Page 1

MAKING MODERN LIVING POSSIBLE

Manual

Application for conguring the EIM 316/336 using MMIMyK

Type EIM 316/336 interface

This application allows the user to congure

the EIM316/336 parameters and display

settings and readouts. In addition it supports

a manual control mode to enable direct

control of the valve opening degree.

Features Congure EIM parameter

Display setting

Read out of status and parameters

Manual control of the valve

© Danfoss A/S (AC-MCI/sw), 2014-03 DKRCC.PS.RQ0.C2.02 / 520H8422

Page 2

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

Contents Page

1. Introduction...........................................................................4

2. References ............................................................................4

3. Loading the application into the MyK ...................................................4

3.1 MyKManager ............................................................................ 4

3.2 Copying ..................................................................................4

4. Connecting the MyK ...................................................................4

5. Starting the application ................................................................5

6. Using the application ..................................................................5

6.1 The main screen ..........................................................................5

6.2 Alarm screen..............................................................................6

6.3 The main menu ...........................................................................6

6.4 Login .....................................................................................6

6.5 Parameters ...............................................................................7

6.6 Manual control ...........................................................................9

6.7 Readouts .................................................................................9

6.8 Service functions ....................................................................... 10

6.9 Service info screens .....................................................................10

6.10 Alarm................................................................................... 11

2

DKRCC.PS.RQ0.C2.02 / 520H8 422

© Danfoss A/S (AC-MCI/sw), 2014-03

Page 3

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

2. References

3. Loading the

application into

the MyK

MyK Manager

MMIMyK Instruction

MMIMyK software

download guide

MMIMyK Manual

http://www.danfoss.com/MCX

(A password and login are needed in order to download the application)

http://dila.danfoss.net/literature/dkrc/AC-E-IT_MMIMYK_DKRCC.PI.RJ0.

B1.1U_520H5326_Low.pdf

http://dila.danfoss.net/literature/dkrc/AC-E-IT_MMIMYKSwDownloadGuide_DKRCC.PS.RJ0.B1.02_520H5547_Low.pdf

http://dila.danfoss.net/literature/dkrc/ITDE_GD_MMIMYK_RS8FP202_EN.

pdf

There are two ways to load the application into

the MyK. The rst is to use the MyKManager

program which lets you easily connect to the

MyK (please refer to the MMIMyK software

3.1 MyKManager

Start the MyKManager program on the PC, and

connect the MyK to the PC using the USB cable.

The screen displays the available drives in the

MyK, where drive 0:/ is the MyK’s own internal

memory, and drive 1:/ is the external memory

(SD/MMC card). If no SD/MMC card is mounted,

only drive 0:/ is displayed.

download guide). The other is to manually copy

the les onto a SD/MMC card and inserting this

card into the MyK.

Create a folder on either the internal or external

drive, by right-clicking on the drive’s name and

selecting “New folder”. The name of the folder

must be 8 characters or less. Then import the two

les by right-clicking on the folder and selecting

“import les”. Browse to the two les (app.pk and

mmimyk.cfg), select them and click “import”. The

MyKManager program can now be closed.

