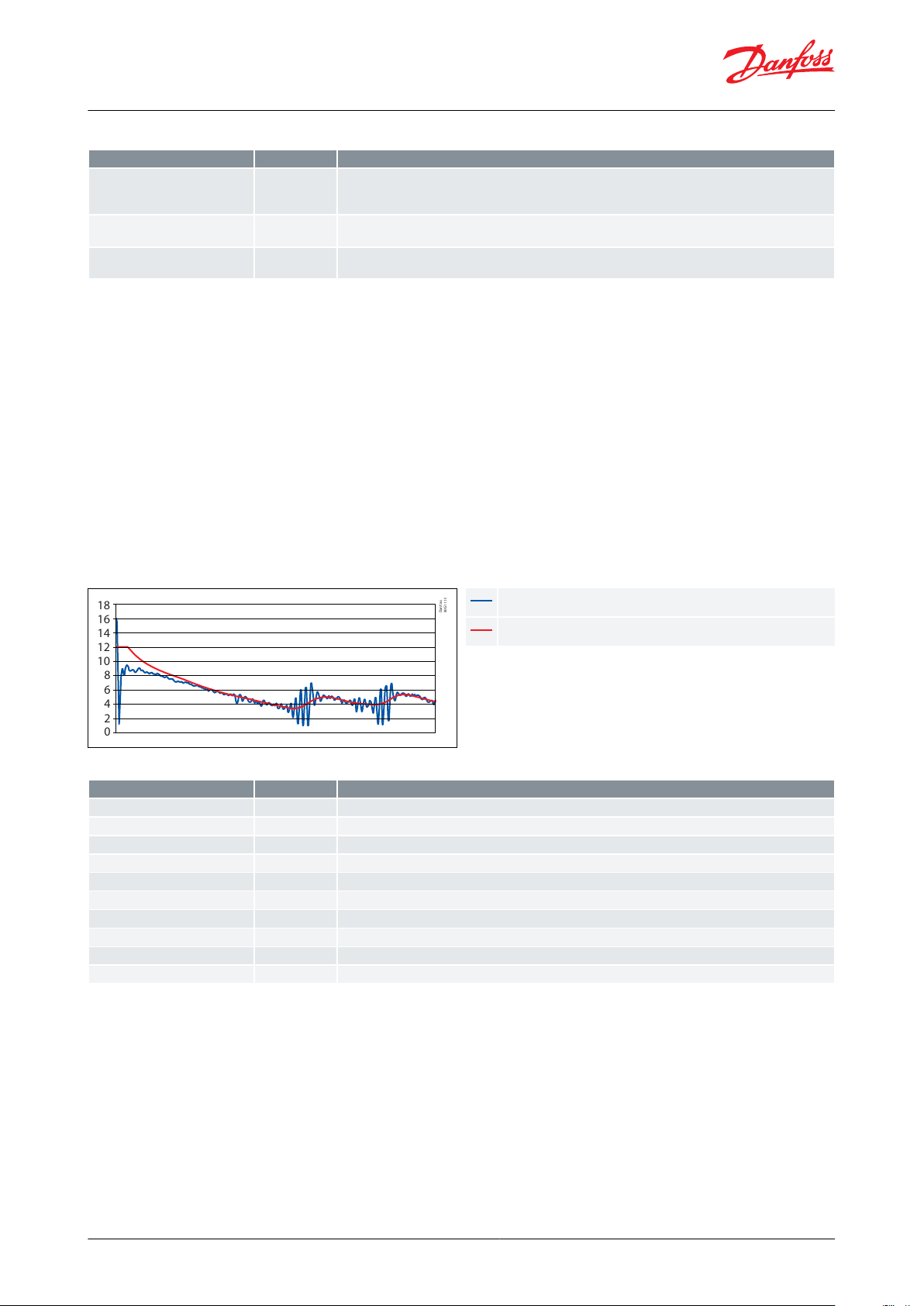

4.3.10 Using the MOP

In order to reduce the current to the compressor it is possible to control the maximum operating pressure of the

evaporator. If the evaporator pressure exceeds the “MOP” limit, the valve opening degree is controlled by the MOP

function which will keep the pressure below the “MOP” limit. This function takes precedence over the superheat

control, so during MOP control the superheat is not controlled.

The MOP function can be disabled by setting the “MOP” to the maximum value (2000 equalling 200 bar absolute).

When the pressure reaches the set MOP point, an increase in OD is restricted. If the pressure reaches MOP + 0.5 Bar,

an increase in OD is prohibited, and instead the OD will start to decrease. If the pressure goes below the MOP point,

the controller will start to regulate the superheat normally.

The MOP controller consists of a separate PI control, which settings can be changed by setting “Kp MOP” and “Tn

MOP”. A large Kp will lead to a large change in opening degree even at small changes in the evaporator pressure,

but may lead to instability. A large Tn will lead to a slow reacting system, while a small Tn will lead to a fast reacting

system.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 14

Page 15

MOP

b

t0

Danfoss

80G12.11

btbar

Time

MOP+0.5

MOP

VOD

P1 P2

Danfoss

84B3084.11

N C F

R

Pe

b

P1

P2

Pe

VODRNCF

At this pressure the OD increases slower and

slower.