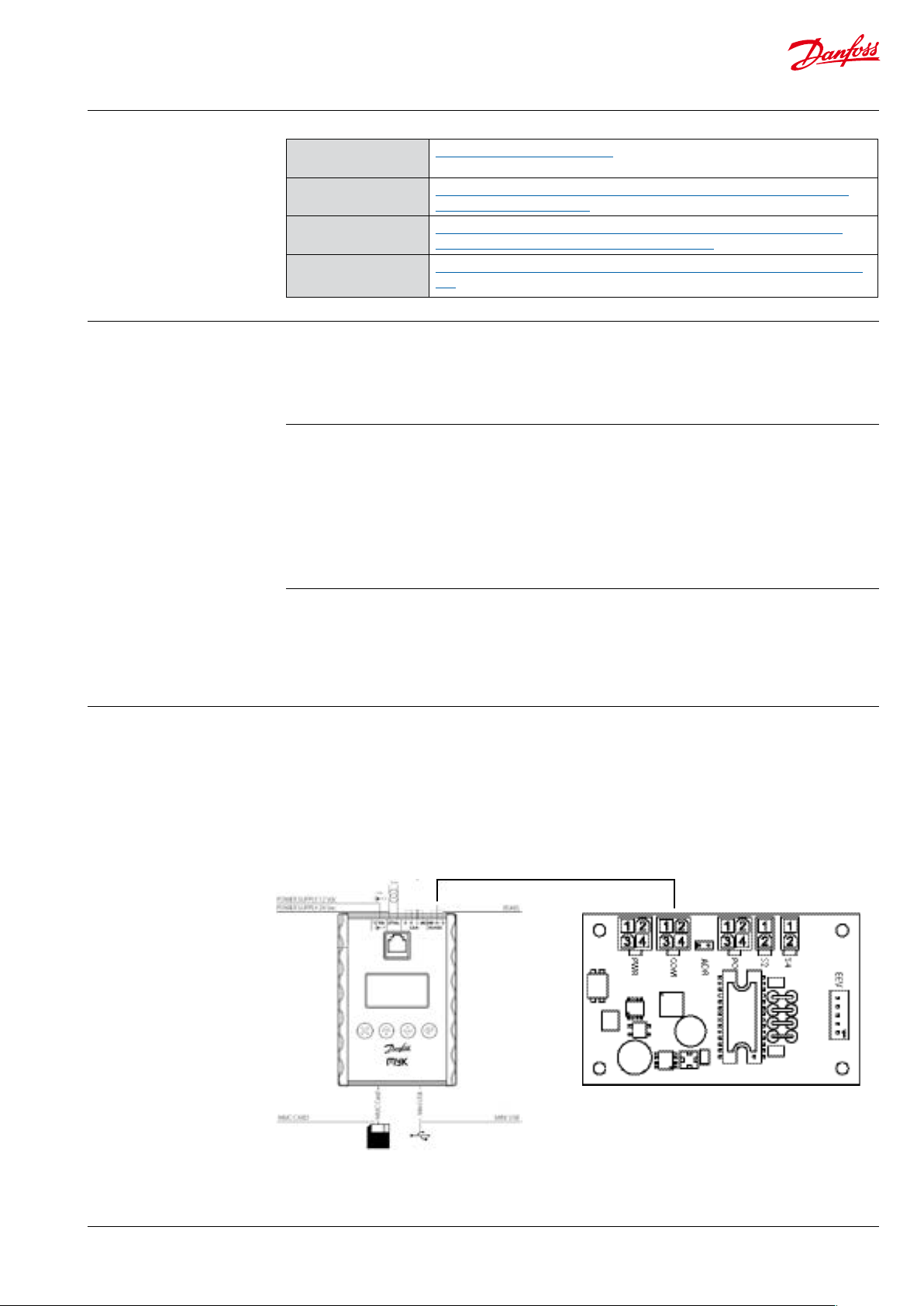

4. Connecting

the MyK

3.2 Copying

The downloaded program les (app.pk and

mmimyk.cfg) can be copied to a SD or MMC card

using the Windows explorer or a similar le

manager.

The MyK needs to be connected to a power

supply. Three options are available for this, it can

run either on a 12 V DC supply, a 24 V AC supply, or

it can be powered through the USB connection.

Modbus connection

ESC Up Down Ent er

First create a folder on the SD/MMC card, the

name of the folder must be 8 characters or less.

Then copy the two les into the folder. The SD/

MMC card can now be inserted into the MyK.

The MyK is connected to the EIM through the

modbus port (RS485), which is wired to the KM5

connector on the EIM.

D+ is connected to KM5,2

D- is connected to KM5,3

GND is connected to KM5,1

© Danfoss A/S (AC-MCI/sw), 2014-03 DKRCC.PS.RQ0.C2.02 / 520H8422

EIM 316 / 336

3

Page 4

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

5. Starting the

application

Setting up the MYK to

specic EIM 336 unit

address.

The MyK will startup in its Bios menu if no

application has previously been loaded. From

this menu it is possible to load the applications

that are stored on the MyK, either in its internal

or external memory. Please refer also to the

MMIMyK software download guide.