At this pressure the OD no longer increases.

Beyond it the OD decreases.

pressure

Valve Opening Digree

Normal regulation

Normal OD

Controlled OD

Force closed OD

Symbolic name

PNU

Description

n11 MOP

3013

Maximum operation pressure. If Pe goes above this value, the controller will control on Pe, and not on superheat.

--- Kp MOP

3113

Kp proportional gain while in MOP control mode.

--- Tn MOP

3114

Tn integration time while in MOP control mode.

Superheat controller, Type EIM 336

Figure 14: MOP controlling

Figure 15: MOP disabling

Table 13: Related parameters

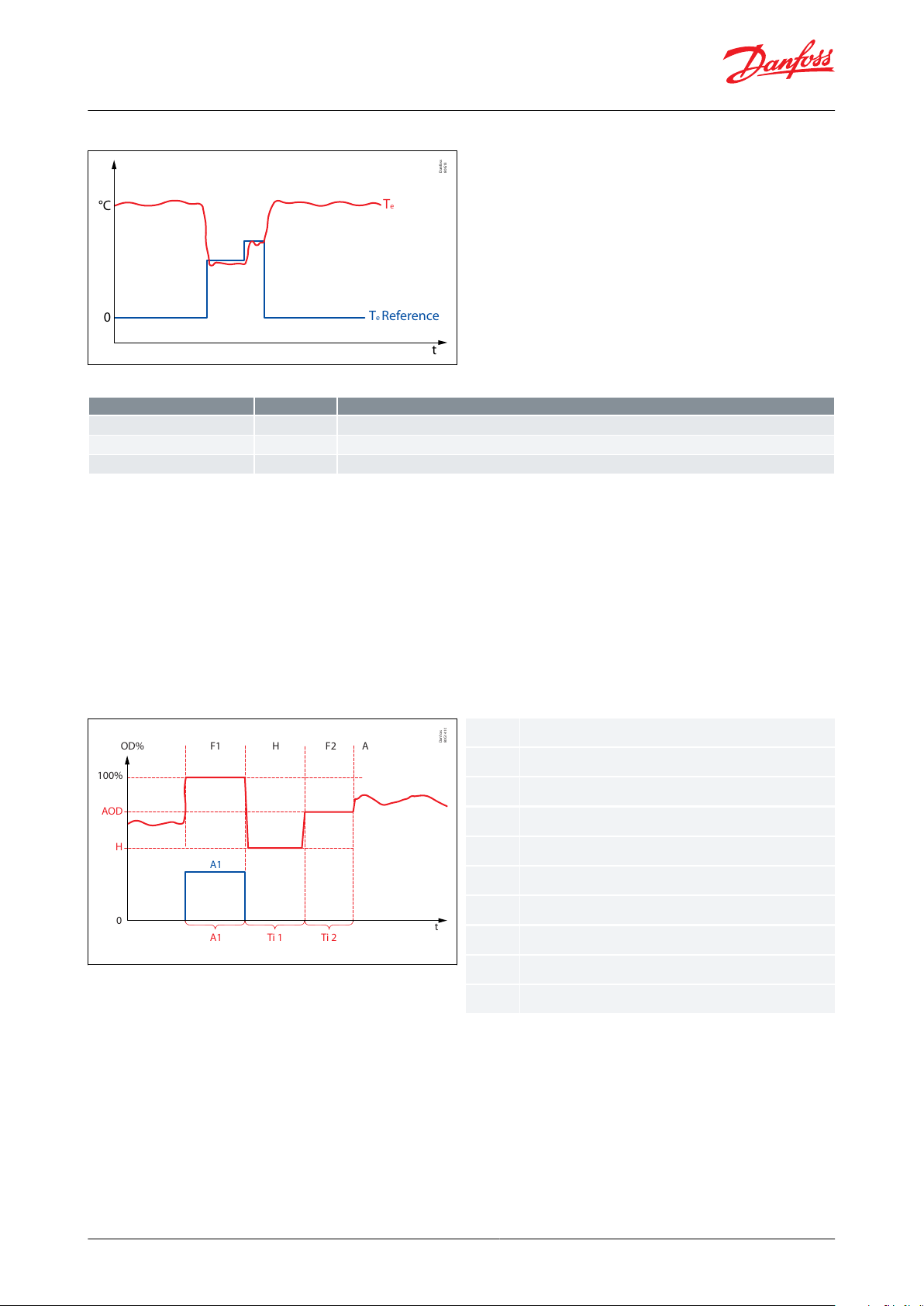

4.3.11 Using Te control

For applications with a need to de-humidify the evaporator, it is possible to control on the saturated evaporator

temperature instead of the normal control signal. If the “Te Reference” register is set to a value above 0, Te control is

activated. Te and the Te reference are used by the controller to calculate a new opening degree.

The Te control consists of a separate PI control, which settings can be changed by setting the gain, “Kp Te” and time

constant, “Tn Te”. A large Kp will lead to a large change in the output even at small changes in the evaporator

temperature, but may lead to instability. A large Tn will lead to a slow reacting system, while a small Tn will lead to a

fast reacting system.

The MOP function is still active during Te control and it will assume control, if the evaporator is above the “MOP”

limit. The SH close function is also active during Te control and will assume control if the SH is below the SH close

limit.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 15

Page 16

AOD

H

Ti 2Ti 1A1

A1

A

t

F2HF1

OD%

100%

0

Danfoss

80G14.10

OD%

t

AODHF1F2AA1Ti 1

Ti 2

Opening degree in percentage

time

Avg. OD

Def Hold OD%

Fixed 100 OD%

Fixed Avg.OD%

Auto control

Defrost activate = 1

Def Hold time 1

Def Hold time 2

t

0

°C

Te Reference

Te

Danfoss

80G13

Symbolic name

PNU

Description

--- Kp T

e

3115

Kp proportional gain while in Te control mode

--- Tn T

e

3116

Tn integration time while in Te control mode

--- Te Reference

3117

Te reference while in Te control mode

Superheat controller, Type EIM 336

Figure 16: Using Te control

Table 14: Related parameters

4.3.12 Defrosting

A defrost sequence is initiated by setting the defrost activate register “Def Activate” to 1. As long as this register is

kept at 1, the valve opening degree is 100%. When “Def Activate” returns to 0, the valve opening degree is kept at

“Def Hold OD” for “Def Hold Ti 1” seconds. When this time expires, the valve opening degree is set to a calculated

average opening degree (PNU 50021) for “Def Hold Ti 2” seconds. When this time expires the controller resumes

normal operation.

The average opening degree is calculated as an average of the last hour while operating in injection state. Other

states such as manual control, defrosting or if the valve is fully closed are not included in the calculation of the

average.

Figure 17: Defrosting

NOTE:

• Defrost is not initiated by the EIM 336, but must be initiated by the master controller. In a standalone

conguration the defrost mode is not possible.

• If a more dynamic control of the opening degree during defrost is required, the user should disable the “Def Hold

Ti 2” by setting it to 0, and only use the “Def Hold Ti 1”. If frequent changes are to be made to the “Def Hold OD”,

the parameter “DefHold shdw” should be used instead. This parameter is an exact copy of the “Def Hold OD”

except that it is not placed in the Eeprom.

• If the communication is lost when the controller was in the process of defrosting, this process will continue. When

the entire sequence is completed it will go to superheat control. However, if the defrost activate signal was set

(50011), it will go to 100% opening. If it is never cleared, the sequence will stop, and it will stay fully open.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 16

Page 17

Danfoss

84N400.10

FOD %

N

R%

VOD%

SOD %

S

t1 t

OD %

SOD%

FOD%

NR%Start OD%

Forced OD%

Normal Reg.

Reg. OD%

Symbolic name

PNU

Description

--- Def. Activate

50011

Defrost activating, 0 = no defrost, 1 = defrost active

--- Def. Hold OD

50008

Opening degree during Def Hold Ti 1

--- Def. HoldTi 1

50009

Defrost hold time 1

--- Def. HoldTi 2

50010

Defrost hold time 2

--- DefHold shdw

64305

Copy of 50008. If it is required to write Def Hold OD frequently, this should be used instead.

Symbolic name

PNU

Description

--- LOC Trig

50003

Trigger value for loss of charge

--- LOC Reset

50004

Reset value for loss of charge

--- LOC Timer

50005

Timer to trigger LOC alarm

--- LOC Alarm

50006

Loss of charge alarm ag, 0 = no alarm, 1 = LOC alarm

--- LOC SH Trig

50007

SH error trigger level for LOC alarm

--- LOC Tmr

3102

Loss Of Charge time readout displays the elapsed time since the alarm became active.

Superheat controller, Type EIM 336

Table 15: Related parameters

4.3.13 LOC detection

When a system loses refrigerant charge the controller will have diculties keeping the superheat low, even when

increasing the valve opening degree. Therefore, if both the valve opening degree and the superheat are high for a

long period of time, this could indicate that refrigerant charge was lost.

When the valve opening degree exceeds the trigger level "LOC Trig, and the superheat exceeds the superheat

trigger level "LOC SH Trig", a timer is started.

When the timer exceeds the user dened time “LOC Timer” the “LOC Alarm” is set. If the valve opening degree drops

below the user dened reset level “LOC Reset”, the timer and the alarm are reset.

The loss of charge alarm does not perform any actions, except setting the “LOC Alarm”.

Table 16: Related parameters

4.3.14 Finding the optimum settings

Details on the controller algorithm and settings

Problems with startup

Sometimes in one-to-one applications, the valve does not open suciently on startup, and troublesome low

pressure trips may occur.