Select Application – Appl.Load, then select the

disc that the application is stored on, 0:/ (internal

memory) or 1:/ (SD/MMC card). Select the folder

If the MyK does not recognize that it is connected to an EIM 336, it will beep to indicate

that it is in alarm.

On the main screen press enter and go to

“Parameters-> MyK setup-> System”.

Under “Active EIM Addr”, set the correct ID of

the EIM 336 you want to connect to. Under

“Serial baud rate (MB)” set the baud rate to the

containing the application and press the enter

button. The application should load automatically and will startup after a few seconds.

The next time the MyK is powered, it will start the

application automatically. To enter the bios menu

again, press the Esc and enter buttons at the same

time, and keep them pressed for a few seconds,

until the MyK enters the bios menu. From here it is

possible to load another application.

correct baud rate (default for EIM is 192 i.e. 19200

Baud) then after set the correct serial settings

under “Serial settings (MB)”, (default value for EIM

336 is 8E1 i.e. 8 data bits, even parity and 1 stop

bit). The MyK should now able to connect with

the EIM 336.

6. Using the

application

6.1 The main screen

The main screen shows the current superheat (SH)

and opening degree (OD) in large characters.

If the main switch is o, this will be shown with

the characters OFF in large characters in the

upper right corner. If the main switch is on, the

currently active superheat reference is shown in

the upper right corner instead.

If an alarm is present, this is indicated by the

word “ALARM” to the right of the opening

degree. If the unit is in manual control mode, this

is indicated with the word “MAN”.

Pressing enter will give access to the main menu.

Pressing escape will give access to the alarm screen.

4

DKRCC.PS.RQ0.C2.02 / 520H8 422

© Danfoss A/S (AC-MCI/sw), 2014-03

Page 5

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

6. Using the

application

(continued)

6.2 Alarm screen

The alarm screen shows the alarms that have still

not been acknowledged. If more than one alarm

is active or has not been acknowledged, pressing

the up or down button will display the next or

previous alarm. Pressing the escape button for

two seconds will acknowledge the alarm and exit

the alarm screen. Pressing the escape button

6.3 The main menu

The main menu gives access to all the parameters and functions of the application. Navigation

is generally done by using the up or down

Main menu

|-----Login

|-----Parameters (see Parameters)

|-----Manual Control

|-----Readout

| |-----Overview

|-----Service

| |-----User2Factory

| |-----Factory2User

|-----Service Info

| |-----Software Info

| |-----Product Info

|-----Alarm

|-----Read Alarm

|-----Active Alarms

|-----Reset Alarms

briey will exit to the main screen without

acknowledging the alarm.

If an alarm becomes active the buzzer will sound

until it has been acknowledged. The alarm can

be muted by pressing the Esc button (or any of

the other buttons).

buttons to select a menu or function, and then

pressing the ok button to enter the menu or

function screen. Pressing escape will change the

screen to the previous menu or function screen.

6.4 Login

The login screen can be used to change the user

level. The default user level is level 0 which

means that no login is required. This user level

gives access to the most basic parameters, that

would be used on a daily basis. Some parameters

require a high user level, in order to be accessed,

see the parameter list for reference (Level). The

access code consists of a 4 digit code. When

entering the login screen the rst digit is

selected. Pressing up or down increases or

© Danfoss A/S (AC-MCI/sw), 2014-03 DKRCC.PS.RQ0.C2.02 / 520H8422

decreases the value of the selected digit.

Pressing enter, saves the digit and advances the

cursor to the next digit. Pressing the left or right

buttons, moves between the digits. When

pressing enter while the last digit is selected, the

access code is checked. If it is not correct, the

code is deleted and a new code can be entered.

If it is accepted, the access level changes and the

main menu is displayed. In the 2nd row from the

top, the current access level is visible.