The force opening of valve function has been implemented in the EIM 336 controller. After startup, this function will

provide a constant, set minimum opening degree during a set time period, regardless of the superheat value. The

setting parameters are called Start OD% (n17) and StartUp time (n15).

Figure 18: Forced opening of valve

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 17

Page 18

Superheat controller, Type EIM 336

Low Pressure Issue due to compressor cut in and cut out

One of the features of TEX valves is the external pressure equalization making a direct and fast responding pressure

connection between the compressor suction line and underside of the diaphragm in the valve. This enables the

valve to open-/ close momentarily with compressor capacity cut in and out.

The same function has been implemented into EIM 336, which is controlled by the parameter n20, KpTo. In this

function. kp factor related directly to the suction pressure (To) with direct eect on the requested signal to the ETS 6

valve .

The default value of KpTo is set to automatic (i.e -1). If the automatic tuning is not fullling the desired order,

Increasing the n20 setting to the xed value will contribute to an improvement. Too high n20 will produce high

uctuation in superheat regulation.

Fluctuating superheat

When the refrigerating system has been made to work steadily, the controller’s factory-set control parameters

should in most cases provide a stable and relatively fast regulating system. If the system however uctuates, this

may be due to the fact that too low superheat parameters have been selected or due set of regulation parameters

which are not optimal.

Usually, the following parameters can be tuned in order to reach fast, stable superheat in EIM controller.

1.

If adaptive superheat has been selected adjust n09 and n10 parameters. For some application using xed

superheat may increase the stability. This can be done by dening n09 and n010 to the xed value.

2.

To optimize the superheat regulation, most safe and direct way is to tune TnSH. For example, if a the control is

too slow, dene new Tn value to half (1/2 Tn), if it is still slow reduce it to another half (1/2 x 1/2 Tn= 1/4 Tn), If the

control start to oscillation, then return back to (~ 3/8 Tn) , alternatively read the time period and tune tn = 1.2 x

time period.

3.

Keep KpT0, Alpha as default, they work for most of the cases.

4.

Tune parameter for force opening of the valve at start up i.e. n15 (startup OD) and n17 (start up time). These

values depends on the system conditions.

NOTE:

Steps (1.) to (3.) are quite easy and safe to tune. For step (4.), caution should be taken, so as not to allow refrigerant

inside the compressor.

Too high uctuating pressure signal

1.

Tune parameter n20 KpT0 to lower value, if this is not working for the system disable by setting it to zero.

2.

If point 1 doesn’t seem to be working, then keep n20 KpT0 disable and increase para TSH (i.e Tan SH). Increase

TSH (default value) by 200 and check the oscillation. If the problem seems to persist, perform the same step up

to higher TSH value.

4.3.15 Alarms and clearing alarms

Several alarms are registered and made available on modbus. Most of these are automatically cleared when the

error is no longer present.

Sensor error : Temperature sensor error has a timeout of 10 minutes. This means that after the reason for a sensor

error has gone, the error will remain active for 10 minutes, and then it is cleared. for the pressure sensor, the timeout

is only 30 seconds.

There is an option to reset the errors externally by setting the 40075 (reset alarms) = 1.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 18

Page 19

1.

2.

3.

Symbolic name

PNU

Description

--- Reset alarm

2046

1 = Clear alarm.

It is possible to clear alarms manually by setting Reset Alarms (40075). After setting this, the alarm is kept

active for

5 seconds before being cleared.

--- EKC Error

20001

Common error ag. EKC Error is SET if any other Error Alarm is ON.

EKC error is auto cleared after the last active alarm has been cleared.

--- S2 Error

20002

S2 sensor error. If the sensor error occurs, the valve OD will be set to 80% of the Avg. opening (PNU 50021) see Troubleshooting.

S2 alarm is auto cleared after 10 min after the alarm condition has been cleared.

--- S4 Error

-

S4 is not monitored

--- Pe inp.error

20005

Pressure transmitter out of range. If the sensor error occurs, the valve OD will be set to 80% of the Avg.

opening (PNU 50021)

- see Troubleshooting.

Pe alarm is auto cleared after 30 seconds.

--- No Rfg. Sel.

20006

Refrigerant not selected.

No Refrigerant selected alarm is auto cleared immediately after setting the refrigerant.

--- LOC Alarm

50006

Loss of charge alarm. No action will be performed except setting the alarm.

--- Ctrl Status

3100

Bit mappped status register, see also Control status

Symptom

Possible Cause

Remedy

Suction pressure too low

Pressure drop across the evaporator too high

-

Lack of subcooling ahead of expansion valve

Check refrigerant ahead of expansion valve. If the valve is placed much

higher than condenser outlet, check pressure dierence.

Evaporator superheat too high

Check superheat performance, the settings SH min and SH max.

Check valve capacity.

Check that the maximum number of steps of valve is same as

parameter n37.

Pressure drop across the expansion valve less than

valve is sized for

Check pressure drop across expansion valve. Replace with larger valve.

Expansion valve too small

Check refrigeration system capacity and compare with expansion valve

capacity. Replace with larger valve if necessary.

Expansion valve block with foreign material

Remove valve and examine the orice.

Evaporator wholly or partly iced up

De-ice evaporator

Liquid hammer in compressor

Superheat of expansion valve too low

Increase the values of SH close and SH min.

Superheat reference set too low

Increase the value of SH min

The S2 sensor not in good contact with the suction

line

Ensure that S2 sensor is secured on suction line. Insulate sensor.

S2 sensor error: PNU 20002

Bad connection or damaged S2 sensor

The controller will go to either the low or high boundary depending on

the error. The lowest value will be shown at a short circuit. The highest

value will be shown for a missing connection. Check the temperature

sensors.

AKS32R out of range: PNU 20005

The suction pressure is above the maximum limit or

below the minimum limit

The controller will go to either the low or high boundary depending on

the error. The highest value will be shown if the signal is above the maximum value. The lowest value will be shown if the signal is below the

minimum value or for a missing connection. Check the pressure range.

LED blinks during operation

No Modbus connection to master controller. (Controller entered autonomous control mode, and it will try

to control on its own if possible, or close if no sensor

signals are available).

Check Modbus connections between Master controller and the EIM

controller.

Chech the Modbus parameter setting in the controller.

Row text

Explanation

PNU

The Parameter Number in the EIM 336 controller. All parameters are addressed as holding register. The Modbus PDU address corresponds to PNU-1. If no translation table is used, this is the register number in modbus.

Min.

Minimum value

Def.

Factory default value

Max.

Maximum value

e2

Is the value stored in EEPROM

W

Is writing to the register possible

Superheat controller, Type EIM 336

Table 17: Related parameters

4.3.16 Troubleshooting

Table 18: Troubleshooting

4.3.17 Parameter list

Table 19: Parameter list legend

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 19

Page 20

Row text

Explanation

*10

The scaling of the parameter. All values are read/written as integers over modbus. Parameters need to be scaled, these are marked with a

checkmark. This means that 0.1 is sent as 1 over modbus, 1.0 is sent as 10 etc.

Symbolic name

The name of the parameter

Description

Short parameter description

Group

PNU

Parameter

Symbolic name

Min.

Max.

Default

Unitse2W

*10

Description

Regulation

Control

117

r12

Main switch

010--✓-

Start/stop of regulation. With this setting the regulation can be started and stopped. This can also be accomplished with the external hardware main switch.

See also Interactions

2075

o18

Manl control

010--✓-

0 = Superheat control, 1= Manual control

2064

o45

Manual OD

0

100 /

480

0

% /

step

-✓-

Manual opening degree for manual control .

Used when the o18 Manual Control is set to 1.

0%/0 step = fully closed,

100%/480 step = fully open.

% is chosen by default.

See PNU 64309 for changing to step.

3017

n15

Startup time

0

10000s✓✓-Time for startup state (in seconds)

3012

n17

Startup OD

0

1000%✓✓-Opening degree during startup state

64308

OOD

OD while OFF

0

1000%✓✓-Opening degree during

O state

Superheat controller, Type EIM 336

NOTE:

Some parameters have what is called a "cong lock". This means that they can only be changed when the main

switch of the EIM 336 is set to OFF (r12 = 0). This applies for instance to the type of refrigerant (o30). So if you want

to change the refrigerant, the main switch (r12) must rst be set to 0, then the refrigerant type (o30) can be

changed.

The following parameters require the main switch (r12) to be OFF:

• n37 Max steps

• n38 Max steps/sec

• o03 Unit address

• o30 Refrigerant

Please refer to the list below. It should be possible to change all other parameters while the unit is running

(regulation parameters etc.).

Shdw (x): Shdw values are stored in the volatile memory and will revert back to the previously stored value in its

main parameter if the power failure occurs. Altering the main parameter will automatically change the shdw value. If

frequent change in parameter required, it is recommended to use shdw parameter.

Table 20: Parameter list

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 20

Page 21

Group

PNU

Parameter

Symbolic name

Min.

Max.

Default

Unitse2W

*10

Description

Super Heat

Control

3015

n09

Max. superheat

25016K✓✓✓

Maximum superheat reference setting

3021

n10

Min. superheat

1504K✓✓✓

Minimum superheat reference setting

3025

n20

KpT0

-120-1-✓✓✓

Pressure feedback gain Automatic = -1, OFF = 0 , Fixed

= 1 and above

3027

n22

SH close

0160.5K✓✓✓

Superheat close level. If the superheat goes below this

value, the valve will close faster

3103

TSH

Tn SH

10

1800

600-✓✓-

Tn integration time for the superheat control. Lower

value give fast regulation response. Very low value

give the risk of unstable regulation.