5

Page 6

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

6.5 Parameters

This is a list of the available parameters of the

MyK application. The parameters in the Control,

Regulation and Setup menus, are settings of the

Group1 Group2 Parameter Description Min Max Default Units Level Notes

Control 0

Reg Control 0

Regulation 0

SH Control 0

MOP 1

Defrost 1

Te Control 1

External sensors 3

connected EIM. If no EIM is connected, “---” is

r12 Main switch 0 1 0 0 OFF;ON

o18 Manl control 0 1 0 1 OFF;MAN

o45 Manual OD % 0 100/480 0 %/step 1 Used when the o18 Manual

tst Startup time 0 1800 0 s 2

SOD Startup OD 0 100 0 % 2

OOD OD while OFF 0 100 0 % 2

RAL Reset alarm 0 1 0 0 OFF;ON

n09 Max superheat 2.0 20.0 16. 0 K 0

n10 Min superheat 1.0 20.0 4.0 K 0

TSH Tn SH 10 1800 600 1

n22 SH close 0 16.0 0.5 K 1

SHL SH Low 3.0 20.0 6.0 K 2

SHH SH High 8.0 40.0 16.0 K 2

GaH Gain High 0.5 50.0 1.0 2

GaL Gain Low 0.1 50.0 12. 5 2

TaH Tau H igh 10 600 45 2

TaL Tau L ow 10 600 110 2

Aph Alpha 15 600 130 1

n20 KpT0 -1.0 20.0 -1.0 2

CoS Comp Speed 0.0 100.0 0.0 3

n09 Dyn max superheat 2.0 20.0 16.0 K 0

n10 Dyn min superheat 1.0 20.0 4.0 K 0

TSH Dyn Tn SH 10 1800 600 1

Aph Dyn Alpha 15 600 130 1

n11 MOP 0.0 200 13.7 bar 1

DMO Di MOP -20.0 0.0 0.0 bar 2

KpM Kp MOP 0.5 10.0 0.5 2

TnM Tn Mop 30 600 180 2

DeA Def Activate 0 1 0 1 OFF;ON

DHO Def Hold OD 0 100 30 % 2

DH1 Def Hold Ti 1 0 32000 120 s 2

DH2 Def Hold Ti 2 0 32000 60 s 2

DDO Dyn def hold OD 0 100 30 % 3

ter Te Reference -200.0 200.0 0.0 °C 1

KpT Kp Te 0.5 10 1 2

TnT Tn Te 30 600 60 2

PEV EvapPress P0 0 32000 0 bar 3

TS2 S2 temp -200.0 200.0 0.0 °C 3

TS4 S4 Air temp -200.0 200.0 0.0 °C 3

displayed instead of the value. The MyK Setup

and Password menus relate to the MyK application itself. Please refer to the EIM manual for a

description of the parameters concerning the

setup of the EIM.

Control is set to 1.

0%/0 step = fully closed,

100%/480 step = fully open.

% is chosen by default.

See “manual OD as steps”

for changing to step.