3105

(1)

SHL

SH Low

3506K✓✓✓

Superheat low setting for non-linear control

3106

(1)

SHH

SH High

85016K✓✓✓

Superheat high setting for non-linear control

3107

(1)

GaH

Gain High

0.5501-✓✓✓

Expected gain at SH high for non-linear control

3108

(1)

GaL

Gain Low

0.15012.5-✓✓✓

Expected gain at SH low for non-linear control

3109

(1)

TaH

Tau High

10

60045-✓✓-Expected tau at SH high for non-linear control

3110

(1)

TaL

Tau Low

10

600

110-✓✓-

Expected tau at SH low for non-linear control

3111

Aph

Alpha

15

600

130-✓✓-

Design time constant. A large alpha means a slow response, a small alpha mean a fast response.

3120

CoS

Comp Speed

0

1000%-✓

✓

Compressor speed Tn=2x Tn if compressor speed is set

to 0% Tn= Tn if the compressor speed is set between

25 - 100% - ref. parameter 3103

64301

n09x

Max. superheat

shdw

25016K-✓✓

Copy of 3015. If it is required to write Max superheat

frequently, this should be used instead

64302

n10x

Min. superheat

shdw

1504K-✓✓

Copy of 3021. If it is required to write Min superheat

frequently, this should be used instead

64303

TSHx

Tn SH shdw

10

1800

600--✓-

Copy of 3103. If it is required to write TnSH frequently,

this should be used instead.

64304

Aphx

Alpha shdw

15

600

130--✓-

Copy of 3111. If it is required to write alpha frequently,

this should be used instead.

MOP

3013

n11

MOP

0

200

13.7

bar

(abs.)

✓✓✓

Maximum operation pressure. If Pe goes above this

value, the controller will control on Pe, and not on superheat

3113

KpM

Kp MOP

0.5100.5-✓✓✓

Kp proportional gain while in MOP control mode

3114

TnM

Tn Mop

30

600

180-✓✓-

Tn integration time while in MOP control mode

3121

DMO

Di MOP

-2000

bar

(abs.)

-✓✓

Dierential MOP. A remote oset that is added to the

MOP. Needs to be written every 5 seconds, else the o-

set is set to 0.

Defrost

50011

DeA

Def Activate

010--✓-

Defrost activating

50008

DHO

Def Hold OD

0

10030%✓✓-Defrost holding level

50009

DH1

Def Hold Ti 1

0

32000

120s✓✓-

Defrost holding timer 1

50010

DH2

Def Hold Ti 2

0

3200060s✓✓-Defrost holding timer 2

64305

DDO

Def hold OD

shdw

0

10030%✓✓

-

Copy of 50008. If it is required to write Def Hold OD

frequently, this should be used instead.

Te Control

3115

KpTe

Kp Te

0.5101-✓✓-

Kp proportional gain while in Te control mode

3116

TnT

Tn Te

30

60060-✓✓

-

Tn integration time while in Te control mode

3117

TeR

Te Reference

-200

2000°C-✓✓Te reference while in Te control mode

External sensors

2643

PEV

ext. EvapPress

P0

0

65535

0

milli

bar

-✓-

External evaporator pressure. This value can be used

instead of a sensor. This register must be written at

least every 5 seconds, otherwise the sensor value will

be used.

2644

TS2

ext. S2 temp

-200

2000°C-✓

✓

External S2. This value can be used instead of a sensor.

This register must be written at least every 5 seconds,

otherwise the sensor value will be used.

2646

TS4

ext. S4 Air temp

-200

2000°C-✓

✓

External S4. This value can be used instead of a sensor.

This register must be written at least every 5 seconds,

otherwise the sensor value will be used.

LOC

50003

LTR

LOC Trig

0

10095%✓✓-Trigger value for loss of charge

50004

LRe

LOC Reset

0

10085%✓✓-Reset value for loss of charge

50005

LTm

LOC Timer

0

7200

3600s✓✓-

Timer to trigger LOC alarm

50007

LST

LOC SH Trig

05020K✓✓✓

SH error trigger level for LOC alarm

Superheat controller, Type EIM 336

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 21

Page 22

Group

PNU

Parameter

Symbolic name

Min.

Max.

Default

Unitse2W

*10

Description

Modbus

20083Unit Addr

1

240

165-✓✓-

Primary unit address is used when jumper KM7 is

mounted

2009

UA2

Unit Addr 2

1

240

164-✓✓-

Secondary unit address is used when the jumper KM7

is not mounted

50060

MBa

MB Baud

021-✓✓-

Communication setting baud rate, 0 =9600 , 1 =

19200, 2 = 38400

50061

MPa

MB Parity

022-✓✓-

Communication setting parity, 0 = no parity, 1 = odd

parity, 2 = even

50062

MSB

MB StopB

121-✓✓-

Communication setting stop bit, 1 = 1 stop bit, 2 = 2

stop bit

64200-Modbus trans

031-✓✓-

1 = Enabling translation tables. If the translation table

is enabled, only registers some are accessible.

Valve

3032

n37

Max steps

100

1000

384-✓✓-

Maximum number of steps (384 x 10 microsteps = 480

half steps)

3033

n38

Max steps/sec

5

30031-✓✓-Steps per second

3034

n39

Start backlash

1

10010%✓✓

-

Backlash (steps) to close in percent at startup (power

on).

3035

n40

Backlash

0

10020%✓✓

-

Backlash (steps) for spindle play compensation. This is

active during normal control

3037

n42

Comp. dir.

121-✓✓-

Compensation direction

3051

n56

Motor current

0

300

150mA✓✓-

Motor current

Regfrigerant

2551

o30

Refrigerant

04223-✓✓-

1 = R12

2 = R22

3 = R134a

4 = R502

5 = R717

6 = R13

7 = R13b1

8 = R23

9 = R500

10 = R503

11 = R114

12 = R142b

13 = User def.

14 = R32

15 = R227

16 = R401A

17 = R507

18 = R402A

19 = R404A

20 = R407C

21 = R407A

22 = R407B

23 = R410A

24 = R170

25 = R290

26 = R600

27 = R600a

28 = R744

29 = R1270

30 = R417A

31 = R422A

32 = R413A

33 = R422D

34 = R427A

35 = R438A

36 = Opteon XP10

37 = R407F

38 = R1234ze

39 = R1234yf

40 = R448A

41 = R449A

42 = R452A

2548

RF1

Rfg. fac. A1

8000

12000

10428

-✓✓-Adiabatic constant A1

2549

RF2

Rfg. fac. A2

-4000

-1000

-2255-✓✓-

Adiabatic constant A2

2550

RF3

Rfg. fac. A3

1000

3000

2557-✓✓-

Adiabatic constant A3

Sensors

113

r09

Adjust S2

-1000K✓✓✓

S2 Oset adjustment to correct the sensor signal due

to long wires etc.

2033

o21

Max. transducer

pressure

1

200

16

bar

(abs.)

✓✓✓

Maximum transducer pressure (in bar absolute * 10)

2034

o20

Min. transducer

pressure

010

bar

(abs.)

✓✓✓

Minimum transducer pressure (in bar absolute * 10)

System

50020-Avg KT0 time

10

3600

180-✓✓-

Average time for KT0 used as ltervalue for the average opening degree calculation when calculating the

KT0

50021

-

Avg OD 3 hours

0

1000

100

per

mill

✓✓✓

Average OD, updated and saved every 3 hours. After

power up the last saved average OD is used as starting

average OD

50051

-

Sampling time

1101

sec.✓✓-Algorithm sampling time

64200

LBO

Limited list

010-✓✓-

Modbus translation table for limited list of sequential

registers

64100

HWM

HW main switch

010-✓✓-

1 = S4 input is HW Main Switch

64309

-

Manual OD as

steps

010-✓✓-

Enable the manual OD in o45 to be entered as halfsteps. Readouts are still in percent

Alarm

2046

RAL

Reset alarm

010--✓-

1 = clear alarm

20001-EKC Error

010----

Common error ag. EKC Error is SET if any other Error

Alarm is ON.

20002-S2 Error

010----

S2 sensor error. If the sensor error occurs, the valve OD

will be set to 80% of the Avg. opening (PNU 50021) see Troubleshooting.

20005-Pe inp.error

010----

AKS 32R out of range. If the sensor error occurs, the

valve OD will be set to 80% of the Avg. opening (PNU

50021) - see Troubleshooting.

20006-No Rfg. Sel.

010----

Refrigerant not selected

50006-LOC Alarm

010----

Loss of charge alarm. No action will be performed except setting the alarm.

Superheat controller, Type EIM 336

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 22

Page 23

Group

PNU

Parameter

Symbolic name

Min.

Max.

Default

Unitse2W

*10

Description

Readout

2531

u16

S4 air temp

-200

2000°C--

✓

S4 temperature in °C measured with PT 1000 sensor

connected to KM2

2535

u22

Superheat Ref

0

1000K--✓Current superheat reference

2536

u21

Superheat

0

1000K--✓Current superheat (S2 - evaporator temperature)

2537

u20

S2 Temp

-200

2000°C--

✓

S2 temperature in °C measured with a PT 1000 sensor

connected to KM1.

2542

u24

opening %

0

1000%---Actual opening degree

2543

u25

Evap Press Pe

-200

200

0

bar

(abs.)

--✓

Evaporator pressure measured with ratiometric pressure transmitter at KM6.

2544

u26

Evap Temp Te

-200

2000°C--

✓

Evaporator temperature (converted from evaporator

pressure)

3101-Closed valve T

0

20000----Closed valve timer

3102-LOC Tmr

0

20000----Loss Of Charge time

50033-Avg opening

0

1000%--

-

Average opening degree. If it has never run before it

will give the value of PNU 50021 at start up.

64306-SWVer shdw

xxx----

Copy of 2003. This displays the version number in a

non-EKC format. For example 123 means vers 1.23

Control status

3099-Control State

05-----

Current state of internal control state machine.

3100-Ctrl Status

0

20000-----Bit mappped status register. See also Control status.