6

DKRCC.PS.RQ0.C2.02 / 520H8 422

© Danfoss A/S (AC-MCI/sw), 2014-03

Page 7

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

6.5 Parameters (continued)

Group1 Group2 Parameter Description Min Max Default Units Level Notes

LOC 2

LTR LOC Trig 0 100 95 % 2

LRe LOC Reset 0 100 85 % 2

LTm LOC Timer 0 7200 3600 s 2

LST LOC SH Trig 0.0 50.0 20.0 K 2

Setup 0

Modbus 3

o03 Unit Addr 1 240 165 3

UA2 Unit Addr 2 1 240 164 3

MBa MB Baud 0 2 1 3 9 6;192; 384

MPa MB Parity 0 2 2 3 NO;ODD;EVEN

MSB MB StopB 1 2 1 3 --;1;2

Valve 2

MST Max steps 100 1000 384 3

MSS Max steps/sec 5 300 31 3

BKS Start backlash 1 100 10 % 2

BKL Backlash 0 100 20 2

COD Comp. dir. 1 2 1 3 UP;DOWN

MCU Motor current 0 300 150 3

Regfrigerant 2

RFG Refrigerant 0 37 23 2 1 : R12

RF1 Rfg. fac. A1 8000 12000 10428 3

RF2 Rfg. fac. A2 -4000 -1000 -2255 3

RF3 Rfg. fac. A3 1000 3000 2557 3

Sensors 2

r09 Adjust S2 -10.0 10.0 0.0 K 2

o20 Min transducer

press

o21 Max transducer

press

System 0

LBO Limited list (BO) 0 1 0 0 OFF;ON

HWM HW main switch 0 1 0 2 OFF;ON

F2U Factory to user 0 1 0 3 OFF;ON

U2F User to factory 0 1 0 3 OFF;ON

TSA Sampling time 1 10 1 3

MOS Manual OD as

steps

MyK Setup 0

System 0

add Active EIM Addr 0 254 165 0

bAU Serial baudrate 0 8 6 MB 0 0;12;24; 48; 96;14 4;192;288;38 4

COM Serial settings 0 2 1 MB 0 8N1;8E1;8N2

Passwords 1

System 1

L01 Level 1 psswd 0 9999 1000 1

L02 Level 2 psswd 0 9999 2000 2

L03 Level 3 psswd 0 9999 3000 3

0 1.0 0.0 Bar

(abs)

1 200 0.0 Bar

(abs)

0 1 0 3 Enable the manual OD in o45 to be

2 : R22

3 : R134a

4 : R502

5 : R717

6 : R13

7 : R13b1

8 : R23

9 : R500

10 : R503

11 : R114

12 : R142b

13 : User D

2

2

entered as halfsteps.

14 : R32

15 : R227

16 : R401A

17 : R507

18 : R402A

19 : R404A

20 : R407C

21 : R407A

22 : R407B

23 : R410A

24 : R170

25 : R290

26 : R600

27 : R600a

28 : R744

29 : R1270

30 : R417A

31 : R422A

32 : R413A

33 : R422D

34 : R427A

35 : R438A

36 : Opteon

XP10

37 : R407F

© Danfoss A/S (AC-MCI/sw), 2014-03 DKRCC.PS.RQ0.C2.02 / 520H8422

7

Page 8

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

6.6 Manual control

The valve can be opened and closed by manually

setting an opening degree, while the controller is in

manual control mode. It is possible to set the

controller in manual control mode, by pressing

enter on the manual control screen. This selects the

manual control setting. Pressing enter again, makes

it possible to toggle the manual control setting on

or o, by pressing the up or down buttons.

After setting the manual control mode to on,

press enter to accept the change. It is now

possible to select the manual opening degree,

by pressing the down button and pressing enter.

Using the up or down buttons, the wanted

opening degree can now be set. Pressing enter

accepts the opening degree, and the valve will

open or close to the selected opening degree.

6.7 Readouts

The readout screen shows some of the important

readout values, read from the controller.

This includes the current superheat, superheat

reference, current opening degree etc.

8

DKRCC.PS.RQ0.C2.02 / 520H8 422

© Danfoss A/S (AC-MCI/sw), 2014-03

Page 9

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

6.8 Service functions

Two service functions are available, resetting to

factory default settings, and setting factory

default settings.

The User2Factory function will copy the current

settings, into the eeprom and save them as

factory defaults. This means that if a factory reset

is performed, these are the settings that will be

used.

The Factory2User function will overwrite the

current settings, with settings that are stored in

the eeprom.

6.9 Service info screens

The service info screens display dierent

information about the application. Software info

displays the name, software version and date of

the application. It also displays the bios version

number and date of the MyK itself.

The product info screen displays the software

version number and order number of the

connected EIM.

© Danfoss A/S (AC-MCI/sw), 2014-03 DKRCC.PS.RQ0.C2.02 / 520H8422

9

Page 10

Manual EIM 316/336 interface application for setup and conguration of MMIMyK

6.1 0 A l a r m

The read alarm screen displays a list of the

currently active alarms reported from the

connected EIM. The status of 8 dierent alarms

are reported back from the EIM. A 0 (zero) means

that the alarm is not active, a 1 means that the

current alarm is active.

The active alarms screen displays details of the

currently unacknowledged alarms. If more than

one alarm has not been acknowledged, pressing

the up or down buttons scrolls between them.

If all alarms have been acknowledged or if no

alarms are present, the text “No alarms” is

displayed instead.

10

DKRCC.PS.RQ0.C2.02 / 520H8 422

© Danfoss A/S (AC-MCI/sw), 2014-03

Loading...

Loading...