Regulation Control

on/o

switch

r12

Result

SH control

Alarm handling

o

(open)o (0)

=oo

o

(open)

on (1)=ononon (closed)

o

(0)

=oo

on (closed)

on (1)=on

on

Regulation Control

on/o

switch

r12

Result

SH control

Alarm handling

o

(open)o (0)

=oo

o

(open)

on (1)=ooon (closed)

o

(0)

=onon

on (closed)

on (1)=on

on

Bit15Bit14Bit13Bit12Bit11Bit10Bit 9

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Unused

MOP Active

Close Timer active

Sensor Errors

Control state

Variables / parameters

bit 10…15: unused

bit 9 : MOP

bit 9 : MOP active.

bit 8 : Close timer

bit 8: timer active

bit 4 …7: Sensor Errors

bit 4 : Te error (pressure sensor

error)

(1)

bit 5 : S2 error

bit 6 : S4 error, (not active)

bit 7 : (not active)

For detail check Alarms and

clearing alarms

CTRLstatus :

bit 0…3 : Controlstate

0: Closed (Main switch is o)

1: Error (Main switch is on and sensor

errors are active)

2: Injection (Normal SH control is active)

3: Dehumidify (Te Ref > 0)

4: Force OD (Manual control)

5: Defrost state (Def Activate = 1)

6: Hold1 state (Until Hold1 Time expires)

7: Hold2 state (Until Hold2 Time expires)

8: Startup (Startup time > 0)

9 -15: unused

Superheat controller, Type EIM 336

(1)

(1)

For Danfoss only!

For Danfoss only!

4.3.18 Interactions

Interaction between internal and regulation On/O switch.

Table 21: Parameter HWMainSwitch (PNU 64100) = 0

Table 22: Parameter HWMainSwitch (PNU 64100) = 1

4.3.19 Control status

Table 23: bit 0-15 Variables / parameters

(1)

(1)

Removing a pressure sensor caused no status bit change for three minutes.

Removing a pressure sensor caused no status bit change for three minutes.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 23

Page 24

80 mm / 3.15 in

5 mm / 0.2 in

5 mm / 0.2 in

Ø 3 mm / 0.118 in

50 mm / 1.97 in

Danfoss

80G15.11

PWR

PO

EEV

S4

S2

CO

M

ADR

Connection port

Description

S2

KM11Pt 1000

2

S4

KM2

1

PNU no 64100 = 1: Digital input for start/stop.

PNU no 64100 = 0: PT1000

2

Power & com.

KM4

1

Power supply (+)

2

RS485 (+)

3

RS485 (-)

4

Power supply (-)

Modbus Adr.

KM7

Jumper mounted =Indoor unit (evaporator) Modbus address stored in PNU no 40041 (default = 165)

Jumper not mounted = Outdoor unit (condenser) Modbus address stored in PNU no. 40042 (default 164)

Com

KM5

1

Drain (D)

2

RS485 (TxD+/RxD+)

3

RS485 (TxD-/RxD-)

4

Not Used

Po

KM6

1

Common

2

Pressure signal 10-90% of supply voltage

3

Power supply for pressure sensor 5 V d.c.

4

Not Used

Valve (EEV)

KM9

1

OUT B+ (Orange)

2

OUT A- (Red)

3

OUT B- (Yellow)

4

OUT A+ (Black)

5

Common (Grey - Only used for Unipolar)

Superheat controller, Type EIM 336

4.4 Dimensions

Figure 19: EIM 336 Dimensions

Table 24: EIM 336 connection port description

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 24

Page 25

A

B

Danfoss

80G158.10

A

B

Connector on ETS 6 coil

Connector on EIM 336

controller

11.6 mm

0.46 in

10.7 mm

0.42 in

8.5 mm

0.33 in

6.3 mm

0.25 in

10.6 mm

0.42 in

80G161.10

Danfoss

80G162.10

Superheat controller, Type EIM 336

Figure 20: JST XHP-5 CONNECTOR

Figure 21: 4 way MINI-FIT RECEPTACLE Molex 39-01-2040 or similar

Figure 22: 2 WAY MINI-FIT RECEPTACLE Molex 39-01-2020 or similar

Figure 23: RECEPT CONTACT

24-18AWG Molex 39-00-0039 or

similar

WARNING:

Caution must be taken against direct grounding of sensor, communiation, power supply or EEV valve

terminals. Failure to apply with this instruction can cause unrecoverable damaged to the controller.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 25

Page 26

Type

Packaging

code no.

EIM 336

Single pack

080G1002

Type /description

Packaging

Code no.

Connector kit for 5x EIM Controller

Single pack

080G1601

MYK - EIM interfacer

(1)

Single pack

080G0073

Superheat controller, Type EIM 336

5 Ordering

Table 25: Ordering

5.1 Accessories

Table 26: Accessories

(1)

(1)

Please contact your local Danfoss supplier for required software

Please contact your local Danfoss supplier for required software

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 26

Page 27

Document name

Document type

Document topic

Approval authority

UA.1O146.D.00071_1-19

UA Declaration

EMCD/LVD

LLC CDC EURO TYSK

Superheat controller, Type EIM 336

6 Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 27: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 27

Page 28

7 Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI219486429676en-000301 | 28

Loading...

Loading...